GE DBVH520GJ3WW, DBVH520GJ4WW, DCVH680GJ0MV, DCVH680GJ2BB, DCVH680GJ2MR Installation Guide

...Page 1

Installation

Gas Drger

Instructions

If you hove any questions, coil 1-800-GECARES (US)or 1-800-561-3344 (Canada)

or Visit our Web site at: www.GEApplionces.com (US)

PEDESTALS FOR DRYERS

(comes with individual installation instructions)

3 models available: SBSD227F,SBSD137H

SBSDIO7H

BEFORE YOU BEGIN

Reed these instructions completely end

carefully.

• IMPORTANT- savethese

instructionsforlocalinspector'suse.

• IMPORTANT- Observe

allgoverningcodesand ordinances.

• Note to Installer- Besure to leave these

instructions with the customer.

• Note to Customer- Keep these

instructions with your Useand Care Book

for future reference.

• Before the old dryer is removed from

serviceor discarded, remove the dryer door.

• Inspect the dryer exhaust outlet and

straighten the outlet walls if they are bent.

• Service information and the wiring diagram

are located in the control console.

• Donot allow children on or in the appliance.

Closesupervision of children is necessary

when the appliance is used near children.

• Install the dryer where the temperature is

above 50°Ffor satisfactory operation of

the dryer control system.

10

, WAR

• To reduce the risk of severe injury or death, follow all installation instructions.

• Clothes dryer installation must be performed by a qualified installer.

Install the clothes dryer according to these instructions and in accordance with local codes. In

the absence of local codes, installation must comply with National Fuel Gas Code,

ANSIZ223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSAB149.1.

• Ca/ifom/a Safe Drinking Water and Toxic Enforcement Act

This act requires the governor of California to publish a list of substances known to the state to

cause cancer, birth defects or other reproductive harm and requires businesses to warn

customers of potential exposure to such substances. Gas appliances can cause minor

exposure to four of these substances, namely benzene, carbon monoxide, formaldehyde and

soot, caused primarily by the incomplete combustion of natural gas or LPfuels. Properly

adjusted dryers will minimize incomplete combustion. Exposure to these substances can be

minimized further by properly venting the dryer to the outdoors.

This dryer must be exhausted to the outdoors.

Use only 4" rigid metal ducting for exhausting the clothes dryer to the outdoors.

DONOTinstall a clothes dryer with flexible plastic ducting materials. If flexible metal (semi-

rigid or foil-type) duct is installed, it must be UL-listed and installed in accordance with the

instructions found in "Connecting The Dryer To House Vent" on page 6 of this manual. Flexible

ducting materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct dryer airflow and increase the risk of fire.

Do not install or store this appliance in any location where it could be exposed to water and or

weather.

Save these instructions. (Installers: Be sure to leave these instructions with the customer).

In the state of Massachusetts, installation must be performed bg a qualified or

licensed contractor, plumber, or gasfitter qualified or licensed by the state.

IN6- RISKOFFIRE

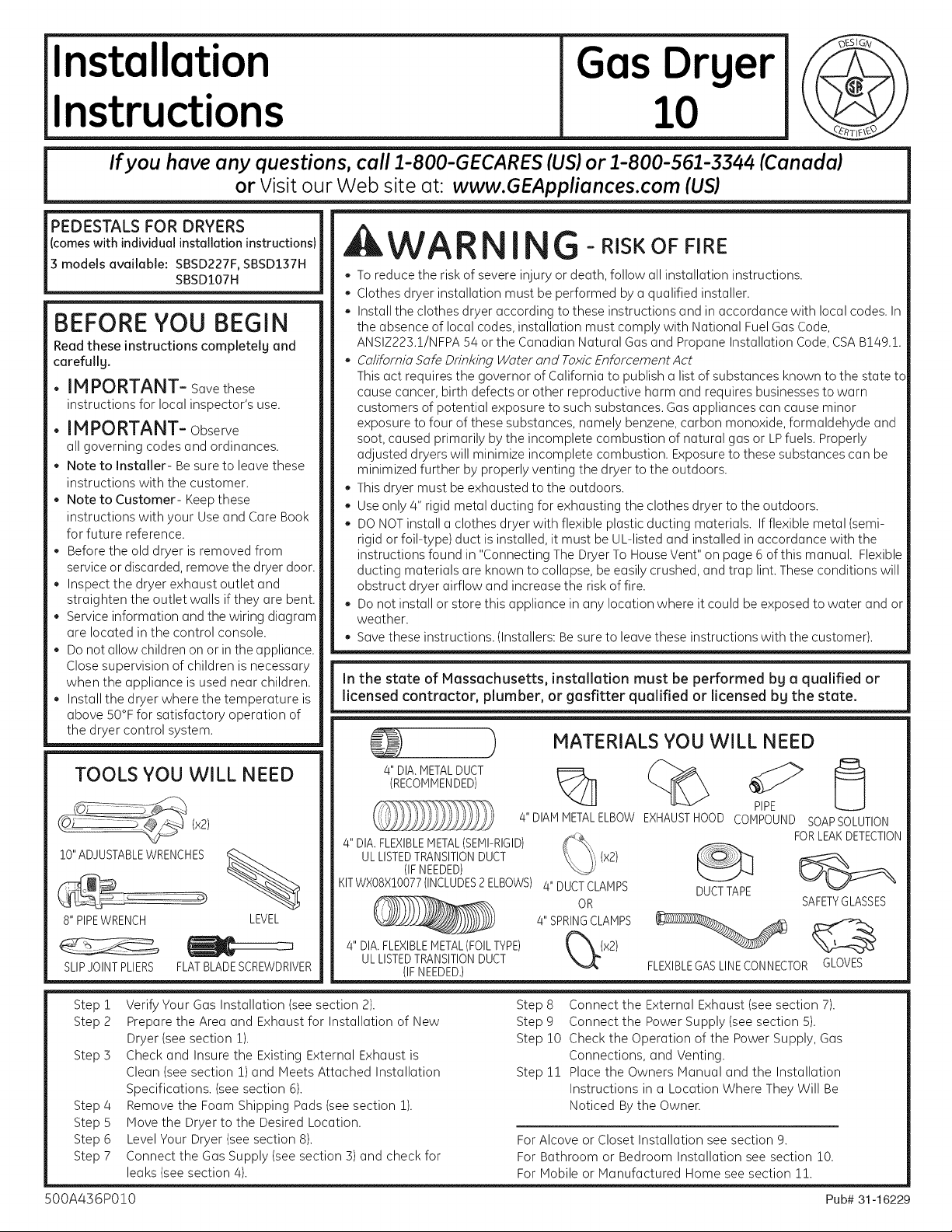

MATERIALS YOU WILL NEED

TOOLS YOU WILL NEED

(x2)

