Page 1

g

GEPowerManagement

DGP

Digital Generator Protection Relay™

Instruction Manual

DGP Revisions:V210.12000P

V210.10000F

V211.32000J

V210.22000D

Manual P/N: GEK-100666D

Copyright © 2000 GE Power Management

All relays must be powered up at least once per year

to avoid deterioration of electrolytic capacitors and

NOTE

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

subsequent relay failure.

Manufactured under an

ISO9002 Registered system.

Page 2

Page 3

These instructions do not purport to co ve r all de tails o r variat ions in e quipment

g

g

g

nor provide for every possible contin

installation, operation, or maintenance. Should further information be desired

or should particular problems arise which are not covered sufficiently for the

purchaser’s purpose, the matter should be refe rred to the General Electric

Company.

To the extent required the products described herein meet applicable ANSI,

ency to be met in connection with

IEEE, and NEMA standards; but no such assurance is

local codes and ordinances because they vary

reatly.

iven with respect to

Page 4

Page 5

TABLE OF CONTENTS

1. PRODUCT DESCRIPTION

1.1 GETTING STARTED

1.1.1 UNPACKING THE RELAY.........................................................................1-1

1.1.2 ORDER CODES & SELECTION GUIDE................................................... 1-2

1.1.3 SPECIAL MODELS....................................................................................1-3

DGP***AAA-0101 and DGP***AAA-0102....................................................... 1-3

