Page 1

g

ASTAT ®-IBP Plus Solid State Starters

Service Instructions

DEH-40417

Page 2

Page 3

WARNINGS

All Rights Reserved

CAUTIONS

NOTES

DEH-40417

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or

other conditions that could cause personal injury are present in this equipment or may be

associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care is not taken.

Notes call attention to information that is especially significant to understanding and operating

the equipment.

This document is based on information available at the time of its publication. While efforts have

been made to ensure accuracy, the information contained herein does not cover all details or

variations in hardware and software, nor does it provide for every possible contingency in

connection with installation, operation, and maintenance. Features may be described herein that

are not present in all hardware and software systems. GE Electrical Distribution & Control

assumes no obligation of notice to holders of this document with respect to changes subsequently

made.

GE Electrical Distribution & Control makes no representation or warranty, expressed, implied, or

statutory, with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency,

or usefulness of the information contained herein. No warrantees of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Company:

ASTAT®-IBP Plus

©Copyright 2001 GE Company

i

Page 4

ASTAT ®-IBP Plus Service Instructions

Table of Contents

Cover Removal and Replacement............................................................................................1

Logic Board Replacement.......................................................................................................2

Power Supply Board Replacement ...........................................................................................3

Protection Board Replacement................................................................................................5

SCR Module Replacement (Sizes K, L, and Y)...........................................................................6

SCR Module Replacement (Sizes M, Z, and N)..........................................................................7

SCR Module Replacement (Sizes P, Q, and R)..........................................................................8

SCR Module Replacement (Size S)...........................................................................................9

Trouble-Shooting Guide........................................................................................................11

Renewal Parts List.................................................................................................................12

ii Prices and data subject to change without notice.

Page 5

WARNING: Power must be removed from the ASTATIBP before any servicing operation.

AVERTISSEMENT: Le courant doit être enlevé du

ASTAT-IBP avant de procéder à toute opération de

service.

Cover Removal and Replacement

1. Remove the two 12-point terminal connectors by

inserting a flat-head screwdriver between the

terminal connector and the ASTAT-IBP cover, as

illustrated in Figure 1.

Do not remove the wiring from the terminal

connectors.

Carefully release the terminal connector from the

pins. Carefully pull the terminal connectors, with

the wiring, straight off the ASTAT-IBP starter.

2. Remove the plastic cover by pressing and releasing

the plastic tab on each side of the cover with a flathead screwdriver, as illustrated in Figure 2.

3. To reattach the cover, lower it over the circuit

boards. Carefully push down on the cover until the

two tabs snap into place. It may be necessary to push

in slightly on the outside of the lower plastic

housing.

4. Replace the terminal connectors through the plastic

cover onto the connector strips. Ensure that the

terminal connectors snap into place.

ASTAT ®-IBP Plus Service Instructions

Terminal Connector

Cover

Figure 1. Removing the terminal connectors.

Figure 2. Removing the cover.

