Page 1

Technical

Publications

2208844

Revision 6

CT Legato/Sytec SRi/Synergy Series

Functional Check /Adjustment

Copyright 1997, 1998, 1999, 2003 by General Electric Company

Operating Documentation

Page 2

Page 3

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

WARNING

AVERTISSEMENT

2208844

D THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

D IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A LANGUAGE OTHER

THAN ENGLISH, IT IS THE CUSTOMER’S RESPONSIBILITY TO PROVIDE

TRANSLATION SERVICES.

D DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS SERVICE

MANUAL HAS BEEN CONSULTED AND IS UNDERSTOOD.

D FAILURE

PROVIDER, OPERATOR OR PATIENT FROM ELECTRIC SHOCK,

MECHANICAL OR OTHER HAZARDS.

D CE MANUEL DE MAINTENANCE N’EST DISPONIBLE QU’EN ANGLAIS.

D SI LE TECHNICIEN DU CLIENT A BESOIN DE CE MANUEL DANS UNE AUTRE

LANGUE QUE L’ANGLAIS, C’EST AU CLIENT QU’IL INCOMBE DE LE FAIRE

TRADUIRE.

D NE PAS TENTER D’INTERVENTION SUR LES ÉQUIPEMENTS TANT QUE LE

MANUEL SERVICE N’A PAS ÉTÉ CONSULTÉ ET COMPRIS.

D LE NON-RESPECT DE CET AVERTISSEMENT PEUT ENTRAÎNER CHEZ LE

TECHNICIEN, L’OPÉRATEUR OU LE PATIENT DES BLESSURES DUES À DES

DANGERS ÉLECTRIQUES, MÉCANIQUES OU AUTRES.

T

O HEED THIS W

ARNING

MA

Y RESUL

T IN INJUR

Y T

O THE SER

VICE

WARNUNG

AVISO

D DIESES KUNDENDIENST–HANDBUCH EXISTIERT NUR IN

ENGLISCHER SPRACHE.

D FALLS EIN FREMDER KUNDENDIENST EINE ANDERE SPRACHE BENÖTIGT,

IST ES AUFGABE DES KUNDEN FÜR EINE ENTSPRECHENDE ÜBERSETZUNG

ZU SORGEN.

D VERSUCHEN SIE NICHT, DAS GERÄT ZU REPARIEREN, BEVOR DIESES

KUNDENDIENST–HANDBUCH

WURDE.

D WIRD

D ESTE MANUAL DE SERVICIO SÓLO EXISTE EN INGLÉS.

D SI

D NO SE DEBERÁ DAR SERVICIO TÉCNICO AL EQUIPO, SIN HABER

D LA NO OBSERVANCIA DEL PRESENTE AVISO PUEDE DAR LUGAR A QUE EL

DIESE W

DES KUNDENDIENSTTECHNIKERS, DES BEDIENERS ODER DES PATIENTEN

DURCH ELEKTRISCHE SCHLÄGE, MECHANISCHE ODER SONSTIGE

GEFAHREN KOMMEN.

ALGÚN PROVEEDOR DE SER

QUE NO SEA EL INGLÉS, ES RESPONSABILIDAD DEL CLIENTE OFRECER UN

SERVICIO DE TRADUCCIÓN.

CONSULTADO Y COMPRENDIDO ESTE MANUAL DE SERVICIO.

PROVEEDOR DE SERVICIOS, EL OPERADOR O EL PACIENTE SUFRAN

LESIONES PROVOCADAS POR CAUSAS ELÉCTRICAS, MECÁNICAS O DE

OTRA NATURALEZA.

ARNUNG NICHT BEACHTET

NICHT

ZU RA

TE GEZOGEN UND VERST

, SO KANN

VICIOS AJENO A GEMS SOLICIT

ES ZU VERLETZUNGEN

A UN

ANDEN

IDIOMA

a

Page 4

GE MEDICAL

REV

0

ATENÇÃO

SYSTEMS

CT XMj/XM1500 SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

2208844

D ESTE MANUAL DE ASSISTÊNCIA TÉCNICA SÓ SE ENCONTRA

DISPONÍVEL EM INGLÊS.

D SE QUALQUER OUTRO SERVIÇO DE ASSISTÊNCIA TÉCNICA, QUE NÃO A

GEMS, SOLICITAR ESTES MANUAIS NOUTRO IDIOMA, É DA

RESPONSABILIDADE

D NÃO TENTE REPARAR O EQUIPAMENTO SEM TER CONSULTADO E

COMPREENDIDO ESTE MANUAL DE ASSISTÊNCIA TÉCNICA.

DO CLIENTE

FORNECER OS SER

VIÇOS DE TRADUÇÃO.

AVVERTENZA

D O NÃO CUMPRIMENTO DESTE

DO TÉCNICO, OPERADOR OU PACIENTE DEVIDO A‘ CHOQUES ELÉTRICOS,

MECÂNICOS OU OUTROS.

D IL PRESENTE MANUALE DI MANUTENZIONE È DISPONIBILE

SOLTANTO IN INGLESE.

D SE

UN ADDETT

MANUALE IN UNA LINGUA DIVERSA, IL

DIRETTAMENTE ALLA TRADUZIONE.

D SI PROCEDA ALLA MANUTENZIONE DELL’APPARECCHIATURA SOLO DOPO

AVER CONSULTATO IL PRESENTE MANUALE ED AVERNE COMPRESO IL

CONTENUTO.

D NON TENERE CONTO DELLA PRESENTE AVVERTENZA POTREBBE FAR

COMPIERE OPERAZIONI DA CUI DERIVINO LESIONI ALL’ADDETTO ALLA

MANUTENZIONE, ALL’UTILIZZATORE ED AL PAZIENTE PER

FOLGORAZIONE ELETTRICA, PER URTI MECCANICI OD ALTRI RISCHI.

O ALLA MANUTENZIONE ESTERNO ALLA GEMS RICHIEDE

A

VISO PODE POR EM PERIGO A SEGURANÇA

CLIENTE È TENUT

O A PROVVEDERE

IL

b

Page 5

CT XMj/XM1500 SERIES

GE MEDICAL

REV

0

SYSTEMS

FUNCTIONAL

CHECK /

ADJUSTMENT

2208844

IMPORTANT! . . . X-RAY PROTECTION

X-ray

equipment if not properly used may cause injury

be

thoroughly read and understood by everyone who will use the equipment before you attempt to place this

equipment in operation. The General Electric Company, Medical Systems Group, will be glad to assist and

cooperate in placing this equipment in use.

. Accordingly

, the instructions

herein contained should

Although this apparatus incorporates a high degree of protection against

practical design of equipment can provide complete protection. Nor can

take adequate precautions to prevent the possibility of any persons carelessly exposing themselves or others to

radiation.

It

is important that everyone having anything to do with x-radiation be properly trained and fully acquainted with the

recommendations

available from NCRP Publications, 7910 Woodmont Avenue, Room 1016, Bethesda, Maryland 20814, and of the

International

The

equipment is sold with the understanding that

and representatives have no responsibility for injury or damage which may result from improper use of the equipment.

Various

protective material and devices are available. It is urged that such materials or devices be used.

of

the National Council on Radiation Protection and Measurements as published in NCRP Reports

Commission on Radiation Protection, and take adequate steps to protect against injury

the General Electric Company

x-radiation other than the useful beam, no

any practical design compel the operator to

.

, Medical Systems Group, its agents,

All electrica

performed by l

b

y l

icense

b

e p

highly sophisticated

d e

erforme

l i

nstallation

icense

lectrica

d b

y q

d e

l c

ualifie

, a

ontractors

nd specia

s that are p

lectrica

l c

d GE M

edica

l e

reliminar

ontractors

. O

the

ngineering competenc

r c

onnection

l p

ersonnel

y t

. I

o p

ositionin

n a

ddition

. The p

s b

g o

, e

lectrica

etwee

roduct

e i

f the e

quipmen

l f

eed

n p

iece

s o

s i

nvolve

s required.

t a

t the site p

s into the P

f e

lectrica

l e

d (and the a

repare

owe

r D

istributio

quipment

ccompanyin

d for the e

n Unit s

, c

alibrations

g e

lectrica

quipmen

hal

l b

e p

, and t

estin

l i

nstallations

t s

hal

l b

erformed

g s

hall

) a

re

e

In performin

work

The purchaser of GE equipment shall only utiliz e qualified personnel (i.e., GE’s field engineers, personnel of thir d-party

service companies wit

on t

hes

g all e

e p

roducts wil

lectrica

h e

l work o

l c

omply wit

quivalen

n t

hes

t t

raining

e p

roducts, GE will use its own s

h the r

equirements o

, o

r l

icense

f the a

d e

lectricians) t

c

peciall

pplicabl

o p

e e

erfor

y t

raine

lectrica

m e

lectrica

d f

l c

iel

d e

odes.

l s

ngineers

ervicin

. All o

g on the e

f GE’s e

quipment.

lectrical

Page 6

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

2208844

DAMAGE IN TRANSPORTATION

All packages should be closely examined at time of delivery. If damage is apparent, have notation “damage in

shipment”

Electric representative or a hospital receiving agent. Whether noted or concealed, damage

carrier immediately

for inspection by the carrier

within

Call Traf

this time be ready to supply name of carrier, delivery date, consignee name, freight or express bill number, item

damaged

Complete instructions regarding claim procedure are found in Section “S” of the Policy & Procedure Bulletins.

written on

this 14 day period.

fic and T

and extent of damage.

all

upon discovery

ransportation, Milwaukee, WI (414) 827–3449

copies of the freight or express bill

, or in any event, within 14 days after receipt, and the contents and containers held

. A transportation company will

not

before

delivery is accepted or

pay a claim for damage if an inspection is not requested

/ 8*285–3449

immediately

“signed for” by a General

MUST

be reported to the

after damage is found. At

OMISSIONS & ERRORS

GE

personnel, please use the GEMS CQA Process to report all omissions, errors, and defects in this documentation.

Customers,

please contact your GE Sales or Service representatives.

CAUTION

Do not use the following devices near this equipment. Use of these devices near this equipment could cause

this equipment to malfunction.

Devices not to be used near this equipment:

Devices

radio–controlled toy

Keep power to these devices turned of

Medical staff in charge of this equipment is required to instruct technicians, patients and other people who may be

around

which intrinsically transmit radio

, etc.

this equipment to fully comply with the above regulation.

waves such as; cellular phone, radio transceiver

f when near this equipment.