10" ADJUSTABLEWRENCHES

8" PIPEWRENCH

SLIPJOINTPLIERS

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

500A436P010 Pub# 31-16229

Verify Your Gas Installation (see section 2).

Prepare the Area and Exhaust for Installation of New

Dryer (see section 1).

Check and Insure the Existing External Exhaust is

Clean (see section 1) and Meets Attached Installation

Specifications. (see section 6).

Remove the Foam Shipping Pads (see section 1).

Move the Dryer to the Desired Location.

Level Your Dryer (see section 8).

Connect the Gas Supply (see section 3) and check for

leaks (see section 4).

FLATBLADESCREWDRIVER

LEVEL

/4"DIA.METALDUCT

(RECOMMENDED)

4" DIAM METALELBOW EXHAUSTHOOD COMPOUND SOAPSOLUTION

4" DIA.FLEXIBLEMETAL(SEMI-RIGID)

ULLISTEDTRANSITIONDUCT

(IFNEEDED)

KITWXO8X10077(INCLUDES2ELBOWS)

4" DIA,FLEXIBLEMETAL(FOILTYPE)

ULLISTEDTRANSITIONDUCT

(IFNEEDED,)

Step 8 Connect the External Exhaust (see section 7).

Step 9 Connect the Power Supply (see section 5).

Step 10 Check the Operation of the Power Supply, Gas

Step 11 Place the Owners Manual and the Installation

For Alcove or Closet Installation see section 9.

For Bathroom or Bedroom Installation see section 10.

For Mobile or Manufactured Home see section 11.

PIPE

FORLEAKDETECTION

(x2)

4" DUCTCLAMPS _"._J" _

0R SAFETYGLASSES

4" SPRINGCLAMPS

FLEXIBLEGASLINECONNECTORGLOVES

Connections, and Venting.

Instructions in a Location Where They Will Be

Noticed By the Owner.

DUCTTAPE

Page 2

Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1 in. rear. Consideration

must be given to provide adequate clearance for proper operation and service.

ITI PREPARING FOR INSTALLATION

OF NEW DRYER

TIP:Install your dryer before installing your washer.

This will allow better accesswheninstalling dryer exhaust

DISCONNECTING_ GAS _i v

TURNGAS _ DISCONNECTANDDISCARDOLD

SHUT-OFF I_>_ FLEXIBLEGASCONNECTORAND _CT' _,

OFF

APPROVEDFLEXIBLEGASLINE

CONNECTORAND ULAPPROVED

TRANSITIONDUCT.

WARNING - NEVER REUSE OLD

FLEXIBLE CONNECTORS.

The use of old flexible connectors can cause leaks and

personal injury. Always use new flexible connectors when

installing gas appliances.

REMOVING LINT FROM WALL

EXHAUST OPENING

_] GAS REQUIREMENTS

_i, WARNING

• Installation must conform to local codes and ordinances,

or in their absence, the NATIONAL FUEL GAS CODE,

ANSI Z223.

This gas dryer is equipped with a Valve & Burner

Assembly for use only with natural gas. Using conversion

kit WE25X0217, your local service organization can

convert this dryer for use with propane (LP) gas. ALL

CONVERSIONS HUST BE HADE BY PROPERLYTRAINED

AND QUALIFIED PERSONNEL AND IN ACCORDANCE WITH

LOCAL CODES AND ORDINANCE REQUIREHENTS.

The dryer must be disconnected from the gas supply

piping system during any pressure testing of that system

at a test pressure in excess of 0.5 PSI (3.4 KPa).

The dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during

any pressure testing of the gas supply piping of test

pressure equal to or less than 0.5 PSI (].4 KPa).