Prices and data subject to change without notice. 1

Page 6

ASTAT ®-IBP Plus Service Instructions

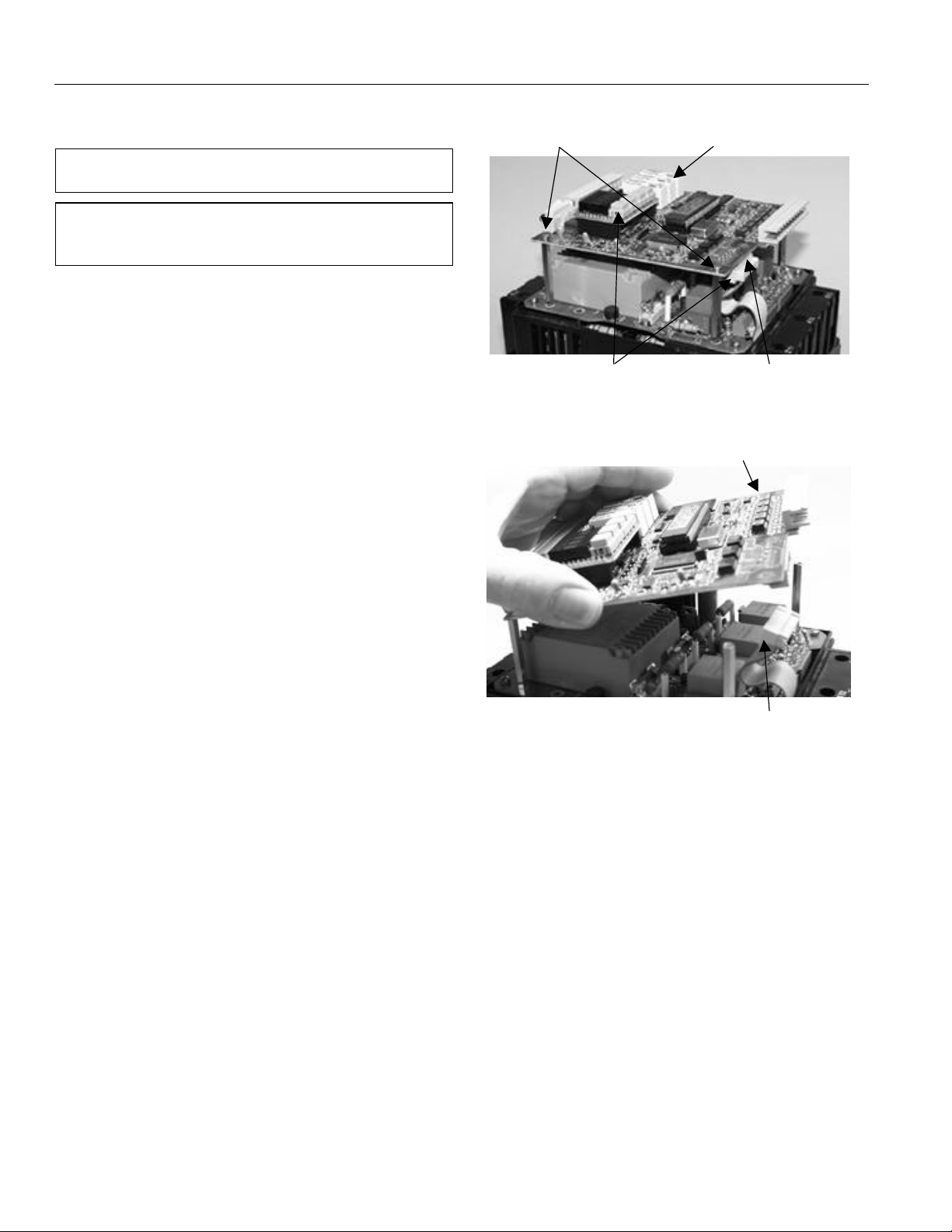

Logic Board

Logic Board

Logic Board Replacement

CAUTION: Always handle circuit boards by their edges

and do not distort the parts on the circuit boards.

ATTENTION: Il faut toujours manipuler les plaques de

circuits par leurs côtés et ne pas déformer les pièces sur

les plaques de circuits.

1. Remove the ASTAT-IBP cover as described in steps

1–2 of Cover Removal and Replacement.

2. Unplug the two ribbon cables from the Logic Board,

as shown in Figure 3.

3. Remove the four corner screws holding the Logic

Board to the stand-offs below the Logic Board. Lift

the Logic Board straight up to remove it, as

illustrated in Figure 4.

4. Reassemble the Logic Board to the starter. With the

display on the Logic Board at the upper left corner,

place the board on the stand-offs. Reattach the four

screws holding the Logic Board to the stand-offs.

5. Reattach the two ribbon cables. Ensure that the

ribbon cable at the bottom of the ASTAT-IBP is fully

seated on both circuit boards and that the ribbon

cable does not interfere with or touch the cover.

