Page 1

, WA I G -RiSKOFFIRE

= To reduce the risk of severe injuryor death, follow' all installation instructions.

Clothes dryer installation must be performed by a qualified installer.

install the clothes dryer according to these instructions and in accordance with local codes. In the absence of local

codes, installation must comply with National Fuel Gas Code, ANSIZ223.1/NFPA 54 or the Canadian Natural Gas

and Propane installation Code, CSA B149.1.

California Safe Drinking Water and Toxic Enforcement Act

This act requiresthe governor of California to publish a list of substances known tothe state to cause cancer, birthdefects or

other reproductive harm and requiresbusinesses to warn customers of potential exposure to such substances. Gas appliances

can cause minorexposure tofour of these substances, namely benzene, carbon monoxide, formaldehyde and soot, caused

primarily by the incomplete combustion of natural gas or LP fuels. Properly adjusted dryers will minimize incomplete combustion.

Exposure to these substances can be minimized further by properlyventing the dryer to the outdoors.

This dryer must be exhausted to the outdoors.

Use only 4" rigid metal ducting for exhausting the clothes dryer to the outdoors.

• DO NOT install a clothes dryer with flexible plastic ducting materials, if flexible metal (semi-rigid or foil-type) duct is

installed, it must be UL listed and installed in accordance with these instructionsand local codes. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will obstruct dryer airflow and

increase the risk of fire.

• Do not install or store this appliance in any location where itcould be exposed to water and or weather.

= Save these instructions. (installers: Be sure to leave these instructionswith the customer).

BEFORE YOU BEGIN- Readthe_einstructions

completely and carefully

• important - Save these instructionsfor local inspector's use.

• important- Observe all governing codes and ordinances.

• Note to Installer

- Be sure to leave these instructions with the customer.

• Note to Customer

- Keep these instructions for local inspector's use.

• Before the old dryer is removed from service or discarded, remove

the dryer door.

• inspect the dryer exhaust outlet and straighten the outlet walls if

they are bent.

• Service information and the wiring diagram are located in the

control console.

• Do not allow children on or in the appliance. Close supervision is

necessary when the appliance is used near children.

• install the dryer where the temperature is above 50°F for satisfactory

operation of the dryer control system.

,_ WARNING: For your safety the information in this manual

must be followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

=WHATTO DO IFYOU SMELL GAS

• Do not try to light any appliance.

, Do not touch

in your building.

, Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire dep't.

- Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

500A436P004

Pub.# 31-16223

any electrical switch; do not use any phone

Tools and Materials

you will need

[] Slip joint pliers, 8" pipe wrench,

10" adjustable wrenches (x2),

[] Screwdrivers (slotted or phillips head)

[] Chains (x2)

[] 2" x 4" studs

[] Wall hoods

[] 4" diameter rigid metal duct, duct clamps,

elbows and exhaust hood.

[] Flexible gas connector

[] Pipe compound

[] Soap solution for leak detection

[] Basic safety protection such as safety

goggles, gloves and arm protection are

recommended.

The ANSI Z21.5.1 standard requires the follow-

ing safety cautions be posted and displayed in a

3rominent location:

a. Instructions to be followed in the event

the user smells gas. The information

to be posted shall be obtained by

consulting with the local gas supplier.

b.This note:

FOR YOUR SAFETY

DONOT STOREOR USEGASOLINEOR

OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

In the state of Massachusetts, installa=

tion must be performed by a qualified or

licensed contractor, plumber, or gas

fitter qualified or licensed by the state.

NOTE: Service of this dryer must be

performed by a qualified service agency.

Page 2

iNSTALLATiON

Preparing the installation Site and Unpacking the Dryer

1.Prepare the area and exhaust for installation of the new' dryer.

2.Check to be sure that the existing external exhaust is clean and that it meets attached installation specifications.

&Using the four shipping carton corner posts as padding (two on each side), carefully lay the dryer on its left side

and remove foam shipping pad.