, mobile radio transmitter

,

d

Page 7

CT XMj/XM1500 SERIES

GE MEDICAL SYSTEMS FUNCTIONAL CHECK / ADJUSTMENT

REV 6

2208844

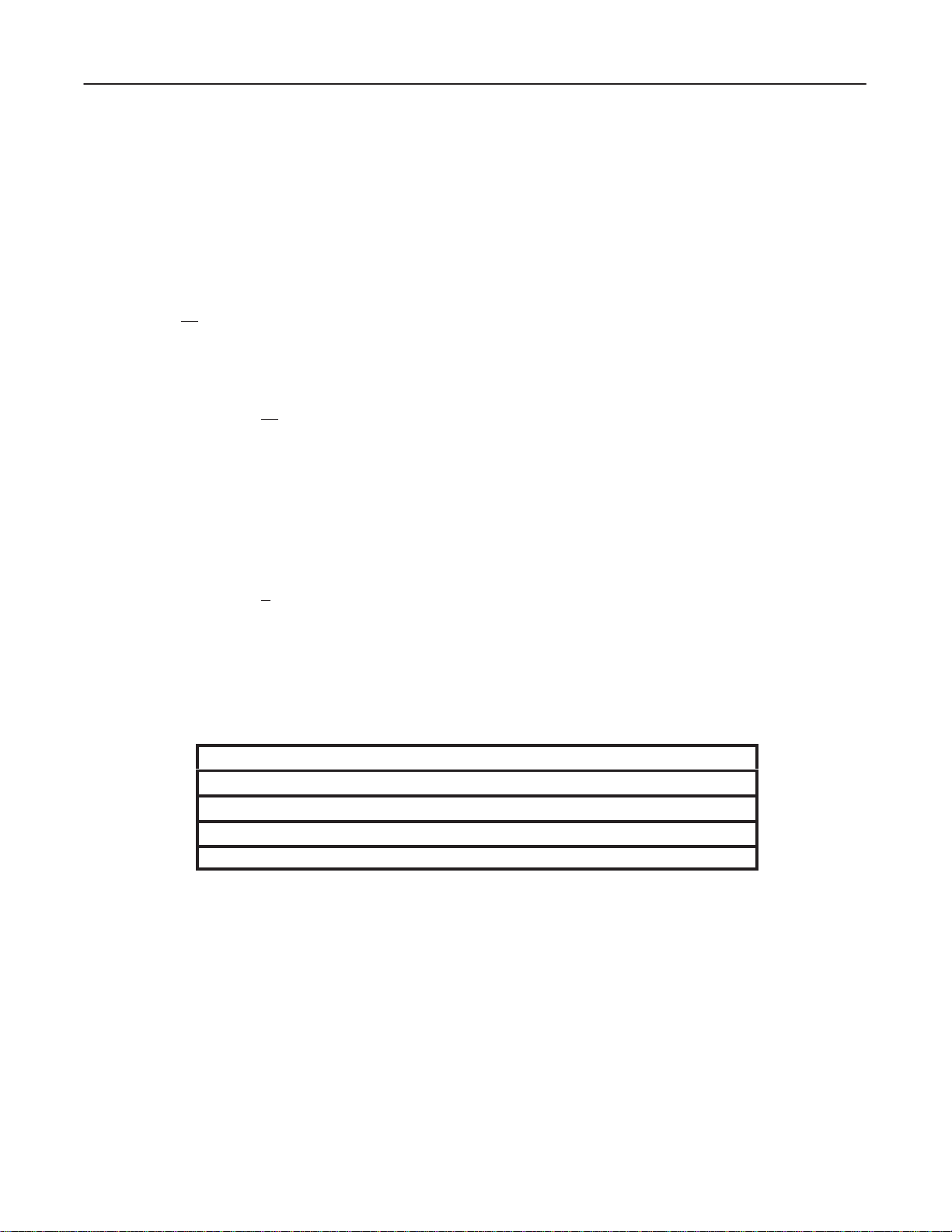

REVISION HISTORY

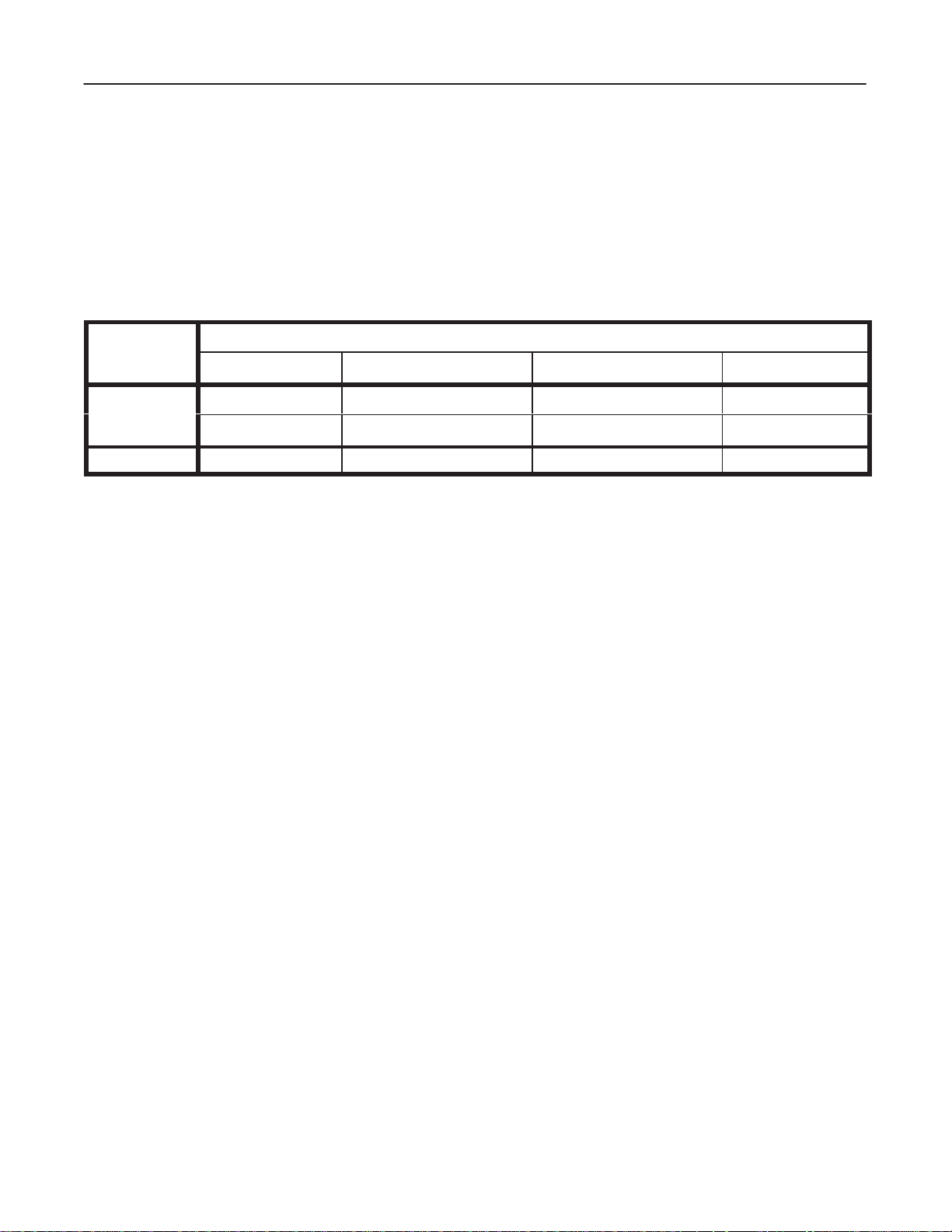

REV DATE PRIMARY REASON FOR CHANGE

0 Jan. 21, 1998 Initial release..

. . . .

1 Mar. 20, 1998 Error correction and additional information about Autovoice Adjustment for Synergy..

. . . .

2 Jul. 28, 1998 Error correction and additional information about Monitor Adjustment for Synergy..

. . . . .

3 Feb. 26, 1999 Error correction, System Setting for Raw Data File No..

. . . .

4 Jun. 07, 1999 Error correction, TGP reset function..

. . . .

5 Dec. 20, 1999 Error correction.

. . . .

6 Feb. 4, 2003 Added: FDD Jumper setting (Tab 8, sec 1).

. . . . .

PAGE REV PAGE REV PAGE REV PAGE REV PAGE REV

Title page 6.

Title

a to d 0.

A6

. . . . . . . . . . . . . . . . .

B blank

. . . . . . . . . . . . .

i to ii 0.

Tab

i0.

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–6 0.

2–1 to 2–5 0.

2–6 blank

Tab

i to ii 0.

1–1 to 1–15 0.

1–16 blank

1–17 to 1–35 0.

1–36 blank

2–1 to 2–9 0.

2–10 3

2–11 to 2–32 0.

. . . . . . . .

page rear

. . . . . . . . . . . .

. . . . . . . . . . . . .

1 (Introduction)

. . . . . . . . . . .

2 (System)

. . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . .

blank.

. . . . . . . .

. . . . . . . .

. . . . . . .

. . . . .

. . . . . . . .

. . . . . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

LIST

3–1 to 3–9 0.

3–10 3

3–11 to 3–26 0.

4–1 0

4–2 5

4–3 0

4–4 blank

5–1 to 5–23 0.

5–2 2

5–3 to 5–6 0.

5–7 2

5–8 to 5–23 0.

5–24 blank

6–1 to 6–35 0.

6–36 blank

7–1 to 7–16 0.

8–1 to 8–3 0.

8–4 blank

8–5 3

8–6 blank

8–7 3

8–8 blank

8–9 to 8–15 0.

8–16 blank

. . . . . . . .

. . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . .

. . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . .

. . . . . . . . . .

OF EFFECTIVE P

9–1 to 9–11 0.

9–12 blank

Tab

3 (Operator Con

sole)

i2.

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–7 0.

1–8 blank

. . . . . . . . . . .

2–1 to 2–6 0.

2–7 2

. . . . . . . . . . . . . . .

2–8 to 2–9 0.

2–10 to 2–26 2.

3–1 to 3–10 0.

3–11 1

3–12 to 3–13 0.

3–14 blank

Tab

4 (Gantry)

i0.

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–10 0.

2–1 to 2–20 0.

. . . . . . .

. . . . . . . . . .

-

. . . . . . . .

. . . . . . . .

. . . . . . . .

. . . . .

. . . . . . .

. . . . . . . . . . . . . .

. . . . .

. . . . . . . . . .

. . . . . . .

. . . . . . .

AGES

3–1 to 3–5 0.

3–6 4

3–7 to 3–10 0.

4–1 0

4–2 blank

5–1 to 5–10 0.

6–1 to 6–13 0.

6–14 blank

7–1 to 7–30 0.

Tab

i0.

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–10 0.

2–1 to 2–12 0.

3–1 to 3–2 3.

Tab

i1.

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–4 0.

2–1 to 2–12 0.

2–13 to 2–21 1.

. . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . .

5 (T

able)

. . . . . . .

. . . . . . .

. . . . . . . .