DGP***ABA-0005 ...................................................................... .... .... .. .... .. .....1-3

1.1.4 DEC 1000 CONTACT EXPANSION UNIT.................................................1-3

1.2 INTRODUCTION

1.2.1 GENERAL..................................................................................................1-4

1.2.2 APPLICATION...........................................................................................1-4

1.3 PROTECTION FEATURES

1.3.1 DESCRIPTION.......................................................................................... 1-6

1.3.2 STATOR DIFFERENTIAL (87G)................................................................1-7

1.3.3 CURRENT UNBALANCE (46T)................ .................................................1-7

1.3.4 LOSS OF EXCITATION (40) ..................................................................... 1-7

1.3.5 ANTI-MOTORING (32)..............................................................................1-8

1.3.6 TIME OVERCURRENT WITH VOLTAGE RESTRAINT 51V.....................1-8

1.3.7 STATOR GROUND (64G/27TN)............................................................... 1-8

1.3.8 GROUND OVERCURRENT (51GN) ........................... ..............................1-9

1.3.9 OVEREXCITATION (24)............. .................................................. ............. 1-9

1.3.10 OVERVOLTAGE (59)..............................................................................1-10

1.3.11 UNDERVOLTAGE (27)......................... ...................................................1-10

1.3.12 OVER AND UNDERFREQUENCY (81)... ...............................................1- 1 0

1.3.13 VOLTAGE TRANSFORMER FUSE FAILURE (VTFF)............................ 1-10

1.3.14 ACCIDENTAL ENERGIZATION (AE)...................................................... 1-11

1.4 OTHER FEATURES

1.4.1 INPUTS....................................................................................................1-17

1.4.2 OUTPUT RELAYS.................................. ................................................. 1-17

1.4.3 START-UP SELF-TESTS ........................................................................1-18

1.4.4 RUN-TIME SELF-TESTS................ ........................................ ................. 1-18

1.4.5 ADAPTIVE SAMPLING FREQUENCY....................................................1-19

1.4.6 TRIP CIRCUIT MONITOR.................................................... ...................1-19

1.4.7 SEQUENCE OF EVENTS....................................... ......................... ....... 1-19

1.4.8 TIME SYNCHRONIZATION..................................................................... 1-20

1.4.9 FAULT REPORT & OSCILLOGRAPHY DATA........................................1-21

1.4.10 LOCAL MAN -MACHINE IN TERFACE............ .............. ............. .. ............ 1-21

1.4.11 LOCAL PRINTER ........................ .. .............. . .............. .. ............. .. ............ 1-21

1.4.12 REMOTE COMMUNICATIONS.......... .....................................................1-22

1.4.13 REMOTE CONTROL............................................................................... 1-22

1.4.14 PASSWORD PROTECTION........................... ......................... ............... 1-22

1.4.15 REMOTE COMMUNICATIONS – MODBUS PROTOCOL...................... 1-22

1.5 ELEMENTARY DIAGRAMS

2. CALCULATION OF

SETTINGS

2.1 GENERAL

2.1.1 DESCRIPTION.......................................................................................... 2-1

2.2 CONFIGURATION SETTINGS

2.2.1 DESCRIPTION........................................................................................ 2-10

101: UNITID – UNIT ID NUMBER ................................................................2-10

102: SYSFREQ – SYSTEM FREQUENCY .................................................. 2-10

103: SEL TVM – SELECT TRIP VOLTAGE MONITORING......................... 2-10

104: SEL TCM – SELECT TRIP CURRENT MONITORING........................ 2-10

105: SELPRIM – SELECT PRIMARY/SECONDARY UNITS .......................2-10

106: CT RATIO – CURRENT TRANSFORMER RATIO.............. .. ...............2-10

GE Power Management DGP Digital Generator Protection System

i

Page 6

TABLE OF CONTENTS

107: VT RATIO – VOLTAGE TRANSFORMER RATIO................................ 2-10

108: COMMPORT – COMMUNICATIONS PORT........................................ 2-11

109: PHASE – PHASE DESIGNATION........................................................ 2-11

110: TIMESYNC – TIME SYNCHRONIZATION SOURCE........................ ... 2-11

111: NUM FLTS – NUMBER OF FAULT EVENTS....................................... 2-11

112: PREFLT – PREFAULT CYCLES.......................................................... 2-12

113: OSC TRIG – EXTERNAL OSCILLOGRAPHY TRIGGER ....................2-12

114: NOM VOLT – NOMINAL VOLTAGE..................................................... 2-12

115: RATEDCUR – RATED CURRENT.......................................................2-12

116: VT CONN – VOLTAGE TRANSFORMER CONNECTION................... 2-12

117: NCTRATIO – NEUTRAL CURRENT TRANSFORMER RATIO ........... 2-12

2.2.2 EXAMPLE CONFIGURATION SETTINGS ..............................................2-12

2.3 PROTECTION FUNCTION SETTINGS

2.3.1 TRIP AND ALARM OUTPUT RELAYS .................................................... 2-13

2.3.2 STATOR DIFFERENTIAL 87G................................................................2-13

2.3.3 CURRENT UNBALANCE ALARM 46A....................................................2-18

2.3.4 CURRENT UNBALANCE TRIP 46T... ................... ............................... ... 2-18

2.3.5 LOSS OF EXCITATION 40, 40-1, 40-2 ...................................................2-20

2.3.6 ANTI-MOTORING (REVERSE POWER).................................................2-21

2.3.7 OVERCURRENT WITH VOLTAGE RESTRAINT (51V)..........................2-22

2.3.8 STATOR GROUND FAULT 64G-1.......................................................... 2-28

2.3.9 STATOR GROUND FAULT 64G-2.......................................................... 2-28

2.3.10 STATOR GROUND FAULT 27TN...........................................................2-28

2.3.11 OVEREXCITATION ALARM (VOLTS/HERTZ: 24A) ............................... 2-29

2.3.12 OVEREXCITATION TRIP (VOLTS/HERTZ: 24T).................................... 2-29

2.3.13 OVERVOLTAGE 59.................................................................................2-34

2.3.14 UNDERVOLTAGE CUTOFF OF 81......................................................... 2-36

2.3.15 UNDERFREQUENCY 81-U.....................................................................2-36

2.3.16 OVERFREQ U EN CY 81-O ......................... .. ........................................ .. .. 2-36

2.3.17 DIGITAL INPUT DI...................................................................................2-36

2.3.18 VOLTAGE TRANSFORMER FUSE FAILURE VTFF.............................. 2-37

2.3.19 ACCIDENTAL ENERGIZATION AE ........................................................ 2-37

2.3.20 GROUND OVERCURRENT 51GN................... ............................ ........... 2-38

2.3.21 UNDERVOLTAGE 27..............................................................................2-38

2.4 COMMISSIONING

2.4.1 DGP***AAA SETTINGS TABLE.............................................................. 2-41

2.4.2 DGP***ABA SETTINGS TABLE ..............................................................2-46

2.4.3 DGP***ACA SETTINGS TABLE ..............................................................2-51

3. HARDWARE

DESCRIPTION

ii

3.1 CASE ASSEMBLY

3.1.1 WARNING.................................................................................................. 3-1

3.1.2 CONSTRUCTION......................................................................................3-1

3.1.3 ELECTRICAL CONNECTIONS & INTERNAL WIRING............................ .3-1

3.1.4 IDENTIFICATION ......................................................................................3-1

3.2 CIRCUIT BOARD MODULES

3.2.1 WARNING.................................................................................................. 3-4

3.2.2 BASIC CONSTRUCTION.......................................................................... 3-4

3.2.3 IDENTIFICATION ...................................................... ................................3-4

3.3 XTM TEST PLUGS

3.3.1 DESCRIPTION .......................................................................................... 3-6

3.3.2 TERMINAL DESIGNATION........... .......................... ......................... ......... 3-6

3.3.3 XTM TEST-CIRCUIT CONNECTIONS....................................... ............... 3-6

3.3.4 T EST PL U G INSERTION ........... .. ........................................ .. ................... 3-6

DGP Digital Generator Protection System

GE Power Management

Page 7

TABLE OF CONTENTS

3.4 INSTALLATION

3.4.1 RECEIVING, HANDLING, & STORAGE.................................................... 3-7

3.4.2 ENVIRONMENT........................................................................................ 3-7

3.4.3 MOUNTING ............................................................................................... 3-7

3.4.4 EXTERNAL CONNECTIONS..... ......................... ......................... ............. 3-7

3.4.5 EXTERNAL CONNECTIONS TEST..........................................................3-7

3.4.6 SURGE GROUND CONNECTIONS.................... ........................... ........... 3-7

4. ACCEPTANCE TESTS

4.1 INTRODUCTION

4.1.1 WARNING..................................................................................................4-1

4.1.2 GENERAL..................................................................................................4-1

a GENERAL TESTS.....................................................................................4-1

b PROTECTION TESTS................ ......................... ......................... ............. 4-1

4.2 TEST PREPARATION

4.2.1 TEST EQUIPMENT...................................................................................4-2

4.2.2 DRAWINGS & REFERENCES..................................................................4-2

a DRAWINGS............................................................................................... 4-2

b REFERENCES..........................................................................................4-2

4.2.3 EQUIPMENT GROUNDING......................................................................4-2

4.2.4 REQUIRED SETTINGS......... .......................... ......................... ................. 4-2

4.3 GENERAL INSTRUCTIONS

4.3.1 PROCEDURE............................................................................................4-3

4.3.2 SETTING CHANGES................................................................................. 4-3

4.3.3 ENTERING THE TEST MODE.................................................................. 4-4

4.3.4 EXITING THE TEST MODE......................................................................4-4

4.4 USING GE-LINK

4.4.1 DESCRIPTION.......................................................................................... 4-5

4.4.2 HARDWARE SETUP................................................................................. 4-5

4.4.3 SO FTWARE SETU P........... .. ............. .. .. ............. .. ............. .. .. .................... 4-5

a LOAD & START GE-LINK..........................................................................4-5

b SET UP A NEW TEST UNIT......................................................................4-5

4.4.4 RELAY SETUP.......................................................................................... 4-6

4.4.5 LOGGING INTO THE RELAY....................................................................4-6

4.4.6 SETTING CHANGES................................................................................. 4-7

4.4.7 ENTERING THE TEST MODE.................................................................. 4-7

4.4.8 EXITING THE TEST MODE......................................................................4-7

4.5 INITIAL TEST SETUP

4.5.1 DESCRIPTION.......................................................................................... 4-8

4.6 GENERAL RELAY TESTS

4.6.1 NOTE......................................................................................................... 4-9

4.6.2 T1: MMI STATUS AND DISPLAY TESTING.............................................4-9

a STATUS CHECK ....................................................................................... 4-9

b WARNING STATUS .................................................................................. 4-9

c DISPLAY TEST........................................................................................ 4-10

4.6.3 T2: DIGITAL OUTPUT TESTS ................................................................4-11

4.6.4 T3: DIGITAL INPUT TESTS ....................................................................4-13

4.6.5 T4: AC SYSTEM INPUT TEST ................................................................ 4-15

4.7 PROTECTION TESTS

4.7.1 DESCRIPTION........................................................................................ 4-17

4.7.2 T5: GENERATOR DIFFERENTIAL TEST 87G.......................................4-18

4.7.3 T6: CURRENT UNBALANCE ALARM 46A ............................................. 4-20

4.7.4 T7: CURRENT UNBALANCE TRIP 46T.................................................. 4-20

4.7.5 T8: LOSS OF FIELD PROTECTION ZONE 1 40-1.................................4-22

4.7.6 T9: LOSS OF FIELD PROTECTION ZONE 2, 40-2................................4-23

GE Power Management DGP Digital Generator Protection System

iii

Page 8

TABLE OF CONTENTS

4.7.7 T10: ANTI-MOTORING & SEQUENTIAL TRIP SUPERVISION 32-1 ..... 4-23

4.7.8 T11: ANTI-MOTORING 32-2 ................................................................... 4-24

4.7.9 T12: TIME OVERCURRENT WITH VOLTAGE RESTRAINT 51V ..........4-24

4.7.10 T13: ACCIDENTAL ENERGIZA TION AE ................................................ 4-25

4.7.11 T14: STATOR GROUND ZONE 1 64G1 ................................................. 4-27

4.7.12 T15: STATOR GROUND ZONE 2 64G2 ................................................. 4-28

4.7.13 T16: VOLTS/HERTZ OVEREXCITATION ALARM 24A..........................4-30

TEST RESULTS:..........................................................................................4-30

4.7.14 T17: VOLTS/HERTZ OVEREXCITATION TRIP 24T...............................4-31

4.7.15 T18: POSITIVE-SEQUENCE OVERVOLTAGE 59..................................4-32

TEST RESULTS...........................................................................................4-32

4.7.16 T19: UNDERFREQUENCY UNIT #1 81-1U ............................................4-33

4.7.17 T20: UNDERFREQUENCY UNIT #2 81-2U ............................................4-33

4.7.18 T21: UNDERFREQUENCY UNIT #3 81-3U ............................................4-34

4.7.19 T22: UNDERFREQUENCY UNIT #4 81-4U ............................................4-34

4.7.20 T23: OVERFREQUENCY UNIT #1 81-1O ...............................................4-35

4.7.21 T24: OVERFREQUENCY UNIT #2 81-2O ...............................................4-35

4.7.22 T25: OVERFREQUENCY UNIT #3 81-3O ...............................................4-36

4.7.23 T26: OVERFREQUENCY UNIT #4 81-4O ...............................................4-36

4.7.24 T27: VOLTAGE TRANSFORMER FUSE FAILURE VTFF ...................... 4-37

4.7.25 T28: TOC GROUND OVERCURRENT 51GN.........................................4-37

4.7.26 T29: UNDERVOLTAGE 27......................................................................4-38

4.7.27 T30: THIRD HARMONIC NEUTRAL UNDERVOLTAGE 27TN...............4-38

4.8 END OF ACCEPTANCE TESTING

4.8.1 DESCRIPTION ........................................................................................ 4-40

5. PERIODIC TESTS

5.1 INTRODUCTION

5.1.1 DESCRIPTION .......................................................................................... 5-1

5.1.2 GENERAL TESTS.....................................................................................5-1

5.1.3 PROTECTION FUNCTION TESTS.... ...................................................... .5-1

5.1.4 GENERAL INSTRUCTIONS......................................................................5-1

5.2 RELAY TESTS

5.2.1 T1: RELAY STATUS & MMI ......................................................................5-2

a STATUS CHECK......................... ................................................... ........... 5-2

b DISPLAY TEST..........................................................................................5-2

5.2.2 T2: DIGITAL OUTPUT TEST.....................................................................5-3

5.2.3 T3: DIGITAL INPUT TEST......................................................................... 5-4

5.2.4 T4: AC SYSTEM INPUT TEST ..................................................................5-5

5.3 MEASURING UNIT TESTS

5.3.1 DESCRIPTION .......................................................................................... 5-6

5.3.2 T5: GENERATOR DIFFERENTIAL TEST 87G ......................................... 5-6

5.3.3 T6: CURRENT UNBALANCE ALARM 46A ...............................................5-6

5.3.4 T7: CURRENT UNBALANCE TRIP 46T....................................................5-7

5.3.5 T8: LOSS OF EXCITATION 40-1 ..............................................................5-8

5.3.6 T9 ANTI-MOTORING TEST 32-1............................................ ..................5-9

5.3.7 T10: TIME OVERCURRENT WITH VOLTAGE RESTRAINT 51V ..........5-10

5.3.8 T11: STATOR GROUND ZONE 1 64G1 ................................................. 5-11

5.3.9 T12: STATOR GROUND ZONE 2 64G2 ................................................. 5-11

5.3.10 T13: VOLTS/HERTZ OVEREXCITATION ALARM 24A..........................5-12

5.3.11 T14: VOLTS/HERTZ EXCITATION TRIP 24T......................................... 5-13

5.3.12 T15: POSITIVE-SEQUENCE OVERVOLTAGE 59..................................5-14

5.3.13 T16: UNDERFREQUENCY UNIT #1 81-1U ............................................5-14

5.3.14 T17: OVERFREQUENCY UNIT #1 81-1O ...............................................5-15

5.3.15 T18: VOLTAGE TRANSFORMER FUSE FAILURE VTFF ...................... 5-15

5.3.16 T19: TOC GROUND OVERCURRENT 51GN.........................................5-16

iv

DGP Digital Generator Protection System

GE Power Management

Page 9

TABLE OF CONTENTS

5.3.17 T20: POSITIVE-SEQUENCE UNDERVOLTAGE 27...............................5-17

5.4 END OF PERIODIC TESTING

5.4.1 ENDING PERIODIC TESTS.................................................................... 5-18

6. SERVICING

7. SPECIFICATIONS

8. INTERFACE

6.1 SPARES

6.1.1 DESCRIPTION.......................................................................................... 6-1

6.2 RELAY SELF-TESTS

6.2.1 DESCRIPTION.......................................................................................... 6-2

6.3 TROUBLESHOOTING

6.3.1 DESCRIPTION.......................................................................................... 6-4

6.3.2 USING THE INFORMATION STATUS COMMAND.................................. 6-4

6.3.3 SERVICING A CRITICAL FAILURE FAIL.................................................. 6-5

6.3.4 SERVICING A NON-CRITICAL FAILURE WARN.....................................6-5

6.3.5 SERVICING SYSTEM STATUS FAILURES ..............................................6-6

6.4 ERROR CODES

6.4.1 ERROR MESSAGES AT STARTUP .........................................................6-7

6.4.2 ERROR MESSAGES AT RUNTIME.......................................................... 6-9

7.1 DGP SPECIFICATIONS

7.1.1 DESCRIPTION.......................................................................................... 7-1

7.1.2 PROTECTION FUNCTIONS AND SETTING RANGES............................ 7-2

8.1 DISPLAY

8.1.1 DESCRIPTION.......................................................................................... 8-1

8.2 TARGET LEDs & TARGET RESET KEY

8.2.1 TARGET LEDs...........................................................................................8-2

8.2.2 TARGET RESET KEY...............................................................................8-2

8.3 KEYPAD

8.3.1 DESCRIPTION.......................................................................................... 8-3

8.3.2 CLEAR KEY [CLR]..................................................................................... 8-3

8.3.3 PRINT KEY [PRT]...................................................................................... 8-4

8.3.4 ARROW KEYS...........................................................................................8-4

8.3.5 ENTER KEY [ENT]........................... .........................................................8-4

8.3.6 DATA ENTRY KEYS........................................ ..........................................8-4

8.3.7 END KEY [END].........................................................................................8-5

8.3.8 SETTINGS KEY [SET]...............................................................................8-5

8.3.9 ACTIONS KEY [ACT]................................................................................. 8-7

1. DISABLE OUTPUTS.................................................................................. 8-7

2. ENABLE OUTPUTS................................................................................... 8-7

3. TRIP............................................................................................................ 8-8

4. RESET........................................................................................................ 8-8

5. DATE/TIME.................. .. ............. .............. .. ............. ............. .. .............. ...... 8-8

6. RELAY TEST..............................................................................................8-9

7. MMI TEST...................................................................................................8-9

8. FIX UP SETTINGS CRC ............................................................................ 8-9

9. ENTER PASSWORD................................................................................ 8-10

10. CHANGE PASSWORD..........................................................................8-10

11. DIGITAL OUTPUT TEST........................................................................8-10

...................................................................................................................... 8-11

GE Power Management DGP Digital Generator Protection System

v

Page 10

TABLE OF CONTENTS

8.3.10 INFORMATION KEY [INF].. .. ........................... .. ...................................... 8-12

1. REQUEST DGP STATUS.........................................................................8-12

2. REQUEST FAULT INFORMATION..........................................................8-12

3. REQUEST PRESENT VALUES ...............................................................8-13

4. REQUEST EVENTS.................................................................................8-13

5. VIEW PASSWORD................................................................................... 8-13

6. REQUEST DGP MODEL/VERSION.........................................................8-13

7. STATION ID..............................................................................................8-13

8. GENERATOR ID.......................................................................................8-13

8.4 ERROR MESSAGES

8.4.1 DESCRIPTION ........................................................................................ 8-15

8.5 PASSWORDS

8.5.1 DESCRIPTION ........................................................................................ 8-16

8.5.2 ENCRYPTED PASSWORD CONVERSION TABLE...............................8-17

9. COMMUNICATIONS

9.1 INTRODUCTION

9.1.1 HARDWARE JUMPERS............................................ ................................ 9-1

9.1.2 MODEM CONNECTIONS & SETTINGS...................................................9-1

9.1.3 PC MODEM............................................................................................... 9-1

9.1.4 DGP MODEM ............................................................................................ 9-2

9.1.5 NULL MODEM CONNECTIONS ...............................................................9-2

9.1.6 RS485 COMMUNICATIONS ....... .......................... .................................... 9-4

9.2 MODBUS COMMUNICATIONS

9.2.1 INTRODUCTION ....................................................................................... 9-5

9.2.2 DATA FRAME FORMAT & DATA RATE...................................................9-5

9.2.3 DATA PACKET FORMAT..................................................... .....................9-5

a SLAVE ADDRESS.....................................................................................9-5

b FUNCTION CODE.....................................................................................9-6

c DATA ......................................................................................................... 9-6

