GE DDC4400SKMWH, DDC4400SLMWH, DDC4400SMMWH, DDC4400SNMWH, DDC4400T0WH Installation Guide

...Page 1

WA I G -RISKOFRRE

To reduce the risk of severe injury or death, follow' all installation instructions.

Clothes dryer installation must be performed by a qualified installer.

Install the clothes dryer according to these instructions and in accordance with local codes.

This dryer must be exhausted to the outdoors.

Use only 4" rigid metal ducting for exhausting the clothes dryer to the outdoors.

DO NOT install a clothes dryer with flexible plastic ducting materials. If flexible metal (semi-rigid or foil-type) duct is

installed, it must be UL listed and installed in accordance with these instructions and local codes. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will obstruct dryer airflow and

increase the risk of fire.

Do not install or store this appliance in any location where it could be exposed to water and or weather.

Save these instructions. (Installers: Be sure to leave these instructions with the customer).

BEFORE YOU BEGIN- Read these instructions completely and carefully

• Important - Save these instructions for local inspector's use.

• Important - Observe all governing codes and ordinances.

Note to Installer - Be sure to leave these instructions with the customer.

Note to Customer - Keep these instructions for local inspector's use.

Before the old dryer is removed from service or discarded, remove the dryer door.

Service information and the wiring diagram are located in the control console.

Do not allow children on or in the appliance. Close supervision is necessary

when the appliance is used near children.

Install the dryer where the temperature is above 50°F for satisfactory

operation of the dryer control system.

Preparing the Installation Site and Unpacking

the Dryer

1.Prepare the area and exhaust for installation of the new dryer.

2.Check to be sure that the existing external exhaust is clean and that it meets

attached installation specifications.

3.Using the four shipping carton corner posts as padding (two on each side),

carefully lay the dryer on its left side and remove foam shipping pad.

4.Return the dryer to an upright position.

5.Move the dryer to the desired location.

INSTALLATION

_ _llL ",IL _lL ",11_ "_IL _IL "lh= _,IL. "qllL "_L _qL "qlh,. "IL ",1_ _llL _ "IL "IlL _lL. _

j ,_4_CAUTION: FOR PERSONAL SAFETY, STACKED j

. UNITS MUST BE FASTENED SECURELY TO WALL. .,

F

Tools and Materials

you will need

[] Slip joint pliers

[] Screwdrivers (slotted or phillips

head)

[] Chains (x2)

[] 2"x 4" studs

[] Wall hoods

[] Two 3/4" UL recognized strain

relief if the power supply is

from a direct wire.

[] Two dryer power cord kit UL

listed, rated 120/240V, 30A with

3 or 4 prongs if the power

supply is from a wall receptacle.

[] 4" diameter rigid metal duct,

duct clamps, elbows and

exhaust hood.

[] Basic safety protection such as

safety goggles, gloves and arm

protection are recommended.