6 (DAS/Detector)

. . . . . . . .

. . . . . . .

. . . . .

2–22 blank

. . . . . . . . . .

Tab 7 (X–ray Generator)

i0.

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–14 0.

2–1 to 2–11 0.

2–12 blank

3–1 to 3–8 0.

Tab

8 (Switch/Jump

er Setting of Boards/

Devices)

i0.

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–56 6.

2–1 to 2–7 0.

2–8 blank

. . . . . . . . . . .

3–1 to 3–6 0.

4–1 to 4–4 0.

5–1 0

. . . . . . . . . . . . . . .

5–2 blank

. . . . . . . . . . .

. . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . . .

. . . . . . .

. . . . . . . .

. . . . . . . .

. . . . . . . .

-

A

Page 8

CT XMj/XM1500 SERIES

GE MEDICAL SYSTEMS FUNCTIONAL CHECK / ADJUSTMENT

blank

2208844

B

Page 9

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

CONTENTS

INTRODUCTION (T

Section 1 – General

Section 2 – T

SYSTEM (T

AB 2)

Section 1 – Checks during System Installation

Section 2 – Software Loading (V2.02)

Section 3 – Software Loading (V3.00)

Section 4 – Software Loading (V3.01)

Section 5 – Software Loading

Section 6 – X–ray Alignment

Section 7 – System Calibration

Section 8 – Image Performance V

Section 9 – Network

AB 1)

orque V

alue for Screw T

2208844

ightening

erification

OPERATOR CONSOLE (T

Section 1 – OC Operation

Section 2 – OC Components

Section 3 – Diag T

GANTR

Y (TAB 4)

Section 1 – DC Power Supplies

Section 2 – Rotational Mechanism

Section 3 – Rotational Operation

Section 4 – Slip Rings and Brushes

Section 5 – Collimator

Section 6 – T

Section 7 – T

ilt Operation

able and Gantry

AB 3)

est

i

Page 10

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

CONTENTS (continued)

TABLE (T

DAS/DETECTOR (T

X–RA

AB 5)

Section 1 – Elevation Function

Section 2 – Longitudinal Function

Section 3 – T

Section 1 – Detector Related Devices

Section 2 – DAS Operation

Y GENERA

Section 1 – X–ray T

Section 2 – KV and mA

Section 3 – PDU

able Accessories

AB 6)

TOR (T

AB 7)

ube

2208844

SWITCH/JUMPER SETTING OF BOARDS/DEVICES (T

Section 1 – Operator Console

Section 2 – Gantry

Section 3 – X–ray Generator

Section 4 – DAS

Section 5 – PDU

AB 8)

ii

Page 11

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

INTRODUCTION

TABLE OF CONTENTS

SECTION PAGE

SECTION

1 – GENERAL

1-1 ABOUT THIS MANUAL 1–1.

1-2 GENERAL WARNING/CAUTION/NOTICE 1–4.

1-2-1 Gantry 1–4

1-2-2 Operator Console 1–5.

1-3 CE MARKING LABEL (LGT, SRI) 1–6

1-4 CE MARKING LABEL (SNG) 1–6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1.

2208844

SECTION

2 – T

ORQUE V

2-1 NORMAL SCREWS 2–2.

2-2 HEXAGON SCREWS 2–5.

ALUE FOR SCREW TIGHTENING

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1.

INTRODUCTIONi

Page 12

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

blank

2208844

INTRODUCTIONii

Page 13

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

INTRODUCTION

TABLE OF CONTENTS

SECTION PAGE

SECTION

1 – GENERAL

1-1 ABOUT THIS MANUAL 1–1.

1-2 GENERAL WARNING/CAUTION/NOTICE 1–4.

1-2-1 Gantry 1–4

1-2-2 Operator Console 1–5.

1-3 CE MARKING LABEL (LGT, SRI) 1–6

1-4 CE MARKING LABEL (SNG) 1–6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1.

2208844

SECTION

2 – T

ORQUE V

2-1 NORMAL SCREWS 2–2.

2-2 HEXAGON SCREWS 2–5.

ALUE FOR SCREW TIGHTENING

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1.

INTRODUCTIONi

Page 14

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

blank

2208844

INTRODUCTIONii

Page 15

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

DEATH

READ AND THOROUGHLY UNDERSTAND THE ‘PREINSTALLATION/SAFETY GUIDELINES’

MANUAL (2111460) BEFORE PERFORMING ANY PROCEDURE IN THIS ‘FUNCTIONAL

CHECK/ADJUSTMENT.’

1-1 ABOUT

OR SERIOUS INJUR

THIS MANUAL

2208844

SECTION 1 – GENERAL

WARNING!

Y!!

Before Using This Manual

This CT system is especially dangerous because its weighty Gantry continuously rotates at high speeds with high

power

electric current (550 ∼ 750 VDC) conducted through its slip rings.

The

hazards, although sometimes obvious, need to be recognized since the potential for serious injury or death exists.

INTRODUCTION1–1

Page 16

CT XMj/XM1500 SERIES

GE MEDICAL

REV

0

1-1 ABOUT THIS MANUAL (continued)

CT Products to Which This Manual Applies to:

This ‘Functional Check/Adjustment’ manual is used for CT products listed in the table below:

T

able 1–1

SYSTEMS

Product Name and Code Name

FUNCTIONAL

CHECK /

ADJUSTMET

2208844

Code Name

GEMS–AM GEMS–E GEMS–A GEYMS

LGT

, SRI

SNG Sytec Synergy Sytec Synergy Sytec Synergy –

Each of the code names represents a product family; for example, Legato, Legato Duo, and Sytec SRi constitute a

product family

In this manual, product names (Legato, Sytec SRi, ...) or product family names (i.e., code

used to indicate some sections, illustrations, or other types of information which are only applied to those products

indicated.

, called ‘LGT

Sytec SRi Sytec SRi Sytec SRi

– – –

, SRI.’

Product Name

Legato Duo

names; LGT

Legato

, SRI, ...) are

INTRODUCTION1–2

Page 17

GE MEDICAL

REV

0

1-1 ABOUT THIS MANUAL (continued)

Use of This Manual

Use this ‘Functional Check/Adjustment’ for the following purposes:

SYSTEMS

D

A during– and post–installation check to ensure that the entire system operates properly

D

As a reference source for Periodic Maintenance which mainly contains abbreviated lists.

D

A post–FMI (Field Modification Instruction) check to verify system operation.

D

A pre–diagnostic check to verify or determine failure symptoms before or during troubleshooting.

D A

post–diagnostic check to verify system operation after repairs, before returning it to the customer to use.

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

2208844

.

INTRODUCTION1–3

Page 18

GE MEDICAL

REV

0

1-2

GENERAL W

1-2-1 Gantry

ROTATION AND ELECTROCUTION HAZARDS!

SWITCH

OF THE GANTRY BASE BEFORE INSERTING ANY OBJECT INTO OR WORKING ON THE

GANTRY.

SYSTEMS

ARNING/CAUTION/NOTICE

OFF THE ‘ROTATE’ AND ‘XG

FUNCTIONAL

WARNING!

(SAFETY LOOP)’ SWITCHES LOCA

WARNING!

CT XMj/XM1500 SERIES

CHECK /

TED A

T THE REAR

ADJUSTMET

2208844

ROTATION HAZARD!

ALWAYS

DETECT

INSERT THE GANTR

OR, HV T

ANK, OR OTHER WEIGHTY COMPONENTS.

Y AZIMUTH LOCK PIN BEFORE REPLACING THE TUBE, DAS,

WARNING!

ELECTROCUTION!

DANGEROUS VOLTAGES ARE PRESENT ON UNSHIELDED TERMINALS. USE EXTREME

CAUTION

WHEN WORKING ON LIVE EQUIPMENT

.

WARNING!

ROTATION HAZARD!

ANY OF THE FOLLOWINGS WILL INITIATE THE GANTR

1. POWERING ON THE SYSTEM OR GANTR

2. SWITCHING ON THE ‘CONTROL

3. PUSHING THE RESET SWITCH ON THE TGP BOARD.

4. PUSHING THE POSITIONING LIGHT BUTT

STAND CLEAR OF THE ROTATING GANTRY.

’ SWITCH.

Y.

ON.

Y ROT

ATION:

INTRODUCTION1–4

Page 19

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

1-2-2

Operator Console

WARNING!

ELECTRICAL SHOCK HAZARD!

DANGEROUS VOLTAGES EXIST ON EXPOSED SURFACES. USE EXTREME CAUTION

WHEN

Rotating fan assemblies!

Do

WORKING ON LIVE EQUIPMENT

.

CAUTION

not place any item into rotating blades. Use extra care when working near fan assemblies.

NOTICE

2208844

Turn

OFF power before removing or inserting any board or plug.

