GE DISR473TWW Technician Service Manual

g

________________________________________________________

GE Appliances Service Training

TECHNICIAN

SERVICE MANUAL

Dryer

MODEL:

DISR473TWW

CIWE1001E

FEBRUARY 2000

CAUTION !

DISCONNECT POWER CORD

BEFORE SERVICING THIS APPLIANCE!

RECONNECT ALL GROUNDING DEVICES

IMPORTANT SAFETY NOTICE !

This service information is intended for use by

individuals possessing adequate backgrounds of

electrical, electronic and mechanical experience.

Any attempt to repair this major appliance may

result in personal injury and property damage. The

manufacturer or seller cannot be responsible for

the interpretation of this information nor can it

assume any liability in connection with its use.

THE MANUAL COVERS THE

FOLLOWING MODELS

MODEL# COUNTRY

DISR473TWW AUSTRALIA

N/A BANGLADESH

N/A CHINA

N/A HONG KONG

N/A INDIA

N/A INDONESIA

N/A JAPAN

N/A KOREA

N/A MALAYSIA

N/A PAKISTAN

N/A PHILIPPINES

N/A SINGAPORE

N/A TAIHITI

N/A TAIWAN

N/A THAILAND

N/A VIETNAM

I. SPECIFICATION

ITEMS SPECIFICATIONS

Colour WW, AA

Dimensions (Inches) (W x H x D) 27 x 42 x 28¼

Total # of Cycles 7

Electrical 240 VAC, 50 Hz, 20 amps

Timed Dry (Min) 80

Capacity (kg) 8

Heat Selection 4

Page 4

II. THEORY OF OPERATION

2.1 How a Dryer Works

All dryers, whether gas or electric, operate

according to the same principle they remove

moisture from damp clothes by bringing the

clothes in contact with a flow of heated air.

Mechanically the clothes must tumble to expose

all of their surfaces to heat, and the heated air

must be circulated within the dryer and then

vented.

Switches, timers and thermostats regulate the

air temperature and duration of the drying cycle.

When the start button is activated with the dryer

door closed, the motor is activated. The motor is

connected to the drum by a drive belt. This

drive belt rotates the drum through a pulley

system attached to the motor shaft. The drum

itself is supported by a bearing and slides at the

front.

2.2 Axial Air Flow

Air is pulled into the cabinet from the rear, and

drawn up across the heaters located behind the

drum. This hot air is pulled through the drum

rear, across the clothes load, through the lint

filter and down the trap direct into the blower.

From the blower the air is pushed out the

exhaust system.

In electric dryers, the heat source is not

energized until the drive motor start turning.

Both the timer and thermostats energize coiled

resistance heaters. The temperature selector

switched control the number of heaters

energized.