d CRC HI & CRC LO.....................................................................................9-6

9.2.4 ERROR CHECKING..................................................................................9-6

9.2.5 DATA FRAMING.................... ............................................................. ....... 9-6

9.3 MODBUS FUNCTIONS

9.3.1 FUNCTION CODE 03/04: READING HOLDING/INPUT REGISTERS......9-7

a DESCRIPTION .......................................................................................... 9-7

b QUERY...................................................................................................... 9-7

c RESPONSE............................................................................................... 9-7

9.3.2 FUNCTION CODE 05: FORCE SINGLE COIL........................................ .. 9-8

a DESCRIPTION .......................................................................................... 9-8

b QUERY...................................................................................................... 9-8

c RESPONSE............................................................................................... 9-8

9.3.3 FUNCTION CODE 06: STORE SINGLE SETPOINT................................9-9

a DESCRIPTION .......................................................................................... 9-9

b QUERY...................................................................................................... 9-9

c RESPONSE............................................................................................... 9-9

9.3.4 FUNCTION CODE 16: PRESET MULTIPLE SETPOINTS......................9-10

a DESCRIPTION ........................................................................................ 9-10

b QUERY.................................................................................................... 9-10

c RESPONSE............................................................................................. 9-10

9.3.5 FUNCTION CODE 56: RETRANSMIT LAST PACKET...........................9-10

a DESCRIPTION ........................................................................................ 9-10

b QUERY.................................................................................................... 9-10

c RESPONSE............................................................................................. 9-10

9.4 MODBUS ERRORS

9.4.1 ER ROR RESPONS ES...... .............. . .. .............. .. .. ............. .. ............. .. .. .... 9-11

vi

DGP Digital Generator Protection System

GE Power Management

Page 11

TABLE OF CONTENTS

9.5 MODBUS MEMORY MAPPING

9.5.1 DATA TYPES.................................. .........................................................9-12

9.5.2 MEMORY MAP ORGANIZATION............................................................9-1 3

9.5.3 FIXED VALUE INPUT REGISTERS........................................................9-13

9.5.4 PRESENT VALUE REPORT REGISTER MA P.......................................9 - 13

9.5.5 EVENT REPORT MEMORY MAP........................................................... 9-14

9.5.6 FAULT STATUS MEMORY MAP ............................................................ 9-14

9.5.7 FAULT REPORT REGISTER MAP .........................................................9-14

9.5.8 OSCILLOGRAPHY REPORT MEMORY M AP ........................................ 9-15

a CONTROL REGISTERS................................ ......................... ................. 9-15

b OSCILLOGRAPHY HEADER..................................................................9-15

c OSCILLOGRAPHY SETTINGS............................................................... 9-15

d OSCILLOGRAPHY DATA........................................................................ 9-16

e COMMUNICATION EXAMPLE................................................................ 9-16

9.5.9 EVENT CODES & STATUS REGISTERS...............................................9-17

a EVENT CODES.......................................................................................9-17

b SP (STATUS) REGISTERS..................................... ................................ 9-20

c OSC SETTINGS......................................................................................9-23

9.5.10 MMI PASSWORDS.................................................................................. 9-24

9.5.11 SETTINGS ............................................................................................... 9-24

9.5.12 STATION & GENERATOR ID REGISTER MAP .....................................9-24

9.5.13 DATE & TIME............................. .............................................................9-24

9.5.14 MEMORY MAP..................................... ................................................... 9-25

9.6 COIL COMMANDS

9.6.1 DESCRIPTION........................................................................................ 9-49

9.7 FACTORY SETTINGS (GE FACTORY TESTS ONLY)

9.7.1 DESCRIPTION........................................................................................ 9-50

10. GE-LINK SOFTWARE

10.1 INTRODUCTION

10.1.1 OVERVIEW.............................................................................................. 10-1

10.1.2 SYSTEM REQUIREMENTS................. ......................... ..........................10-1

a HARDWARE..................................... ......................... ......................... ..... 10-1

b SOFTWARE.................................. ......................... ......................... ......... 10-1

10.1.3 INSTALLATION... ......................... ......................... ......................... ......... 10-1

10.2 GENERAL OPERATION

10.2.1 PROTECTION JUMPERS.................. ......................... ......................... ...10-2

10.2.2 GE-LINK USER INTERFACE.................................................................. 10-2

10.2.3 ADDING/MODIFYING A SITE (LOCATION) ........................................... 10-2

10.2.4 DELETING A SITE (LOCATION)............................................................. 10-3

10.3 IED CONNECTION

10.3.1 SERIAL CONNNECTION.... ................................................... ................. 10-4

10.3.2 MODEM CONNECTION ..........................................................................10-4

10.3.3 IED MODES................... ......................... ......................... ........................10-5

10.3.4 ADDING/M O D Y F YING AN IED ............. ............. ........................... .......... 10-5

a ADDING AN IED................... .. ............. .. ............. .. ............. .. .............. ...... 10-5

b MODIFYING IED PROPERTIES.............................................................10-6

c DELETING AN IED..................................................................................10-6

10.3.5 RETREIVING INFORMATION.................................................................10-6

10.4 MANIPULATING SETTINGS

10.4.1 EDIT MODE............................................................... ......................... ..... 10-8

10.4.2 SETTINGS MODE................................................................................... 10-8

10.5 PERFORMING OPERATIONS

10.5.1 DESCRIPTION........................................................................................ 10-9

10.5.2 CHANGE PASSWORD........ .......................... .......................................... 10-9

GE Power Management DGP Digital Generator Protection System

vii

Page 12

TABLE OF CONTENTS

10.5.3 MANUAL TRIP........................................................... .............................. 10-9

10.5.4 ENABLE OUTPUTS.......................................................................... ....... 10-9

10.5.5 DISABLE OUTPUTS................................................................................10-9

10.5.6 CHANGE DATE & TIME........................................................................ 10-10

10.5.7 CHANGE GENERATOR/STATION ID................................. ..................10-10

10.5.8 RELAY TEST.........................................................................................10-10

10.5.9 DIGITAL OUTPUT TEST....................................................................... 10-10

10.5.10 DIGITAL RESET.................................................................................... 10-10

10.6 GETTING INFORMATION

10.6.1 DESCRIPTION ......................................................................................10-11

10.6.2 PRESENT VALUES...............................................................................10-11

10.6.3 FAULT REPORT IDENTIFICATION ...................................................... 10-11

10.6.4 FAULT REPORT.................................................................................... 10-11

10.6.5 EVENTS LOG........................................................................................10-11

10.6.6 OSCILLOGRAPHY DATA......................................................................10-12

10.6.7 DGP STATUS........................................................................................ 10-12

10.6.8 DGP MODEL .........................................................................................10-12

10.6.9 STATION/GENERATOR ID...................................................................10-12

10.6.10 MMI PASSWORD..................................................................................10-12

A. TABLES AND FIGURES

B. REVISIONS

C. DGP FAQ

D. WARRANTY

A.1 TABLES AND FIGURES

A.1.1 LIST OF TABLES.......................................................................................A-1

A.1.2 LIST OF FIGURES ........ ......................... ......................... ......................... .A-1

B.1 CHANGE NOTES

B.1.1 REVISION HISTORY.................................................................................B-1

B.1.2 ADDITIONS TO DGP MANUAL..................................... ......................... ...B-1

B.1.3 CHANGES TO DGP MANUAL..................................................................B-3

C.1 DGP FAQ

C.1.1 FREQUENTLY ASKED QUESTIONS .......................................................C-1

C.1.2 NOT-SO-FREQUENTLY ASKED QUESTIONS ........................................C-4

D.1 DGP WARRANTY

viii

DGP Digital Generator Protection System

GE Power Management

Page 13

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED 1.1.1 UNPACKING THE RELAY

The following procedure describes how to unpack and setup the DGP.

1. Unpack and examine the DGP Digita l Generator Protection relay. Ensure each module is properly s eated

in the relay prior to applying power.

2. Apply rated DC power to the relay at the power supply input terminals. Refer to the appropriate elementary

diagram in Section 1 .5: ELE MENTARY DIAGRAMS on page 1–23 for th e loca tion of these t ermin als. Th e

rated DC value (Vps) fo r the relay is found on the na meplate located inside the fr ont cover on the right

side.

3. The DGP settings and control functions are protected by passwords on both MMI and remote access. The

relay is shipped with the factory default passwords that mus t be changed before any setting change or

control command can be executed (GE Modem Version only). The default passwords are listed below:

MODE PAS SWORD

MMI - SETTING 1234.

MMI - MASTER 5678.

REMOTE LINK - VIEW VIEW!

REMOTE LINK - SETTING SETT!

REMOTE LINK - CONTROL CTRL!

Note that the characters "." and "!" are part of the default passwords.

1

4. Instructions on how to use the key pa d to ch ang e s etti ng s a nd p ut t he r elay i nto t es t mo de c an be foun d i n

Section 4.3.2: SETTING CHANGES on page 4–3. Complete instructions on how to operate the keypad are

found in Section 8.3: KEYPAD on page 8–3.

5. To communicate with the relay from a PC, connect the relay to a serial port of an IBM compatible computer

with a DGP null-mode m cable. Connectio n can be made either to the 25 pin D- connector on the b ack of

the relay (PL-1) or the 9 pin D-connector on the front (COM).

6. Refer to Figure 9–1: DGP COMMUNICATIONS WIRING on page 9–3 for the internal wiring of the cable.

7. GE-Link, the communicatio ns software required to access the relay from a PC, is included on the GE

Power Management Pr oduct s CD or avail able f rom the G E P ower Man agement web s ite at www.ge.com/

indsys/pm. Follow instructions in 10.1.3: INSTALLATION on page 10–1 to load GE-Link onto the PC.

8. To log into the relay, follow the instructions in Section 4.4: USING GE-LINK on page 4–5.

9. This instruction book describes functions available in DGP models with standard function groups A, B, and

C. Refer to the Nomenclature Sel ection Guide sh own below to determine func tions included in a specific

model.

GE Power Management DGP Digital Generator Protection System 1-

1

Page 14

1.1 GETTING STARTED 1 PRODUCT DESCRIPTION

g

g

1

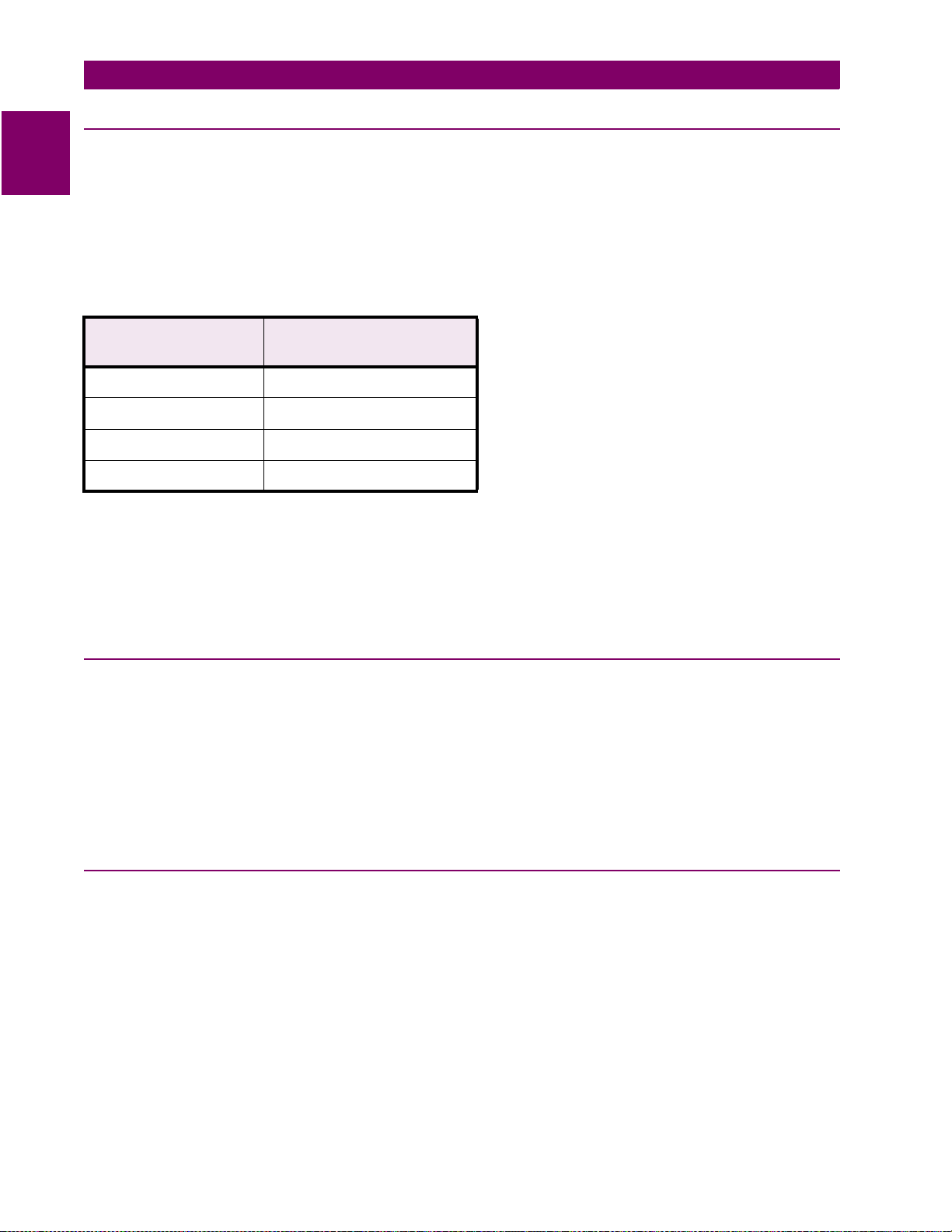

Table 1–1: ORDER CODES

Base Unit

Current Rating

Power Supply

Test Blocks

Protocol

Functions and

Features

Revision

DGP

DGP

* * *

||||||

1

5

0

1

2

3

4

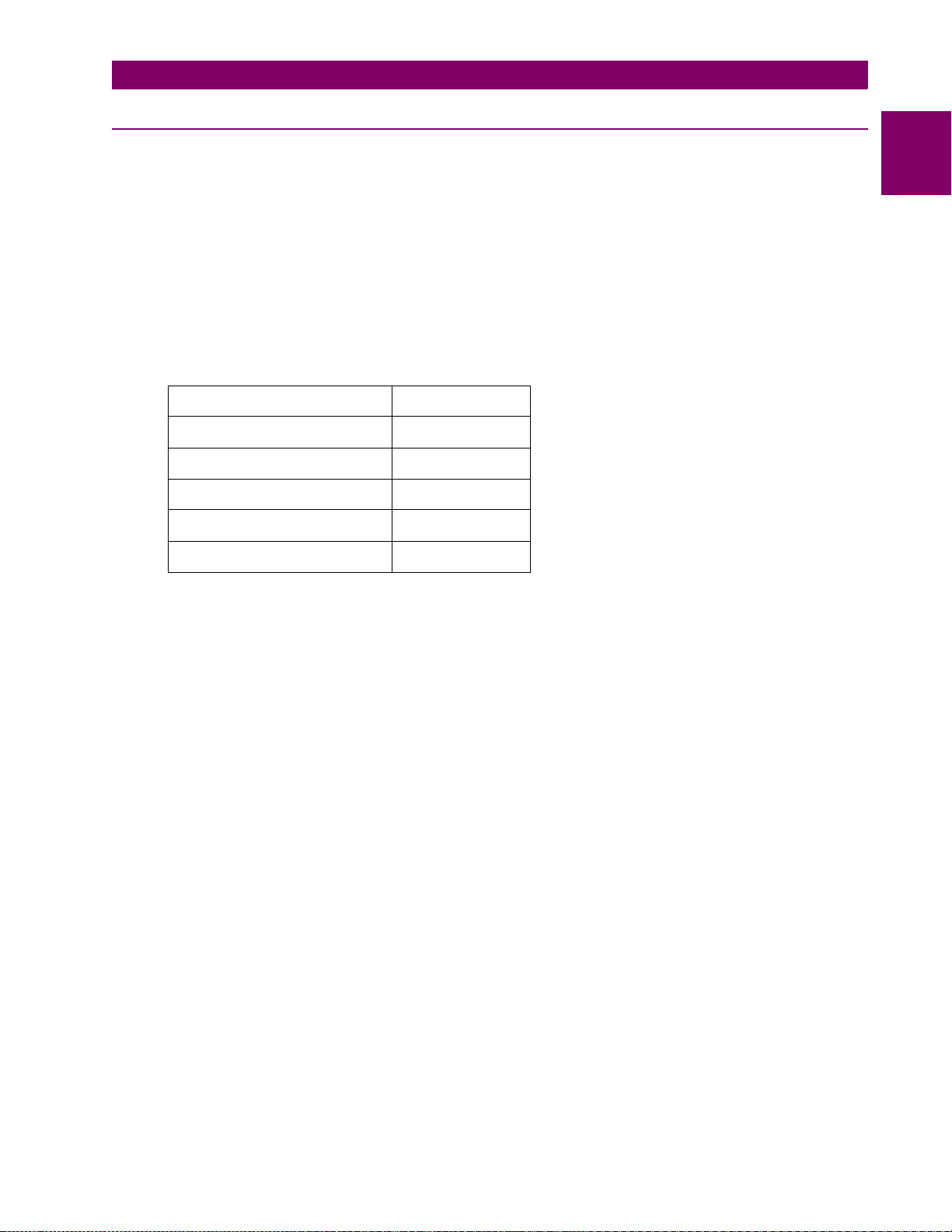

Table 1–2: DGP SELECTION GUIDE

FUNCTIONS & FEATURES A B C

Stator Differential 87G

Current Unbalance 46

Loss of Exc itation 40-1, 40-2

Anti-motorin

Overcurrent Volta

Stator Ground 64G1

Stator Ground 64G2

Stator Ground 27TN

Neutral Overcurrent 51GN Overexcitation 24 (Volts/Hz)

Overvoltage 59

Undervoltage 27 Underfrequency 81-U 424

Overfrequency 81-O 422

Accidental Engergization Logic

Sequential Trip Logic

Voltage Transformer Fuse Failure VTFF

Oscillography Data Capture

RS232 Communications Ports 222

Printer Output

IRIG-B Input

DEC1000 compatible --

c

64G1 is Fundamental Frequency Overvoltage, also known as 59GN

d

64G2 uses 3rd harmonic comparator algorithm for enhanced security

e

27TN is 3rd Harmonic Undervoltage supervised by an adjustable window of forward power.