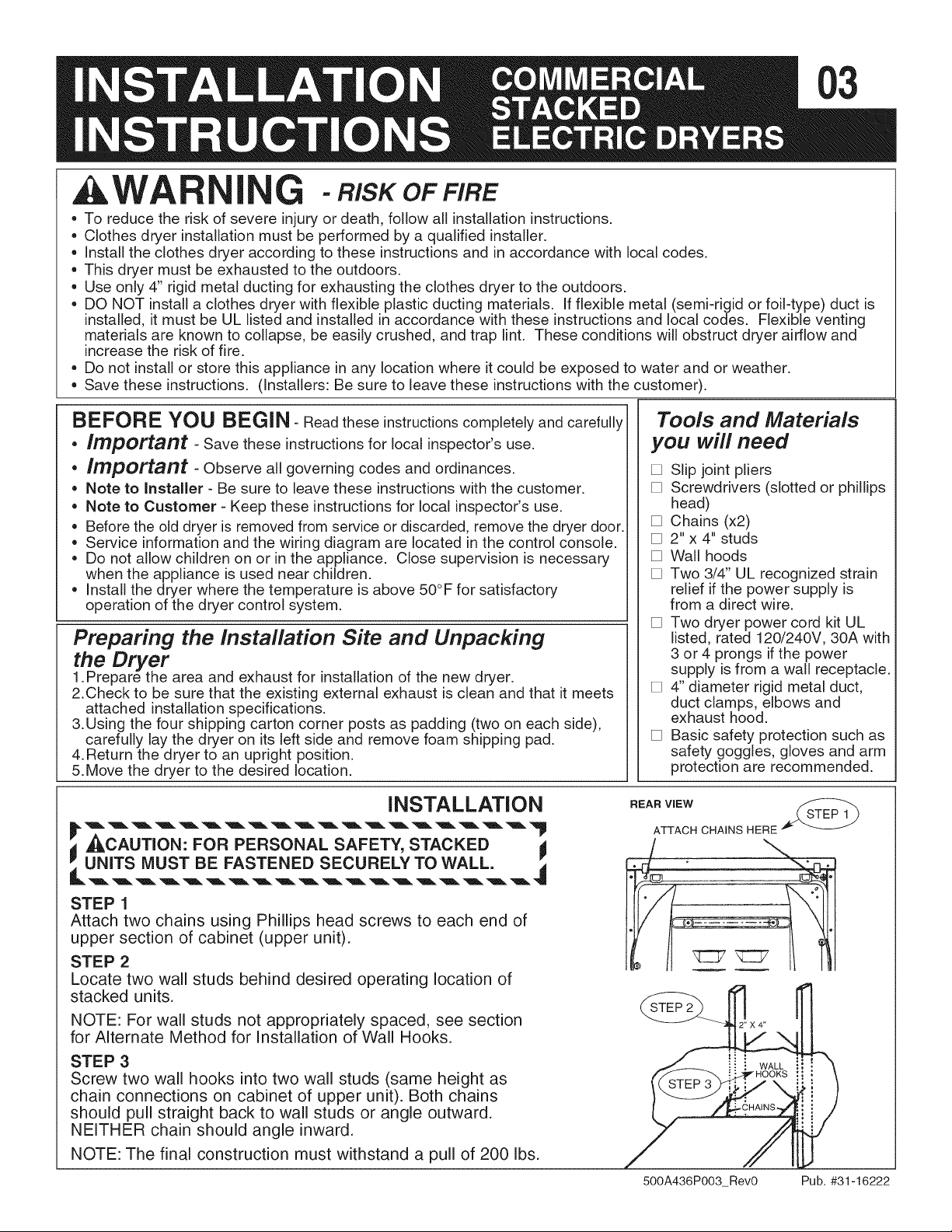

REAR ViEW

ATTACH CHAINS HERE

STEP 1

Attach two chains using Phillips head screws to each end of

upper section of cabinet (upper unit).

STEP 2

Locate two wall studs behind desired operating location of

stacked units.

NOTE: For wall studs not appropriately spaced, see section

for Alternate Method for Installation of Wall Hooks.

STEP 3

Screw two wall hooks into two wall studs (same height as

chain connections on cabinet of upper unit). Both chains

should pull straight back to wall studs or angle outward.

NEITHER chain should angle inward.

NOTE: The final construction must withstand a of 200 Ibs.

:: } WALL

500A436POO3RevO Pub.#31-16222

Page 2

iNSTALLATiON (continued)

STEP 4

Connect both dryers to power supply. (See ELECTRICAL

CONNECTION INFORMATION section of this instruction.) SiDEWEW

STEP 5

Connect both dryers to external exhaust. (See EXHAUST

INFORMATION of this instruction.)

STEP 6

Hook both chains from upper unit to appropriate wall hooks

taking up any slack.

STEP 7

4 LEVELLING LEGS

Adjust all 4 levelling legs. Dryer must be levelled and rest

firmly on all 4 levelling legs.

Alternate Method for Installation of Waft Hooks

STEP 1

If wall studs are not correctly spaced or centered behind upper unit, it

may be necessary to attach a horizontal 2" x 4" board to the existing

wall.

STEP 2

Attach wall hooks in approximate position of two chains of upper unit so

each chain pulls straight back to wall.

NOTE: If wall is concrete or block, drill holes and use appropriate wall

anchors. The final construction must withstand a pull of 200 Ibs.