INTRODUCTION1–5

Page 20

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

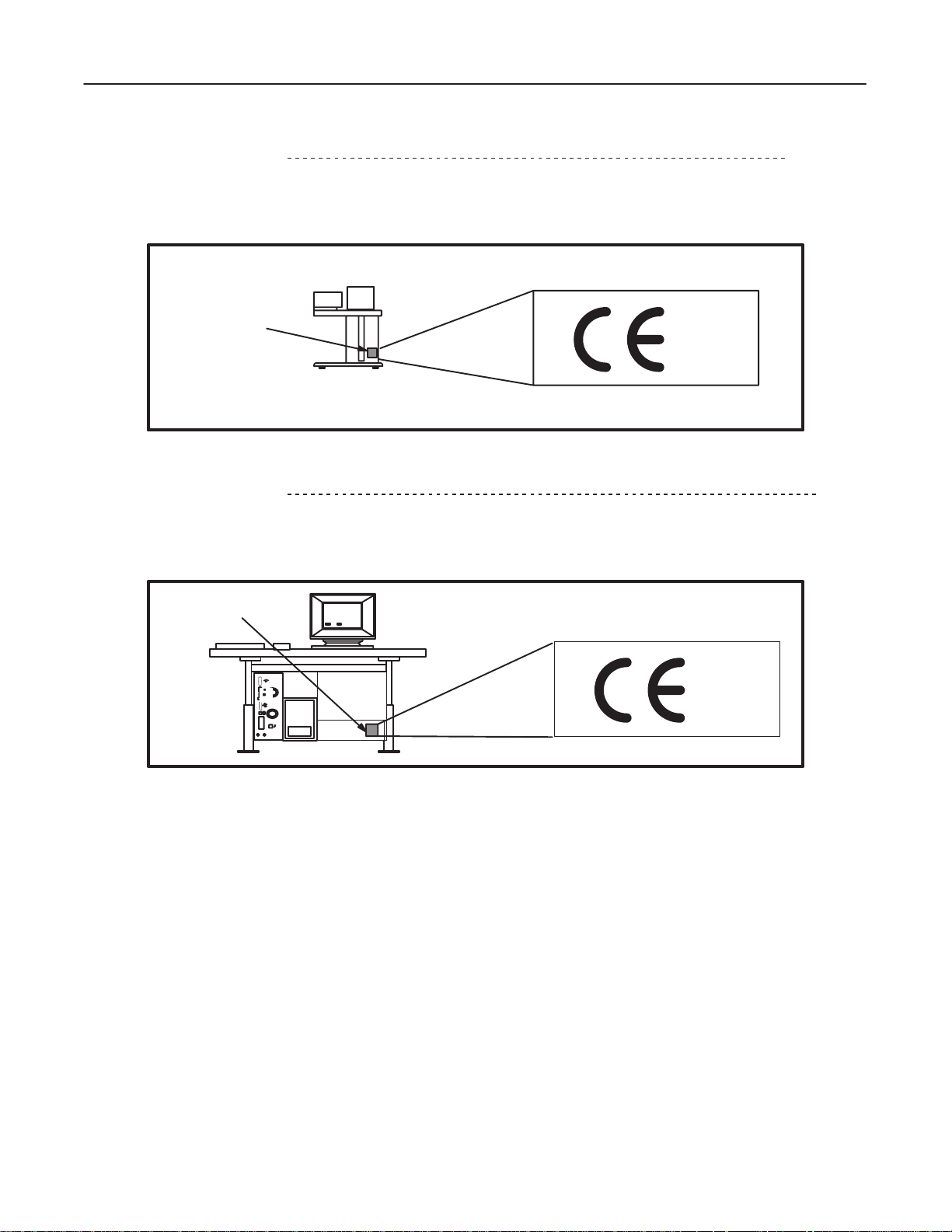

1-3

CE MARKING LABEL

This CT system is either an EMC model, or non–EMC model. (EMC: Electromagnetic Compatibility)

For

the EMC

models, a ‘CE Marking Label’ is attached on the rear side of the Operator Console, near its rating plate.

CE MARKING

LABEL

0459

OC

REAR

VIEW

1-4

CE MARKING LABEL

This CT system is either an EMC model, or non–EMC model. (EMC: Electromagnetic Compatibility)

For

the EMC

models, a ‘CE Marking Label’ is attached on the rear side of the Operator Console, near its rating plate.

2208844

(LGT

, SRI)

(SNG)

CE MARKING

LABEL

OC REAR VIEW

0459

INTRODUCTION1–6

Page 21

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

2208844

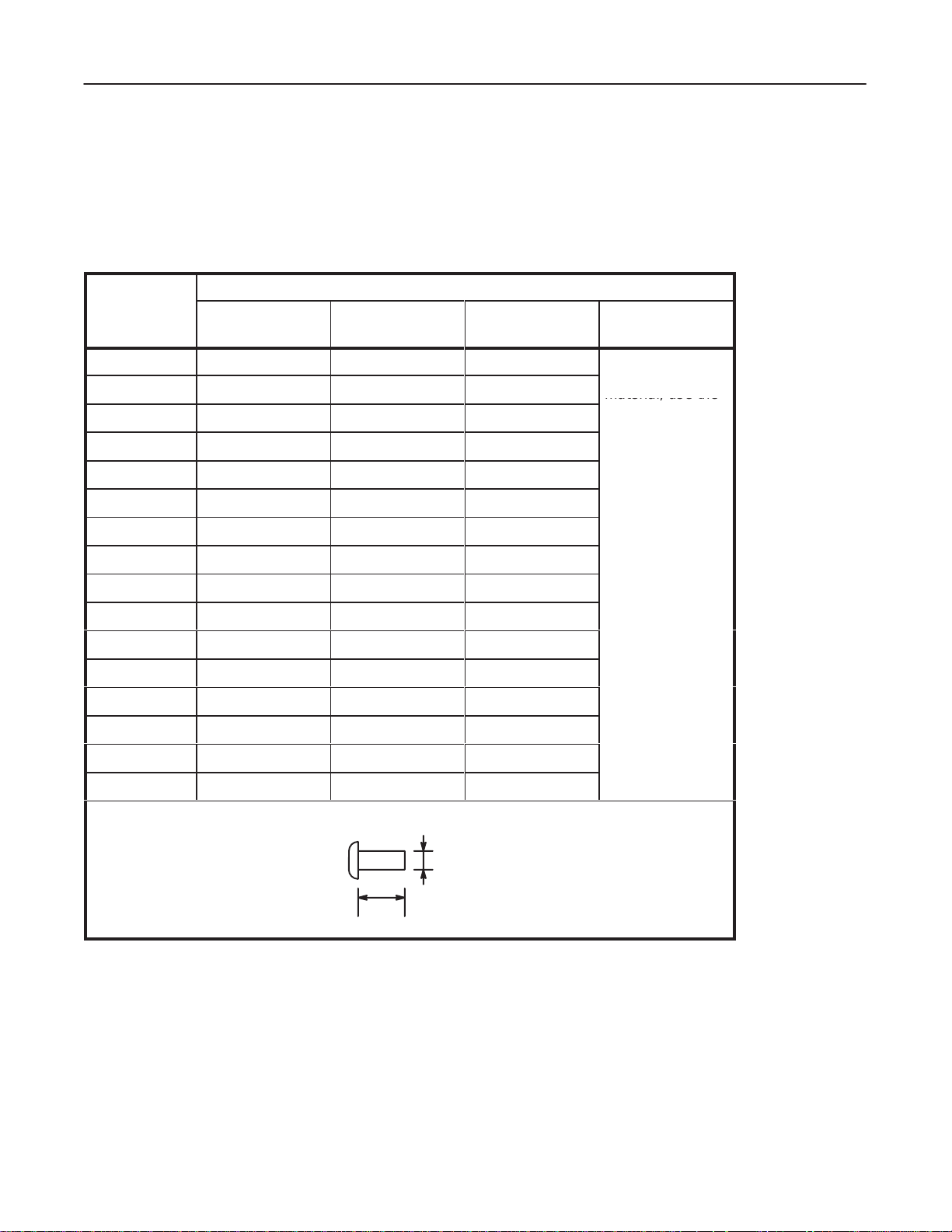

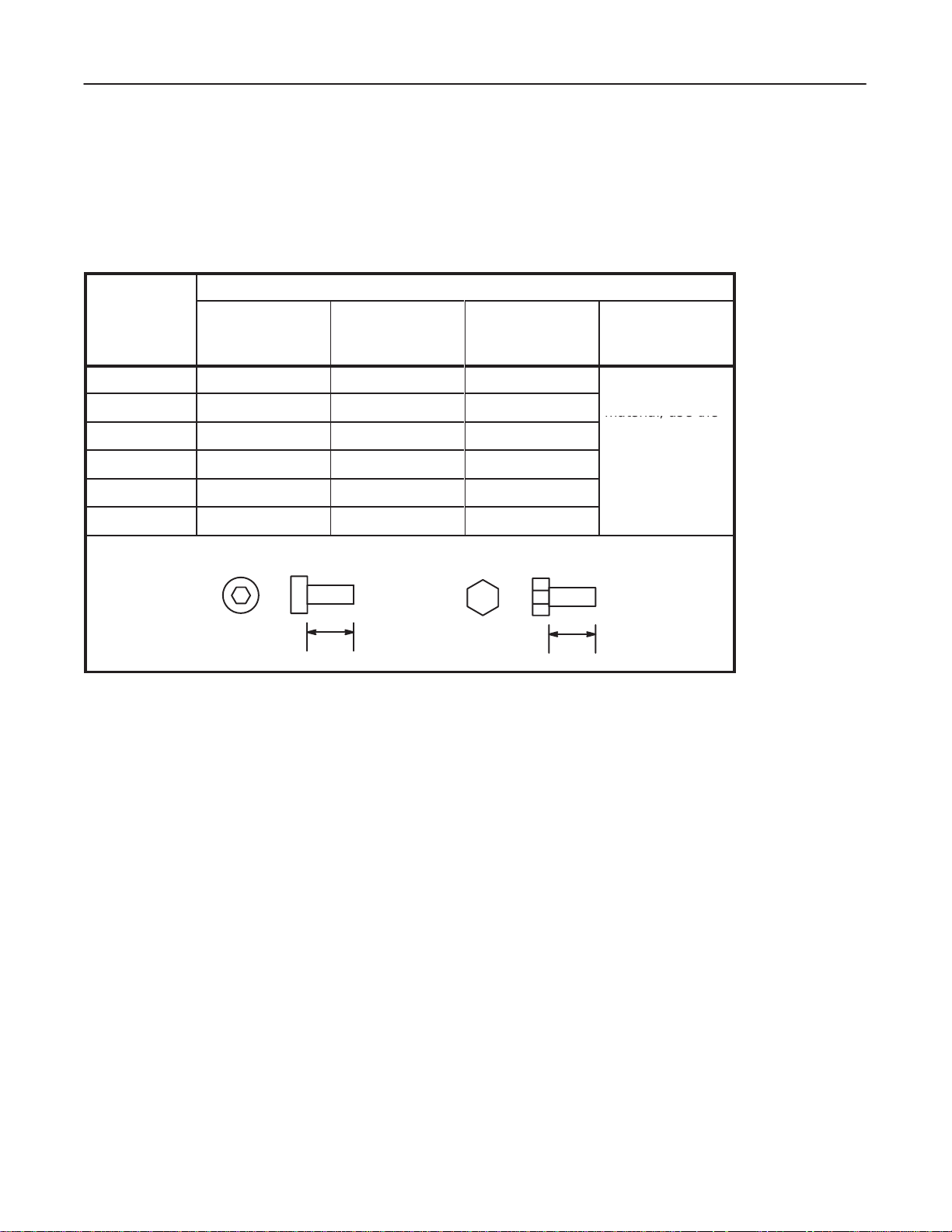

SECTION 2 – TORQUE VALUE FOR SCREW TIGHTENING

CAUTION

Use locktite for screws which are installed to the Gantry rotation block. Use stud bolt with

locktite

When you secure stud bolts with locktite, you must keep the screw torque shown in Table

‘Stud Bolt (Steel) with Locktite.’

Do

100

or nylon nut to prevent loosening if a screw is removed in service maintenance.

CAUTION

not rotate the Gantry until the locktite hardens.

% after 16 hours.)

(75 % of maximum strength after 2 hours;

If it is not possible to wait for the time period mentioned above, use nylon nuts.