4. Return the dryer to an upright position.

5.Move the dryer to the desired location.

CAUTION: FOR PERSONAL SAFETY, STACKED

iTS MUST BE FASTENED SECURELY TO WALL. r

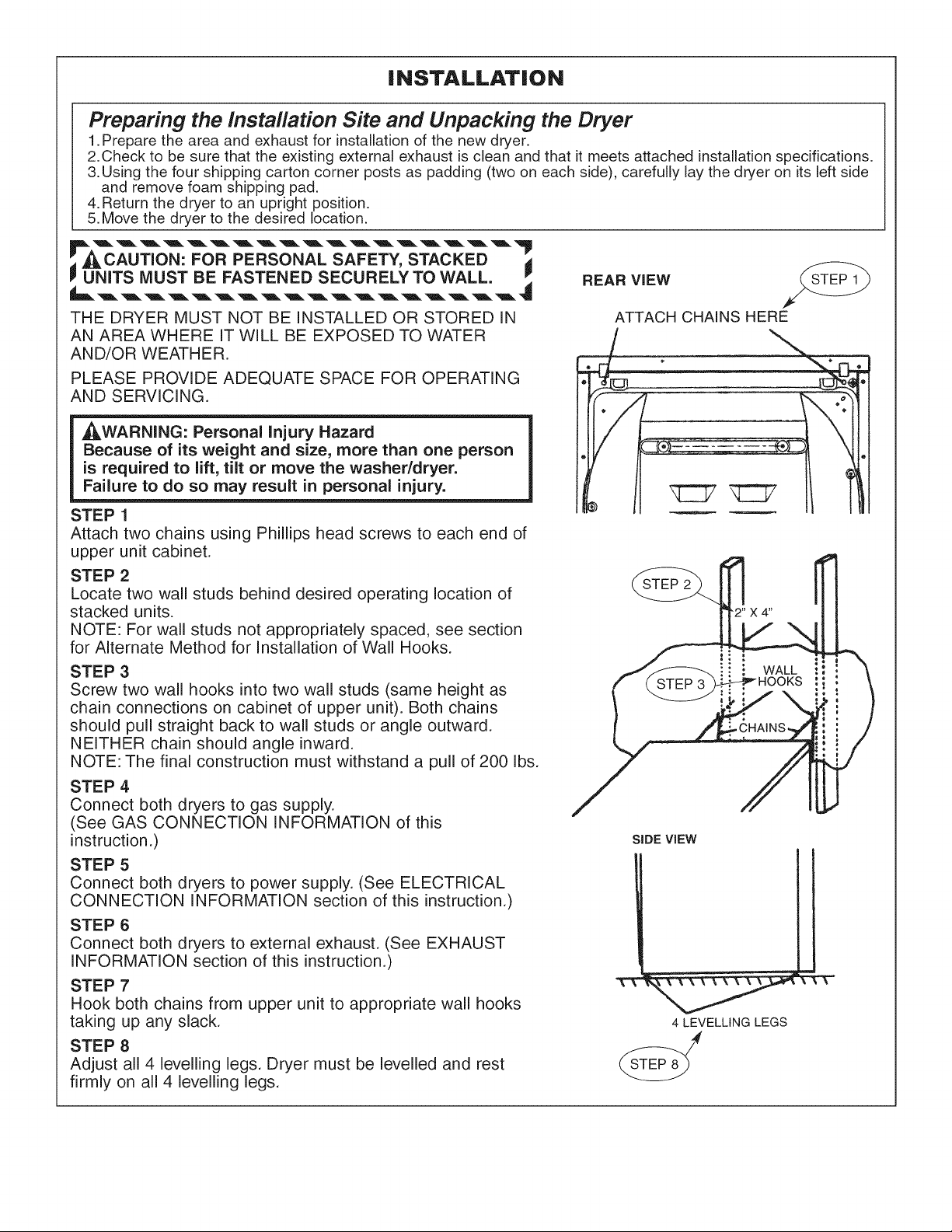

REAR ViEW

THE DRYER MUST NOT BE iNSTALLED OR STORED iN

AN AREA WHERE iT WILL BE EXPOSED TO VVATER

AN D/O R WEATH ER.