6. Reinstall the plastic cover and the terminal

connectors as described in steps 3–4 of Cover Removal

and Replacement.

Screws

Unplug Cable

Ribbon

Power Supply

Figure 3. Logic board and part locations.

Board

Cable Ribbon

Figure 4. Removing the Logic Board.

2 Prices and data subject to change without notice.

Page 7

ASTAT ®-IBP Plus Service Instructions

Screw

Power Supply Board Replacement

The Power Supply Board is located as shown in Figure 5.

It contains gray and orange transformers visible from the

sides.

1. Remove the following components:

a. The cover, as described in steps 1–2 of Cover

Removal and Replacement.

b. The Logic Board, as described in steps 2–3 of

Logic Board Replacement.

2. Remove the four screws holding the Power Supply

Board to the black plastic housing, as shown in

Figure 6.

3. If a yellow-green wire is connected to the bottom of

the Power Supply Board, it must be disconnected.

Lower the top of the Power Supply Board to view the

red and white gate leads to the SCRs, as shown in

Figure 7.

NOTE: Check the red and white gate wires for a marked

number before removing these wires. Each gate wire

must have a number corresponding to the terminal

numbers (1–12) on the Power Supply Board to facilitate

reassembly.

Power Supply Board

Ribbon Cable

Figure 5. Location of the Power Supply Board.

NOTE: Vérifier les chiffres sur les fils de porte avant

d’enlever ceux-ci. Chaque fil de porte doit avoir un

chiffre correspondant aux chiffres de la borne (1–12)

sur la plaque de la boîte d’alimentation pour faciliter le

réassemblage.

4. With a small screwdriver, remove the red and white

gate wires from the small four-point gate Terminal

Boards, one on the component side and two on the

solder side of the Power Supply Board.

These wires must be reconnected to the new Power

Supply Board at the proper number terminals for

proper operation of the starter.

5. Lift off the Power Supply Board. Remove and save

the hex stand-offs, nuts, and washers from the Power

Supply Board for use on the replacement board.

6. Attach the stand-offs to the new Power Supply Board.

Place the new Board in position in the ASTAT-IBP.

Figure 6. Removing the screws holding the Power Supply Board

to the housing.

Gate Leads

Bottom of Power

Supply Board

Protection Board

Gate Terminal

Board

Figure 7. Gate leads, Power Supply Board, and Protection Board.

Prices and data subject to change without notice. 3

Page 8

ASTAT ®-IBP Plus Service Instructions

7. Reconnect the red and white gate wires to the fourpoint Terminal Boards, one on the component side

and two on the solder side of the Power Supply

Board, as illustrated in Figures 8, 9, and 10.

8. Secure the Power Supply Board with the four screws

removed earlier.

9. Reinstall the following components:

a. The Logic Board, as described in steps 4–5 of

Logic Board Replacement.

d. The cover, as described in steps 3–4 of Cover

Removal and Replacement.

Figure 8. Gate lead connections for sizes K, L, and Y.

Figure 9. Gate lead connections for sizes M, Z, and N.

Figure 10. Gate lead connections for sizes P, Q, R, and S.

4 Prices and data subject to change without notice.

Page 9

Protection Board Replacement

Wire Connectors

ASTAT ®-IBP Plus Service Instructions

1. Remove the following components:

a. The cover, as described in steps 1–2 of Cover

Removal and Replacement.

b. The Logic Board, as described in steps 2–3 of

Logic Board Replacement.

c. The Power Supply Board, as described in steps 2–

5 of Power Supply Board Replacement.

2. Remove the six wire connectors from the Protection

Board, as shown in Figure 11. Note the locations of

these terminals for reassembly.

3. Disconnect the four leads from the two current

transformers and the two leads from the thermostat

connecting to the six-point Terminal Board, located

at the top-right edge of the Protection Board. Label

these leads to ensure that they are connected to the

same terminals on the new Protection Board.

4. Loosen the four screws holding the Protection Board

to the housing. Remove the Protection Board from

the ASTAT-IBP.