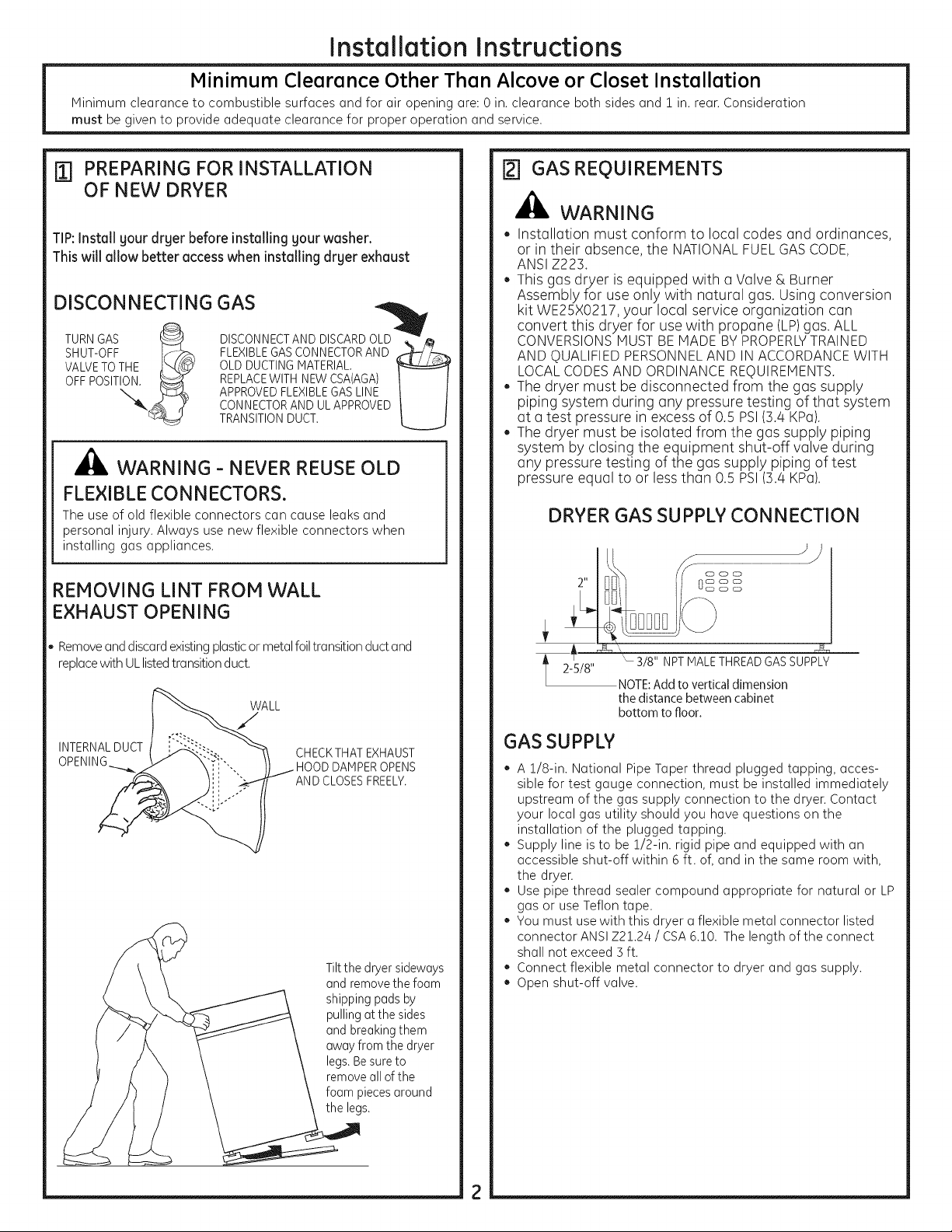

DRYER GAS SUPPLY CONNECTION

• Removeand discardexistingplasticor metalfoil transitionduct and

replacewith ULlistedtransitionduct.

WALL

INTERNALDUCT

CHECKTHAT EXHAUST

DAMPEROPENS

AND CLOSESFREELY,

Tiltthe dryer sideways

andremovethe foam

shippingpads by

pullingatthe sides

andbreakingthem

awayfrom the dryer

legs.Besureto

removeall of the

foam piecesaround

the legs.

2-5/8"

t

'- 3/8" NPT MALETHREADGASSUPPLY

NOTE: Add to vertical dimension

the distance between cabinet

bottom to floor.

GAS SUPPLY

A 1/8-in. National Pipe Taper thread plugged tapping, acces-

sible for test gauge connection, must be installed immediately

upstream of the gas supply connection to the dryen Contact

your local gas utility should you have questions on the

installation of the plugged tapping.

Supply line isto be 1/2-in. rigid pipe and equipped with an

accessible shut-off within 6 ft. of, and in the same room with,

the dryen

Use pipe thread sealer compound appropriate for natural or LP

gas or use Teflon tape.

You must use with this dryer a flexible metal connector listed

connector ANSI Z21.24 / CSA6.10. The length of the connect

shall not exceed ] ft.

Connect flexible metal connector to dryer and gas supply.

Open shut-off valve.