32

e Restraint 51V

c

d

e

| | | | |

| | | | |

||||

||||

||||

||||

||||

| | |

A

| | |

B

||

A

||

B

A

B

C

1.1.2 ORDER CODES & SELECTION GUIDE

Base Unit

1 Ampere Rated Current

5 Ampere Rated Current

One Power Supply, 48 V DC

One Power Supply, 110 to 125 V DC

One Power Supply, 220 to 250 V DC

Two Power Supplies, 4 8 V DC

Two Power Supplies, 110 to 125 V DC

With T est Blocks

Without Te st Blocks

GE Modem Protocol

Modbus RTU Protcol (DGP***BCA only)

Functions and Features – see DGP selection guide below.

|

|

|

DGP Revision A Firmware

A

✔✔✔

✔✔✔

✔✔✔

212

✔✔✔

✔✔✔

✔

-

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔

✔✔✔

-

✔

✔✔

✔✔

✔✔

-

✔

✔

1-

2

DGP Digital Generator Protection System GE Power Management

Page 15

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED

1.1.3 SPECIAL MODELS

In addition to the stan dard D GP model descri bed by the order codes a bove, s everal specia l mo dels ar e available. Some of these are shown below with a brief description.

DGP***AAA-0101 and DGP***AAA-0102

This model is similar to the standard DGP***AAA except for the following major changes:

• All digital inputs are rated for nominal voltage of 110 to 125 V DC instead of the standard 48 to 250 V DC

• The logic for function 51V is modified to remove fault detector supervision

• Seperate terminals are provided for the optional second power supply input

Refer to instruction book GEK-105552 for additional detail.

DGP***ABA-0005

This model is similar to the standard DGP***ABA except for the following major changes:

• Includes the Stator Ground 27TN function

• Includes oscillography data capture and IRIG-B input capabilities

• Suitable for application with 208 V AC nominal input

Refer to instruction book GEK-105587 for additional detail.

1.1.4 DEC 1000 CONTACT EXPANSION UNIT

1

The DEC 1000 is a relay expan sion unit for the DGP consisti ng of five form C relays and six form A relays.

These contacts can be used for signalling or alarm purposes. Any protection function available in the companion DGP relay can be sele cted for DEC output relay assignment. T he DEC 1000 is connected via the DGP

printer port PL2.

The DEC 1000 expansion unit is only compatible with the DGP

NOTE

kkkkk

C units.

GE Power Management DGP Digital Generator Protection System 1-

3

Page 16

1.2 INTRODUCTION 1 PRODUCT DESCRIPTION

1.2 INTRODUCTION 1.2.1 GENERAL

1

The DGP Digital Generator Protection™ System is a microprocessor-based digital relay system that uses

waveform sampling of curren t and voltage inputs to provide protecti on, control and monitoring of gener ators.

These samples are used to compute current and vol tage phasors that are used for the protection-function

algorithms. The DGP™ system uses a man-machine interface (MMI) and GE-Link software for local and

remote communication respectively.

This instruction book describes all the functions available in the various standard DGP models. Refer

to the SELECTION GUIDE in the previous section to determine functions included in a specific model.

1.2.2 APPLICATION

The DGP system is designed to be used on hydroelectric, gas, and steam generating units. Any size of generator can be protected with this digital system.

More detailed appl ication cons ider ations are contai ned b elow i n the rem aining head ings of this sec tion and i n

Chapter 2: CALCULATION OF SETTINGS.

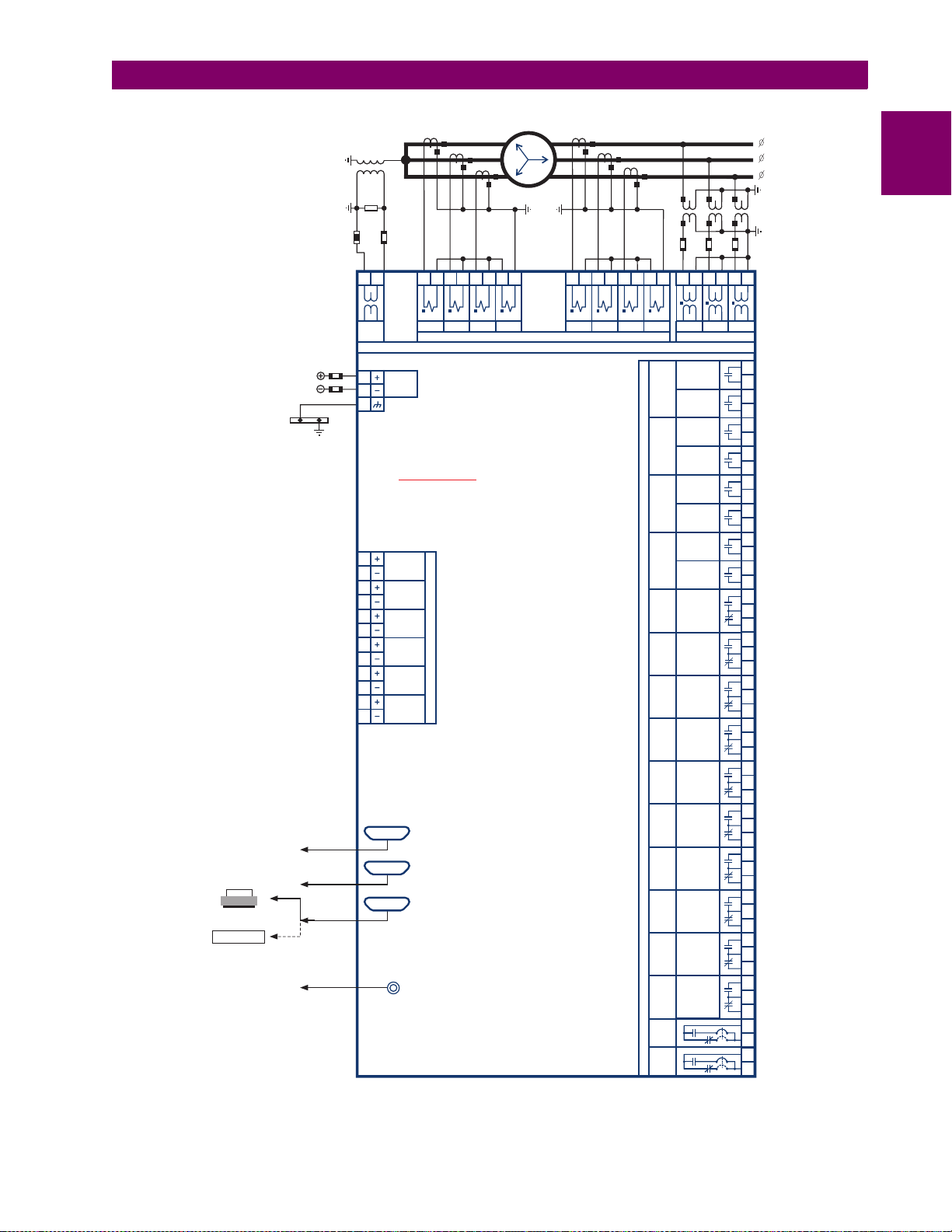

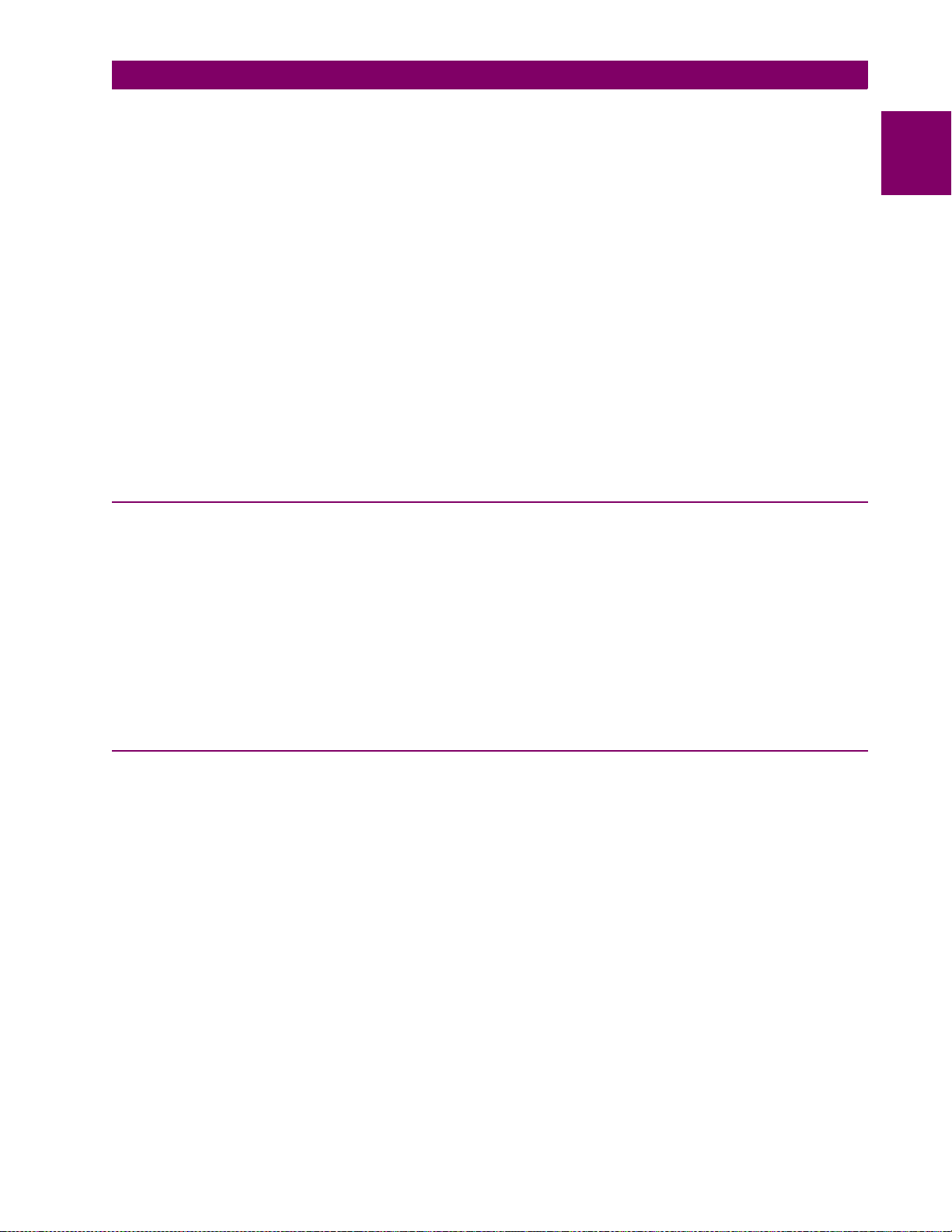

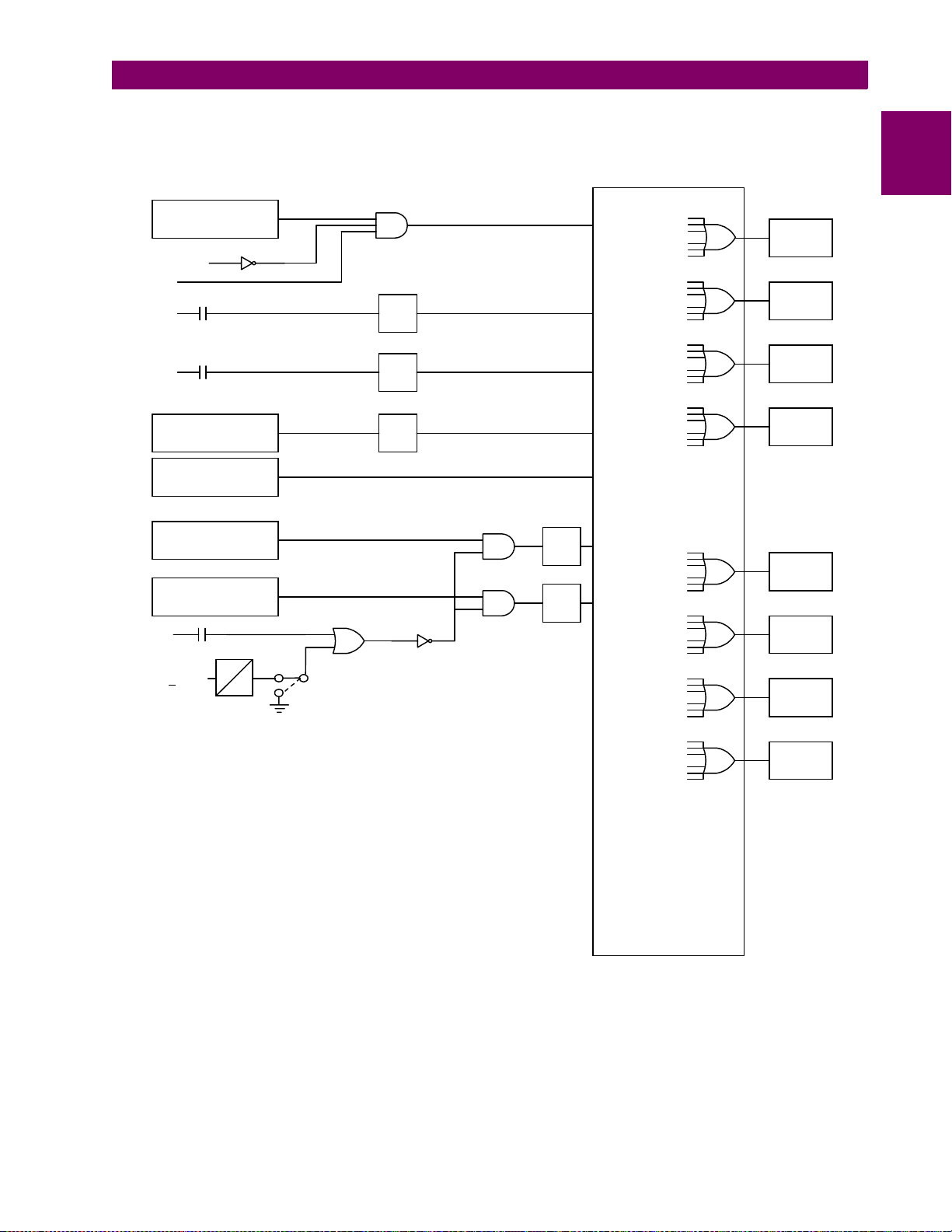

A typical wiring diagram for the DGP relay is shown on the following page.