PLEASE PROVIDE ADEQUATE SPACE FOR OPERATING

AND SERVICING.

_WARNING: Personal injury Hazard

Because of its weight and size, more than one person

is required to lift, tilt or move the washer/dryer.

Failure to do so may result in personal injury.

STEP 1

Attach two chains using Phillips head screws to each end of

upper unit cabinet.

STEP 2

Locate two wall studs behind desired operating location of

stacked units.

NOTE: For wall studs not appropriately spaced, see section

for Alternate Method for Installation of Wall Hooks.

STEP 3

Screw two wall hooks into two wall studs (same height as

chain connections on cabinet of upper unit). Both chains

should pull straight back to wall studs or angle outward.

NEITHER chain should angle inward.

NOTE: The final construction must withstand a pull of 200 Ibs.

STEP 4

Connect both dryers to gas supply.

(See GAS CONNECTION INFORMATION of this

instruction.)

STEP 5

Connect both dryers to power supply. (See ELECTRICAL

CONNECTION INFORMATION section of this instruction.)

STEP 6

Connect both dryers to external exhaust. (See EXHAUST

INFORMATION section of this instruction.)

STEP 7

Hook both chains from upper unit to appropriate wall hooks

taking up any slack.

STEP 8

Adjust all 4 levelling legs. Dryer must be levelled and rest

firmly on all 4 levelling legs.