Page 3

Installation

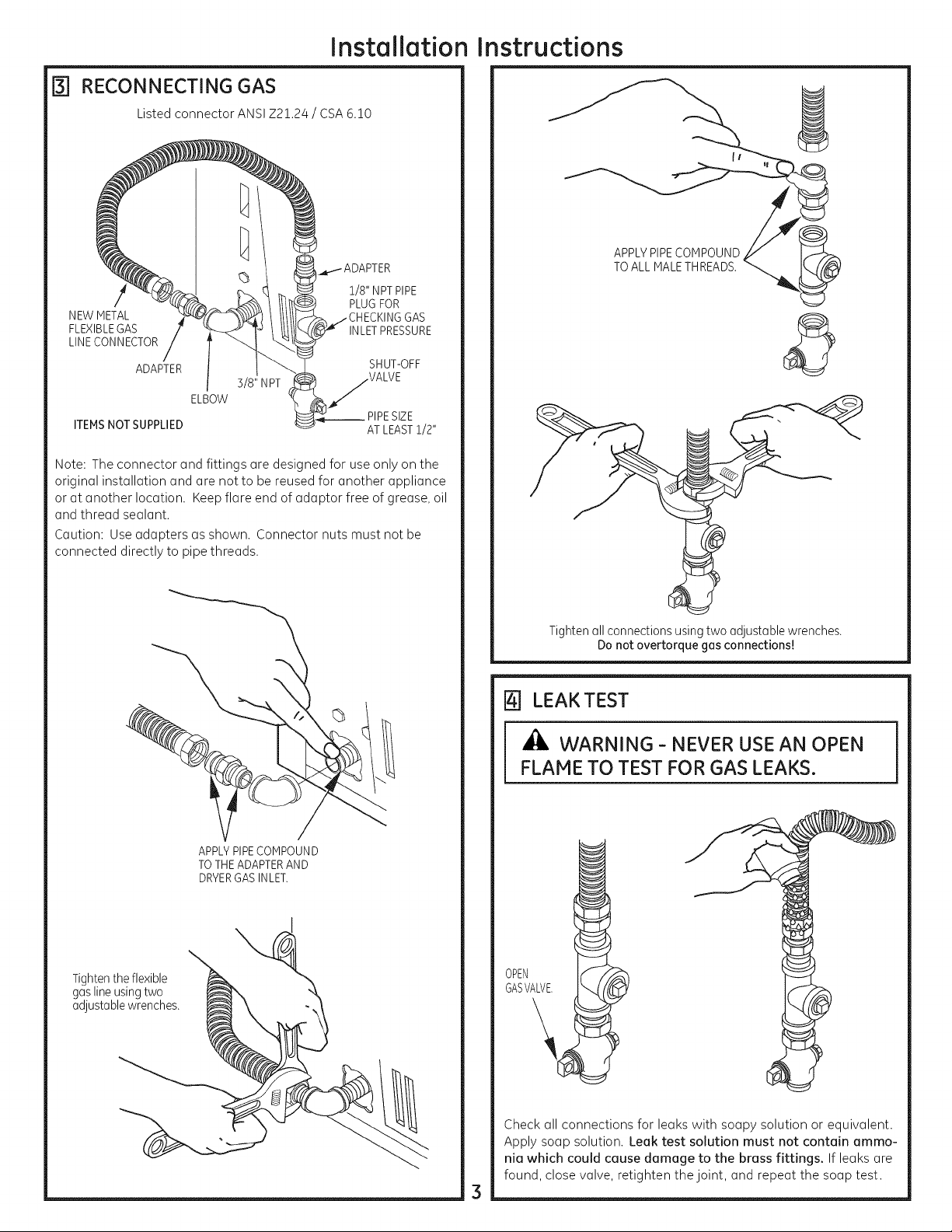

RECONNECTING GAS

B1

Listed connector ANSI Z21.24 / CSA 6.10

1/8" NPTPIPE

NEW METAL

FLEXIBLEGAS INLETPRESSURE

LINECONNECTOR

ADAPTER

3/8" NPT

ELBOW

ITEMSNOT SUPPLIED __ PIPESIZE

Note: The connector and fittings are designed for use only on the

original installation and are notto be reused for another appliance

or at another location. Keep flare end of adaptor free of grease, oil

and thread sealant.

Caution: Useadapters as shown. Connector nuts must not be

connected directly to pipe threads.

PLUGFOR

SHUT-OFF

ATLEAST1/2"

instructions

APPLYPIPECOMPOUND

TOALL MALETHREADS.

Tighten the flexible

gas line using two

adjustable wrenches.

APPLYPIPECOMPOUND

TOTHEADAPTERAND

DRYERGASINLET.

Tighten all connections using two adjustable wrenches.

Do not overtorque gas connections!

[] LEAK TEST

WARNING - NEVER USE AN OPEN

FLAME TO TEST FOR GAS LEAKS.

GASVALVE.

OPEN

Check all connections for leaks with soapy solution or equivalent.

Apply soap solution. Leak test solution must not contain ammo-

nia which could cause damage to the brass fittings. If leaks are

found, close valve, retighten the joint, and repeat the soap test.

Page 4

Installation

Instructions

rs-] ELECTRICAL CONNECTION

INFORMATION

A

_l& WARNING-TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK, AND PERSONAL INJURY:

,, DO NOT USE AN EXTENSION CORD OR AN

ADAPTER PLUG WITH THIS APPLIANCE.

Dryer must be electrically grounded in accordance

with local codes and ordinances, or in the absence of

local codes, in accordance with the NATIONAL ELEC-

TRICAL CODE, ANSI/NFPA NO. 70.

ELECTRICAL REQUIREMENTS

This appliance must be supplied with 120V, 60Hz, and connected

to a properly grounded branch circuit, protected by a 15- or

20-amp circuit breaker or time-delay fuse. If electrical supply

provided does not meet the above specifications, it is recom-

mended that a licensed electrician install an approved outlet.

A

ml, WARNING-THIS DRYER IS EQUIPPED A

THREE-PRONG (GROUNDING) PLUG FOR YOUR

PROTECTION AGAINST SHOCK HAZARD AND

SHOULD BE PLUGGED DIRECTLY INTO A PROP-

ERLY GROUNDED THREE-PRONG RECEPTACLE.

DO NOT CUT OR REMOVE THE GROUNDING

PRONG FROM THIS PLUG.

