Page 1

A

WARNING - POTENTIAL FIRE AND SHOCK HAZARD

• Use only rigid metal or flexible metal 4_'diameter ductwork inside the dryer cabinet or for exhausting to

the outside Never use plastic or other combustible ductwork Never use foil or other thin ductwork that

can be easily punctured with a screwdriver or nail

• This appliance must be properly grounded and installed as described in these instructions

Tools you will need

° The dryers must be exhausted to the outside

° Use only metal duct inside dryer cabinet or for exhausting

to outside

WARNING: For your safety the information in

this manual must be followed to minimize the risk

of fire or explosion or to prevent property

damage, personal injury or loss of life.

• Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

, Clear the room, building or area of all

occupants.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions

• if you cannot reach your gas supplier call the

fire department

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

The American Gas Association requires the following

safety cautions be posted and displayed in a

a. Instructions to be followed in the event the user

Slip joint pliers

Phillips and flat head screwdrivers

prominent location:

smells gas. The information to be posted shall be

obtained by consulting with the local gas supplier.

b. This note:

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND LIQUIDS

tN THE VICINITY OF THIS

OR ANY OTHER APPLIANCE

500A 187P009

aev _ Pub, NO. 31-1724

Page 2

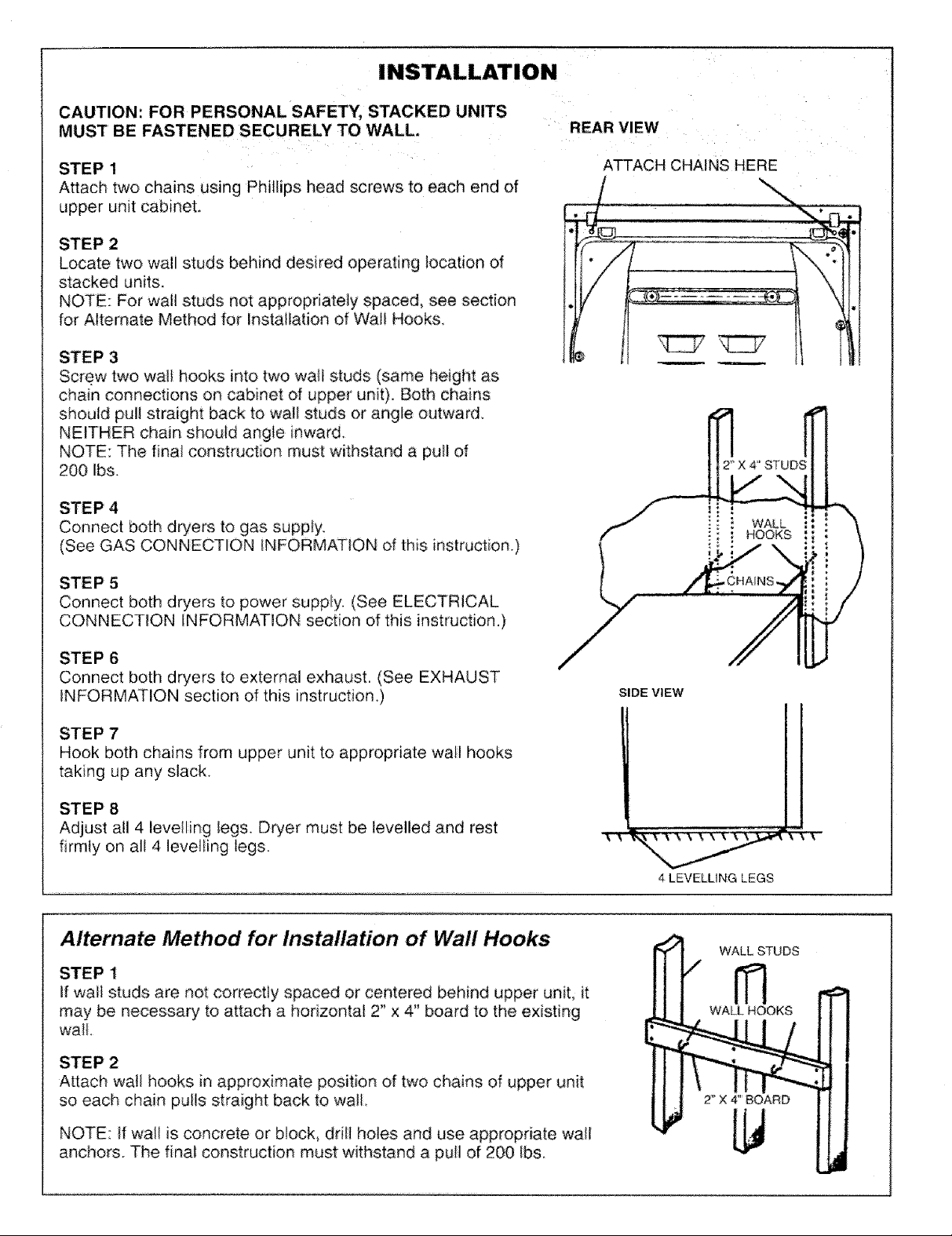

CAUTION: FOR PERSONAL SAFETY, STACKED UNITS

MUST BE FASTENED SECURELY TO WALL.

REAR VIEW

STEP 1

Attach two chains using Phillips head screws to each end of

upper unit cabinet.

STEP 2

Locate two wall studs behind desired operating _ocation of

stacked units.

NOTE: For wall studs not appropriately spaced, see section

for Alternate Method for installation of Wall Hooks.

STEP 3

Screw two wall hooks into two wall studs (same height as

chain connections on cabinet of upper unit). Both chains

should pul! straight back to wall studs or angle outward.

NEITHER chain should angle inward.

NOTE: The final construction must withstand a pull of

200 Ibs.

STEP4

