Page 1

g

GEPowerManagement

DGP

Digital Generator Protection Relay™

Instruction Manual

DGP Revisions:V210.12000P

V210.10000F

V211.32000J

V210.22000D

Manual P/N: GEK-100666D

Copyright © 2000 GE Power Management

All relays must be powered up at least once per year

to avoid deterioration of electrolytic capacitors and

NOTE

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

subsequent relay failure.

Manufactured under an

ISO9002 Registered system.

Page 2

These instructions do not purport to co ve r all de tails o r variat ions in e quipment

g

g

g

nor provide for every possible contin

ency to be met in connection with

installation, operation, or maintenance. Should further information be desired

or should particular problems arise which are not covered sufficiently for the

purchaser’s purpose, the matter should be refe rred to the General Electric

Company.

To the extent required the products described herein meet applicable ANSI,

IEEE, and NEMA standards; but no such assurance is

local codes and ordinances because they vary

reatly.

iven with respect to

Page 3

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED 1.1.1 UNPACKING THE RELAY

The following procedure describes how to unpack and setup the DGP.

1. Unpack and examine the DG P Digital Gene rator Prote ction relay. Ensure each module is pro perly seated

in the relay prior to applying power.

2. Apply rated DC power to the relay at the power supply input terminals. Refer to the appropriate elementary

diagram in Section 1 .5: ELE MENTARY DIAGRAMS on page 1–23 for th e loca tion of these t ermin als. Th e

rated DC value (Vps) fo r the relay is found on the na meplate located inside the fr ont cover on the right

side.

3. The DGP settings and control functions are protected by passwords on both MMI and remote access. The

relay is shipped with the factory default passwords that mus t be changed before any setting change or

control command can be executed (GE Modem Version only). The default passwords are listed below:

MODE PAS SWORD

MMI - SETTING 1234.

MMI - MASTER 5678.

REMOTE LINK - VIEW VIEW!

REMOTE LINK - SETTING SETT!

REMOTE LINK - CONTROL CTRL!

Note that the characters "." and "!" are part of the default passwords.

1

4. Instructions on how to use the keypad to change setti ng s a nd p ut the relay into test mo de can be found in

Section 4.3.2: SETTING CHANGES on page 4–3. Complete instructions on how to operate the keypad are

found in Section 8.3: KEYPAD on page 8–3.

5. To communicate with the relay from a PC, connect the relay to a serial port of an IBM compatible computer

with a DGP null-mode m cable. Connectio n can be made either to the 25 pin D- connector on the b ack of

the relay (PL-1) or the 9 pin D-connector on the front (COM).

6. Refer to Figure 9–1: DGP COMMUNICATIONS WIRING on page 9–3 for the internal wiring of the cable.

7. GE-Link, the communications software required to access the relay from a PC, is included on the GE

Power Management Pr oduct s CD or avail able f rom the G E P ower Man agement web s ite at www.ge.com/

indsys/pm. Follow instructions in 10.1.3: INSTALLATION on page 10–1 to load GE-Link onto the PC.

8. To log into the relay, follow the instructions in Section 4.4: USING GE-LINK on page 4–5.

9. This instruction book describes functions available in DGP models with standard function groups A, B, and

C. Refer to the Nomenclature Sel ection Guide sh own below to determine func tions included in a specific

model.

GE Power Management DGP Digital Generator Protection System 1-

1

Page 4

1.1 GETTING STARTED 1 PRODUCT DESCRIPTION

g

g

1

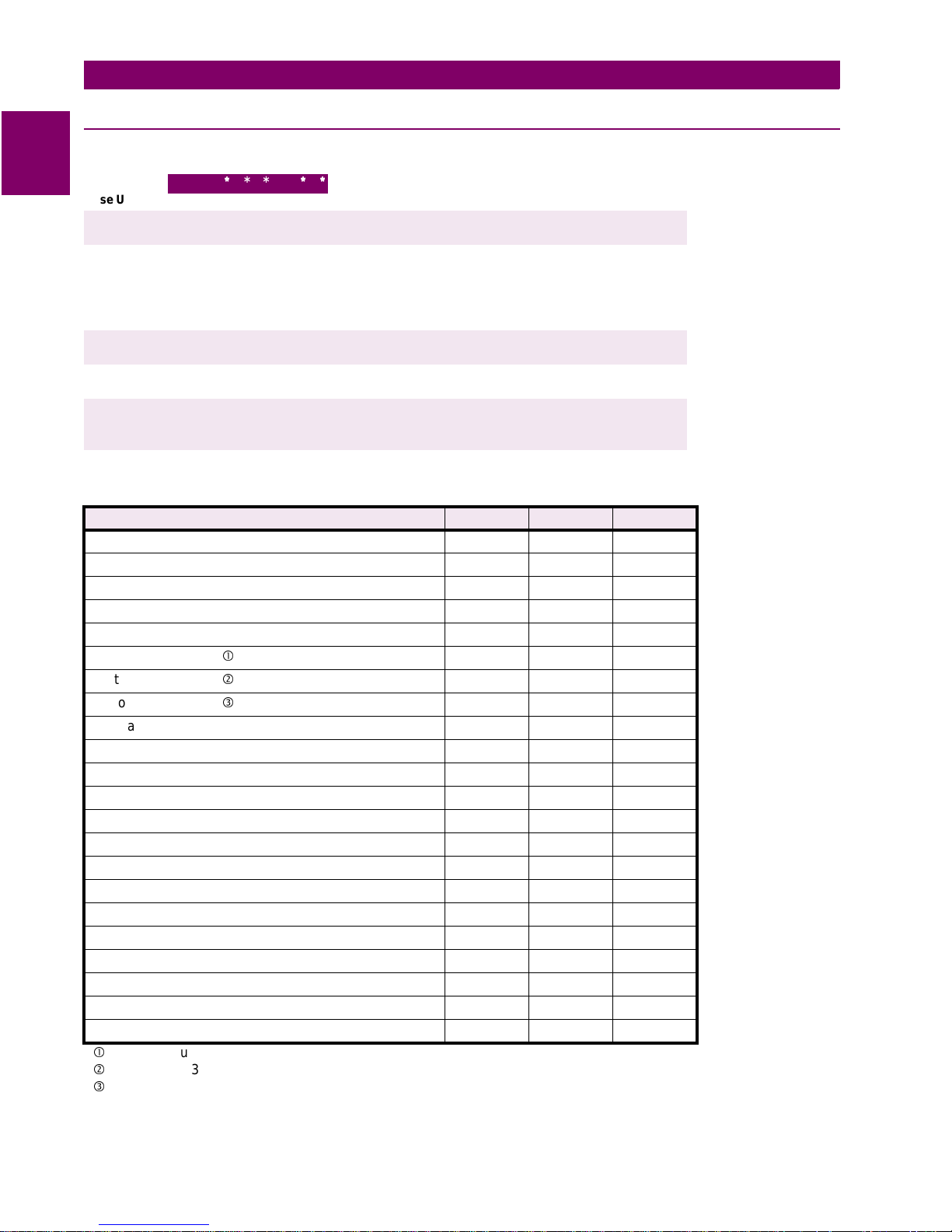

Table 1–1: ORDER CODES

Base Unit

Current Rating

Power Supply

Test Blocks

Protocol

Functions and

Features

Revision

DGP

DGP

* * *

||||||

1

5

0

1

2

3

4

Table 1–2: DGP SELECTION GUIDE

FUNCTIONS & FEATURES A B C

Stator Differential 87G

Current Unbalance 46

Loss of Exc itation 40-1, 40-2

Anti-motorin

Overcurrent Volta

Stator Ground 64G1

Stator Ground 64G2

Stator Ground 27TN

Neutral Overcurrent 51GN Overexcitation 24 (Volts/Hz)

Overvoltage 59

Undervoltage 27 Underfrequency 81-U 424

Overfrequency 81-O 422

Accidental Engergization Logic

Sequential Trip Logic

Voltage Transformer Fuse Failure VTFF

Oscillography Data Capture

RS232 Communications Ports 222

Printer Output

IRIG-B Input

DEC1000 compatible --

c

64G1 is Fundamental Frequency Overvoltage, also known as 59GN

d

64G2 uses 3rd harmonic comparator algorithm for enhanced security

e

27TN is 3rd Harmonic Undervoltage supervised by an adjustable window of forward power.

32

e Restraint 51V

c

d

e

| | | | |

| | | | |

||||

||||

||||

||||

||||

| | |

A

| | |

B

||

A

||

B

A

B

C

1.1.2 ORDER CODES & SELECTION GUIDE

Base Unit

1 Ampere Rated Current

5 Ampere Rated Current

One Power Supply, 48 V DC

One Power Supply, 110 to 125 V DC

One Power Supply, 220 to 250 V DC

Two Power Supplies, 4 8 V DC

Two Power Supplies, 110 to 125 V DC

With T est Blocks

Without Te st Blocks

GE Modem Protocol

Modbus RTU Protcol (DGP***BCA only)

Functions and Features – see DGP selection guide below.

|

|

|

DGP Revision A Firmware

A

✔✔✔

✔✔✔

✔✔✔

212

✔✔✔

✔✔✔

✔

-

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔

✔✔✔

-

✔

✔✔

✔✔

✔✔

-

✔

✔

1-

2

DGP Digital Generator Protection System GE Power Management

Page 5

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED

1.1.3 SPECIAL MODELS

In addition to the stan dard D GP model descri bed by the order codes a bove, s everal specia l mo dels ar e available. Some of these are shown below with a brief description.

DGP***AAA-0101 and DGP***AAA-0102

This model is similar to the standard DGP***AAA except for the following major changes:

• All digital inputs are rated for nominal voltage of 110 to 125 V DC instead of the standard 48 to 250 V DC

• The logic for function 51V is modified to remove fault detector supervision

• Seperate terminals are provided for the optional second power supply input

Refer to instruction book GEK-105552 for additional detail.

DGP***ABA-0005

This model is similar to the standard DGP***ABA except for the following major changes:

• Includes the Stator Ground 27TN function

• Includes oscillography data capture and IRIG-B input capabilities

• Suitable for application with 208 V AC nominal input

Refer to instruction book GEK-105587 for additional detail.

1.1.4 DEC 1000 CONTACT EXPANSION UNIT

1

The DEC 1000 is a relay expan sion unit for the DGP consisti ng of five form C relays and six form A relays.

These contacts can be used for signalling or alarm purposes. Any protection function available in the companion DGP relay can be sele cted for DEC output relay assignment. T he DEC 1000 is connected via the DGP

printer port PL2.

The DEC 1000 expansion unit is only compatible with the DGP

NOTE

kkkkk

C units.

GE Power Management DGP Digital Generator Protection System 1-

3

Page 6

1.2 INTRODUCTION 1 PRODUCT DESCRIPTION

1.2 INTRODUCTION 1.2.1 GENERAL

1

The DGP Digital Generator Protection™ System is a microprocessor-based digital relay system that uses

waveform sampling of curren t and voltage inputs to provide protecti on, control and monitoring of gener ators.

These samples are used to compute current and vol tage phasors that are used for the protection-function

algorithms. The DGP™ system uses a man-machine interface (MMI) and GE-Link software for local and

remote communication respectively.

This instruction book describes all the functions available in the various standard DGP models. Refer

to the SELECTION GUIDE in the previous section to determine functions included in a specific model.

1.2.2 APPLICATION

The DGP system is designed to be used on hydroelectric, gas, and steam generating units. Any size of generator can be protected with this digital system.

More detailed appl ication cons ider ations are contai ned b elow i n the rem aining head ings of this sec tion and i n

Chapter 2: CALCULATION OF SETTINGS.

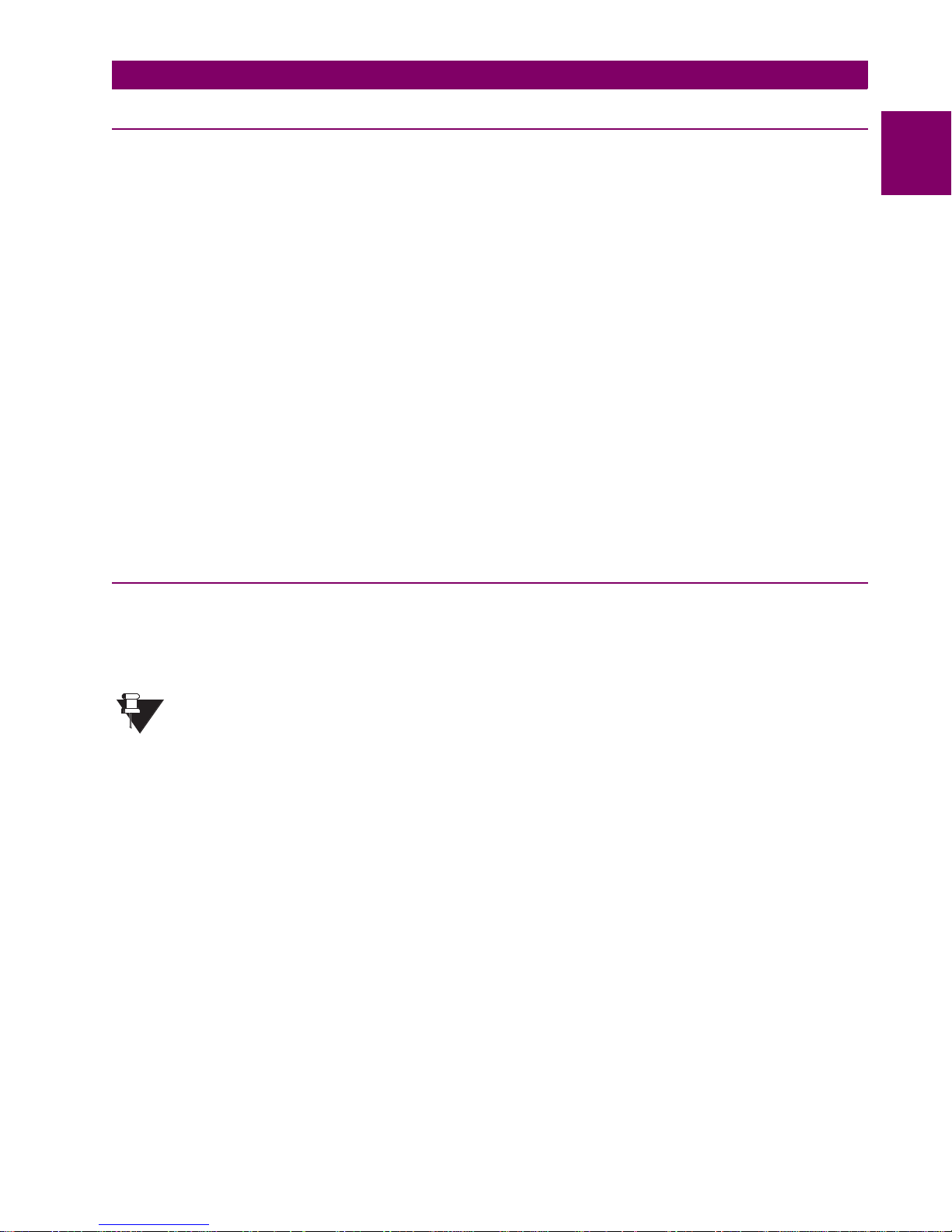

A typical wiring diagram for the DGP relay is shown on the following page.