5. Place the new Protection Board in position in the

ASTAT-IBP and secure it with the four mounting

screws to the housing.

6. Attach the four current transformer leads and the

two thermostat leads to the six-point Terminal

Board.

7. Attach the six push-on wire connectors to the

Protection Board.

8. Reinstall the following components:

a. The Power Supply Board, as described in steps 6–

9 of Power Supply Board Replacement.

b. The Logic Board, as described in steps 4–5 of

Logic Board Replacement.

c. The cover, as described in steps 3–4 of Cover

Removal and Replacement.

Six-Point

Terminal Board

Protection Board

Mounting Screw

Figure 11. Removing the wire connectors from the Protection

Board.

Prices and data subject to change without notice. 5

Page 10

ASTAT ®-IBP Plus Service Instructions

SCR Module Replacement (Sizes K, L,

and Y)

This procedure requires the following tools and

materials:

• #2 Philips-head screwdriver, 3/16" Allen wrench,

torque wrench

• Scotchbrite or equivalent abrasive

• Mild solvent to clean mounting surfaces

• Electrolube 2GX or equivalent thermal grease

1. Loosen the screws holding the MOVs and bus bars

to the SCR Module to be replaced, as illustrated in

Figure 12, and remove the MOVs and bus bars.

2. Remove the mounting screws at each end of the SCR

Module, as shown in Figure 13, then lift out the

Module. Retain all the parts and hardware removed

from the SCR Module for reassembly with the

replacement Module.

3. Clean the heat sink surface of the replacement

Module with a fine abrasive, such as Scotchbrite.

Remove all particles from the heat sink surface and

wipe the SCR mounting surface with a mild solvent.

Apply a light coat of thermal grease, such as

Electrolube 2GX to both the SCR and heat sink

surfaces.

4. Place the contact face of the SCR Module on the

mating heat sink surface. Move the Module back

and forth several times to distribute the thermal

grease evenly over the contact surfaces.

5. Attach the SCR Module to the heat sink with the

screws removed earlier. Tighten the screws to 44 inlb.

6. Reattach the bus bars and MOVs to the SCR Module

with the screws removed earlier. Tighten the screws

to 26 in-lb.

Figure 12. Removing the MOVs and bus bars from an SCR to be

replaced.

Figure 13. Removing the SCR module.

6 Prices and data subject to change without notice.

Page 11

SCR Module Replacement (Sizes M, Z,

and N)

This procedure requires the following tools and

materials:

• #2 Philips-head screwdriver, 3/16" Allen wrench,

torque wrench

• Scotchbrite or equivalent abrasive

• Mild solvent to clean mounting surfaces

• Electrolube 2GX or equivalent thermal grease

ASTAT ®-IBP Plus Service Instructions

1. Loosen the screws holding the MOVs and bus bars

to the SCR Module to be replaced, shown in Figure

14, and remove the MOVs and bus bars.

2. Remove the mounting screws at each end of the SCR

Module, then lift out the Module. Retain all parts

and hardware removed from the SCR Module for

reassembly with the replacement Module.

3. Clean the heat sink surface of the replacement

Module with a fine abrasive, such as Scotchbrite.

Remove all particles from the heat sink surface and

wipe the SCR mounting surface with a mild solvent.

Apply a light coat of thermal grease, such as

Electrolube 2GX to both the SCR and heat sink

surfaces.

4. Place the contact face of the SCR Module on the

mating heat sink surface. Move the Module back

and forth several times to distribute the thermal

grease evenly over the contact surfaces.

5. Attach the SCR Module to the heat sink with the

screws removed earlier. Tighten the screws to 44 inlb.

6. Reattach the bus bars and MOVs to the SCR Module

with the screws removed earlier. Tighten the screws

to 80 in-lb.

Figure 14. Location of SCRs on size M, Z, N ASTAT-IBP.