ATTACH CHAINS HERE

STEP 2

SIDE VIEW

4 LEVELLING LEGS

Page 3

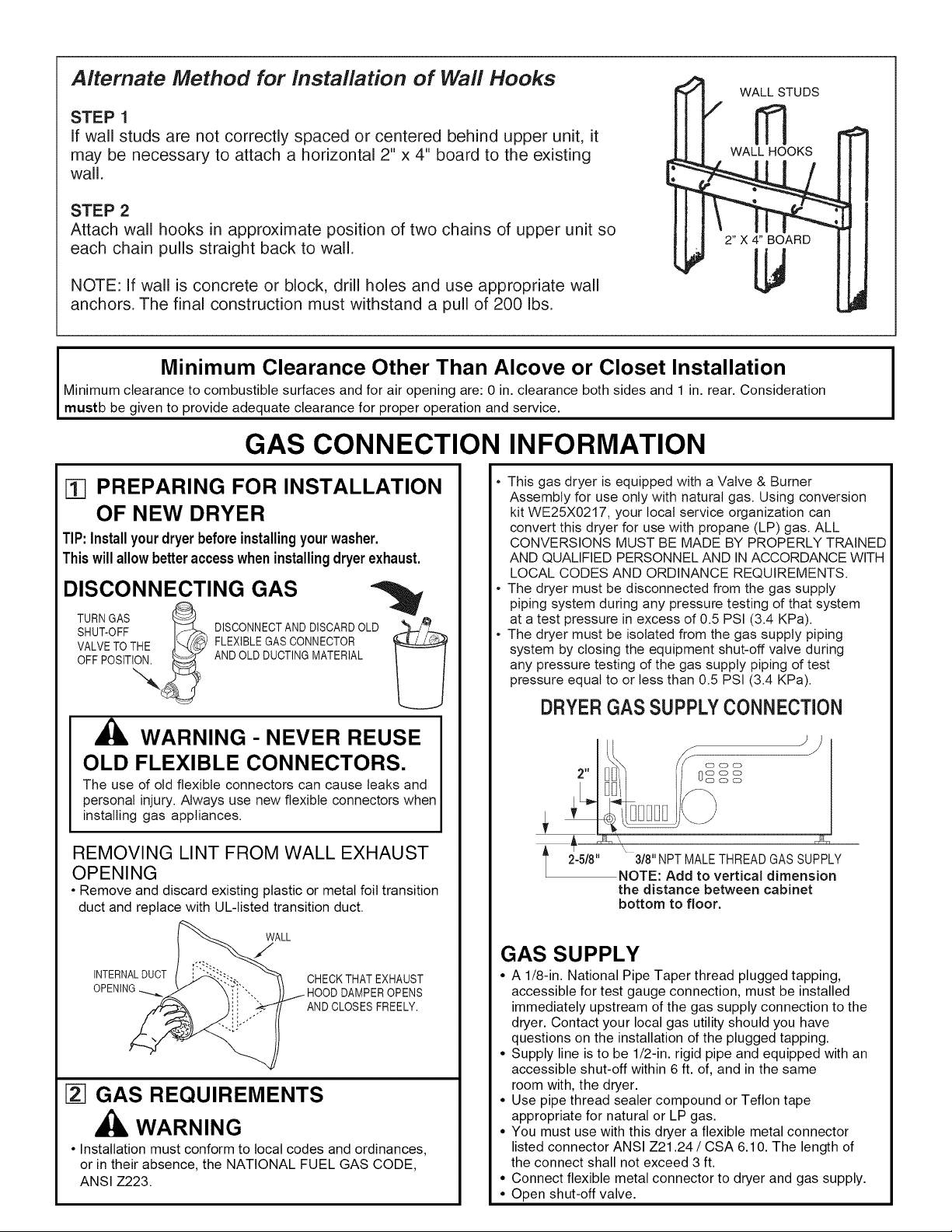

Alternate Method for Installation of Wall Hooks

STEP 1

If wall studs are not correctly spaced or centered behind upper unit, it

may be necessary to attach a horizontal 2" x 4" board to the existing

wall.

STEP 2

Attach wall hooks in approximate position of two chains of upper unit so

each chain pulls straight back to wall.

NOTE: If wall is concrete or block, drill holes and use appropriate wall

anchors. The final construction must withstand a pull of 200 Ibs.

E

WAr_TUDS

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1 in. rear. Consideration

mustb be given to provide adequate clearance for proper operation and service.

GAS CONNECTION INFORMATION

[i] PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Installyourdryerbeforeinstallingyourwasher.

Thiswill allowbetteraccesswheninstallingdryerexhaust.

DISCONNECTING GAS

SHUT-OFF

VALVETOTHE

OFFPOSITION.

TURNGAS

",.,.

DISCONNECTANDDISCARDOLD _

FLEXIBLEGASCONNECTOR

ANDOLDDUCTINGMATERIAL

U

• This gas dryer is equipped with a Valve & Burner

Assembly for use only with natural gas. Using conversion

kit WE25X0217, your local service organization can

convert this dryer for use with propane (LP) gas. ALL

CONVERSIONS MUST BE MADE BY PROPERLY TRAINED

AND QUALIFIED PERSONNEL AND IN ACCORDANCE WITH

LOCAL CODES AND ORDINANCE REQUIREMENTS.

• The dryer must be disconnected from the gas supply

piping system during any pressure testing of that system

at a test pressure in excess of 0.5 PSI (3.4 KPa).

• The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI (3.4 KPa).

DRYERGASSUPPLYCONNECTION

I

J

_ WARNING - NEVER REUSE

OLD FLEXIBLE CONNECTORS.

The use of old flexible connectors can cause leaks and

personal injury. Always use new flexible connectors when

installing gas appliances.

REMOVING LINT FROM WALL EXHAUST

OPENING

• Remove and discard existing plastic or metal foil transition

duct and replace with UL-listed transition duct.

WALL

INTERNALDUCT

CHECKTHATEXHAUST

HOODDAMPEROPENS

ANDCLOSESFREELY.

[_ GAS REQUIREMENTS

WARNING

• Installation must conform to local codes and ordinances,

or in their absence, the NATIONAL FUEL GAS CODE,

ANSI Z223.