1-

4

DGP Digital Generator Protection System GE Power Management

Page 7

1 PRODUCT DESCRIPTION 1.2 INTRODUCTION

PRINTER

or

DEC1000

Contact Expansion

Unit

GROUND

BUS

RS-232

RS-232

PRINTER

IRIG-B

CONTROL

POWER

g

AH

AH

AH

AH

1

2

3

4

IBR IBS

IAR

GE Power Management

AG1

AG2

AH

12

VOLT

BH

14

GND

AH

11

DGP

Digital Generator Protection

BG

8

GENERATOR

BG

OFF LINE

7

BG

TURBINE

6

INLET VALVE

BG

LIMIT SWITCH

5

BG

EXTERNAL

4

TRIP 1

BG

3

BG

2

BG

1

BE

4

BE

3

BE

2

BE

1

OSCILLOGRAPH

Disable Prot.

DB9

DB25

DB25

EXTERNAL

TRIP 2

TRIGGER

EXT. VTFF/

(REAR)

(FRONT)

(REAR)

(REAR)

PL3

TS

PU

IN

PL1

PL2

A

C(B)

B(C)

BH

BH

BH

AH

AH

AH

AH

5

6

7

8

ICR ICS

INR INS

CURRENT

INPUTS

BH

1

2

3

4

IAS

A

B

C

BH

BH

BH

BH

BH

BH

BH

8

5

6

7

94G

94G1

94G2

94G3

74A

74B

74C

S

T

U

P

T

U

O

74D

74FF

DOR 12

DOR 13

DOR 9

74 NC

74 CR

POWER

SUPPLY

ALARM 1

POWER

SUPPLY

ALARM 2

9

10

VA

VOLTAGE

TRIP A

(DRY)

TRIP A

TRIP B

(DRY)

TRIP B

TRIP C

(DRY)

TRIP C

TRIP D

(DRY)

TRIP D

ALARM A

ALARM B

ALARM C

ALARM D

VT FUSE FAIL

TEST PICKUP

TEST TRIP

SPARE

SELF TEST

NON

CRITICAL

SELF-TEST

CRITICAL

BH

AH

11

12

9

VB

704753A7.CDR

AH

10

VC

BE

10

BF

10

BE

(+)

14

BF

(-)

14

BE

9

BF

9

BE

(+)

13

BF

(-)

13

BE

8

BF

8

BE

(+)

12

BF

(-)

12

BE

7

BF

7

BE

(+)

11

BF

(-)

11

AG

14

AF

14

AE

14

AG

13

AF

13

AE

13

AG

12

AF

12

AE

12

AG

11

AF

11

AE

11

AG

10

AF

10

AE

10

AG

6

AF

6

AE

6

AG

5

AF

5

AE

5

AG

9

AF

9

AE

9

AG

8

AF

8

AE

8

AG

7

AF

7

AE

7

BF

5

BE

5

BF

BF

6

6

BE

BF

6

6

1

GE Power Management DGP Digital Generator Protection System 1-

Figure 1–1: TYPICAL WIRING DIAGRAM

5

Page 8

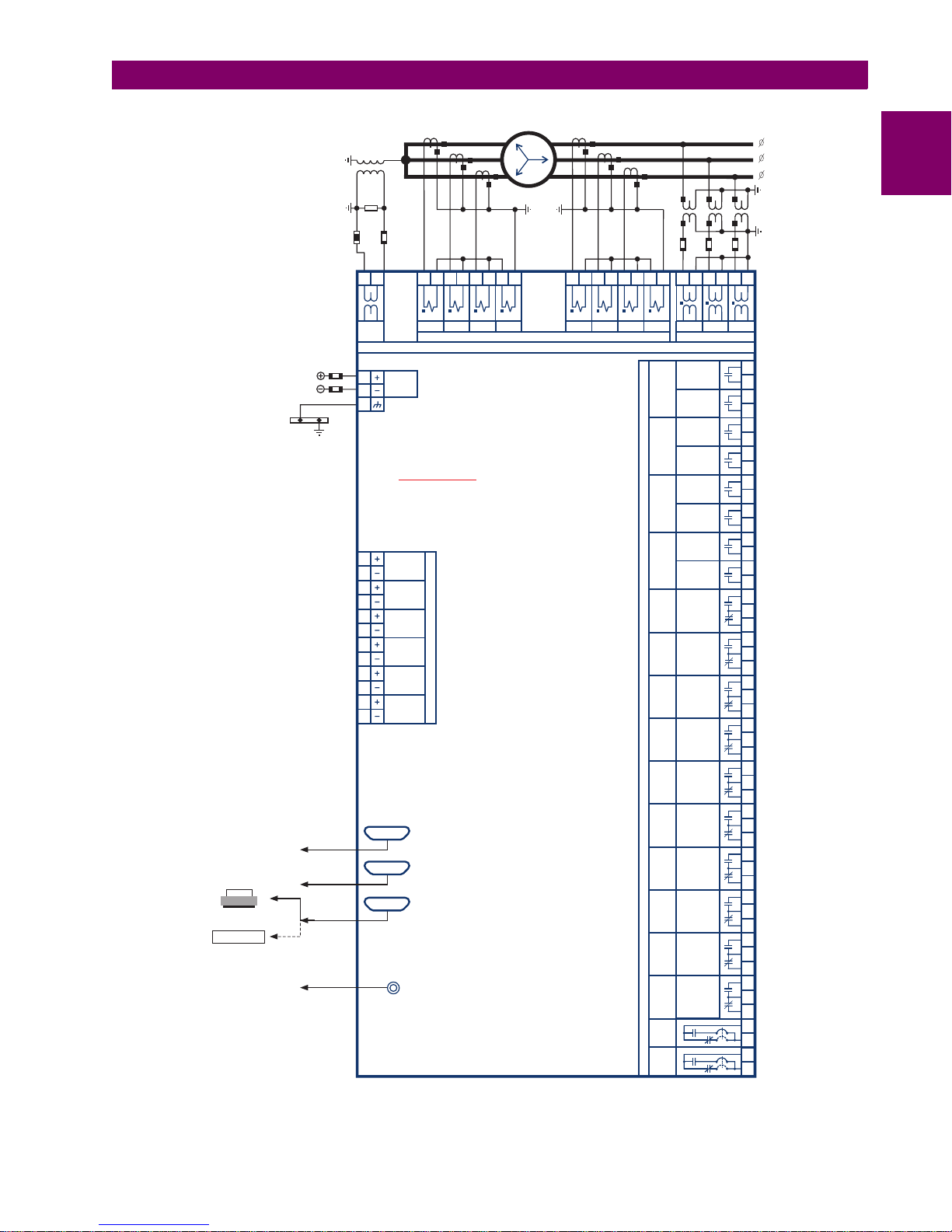

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

1.3 PROTECTION FEATURES 1.3.1 DESCRIPTION

1

The following protection functions are included with the DGP system.

Table 1–3: DGP PROTECTION FUNCTIONS

PROTECTION FUNCTION ANSI CODE(S)

Stator Differential 87G

Current Unbalance 46

Loss of Excitation 40

Anti-Motoring 32

Time Overcurrent with Voltage Restraint 51V

Stator Ground 64G1, 64G2, 27TN

Ground Overcurrent 51GN

Over-excitation 24

Overvoltage 59

Undervoltage 27

Over and Underfrequency 81

Voltage Transformer Fuse Failure VTFF

Accidental Energization AE

A single-line diagram for the DGP is shown below.

GEN.

51GN

27NT

64G2

64G1

RS232

87G

VTFF

51V

32

RS232

40

46

24

VTFF

64G2

51V

GSU

Transf.

32

40

27

59

52G

81

TO

POWER

SYSTEM

DGP

To

MODEM

1-

6

DGP Digital Generator Protection System GE Power Management

To

ALARM

LAPTOP

PC

TRIP

Figure 1–2: SINGLE LINE DIAGRAM

Page 9

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

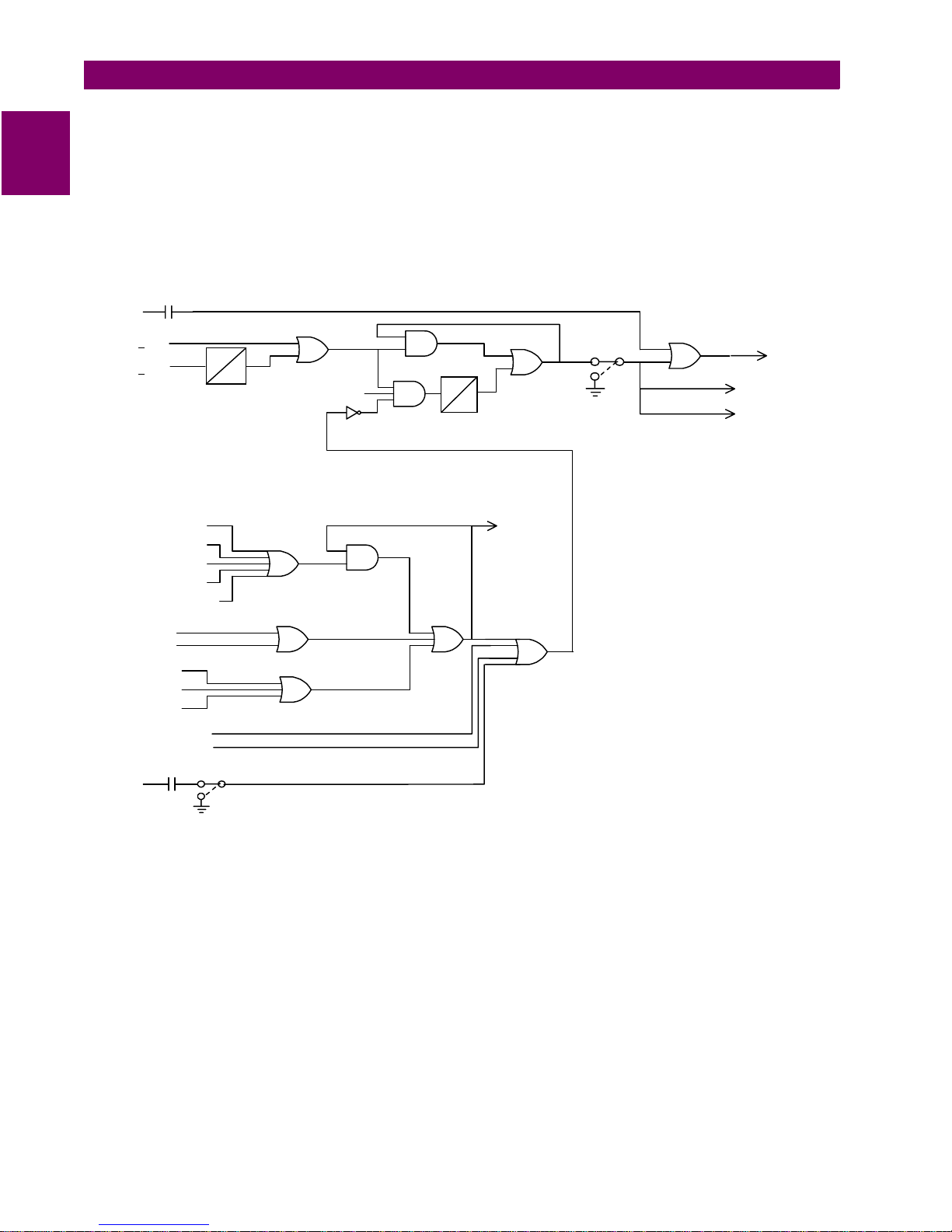

1.3.2 STATOR DIFFERENTIAL (87G)

This function provides high -speed pr otection of the genera tor stat or during inter nal pha se-to- phase an d threephase faults. It uses a product-restraint algorithm with dual-slope characteristic described in Section 2.3.2:

STATOR DIFFER ENTIAL 87G on page 2–13. R efer to Figure 1–3: S IMPLE LOGIC DIAG RAM – 87G, 32 , 27 ,

59, AND AE on page 1–12 for the logic diagram of this function.

Function 87G will not operate for turn-to-turn faults in the machine windings.

It will also not operate for single-phase-to-ground faults if the system is ungrounded or high-impedance

grounded. Phase-to-ground protection by this function requires that the neutral of the machine (or another

machine operating i n parallel) be grounded. A small portio n of the windi ng next to th e neutral will no t be protected, the amount being determined by the voltage necessary to cause minimum pickup current to flow

through the neutral-to-g round impedance. Current-limiting devices in the neutral-ground c ircuit increase this

impedance and will decrease the ground-fault-protection coverage of this function.