Prices and data subject to change without notice. 7

Page 12

ASTAT ®-IBP Plus Service Instructions

SCR Module Replacement (Sizes P, Q,

and R)

This procedure requires the following tools and

materials:

•1/2" wrench, 3/16" Allen wrench, torque wrench

• Scotchbrite or equivalent abrasive

• Mild solvent to clean mounting surfaces

• Electrolube 2GX or equivalent thermal grease

1. Disconnect the control wiring harness for the SCRs

to be replaced. If necessary, disconnect the wiring

harness of the CTs.

2. Remove the bolt holding the busbar to the line side

of the SCR Module.

3. Remove the bolt holding the CT, spacer, and loadside busbar to the SCR Module, as shown in Figure

15.

4. Remove the four screws holding the SCR Module to

the mounting plate, as shown in Figure 16.

5. Lift out the SCR Module, as shown in Figure 17.

Retain all parts and hardware for reassembly with

the replacement Module.

6. Remove the MOV by disconnecting it at the spade

connectors. Attach the MOV to the replacement

SCR Module in the same manner.

7. Clean the heat sink surface of the replacement

Module with a fine abrasive, such as Scotchbrite.

Remove all particles from the heat sink surface and

wipe the SCR mounting surface with a mild solvent.

Apply a light coat of thermal grease, such as

Electrolube 2GX to both the SCR and heat sink

surfaces.

8. Place the new SCR Module in the proper position on

the mounting surface. Move the Module back and

forth several times to evenly distribute the grease on

the plate.

9. Secure the SCR Module to the mounting plate with

the screws removed earlier. Tighten the screws to 44

in-lb torque.

10. Reattach the busbars, CT, and spacer to the SCR

Module with the bolts removed earlier. Tighten the

bolts to 150 in-lbs torque.

11. Attach the wiring harness of the new SCR Module to

its mating piece. Attach the wiring harness of the

CTs, if necessary.

Figure 15. Disconnecting the SCR load side..

Figure 16. Removing the SCR mounting screws.

Figure 17. Removing an SCR Module.

8 Prices and data subject to change without notice.

Page 13

SCR Module Replacement (Size S)

This procedure requires the following tools and

materials:

•9/16" wrench, 11/16" wrench, 3/16" Allen wrench,

torque wrench

• Scotchbrite or equivalent abrasive

• Mild solvent to clean mounting surfaces

• Electrolube 2GX or equivalent thermal grease

1. Disconnect the control wiring harness for the SCRs

to be replaced. If necessary, disconnect the wiring

harness of the CTs.

2. Remove the bolt holding the busbars connected to

the blocks on the load and line sides of the SCR

Module, as shown in Figure 18.

3. Remove the bolt holding the CT, the threaded stud,

and the load-side busbar from the Module.

4. Remove the bolts holding the load-side lug in place.

Remove the lug.

5. Remove the L-shaped busbar and CT, if applicable,

from the assembly, as shown in Figure 19.

6. Remove the four screws holding the SCR Module to

the mounting plate, as shown in Figure 20.

ASTAT ®-IBP Plus Service Instructions

Figure 18. Removing the busbar mounting bolt.

Figure 19. Removing the L-shaped busbar.

Figure 20. Removing the SCR mounting screws.

Prices and data subject to change without notice. 9

Page 14

ASTAT ®-IBP Plus Service Instructions

7. Lift out the SCR Module, as shown in Figure 21.

Retain all parts and hardware for reassembly with

the replacement Module.

8. Remove the threaded stud from the SCR Module

and attach it to the new Module. Tighten to 200 inlb torque.

9. Clean the heat sink surface of the replacement

Module with a fine abrasive, such as Scotchbrite.

Remove all particles from the heat sink surface and

wipe the SCR mounting surface with a mild solvent.

Apply a light coat of thermal grease, such as

Electrolube 2GX to both the SCR and heat sink

surfaces.

10. Place the new SCR Module in the proper position on

the mounting surface. Move the Module back and

forth several times to evenly distribute the grease on

the plate.