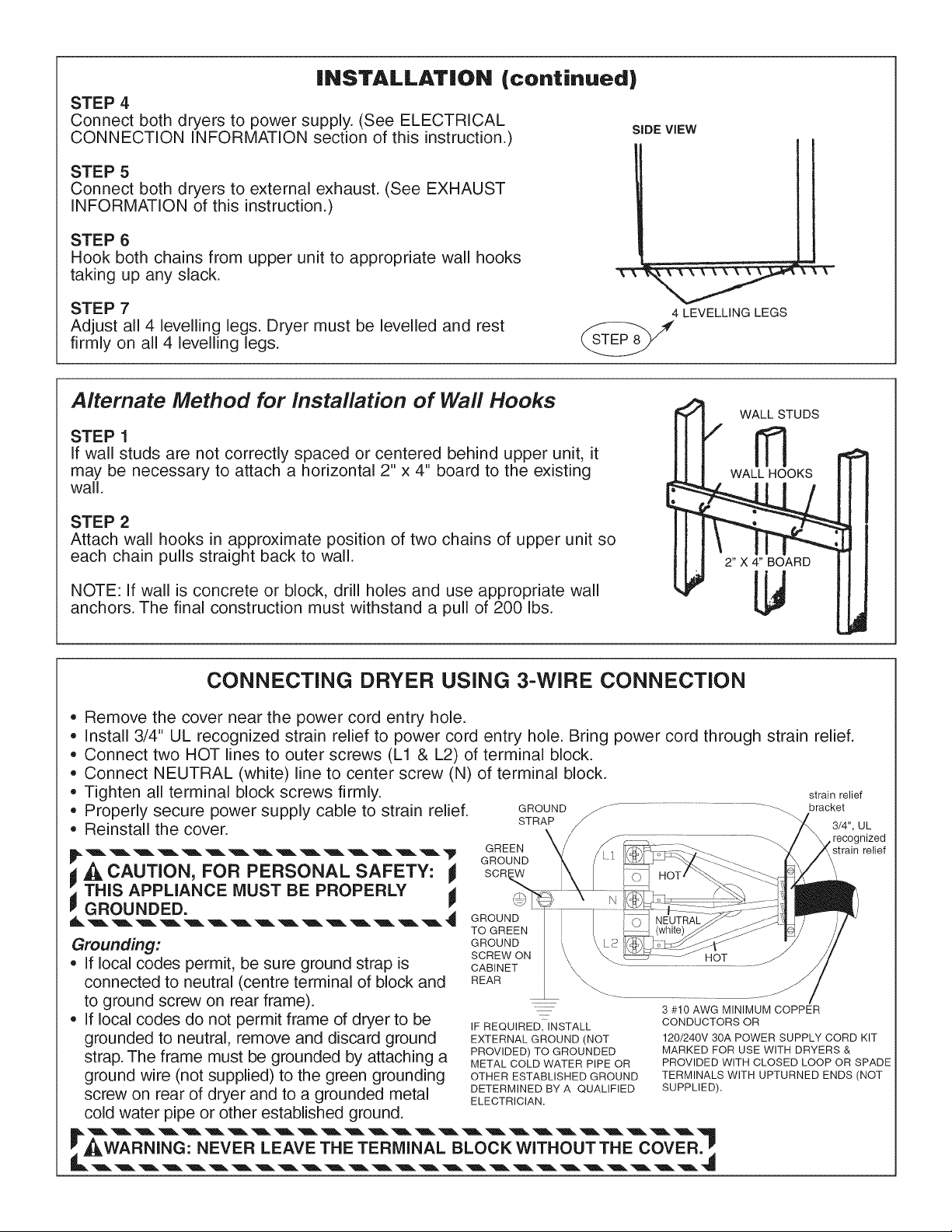

CONNECTING DRYER USING 3-WIRE CONNECTION

,, Remove the cover near the power cord entry hole.

,, Install 3/4" UL recognized strain relief to power cord entry hole. Bring power cord through strain relief.

,, Connect two HOT lines to outer screws (L1 & L2) of terminal block.

,, Connect NEUTRAL (white) line to center screw (N) of terminal block.

,, Tighten all terminal block screws firmly.

,, Properly secure power supply cable to strain relief.

,, Reinstall the cover.

_ I "!IL "_IL. I I "_IIL "_11_ "qL. "IlL I "_Li_mL I I I _

,_ CAUTION, FOR PERSONAL SAFETY:

d THIS APPLIANCE MUST BE PROPERLY j

F GROUNDED. "

Grounding:

,, If local codes permit, be sure ground strap is

connected to neutral (centre terminal of block and

to ground screw on rear frame).

,, If local codes do not permit frame of dryer to be

grounded to neutral, remove and discard ground

strap. The frame must be grounded by attaching a

ground wire (not supplied) to the green grounding

screw on rear of dryer and to a grounded metal

cold water pipe or other established ground.

GROUND bracket

STRAP 3/4", UL

GREEN strain relief

GROUND

GROUND

TO GREEN

GROUND

SCREW ON

CABINET

REAR

4'' .......