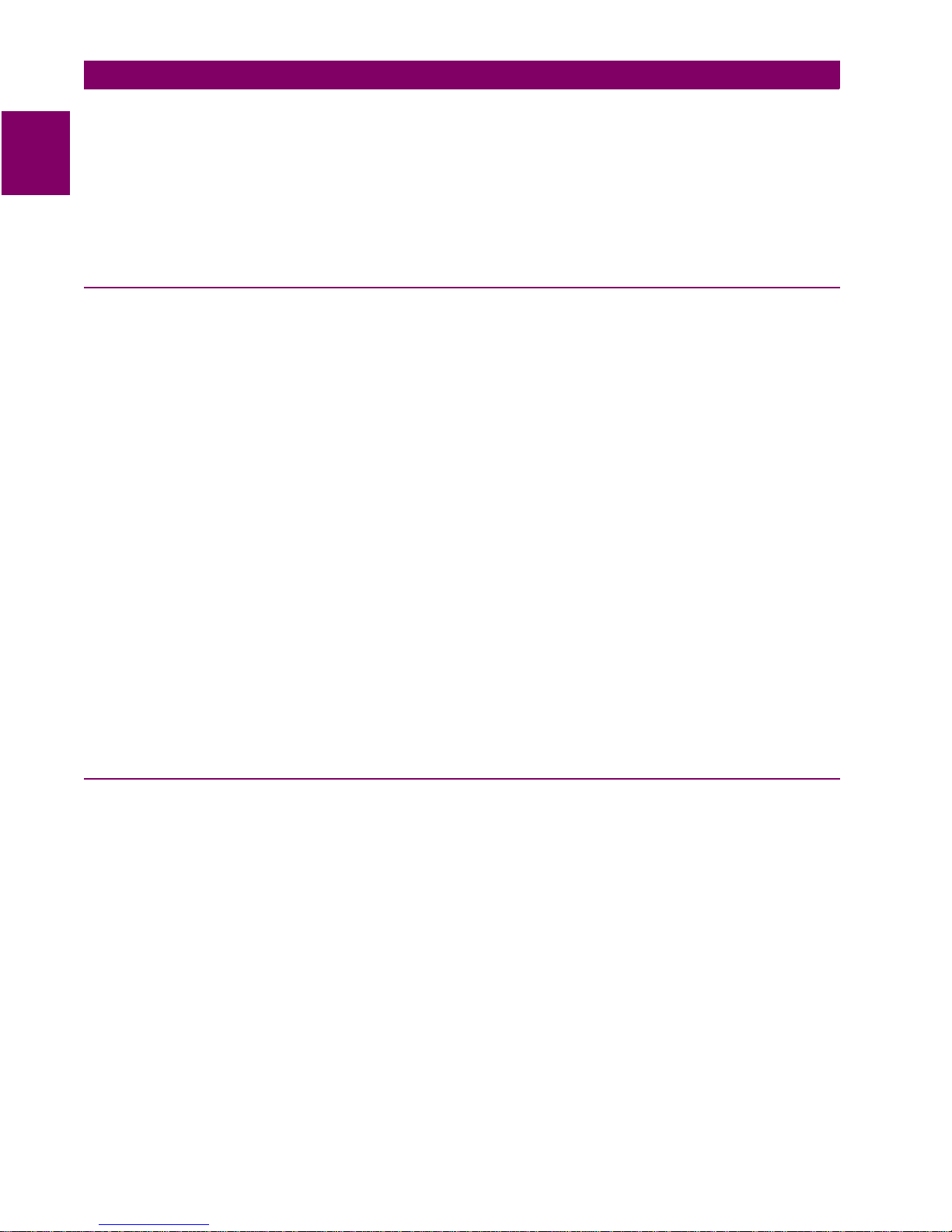

1.3.3 CURRENT UNBALANCE (46T)

There are several cause s of generator unba lance . Som e of th ese i nclude unbala nced loads , unbal ance d sy s-

I

tem faults, and/or op en circuits. Th e negative-seque nce component (

) of stator current is directly r elated to

2

this unbalance and sets up a co unter-rota tin g flux fie ld in the mach ine . This in turn ca uses local he ating in the

rotor iron. The c apability of machines to withstand heating caused by unbalance current s is typically experessed in terms of an constant, and is supplied by the manufacturer of the machine.

The current unbalance tri p function (46T) of the DGP provides operating-tim e characteristics expressed as

2

I

T

= K, as shown in Fig ure 2 –6: TIME CURRENT CHARACTE RIS TIC O F 4 6T FUNC TI ON on pa ge 2–1 9. A

2

2

I

T

2

linear reset characteristic is incorporated to approximate the machine cooling following an intermittent currentunbalance condition. In addition to 46T, the DGP s ystem also includes a current-unba lance alarm function,

46A, which is operated by the nega tive-sequence component (I2) with an adj ustable pickup and time delay.

See Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V on page 1–13 for the logic diagram.

1

1.3.4 LOSS OF EXCITATION (40)

This function is used to detect loss of excitation on synchronous machines. It includes two mho characteristics

looking into the machine, each with adjustable reach, offset, and time delay. Logic is provided to block this

function by presence of a negative-sequence voltage (indic ating a voltage trans former fuse failure VTFF condi tion) and/or an external VTFF Digital Input DI6 (see Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V

on page 1–13).

Excitation can be los t due to ina dverten t trippi ng of the fi eld brea ker, open or short circui t on the fie ld wind ing,

regulator failure, or loss of the sour ce to the fie ld win ding. Loss of exci tation can b e dama ging to the m achin e

and/or detrimental to t he operation o f the sys tem. When a sy nchronous generator l oses exci tation, it will tend

to act as an induction generator: it will run above normal speed, operate at reduced power and receive its excitation (VARS) from the system. The impedance seen by a relay looking in to a generator will depend on the

machine characteristics, the load flow prior to the loss of excitation, and the type of excitation failure.

Studies indicates that first zone mho function (40-1) can be set to detect severe cases of excitation failure with

a shorter time d elay, whereas the second zone (40-2) c an be set to det ect all the excitation failure cases. A

longer time delay s etting is required for t he 4 0- 2 fu nc tio n fo r se cu ri ty duri ng sta ble power system swin g c ond itions. Figure 2–7: MHO CHARACTERISTICS FOR 40-1 & 40-2 FUNCTIONS on page 2–21 shows the characteristics of this function.

GE Power Management DGP Digital Generator Protection System 1-

7

Page 10

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

1.3.5 ANTI-MOTORING (32)

1

On a total or partial loss of prime mover, if the power generated is less than no-load losses of the machine, real

power will start flowing into the generator. Typical motoring power of different kinds of prime movers are shown

in the table below. For a specific application, the minimum motoring power of the generator should be obtained

from the supplier of the unit.

The DGP system includes a reverse power function with adjustable time-delay. Either one or two (32-1 & 32-2)

independent setpoints are incorporated depending on the model number.

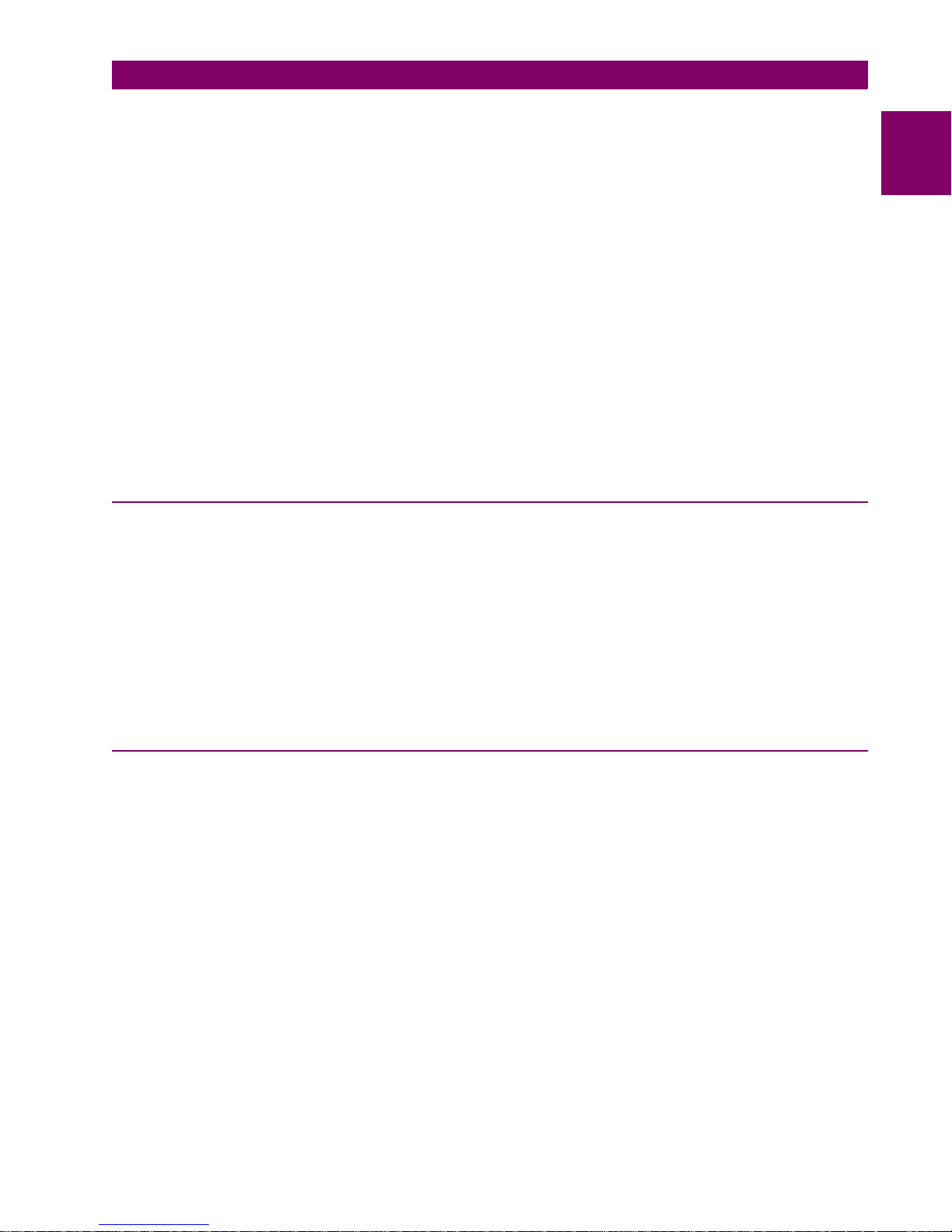

Table 1–4: TYPICAL MOTORING POWER

TYPE OF PRIME

MOVERS

Gas Turbine 10 to 100

Diesel 15 to 25

Hydraulic Turbine 2 to 100

Steam Turbine 0.5 to 4

The 32-1 can be configured as a part of sequential tripping logic as shown in Figure 1–3: SIMPLE LOGIC DIAGRAM – 87G, 32, 27, 59, AND AE on page 1–12. If the sequential trip logic is used, 32-1 is enabled when closing of turbine inlet v alves is indicated by digital in put DI2 following a turbine trip . The trip sequence is then

continued when timer TL1 times out. The 32-2, if included, is not dependent on the DI2 and is primarily

intended to provide bac k up t o th e s equ ent ial trip . If the sequential trip is no t en abl ed, the 32-1 can be used as

anti-motoring similar to 32-2.

A system must be protected against prolonged generator contribution to a fault. The DGP incorporates a timeovercurrent functio n with vo ltage re straint (51V ) to provi de part of the syst em backu p protecti on. As s hown in

Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V on page 1–13, this function is supervised by a fault

detector and VTFF. The VTFF supervision can be by an internal an d/or external (DI6) VTFF fun ction. See Section 2.3.7: OVERCURRENT WITH VOLTAGE RESTRAINT (51V) on page 2–22 for the characteristic curves of

the 51V . Note that a separate algorithm is processed for each phase, with the restraint provided by corresponding phase voltage. The restraint is proportional to the magnitude of the voltage and is independent of the phase

angle. A linear reset characteristic is incorporated for this function.

MOTORING POWER IN %

OF UNIT RATING

1.3.6 TIME OVERCURRENT WITH VOLTAGE RESTRAINT 51V

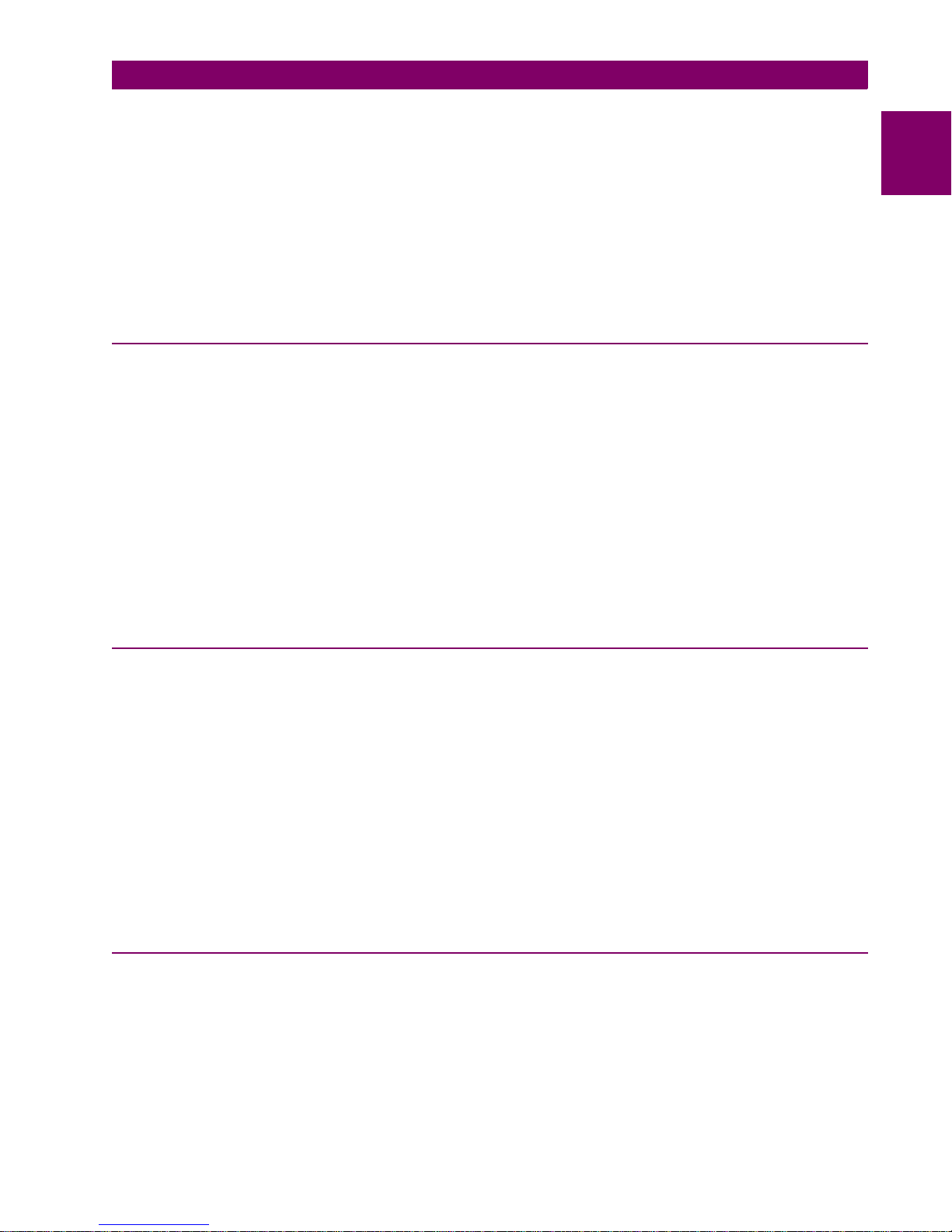

This function consists of two overlapping zones (64G1 and 64G2/27TN) to detect stator ground faults in a highimpedance-grounded generator system. The 64G1 is standard in all DGP models; however, the 64G2/27TN

function is provided in some models only. Together, the two zones cover 100% of the stator windings. See Figure 1–5: SIMPLE LOGIC DIAGRAM – 64G1, 64G2, 51GN, AND 24 on page 1–14.

