GE DDHF Multistage Centrifugal Pump Brochure

GE Oil & Gas

DDHF pump for

CO

Proven experience &

value-adding technologies

GE Oil & Gas has extensive experience in liquefied gas

pumping, and provides customers with all the technological

resources needed for the challenges of CO2 re-injection,

transportation and storage.

Our domain knowledge in turbomachinery enables a unique

centrifugal compressor plus pump solution for carbon

capture and sequestration (CCS) and enhanced oil recovery

(EOR) applications. It gives customers the opportunity to

realize significant power savings as well as highly flexible

performance upgrades.

With a high molecular weight, CO2 reaches the liquid phase

at high pressure (> 90 bar) and water-cooled temperature

without the need for any additional power installation.

applications

2

The optimized solution for CCS and EOR

re-injection, transportation and storage

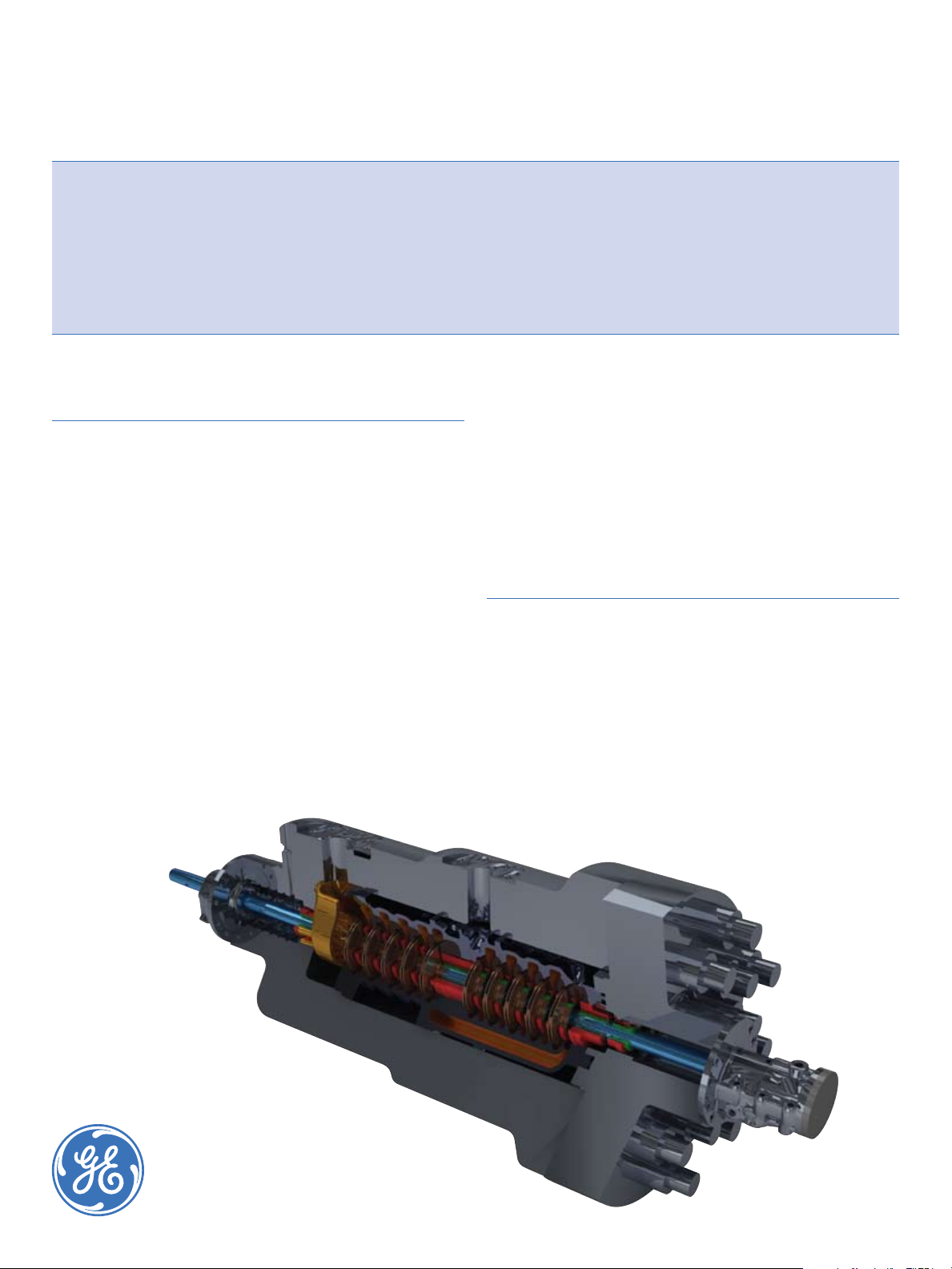

The enhanced DDHF is a multistage centrifugal pump with

double casing and barrel-type, back-to-back arrangement.

It is based on our proven hydraulic design, but specially

re-engineered for CO2 pumping and EOR. It delivers 540 bar

discharge pressure – the highest ever provided by a

centrifugal pump.