1-

4

DGP Digital Generator Protection System GE Power Management

Page 17

1 PRODUCT DESCRIPTION 1.2 INTRODUCTION

PRINTER

or

DEC1000

Contact Expansion

Unit

GROUND

BUS

RS-232

RS-232

PRINTER

IRIG-B

CONTROL

POWER

g

AH

AH

AH

AH

1

2

3

4

IBR IBS

IAR

GE Power Management

AG1

AG2

AH

12

VOLT

BH

14

GND

AH

11

DGP

Digital Generator Protection

BG

8

GENERATOR

BG

OFF LINE

7

BG

TURBINE

6

INLET VALVE

BG

LIMIT SWITCH

5

BG

EXTERNAL

4

TRIP 1

BG

3

BG

2

BG

1

BE

4

BE

3

BE

2

BE

1

OSCILLOGRAPH

Disable Prot.

DB9

DB25

DB25

EXTERNAL

TRIP 2

TRIGGER

EXT. VTFF/

(REAR)

(FRONT)

(REAR)

(REAR)

PL3

TS

PU

IN

PL1

PL2

A

C(B)

B(C)

BH

BH

BH

AH

AH

AH

AH

5

6

7

8

ICR ICS

INR INS

CURRENT

INPUTS

BH

1

2

3

4

IAS

A

B

C

BH

BH

BH

BH

BH

BH

BH

8

5

6

7

94G

94G1

94G2

94G3

74A

74B

74C

S

T

U

P

T

U

O

74D

74FF

DOR 12

DOR 13

DOR 9

74 NC

74 CR

POWER

SUPPLY

ALARM 1

POWER

SUPPLY

ALARM 2

9

10

VA

VOLTAGE

TRIP A

(DRY)

TRIP A

TRIP B

(DRY)

TRIP B

TRIP C

(DRY)

TRIP C

TRIP D

(DRY)

TRIP D

ALARM A

ALARM B

ALARM C

ALARM D

VT FUSE FAIL

TEST PICKUP

TEST TRIP

SPARE

SELF TEST

NON

CRITICAL

SELF-TEST

CRITICAL

BH

AH

11

12

9

VB

704753A7.CDR

AH

10

VC

BE

10

BF

10

BE

(+)

14

BF

(-)

14

BE

9

BF

9

BE

(+)

13

BF

(-)

13

BE

8

BF

8

BE

(+)

12

BF

(-)

12

BE

7

BF

7

BE

(+)

11

BF

(-)