T

ABLE 2–1

Screw Size

M 4

M 5

M 6

M 8

*Unless otherwise specified

UNIT

Kg–cm

Stud Bolt (Steel) with Locktite

Torque [kg–cm]

(Unless other

wise specified)

10

15

35

70

-

INTRODUCTION2–1

Page 22

GE MEDICAL

material, use the

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

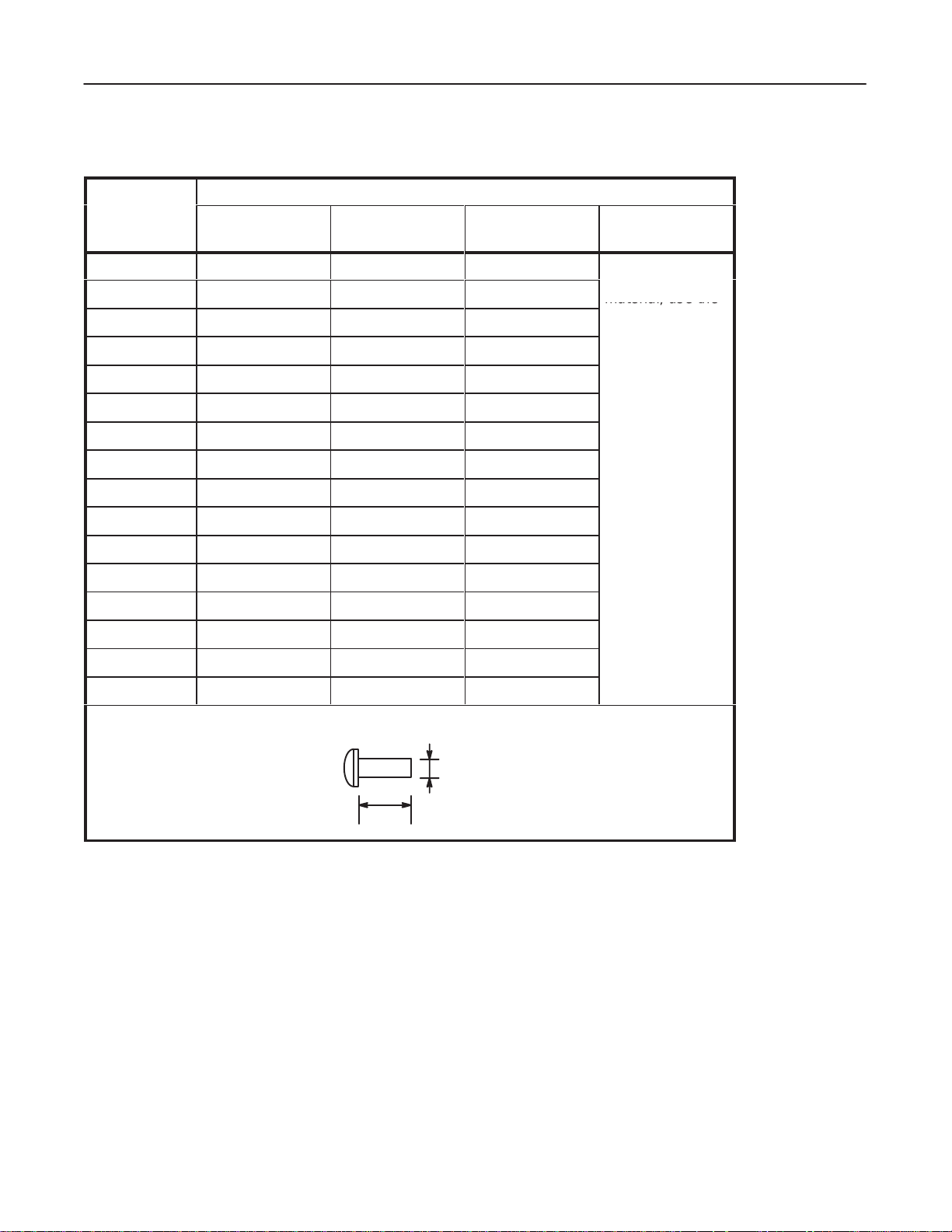

2-1

NORMAL SCREWS

Secure normal screws with the tightening torque shown in the following tables

T

ABLE 2–2

Screw Size

M 1

M 1.2

M 1.4

M 1.7

M 2

M 2.2

M 2.3

Pan Head Screw

T

orque [kg–cm] (Unless otherwise specified)

Brass

(Screw & Nut)

Steel (4.8)

(Screw & Nut)

0.17 0.18 0.22

0.32 0.34 0.42

0.49 0.52 0.65

0.90 0.96 1.2

1.5 1.6 1.9

1.9 2.0 2.5

2.3 2.5 3.1

Stainless

(Screw & Nut)

If screw and nut

are of dif

material, use the

weakest torque.

unless otherwise specified

(Combination)

ferent

2208844

.

M 2.5

M 2.6

M 3

M 3.5

3.0 3.2 4.0

3.4 3.6 4.5

5.3 5.7 7.1

8.2 8.7 11

M 4

M 4.5

M 5

M 6

M 8

*Unless otherwise specified

UNIT

Kg–cm

17.5 19 23.5

24.5 26.5 33

41.5 44 55

101 108 135

12 13 16

Style

M

L

INTRODUCTION2–2

Page 23

GE MEDICAL

material, use the

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

Screw Size

M 1

M 1.2

M 1.4

M 1.7

M 2

M 2.2

M 2.3

M 2.5

M 2.6

M 3

M 3.5

T

ABLE 2–3

Binder Screw

T

orque [kg–cm] (Unless otherwise specified)

Brass

(Screw & Nut)

Steel (4.8)

(Screw & Nut)

– – –

– – –

– – –

– – –

1.6 1.7 2.1

2.0 2.2 2.7

2.5 2.7 3.4

3.2 3.4 4.2

3.6 3.9 4.8

5.6 6.0 7.5

8.7 9.3 11.5

Stainless

(Screw & Nut)

(Combination)

If screw and nut

are of dif

ferent

material, use the

weakest torque.

2208844

M 4

M 4.5

18.5 20 25

M 5

M 6

M 8

*Unless otherwise specified

UNIT

Kg–cm

107 114 143

13 13.5 17

26 27.5 34.5

44 47 58.5

Style

M

L

INTRODUCTION2–3

Page 24

GE MEDICAL

material, use the

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

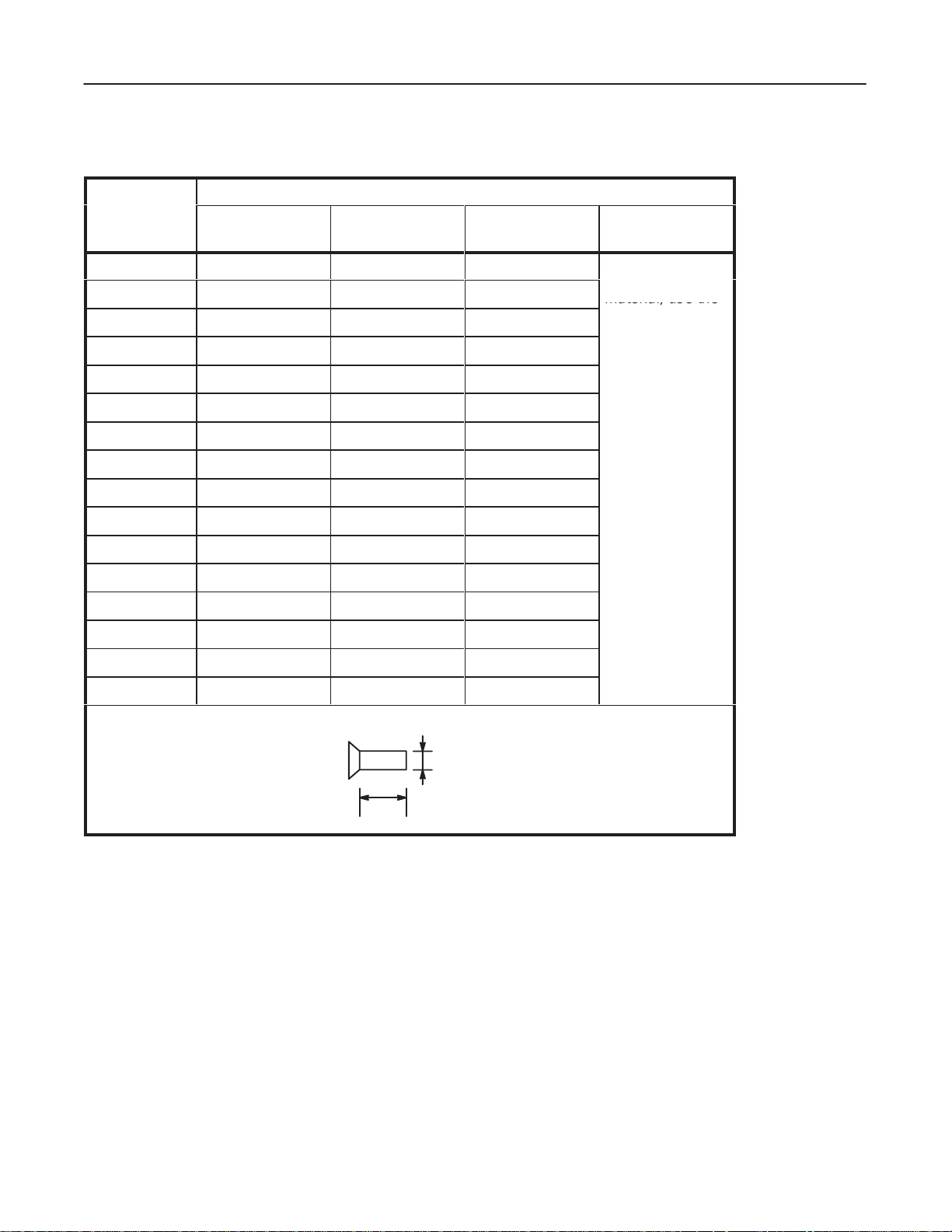

Screw Size

M 1

M 1.2

M 1.4

M 1.7

M 2

M 2.2

M 2.3

M 2.5

M 2.6

M 3

M 3.5

T

ABLE 2–4

Flat Head Screw

T

orque [kg–cm] (Unless otherwise specified)

Brass

(Screw & Nut)

Steel (4.8)

(Screw & Nut)

0.21 0.22 0.27

0.39 0.42 0.52

0.61 0.65 0.82

1.1 1.2 1.5

1.9 2.0 2.5

2.4 2.6 3.2

3.0 3.2 4.0

3.8 4.1 5.1

4.4 4.6 5.8

6.8 7.2 9.0

10.5 11 14

Stainless

(Screw & Nut)

(Combination)

If screw and nut

are of dif

ferent

material, use the

weakest torque.