,)

/

211 _ o o o

_ _,,,

2-5/8" 3/8"NPTMALETHREADGASSUPPLY

t

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

GAS SUPPLY

• A 1/8-in. National Pipe Taper thread plugged tapping,

accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to the

dryer. Contact your local gas utility should you have

questions on the installation of the plugged tapping.

• Supply line is to be 1/2-in. rigid pipe and equipped with an

accessible shut-off within 6 ft. of, and inthe same

room with, the dryer.

• Use pipe thread sealer compound or Teflon tape

appropriate for natural or LP gas.

• You must use with this dryer a flexible metal connector

listed connector ANSI Z21.24 / CSA 6.10. The length of

the connect shall not exceed 3 ft.

• Connect flexible metal connector to dryer and gas supply.

• Open shut-off valve.

Page 4

GAS CONNECTION

m

RECONNECTINGGAS

Listed connector ANSI Z21.24 / CSA 6.10

118" NPT PIPE

NEWMETAL PLUG FOR

FLEXIBLEGAS INLET PRESSURE

LINECONNECTOR

ADAPTER

318" NPT

ELBOW

ITEMSNOT SUPPLIED AT LEAST 1/2"

Note:The connector and fittings ore designed for useonly

on the original installation and are not to be reusedfor

another appliance or at another location. Keepflare end of

adaptor free of grease,oil and thread sealant.

Caution: Useadapters as shown. Connector nuts must not

be connected directly to pipe threads.

GAS

SHUT-OFF

PIPE SIZE

INFORMATION (continued)

APPLYPiPECOMPOUND

TOALL MALETHREADS.

/

Tighten the flexible

gas line using two

adjustable wrenches.

APPLYPIPECOMPOUND

TOTHEADAPTERAND

DRYERGAS INLET.

Tighten all connections using two adjustable wrenches.

Do not overtorque gas connections!

[] LEAKTEST

A_, WARNING- NEVERUSEANOPEN

FLAMETOTEST FORGAS LEAKS.

OPEN

GASVALVE.

Check olt connections for leaks with soapg solution or equivalent.

Applg soap solution. Leak test solution must not contain ammo-

nia which could cause damage to the brass fittings. If leaks are

found, dose valve, retighten the joint, and repeat the soap test.

Page 5

EXHAUST INFORMATION

l I Illlll Illll II_ll_

WARNING - TO REDUCE THE RiSK OF

FiRE OR PERSONAL iNJURY: r

- This clothes dryer must be exhausted to the outdoors.

- Use only 4" rigid metal ducting for the home exhaust

duct.

- Use only 4" rigid metal or UL-listed flexible metal

(semi-rigid or foil-type) duct to connect the dryer to

accordance with these instructions and local codes.

I the home exhaust duct. It must be installed in d

- Do not terminate exhaust in a chimney, a wall, a ceil-

floor, or in any other concealed space of a building.

I ing, gas vent, crawl space, attic, under an enclosed

The accumulated lint could create a fire hazard.

with a kitchen exhaust system. A combination of

- Never terminate the exhaust into a common duct

grease and lint creates a potential fire hazard.

- o not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

- ever install a screen in or over the exhaust duct.

This will cause lint to accumulate, creating a poten-

tial fire hazard.

- Do not assemble ductwork with any fasteners that

ate lint, creating a potential fire hazard.

I extend into the duct. These fasteners can accumul-

- Do not obstruct incoming or exhausted air.

- rovide an access for inspection and cleaning of the

exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

the dryer to the house vent using a flexible metal (foil-

- n special installations, it may be necessary to connect

type) duct. A UL-listed flexible metal (foil4ype) duct

REAR EXHAUST LOCATION

The dryers come ready for rear exhausting. Units

have separate exhausts.

J i_i_/_ _ dNOenTE:siAodlt;vdiedt_Cale

' !! II iJli'i' I- ---..........................................._..I _1 between cabinetbottomto

;13/4 " _ ........................... '0 .... rface.

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

,, Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

,, Termination should present minimal resistance

to the exhaust air flow and should require little

or no maintenance to prevent clogging.