Normally the generator-stato r neutral has a potential cl ose to ground. With the occurren ce of a stator ground

fault, a potential increase will occur on the neutral for all faults except those near the neutral. 64G1 uses a fundamental-frequency neutral overvoltage to cover about 95% of th e stator winding, depending on the pic kup

voltage setting. Alternately, 64G1 can be used as a generator-bus ground detector in a high-impedance

grounded or an ungrounded system. For this application, the VN input must be a zero-sequence voltage

derived from the generator bus, and functions 64G2/27TN must be disabled.

1-

8

DGP Digital Generator Protection System GE Power Management

1.3.7 ST ATOR GROUND (64G/27TN)

Page 11

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

64G2 is based on the perc entage of third-harmonic vo ltage at the generator neutral (VN 3) compared to the

total third-harmonic vol tage gener ated. This func tion is design ed to cover 15 % of the neutral end o f the stator

windings, and is supervised by fundamental and third-harmonic voltage thresholds. These thresholds are fixed

at 30 and 0.5 volts respectively. The third-harmonic comparator method eliminates the need to know the generator harmonic characteristic to use or set this function.

proper operation of 64G2

27TN is the third- harmonic neutral u ndervoltage functio n with a forward power supervision and can be used

with either wye or delta connected VTs. The percentage of stator windings covered by this function depends on

its threshold setting as well as the VN3 generated b y the machine at the time of th e fault. The magnitude of

VN3 under normal condi tions is a function of several factors, su ch as type of generator, load current, load

power factor, system status, etc. It can be very small (nearly zero) under some conditions. T o enhance security

during low VN3 vo lta ge conditions, this f unc tio n can b e i nhi bi ted by a se tt able window of forward power. However, it should be noted that other condi tions influenci ng the VN3 vol tage may make 2 7TN insecu re. In these

cases, function 64G 2 (available in some models; see the DGP nomenclature guide) or some other means

should be considered.

Digital input DI1 can be co nfigured to bloc k 64G2/27T N when the gener ator is off-line. Thi s provision is made

to enhance security of the functions under conditions such as static start of a gas turbine generator. Temporary

ungrounding of generator neutral during the static start can look like a ground fault near the neutral.

.

Note that wye-connected VTs are required for

1.3.8 GROUND OVERCURRENT (51GN)

1

51GN is an inverse overcurrent function available in some models. It can be used to detect stator ground faults

in a high or low resist ance grounded generator sy stem. See Fig ure 1–5: SIM PLE LOGIC DIA GRAM – 64G1,

64G2, 51GN, AND 24 on pa ge 1–14 for simplified logic diagram and Figure 2 –16: 51GN TIME-CURRENT

CHARACTERISTICS on page 2–39 for the inverse time-current characteristics.

This function uses current INR which can be derived by residual connection or by using a generator neutral CT

as noted in F igures 1–9: ELEMENTARY DIAGRAM WITH TE ST BLOCKS, WYE VTs and 1–12: ELEMENTARY DIAGRAM WITHOUT TEST BLOCKS, DELTA VTs.

Since this function is independen t of the phase current inputs , it can alterna tely be connect ed to a CT in the

neutral of the generator step-up transformer.

1.3.9 OVEREXCITATION (24)

Overexcitation can b e caus ed by reg ulator failure , load r eject ion, or an exce ssiv e excit ation wh en the ge nerator is off-line. It can also resul t from decr easing spee d while the regulator o r an operator a ttempts to m aintain

rated stator voltage. The Volts/Hertz quantity is proportional to magnetic flux in the generator and step-up

transformer cores, and is use d to detect the overexcitation condition. Se e Figure 1–5: SIMPLE LOGIC DIAGRAM – 64G1, 64G2, 51GN, AND 24 for details.

The overexcitation protection includes trip (24T) and alarm (24A) functions. 24T consists of an inverse function

and an instantaneous fu nction with time-delay characteris tics. The combination of these two char acteristics

allows the 24T setting to cl osely follow the generator and/or ste p-up transformer V/Hz limit curve. Bo th 24A

and 24T are computed for each of the three phase voltages (see Table 2–3: 24A VOLTAGES on page 2–30).

Function 24T can be c onfigu red to operate d ifferent ou tput re lays for gene rator on -lin e and o ff-line condi tions.

This function incorpora tes a user-settable li near reset character istic to mimic machi ne cooling. The figu res in

Section 2.3.12: OVEREXCITATION TRIP (VOLTS/HERTZ: 24T) show the characteristics of this function.

GE Power Management DGP Digital Generator Protection System 1-

9

Page 12

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

1.3.10 OVERVOLTAGE (59)

1

This function consists of a positive-sequence overvoltage with an user selectable inverse or definite time characteristic. See Figure 1–3: S IMPLE LOGIC DIAGRAM – 87G, 32, 27, 59, AND AE on page 1–12 fo r the logic

diagram and Figure 2–15: 59 TIME-VOLTAGE CHARACTERISTICS on page 2–35 for the inverse time-voltage

characteristics. A l inear reset charact eristic is incorp orated for this function. The overvoltage functi on can be

considered as a backup to the Volts/Hz function. Some possible causes of this cond ition are a system dis turbance or regulator failure.

1.3.11 UNDERVOLTAGE (27)

This function consists of a positive-sequence undervoltage with an user selectable inverse or definite time

characteristic. See Figur e 1–3: SIMPLE LOGIC DIAG RAM – 87G, 32, 27, 59, AND AE on p age 1–12 for the

logic diagram and Figu re 2–17: 27 TIME -VOLTAGE CHARACTER ISTICS on pa ge 2–40 for the inv erse timevoltage characteristics. A linear reset characteristic is incorporated for this function.

1.3.12 OVER AND UNDERFREQUENCY (81)

This function provides over and underfrequency protection, each with an adj ustable time delay. Two or four

over and underfrequency ste ps are provided dep ending on the model. Al l frequency functi ons are supervise d

by an adjustable positive-sequence voltage level. This undervoltage cut-off level and/or digital input DI1 can be

used to block the freq uency functions during sta rt-up. Fr equency dis turbance c an occur due to a system fault

or islanding of the unit or an unconnected unit can operate at abnormal frequency due to malfunction of speed

control. Figure 1 –6: SIMPLE LOGIC DIA GRAM – 81-O A ND 81-U on page 1 –15 show s the l ogic diag ram for

this function.

1.3.13 VOLTAGE TRANSFORMER FUSE FAILURE (VTFF)

Functions 40 and 51V may operate for a full or partial loss of AC potential caused by one or more blown fuses.

The DGP makes provisions to block tripping by these functions when a fuse failure is detected; all other protection functions are a llowe d to t rip. Fig ure 1–7: SIMP LE L OGIC DIA GRAM – VT F USE FAILURE on pag e 1–1 6

shows the logic diagram for the VTFF function.

If AC potential is lost on one or more phas es, the negative-seque nce voltage (V2) rise s and/or the positivesequence voltage ( V1) drops. Either V2 > 15V or V1 < 50V pro vides a bas ic indic ation of th e VTFF con dition.

This signal is supervi sed by a Distur bance Dete ctor (DD) and gene rator posit ive-se quence cu rrent (I1) dete ctor (see three-inp ut AND gate on the log ic diagram). Supervision by the DD and I1 signa ls provide security

against false ope ration du ring fault a nd genera tor out of service conditio ns respec tively. Security is enhance d

by use of the A/0 and B/0 timers shown in the logic diagram.

Signal DD is derived from a combination of sequence current levels, change in levels, and pickup flags of various protection functions as shown in the logic diagram.

The VTFF logic allows integration of an external VTFF contact. Either of the two fuse-failure signals or both

signals can be configured to block tripping of functions 40 and 51V.

Detection of VTFF energizes the 74FF (Fuse Failure alarm) relay, de-energizes the 74CR (critical alarm) relay,

and turns the status LED red, even though all protection functions except 40 and 51V are unaffected.

1-

10

DGP Digital Generator Protection System GE Power Management

Page 13

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

1.3.14 ACCIDENTAL ENERGIZATION (AE)

The DGP includes logic to detect accidental energization of the gener ator (see Figure 1–3: SIMPLE LOGIC

DIAGRAM – 87G, 3 2, 27, 59, AND AE on page 1–12). When a generator is energized while at standstill or

reduced speed, it behaves and acc elerates as an induction mot or. The machine terminal voltage and current

during such an event will be a function of generator, transformer, and system impedances.

An instantaneous over cu rren t si gna l (50) is used to det ect t he acci de ntal ener g izati on. T his s ig nal is arm ed by

a logic signal de rived from positive- sequence voltage and GEN O FF LINE input DI1. These two "arming " signals can be confi gured in AND or O R mode by Se tting 2703:

after the generator is taken out of service. The logic automatically disarms itself during a normal start-up

sequence when the voltage detector picks up and/or the generator is on-line.

For the AE logic to perform, special precautions must be taken to ensure that the DGP system and associated

trip circuits remain in service when the generator is out of service. Additionally, the generator off-line input, DI1,

must be reliable. It should also be noted that the pickup flag of function 51V is used as signal 50; therefore this

logic will automatically be disabled if function 51V is disabled.

AE ARM

. The 50 function is armed 5 seconds

1

GE Power Management DGP Digital Generator Protection System 1-

11

Page 14

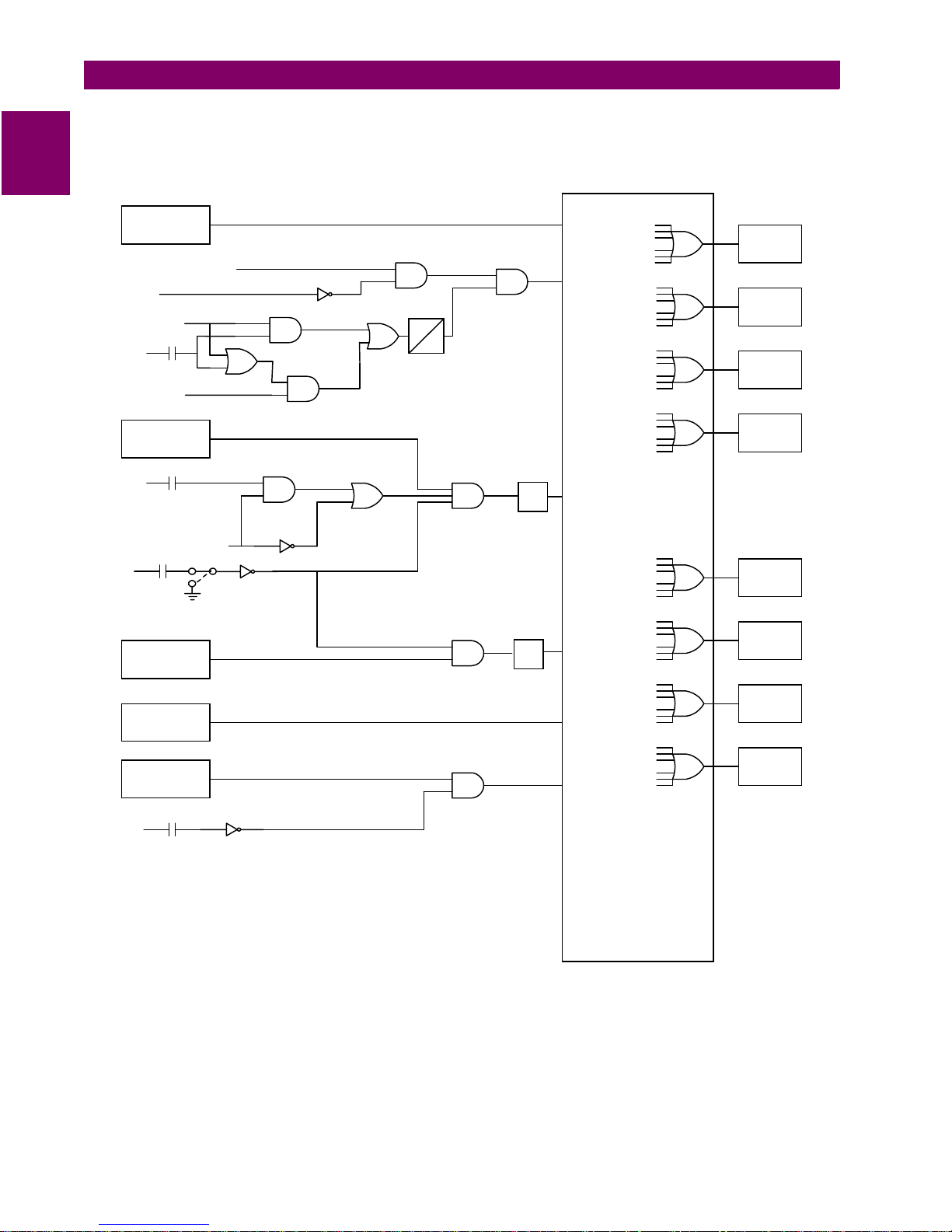

1

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

Stator

Differential

50 (51V Pickup Flag)

VTFF

V1 < 30V

DI1

(+)

Gen. Off-line

OR

AE ARM

Reverse Pwr.

No. 1

(+)

DI2

Turbine Inlet Valve

Closed

Seq. Trip Enabled

DI1

(+)

Gen.

Off-Line

SELBKDI1

Reverse Pwr.

No. 2 (1)

AND

AND

AND

AND

PU

OR

PU=5 sec

DO=0.25 sec

DO

ANDOR

AND

AND

AND

TL1

TL2

87G

87G

AE

AE

32-1

32-2

OR

OR

OR

OR

OR

OR

TRIP A

94G

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

ALARM

74A

ALARM

74B

Overvoltage

59

Undervoltage

(+)

(1)

DI1

Gen.

Off-Line

AND

27

NOTES:

(1) Indicates an optional function (includes associated logic). Refer to

CONFIGURABLE

DGP nomenclature selection guide for available functions in a

specific model.