2208844

M 4

M 4.5

M 5

15.5 16.5 20.5

22.5 24 30

31.5 33.5 42

M 6

M 8

*Unless otherwise specified

UNIT

Kg–cm

130 139 173

53 56.5 71

Style

M

L

INTRODUCTION2–4

Page 25

GE MEDICAL

material, use the

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

REV 0

2-2

HEXAGON SCREWS

T

ighten allen (hexagonal) screws with the torque shown in T

T

ABLE 2–5

Screw Size

M 4

M 5

M 6

M 8

M 10

M 12

Hexagon Screw

T

orque [kg–cm] (Unless otherwise specified)

Ferrite

(Screw & Nut)

Aluminum

(Screw & Nut)

35 28 17.5

70 56 35

117 96.3 58.5

285 228 142.5

563 450.4 281.5

976 780.8 488

able below

unless otherwise specified

Aluminum Steel

Alloy

(Screw & Nut)

(Combination)

If screw and nut

are of dif

ferent

material, use the

weakest torque.

2208844

.

Style

*Unless otherwise specified

UNIT

Kg–cm

or

L

L

INTRODUCTION2–5

Page 26

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMET

blank

2208844

INTRODUCTION2–6

Page 27

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

SYSTEM

TABLE OF CONTENTS

SECTION PAGE

SECTION

1 – CHECKS DURING SYSTEM INST

1 GROUND CONTINUITY 1–1.

2 LOAD DISTRIBUTION 1–1.

2–1 PDU:2108024/2108025 (LGT, SRI) 1–2.

2–2 PDU:2108024/2108025 (SNG) 1–9.

2–3 2121798 PDU (LGT, SRI) 1–11.

2–4 2121798 PDU (SNG) 1–14.

3 GANTRY ROTATION CHECK 1–17.

4 EMERGENCY OFF TEST 1–18.

5 X–RAY TUBE OVERHEAT SAFETY 1–22.

6 X–RAY TUBE OIL 1–24.

7 FANS 1–26

8 FILTER 1–27

9 SCAN TEST (LGT, SRI) 1–28.

10 SCAN TEST (SNG) 1–31.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALLATION 1–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2208844

SECTION

SECTION

SECTION

2 – SOFTW

1 GENERAL 2–1.

2 FLOPPY DISKS FOR SYSTEM/OPTION SOFTWARE 2–3.

3 PRE–ATINST PROCEDURE 2–5.

4 SOFTWARE LOADING (ATINST) 2–15.

5 POST–ATINST PROCEDURE 2–21.

3 – SOFTW

1 GENERAL 3–1.

2 FLOPPY DISKS FOR SYSTEM/OPTION SOFTWARE 3–3.

3 PRE–ATINST PROCEDURE 3–5.

4 SOFTWARE LOADING (ATINST) 3–15.

5 POST–ATINST PROCEDURE 3–21.

4 – SOFTW

1 GENERAL 4–1.

2 SOFTWARE LOADING 4–2.

ARE LOADING (V2.02)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARE LOADING (V3.00)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARE LOADING (V3.01)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(LGT

, SRI)

. . . . . . . . . . . . . . . . . . . . . . . .

(LGT

, SRI)

. . . . . . . . . . . . . . . . . . . . . . . .

(LGT

, SRI)

2–1

3–1

4–1

SYSTEMi

Page 28

GE MEDICAL

REV

0

SECTION PAGE

SYSTEMS

TABLE OF CONTENTS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

SECTION

SECTION

SECTION

SECTION

5 – SOFTW

1 GENERAL 5–1.

2 DATA SAVE 5–2.

3 HARDWARE SETTING 5–5.

4 SOFTWARE LOADING 5–7.

5 DATA RESTORE 5–20.

6 – X–RA

1 GENERAL 6–1.

2 PLANE OF ROTATION 6–5.

3 DETECTOR BEAM–ON–WINDOW 6–11.

4 GRAVITY SAG 6–17.

5 ISO CENTER ALIGNMENT 6–24.

6 FILTER CENTER ALIGNMENT 6–30.

7 – SYSTEM CALIBRA

1 GENERAL 7–1.

2 CAM AMPLIFIER LINEARITY CHECK (X–RAYS) (LGT, SRI) 7–3

3 AIR AND PHANTOM CALIBRATIONS (LGT, SRI) 7–7

4 CT NUMBER ADJUSTMENT (LGT, SRI) 7–9

5 CAL + AUTO CT NUMBER ADJUSTMENT (SNG) 7–13

6 AUTO CT NUMBER ADJUSTMENT (SNG) 7–16

8 – IMAGE PERFORMANCE VERIFICA

1 IMAGE PERFORMANCE (LGT, SRI) 8–1

2 IMAGE PERFORMANCE (SNG) 8–9

ARE LOADING (SNG) 5–1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y ALIGNMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TION 7–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TION 8–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–1.

SECTION

9 – NETWORK

1 GENERAL (SNG) 9–1

2 COMMUNICATION DATA HANDLING (SNG) 9–1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9–1.

SYSTEMii

Page 29

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

SECTION 1 – CHECKS DURING SYSTEM INSTALLATION

1. GROUND

Refer

to Section 4, Ground Continuity Check, of the Installation tab of the Installation/Component Replacement manu

al

(2111461 or 2121807).

2. LOAD DISTRIBUTION

ELECTROCUTION! DANGEROUS VOLTAGES EXIST WITHIN THE UNITS, USE EXTREME

CARE TO A

CONTINUITY

VOID INJUR

WARNING!

Y T

O PERSONNEL AND EQUIPMENT

.

2208844

-

CAUTION

Leave all power to the system OFF and tagged until power is called for in specific steps.

Follow the steps below

Follow this sequence to protect you and the equipment from irreparable damage.

PDU Model

Select a correct PDU model from the menu which your system includes.

exactly

in the order they are written. This procedure is developed with your safety in mind.

SYSTEM1–1

Page 30

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

2–1.

PDU:2108024/2108025

1. Preparation.

a. V

erify that all the breakers and switches listed below are set to OFF

Breaker on the Power Distribution Box (hospital supply).

Breaker (SW20) on the PDU

Five switches (‘Rotate,’ ‘XG,’ ‘T

Servo Amp. breaker

Service switch on the Sub Board on the Gantry

SYS/OFF/MNL switch on the TGP Board on the Gantry

T

wo breakers (NFB1, NFB2) on the OC See Illustration.2.

b.

Remove the front panel from the PDU.

c.

Remove the top cover from the OC.

able/T

ilt,’ ‘Control,’ and ’Slip Ring 1

.

15V’) at the Gantry rear base

2208844

(LGT

, SRI)

d.

Remove the left side cover from the Gantry

2.

Switch ON two breakers (NFB1, NFB2) on the OC.

3.

Switch ON the breaker on the Power Distribution Box (hospital supply).

4.

Switch ON the SW20 breaker on the PDU.

V

erify that the ‘Power

’ lamp on the front upper left corner of the PDU turns ON.

.

SYSTEM1–2

Page 31

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

5.

Measure 1

It should be

6.

Switch ON the ‘Slip Ring 1

Verify

15 V

AC between terminals 15 and 16 on TB37 on the PDU.

103.5 ~ 126.5 VAC. See Illustration.1.

15V (DAS/DET)’ switch at the Gantry rear base.

that the x–ray generator on the rotating assembly is powered ON, and that the x–ray tube fan and pump

start to operate.

7.

Push the ‘Power

V

erify that the voltage between terminals 1

8.

Measure

9. V

erify that the Servo Amp. breaker is set to OFF

10.

Switch ON the ‘Rotate’ switch at the Gantry rear base.

103.5 ~ 126.5 VAC between terminals 10 and 1

’ switch on the OC.

1 and 12 on TM 1 of the OC is

1 on TB37 on the PDU. See Illustration.5.

.

Measure 180 ~ 220 VAC on the Servo Amp. input (between terminals R & S, S & T

23

22

19

18

90 ~ 1

10 VAC. See Illustration.2.

, and T & R). See Illustration.6.

2208844

PDU TB37 TERMINALS NO. 15, 16

ILLUSTRATION 1

21

21

20

20

17

16

15

14

7

6

5

4

BROWN

LIGHT

BLUE

NO.

4

CABLE

SYSTEM1–3

Page 32

GE MEDICAL

REV

0

SYSTEMS

NFB2

NFB1

CT XMj/XM1500 SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

2208844

REMOVE THE OC

T

OP COVER

11112

TM1

PS DISTR ASSY

PS ADP ASSY

(TOP VIEW)

OPERATOR CONSOLE

ILLUSTRATION 2

SYSTEM1–4

Page 33

GE MEDICAL

REV

0

SYSTEMS

OC LEFT SIDE METAL COVER

FUNCTIONAL

REMOVE THE RIGHT METAL COVER

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

OC

POWER

P

ANEL T

OP COVER

CB1

OPERATOR CONSOLE

ILLUSTRATION 3

SYSTEM1–5

Page 34

GE MEDICAL

REV

0

REAR VIEW

SYSTEMS

CB1

OC Power Panel

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

TB1

Filter

OC POWER PANEL

ILLUSTRATION 4

SYSTEM1–6

Page 35

GE MEDICAL

ÁÁÁÁ

ÁÁÁÁ

REV

0

SYSTEMS

FUNCTIONAL

7

6

5

4

21

21

20

20

17

16

15

14

13

12

11

10

9

8

7

6

5

4

BROWN

LIGHT BLUE

BROWN

LIGHT BLUE

BLACK

WHITE

RED

LIGHT BLUE

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

NO.4 CABLE

NO.

3

CABLE

NO.2 CABLE

NO.5 CABLE

100V AC

PDU TB37 TERMINALS NO. 10, 11

ILLUSTRATION 5

SYSTEM1–7

Page 36

GE MEDICAL

REV

0

SYSTEMS

front

view

left view

SER

VO AMP

SUB

board

1 byte segment led

TGP

BOARD

CT XMj/XM1500 SERIES

FUNCTIONAL

.

CHECK /

ADJUSTMENT

2208844

SERVO AMP.

CONNECTOR

SERVO AMP. TERMINALS R, S, T

RST

ILLUSTRATION 6

SYSTEM1–8

Page 37

GE MEDICAL

REV

0

2–2.

PDU: 2108024/2108025

1. Preparation.

a. V

SYSTEMS

erify that all the breakers and switches listed below are set to OFF

Breaker on the Power Distribution Box (hospital supply).

Breaker (SW20) on the PDU

FUNCTIONAL

.

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

(SNG)

Five switches (‘Rotate,’ ‘XG,’ ‘T

Servo Amp. breaker

Service switch on the Sub Board on the Gantry

SYS/OFF/MNL switch on the TGP Board on the Gantry

Power Panel Breaker CB1 on the OC See Illustration.3.

Remove the front panel from the PDU.

Remove the OC Power Panel T

Remove the left side cover from the Gantry

b.

Switch ON Power Panel Breaker CB1 on the OC.

c.

Switch ON the breaker on the Power Distribution Box (hospital supply).

d.

Switch ON the SW20 breaker on the PDU.