Connect both dryers to gas supply.

(See GAS CONNECTION iNFOR:MATiON of this instruction.)

STEP 5

Connect both dryers to power supply. (See ELECTRICAL

CONNECTION INFORMATION section of this instruction,)

ATTACH CHAINS HERE

o

! '

STEP 6

Connect both dryers to external exhaust. (See EXHAUST

iNFORMATION section of this instruction.)

STEP 7

Hook both chains from upper unit to appropriate walt hooks

taking up any slack.

STEP 8

Adjust all 4 levelling legs. Dryer must be levelled and rest

firmly on alt 4 levelling legs.

/

Alternate Method for Installation of Wall Hooks

STEP 1

if wall studs are not correctly spaced or centered behind upper unit, it

may be necessary, to attach a horizontal 2" x 4" board to the existing

wall.

STEP 2

Attach wall hooks in approximate position of two chains of upper unit

so each chain pulls straight back to wall.

SIDE VIEW

4 LEVELLING LEGS

WALL STUDS

ffl

WALL HOOKS

NOTE: if wall is concrete or b!ock_ ddll holes and use appropriate wall

anchors. The final construction must withstand a puil of 200 Ibs,

Page 3

ELECTRICAL CONNECTION INFORMATION

CAUTIONs FOR PERSONAL SAFETY:

DO NOT USE AN EXTENSION CORD OR AN ADAPTER

PLUG WiTH THIS APPLIANCE,

DO NOT, UNDER ANY C_RCUMSTANCES, CUT OR

REMOVE THE THIRD GROUNDING PRONG FROM THE

POWER CORD,

Dryer must be e_ectficaHy grounded in accordance with

local codes and ordinances, or in the absence of local

codes, in accordance with the NATIONAL ELECTRICAL

CODE, ANSI/NFPA NO. 70-1990

The electrical diagram is located inside control panel

Electrical requirements

. This appliance must be supplied with !20V, 60 Hz, and

connected to an individual, properly grounded branch cir-

cuit, protected by a 15 or 20 amp circuit breaker or time-

delay fuse.

GAS CONNECTION INFORMATION

If the electric supply provided

does not meet the above specifi-

cations, it is recommended that a

licensed electrician install an

approved outlet

INSURE PROPER

GROUND EXISTS

External ground (if required)

An external ground wire, (not prom

vided), which meets local codes, REAR VIEW

may be added by attaching to the ];I "\_. _ LI

green ground screw on the rear ]// "--._.._t__}

of the dryer, and to grounded

metal cold water pipe or other

established ground.