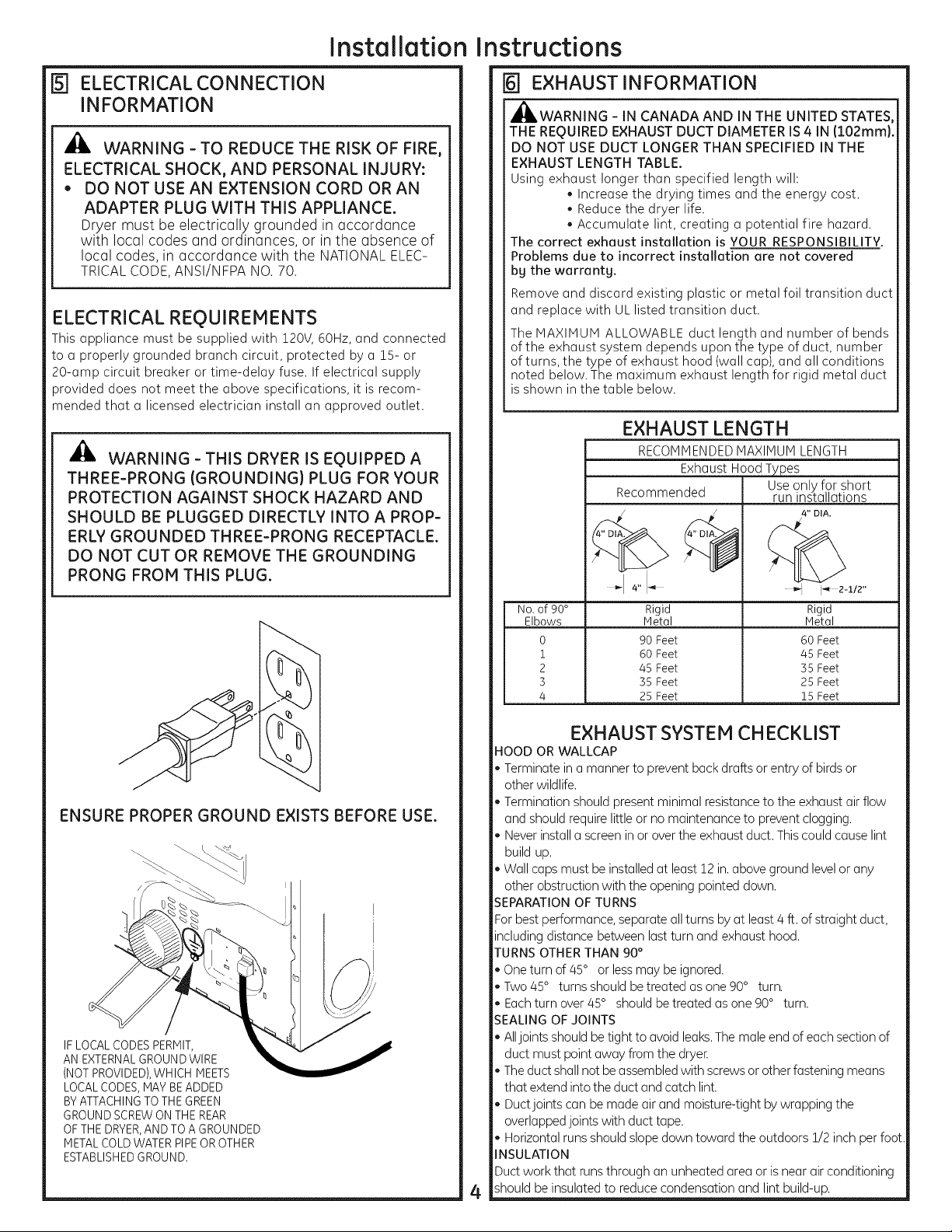

[63 EXHAUST INFORMATION

_I_WARNING - IN CANADA AND IN THE UNITED STATES,

THE REQUIRED EXHAUST DUCT DIAMETER IS4 IN (102mm).

DO NOT USE DUCT LONGER THAN SPECIFIED IN THE

EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

• Increase the drying times and the energy cost.

• Reduce the dryer life.

. Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR RESPONSIBILITY.

Problems due to incorrect installation are not covered

by the warranty.

Remove and discard existing plastic or metal foil transition duct

and replace with UL listed transition duct.

The HAXIHUH ALLOWABLE duct length and number of bends

of the exhaust system depends upon the type of duct, number

of turns, the type of exhaust hood (wall cap), and all conditions

noted below. The maximum exhaust length for rigid metal duct

is shown in the table below.

EXHAUST LENGTH

RECOHHENDEDHAXIHUH LENGTH

Exhaust Hood Types

Recommended run installations

4" "q _ _'_ 2-I/2"

No.of 90° Rigid Rigid

Elbows Hetal Hetal

0 90Feet 60Feet

i 60Feet 45 Feet

2 45Feet 35Feet

3 35Feet 25Feet

4 25Feet 15Feet

Use only for short

4" DIA.

ENSURE PROPER GROUND EXISTS BEFORE USE.

IFLOCALCODESPERMIT,

AN EXTERNALGROUNDWIRE

(NOTPROVIDED),WHICH MEETS

LOCALCODES,MAY BEADDED

BYATTACHINGTO THE GREEN

GROUNDSCREWONTHE REAR

OFTHE DRYER,AND TO A GROUNDED

METALCOLD WATERPIPEOR OTHER

ESTABLISHEDGROUND.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALLCAP

• Terminate in a manner to prevent backdrafts or entry of birds or

other wildlife.

• Termination should present minimal resistanceto the exhaust airflow

and should requirelittle or no maintenance to prevent clogging.

• Never install a screenin or over the exhaust duct. Thiscould cause lint

build up.

• Wall capsmust be installed at least12 in.above ground levelor any

other obstruction with the opening pointed down.

SEPARATIONOF TURNS

Forbest performance, separate allturns by at least4 ft. of straight duct,

includingdistance between last turn and exhaust hood.

TURNS OTHERTHAN 90°

• Oneturn of 45° or lessmay be ignored.

• Two 45° turns should betreated asone 90° turn.

• Eachturn over 45° shouldbe treated as one 90° turn.

SEALING OF JOINTS

• Alljoints should betight to avoid leaks.The male end of each sectionof

duct must point away from the dryer

• The duct shall not beassembledwith screwsor other fastening means

that extend into the duct and catch lint.

• Duct joints can be made air and moisture-tight by wrapping the

overlappedjoints with duct tape.

• Horizontal runsshould slope down toward the outdoors 1/2 inch perfoot.

INSULATION

Ductwork that runs through an unheated area or isnear airconditioning

shouldbe insulated to reduce condensation and lint build-up.