11. Secure the SCR Module to the mounting plate with

the screws removed earlier. Tighten the screws to 44

in-lb torque.

12. Reattach the load-side lug, L-shaped busbar, and

CT, if applicable. Tighten the mounting bolts to 200

in-lb torque.

13. Reattach the busbars to the SCR Module. Tighten

the mounting bolts to 150 in-lb torque.

14. Attach the wiring harness of the new SCR Module to

its mating piece. Attach the harness of the CTs, if

necessary.

Figure 21. Removing the SCR Module from the mounting plate..

10 Prices and data subject to change without notice.

Page 15

ASTAT ®-IBP Plus Service Instructions

Troubleshooting Guide

This guide is provided for troubleshooting and isolating common problems. It does not cover every possible situation.

Contact the Customer Support Center at 800-843-3742 if any problem is not resolved by these procedures.

Symptom or Error & (Error Code)Symptom or Error & (Error Code) Possible CausePossible Cause Measures to Be TakenMeasures to Be Taken

Display OFF

Equipment does not respond to STOP /

START controls

Frequency error (admits

45Hz ≤ f main ≤ 65Hz) (Ex10)

Overload trip (Ex11) Excessive load or excessive current

Synchronism loss (Ex13) Phase 1L1 1L1 lost Check 1L11L1 phase

Phase A, B, C thyristor (Ex14)

(Ex15)

(Ex16)

Heatsink thermostat (Ex17) Heatsink thermostat tripped by

Motor thermistor(Ex18) Motor thermistor tripped by

Phase A, B, C loss (Ex19)

(Ex20)

(Ex21)

Stalled rotor (Ex22) Equipment detected stalled motor

Internal error (Ex23) Micro-controller malfunction Check IC1 and IC8 are correctly inserted

Long start time (Ex25) Current limit condition present more

Lock-out (Ex27) The time between startings is less

Undervoltage (Ex28)

Overvoltage (Ex29)

Undercurrent (Ex30)

Overcurrent (Ex31)

No control voltage.

Main breaker tripped or fuse blown

F1 fuse blown on power supply PCB Check and change.

Bad connection of flat ribbon wire

joining power supply PCB to control

PCB

F2 fuse blown on power supply PCB Check and change.

No 1L11L1 phase or frequence is out of

range

during starting

Short circuited thyristor Check thyristor module.

No output phases Check 2T1, 4T2 2T1, 4T2 and 6T3 6T3 phases

overheating or defective

overheating or defective

No input / output phases Check power wire harness for 1L1,1L1,

Defective thyristor or ribbon wire

harness loose or defective

rotor

than2 x ta sec. or 240 sec. (ta =

acceleration ramp time)

that the adjusted in parameter "LKxx"

The line voltage exceeds of limit set in

parameters "UVxx" or "OVxx"

The motor current exceeds of limit set

in parameters "UCxx" or "OCxx"

Check wire harness and control voltage

Verify connectors.

Check power supply board and logic

board for 5VDC. Use a DC voltmeter on

the power supply board, (-) lead of

voltmeter on the top lead of C6 (located

next to the black heatsink on the right

edge of the power supply board) and the

(+) lead of voltmeter on top lead of Diode

AD21 or R25 (located on the upper right

corner of the power supply board.)

Check 1L11L1 phase and/or mains

frequence

Verify overload conditions during starting

time and steady state. Check settings in

parameters "Nxxx", "Lxxx", and "oxxx"

Check ground connections and voltage to

ground.

Poor ribbon cable connection

Check for adequate ventilation.

Check thermostat and wiring

Check thermistor and wiring, if no

thermistor terminal 5 and 6 must be

jumpered

3L2, 5L3, 2T1, 4T2 3L2, 5L3, 2T1, 4T2 and 6T36T3

Verify gate and cathode wire harness.

Verify thyristors

Restart equipment and check for an

appreciable loss in motor speed at any

time

in their sockets.

Check for noise on control voltage power

or line

Increase current limit and / or acceleration

ramp time

Check if settings are correct.