,, Wall caps must be installed at least 12" above

ground level or any other obstruction with the

opening pointed down.

SEPARATION OF TURNS

Separate all turns by at least 3 ft. of straight duct,

including distance between last turn and

dampered wall cap. If two turns must be closer

than 3 ft., deduct 10 ft. from the maximum

lengths shown in the table for each occurrence.

TURNS OTHER THAN 90 °

flexible metal (semi-rigid) ducting cannot be used AND

I may be used ONLY in installations where rigid metal or d

where a 4" diameter can be maintained throughout the

entire length of the transition duct. In Canada and in _

, the United States, only the,!lexible metal (foil-type)

| ducts that comply with the Outline for Clothes Dryer

,,_'_,_'_mm,_l_,_m'_'_m,_,__Transition Duct Subject 2158A" shall be used. ,_

EXHAUST LENGTH

The MAXIMUM ALLOWABLE duct length and number of

bends of the exhaust system depends upon the type of duct,

number of turns, the type of exhaust hood (wall cap), and all

conditions note below. The maximum allowable length for

rigid metal duct is shown inthe

PREFERRED

table below. More than two 90 °

turns is not recommended. The

total length of flexible metal duct

shall not exceed 8 ft.(2.4 m). In

Canada and in the United States,

the required exhaust duct diameter

is 4in (102mm). NUMBER

OF 90°

TURNS

RIGID METAL DUCT 0

4 in. 2 1/in.

MAXIMUM LENGTH

EXHAUST

- HOOD TYPE -

A B

45 ft. 30 ft.

35 ft. 2O ft.

4" DIAMETER 2

25 ft. 10 ft.

,, One turn of 45 ° or less may be ignored.

,, Two 45 ° turns should be treated as one 90 °.

,, Each turn over 45 ° should be treated as one 90 °.

I

SEALING OF JOINTS

All joints should be tight to avoid leaks. The male

end of each section of duct must point away

from the dryer.

Do not assemble the duct work with fasteners

that extend into the duct. They will serve as a

collection point for lint.

Duct joints can be made air and moisture-tight

by wrapping the overlapped joints with duct tape.

INSULATION

Duct work which runs through an unheated area

or is near an air conditioning duct should be

insulated to reduce condensation and lint build up

and be sloped down toward outdoors.

NOTE: Never install screen inside exhaust duct.

Page 6

EXHAUST iNFORMATiON {continued)

STEPS TO CHANGE DRYER TO LEFT SIDE OR BOTTOM EXHAUST DIRECTLY ON CABINET

NOTE: This dryer can not be exhausted to the right side.

WARNING: Protect your hands and arms from sharp

edges when working inside dryer cabinet.

= Never use flexible duct inside dryer.

,, Detach and remove the desired knockout.

,, Remove the screw inside the dryer exhaust duct end.

Keep the screw for step 5. Pull on the duct to remove

it.

,, Cut the duct as shown. Keep portion A.

,, Through the rear opening, locate the tab in the middle

of the appliance base. Lift the tab to about 45° using a

flat screwdriver.

,, Reconnect and secure the cut portion (A) of the duct

to the blower housing. Make sure that the fixing hole is

aligned with the tab in the base. Use the screw of item

2 to secure the duct in place through the tab on the

appliance base.

,, Use standard metal elbows and duct to complete

exhaust system. Insert standard elbow and ducts

through rear and side or bottom openings.

,, Cover the opening at the back with the plate (Kit

WE1 M454) available from your Local Service Provider.

HOUSING BASE TAB

LOCATION

9 " CUT (UNDER EXHAUST

PORTION

11 1/4 " BACK OF

_-- _ SIDE PANEL

Only metal duct

may be used

inside the dryer

cabinet

i

WARNING: NEVER LEAVE THE BACK OPENING

WITHOUT THE PLATE.