V

erify that the ‘Power

’ lamp on the front upper left corner of the PDU turns ON.

able/T

op cover.

ilt,’ ‘Control,’ and ’Slip Ring 1

.

15V’) at the Gantry rear base

SYSTEM1–9

Page 38

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

5.

Measure 1

It should be

6.

Switch ON the ‘Slip Ring 1

Verify

start to operate.

7. T

urn on the CONSOLE Power by depressing the Scan T

8.

Open the OC power panel cover to access the Power strip.

See Illustration.4.

9.

Measure the power at the OC Console Power Strip. V

See Illustration.4.

10.

Measure

11. V

erify that the Servo Amp. breaker is set to OFF

12.

Switch ON the ‘Rotate’ switch at the Gantry rear base.

Measure 180 ~ 220 VAC on the Servo Amp. input (between terminals R & S, S & T

15 V

AC between terminals 15 and 16 on TB37 on the PDU.

103.5 ~ 126.5 VAC. See Illustration.1.

15V (DAS/DET)’ switch at the Gantry rear base.

that the x–ray generator on the rotating assembly is powered ON, and that the x–ray tube fan and pump

ower Power Switch.

103.5

~

126.5 VAC between terminals 10 and 1

.

erify there is

1 on TB37 on the PDU. See Illustration.5.

108 ~ 122 VAC at the Power strip.

2208844

, and T & R). See Illustration.6.

SYSTEM1–10

Page 39

GE MEDICAL

REV

0

2–3.

PDU: 2121798

1. Preparation.

a. V

SYSTEMS

erify that all the breakers and switches listed below are set to OFF

Breaker on the Power Distribution Box (hospital supply).

Breaker (CB20) on the PDU

FUNCTIONAL

.

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

(LGT

, SRI)

Five switches (‘Rotate,’ ‘XG,’ ‘T

Servo Amp. breaker

Service switch on the Sub Board on the Gantry

SYS/OFF/MNL switch on the TGP Board on the Gantry

T

wo breakers (NFB1, NFB2) on the OC See Illustration.2.

b.

Remove the front panel from the PDU.

c.

Remove the top cover from the OC.

d.

Remove the left side cover from the Gantry

2.

Switch ON two breakers (NFB1, NFB2) on the OC.

3.

Switch ON the breaker on the Power Distribution Box (hospital supply).

4.

Switch ON the CB20 breaker on the PDU.

V

erify the ‘Power

’ lamp on the front upper left corner of the PDU turns ON.

able/T

ilt,’ ‘Control,’ and ’Slip Ring 1

.

15V’) at the Gantry rear base

SYSTEM1–11

Page 40

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

5.

Measure 1

It should be

6.

Switch ON the ‘Slip Ring 1

Verify

15 V

AC between terminals 8 and 9 on the PDU.

103.5 ~ 126.5 VAC. See Illustration.7.

15V (DAS/DET)’ switch at the Gantry rear base.

that the x–ray generator on the rotating assembly is powered ON, and that the x–ray tube fan and pump

start to operate.

7.

Push the ‘Power

V

erify that the voltage between terminals 1

8.

Measure

9. V

erify that the Servo Amp. breaker is set to OFF

10.

Switch ON the ‘Rotate’ switch at the Gantry rear base.

103.5 ~ 126.5 VAC between terminals 1

’ switch on the OC.

1 and 12 on TM 1 of the OC is

1 and 12 on the PDU. See Illustration.8.

.

Measure 180 ~ 220 VAC on the Servo Amp. input (between terminals R & S, S & T

90 ~ 1

10 VAC. See Illustration.2.

, and T & R). See Illustration.6.

2208844

171617

RED

NO.2 CABLE

NO.3 CABLE

NO.

4

CABLE

NO.21 CABLE

L3

L2

L1

PDU TERMINALS NO. 8, 9

YELLOW/GREEN

ILLUSTRATION 7

WHITE

BLACK

BROWN

LIGHT BLUE

BROWN

LIGHT

BLUE

15

14

13

12

11

10

989

7

16

15

14

13

12

11

10

ROTATE

PWR

TABLE/TILT

&

CONTROL

PWR

SLIP RING

1

8

7

15V PWR

GND

SYSTEM1–12

Page 41

GE MEDICAL

REV

0

SYSTEMS

CT XMj/XM1500 SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

2208844

171617

RED

NO.2 CABLE

NO.

3

CABLE

NO.4 CABLE

NO.21 CABLE

L3

L2

L1

YELLOW/GREEN

WHITE

BLACK

BROWN

LIGHT

BLUE

BROWN

LIGHT BLUE

15

14

13

12

11

10

989

7

16

15

14

13

12

11

10

ROTATE

PWR

TABLE/TILT

CONTROL

PWR

&

SLIP RING

1

8

7

15V PWR

GND

PDU TERMINALS NO. 11, 12

ILLUSTRATION 8

SYSTEM1–13

Page 42

GE MEDICAL

REV

0

2–4.

PDU: 2121798

1. Preparation.

a. V

SYSTEMS

erify that all the breakers and switches listed below are set to OFF

Breaker on the Power Distribution Box (hospital supply).

Breaker (CB20) on the PDU

FUNCTIONAL

.

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

(SNG)

Five switches (‘Rotate,’ ‘XG,’ ‘T

Servo Amp. breaker

Service switch on the Sub Board on the Gantry

SYS/OFF/MNL switch on the TGP Board on the Gantry

Power Panel Breaker CB1 on the OC See Illustration.3.

b.

Remove the front panel from the PDU.

c.

Remove the OC Power Panel T

d.

Remove the left side cover from the Gantry

2.

Switch ON Power Panel Breaker CB1 on the OC.

3.

Switch ON the breaker on the Power Distribution Box (hospital supply).

4.

Switch ON the CB20 breaker on the PDU.

V

erify the ‘Power

’ lamp on the front upper left corner of the PDU turns ON.

able/T

ilt,’ ‘Control,’ and ’Slip Ring 1

op cover.

.

15V’) at the Gantry rear base

SYSTEM1–14

Page 43

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

5.

Measure 1

It should be

6.

Switch ON the ‘Slip Ring 1

Verify

start to operate.

7. T

urn on the CONSOLE Power by depressing the Scan T

8.

Open the OC power panel cover to access the Power strip.

See Illustration.4.

9.

Measure the power at the OC Console Power Strip. V

See Illustration.4.

10.

Measure

11. V

erify that the Servo Amp. breaker is set to OFF

12.

Switch ON the ‘Rotate’ switch at the Gantry rear base.

Measure 180

15 V

AC between terminals 8 and 9 on the PDU.

103.5

~

126.5 VAC. See Illustration.7.

15V (DAS/DET)’ switch at the Gantry rear base.

that the x–ray generator on the rotating assembly is powered ON, and that the x–ray tube fan and pump

103.5

~

126.5 VAC between terminals 1

~

220 VAC on the Servo Amp. input (between terminals R & S, S & T

ower Power Switch.

erify there is

1 and 12 on the PDU. See Illustration.8.

.

108

~

122 VAC at the Power strip.

, and T & R). See Illustration.6.

2208844

SYSTEM1–15

Page 44

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

blank

2208844

SYSTEM1–16

Page 45

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

3. GANTR

Y ROTATION CHECK

WARNING!

ROTATION

ARE HAZARDS INVOLVED IN WORKING ON OR NEAR THE GANTRY. THE MOST OBVIOUS

HAZARD IS THE AXIAL MOTION OF THE GANTRY. THE HIGH VOLTAGE (HV) SUBSYSTEM

IS MOUNTED DIRECTLY ONTO THE GANTRY. THE HV SUBSYSTEM CONSISTS OF

COMPONENTS THA

1.

Switch OFF the ‘Rotate’ switch.

2.

Remove the front and both side covers from the Gantry

3.

Set the safety bracket located on the right side of the Gantry

4.

Switch ON the ‘Control’ and ‘T

HAZARD! BECAUSE OF THE CONTINUOUS ROTATION OF

T ARE BULKY AND HEAVY. GIVE ROTATION HAZARDS RESPECT

able/T

ilt’ switches at the Gantry rear base.

2208844

THE GANTR

.

.

Y THERE

.

5.

Set the Service switch to ON on the SUB Board on the Gantry

6. Rotate

7. Set

8.

9.

10.

11.

10.

11.

12. Verify

the Gantry manually in

etc.).

the Service switch to OFF

Switch ON the ‘Rotate’ switch.

Switch ON the Servo Amp. breaker

Switch OFF the ‘Power’ switch on the OC.

Switch ON the ‘Power

Push OFF “Power” switch on the Scan T

Push ON the “Power” switch on the Scan T

that the Gantry starts to

making

two revolutions.

’ switch on the OC.

the CW direction to verify that nothing interferes the Gantry during rotation (cables,

.

.

ower.

rotate, and it stops at the home position (x–ray tube at 12 o’clock position) before

ower.

.

(LGT

, SRI)

(SNG)

(LGT

, SRI, SNG)

SYSTEM1–17

Page 46

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

4.

EMERGENCY OFF TEST

Eight

emergency switches in total are equipped on the system.

Illustration.9.

EMERGENCY SWITCH

ILLUSTRATION 9

1.

Remove the Gantry left side cover

2.

Press the emergency switch located on the front of the PDU.

V

erify that power is removed from the Gantry and T

. (The other covers should be installed)

The switches take either one of the two shapes. See

RED

COLOR

able; check the following:

2208844

(LGT,

SRI)

One byte segment LED on the Servo Amp. is extinguished. See Illustration.10.

Gantry Display Panels (right and left) are extinguished.

3.

Press the power switch on the OC

V

erify that power is applied to the Gantry and T

One byte segment LED on the Servo Amp. is illuminated. See Illustration.10.

Gantry Display Panels (right and left) are illuminated.

twice.

able; check the following:

SYSTEM1–18

Page 47

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

4.

Repeat the above check for emergency switches located on the followings:

Operator Console (one)

Gantry front cover (two; right and left)

1.

Remove the Gantry left side cover

2.

Press the emergency switch located on the front of the PDU.

V

erify that power is removed from the Gantry and T

One byte segment LED on the Servo Amp. is extinguished. See Illustration.10.

Gantry Display Panels (right and left) are extinguished.

3.

Power down the W

4. T

urning of

5.

Push (of

6.

Push (on) Scan T

V

erify that power is applied to the Gantry and T

f the W

f) Scan T

orkstation by exiting from the application software.

orkstation power switch

ower Power Switch.

ower Power Switch.

. (The other covers should be installed)

able; check the following:

.

able; check the following:

2208844

(SNG)

One byte segment LED on the Servo Amp. is illuminated. See Illustration.10.

Gantry Display Panels (right and left) are illuminated.

7.

Repeat the above check for emergency switches located on the followings:

Operator Console Scan Box (one)

Gantry front cover (two; right and left)

SYSTEM1–19

Page 48

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

Emergency Switches on Gantry Frame

1.