11

AG

14

AF

14

AE

14

AG

13

AF

13

AE

13

AG

12

AF

12

AE

12

AG

11

AF

11

AE

11

AG

10

AF

10

AE

10

AG

6

AF

6

AE

6

AG

5

AF

5

AE

5

AG

9

AF

9

AE

9

AG

8

AF

8

AE

8

AG

7

AF

7

AE

7

BF

5

BE

5

BF

BF

6

6

BE

BF

6

6

1

Figure 1–1: TYPICAL WIRING DIAGRAM

GE Power Management DGP Digital Generator Protection System 1-

5

Page 18

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

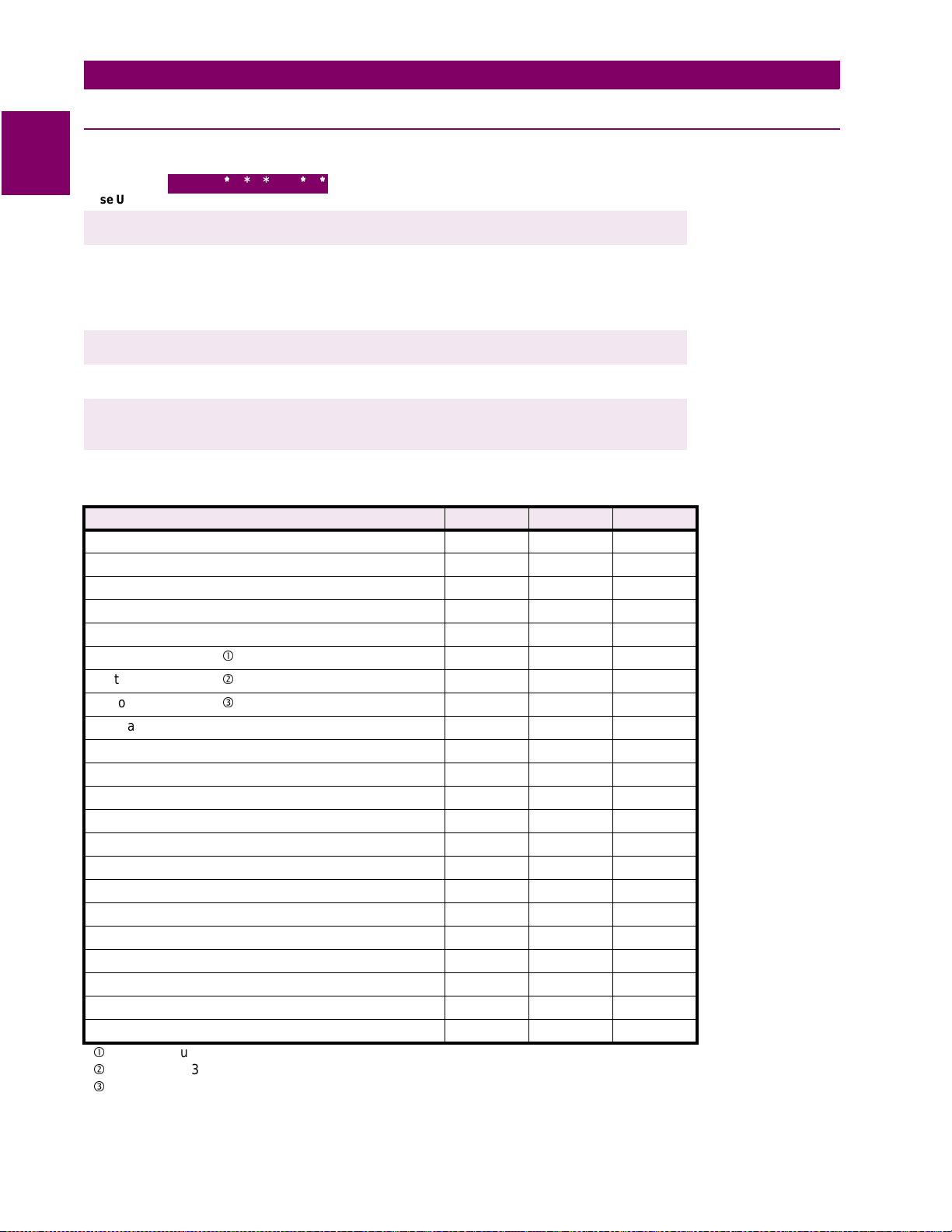

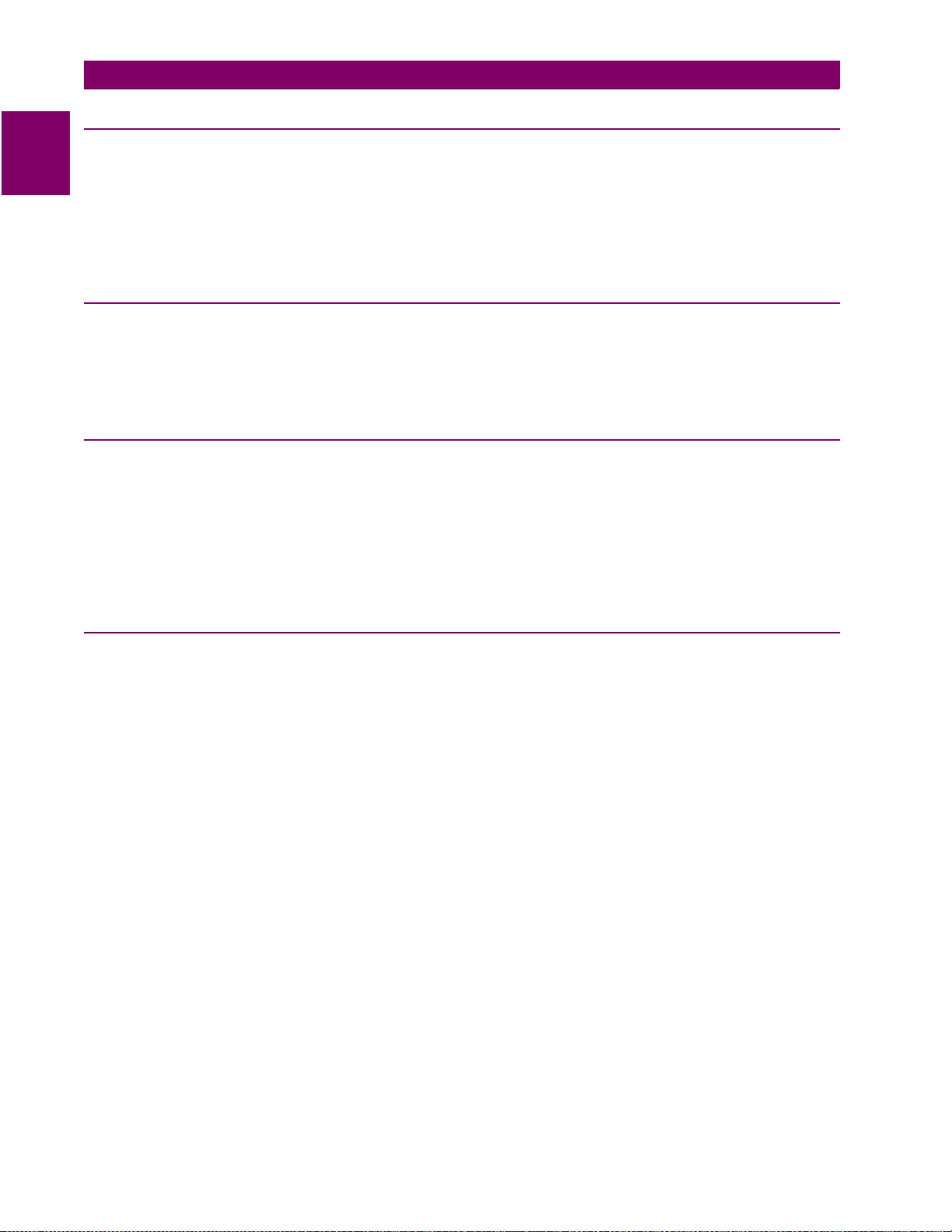

1.3 PROTECTION FEATURES 1.3.1 DESCRIPTION

1

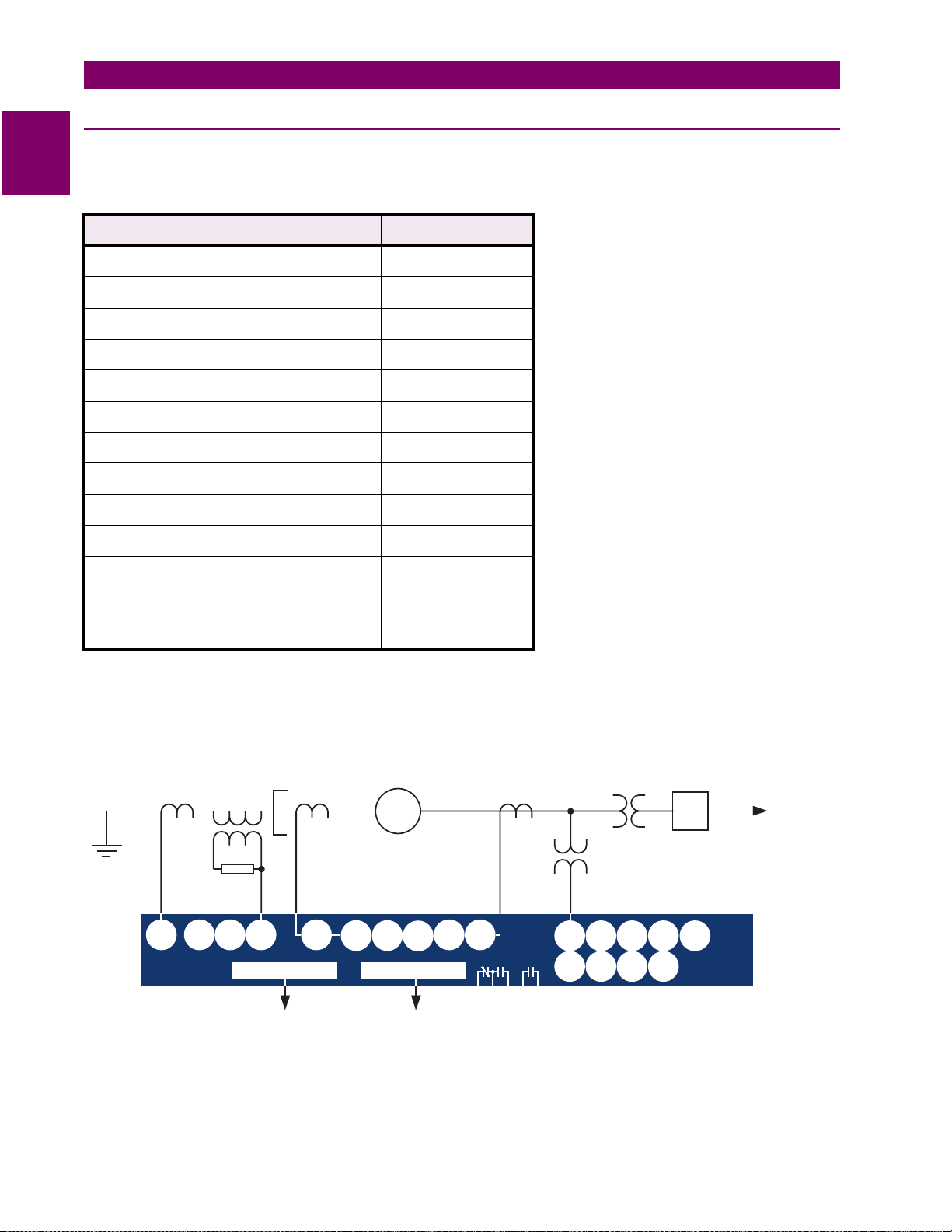

The following protection functions are included with the DGP system.

Table 1–3: DGP PROTECTION FUNCTIONS

PROTECTION FUNCTION ANSI CODE(S)

Stator Differential 87G

Current Unbalance 46

Loss of Excitation 40

Anti-Motoring 32

Time Overcurrent with Voltage Restraint 51V

Stator Ground 64G1, 64G2, 27TN

Ground Overcurrent 51GN

Over-excitation 24

Overvoltage 59

Undervoltage 27

Over and Underfrequency 81

Voltage Transformer Fuse Failure VTFF

Accidental Energization AE

A single-line diagram for the DGP is shown below.

GEN.

51GN

27NT

64G2

64G1

RS232

87G

VTFF

51V

32

RS232

40

46

24

VTFF

64G2

51V

GSU

Transf.

32

40

27

59

52G

81

TO

POWER

SYSTEM

DGP

1-

To

MODEM

To

ALARM

LAPTOP

PC

TRIP

Figure 1–2: SINGLE LINE DIAGRAM

6

DGP Digital Generator Protection System GE Power Management

Page 19

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

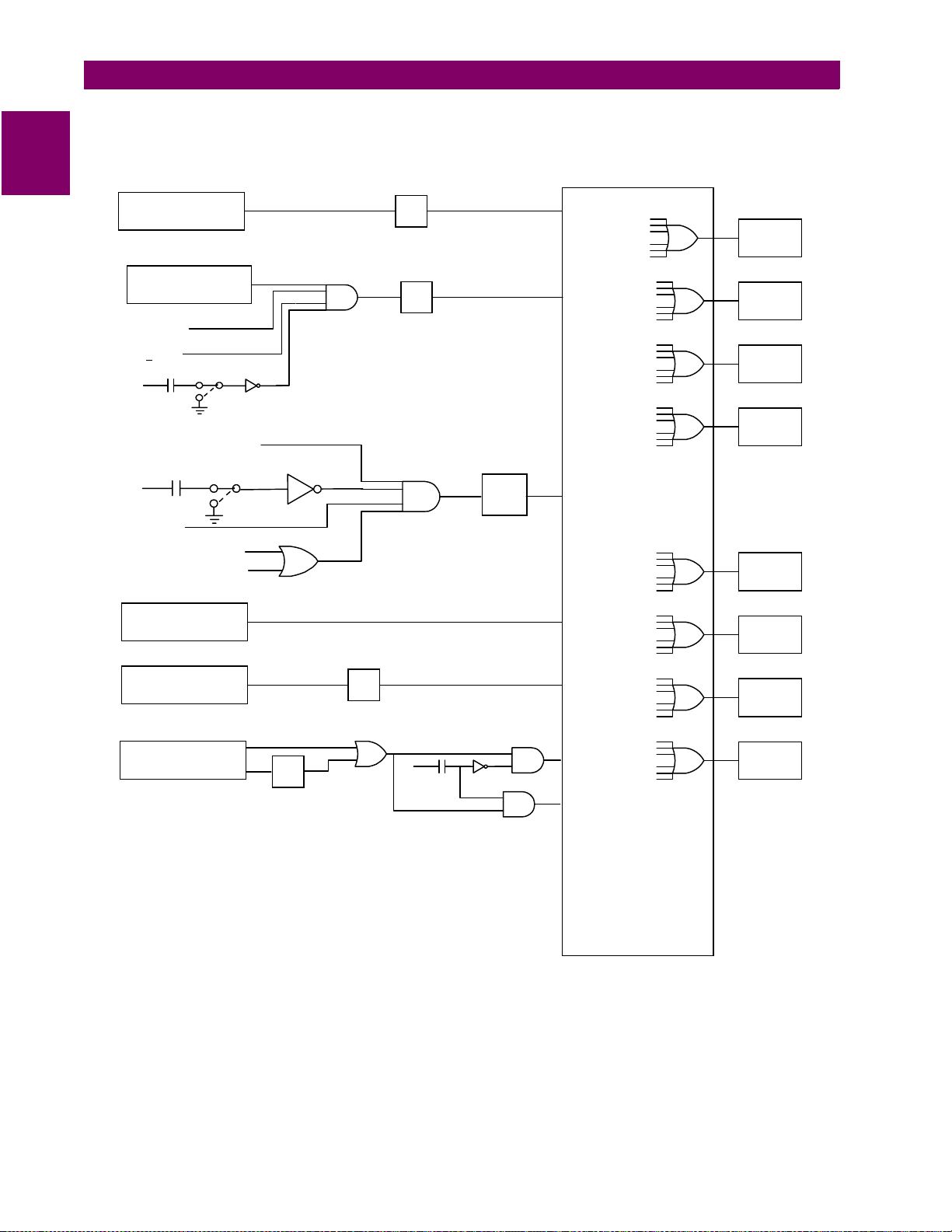

1.3.2 STATOR DIFFERENTIAL (87G)

This function provides high -speed pr otection of the genera tor stat or during inter nal pha se-to- phase an d threephase faults. It uses a product-restraint algorithm with dual-slope characteristic described in Section 2.3.2:

STATOR DIFFER ENTIAL 87G on page 2–13. R efer to Figure 1–3: S IMPLE LOGIC DIAG RAM – 87G, 32 , 27 ,

59, AND AE on page 1–12 for the logic diagram of this function.

Function 87G will not operate for turn-to-turn faults in the machine windings.

It will also not operate for single-phase-to-ground faults if the system is ungrounded or high-impedance

grounded. Phase-to-ground protection by this function requires that the neutral of the machine (or another

machine operating i n parallel) be grounded. A small portio n of the windi ng next to th e neutral will no t be protected, the amount being determined by the voltage necessary to cause minimum pickup current to flow

through the neutral-to-g round impedance. Current-limiting devices in the neutral-ground c ircuit increase this

impedance and will decrease the ground-fault-protection coverage of this function.

1.3.3 CURRENT UNBALANCE (46T)

There are several cause s of generator unba lance . Som e of th ese i nclude unbala nced loads , unbal ance d sy s-

I

tem faults, and/or op en circuits. Th e negative-seque nce component (

) of stator current is directly r elated to

2

this unbalance and sets up a co unter-rota tin g flux fie ld in the mach ine . This in turn ca uses local he ating in the

rotor iron. The c apability of machines to withstand heating caused by unbalance current s is typically experessed in terms of an constant, and is supplied by the manufacturer of the machine.

The current unbalance tri p function (46T) of the DGP provides operating-tim e characteristics expressed as

2

I

T

= K, as shown in Fig ure 2 –6: TIME CURRENT CHARACTE RIS TIC O F 4 6T FUNC TI ON on pa ge 2–1 9. A

2

2

I

T

2

linear reset characteristic is incorporated to approximate the machine cooling following an intermittent currentunbalance condition. In addition to 46T, the DGP s ystem also includes a current-unba lance alarm function,

46A, which is operated by the nega tive-sequence component (I2) with an adj ustable pickup and time delay.

See Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V on page 1–13 for the logic diagram.

1

1.3.4 LOSS OF EXCITATION (40)

This function is used to detect loss of excitation on synchronous machines. It includes two mho characteristics

looking into the machine, each with adjustable reach, offset, and time delay. Logic is provided to block this

function by presence of a negative-sequence voltage (indic ating a voltage trans former fuse failure VTFF condi tion) and/or an external VTFF Digital Input DI6 (see Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V

on page 1–13).

Excitation can be los t due to ina dverten t trippi ng of the fi eld brea ker, open or short circui t on the fie ld wind ing,

regulator failure, or loss of the sour ce to the fie ld win ding. Loss of exci tation can b e dama ging to the m achin e

and/or detrimental to t he operation o f the sys tem. When a sy nchronous generator l oses exci tation, it will tend

to act as an induction generator: it will run above normal speed, operate at reduced power and receive its excitation (VARS) from the system. The impedance seen by a relay looking in to a generator will depend on the

machine characteristics, the load flow prior to the loss of excitation, and the type of excitation failure.

Studies indicates that first zone mho function (40-1) can be set to detect severe cases of excitation failure with

a shorter time d elay, whereas the second zone (40-2) c an be set to det ect all the excitation failure cases. A

longer time delay s etting is required for t he 4 0- 2 fu nc tio n fo r se cu ri ty duri ng sta ble power system swin g c ond itions. Figure 2–7: MHO CHARACTERISTICS FOR 40-1 & 40-2 FUNCTIONS on page 2–21 shows the characteristics of this function.

GE Power Management DGP Digital Generator Protection System 1-

7

Page 20

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

1.3.5 ANTI-MOTORING (32)

1

On a total or partial loss of prime mover, if the power generated is less than no-load losses of the machine, real

power will start flowing into the generator. Typical motoring power of different kinds of prime movers are shown

in the table below. For a specific application, the minimum motoring power of the generator should be obtained

from the supplier of the unit.

The DGP system includes a reverse power function with adjustable time-delay. Either one or two (32-1 & 32-2)

independent setpoints are incorporated depending on the model number.

Table 1–4: TYPICAL MOTORING POWER

TYPE OF PRIME

MOVERS

Gas Turbine 10 to 100

Diesel 15 to 25

Hydraulic Turbine 2 to 100

Steam Turbine 0.5 to 4

The 32-1 can be configured as a part of sequential tripping logic as shown in Figure 1–3: SIMPLE LOGIC DIAGRAM – 87G, 32, 27, 59, AND AE on page 1–12. If the sequential trip logic is used, 32-1 is enabled when closing of turbine inlet v alves is indicated by digital in put DI2 following a turbine trip . The trip sequence is then

continued when timer TL1 times out. The 32-2, if included, is not dependent on the DI2 and is primarily

intended to provide bac k up t o th e s equ ent ial trip . If the sequential trip is no t en abl ed, the 32-1 can be used as

anti-motoring similar to 32-2.

A system must be protected against prolonged generator contribution to a fault. The DGP incorporates a timeovercurrent functio n with vo ltage re straint (51V ) to provi de part of the syst em backu p protecti on. As s hown in

Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V on page 1–13, this function is supervised by a fault

detector and VTFF. The VTFF supervision can be by an internal an d/or external (DI6) VTFF fun ction. See Section 2.3.7: OVERCURRENT WITH VOLTAGE RESTRAINT (51V) on page 2–22 for the characteristic curves of

the 51V . Note that a separate algorithm is processed for each phase, with the restraint provided by corresponding phase voltage. The restraint is proportional to the magnitude of the voltage and is independent of the phase

angle. A linear reset characteristic is incorporated for this function.