IF REQUIRED, INSTALL

EXTERNAL GROUND (NOT

PROVIDED) TO GROUNDED

METAL COLD WATER PIPE OR

OTHER ESTABLISHED GROUND

DETERMINED BY A QUALIFIED

ELECTRICIAN.

3 #10 AWG MINIMUM COPPER

CONDUCTORS OR

120/240V 30A POWER SUPPLY CORD KIT

MARKED FOR USE WITH DRYERS &

PROVIDED WITH CLOSED LOOP OR SPADE

TERMINALS WITH UPTURNED ENDS (NOT

SUPPLIED).

strain relief

recognized

i

J

WARNING: NEVER LEAVE THE TERMINAL BLOCK WITHOUT THE COVER. p.

Page 3

CONNECTING DRYER USING 4-WIRE CONNECTION

,, Remove the cover near the power cord entry hole.

,, Install 3/4" UL recognized strain relief to power

cord entry hole. Bring power cord through strain

relief.

,, Connect two HOT lines to outer screws (L1 & L2)

of terminal block.

,, Connect NEUTRAL (white) line to center screw (N)

of terminal block.

,, Attach ground wire of the power cord with the

green ground screw (hole above strain relief bracket).

,, Tighten all terminal block screws firmly.

,, Properly secure power supply cable to strain relief.

,, Reinstall the cover.

,_ WARNING: Only a 4-conductor cord shall be used when the

appliance is installed in a location where grounding through the

neutral conductor is prohibited. Grounding through the neutral is

prohibited for the new branch-circuit installations, mobile homes,

recreational vehicles, and areas where local codes prohibit

grounding through the neutral conduction.

REMOVE GROUND STRAP AND DISCARD

KEEP GREEN GROUND SCREW

-sRELOCATE GREEN GRouND_ bracket

4 #10 AWG MINIMUM COPPER CONDUCTORS OR 120/240V 30A

POWER SUPPLY CORD KIT MARKED FOR USE WITH DRYERS &

PROVIDED WITH CLOSED LOOP OR SPADE TERMINALS WITH

UPTURNED ENDS (NOT SUPPLIED).

_IL CAUTION: For personal safety this appliance

must be properly grounded.

_l_ WARNING Never leave the terminal block without the

EXHAUST INFORMATION

WARNING =TO REDUCE THE RiSK OF REAR EXHAUST LOCATION

FiRE OR PERSONAL iNJURY: _ The dryers come ready for rear exhausting. Units

- This clothes dryer must be exhausted to the outdoors,_ have separate exhausts.

- Use only 4" rigid metal ducting for the home exhaust

strain relief

CREW HERE 3/4", UL

q relief

cover,

- Use only 4" rigid metal or UL-listed flexible metal

duct. I

(semi-rigid or foil-type) duct to connect the dryer to

accordance with these instructions and local codes.

I the home exhaust duct. It must be installed in d

- Do not terminate exhaust in a chimney, a wall, a ceil-

floor, or in any other concealed space of a building.

I ing, gas vent, crawl space, attic, under an enclosed

The accumulated lint could create a fire hazard.

with a kitchen exhaust system. A combination of

- ever terminate the exhaust into a common duct j

grease and lint creates a potential fire hazard.

- o not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

- Never install a screen in or over the exhaust duct.

This will cause lint to accumulate, creating a poten-

tial fire hazard.

extend into the duct. These fasteners can accumul-

- o not assemble ductwork with an:, fasteners that P

ate lint, creating a potential fire hazard.

Do not obstruct incoming or exhausted air.

- Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints.

Exhaust system shall be inspected and cleaned at

least once a year.

the dryer to the house vent using a flexible metal (foil-

- n special installations, it may be necessary to connect

type) duct. A UL-listed flexible metal (foil-type) duct

flexible metal (semi-rigid) ducting cannot be used AND

I may be used ONLY in installations where rigid metal or d

where a 4" diameter can be maintained throughout the

entire length of the transition duct. In Canada and in

the United States, only the flexible metal (foil4ype)

L ducts that comply with the "Outline for Clothes Dryer

Transition Duct Subject 2158A" shall be used. I_

'_li _mll_ 'IlL '_ll. 'IlL 'IR_ 11_ 'ILL. Ilk. 'IlL 'lmL 'IlL '_mL _IL "ImL "_m

_ I i/_'_:'_ / inside duct I .....

I It r

J 11314"_i ...............................................

NOTE: Add to vertical

dimension the distance

between cabinet bottom to

floor surface.