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

Figure 1–3: SIMPLE LOGIC DIAGRAM – 87G, 32, 27, 59, AND AE

LOGIC (2)

OR

OR

ALARM

74C

ALARM

74D

1-

12

DGP Digital Generator Protection System GE Power Management

Page 15

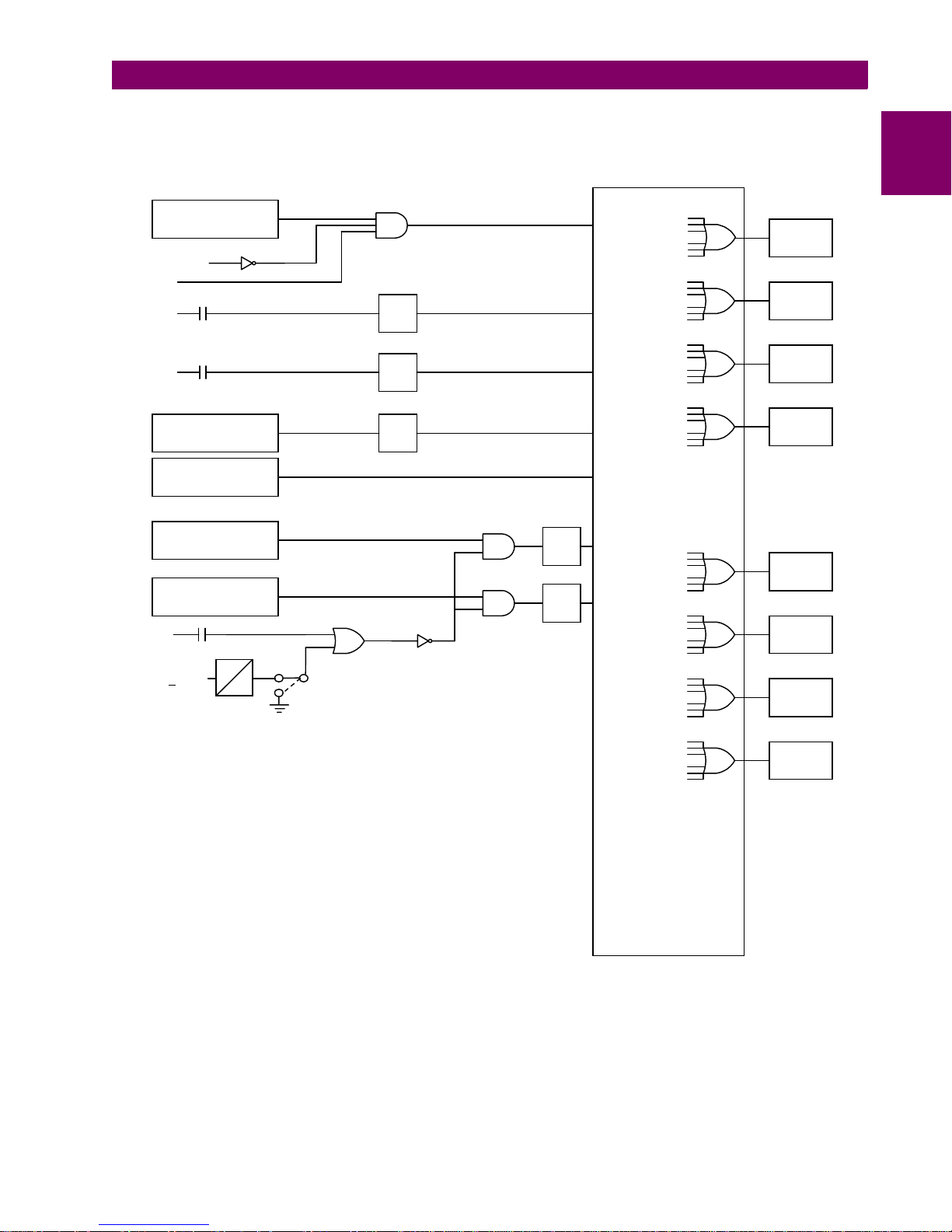

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

1

Overcurrent

(voltage restraint)

VTFF + DI6

FD

(+)

(+)

DI3

External Trip - 1

DI4

External Trip - 2

Current Unbalance

(Alarm)

Current Unbalance

(Trip)

Loss of Excitation

Zone 1

Loss of Excitation

Zone 2

DI6

(+)

V

2

Ext. VTFF

>

PU

15V

PU=3 Samples

DO=5 Samples

DO

ENA

SELV2SUP

DIS

OR

AND

TL21

(1)

TL22

(1)

TL14

87G

51V

OR

TRIP A

94G

AE

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

DI3

DI4

46A

OR

OR

OR

46T

TL12AND

TL13AND

40-1

40-2

OR

OR

OR

ALARM

74A

ALARM

74B

ALARM

74C

OR

ALARM

74D

NOTE:

(1) Timers TL21 and TL22 are available in models DGP***ACA only.

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

CONFIGURABLE

LOGIC (2)

DSPLGC2.VSD

Figure 1–4: SIMPLE LOGIC DIAGRAM – 46, 40, AND 51V

GE Power Management DGP Digital Generator Protection System 1-

13

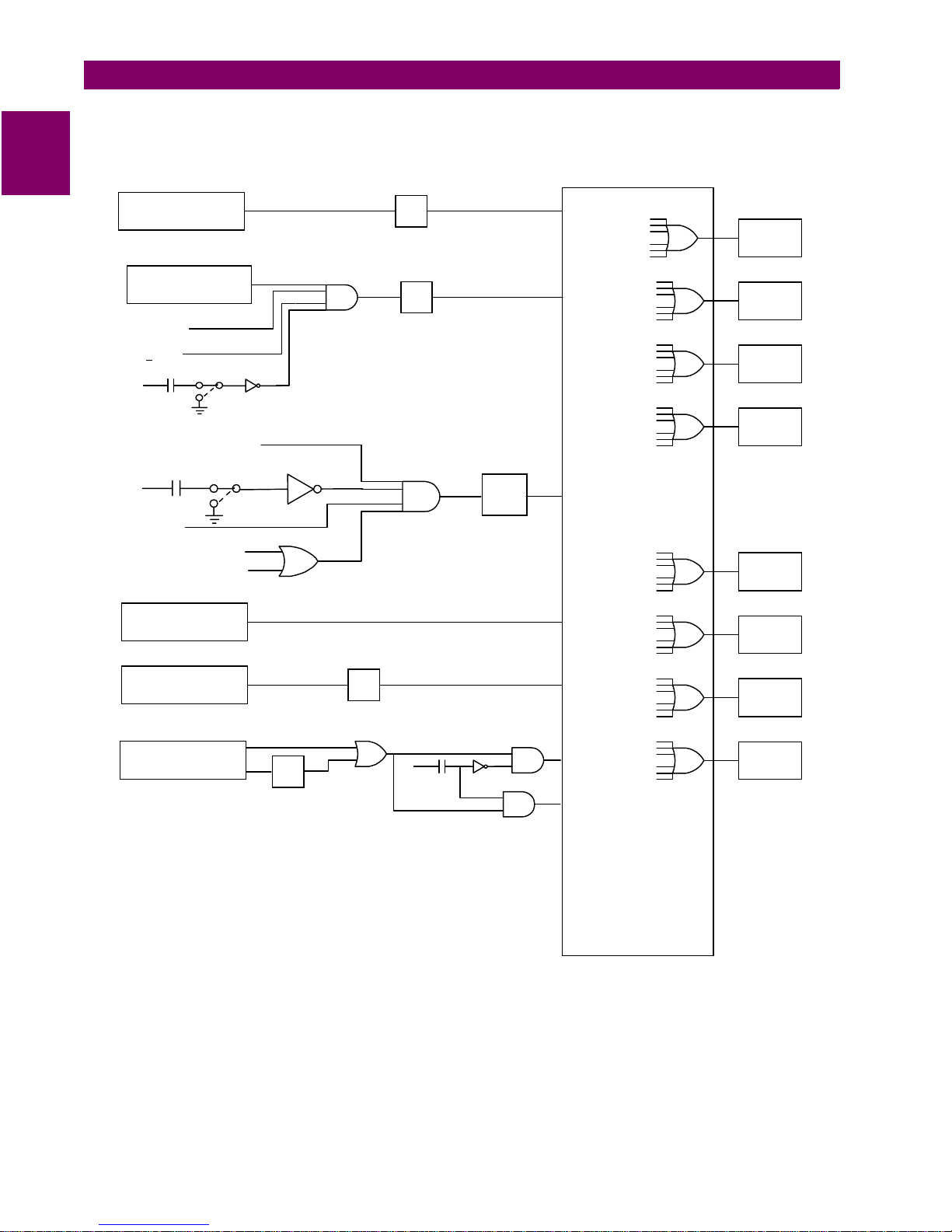

Page 16

1

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

Stator Ground

Zone 1

Stator Ground

Zone 2 (1)

VP3 > 0.5V

V1

30V

>

DI1

(+)

Gen.

Off-Line

V

≤

N3

GEN. OFF-LINE

(+)

DI1

V

25V

≥

1

SELBKDI1

27TN PICKUP

SELBKDI1

POWER < FORPWR-L

POWER > FORPWR-H

Neutral Overcurrent

(1)

OR

AND

TL4

TL5

AND

TL20

64G1

64G2

27TN

(1)

51GN

OR

OR

OR

OR

OR

OR

TRIP A

94G

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

ALARM

74A

ALARM

74B

Overexcitation

(Alarm)

Overexcitation

(Trip)

Time

Inst

TL7

TL6

OR

(+)

DI1

Gen.

Off-Line

AND

AND

24A

24T

(On-Line)

24T

(Off-Line)

NOTES:

(1) Indicates an optinal function (includes associated logic). Refer to

DGP nomenclature selection guide for available functions in a

specific model.

CONFIGURABLE

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

Figure 1–5: SIMPLE LOGIC DIAGRAM – 64G1, 64G2, 51GN, AND 24

LOGIC (2)

OR

OR

ALARM

74C

ALARM

74D

1-

14

DGP Digital Generator Protection System GE Power Management

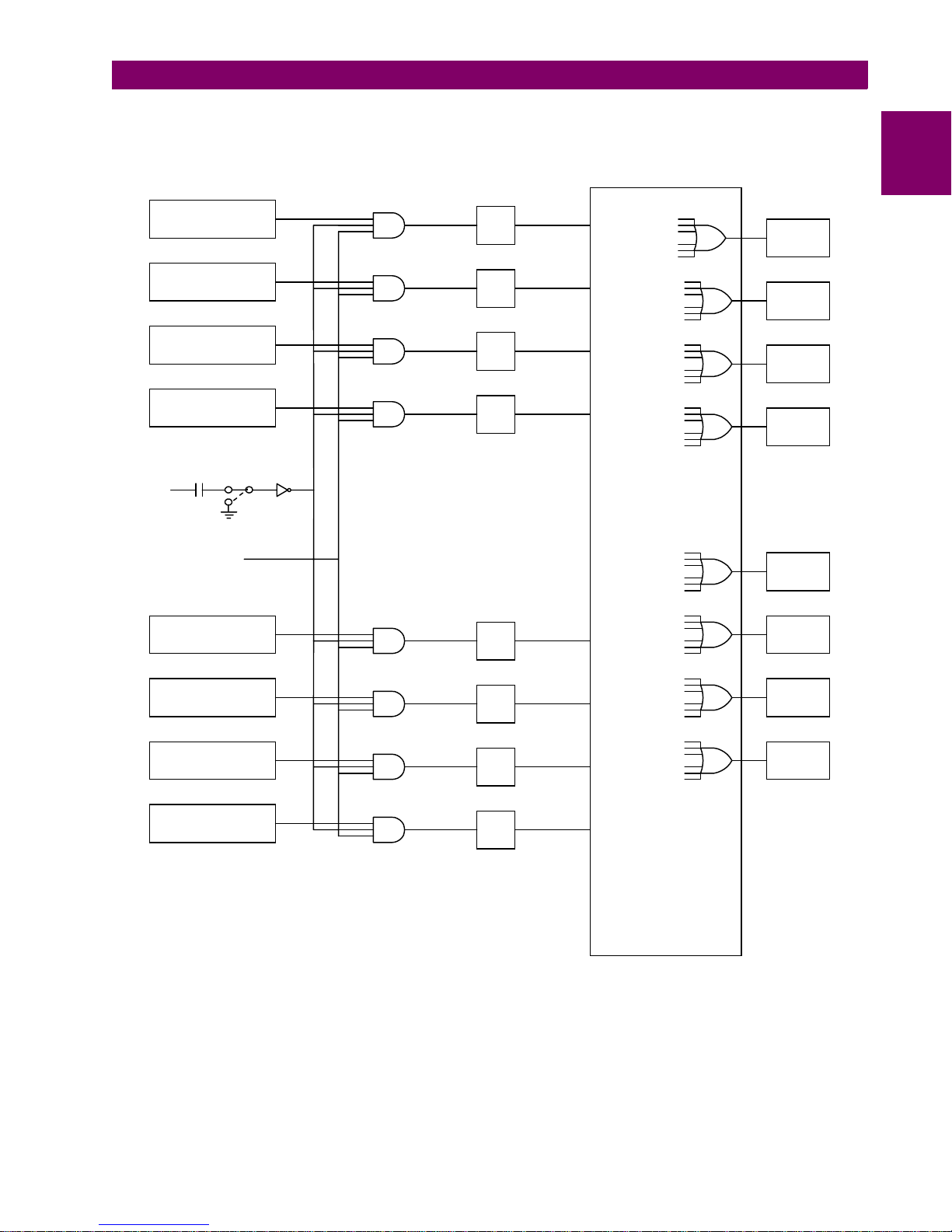

Page 17

1 PRODUCT DESCRIPTION 1.3 PROTECTION FEATURES

1

Under Frequency

Set Point - 1

Under Frequency

Set Point - 2

Under Frequency

Set Point - 3 (1)

Under Frequency

Set Point - 4 (1)

DI1

(+)

Gen.

Off-Line

SELBKDI1

V1 > UVCUTOFF

Over Frequency

Set Point - 1

AND

AND

AND

AND

AND

TL8

TL9

TL10

TL11

TL15

81-1U

AE

81-2U

81-3U

81-4U

81-1O

OR

OR

OR

OR

OR

OR

TRIP A

94G

TRIP B

94G1

TRIP C

94G2

TRIP D

94G3

ALARM

74A

ALARM

74B

Over Frequency

Set Point - 2

AND

TL16

81-2O

Over Frequency

Set Point - 3 (1)

AND

TL17

81-3O

Over Frequency

Set Point - 4 (1)

AND

TL18

81-4O

NOTES:

(1) Indicates an optional function (includes associated logic). Refer to

DGP nomenclature selection guide for available functions in a

specific model.

(2) Each of the available protection functions can be configured to

operate any combination of the 8 output relays (4-Trip and 4-Alarm).

CONFIGURABLE

Figure 1–6: SIMPLE LOGIC DIAGRAM – 81-O AND 81-U

OR

OR

LOGIC (2)

ALARM

74C

ALARM

74D

GE Power Management DGP Digital Generator Protection System 1-

15

Page 18

1

1.3 PROTECTION FEATURES 1 PRODUCT DESCRIPTION

DI6

(+)

External VTFF

V2

15V

>

50V

V1

<

51V Pickup Flag

40 Pickup Flag

87G Pickup Flag

51GN Pickup Flag

21 Pickup Flag (Fut.)

I0 ≥ 0.6 / *

∆

∆

I2 ≥ 0.6 / *

∆

I0| ≥ 0.2 / *

|

I1| ≥ 0.2 / *

|

∆

|∆I2| ≥ 0.2 / *

64G1 Pickup Flag

64G2 Pickup Flag

DI1

(+)

Gen.