MOTORING POWER IN %

OF UNIT RATING

1.3.6 TIME OVERCURRENT WITH VOLTAGE RESTRAINT 51V

1.3.7 ST ATOR GROUND (64G/27TN)

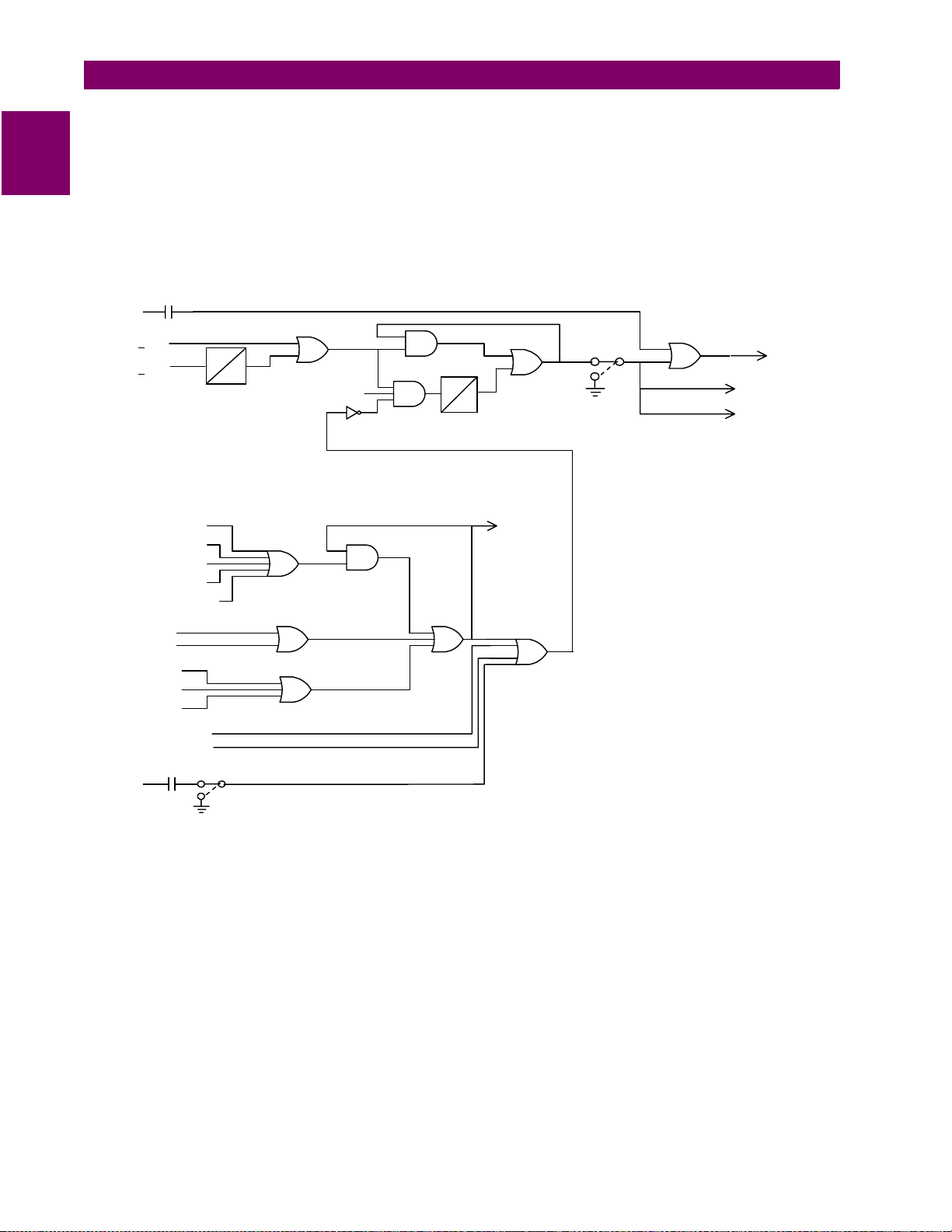

This function consists of two overlapping zones (64G1 and 64G2/27TN) to detect stator ground faults in a highimpedance-grounded generator system. The 64G1 is standard in all DGP models; however, the 64G2/27TN

function is provided in some models only. Together, the two zones cover 100% of the stator windings. See Figure 1–5: SIMPLE LOGIC DIAGRAM – 64G1, 64G2, 51GN, AND 24 on page 1–14.

Normally the generator-stato r neutral has a potential cl ose to ground. With the occurren ce of a stator ground

fault, a potential increase will occur on the neutral for all faults except those near the neutral. 64G1 uses a fundamental-frequency neutral overvoltage to cover about 95% of th e stator winding, depending on the pic kup

voltage setting. Alternately, 64G1 can be used as a generator-bus ground detector in a high-impedance

grounded or an ungrounded system. For this application, the VN input must be a zero-sequence voltage

derived from the generator bus, and functions 64G2/27TN must be disabled.

1-

8

DGP Digital Generator Protection System GE Power Management

Page 21

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

64G2 is based on the perc entage of third-harmonic vo ltage at the generator neutral (VN 3) compared to the

total third-harmonic vol tage gener ated. This func tion is design ed to cover 15 % of the neutral end o f the stator

windings, and is supervised by fundamental and third-harmonic voltage thresholds. These thresholds are fixed

at 30 and 0.5 volts respectively. The third-harmonic comparator method eliminates the need to know the generator harmonic characteristic to use or set this function.

proper operation of 64G2

27TN is the third- harmonic neutral u ndervoltage functio n with a forward power supervision and can be used

with either wye or delta connected VTs. The percentage of stator windings covered by this function depends on

its threshold setting as well as the VN3 generated b y the machine at the time of th e fault. The magnitude of

VN3 under normal condi tions is a function of several factors, su ch as type of generator, load current, load

power factor, system status, etc. It can be very small (nearly zero) under some conditions. T o enhance security

during low VN3 vo lta ge conditions, this f unc tio n can b e i nhi bi ted by a se tt able window of forward power. However, it should be noted that other condi tions influenci ng the VN3 vol tage may make 2 7TN insecu re. In these

cases, function 64G 2 (available in some models; see the DGP nomenclature guide) or some other means

should be considered.

Digital input DI1 can be co nfigured to bloc k 64G2/27T N when the gener ator is off-line. Thi s provision is made

to enhance security of the functions under conditions such as static start of a gas turbine generator. Temporary

ungrounding of generator neutral during the static start can look like a ground fault near the neutral.

.

Note that wye-connected VTs are required for

1.3.8 GROUND OVERCURRENT (51GN)

1

51GN is an inverse overcurrent function available in some models. It can be used to detect stator ground faults

in a high or low resist ance grounded generator sy stem. See Fig ure 1–5: SIM PLE LOGIC DIA GRAM – 64G1,

64G2, 51GN, AND 24 on pa ge 1–14 for simplified logic diagram and Figure 2 –16: 51GN TIME-CURRENT

CHARACTERISTICS on page 2–39 for the inverse time-current characteristics.

This function uses current INR which can be derived by residual connection or by using a generator neutral CT

as noted in F igures 1–9: ELEMENTARY DIAGRAM WITH TE ST BLOCKS, WYE VTs and 1–12: ELEMENTARY DIAGRAM WITHOUT TEST BLOCKS, DELTA VTs.

Since this function is independen t of the phase current inputs , it can alterna tely be connect ed to a CT in the

neutral of the generator step-up transformer.

1.3.9 OVEREXCITATION (24)

Overexcitation can b e caus ed by reg ulator failure , load r eject ion, or an exce ssiv e excit ation wh en the ge nerator is off-line. It can also resul t from decr easing spee d while the regulator o r an operator a ttempts to m aintain

rated stator voltage. The Volts/Hertz quantity is proportional to magnetic flux in the generator and step-up

transformer cores, and is use d to detect the overexcitation condition. Se e Figure 1–5: SIMPLE LOGIC DIAGRAM – 64G1, 64G2, 51GN, AND 24 for details.

The overexcitation protection includes trip (24T) and alarm (24A) functions. 24T consists of an inverse function

and an instantaneous fu nction with time-delay characteris tics. The combination of these two char acteristics

allows the 24T setting to cl osely follow the generator and/or ste p-up transformer V/Hz limit curve. Bo th 24A

and 24T are computed for each of the three phase voltages (see Table 2–3: 24A VOLTAGES on page 2–30).

Function 24T can be c onfigu red to operate d ifferent ou tput re lays for gene rator on -lin e and o ff-line condi tions.

This function incorpora tes a user-settable li near reset character istic to mimic machi ne cooling. The figu res in

Section 2.3.12: OVEREXCITATION TRIP (VOLTS/HERTZ: 24T) show the characteristics of this function.

GE Power Management DGP Digital Generator Protection System 1-

9

Page 22

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

1.3.10 OVERVOLTAGE (59)

1

This function consists of a positive-sequence overvoltage with an user selectable inverse or definite time characteristic. See Figure 1–3: S IMPLE LOGIC DIAGRAM – 87G, 32, 27, 59, AND AE on page 1–12 fo r the logic

diagram and Figure 2–15: 59 TIME-VOLTAGE CHARACTERISTICS on page 2–35 for the inverse time-voltage

characteristics. A l inear reset charact eristic is incorp orated for this function. The overvoltage functi on can be

considered as a backup to the Volts/Hz function. Some possible causes of this cond ition are a system dis turbance or regulator failure.

1.3.11 UNDERVOLTAGE (27)

This function consists of a positive-sequence undervoltage with an user selectable inverse or definite time

characteristic. See Figur e 1–3: SIMPLE LOGIC DIAG RAM – 87G, 32, 27, 59, AND AE on p age 1–12 for the

logic diagram and Figu re 2–17: 27 TIME -VOLTAGE CHARACTER ISTICS on pa ge 2–40 for the inv erse timevoltage characteristics. A linear reset characteristic is incorporated for this function.

1.3.12 OVER AND UNDERFREQUENCY (81)

This function provides over and underfrequency protection, each with an adj ustable time delay. Two or four

over and underfrequency ste ps are provided dep ending on the model. Al l frequency functi ons are supervise d

by an adjustable positive-sequence voltage level. This undervoltage cut-off level and/or digital input DI1 can be

used to block the freq uency functions during sta rt-up. Fr equency dis turbance c an occur due to a system fault

or islanding of the unit or an unconnected unit can operate at abnormal frequency due to malfunction of speed

control. Figure 1 –6: SIMPLE LOGIC DIA GRAM – 81-O A ND 81-U on page 1 –15 show s the l ogic diag ram for

this function.

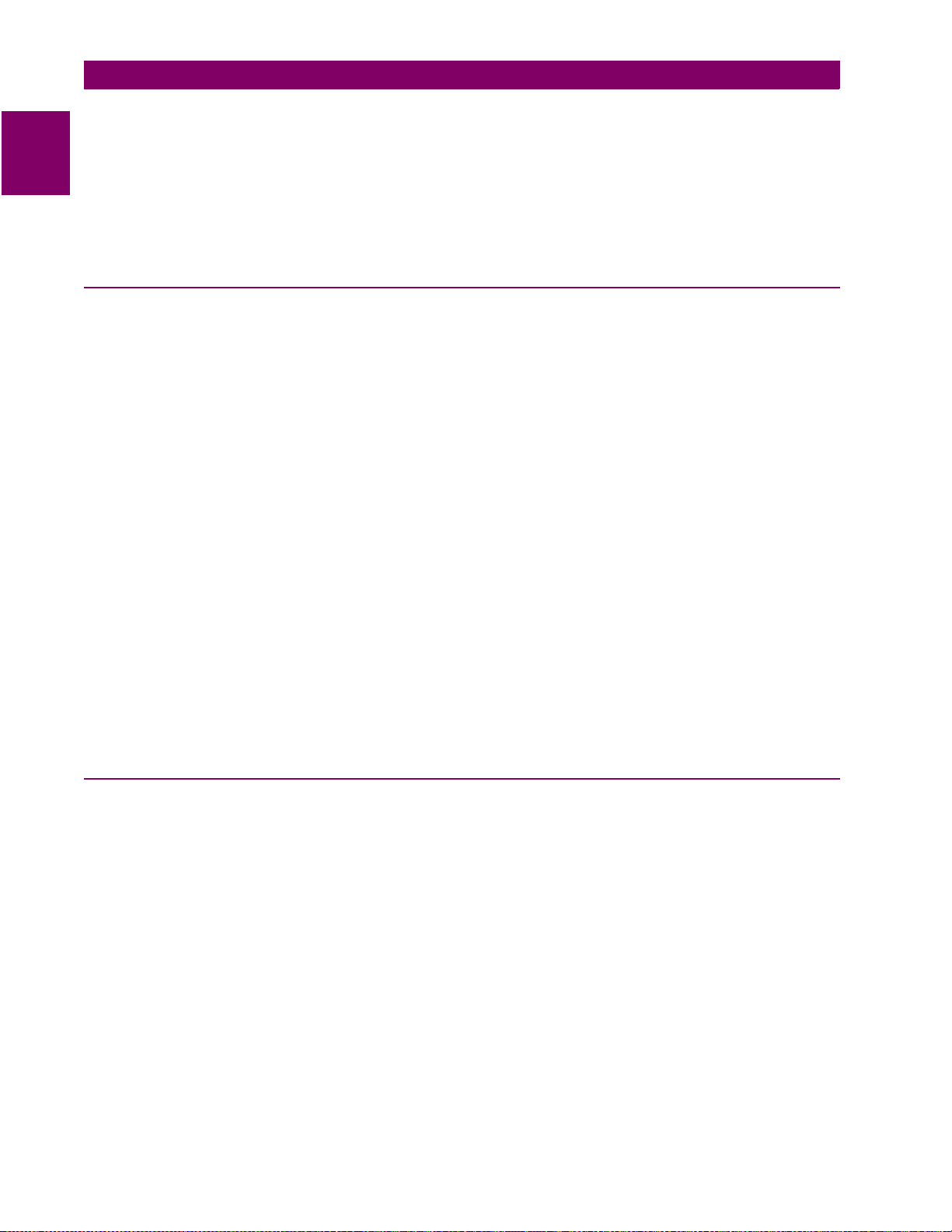

1.3.13 VOLTAGE TRANSFORMER FUSE FAILURE (VTFF)

Functions 40 and 51V may operate for a full or partial loss of AC potential caused by one or more blown fuses.

The DGP makes provisions to block tripping by these functions when a fuse failure is detected; all other protection functions are a llowe d to t rip. Fig ure 1–7: SIMP LE L OGIC DIA GRAM – VT F USE FAILURE on pag e 1–1 6

shows the logic diagram for the VTFF function.