4

Page 5

Installation

instructions

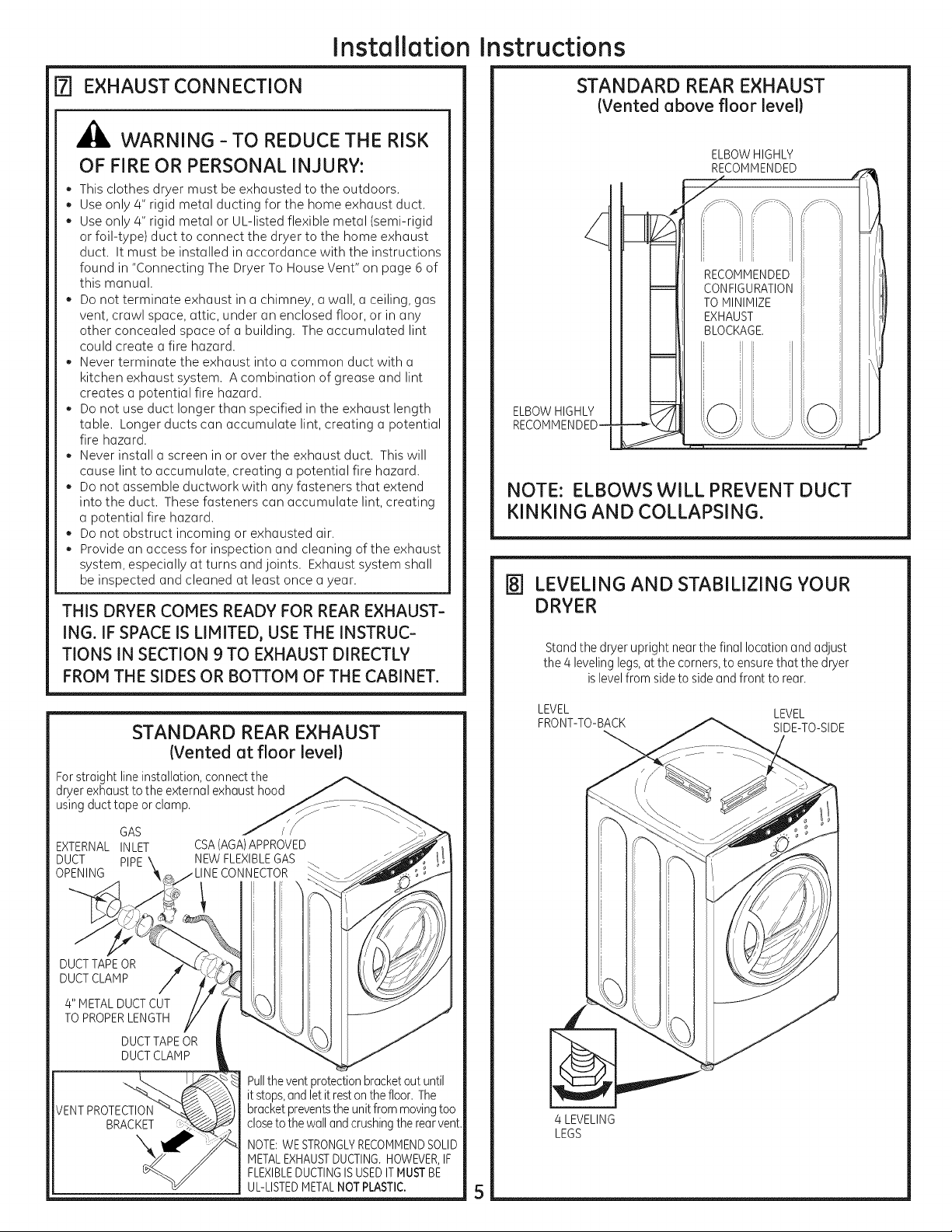

EXHAUST CONNECTION

[]

_1_ WARNING - TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

* This clothes dryer must be exhausted to the outdoors.

. Use only 4" rigid metal ducting for the home exhaust duct.

Use only 4" rigid metal or UL-listed flexible metal (semi-rigid

or foil-type) duct to connect the dryer to the home exhaust

duct. It must be installed in accordance with the instructions

found in "Connecting The Dryer To House Vent" on page 6 of

this manual.

Do not terminate exhaust in a chimney, a wall, a ceiling, gas

vent, crawl space, attic, under an enclosed floor, or in any

other concealed space of a building. The accumulated lint

could create a fire hazard.

Never terminate the exhaust into a common duct with a

kitchen exhaust system. A combination of grease and lint

creates a potential fire hazard.

Do not use duct longer than specified in the exhaust length

table. Longer ducts can accumulate lint, creating a potential

fire hazard.

Never install a screen in or over the exhaust duct. This will

cause lint to accumulate, creating a potential fire hazard.

Do not assemble ductwork with any fasteners that extend

into the duct. These fasteners can accumulate lint, creating

a potential fire hazard.

Do not obstruct incoming or exhausted air.

Provide an access for inspection and cleaning of the exhaust

system, especially at turns and joints. Exhaust system shall

be inspected and cleaned at least once a year.

THIS DRYERCOMES READY FOR REAR EXHAUST-

ING. IF SPACEIS LIMITED, USETHE INSTRUC-

TIONS IN SECTION 9 TO EXHAUST DIRECTLY

FROM THE SIDESOR BOTTOM OF THE CABINET.

STANDARD REAR EXHAUST

(Vented above floor level}

ELBOW HIGHLY

ELBOWHIGHLY

RECOMMENDED--

NOTE: ELBOWS WILL PREVENT DUCT

KINKING AND COLLAPSING.

[] LEVELING AND STABILIZING YOUR

DRYER

Standthe dryer upright nearthe final locationand adjust

the 4 levelinglegs,atthe corners,to ensurethat the dryer

islevelfrom sideto sideand front to rear.

STANDARD REAR EXHAUST

{Vented at floor level}

For straight line installation, connect the

dryer exhaust to the external exhaust hood

using duct tape or clamp.

EXTERNALINLET

DUCT PIPE

OPENING

DUCT TAPEOR

DUCT CLAMP

4" METAL DUCT CUT

TO PROPERLENGTH

VENTPROTECTION

GAS

DUCTTAPEOR

DUCTCLAMP

BRACKET

CSA(AGA)APPROVED

Pullthe ventprotectionbracketout until

itstops,andletit restonthefloor. The

bracketpreventstheunitfrommovingtoo

closeto thewallandcrushingthe rearvent.

NOTE:WE STRONGLYRECOMMENDSOLID

METALEXHAUSTDUCTING.HOWEVER,IF

FLEXIBLEDUCTINGISUSEDITMUSTBE

UL-LISTEDMETALNOT PLASTIC.

LEVEL LEVEL

FRONT-TO-BACK SIDE-TO-SIDE

4 LEVELING

LEGS

5

Page 6

Installation

Instructions,Exhausting

CONNECTING THE DRYER TO HOUSE VENT

RIGID METAL TRANSITION DUCT

* For best drying performance, a rigid metal transition duct is

recommended.

* Rigid metal transitions ducts reduce the risk of crushing and

kinking.

UL-LISTED FLEXIBLEMETAL(SEMI-RIGID}TRANSITION DUCT

* Ifrigid metal duct cannot be used, then UL-listed flexible metal

(semi-rigid) ducting can be used (Kit WX08X!0077).

Never install flexible metal duct in walls, ceilings, floors or other

enclosed spaces.