Off-Line

PU

PU=9000 samples

DO=0

SELBKDI1

DO

OR

I1 > 0.1/*

OR

OR OR

OR

AND

AND

AND

PU

DO

PU = 36 samples

DO = 0

FD

OR

Supervise

51V,

21(Future)

OR

DD

ENA

DIS

VTFF

VTFF + DI6

OR

Supervise

51V,

21(Future)

VTFF Alarm

Critical Alarm

NOTE:

* = 1 FOR 5 AMP RATED DGPs.

* = 5 FOR 1 AMP RATED DGPs.

Figure 1–7: SIMPLE LOGIC DIAGRAM – VT FUSE FAILURE

1-

16

DGP Digital Generator Protection System GE Power Management

DGP_VTFF.VSD

Page 19

1 PRODUCT DESCRIPTION 1.4 OTHER FEATURES

1.4 OTHER FEATURES 1.4.1 INPUTS

The DGP system takes eight current and four voltage inputs (refer to Section 1.5: ELEMENTARY DIAGRAMS).

The input currents in terminals BH1, BH3, and BH5 (I

, IBS, and ICS) are used to process functions 46, 40, 32,

AS

and 51V. As noted in the elementary diagrams, these currents can be derived from system side or neutral side

CTs as de sired. Either the sy stem or n eutral s ide CTs can be used fo r these functi ons if the Stator D ifferential

(87G) function is enabled.

The current input s I

and INR are derived from th e resid ual connec tions of t he respe ctive phas e CTs and do

NS

not require dedicated neutral CTs. Zero-sequence current at system and/or neutral side of the generator stator

windings is calculated and then compared with the measured I

and/or INR values by the DGP as a part of the

NS

background self-test.

The I

icated neutral CT can be used for the input I

The DGP phase volta ge i npu ts c an be wye or delta and are derived f ro m the gen er ato r term in al v ol tag e. V

current is used to process the 51GN function (not available on DGP***AAA models). If desired, a ded-

NR

NR

.

is

N

derived from the generator neutral grounding transformer.

A time synchronizin g signal can be connected to the DGP for syn chronization to within 1 ms of a referenc e

clock. Either IRIG-B or GE's G-NET system signal can be used. This signal is required only if it is necessary to

synchronize the DGP to an external reference clock.

Six digital inputs can be connected to the DGP. Two of these inputs (DI3 and DI4) are a ssigned for possi ble

routing of external trip/alarm signals to take advantage of the output configuration or sequence-of-events capability. Generator off-line (DI1), turbine inlet-valve-close indication (DI2), and external VTFF (DI6) inputs are

used for various relay logic functions. A contact input, (DI5), can also be used to trigger the optional oscillography feature. In some models, the DI6 input can be configured as external VTFF or DISABLE ALL PROTECTION (refer to Section 1.5: ELEMENTARY DIAGRAMS for details).

1

The digital input circuits are universally rated for nominal control voltages of 48 to 250 V DC.

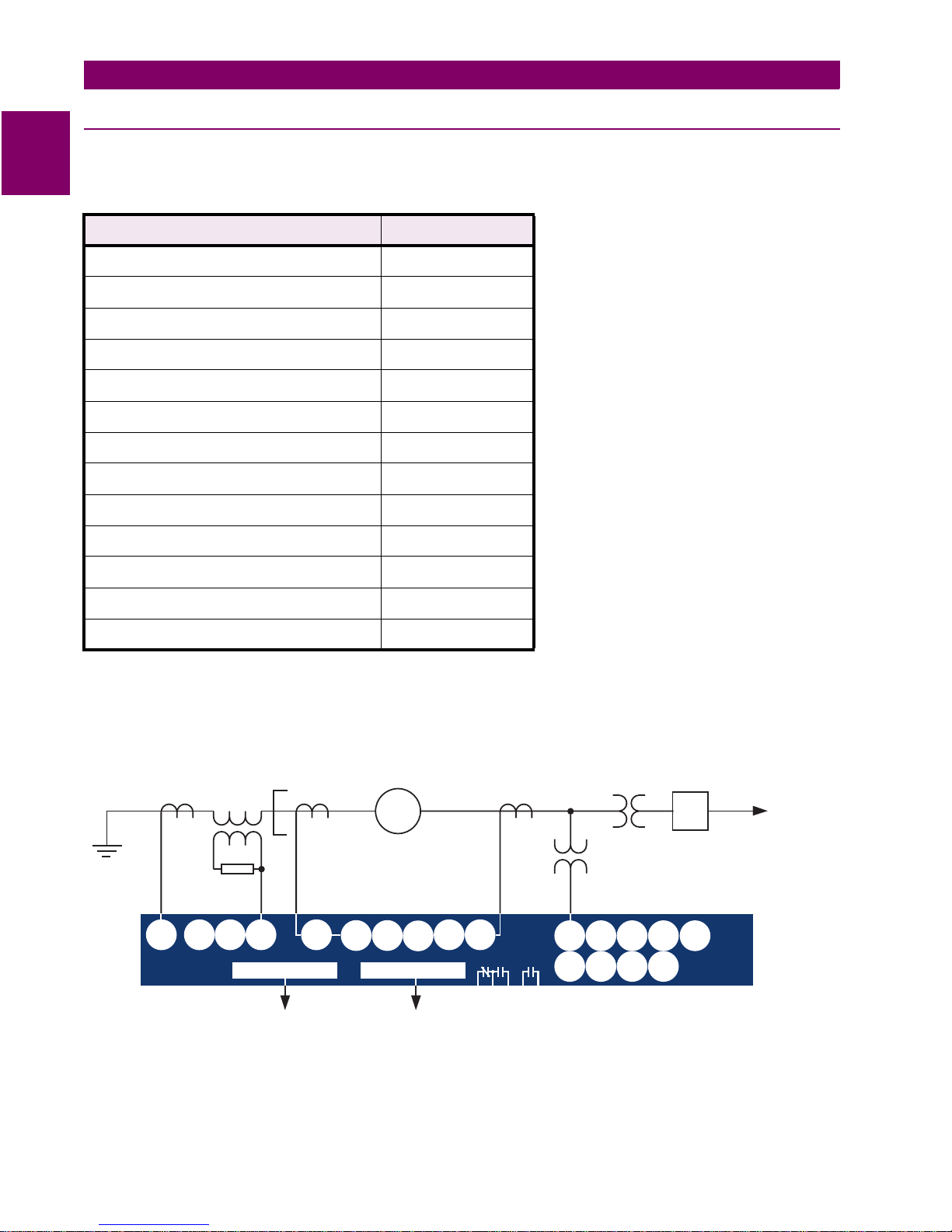

1.4.2 OUTPUT RELAYS

The DGP system includes ei ght user-configur able output relays. Four of these relays (94G, 94G1, 94G2 and

94G3) are high speed (4 ms) trip-duty rated with two form A contacts each. The remaining four (74A, 74B, 74C

and 74D) are standard speed (8 ms) with one form C contact each, intended for alarms. Each of the protection

functions can be configured to operate any number of these output relays. The trip outputs are intended for, but

not limited to, the following purposes:

• 94G: trip a lockout relay to shut down the machine

• 94G1: trip field breaker

• 94G2: trip main generator breaker or breakers

• 94G3: operate a lockout relay to trip turbine.

In addition to the configu rable output relays, fi ve pre-defined alarm duty relays with one form C c ontact each

are included. These alar m relays inc lude critical and non-cri tical self- test alarms ( 74CR and 74NC) , the VTFF

alarm (74FF), and loss of power-supply alarms (PS1 and PS2). The form C contact of each of the alarm relays,

except PS1 and PS2, are wired out to the terminal block. A hard wire jumper is used to select either the form A

or the form B conta ct of each of the PS1 and P S2 relays, as shown in Figure 3–3: DGP POWER S UPPLY

MODULE on page 3–4.

All alarm relays, wi th the exc eption of 74CR, PS1 a nd PS2, are e nergized wh en the appr opriate al arm conditions exist. Relays 74CR, PS1 and PS2, however, are energized under no rmal conditions and will dro p out

when the alarm conditions exist.

GE Power Management DGP Digital Generator Protection System 1-

17

Page 20

1.4 OTHER FEATURES 1 PRODUCT DESCRIPTION

Also included are two additional relays (TEST PICKUP and TEST TRIP) that can be configured to operate by a

selected protectio n function pi ckup flag an d trip output. T hese two outpu ts are inten ded to facilitate testing of

1

the selected protection function.

A Contact Expansi on Unit is al so av ailable whic h can be u sed with DGP* **ACA models . The Gene ral El ectric

DEC1000 Contact Expa nsion Unit provides eleven a dditional output relays that can be factory config ured to

user specifications. Refer to the GE Power Mana gement Product Ca talog, the GE Pow er Management Products CD, or instruction book GEK-105561 for additional details on the DEC1000.

1.4.3 START-UP SELF-TESTS

The most comprehens ive testing of the DGP is perform ed during powe r-up. Since the DG P is not perform ing

any protection activities at that time, tests (such as RA M tests) that would norm ally be disruptive to ru n-time

processing are per formed during the start-up. Al l processors p articipate in th e start-up sel f-test process. T he

processors commun ic ate th eir results to each other so that any failures foun d c an be r epo rt ed to t he us er an d

to ensure each processor successfully completes its assigned self-tests before the DGP system begins protection activity.

During power-up, the micr oprocessors perfor m start-up self-test s on their associated ha rdware (PROM, local

RAM, shared RAM, interrup t controller, timer chip, serial and parallel I/O ports, non-volatile memory, analog

and digital I/O circuitry, MMI hardware, etc.). In addition, the DGP system verifies that the PROM version numbers in all processor boards are compatible. The components tested at start-up are listed in Table 6–1: ST ARTUP SELF-TESTS on page 6–2.

In most cases, if any critical self-test failure is detected, the DGP will not continue its start-up but will not cause

a reset. An attempt will be made to store the sy stem status, to initi alize the MMI and remote communications

hardware/software for communication status, and to print a diagnostic message. The critical alarm relay will be

de-energized.

If no failures are detected, the DGP completes initialization of its hardware and software. Next, each processor

board (DAP and S SP) will enable the outputs. As a f inal step, the DG P checks the res ults of all the te sts to

determine whether to turn the front panel status LED to green.

The start-up procedure takes approximately one minute. As soon as the SSP successfully completes its

PROM test and in itializ es the disp lay h ardwa re, th e mes sage

system initialization is completed, the display is blanked and the relay begins acquiring and processing data.

Each of the processors has "idle time" when the system is in a quies cent state; that is, when the DGP is not

performing fault or po st-fa ult proc essi ng. During this i dle tim e, each proce ssor pe rforms backg round self-tes ts

that are non-disruptive to the foreground proc essing. If any back ground self-tes t fails, the test is repeat ed. To

declare a component FAILED , the test must fail three consec utive times. In the case of criti cal failures, the

DGP forces a self reset to resume operation again after an intermittent failure. The reset activities are identical

to the start-up activities except that not all start-up self-tests are performed.

A reset is not reported to the user by the DGP system. If the reset is successful, no message is printed, no failure status is recorded, an d the critical alarm is not generated. However, during the reset proc edure, the red

LED on the MMI panel will light and a failure code ma y appear on the MM I displa y. If the reset is not successful, the processor boar d will be shut down, leaving the MMI panel displaying the error information. Ref er to

Section 6.4: ERROR CO DES on page 6–7 fo r error codes. To prevent continual resets in the ca se of a solid

failure, both hardware and software will permit only four resets in a one hour period. On the fifth reset, the DGP

will not perform initialization, but will attempt to initialize MMI, communications, and the critical alarm output, as

in the case of a start-up with a critical self-test failure.

INITIALIZING

will be displayed. When the DGP

1.4.4 RUN-TIME SELF-TESTS

1-

18

DGP Digital Generator Protection System GE Power Management

Page 21

1 PRODUCT DESCRIPTION 1.4 OTHER FEATURES

The components tested in the backg round are listed in Table 6–2: RUN-TIME BACKGROUND SELF-TESTS

on page 6–3. The testing of I/O hardware is done in the foreground so the processors know when a given component or port is in u se and therefore n ot available f or testing. The com ponents tested in the foreground are

listed in Table 6 –3: RUN-TIME FOREGROUND SELF-TESTS on p age 6–3. Some foreground tests are performed every sample period while others are performed less frequently. As with background self-tests, any

failed test is repeated and must fail three consecutive times to be considered a failure. Although not specifically

a self-test, trip circuit c onti nui ty mo nit or ing is a lso p er forme d a s a foreg ro und tes t. Refe r to th e T RIP CIR CUIT

MONITOR section below.

In addition to backgroun d self-tests, the operato r may initiate a vi sual-response test of the MMI components.

Refer to Section 4.6.2 T1: MMI STATUS AND DISPLAY TESTING on page 4–9 for details.