If AC potential is lost on one or more phas es, the negative-seque nce voltage (V2) rise s and/or the positivesequence voltage ( V1) drops. Either V2 > 15V or V1 < 50V provides a basic ind ication o f the VTFF c ondition .

This signal is supervi sed by a Distur bance Dete ctor (DD) and gene rator posit ive-se quence cu rrent (I1) dete ctor (see three-inp ut AND gate on the log ic diagram). Supervision by the DD and I1 signa ls provide security

against false ope ration du ring fault a nd genera tor out of service conditio ns respec tively. Security is enhance d

by use of the A/0 and B/0 timers shown in the logic diagram.

Signal DD is derived from a combination of sequence current levels, change in levels, and pickup flags of various protection functions as shown in the logic diagram.

The VTFF logic allows integration of an external VTFF contact. Either of the two fuse-failure signals or both

signals can be configured to block tripping of functions 40 and 51V.

Detection of VTFF energizes the 74FF (Fuse Failure alarm) relay, de-energizes the 74CR (critical alarm) relay,

and turns the status LED red, even though all protection functions except 40 and 51V are unaffected.

1-

10

DGP Digital Generator Protection System GE Power Management

Page 23

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

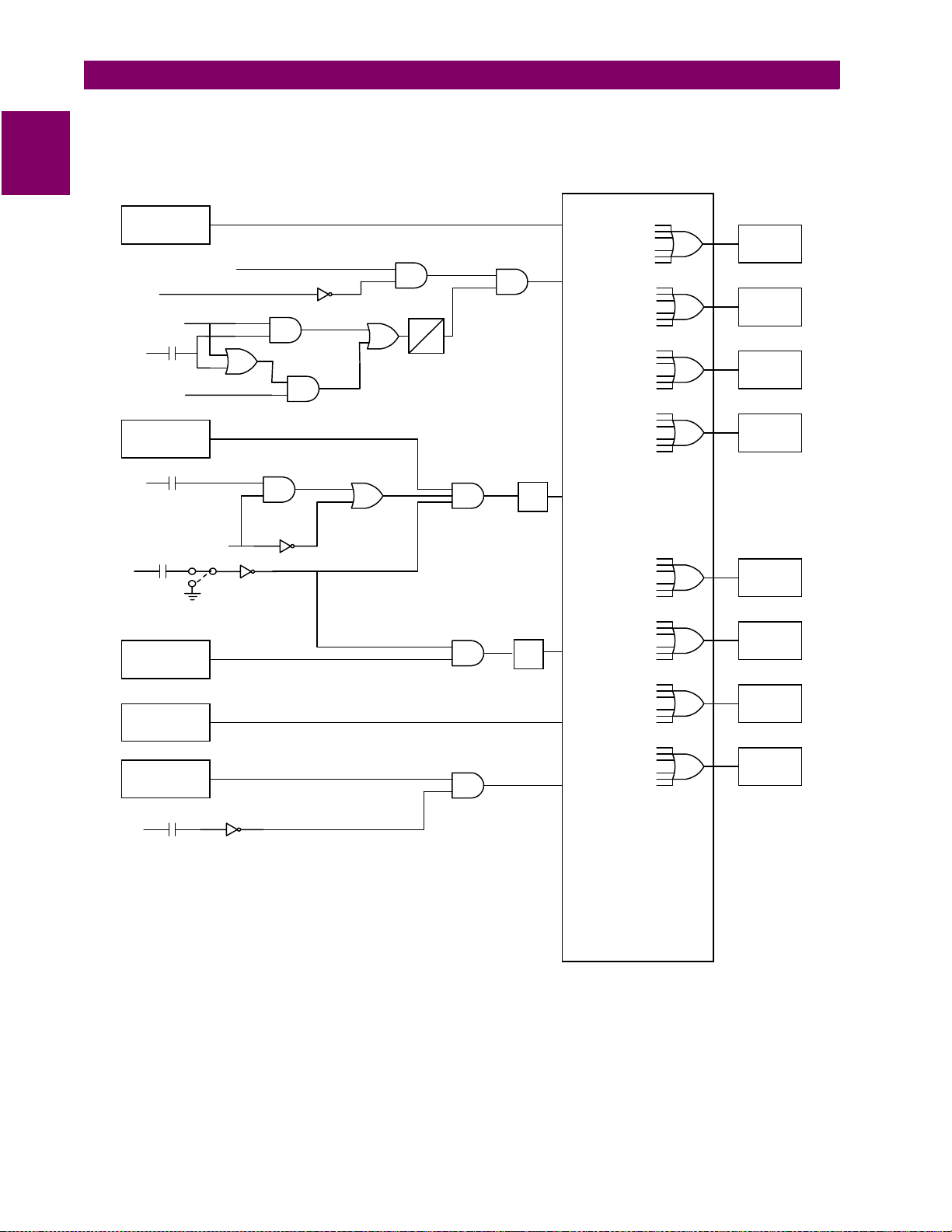

1.3.14 ACCIDENTAL ENERGIZATION (AE)

The DGP includes logic to detect accidental energization of the gener ator (see Figure 1–3: SIMPLE LOGIC

DIAGRAM – 87G, 3 2, 27, 59, AND AE on page 1–12). When a generator is energized while at standstill or

reduced speed, it behaves and acc elerates as an induction mot or. The machine terminal voltage and current

during such an event will be a function of generator, transformer, and system impedances.

An instantaneous over cu rren t si gna l (50) is used to det ect t he acci de ntal ener g izati on. T his s ig nal is arm ed by

a logic signal de rived from positive- sequence voltage and GEN O FF LINE input DI1. These two "arming " signals can be confi gured in AND or O R mode by Se tting 2703:

after the generator is taken out of service. The logic automatically disarms itself during a normal start-up

sequence when the voltage detector picks up and/or the generator is on-line.

For the AE logic to perform, special precautions must be taken to ensure that the DGP system and associated

trip circuits remain in service when the generator is out of service. Additionally, the generator off-line input, DI1,

must be reliable. It should also be noted that the pickup flag of function 51V is used as signal 50; therefore this

logic will automatically be disabled if function 51V is disabled.

AE ARM

. The 50 function is armed 5 seconds

1

GE Power Management DGP Digital Generator Protection System 1-

11

Page 24

1

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

Stator

Differential

50 (51V Pickup Flag)

VTFF

V1 < 30V

DI1

(+)

Gen. Off-line

OR

AE ARM

Reverse Pwr.

No. 1

(+)

DI2

Turbine Inlet Valve

Closed

Seq. Trip Enabled

DI1

(+)

Gen.

Off-Line

SELBKDI1

Reverse Pwr.

No. 2 (1)

AND

AND

AND

AND

PU

OR

PU=5 sec

DO=0.25 sec

DO

ANDOR

AND

AND

AND

TL1

TL2

87G

87G

AE

AE

32-1

32-2

OR

OR

OR

OR

OR

OR

TRIP A

94G

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

ALARM

74A

ALARM

74B

Overvoltage

59

Undervoltage

(+)

(1)

DI1

Gen.

Off-Line

AND

27

NOTES:

(1) Indicates an optional function (includes associated logic). Refer to

CONFIGURABLE

DGP nomenclature selection guide for available functions in a

specific model.

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

Figure 1–3: SIMPLE LOGIC DIAGRAM – 87G, 32, 27, 59, AND AE

LOGIC (2)

OR

OR

ALARM

74C

ALARM

74D

1-

12

DGP Digital Generator Protection System GE Power Management

Page 25

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

1

Overcurrent

(voltage restraint)

VTFF + DI6

FD

(+)

(+)

DI3

External Trip - 1

DI4

External Trip - 2

Current Unbalance

(Alarm)

Current Unbalance

(Trip)

Loss of Excitation

Zone 1

Loss of Excitation

Zone 2

DI6

(+)

V

2

Ext. VTFF

>

PU

15V

PU=3 Samples

DO=5 Samples

DO

ENA

SELV2SUP

DIS

OR

AND

TL21

(1)

TL22

(1)

TL14

87G

51V

OR

TRIP A

94G

AE

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

DI3

DI4

46A

OR

OR

OR

46T

TL12AND

TL13AND

40-1

40-2

OR

OR

OR

ALARM

74A

ALARM

74B

ALARM

74C

OR

ALARM

74D

NOTE:

(1) Timers TL21 and TL22 are available in models DGP***ACA only.

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

CONFIGURABLE

LOGIC (2)

DSPLGC2.VSD

Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V

GE Power Management DGP Digital Generator Protection System 1-

13

Page 26

1

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

Stator Ground

Zone 1

Stator Ground

Zone 2 (1)

VP3 > 0.5V

V1

30V

>

DI1

(+)

Gen.

Off-Line

V

≤

N3

GEN. OFF-LINE

(+)

DI1

V

25V

≥

1

SELBKDI1

27TN PICKUP

SELBKDI1

POWER < FORPWR-L

POWER > FORPWR-H

Neutral Overcurrent

(1)

OR

AND

TL4

TL5

AND

TL20

64G1

64G2

27TN

(1)

51GN

OR

OR

OR

OR

OR

OR

TRIP A

94G

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

ALARM

74A

ALARM

74B

Overexcitation

(Alarm)

Overexcitation

(Trip)

Time

Inst

TL7

TL6

OR

(+)

DI1

Gen.

Off-Line

AND

AND

24A

24T

(On-Line)

24T

(Off-Line)

NOTES:

(1) Indicates an optinal function (includes associated logic). Refer to

DGP nomenclature selection guide for available functions in a

specific model.

CONFIGURABLE

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

Figure 1–5: SIMPLE LOGIC DIAGRAM – 64G1, 64G2, 51GN, AND 24

LOGIC (2)

OR

OR

ALARM

74C

ALARM

74D

1-

14

DGP Digital Generator Protection System GE Power Management

Page 27

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

1

Under Frequency

Set Point - 1

Under Frequency

Set Point - 2

Under Frequency

Set Point - 3 (1)

Under Frequency

Set Point - 4 (1)

DI1

(+)

Gen.

Off-Line

SELBKDI1

V1 > UVCUTOFF

Over Frequency

Set Point - 1

AND

AND

AND

AND

AND

TL8

TL9

TL10

TL11

TL15

81-1U

AE

81-2U

81-3U

81-4U

81-1O

OR

OR

OR

OR

OR

OR

TRIP A

94G

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

ALARM

74A

ALARM

74B

Over Frequency

Set Point - 2

AND

TL16

81-2O

Over Frequency

Set Point - 3 (1)

AND

TL17

81-3O

Over Frequency

Set Point - 4 (1)

AND

TL18

81-4O

NOTES:

(1) Indicates an optional function (includes associated logic). Refer to

DGP nomenclature selection guide for available functions in a

specific model.

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

CONFIGURABLE

Figure 1–6: SIMPLE LOGIC DIAGRAM – 81-O AND 81-U

OR

OR

LOGIC (2)

ALARM

74C

ALARM

74D

GE Power Management DGP Digital Generator Protection System 1-

15

Page 28

1

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

DI6

(+)

External VTFF

V2

15V

>

50V

V1

<

51V Pickup Flag

40 Pickup Flag

87G Pickup Flag

51GN Pickup Flag

21 Pickup Flag (Fut.)

I0 ≥ 0.6 / *

∆

∆

I2 ≥ 0.6 / *

∆

I0| ≥ 0.2 / *

|

I1| ≥ 0.2 / *

|

∆

|∆I2| ≥ 0.2 / *

64G1 Pickup Flag

64G2 Pickup Flag

DI1

(+)

Gen.

Off-Line

PU

PU=9000 samples

DO=0

SELBKDI1

DO

OR

I1 > 0.1/*

OR

OR OR

OR

AND

AND

AND

PU

DO

PU = 36 samples

DO = 0

FD

OR

Supervise

51V,

21(Future)

OR

DD

ENA

DIS

VTFF

VTFF + DI6

OR

Supervise

51V,

21(Future)

VTFF Alarm

Critical Alarm

1-

NOTE:

* = 1 FOR 5 AMP RATED DGPs.

* = 5 FOR 1 AMP RATED DGPs.

Figure 1–7: SIMPLE LOGIC DIAGRAM – VT FUSE FAILURE

16

DGP_VTFF.VSD

DGP Digital Generator Protection System GE Power Management

Page 29

1 PRODUCT DESCRIPTION 1.4 OTHER FEATURES

1.4 OTHER FEATURES 1.4.1 INPUTS

The DGP system takes eight current and four voltage inputs (refer to Section 1.5: ELEMENTARY DIAGRAMS).

The input currents in terminals BH1, BH3, and BH5 (I

, IBS, and ICS) are used to process functions 46, 40, 32,

AS

and 51V. As noted in the elementary diagrams, these currents can be derived from system side or neutral side

CTs as de sired. Either the sy stem or n eutral s ide CTs can be used fo r these functi ons if the Stator D ifferential

(87G) function is enabled.

The current input s I

and INR are derived from th e resid ual connec tions of t he respe ctive phas e CTs and do

NS

not require dedicated neutral CTs. Zero-sequence current at system and/or neutral side of the generator stator

windings is calculated and then compared with the measured I

and/or INR values by the DGP as a part of the

NS

background self-test.

The I

icated neutral CT can be used for the input I

The DGP phase volta ge i npu ts c an be wye or delta and are derived f ro m the gen er ato r term in al v ol tag e. V

current is used to process the 51GN function (not available on DGP***AAA models). If desired, a ded-

NR

NR

.

is

N