PARTS AVAILABLE FROM LOCAL SERVICE

ORGANiZATiON

,, Rigid Metal Duct Components

WX8X63 4" X 1' Duct

WX8X64 4" x 2' Duct

,, Flexible Metal Duct Components

WX08X10077 4" dia. Flexible Metal (Semi-Rigid)

UL-Listed Transition Duct (includes 2 elbows)

WX8X51 4" Elbow

WX8X59 Aluminum Hood

MiNiMUM CLEARANCES

MINIMUM CLEARANCES FROM COMBUSTIBLE SURFACES AND NON-COMBUSTIBLE SURFACES

FOR AIR INTAKE PURPOSES.

Minimum clearances are - 0" both sides

- 1" at rear

- 88" vertical space from floor to ceiling

Page 7

ELECTRICAL CONNECTION iNFORMATiON

_CAUTION, FOR PERSONAL SAFETY:

DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WiTH THiS APPLIANCE.

DO NOT, UNDER ANY CIRCUMSTANCES,

CUT OR REMOVE THE THIRD GROUNDING

PRONG FROM THE POWER CORD.

Dryer must be electrically grounded in accordance

with local codes and ordinances, or in the absence

of local codes, in accordance with the NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70-1990.

The electrical diagram is located inside control

panel.

Electrical requirements

,, This appliance must be supplied with 120V, 60

Hz, and connected to an individual, properly

grounded branch circuit, protected by a 15 or 20

amp circuit breaker or time-delay fuse.

if the electric supply

provided does not meet the

above specifications, if is

recommended that a

licensed electrician install an

approved outlet.

External ground (if

REAR VIEW

iNSURE PROPER

GROUND EXISTS

BEFORE USE

required)

An external ground wire, (not

provided), which meets local

codes, may be added by

attaching to the green

ground screw on the rear of

the dryer, and to grounded

metal cold water pipe or

other established ground.

[ _ "ILL "IL "111_ "IL_ I "!IL. "_IL "_IIL "_EL I "qlL I "_lllb_ "qll_ "_

,_CAUTION: Label all wires prior to ,_

disconnection when servicing controls. Wiring F

error can cause improper and dangerous

sOperation. Verify proper operation after |

ervicing. "_

"_llL_ "_mL "_E_ "!IL "IL "_Jm=_lm_ "qlL "IL "_lb= "IL "_lh= "_IL. "IL "1t= "_

ATTACH GROUND WERE TO

EACH DRYER (OBTAIN LOCAL-

LY)

I

CARE AND CLEANING

USER MAINTENANCE iNSTRUCTiONS

The Drum. The drum is rust-resistant and requires

no special care.

The Exterior. Wipe off any spills or washing

compounds. Wipe or dust with damp cloth. Try not

to strike the surface with sharp objects.

The Lint Filter. Wipe lint filter before every use.

Periodically lint filter should be removed and

suction hose from vacuum cleaner should be

inserted into the opening.

Dryer Exhaust. Inspect and clean the dryer

exhaust ducting at least once a year.

Do not obstruct the flow of combustion and

ventilating air. The air intake is located on rear of

dryer.

Keep dryer area clear and free from combustible

materials, gasoline and other flammable vapors

and liquids.

Note to Installer:

After Installation check the following:

[] Exhaust Duct - must meet specs as mentioned

in "Exhaust information" section of this

installation instructions.

[] Grounding - Dryer must be properly grounded to

conform to local codes and ordinance

requirements.

To store dryer. For short period of time, disconnect

power supply and clean lint filter.

Do not install or store dryer where it will be

exposed to the weather.

ACAUTIONS

,, Dryer control panel and finishes may be

damaged by some laundry pre-treatment soil

and stain remover products if such products

are sprayed on or have direct contact with the |

dryer.

Apply these pre-treatment products away from the

dryer. The fabric may then be washed and dried

normally. Damage to your dryer caused by pre-

treatment products is not covered by your warranty.

[] Operation - Turn dryer ON and check for heat.

[] Hand Customer the Use and Care Book - Give

instructions on operating the dryer - answer any

questions.

[] Give these installation instructions to the

customer.

Loading...

Loading...