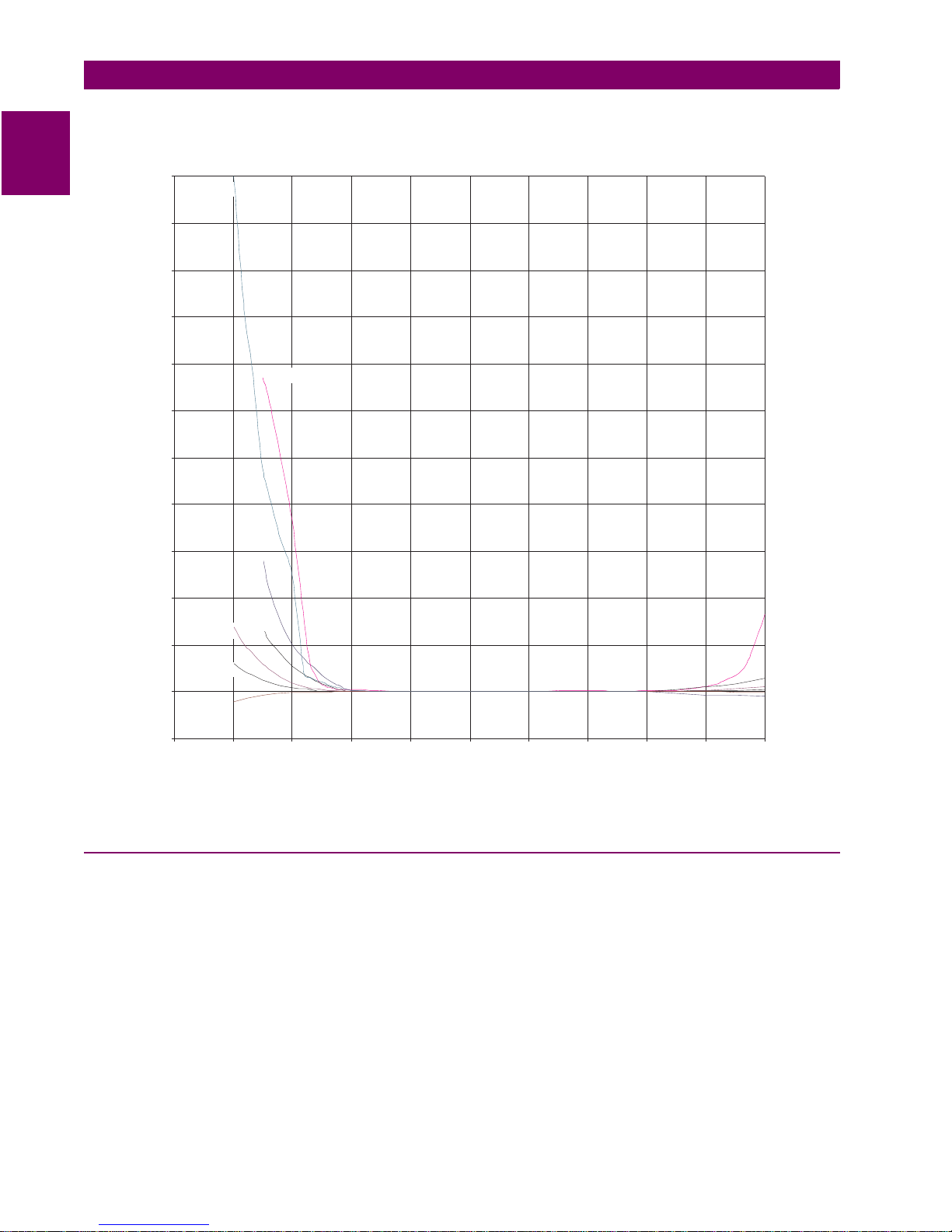

1.4.5 ADAPTIVE SAMPLING FREQUENCY

The DGP system samples analog input waveforms at a rate of 12 samples per cycle. An adaptive sampling frequency is used to m aintain th is rate ov er the power system fr equencies of 30.5 to 7 9.5 Hz. As a resu lt of this

feature, the measurem ent accuracy of the analog inp uts and the sensitivities of t he protection functions ar e

maintained over the ran ge of power system frequenci es. This feature provid es improved protection for fau lts

during off-normal frequenci es (such as start-up conditions). Figure 1–8: FREQUENCY-SENS ITIVITY CHARACTERISTICS shows variations in sensitivity of protection functions at different power system frequencies.

The sampling frequency is bas ed on 30.5 Hz for powe r system frequencies below 30.5 Hz and 79.5 Hz for the

frequencies above 79.5 Hz. In eit her case, i f the AC v oltage to the DGP drops below approx imately 20 V, the

sampling freque ncy is automati cally reca lculated on the basis of the nominal system frequency (S etting 102:

SYSFREQ

).

1

The sampling fr equency, which is 12 times the meas ured system freque ncy, can be accessed as one of the

Present Values.

1.4.6 TRIP CIRCUIT MONITOR

The trip circuit m onitor c onsis ts of D C vol tage an d curr ent mon itors ( TVM a nd TC M respe ctiv ely). E ach o f the

trip contacts shown with polarity marks in the elementary diagrams (see Section 1.5: ELEMENTARY DIAGRAMS) is monitored. TVM and TCM can be selectively disabled for each of the trip circuits.

Under normal conditions, DC vo ltage ac ross each of the contac ts is conti nuous ly monitored . If the DC voltag e

becomes virtually zero, then the trip circuit has "failed open". The TVM is active only when the generator is online, as indicated by th e i nput DI1. Th is function is intended to r ep lac e t he i ndi ca tin g l igh t typi ca ll y u se d for tri p

circuit monitoring. It is universally r ated for 48 through 2 50 V DC. A non-crit ical alarm is ge nerated when the

TVM detects an abnormality.

When the DGP system issues a trip, DC current through each of the appropriate trip contacts is monitored. The

trip relay is sealed -in, a s l ong as the cur r ent is flo win g, to pr ote ct th e contact. A minimum current o f 15 0 mA is

required for the TCM to recognize the trip current. Status of the trip current flow following issuance of any trip is

logged in the sequence of events.

1.4.7 SEQUENCE OF EVENTS

This function time -tags an d stor es the l ast 1 00 ev ents in m emory. The resolution of th e time -tagging is 1 mill isecond. The event list conta ins power sy stem events , opera tor actions, and se lf-te st alarms . The sequenc e of

events can be accessed, either locally or remotely, by a PC via one of the RS232 ports. A full description of this

function is contained in the Chapter 8: INTERFACE.

GE Power Management DGP Digital Generator Protection System 1-

19

Page 22

1.4 OTHER FEATURES 1 PRODUCT DESCRIPTION

1

12

11

10

9

8

7

6

Relative Sensitivity

5

4

Frequency Vs Sensitivity

DGP Relay System

64G1

32

24

3

46

2

1

0

59

51V

87G

0 102030405060708090100

System Frequency

32

46

24

Figure 1–8: FREQUENCY-SENSITIVITY CHARACTERISTICS

1.4.8 TIME SYNCHRONIZATION

The DGP system includes a real time clock that can run freely or be synchronized from an external signal. Two

different external time-sync signals are possible. If the DGP is connected to the host computer of a G-NET substation information and contr o l s yste m, then th e DG P rec ei ves a ti me-s yn c puls e v ia pi n 2 5 o f p or t P L-1. If the

DGP is not connected to a G-NET host computer, then a demodulated IRIG-B signal connected to optional port

PL-3 may be used to sy nchroni ze the clock. In bo th cases , the cl ock i n a given DG P is synch ronized to withi n

±1 mill is ec o nd of any o t he r di g it a l re lay cl ock, provided the two relays a re wi re d t o th e sa m e sy nc hr on iz in g s ig nal.

1-

20

DGP Digital Generator Protection System GE Power Management

Page 23

1 PRODUCT DESCRIPTION 1.4 OTHER FEATURES

1.4.9 FAULT REPORT & OSCILLOGRAPHY DATA

A fault report is initiated by any one of the protection-function pickup flags or an optional external oscillography

trigger input, DI5. For the fault report to be completed and stored, the DGP either has to issue a trip or the DI5

input contact must close any tim e during the fault report period. The fau lt report period begins when the firs t

protection function fla g is up or the DI5 in put co ntact is c losed. It end s when the DGP is sues a trip or when i t

has captured the selected number of post-fault waveform cycles, whichever is later. If all the pickup flags reset

without issuing a trip and the DI5 does not close, the fault report initiated by the protection flag will not be completed or stored.

The fault report includes the Unit ID, date and time, system operating time, pre-fault metering values, fault currents and voltages, trip/fa ult types, and up to 14 s equence-of-even t points logged after init iation. The system

operating time (OP TIME) is the time difference between the first prote ction function pickup flag and the first

protection function tri p. The DG P st ores the last three f ault repo rts i n its memory. A full description of the fault

report is contained in Chapter 8: INTERFACE.

DGP models with oscillography data capture capability will store waveform data in their memory each time the

system stores a fault report. A total of 120 cycles of data can be stored. The 120 cycles in memory are divided

in one, two, or three pa rtitions , bas ed on Setti ng 111:

fault can be set up to 20 cycles. It should be noted that the pre-fault cycles are based on the first flag or DI5 to

initiate the data capture.

Oscillography data in cludes station and generator identificat ion, a complete list of settings, the fault report,

internal flags, and a se lected number of pre-fault and post-fault wavef orm cycles. This data can be displa yed

using the GE-Link software program. See Chapter 10: GE-LINK SOFTWARE for details.

NUM FLTS

. The number of prefa ult cyc les cap tured per

1.4.10 LOCAL MAN-MACHINE INTERFACE

1

A local man-machine inte rf ace (M MI) , inc or porati ng a key pa d, LE D di splay, and 19 target LEDs, is pro vided to

allow the user to enter settin gs, display pres ent values, view fault ta rget informati on, and access sto red data.

The use and functioning of the MMI is fully described in the Chapter 8: INTERFACE.

1.4.11 LOCAL PRINTER

An optional printer port (PL- 2) on the rear of th e DGP permits the us e of a serial printe r. The port can also be

used to connect the DEC1000 Contact Expansion Unit (DGP***ACA models only) which provides eleven additional output relay s. The sequence-of-even ts (SOE) data are avai lable at this port for immediate printing as

they occur. Additionally, for DGP***AAA models, a variety of inform ation stored in the DGP system memo ry

can be printed when requested via the local MMI; see Chapter 8: INTERFACE for details.

GE Power Management DGP Digital Generator Protection System 1-

21

Page 24

1.4 OTHER FEATURES 1 PRODUCT DESCRIPTION

1.4.12 REMOTE COMMUNICATIONS

1

Two RS232 serial ports permit the u ser to communicate with the DGP from a n IBM PC- compatibl e compute r.

One of the ports, a DB-25 (PL-1), is located on th e rear of the case an d the othe r, a DB-9 (COMM), is located

on the front plate of the MMI module.

A PC may be connecte d to the DGP with a proper null-modem cable, provided the cable length does not

exceed 50 feet. The PC can also be connected via interposing modems if it is physically remote from the DGP.

GE-Link software is required to communicate with the DGP. The capabilities and use of the software are

described in Chapter 10: GE-LINK SOFTWARE. Refer to Chapter 9: COMMUNICATIONS for details regarding

the required cables and proper connection.

When a connection to the ho st computer of a stati on integratio n system is desi red, the following two ph ysical

connectio ns are possible:

• Standard hard-wire cables may be used for distances up to 50 feet.

• For longer distances it is possible to add an optional external adapter that plugs into PL-1 to provide a fiber

optic link between the DGP and the host computer. An isolated 5 V DC supply is internally connected to pin

11 of PL-1 to power this external adapter.

Cables and associate d equipment can be connected to each port si multaneousl y. However, when one port is

active the other is effectively disabled. For instance, when PL-1 is connected to host computer of an integration

system, it is not possible to log into the DGP from the front port when the integration system is active. If PL-1 is

connected to a modem and the front port is connected to a PC usi ng a null-modem cable, then th e first port

that becomes active is given preference, and the other port is disabled until the first is released.

1.4.13 REMOTE CONTROL

By using the local MMI or a remote PC connected to the RS232 port, it is possible to selectively operate any of

the four trip output relays fo r remote control. The control actio n may include shutdown of the mac hine, field

breaker trip, main g enerator brea ker trip, turbine trip, etc., depending on the equ ipment c onnected to the outputs. The controls descr ibed above are enabled or disabled by a ha rd-wired ju mper loca ted on the MMI module (see Figure 3–4: DGP MMI MODUL E on page 3– 5). As shi pped from the f actory, this jumper is physic ally

present and the Remote Control is disabled. To enable Remote Control, the jumper must be removed.

1.4.14 PASSWORD PROTECTION

Passwords provide sec urity when using the lo cal int erface (MMI) or duri ng remote commun ication s while running the GE-Link program. Two different passwords provide local MMI security for:

1. control operations (close trip-output contacts)

2. settings changes.

Three different passwords in the GE-Link program provide remote communications security for:

1. view and upload information

2. control operations

3. settings changes

Refer to the Chapter 8: INTERFACE for a descripti on of MMI password usag e, and refer to Chapter 10 : GELINK SOFTWARE for a description of GE-Link password usage.

The RS232 serial ports can be used with an optional RS485 to RS232 converter. Refer to Chapter 9: COMMUNICATIONS for further information on Modbus communication.

1-

22

DGP Digital Generator Protection System GE Power Management

1.4.15 REMOTE COMMUNICATIONS – MODBUS PROTOCOL

Page 25

1 PRODUCT DESCRIPTION 1.5 ELEMENTARY DIAGRAMS

1.5 ELEMENTARY DIAGRAMS

1

Figure 1–9: ELEMENTARY DIAGRAM WITH TEST BLOCKS, WYE VTs

GE Power Management DGP Digital Generator Protection System 1-

23

Page 26

1

1.5 ELEMENTARY DIAGRAMS 1 PRODUCT DESCRIPTION

Figure 1–10: ELEMENTARY DIAGRAM WITH TEST BLOCKS, DELTA VTs

1-

24

DGP Digital Generator Protection System GE Power Management

Page 27

1 PRODUCT DESCRIPTION 1.5 ELEMENTARY DIAGRAMS

1

Figure 1–11: ELEMENTARY DIAGRAM WITHOUT TEST BLOCKS, WYE VTs

GE Power Management DGP Digital Generator Protection System 1-

25

Page 28

1

1.5 ELEMENTARY DIAGRAMS 1 PRODUCT DESCRIPTION

Figure 1–12: ELEMENTARY DIAGRAM WITHOUT TEST BLOCKS, DELTA VTs

1-

26

DGP Digital Generator Protection System GE Power Management

Page 29

1 PRODUCT DESCRIPTION 1.5 ELEMENTARY DIAGRAMS

1

0286A2925ASH1.DWG

Figure 1–13: DIGITAL RELAY SYMBOL LEGEND

GE Power Management DGP Digital Generator Protection System 1-

0286A4911 SH9.DWG

27

Page 30

9 COMMUNICATIONS 9.1 INTRODUCTION

9 COMMUNICATIONS 9.1 INTRODUCTION 9.1.1 HARDWARE JUMPERS

There are two factory-ins talled hardware jumpers in the M MI module set to inhibit the ability to per form the

Remote Manual Trip function, the Remote Change S ettings function, the Remote Disable Outputs function ,

and the Remote Enable Outputs function. These hardware jumpers

tions are to be allowed (see Figure 3–4: DGP MMI MODULE on page 3–5 for details).

When establishing com munication betwe en the DGP and a remo te PC, two modems conn ected via a phon e

line are required. One modem is located at the DGP and the other modem is located at the PC. The cable that

connects the modem s with the DGP and PC is sh own in Figure 9–1: DGP CO MMUNICATIONS WIRING on

page 9–3. Each of these modems must be "Hayes-compatible". This is necessary since the GE-Link communications software send s a Hayes-com patible command string to the PC modem. The DGP do es not send any

configuration comm ands to i ts modem . The DGP modem and the PC modem mu st be uni quely con figured t o

permit the user to log into and communicate with the DGP system with GE-Link.

The required configuration settings are presented as changes to the factory-default configuration settings for a

Hayes SmartModem. These default settings are:

B1 P Y0 &K3 &S0 S7=30 S11=95 S26=1

E1 Q0 &C0 &L0 &T4 S8=2 S12=50 S36=1

L2 V1 &D0 &P0 &X0 S9=6 S18=0 S37=0

M1 W0 &G0 &Q5 S0=0 S10=14 S25=5 S38=20

N1 X4 &J0 &R0 S6=2

must

be removed if the above remote func-

9.1.2 MODEM CONNECTIONS & SETTINGS

Other Hayes-compatible modems may implement a subset of the full Hayes command set. It is the responsibility of the user to as certa in the ex act co mma nds a cc ept ed b y a pa rtic ula r mod em. The p ro per syn tax for e ntering the Hayes-compatible commands (s ome times referred to as the "AT" command set) is not des c ribe d he re.