EXHAUST LENGTH

The MAXIMUM ALLOWABLE duct length and number of

bends of the exhaust system depends upon the type of duct,

number of turns, the type of exhaust hood (wall cap), and all

conditions note below. The maximum allowable length for

rigid metal duct is shown inthe PREFERRED

table below. More than two 90° f-'_Z

turns is not recommended. The

total length of flexible metal duct

shall not exceed 8 ft.(2.4 m). In

Canada and in the United States,

the required exhaust duct diameter

J

is 4in (102mm). NUMBER

TURNS

RIGID METAL DUCT

OF 90°

0

4 in. 2 Y in.

MAXIMUM LENGTH

- HOOD TYPE -

45 ft. 30 ft.

.'M

EXHAUST

A B

35 ft. 2Oft.

4" DIAMETER

2

25 ft. 10 ft.

PARTS AVAILABLE FROM LOCAL SERVICE

ORGANiZATiON

Rigid Metal Duct Components

WX8X63 4" X 1' Duct WX8X51 4" Elbow

WX8X64 4" x 2' Duct WX8X59 4" Aluminum Hood

Flexible Metal Duct Components

WXO8X10077 4" dia. flexible metal (semi-rigid)

UL-listed transition duct (includes 2 elbows)

Page 4

EXHAUST iNFORMATiON (continued)

EXHAUST SYSTEM CHECK LiST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

• Termination should present minimal resistance to the

exhaust air flow and should require little or no

maintenance to prevent dogging.

• Wall caps must be installed at least 12" above

ground level or any other obstruction with the

opening pointed down.

SEPARATION OF TURNS

Separate all turns by at least 3 ft. of straight duct,

including distance between last turn and dampered

wall cap. if two turns must be closer than 3 ft., deduct

10 ft. from the maximum lengths shown in the table for

each occurrence.

TURNS OTHER THAN 90 °

• One turn of 45 ° or less may be ignored.

• Two 45 ° turns should be treated as one 90 °

• Each turn over 45 ° should be treated as one 90°

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male

end of each section of duct must point away from

the dryer.

• Do not assemble the duct work with fasteners that

extend into the duct. They will serve as a collection

point for lint.

• Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

iNSULATiON

Duct work which runs through an unheated area or is

near an air conditioning duct should be insulated to

reduce condensation and lint build up and be sloped

down toward outdoors.

NOTE: Never install screen inside exhaust duct.

SiDE OR BOTTOM EXHAUST

STEPS TO CHANGE DRYER TO SiDE OR BOTTOM EXHAUST DIRECTLY ON CABINET

NOTE: Protect your hands and arms from sharp edges when working inside dryer cabinet.

,, Detach and remove the desired knockout.

,, Remove the screw inside the dryer exhaust duct end.

Keep the screw for step 5. Pull on the duct to remove it.

,, Cut the duct as shown. Keep portion A.

,, Through the rear opening, locate the tab in the middle of

the dryer base. Lift the tab to about 45 ° using a fiat

screwdriver.

,, Reconnect and secure the cut portion (A) of the duct to

the blower housing. Make sure that the fixing hole is

aligned with the tab in the base. Use the screw of item 2

to secure the duct in place through the tab on the dryer

base.

,, Use standard metal elbows and duct to complete

exhaust system, insert standard elbow and ducts

through rear and side or bottom openings.

,, Cover the opening at the back with the plate (Kit

WE1 M454) available from your Local Service Provider.

229 mm CUT _'-'_ TAB LOCATION insidethe dryer

PORTION91_m"_I !A///(UNDER DUCT) cabinet

................................_.... [ j__ I ..... SIDE PANEL

121 mm 121 mrn_

4 3/4 " 4 3/4 "

...................._..........

......

BACKOF

WARNING: NEVER LEAVE THE BACK OPENING WITHOUT THE PLATE. P,

MiNiMUM CLEARANCES

Minimum clearances are - 0" both sides

- 1" at rear

- 88" vertical space from floor to ceiling

Note to installer:

After installation check the following:

[] Exhaust Duct - must meet specs as mentioned in

"Exhaust Information" section of this installation

instructions.

[] Grounding - Dryer must be properly grounded to

conform to local codes and ordinance

requirements.

[] Operation - Turn dryer ON and check for heat.

[] Hand Customer the Use and Care Book - Give

instructions on operating the dryer - answer any

guestions.

[] Give these Installation Instructions to the customer.

Loading...

Loading...