AT3['ACH GROUND W_E TO

_AON ORY£R (OBTAIN LOCALLY}

BEFORE USE

Installation must conform with local codes and ordi-

nances, or in their absence the NATIONAL FUEL GAS

CODE, ANSi 2223 1-1988

GAS BURNER ORIFICE

This gas dryer is equipped with a Valve & Burner

Assembly for use on{y with natural gas. Using a separate

conversion kit your local Service organization can convert

this dryer for use with gases listed on the rating piate.

ALL CONVERSIONS MUST BE MADE BY PROPERLY

TRAINED AND QUALIFIED PERSONNEL, AND iN

ACCORDANCE WITH LOCAL CODE AND ORDINANCE

REQUIREMENTS.

GAS SUPPLY

• Supply line is to be 1/2" rigid pipe, (3/4" copper tubing

may be used if the dryer is operated on Liquefied

Petroleum gas), and equipped with an accessible shut-

off within 6 feet of, and in the same room with the dryer

increase pipe size for runs longer than 20 feet,

• Protection of Dryer During Pressure Test:

- When test pressure is in excess of 1/2 PSiG

(3,45kPa), disconnect dryer and its individual shutoff

valve from gas supply line prior to test

- When test pressure is equal to or less than 1/2 PSIG

(3,45kPa), close the dryer shutoff valve prior to test

• A 1/8_'National Pipe Taper thread plugged tapping,

accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to

the dryer, Contact your tocal gas utility should you have

questions on the installation of the plugged tapping.

- Pipe dope must be resistant to the action of L P. gases

and applied sparingly to all male threads

• If tocal codes permit, it is recommended the dryer be

connected to the gas supply with approved semi-rigid

metal tubing or listed connectors_

LEAK TEST

Check all connections for leaks with soapy solution or

equivalent. Leak test solutions must not contain ammonia

which could cause damage to brass fittings or pipe, CAU_

TION: NEVER USE AN OPEN FLAME TO TEST FOR

GAS LEAKS

GAS SUPPLY LOCATION

Note: Units have separate gas suppiies

2 5/8_J

©

t

1

\

_/a"MALE THREAD

GAS SUPPLY

Page 4

EXHAUST INFORMATION

CAUTION, FOR PERSONAL SAFETY:

- The dryers must be exhausted to the outside.

- Do not use non metallic flexible ducL

- Never use flexible duct inside the dryer.

- Do not terminate exhaust in a chimney, range hood, gas

vent, floor or attic. The combination of lint and grease

could create a fire hazard or damages.

- Provide an access for inspection and cleaning the

exhaust system at least once a year, especially at the

turns.

REAR EXHAUST LOCATION

The dryers come ready for rear exhausting. Units have

separate exhausts.

27"

r_

tt-'_'---"-_ _ NOTE:

Y_,_ J J SION THE DIS-

wJ -,-^D L I I TANCETHE

I _D . I I DRYER IS OFF

[ ADD TO VERT|_

I CAL DIMEN-

.........

///

I///Iit//11/

298 mm

EXHAUST LENGTH

The MAXIMUM ALLOWABLE length of the exhaust sys-

tem depends upon the type of duct, number of turns, the

type of exhaust hood (wall cap),

and aII conditions noted below

The maximum allowable length

for both rigid and flexible metal

duct is shown in the table below.

More than two 90_'turns is not

recommended.

/\,\////////I//II/IIf//1LFLOOR

',-- EXAUST Duct

PREFERRED

4 in_ 2 '/in.

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

. Terminate in a manner to prevent back drafts or entry of

birds or other wildlife

• Termination should present minimal resistance to the

exhaust air flow and should require littie or no mainte-

nance to prevent clogging

° Walt caps must be installed at least 12" above ground

level or any other obstruction with the opening pointed

down,

• If roof vents or Iouvered plenums are used, they must be

equivalent to a 4" dampered wall cap in regard to resis-

tance to air flow, prevention of back drafts and mainte-

nance required to prevent clogging,

SEPARATION OF TURNS

Separate all turns by at least 3 ft. of straight duct, includ-

ing distance between last turn and dampered wall cap_ if

two turns must be closer than 3 ft,, deduct 10 fL from the

maximum lengths shown in the table for each occurrence,

TURNS OTHER THAN 90 _

• One turn of 45'-' or less may be ignored

• Two 45" turns should be treated as one 90,

• Each turn over 45: should be treated as one 90'-'.

