Page 1

GE Transportation

5GEB22

AC Drilling Motor

Oshore Features

1150 HP (858kW)

GE’s AC and DC motors have delivered industry leading

technology for more than 50 years. Pioneering the application

of AC technology to oileld equipment, GE has more than 4,000

AC units in operation on more than 600 rigs worldwide.

GE’s AC motors have been eld proven in the harshest

conditions and are now compliant to a broader range of

industry certications: ATES, IECEx, and CSAus, satisfying

the new North American AEx requirements and increasing

operations across more rigs, geographies and regulated

territories. GE AC motors, 5GEB20 & 5GEB22, in the 1150hp

class oers rotor inertia levels that are among the lowest in

the industry and optimal for drawworks applications. Torque

& power density levels are also among the highest in the

industry, optimal for deeper-water oshore applications, where

space is a premium.

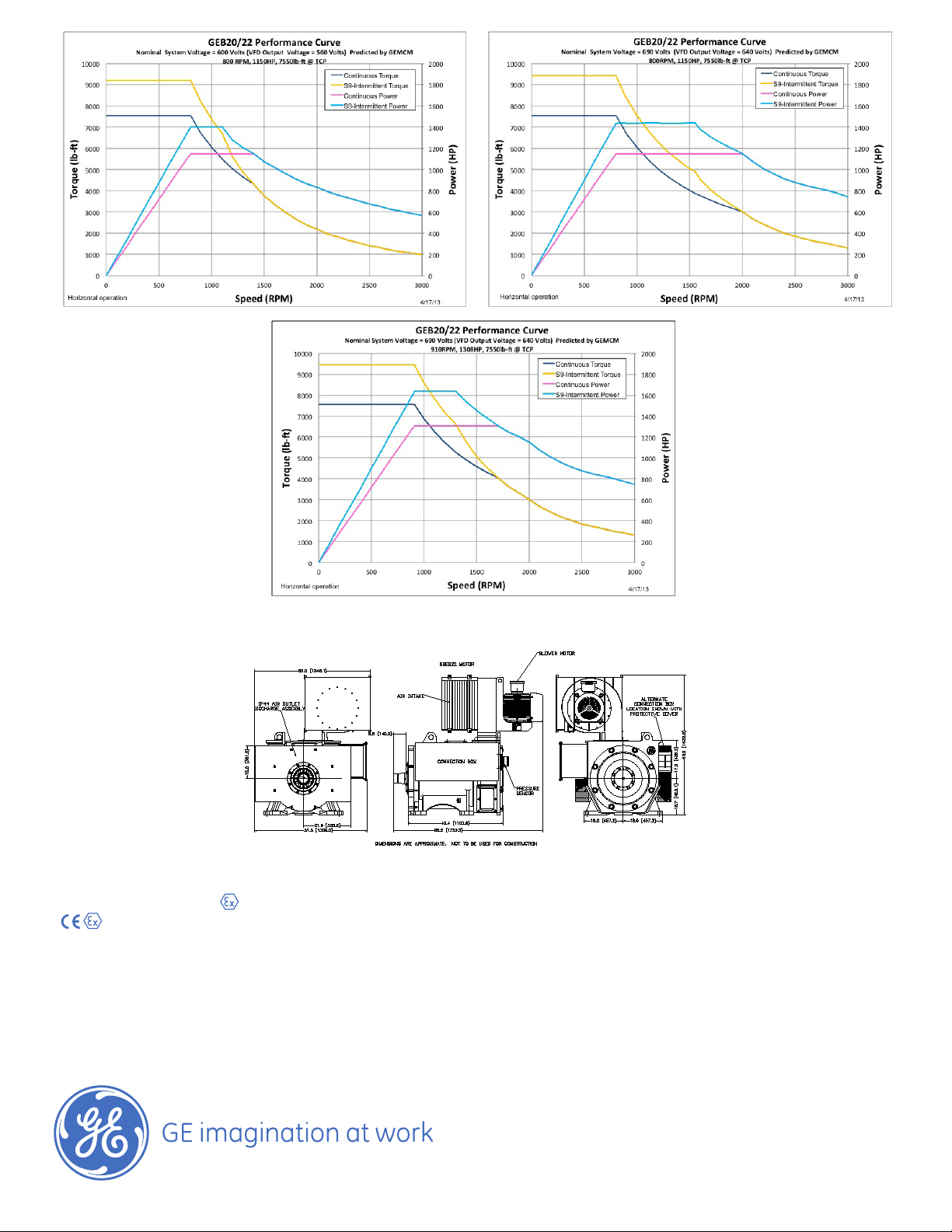

Performance ratings

The 5GEB22 AC drilling motor with 3000 SCFM airow and temperature rise of 110oC at 45oC ambient.

Continuous Rating

Rated Volts (AC) 587 587

Current (Amps) 1120 1380

Base Speed (RPM) 800 910 800 910

with 600v VFD

Speed @ Rated HP (RPM) 800-1400 800-1100

HP (kw) 1150 (858) 1403 (1046)

with 690v VFD

Speed @ Rated HP (RPM) 800-2000 910-1700 800-1538 910-1300

HP (kW) 1150 (858) 1308 (975) 1438 (1072) 1635 (1219)

Torque lb-ft (Nm) 7550 (10236) 9438 (12796)

Speed @ Rated Torque 0-800 0-910 0-800 0-910

Max Speed (RPM) 3000 3000

Standard Features

• 6-pole stator with FORM WOUND windings

• Copper chromium alloy rotor bars

• Class H insulation, robotically taped, Mica-Kapton system

• 4340 alloy shaft, ABS certied

• Insulated bearing on non-drive end

• Single-shaft extension with hub

• IP56 stainless steel universal (eld convertible from A to B

side) connection box with bus bar connections for main

cables and terminals for RTDs and tape heaters

• Six (6) RTDs; Two (2) 100 ohm platinum in each stator winding

• Pressure sensor to verify ventilation

• 15 HP (11kW) blower assembly providing 3000 SCFM

• Intake louvers to protect from water ingress

• Tape heater – 400 watts (200 watts per each end of motor)

• Same shaft height and mounting feet dimensions as the

5GE752.

Intermittent Rating - S9

(120 sec on ~ 90 sec off)

Page 2

Approximate Dry Weight: 6500 lbs., 2948 kg.

Optional Features

• ATEX Certied Ex e II T3, II 2 G c T3 Tamb -40ºC to +55ºC

• when motor is used in hazardous areas with approved

Variable Frequency Drivers (VFD).

• ABS and/or DNV certication

• Encoder

• Sound attenuation

• Bearing RTDs

• Totally Enclosed Water to Air cooling (IP56)

Models Oered:

5GEB22A - large roller bearing with 4340 alloy shaft

5GEB22D - large roller bearing with oversized 4340 alloy shaft

5GEB22E - small roller bearing for direct (axially) connected

loads with 1045 shaft steel

To nd out more,

fax inquiries to 832-295-7600

or visit us online at

www.getransportation.com

new code???

Loading...

Loading...