Refer to the modem documentation for an explanation of this syntax.

9.1.3 PC MODEM

The PC modem must be configured for intelligent operation (that is, command recognition enabled). The

default settings li sted abo ve ar e vali d for GE-L ink. T hose conf igu ratio n setti ngs cri tical to the oper ation of GELink are changed by the software. The configuration commands sent to the modem from GE-Link are:

+++

ATE0L3Q0S7=60V0X4Y0

Command explanation:

AT Modem attention command

E0 Disable command state echo

L0 Low speaker volume

Q0 Modem returns result codes

V0 Result codes returned in numeric form

X4 Enables features represented by result codes

Y0 Disable long space disconnect

S7=60 Allows modem to hang up if connection is not made within 60 seconds

(set modem to command mode)

(delay 2 seconds)

(see explanation below)

9

GE Power Management DGP Digital Generator Protection System 9-

1

Page 31

9.1 INTRODUCTION 9 COMMUNICATIONS

If all of the above c ommands ar e not program mable, the mo dem may not operate proper ly. In addition to the

required configuration settings above, it is suggested that two other settings be made. These are:

&D3 Causes the modem to reset on the ON-to-OFF transition of DTR (Data Terminal Ready)

&C1 Causes DCD (Data Carrier Detect ) to track the received carrier signal

The modem will ope rate properly without making these tw o settings but the modem will n ot hang up if the

appropriate handshaking signal is lost.

A GE-Link setting establi shes the baud rate, whi ch m ust matc h the DGP baud rate s etting. GE-L ink then sets

the specified PC s erial port (i.e., COM1 , COM2) to the proper baud rate , parity, data bits, and stop b its. If the

PC modem is capable of operating at more than one baud rate, then it must be able to automatically configure

its baud rate, character length, and parity setting by examining the AT command prefix.

9.1.4 DGP MODEM

The DGP modem must be configured for "dumb " opera tion (tha t is, command recogniti on disa bled) . Since the

DGP does not send any co nfiguration commands to its modem , the required configuration setti ngs must be

made prior to connecti on. Additionally, the modem must be initialized to the required con figuration settings

each time modem power is turned OFF then ON. Depending on the design of the modem, this is accomplished

by making the required settings via switches or saving the settings in non-volatile memory.

The required configuration settings are:

E0 Disable command state echo

L0 Low speaker volume

Q1 Disable result code display

&C1 Causes DCD (Data Carrier Detect) to track the received carrier signal

&D3 Causes the modem to reset on the ON-to-OFF transition of DTR (Data Terminal Ready)

&Q0 Asynchronous mode

S0=1 Enable auto-answer

If any of the above se ttings cannot be implemen ted, the modem may not ans wer, the DGP system may not

connect properly, or the user may not be able to log into the DGP.

With a Hayes SmartModem or equivalent, the DGP modem pe rforms a modulation handshake with t he PC

modem to set the DGP modem baud rate. The default setting N1 permits ha ndshaking to occur at any bau d

rate supported by both modems. This is one reason why it is preferable to use identical modems at each end.

Note that auto-answering is contr olled with register S0. S0=0 disables auto-an swer. S0=1 causes the DGP

modem to answer the in coming c all after one r ing. If it is de sirabl e to delay mo dem answeri ng, S0 can b e set

for any value between 1 and 255 (for the Hayes-compatible modem assumed). Note that GE-Link (versions 2.0

and higher) configur es the PC mod em to wait 60 se conds for the DGP modem to answer. If the DGP modem

register S0 is set higher than 12, the PC modem may time-out and hang up before the DGP modem can

answer. S0=12 sets the DGP modem to answer after twelve rings, corresponding to an approximate 60 second

delay (S7=60) at the PC mode m. However, the number of rings corr esponding to 60 sec onds should be v erified for a particular application.

9.1.5 NULL MODEM CONNECTIONS

9

A PC can be connected to the DGP with out the intervenin g modems a nd phone l ine by usin g a "null mod em"

cable. The required pin-to-pi n connec tions for this null modem cab le are shown in the following diagra m. The

pin-to-pin connection s for a null modem ca ble to DGP COMM connecto r are also shown below. Neither null

modem cable should exceed 50 feet in length.

9-

2

DGP Digital Generator Protection System GE Power Management

Page 32

9 COMMUNICATIONS 9.1 INTRODUCTION

TO RELAY

PL-2

TO RELAY

PL-1

25 PIN D-TYPE

MALE

TD

RD

CTS

GND

TD

RD

RTS

CTS

DSR

GND

DCD

DTR

RI

2

3

5

7

A) PRINTER CONNECTIONS

25 PIN D-TYPE

MALE

2

3

4

5

6

7

8

20

22

B) REMOTE COMMUNICATIONS VIA MODEM CABLE

25 PIN D-TYPE

MALE / FEMALE

TD

2

RD

3

GND

7

DTR

20

25 PIN D-TYPE

MALE / FEMALE

2

TD

3

RD

4

RTS

5

CTS

6

DSR

7

GND

8

DCD

20

DTR

22

TO

PRINTER

TO

MODEM

RI

TO RELAY

PL-1

TO RELAY

MMI MODULE

COMM

25 PIN D-TYPE

MALE

TD

RD

RTS

CTS

DCD

DSR

RI

DTR

GND

TD

RD

DSR

RI

DTR

RTS

CTS

DCD

GND

2

3

4

5

8

6

22

20

7

C) REMOTE COMMUNICATIONS TO PC DIRECTLY

9 PIN D-TYPE

MALE

3

2

6

9

4

7

8

1

5

D) REMOTE COMMUNICATIONS FROM MMI MODULE TO PC

25 PIN D-TYPE

MALE / FEMALE

TD

2

RD

3

RTS

4

CTS

5

DCD

8

DSR

6

22

DTR

20

GND

7

9 PIN D-TYPE

MALE / FEMALE

TD

3

RD

2

DSR

6

RI

9

DTR

4

RTS

7

CTS

8

DCD

1

GND

5

TO

PC

RI

TO

PC

9

CABLES AVAILABLE AS GE PART NO. 0246A9866. SPECIFY CABLE TYPE AND CONNECTOR GENDER.

GE Power Management DGP Digital Generator Protection System 9-

Figure 9–1: DGP COMMUNICATIONS WIRING

3

Page 33

9.1 INTRODUCTION 9 COMMUNICATIONS

9.1.6 RS485 COMMUNICATIONS

The DGP with Modbus comm unications can be used with a G E Power Management RS485 to RS23 2 converter when necessary. For computers without RS485 capabi lity, a “master” SCI box is required as shown in

the figure below. The SCI boxes are available from GE Power Management as catalog number S14200

where

X

specifies the voltage input. Please consult the SCI documentation for additional configuration informa-

tion.

X

,

For RS485 communications, the Master SCI box switch #2 must be set for

default) and the Slave switch #2 must be set for

NOTE

Correct polarity is also ess en tia l. A LL wi res fro m the Mas ter SCI to the Slave SCI must be wired wi th the pos itive (+) terminal s connected together and th e negative (–) terminals con nected together. Each relay must be

daisy-chained to the next. Avoid sta r or stub conne cted confi gurations. The last device ( SCI box) at each en d

of the daisy-chain should be terminate d with a 12 0 Ω, ¼ W resistor in series with a 1 nF capacitor across the

positive (+) and negative (–) terminal s.

Table 9–1: SCI DIP SWITCH CONFIGURATION

SWITCH 1 1234

Data Controlled ON OFF ON X

DTR Controlled OFF ON OFF X

SWITCH 2 1234

Direct ON OFF ON OFF

Modem OFF ON OFF ON

MODEM

. Set switch #1 for

DIRECT

DATA CONTROLLED

(the factory

.

9

Figure 9–2: RS485 COMMUNICATIONS

9-

4

DGP Digital Generator Protection System GE Power Management

Page 34

9 COMMUNICATIONS 9.2 MODBUS COMMUNICATIONS

9.2 MODBUS COMMUNICATIONS 9.2.1 INTRODUCTION

This section describe s the Mod icon Modbus RTU comm unicati on prot ocol use d by the DGP Digita l Gene rator

Protection Relay.

The device serial communi cation parameter s, such as baud rate an d DGP Unit ID, are set via the keypad. If

the DGP baud rate differs from the Modbus server baud rate , the device will not comm unicate to the server.

The Unit ID also must be set properly to avoid confli ct with other devices connected on the same network.

Even though the setti ng range allow s 16 bit va lues for Unit ID, the relay s hould be pr ogrammed for a Unit ID

ranging from 1 to 127.

The DGP impleme nts a subset of protocols defined b y the Modicon Modbus RTU p rotocol standar d. Multiple

DGP relays can be c onfigu red as s laves t o a si ngle Modb us mas ter thr ough th e RS485 port (u sing an RS48 5

to RS232 converter ). The DGP is alway s a slave – it cann ot be programmed as a master. Even though the

Modbus protocol is availa ble in Modbus RTU, Modbus ASCII and Modb us Plus protocols, only the Modbus

RTU protocol is supported by the DGP.

9.2.2 DATA FRAME FORMAT & DATA RATE

One data frame of asynchr onous transmission fro m the DGP is defaulted to 1 start bit, 8 data bits, no p arity

bits, and 1 stop bit at 96 00 baud. The b aud rate, parity bi ts and number o f stop bits can b e changed thr ough

the DGP keypad. This setting cannot be changed through the Modbus COM port.

9.2.3 DATA PACKET FORMAT

A complete request/response sequence consists of the following bytes.

Modbus Request Transmission: Bytes

SLAVE ADDRESS 1

FUNCTION CODE 1

DATA STARTING ADDRESS 2

DATA variable number depending on function code

REGISTER CODE 2 bytes

CRC Hi High byte of CRC

CRC Lo Low byte of CRC

Slave Response Transmission: Bytes

SLAVE ADDRESS 1

FUNCTION CODE 1

BYTE COUNT variable depending on number of registers

DATA variable number depending on the function

CRC Hi High Byte of CRC

CRC Lo Low byte of CRC

a) SLAVE ADDRESS

9

This is the first byte of every transmission. It represents the Unit ID of the device programmed through the DGP

keypad. In the master request, the slave address represents the address of the slave the message is intended

for. In the slave response it is the address of the slave that is responding to the master request. Slave address

0 is reserved for broadcas t transm issions by the m aster as s pecifi ed by the Modbus protocol. The DGP d oes

not support the broadcast transmissions. The DGP will respond only if the slave address specified by the master request matches its Unit ID; otherwise the DGP relay will not respond.

GE Power Management DGP Digital Generator Protection System 9-

5

Page 35

9.2 MODBUS COMMUNICATIONS 9 COMMUNICATIONS

b) FUNCTION CODE

This is the second byte of every transmission. Modbus defines function codes 1 to 127 but the DGP impl ements only a subset of these functions. In a master request, the function code represents the action to be performed by the slave. The slav e resp onds wi th function c ode ide ntica l to that se nt by the ma ster if ther e are no

errors. In case of an error or exception, the slave sets the MS bit of the function code to 1 to indicate an error.

c) DATA

This will be a variable number of bytes depending on the function code.

d) CRC HI & CRC LO

This is a two-byte cycl ic redun dancy check . The MS by te is sent fi rst and th e LS by te next in accor danc e with

the Modbus protocol reference guide.

9.2.4 ERROR CHECKING

In RTU mode, messages i nclude an error checking fiel d that is ba sed on a cy clic redundan cy check me thod.

The CRC field checks the contents of the entire me ssage. It is appli ed regardless of any parity check method

used for the individual characters of the message.

The CRC field is two byte s, containing a 1 6-bit binar y value. The CRC value is ca lculated by the t ransmittin g

device, which appends the CRC to the me ssage. The receiving device recalc ulates CRC and compares with

the value it received in the CRC field. If they are not equal an error message results.

The CRC is calculated by fi rst pre-loading a 16-bit register to al l 1’s (in GE relays, all registers are pre-loade d

with zeros). Then using a CRC polynomial specified by the CCITT, the CRC is computed (0xA001).

9.2.5 DATA FRAMING

Modbus RTU messages are s eparated by a silence period of at least 3.5 characters. The sl ave flushes the

COM port and reads for th e f irst c harac ter. This marks th e s tart of tra nsmi ssio n. Th e sl av e k ee ps r ead ing un til

a silent interval of 3.5 c haracter s which is abou t 3.65 ms at 9600 baud, wh ich marks the end of tra nsmission .

At this stage it builds the message and resets the port.

9

9-

6

DGP Digital Generator Protection System GE Power Management

Page 36

9 COMMUNICATIONS 9.3 MODBUS FUNCTIONS

9.3 MODBUS FUNCTIONS 9.3.1 FUNCTION CODE 03/04: READING HOLDING/INPUT REGISTERS

a) DESCRIPTION

Reads the binary c ontents ho lding/in put regi sters (ac tual va lues) in the sl ave. They can be s et point registers

or any of the information reports, such as actual values.

b) QUERY

The query message specifies the starting register and the number of registers to be read.

Field: Bytes Example (hex):

SLAVE ADDRESS 1 11 Message for slave 17

FUNCTION CODE 1 03/04 Read registers

Starting address 2 Starting address of the register. High byte first and then the Low Byte

Num points 2 Number of registers to read. High Byte first then Low byte

CRC 2 CRC Calculated by master. High byte first. Low byte next

c) RESPONSE

The register data i n the r espo nse i s packe d as two by tes per registe r. For each register t he fir st byte co ntains

the higher order byte and the second contains the lower order byte.

Example of typical response message

Field: Bytes Example (hex):

SLAVE ADDRESS 1 11 Message from slave 17

FUNCTION CODE 1 03/04 Read registers

Byte Count 1 Number of registers to read.

Data 1 2 High Byte first then Low byte

......

Data n 2 High Byte first then Low byte

CRC 2 CRC calculated by slave. High byte first, Low byte next

9

GE Power Management DGP Digital Generator Protection System 9-

7

Page 37

9.3 MODBUS FUNCTIONS 9 COMMUNICATIONS

9.3.2 FUNCTION CODE 05: FORCE SINGLE COIL

a) DESCRIPTION

This function code allows the master to request a DGP slave to perform a specific command operation.

b) QUERY

The query message specifies the command to be executed.

Field: Bytes Example (hex):

SLAVE ADDRESS 1 11 Message for slave 17

FUNCTION CODE 1 05 Execute a command