SEALING OF JOINTS

• All joints should be tight to avoid leaks The male end of

each section of duct must point away from the dryer.

° Do not assembte the duct work with fasteners that

extend into the duct. They willserve as a collection point

for lint.

o Duct joints can be made air and moisture-tight by wrap-

ping the overlapped joints with duct tape,

INSULATION

Duct work which runs through an unheated area or is

near an air conditioning duct should be insulated to

reduce condensation and lint build up and be sloped

down toward outdoors.

NOTE: Never install screen inside exhaust duct.

RIGID METAL DUCT

4_'DIAMETER

FLEXIBLEMETALDUCT

4" DIAMETER

NUMBER

OF 90°

TURNS

2

0

1

2

MAXIMUM LENGTH

EXHAUST

- HOOD TYPE -

A B

45 ft. 30 ft.

35 ft, 20 ft.

25 ft, 10 ft.

30 ft. 15 ft.

20 ft, 10 ft.

10 ft,

Page 5

EXHAUST INFORMATION (continued)

FOR LEFT SIDE EXHAUST

F__ 8 3/1, -=4

• Never use flexible duct inside dryer

I JL

• Straighten up the tab inside the exhaust duct at the back of

appliance (see figure on pg. 4), then remove the internaI duct

connected to the blower housing.

• Cut as shown to remove 8Wls' from the duct and reconnect it to

the blower housing. Make sure that the tab opening is at the

bottom of the duct.

• To secure the duct, insert the tab (located on the appliance

base) in the opening and bend it

• Detach and remove the knockout on the left side panel.

• Use a standard and adjustable metal elbow and a metal straight

duct to exhaust the dryer through the knockout.

• Use only 4" diameter rigid metallic duct 43/4_ i_

• Cover the opening at the back with the plate provided installed

on the back of the appliance L

BASE OF/ ZTA B

DRYER

'_ SAVE THIS

_\. '- _PORTION

CUT HERE

BLOWER

_[[ HOUSI NG EXHAUST

///-DUCT

BEND TAB IN

I I <--THIS

p I DIRECT ON

REAR OF

/DRYER

PARTS AVAILABLE FROM LOCAL SERVICE ORGANIZATION

• Rigid Metal Duct Components

WX8X63 4" x 1 Duct

WX8X64 4" x 2 Duct

WX8X51 4 Eibow

WX8X59 4" Aluminum hood

• Flexible Metal Duct Components

Kit WX8X66 7 Aluminum duct

4" aluminum hood and two clamps

WX8X65 7 Aluminum flexible duct

WX8X58 4 Clamps (2)

MINIMUM CLEARANCES

Minimum clearances are - 0 both sides

"\-- BLOWER HOUSING

_!INSTALL

THE _-'REW- THE PLATE

OPENING SUPPLIED

1 at rear

88" vertical space from floor to ceiling

Page 6

CARE AND CLEANING

USER MAINTENANCE INSTRUCTIONS

The Drum. The drum is rust resistant and requires no

special care

The Exterior Wipe off any spills or washing compounds

Wipe or dust with damp cloth Try not to strike the surface

with sharp objects

The Lint Filter Wipe _intfilter before every use

Periodically lint filter should be removed and suction hose

from vacuum cleaner should be inserted into the opening

Dryer Exhaust Inspect and c{ean the dryer exhaust

ducting at least once a year

Do not obstruct the flow of combustion and ventilating air

The air intake is located on rear of dryer

To store dryer For short period of time disconnect

power supply and clean lint fi_ter

Do not install or store dryer where it wil_be exposed to

the weather

CAUTIONS

• Dryer control panel and finishes may be damaged by

some laundry pre treatment soil and stain remover

products if such products are sprayed on or have direct

contact with the dryer

Apply these pre treatment products away from the dryer

The fabric may then be washed and dried normally

Damage to your dryer caused by pre treatment products

is not covered by your warranty

SERVICE

Parts and service are available from your General Electric Commercia_ Laundry Distributor

Pub. No. 31-1724

Loading...

Loading...