This protection may be disabled

Check if settings are correct.

This protection may be disabled

Check if settings are correct.

This protection may be disabled

Prices and data subject to change without notice. 11

Page 16

ASTAT ®-IBP Plus Service Instructions

Renewal Parts List

The following parts and assemblies are available as replacement parts for ASTAT-IBP Solid State Starters. Renewal

parts as furnished may not be identical to the original parts since design changes may have been made in the interim.

The parts supplied will, however, be interchangeable with the original parts.

Catalog NumberCatalog Number

DescriptionDescription Where UsedWhere Used

SCR Module

Bypass Contactor

Protection Circuit Board

Logic Printed Circuit Board with EPROM ALL QIX000150 1 650.00

Power Supply PCB ALL QIX000151 1 360.00

MOV (with terminals and insulators)

Terminal Strip (Logic P.C.B.) All, 12-point QIX000159 1 16.00

Terminal Strip (Control Power Input to

ASTAT)

Type GMC, 250 Vac)

Ribbon Cable, Top-Logic Board to Power

Supply Board

Ribbon Cable, Bottom-Logic Board to

Protection Board

Thermostat QC2K,L,M QIX000165 1 10.00

Plastic Cover-ASTAT-IBP Plus ALL QIX000166 1 30.00

À List Price, GO-10C2.

QI3KDP QIX000111 1/phase $117.00

QI3LDP QIX000112 1/phase 117.00

QI3YDP QIX000113 1/phase 117.00

QI3MDP QIX000114 QIX000115 QIX000116 1/phase 430.00

QI3ZDP QIX000117 QIX000118 QIX000119 1/phase 430.00

QI3NDP QIX000120 QIX000121 QIX000122 1/phase 430.00

QI3PDP QIX000123 QIX000124 QIX000125 1/phase 945.00

QI3QDP QIX000126 QIX000127 QIX000128 1/phase 945.00

QI3RDP QIX000129 QIX000130 QIX000131 1/phase 945.00

QI3SDP QIX000132 QIX000133 QIX000134 1/phase 1,512.00

QI3(K,L)DP QIX000135 1 295.00À

QI3(Y,M)DP QIX000136 1 475.00À

QI3(Z,N)DP QIX000137 1 945.00À

QI3(P,Q,R)DP QIX000138 1 1800.00À

QI3SDP QIX000139 1 2700.00

QI3KDP QIX000140 1 140.00

QI3LDP QIX000141 1 140.00

QI3YDP QIX000142 1 140.00

QI3MDP QIX000143 1 140.00

QI3ZDP QIX000144 1 140.00

QI3NDP QIX000145 1 140.00

QI3PDP QIX000146 1 140.00

QI3QDP QIX000147 1 140.00

QI3RDP QIX000148 1 140.00

QI3SDP QIX000149 1 140.00

QI3KDP QIX000154 1/phase 40.00Current Transformer

ALL Others QIX000155 1/phase 120.00

QI3(K,L,Y)DP QIX000156 2/phase 35.00

QI3(M,Z,N)DP QIX000157 2/phase 35.00

QI3(P,Q,R,S)DP QIX000158 2/phase 35.00

All, 5-point QIX000160 1 10.00

F2, ALL, 500mA QIX000161 1 3.00Fuses on Power Supply Board (Bussman

F1, ALL, 2A QIX000162 1 3.00

ALL QIX000163 1 5.00

ALL QIX000164 1 6.00

Phase 1Phase 1 Phase 2Phase 2 Phase 3Phase 3

Req.Req.

Qty.Qty.

ListList

Price,Price,

GO-11GGO-11G

12 Prices and data subject to change without notice.

Page 17

Page 18

These instructions do not cover all details or variations in equipment nor do they provide for every possible

contingency that may be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise that are not covered sufficiently for the purchaser’s

purposes, the matter should be referred to the GE Company.

DEH-40417 0901 © 2001 General Electric Company

g

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

Loading...

Loading...