Total length of flexible metal duct should not exceed 8 feet

(2.4m).

For many applications, installing elbows at both the dryer and

the wall is highly recommended (seeillustrations below). Elbows

allow the dryer to sit close to the wall without kinking and or

crushing the transition duct, maximizing drying performance.

Avoid resting the duct on sharp objects.

UL-LISTED FLEXIBLEMETAL(FOIL-TYPE)TRANSITION DUCT

* Inspecial installations, it may be necessary to connect the dryer

to the house vent using a flexible metal (foil- type) duct. A

UL-listed flexible metal (foil-type)duct may be used ONLYin

installations where rigid metal or flexible metal (semi-rigid)

ducting cannot be used AND where a 4" diameter can be

maintained throughout the entire length of the transition duct.

InCanada and the United States, only the flexible metal(foil-

type) ducts that comply with the "Outline for Clothes Dryer

Transition Duct Subject 2!58A" shall be used.

Never install flexible metal duct in walls, ceilings, floors or other

enclosed spaces.

Total length of flexible metal duct should not exceed 8 feet

(2.4m).

Avoid resting the duct on sharp objects.

For best drying performance:

!. Slide one end of the duct over the clothes dryer outlet

pipe.

2.Secure the duct with a clamp.

3.With the dryer in its permanent position, extend the

duct to its full length. Allow 2" of duct to overlap the

exhaust pipe. Cut off and remove excess duct. Keep the

duct as straight as possible for maximum airflow.

4.Secure the duct to the exhaust pipe with the other

clamp.

Do

EXCESSIVE

LENGTH

EXHAUST_

19-IALCOVE OR CLOSET INSTALLATION

Ifyour dryer is approved for installation in an alcove or closet,

it will be stated on a label on the dryer back.

The dryer MUSTbe vented to the outdoors. See the EXHAUST

INFORMATIONsection.

Minimum clearance between dryer cabinet and adjacent

walls or other surfaces is:

0 in. either side

3 in. front and rear

Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is 43 in. without pedestal, 55 in. with pedestal.

Closet doors must be Iouvered or otherwise ventilated and must

contain a minimum of 60 sq. in. of open area equally distributed.

Ifthe closet contains both a washer and a dryer, doors must

contain a minimum of 120 sq. in. of open area equally distributed.

The closet should be vented to the outdoors to prevent gas

pocketing in case of a gas leak in the supply line.

No other fuel-burning appliance shall be installed in the same

closet with the dryen

NOTE:WHEN THE EXHAUSTDUCT IS LOCATED AT THE REAROF

THE DRYER,MINIMUM CLEARANCE FROM THE WALL IS 5.5 IN.

[_ BATHROOM OR BEDROOM INSTALLATION

* The dryer MUSTbe vented to the outdoors. See EXHAUST

INFORMATIONsection 6.

* The installation must conform with local codes or, in the absence

of local codes, with the NATIONALFUELGASCODE,ANSI Z223.

ELBOW HIGHLY

RECOMMENDED

_LBOWS HIGHLY

[] MOBILE OR MANUFACTURED HOME

INSTALLATION

* Installation must conform to the MANUFACTUREDHOME

CONSTRUCTION& SAFETYSTANDARD,TITLE24, PART52-80 or,

when such standard is not applicable, with AMERICAN

NATIONALSTANDARDFORMOBILEHOME,NO.50lB.

* The dryer MUSTbe vented to the outdoors with the termina-

tion securely fastened to the mobile home structure. (See

EXHAUSTINFORMATIONsection 6.)

* The vent MUSTNOT be terminated beneath a mobile or

manufactured home.

* The vent duct material MUST BEMETAL.

* KIT!4-D346-33 MUSTbe used to attach the dryer securely to

the structure.

The vent MUSTNOTbe connected to any other duct, vent, or

chimney.

Do not use sheet metal screws or other refastening devices

which extend into the interior of the exhaust vent.

Provide an opening with a free area of at least 25 sq. in. for

introduction of outside air into the dryer room.

6

Page 7

Installation Instructions

DRYER EXHAUST TO LEFT OR

BOTTOM OF CABINET

_b, WARNING - PROTECT YOUR HANDS

AND ARMS FROM SHARP EDGES WHEN

WORKING INSIDE CABINET.

REMOVE

SCREW

AND SAVE.

O_REMOVE

DESIRED

KNOCKOUT

(ONEONLY).

Detach and remove the bottom or left side knockout

as desired. Remove the screw inside the dryer exhaust duct

and save. Pull the duct out of the dryer. Protect sharp edges

around the knockout and exhaust opening with the tape.

FIXING HOLE

ADDING NEW DUCT

FIXING

HOLE

LEFTSIDE

EXHAUST

Reconnect the cut portion (A)of the duct to the blower

housing. Make sure that the fixing hole is aligned with

the tab in the base. Use the screw saved previously to secure

the duct in place through the tab on the appliance base.

ADDING ELBOW AND DUCT FOR EXHAUST

TO SIDE OF CABINET

• Pre-assemble 4" elbow with 4" duct. Wrap duct tape around

joint.

• Insert duct assembly, elbow first, through the side opening

and connect the elbow to the dryer internal duct.

CAUTION: Besure not to pull or damage the

electrical wires inside the drger when

inserting the duct.

B A

I_ 11,25"

Cut the duct as shown and keep portion A.

TAB LOCATION

BEND TAB

UP45 °

Through the rear opening, locate the tab in the middle of

the appliance base. Lift the tab to about 45° using a flat

blade screwdriver.

• Apply duct tape as shown on the joint between the dryer

internal duct and the elbow.

DUCT

,TAPE

CAUTION:

Internal duct joints must be

secured with tape, otherwise

theg mag separate and cause

a safetg hazard.

7

Page 8

Installation

nstructions

ADDING ELBOW FOR EXHAUST

THROUGH BOTTOM OF CABINET

Insert the elbow through the rear opening and connect it to

the drger internal duct

Applg duct tape on the joint between the drger internal duct

and elbow, as shown on page 7.