Key features

API 10,000 barrel design•

Onshore and offshore application (ABS certified for FPSO)•

Mechanical seals dynamically qualified up to 550 bar•

Dry gas seals available •

Can be fully integrated with our high-pressure centrifugal •

compressors

Detailed thermodynamic and rotor dynamic assessment •

as a result of proprietary centrifugal compressor technology

Standard performance tested at API 610, latest edition•

Advanced CO•

full-load test to simulate operating conditions

2

Mechanical design

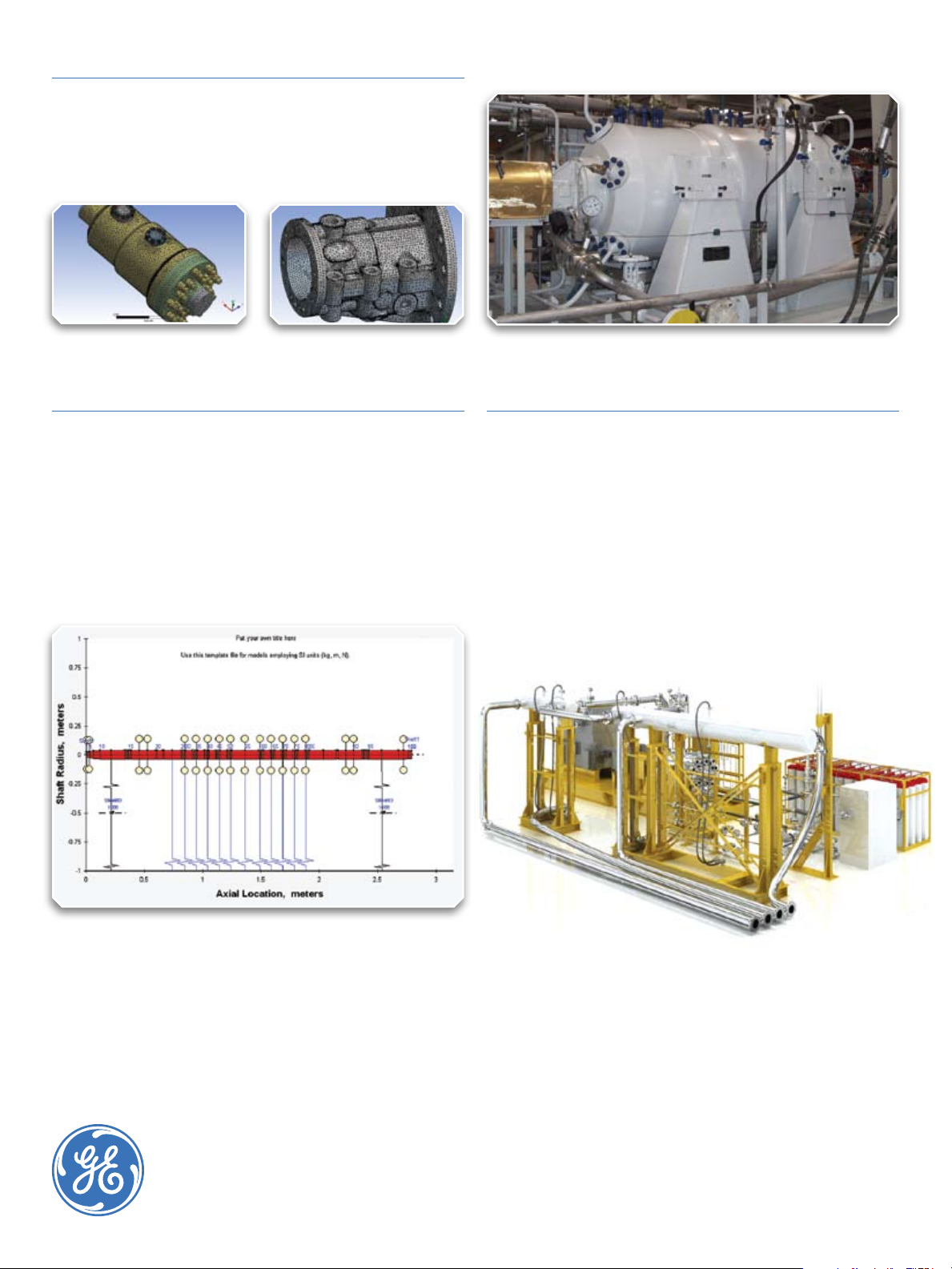

The DDHF pump design was developed using finite element

analysis (FEA) to avoid resonance in structural and foundation

natural frequencies. Additional FEA with ANSYS codes has

ensured sizing accuracy (to ASME VIII Div. II Appendix 4) of

the pump’s outer barrel as the main pressure retaining part.

Stress analysis Support resonance analysis

Rotordynamics

Testing performance &

discovering opportunities

Dry and wet analyses have been carried out with acceptance

criteria as stated in API 617. Drawing on the strengths of our

centrifugal compressor design, the wet analysis was performed

with annular seal stiffness and damping coefficients based

on process fluid properties slightly variable versus pressure

and temperature. Rotordynamic and thermodynamic tools

has been implemented, and hydraulic forces have been

calculated by CFD code, taking into account the cross-coupled

aerodynamic coefficients for impeller-stator interaction.

Like every product GE designs for the oil and gas industry,

our pumps undergo stringent testing at every stage of the

design and manufacturing process. With the most advanced

techniques and seasoned professionals, our goal is not

simply to confirm specifications (API610) and deliver reliable

machines, but to find new opportunities to improve

performance. The GE Oil & Gas Center of Excellence for

pumps in Bari, Italy, includes advanced testing facilities

for liquefied CO2 pumps, including a CO2-filled closed loop

for performance assessment under the specified in-field

conditions.

Rotordynamics

GE imagination at work

CO2 test bed

ge.com/oilandgas

© 2010 General Electric Company. All rights reserved.

DDHF_Pump_FS_101810

Loading...

Loading...