Page 5

2.2 Axial Air-Flow Dryers

II. THEORY OF OPERATION

Page 6

2.2 Air Flow Diagram

II. THEORY OF OPERATION

Page 7

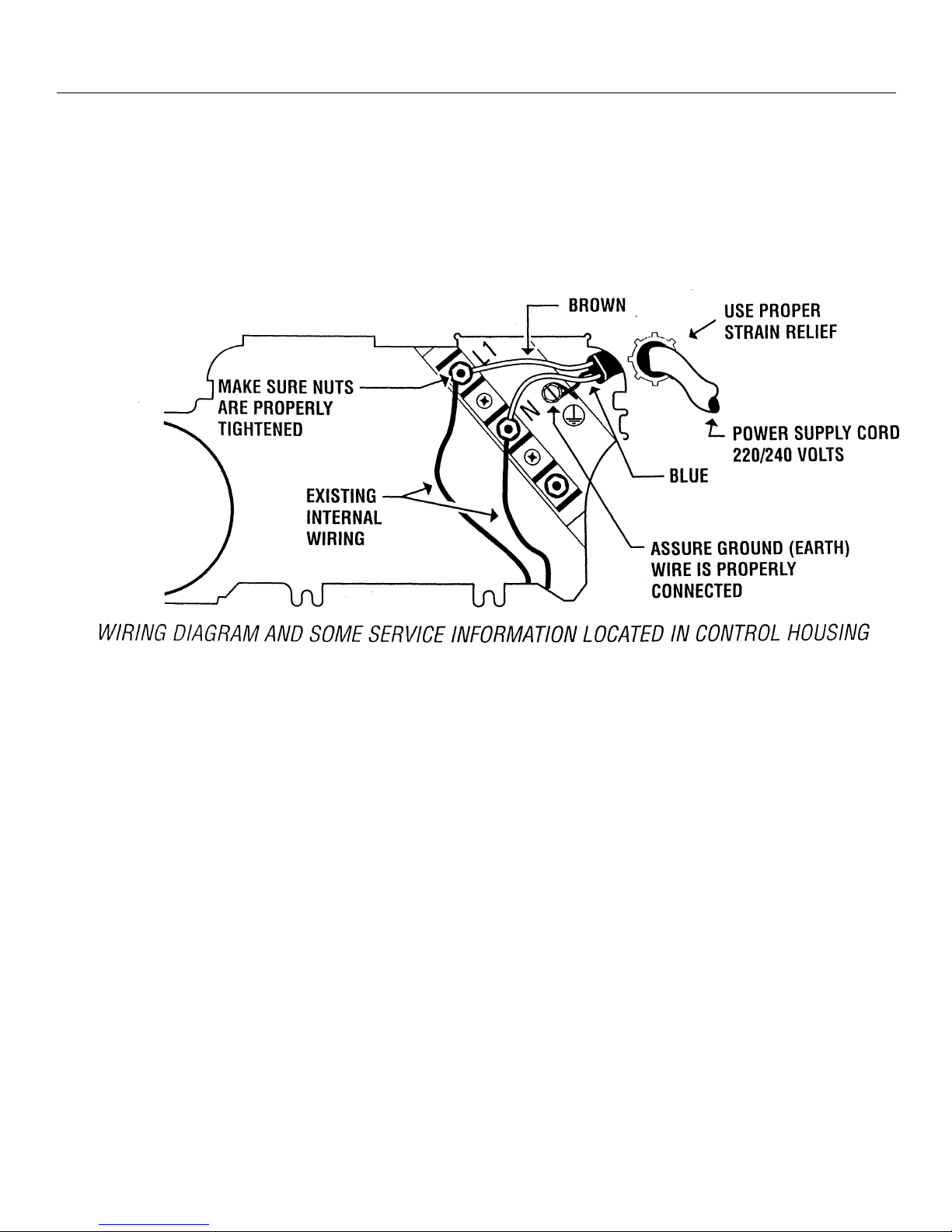

III. GROUNDING EQUIPMENT

IF THE DRYER IS SUPPLIED WITH A FLEXIBLE POWER CORD

Plug the cordset into its own separate grounded out. Do Not, UNDER ANY CIRCUMSTANCES, CUT OR REMOVE

THE GROUND PRONG FROM THE POWER CORD.

Page 8

IV. DRYER CONSTRUCTION AND SERVICE

Control Panel : Provide access to timer & switches.

Service : Remote four #15 Torx screws from top. Switches & timer are tab interlock. The timer is

not technical serviceable.

Cabinet : 4 x Parts

2 - Side painted panels with knowckouts for side exhaust

L - Shape galvanized steel chassis : Back - Base Front

BACK with louvers for air entry and Service access panel

BASE with leveling legs and knockout for buttom exhaust

Service : All cabinet parts are hold together by screws.

Top : Upswept, galvanized steel, power painted

Service : Remove two screws in door opening and lift it up

Door : Embedded in front cabinet

Two parts : Front door and inner door hold by screws

Plugs 2 hinges and a latch strike

Service : Just loose hinge screws in key holes

Front : One-piece construction

Outside : Filter snapped in

Inside : Latch

Front seal and felt

Drum slide

Trap duct

Service : Front - Remove the top

Remove screws on the inside right and left of cabinet

Lift it up from the two supports it rest on at the bottom

Note : The drum must be supported by one hand while removing the front.

Disconnect wires from door switch

Front Seal - Clip on trap duct

Front Felt - Clip on door opening flange

Trap Duct - Clip on door opening flange

Drum Slides - The teflon slides are removable

There are two color slides (grey & white) - do not mix

Do not lubricate the slides

Page 9

IV. DRYER CONSTRUCTION AND SERVICE

Drum : 7 x Parts

Belt

One-piece drum (front Wrapper Rear)

3 baffles

Diffuser

Shaft

Bearing

Service : Drum Removal Remove belt from idler pulley

Release idler arm (belt tension system)

Lift up the drum or through port at right

Reach under the drum behind the motor

Pull idler arm at the pulley end down

Hook the idler end on the motor mount bracket

The bracket has a hook that will hold idelr arm and allow to easily place or remove the belt

over the idelr pulley and motor pulley.

Slide the drum out

Baffles Hold with 3 screws

Diffuser Secure with 4 x Torx # 15 screws

Shaft bracket Same screw as the diffuser. Be careful when re-installing the drum that

the bearing and washers are in place.

Motor / Blower : Motor

Motor mount bracket

Blower housing

Blower

Idler spring

Service : Motor, blower, idler swith are all mounted on motor bracket.

Unscrew the two long screws (9 cm) securing the motor bracket to the blower housing and

two 3/8 hex. Screws through the base.

Heater : Heater assembly

Hi limit thermostat at 2:00 oclock

Safety control thermostat

Control thermos

Service : Heater - The heater is not reastringale and must be replaced as a complete part.

Thermostat - Secure with screw and tab.

Its mounted with 4 screws.

Page 10

Loading...

Loading...