CAUTION:

Internal duct joints must be secured with tape,

otherwise they mag separate and cause a

safety hazard.

ADDING COVER PLATE TO REAR OF

CABINET

| REVERSING THE DOOR SWING

IMPORTANT NOTES

Read the instructions all the wag through before starting.

Handle parts carefullg to avoid scratching paint

Set screws down bg their related parts to avoid using them in

the wrong places.

Provide a non-scratching work surface for the doors.

Normal completion time to reverse the door swing is30-60

minutes.

IMPORTANT: Once gou begin, do not move the cabinet until

door-swing reversal is completed.

These instructions are for changing the hinges from the right side

to the left side - if gou ever want to switch them back to the right

side, follow these same instructions and reverse all references to

the left and right

TOOLS YOU WILL NEED

CresentWrench

(Adjustable)

C¢

°-'°'"°'i i_

PLATE

(KIT WE1H454)

Connect standard metal elbows and ducts to complete the

exhaust sgstem. Cover back opening with a plate (Kit WEIH454)

available from gour local service provider. Place drger in final

location.

_1_ WARNING - NEVER LEAVE THE BACK

OPENING WITHOUT THE PLATE.

TO REGISTER YOUR DRYER

CALLTOLL-FREE

Phillips-Head

Screwdriver

DOOR PARTS

HingeAssembtg

Hinge

Cover

PuttgKnifeor Thin-

BladeScrewdriver

O

Nut(#8)- 2

PlasticCover

©

Washer- 2

1-888-269-1192

Prompt registration confirms gour right to protection under the

terms of gour warrantg.

www.GEAppliances.com (US)

For Questions on Installation, Call: 1-800-626-2005 (US)or

1-800-561-5544 (Canada).

500A456P010 Pub # 51-16229

8

LargeTapping

Screw(#10)...6

A

Tapping

Screw(#8)...2

Machine

Screw(#8)...6

Page 9

Installation Instructions

BEFORE YOU START

1. Unplug the drger from its electrical outlet.

REMOVE DOOR ASSEMBLY

2. Open the door to approximatelg 90 degrees. Remove the 4

screws starting from the bottom to the top. Make sure the

door is supported while removing the screws.

4_

Lag the door down on a soft protected flat surface so that

the inner part faces upward (door resting on the handle side).

5_

Remove the 6 large tapping screws (#10) located around the

perimeter of the door outlining the gasket and the 2 machine

screws (#8)on the hinge side.

2 #8 Machine

Screws

6#10 Large

Screws

2#8 Machine

Screws

Removethe

four screws.

3. Loosen the top screw as shown. Unhook the door bg lifting

and pulling as shown bg the arrows.

6_

With the screws removed, turn the door over and separate

the silver cover part of the door from the door frame and set

aside.

7. Unlock the 4 tabs on the plastic cover and separate the

plastic cover from the frame.

NOTE:Disregard the "DO NOT REMOVE"label on the plastic cover.

//

/ /

/ /

//

/

9

Page 10

Installation Instructions

REMOVE HINGE

IMPORTANT: Note the location of the hinge (left or right) before

removing.

8_

With the door frame part of the door laid down on a

protected soft surface, remove the hinge cover bg removing

the 2 tapping screws (#8) that fasten it to the frame. The

hinge cover is located at the opposite side of the hinge

assemblg_

REINSTALL HINGE ASSEMBLY

11. Place the hinge assemblg in the opposite side of the door.

Align the hinge holes with the door holes.

12. Looselg fasten the hinge assemblg to the edge using

2 machine screws (#8).

cj. Remove the 2 nuts, washers, and the 2 machine screws (#8).

10. Remove the hinge assemblg bg removing the 2 machine

screws (#8) that fasten it to the frame. Pull the hinge

assemblg out and set it aside.

%

l& Hold the door on its side with one hand and fasten the

remaining 2 screws as shown. Then tighten the 2 screws

(#8) holding the hinge assemblg.

1(]

Page 11

Installation Instructions

REINSTALL NUTS AND HINGE COVER

14. Place the door on its edge. Assemble the 2 machine

screws (#8),washers, and nuts. Tighten using a

wrench and screwdriver.

\

1E Placethe hinge cover.in position. Align the hinge cover holes

with the holes in the door.

REASSEMBLE DOOR ASSEMBLY

IMPORTANT: Make sure there is no dirt or ang other foreign

material in between the window panes.

17. Place the plastic cover onto the inner door and lock

in place with the 4 tabs.

18. Place the outer door onto the inner door.

l& Secure the hinge cover with the 2 tapping screws (#8).

/ :

// •/

®

Topof Door

19. After reversing door, there will be a mismatch between the

outer door and the inner door.

Make sure that the handle part of the outer door is opposite

the hinge as shown.

11

Page 12

Installation Instructions

20. Turn the door over and fasten the outer door to the inner

door using the 6 large tapping screws (#!0).

iii,

¢,

MOVE STRIKE BRACKET

21. Using a puttg knife or ang other flat tool, remove the 5

plastic screw caps located on the drger where the door will

be installed and install them on the opposite side.

REINSTALL DOOR ASSEMBLY

23. The door is now readg to be installed on the drger. Toease

this step, the hinge has kegholes that allow a partiallg

fastened screw to be used as a hook.

Partiallg fasten a screw to the uppermost screw hole. Hook

the door on the partiallg fastened screw.

Fasten the hinge bg installing the other 4 screws and

tightening the partiallg fastened screw above.

Partiattg

K

Screws

22. Switch the strike bracket and its cover to the opposite side bg

removing the screws; then reinstall both on the opposite side.

SERVICING

WARNING - LABEL ALL WIRES PRIOR

TO DISCONNECTING WHEN SERVICING

CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION

AFTER SERVICING/INSTALLATION,

For replacement parts and other information, refer to Owner's

Manual for servicing phone numbers.

12

Page 13

ROUGH-IN DIMENSIONS

53 518"

30 518"

40 114"

39 1/8"

13

Page 14

NOTES

Loading...

Loading...