Remove the front, rear

2.

Connect the emergency cable, as shown in Illustration.1

3. Repeat

‘D’

4. Repeat

and

1.

Remove the front, rear

2.

Connect the emergency cable, as shown in Illustration.1

3. Repeat

‘D’

4. Repeat

and

the emergency switch check as performed in steps 2 and 3 for the emergency switches ‘A

located on the Gantry frame. See Illustration.12.

the emergency switch

‘D’ located on the Gantry frame. See Illustration.12.

the emergency switch check as performed in steps 2 and 3 for the emergency switches ‘A

located on the Gantry frame. See Illustration.12.

the emergency switch

‘D’ located on the Gantry frame. See Illustration.12.

, and right side covers from the Gantry

check as performed in steps 2 and 3 6 for the emergency switches ‘A

, and right side covers from the Gantry

check as performed in steps 2 and 3 6 for the emergency switches ‘A

1.

1.

2208844

(LGT

, SRI)

.

’, ‘B’, ‘C’,

.

’, ‘B’, ‘C’,

and

’, ‘B’, ‘C’,

(SNG)

and

’, ‘B’, ‘C’,

front view

1 byte segment led

servo amp.

sub

board

TGP

BOARD

LED ON SERVO AMP

ILLUSTRATION 10

gantry

front

SYSTEM1–20

Page 49

GE MEDICAL

REV

0

SYSTEMS

EMERGENCY SW

X–RAY

TUBE

GANTRY

CT XMj/XM1500 SERIES

FUNCTIONAL

CHECK /

FRONT COVER

REVERSE

SIDE

ADJUSTMENT

2208844

CONNECTOR

EMERGENCY

SW ‘A’

EMERGENCY

SW ‘B’

STEP 2:

CONNECT

STEP 1:

DISCONNECT THE 2–PIN

WHITE/BLACK

CONNECTORS

TWIST CABLE

EMERGENCY SW CABLE CONNECTION

ILLUSTRATION 11

X–RAY

TUBE

EMERGENCY

SW ‘D’

EMERGENCY

SW ‘C’

GANTRY FRONT VIEW

EMERGENCY SWITCH LOCATIONS

ILLUSTRATION 12

GANTRY REAR VIEW

SYSTEM1–21

Page 50

GE MEDICAL

REV

0

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

5 X–RA

Check for the overheat detection function by performing the following:

1.

2.

3.

4.

5. T

Y TUBE OVERHEA

Switch OFF the ‘Rotate’ switch.

Remove the front and both side covers from the Gantry

Disconnect the rotor cable connector (12–pin, brown). See Illustration.13.

If the connector is not accessible, perform the following.

a.

Set the Service switch to ON on the SUB Board.

b.

Rotate the Gantry manually in the CW direction to a position where the connector can be accessed.

c.

Set the Service switch to OFF

Switch ON the ‘Rotate’ switch.

ry to perform a scan.

Verify

that a scan can not be performed and that the “XG ERROR 148” message is reported on the status screen.

T SAFETY

.

.

(LGT

, SRI)

(SNG)

5. Verify

the resume button appears on CR

The MESSAGE VIEW is shown as following message.

T and a scan is NOT taken.

Scan Hardware Stopped Scan

6. Verify

the following error appears in the MESSAGE VIEW using V

Click on ; [Utilities]

'

[View

Error Log] ! Hit return to continue

Error : 28033

XG Error : Generator safety loop open

XG State : Standby

7.

Switch OFF the ‘Rotate’ switch.

8.

Reconnect the connector

.

iew Error Log function.

(LGT,

SRI, SNG)

SYSTEM1–22

Page 51

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

2208844

APPROXIMATE LOCATION OF

THE 12–PIN CONNECTOR

(BROWN)

ROTOR CABLE CONNECTOR AT X–RAY TUBE

ILLUSTRATION 13

SYSTEM1–23

Page 52

GE MEDICAL

REV

0

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

6. X–RA

1.

2.

3.

4.

5.

6.

Y TUBE OIL

Switch OFF the ‘Rotate’ switch at the Gantry rear base.

Remove the front, rear

, and both side covers front the Gantry

.

Switch ON the Service switch on the SUB Board.

Rotate the Gantry by hand in the CW direction until the x–ray tube is positioned at 3 o’clock.

Switch OFF the Service switch.

Insert the azimuth lock pin.

CAUTION

Electric

connect

7.

Remove the x–ray tube HV connectors. See Illustration.14.

shock!

it.

Use a ground bar to discharge the high voltage connector any time you dis

-

DISCHARGE

c

WIPE CLEAN

b

a

REMOVE

REMOVING HV CONNECTORS

ILLUSTRATION 14

SYSTEM1–24

Page 53

CT XMj/XM1500 SERIES

GE MEDICAL

REV

0

SYSTEMS

FUNCTIONAL

CHECK /

ADJUSTMENT

2208844

8. Verify that the both HV connectors (Anode and Cathode) are completely immersed in oil. Check all over the

surface

of the connectors.

If not, supply an appropriate amount of silicone oil into the connector wells. See Illustration.15.

SILICON OIL ADDITION

ILLUSTRATION 15

SYSTEM1–25

Page 54

GE MEDICAL

REV

0

7. FANS

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

X–ray T

1. Verify

ube Heat Exchanger Fans

at

the Gantry rear base) See Illustration below

that the x–ray tube heat exchanger fans are operating. (The ‘Slip Ring 1

.

HEAT

EXCHANGER FAN

15V’ switch should be set to ON

PDU

Fans

2. Verify

set

to ON) See Illustration below

X–RAY TUBE HEAT EXCHANGER FAN

ILLUSTRATION 16

that the PDU fans equipped on the rear side of the PDU are operating. (The PDU main switch should be

.

FANS

REAR SIDE

PDU FAN LOCATION

ILLUSTRATION 17

SYSTEM1–26

Page 55

GE MEDICAL

REV

0

8. FILTER

There are two filters on the OC and two on the PDU.

Perform the following cleaning procedure.

1.

Slide the filter at the bottom of the OC forward until it is removed from the OC.

(The OC front cover does not need to be removed)

2.

Remove the right and left covers of the PDU and gently pull the foam out of each enclosure.

3.

Suck up any dust on the filters with a vacuum cleaner

SYSTEMS

OC: Horizontal, one on the bottom of console – housed within a gold mesh filter enclosure

PDU: V

ertical, one each on the right and left covers – housed within a gold mesh filter enclosure

.

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

2208844

(LGT

, SRI)

(LGT

, SRI, SNG)

(LGT

, SRI)

(LGT

, SRI, SNG)

4.

Slide or fit each filter back into its enclosure.

SYSTEM1–27

Page 56

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

9

SCAN TEST

This ‘Scan Test’ procedure assumes that all the subsystems (Operator Console, Gantry, T

X–ray

generator) are functioning normally

In this procedure refer to the Operator manual for detailed information.

W

arm Up Scan

1.

Make sure that the ‘New Patient’ and the ‘W

‘W

arm Up’ should blink following the completion of the system power–up sequence.

2.

Make sure that nothing is in the scan area in the Gantry room.

3. T

ouch the ‘W

Make sure that all warm up scans complete without error

Scoutview Scan

arm Up’ button to start the x–ray tube warm up program.

.

arm Up’ buttons are blinking on the touch panel screen.

Note

.

2208844

(LGT

able, DAS/Detector

, SRI)

, and

4.

Perform a series of scout scans to check scout scan operations.

Use the following scan parameters:

FOV :

THICKNESS :

KV :

MA :

a. T

ilt the Gantry

Make sure that the software prohibits a scout scan with the Gantry tilted.

b.

Release the ‘Scan’ button during a scout scan.

V

erify that the scan continues.

c. ca.

Select Auto V

cb.

Lay the water phantom horizontally on the cradle.

cc.

Perform an AP (0°) scout scan on the phantom.

Make sure that you can hear and understand each voice.

V

erify that the phantom diameter (In–Out direction) on the image is

50 cm

1 mm

120 kV

60, 80, 100 mA

.

oice Start 1 and Auto Voice End 1.

266 mm

±

3 mm.

SYSTEM1–28

Page 57

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

Scoutview Scan (continued)

d. da.

Localize

5.

Perform a Localize function.

a.

b.

c.

Select Auto V

db.

Set the QA phantom on the phantom holder

dc.

Perform an L

Make sure that you can hear and understand each voice.

Release the ‘Scan’ button before the whole image is displayed and verify that the scan continues.

Push the ‘Abort’ key and verify that the cradle and scan stop.

Display a scoutview image (use the image acquired in step 4).

Select the Localize function.

Prescribe and confirm an axial scan plan.

oice Start 2 and Auto Voice End 1.

T (90°) scout scan on the phantom.

2208844

.

d.

Make sure that the ‘T

e.

Depress and hold down the ‘T

Check that the cradle advances to the prescribed position.

Axial Scan

6.

Perform a series of axial scans to check axial scan operations.

a.

Use the following scan parameters:

Acquisition No.

Scan T

THICKNESS :

KV :

MA :

INTERVAL :

Select each of the auto voice messages (Start 1, Start 2, Start 3, and End 1).

V

erify that each scan completes with no error occurred.

ime [sec]

able Set’ button blinks.

able Set’ button.

1 2 3 4 5 6 7 8

1.5 1.5 2 2 3 3 5 5

10 mm

120 kV

80 mA

10 mm

V

erify that you can hear and understand each voice.

SYSTEM1–29

Page 58

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

Abort

7.

Perform the following scan and press the ‘Abort’ button before the scan completes.

SCAN TIME

THICKNESS :

KV :

MA :

V

erify that the scan is terminated.

Emergency OFF

8.

Perform the above scan (step 7) and press the Emergency button on the Console before the scan completes.

V

erify that the scan is terminated and that the Gantry comes to a stop within two inertial revolutions.

: 1.5 sec

10 mm

120 kV

60 mA

2208844

SYSTEM1–30

Page 59

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

10

SCAN TEST

This check assumes that you have successfully completed all functional checks for the X–Ray

Generator, Gantry, Table and Operator Console. Check the CT SYTEC SYNERGY Operator

Manual

W

arm Up Scan

If

1. Make

2.

Make sure nothing is in the scan area in the Gantry room.

3.

Click on the [T

4.

Click on the [Confirm] .

5.

Depress the ‘Start Scan’ button on the Scan Box.

for scanning operation instructions.

the system has never been calibrated, or has old / invalid cal’

sure system power is ON and the system is at the application level.

ube W

arm Up] to start the tube warm up program.

Note

Note

s, the W

2208844

(SNG)

ARM UP will fail (10th scan).

6.

Make sure all warm up scans complete without error

.

SYSTEM1–31

Page 60

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

Scoutview Scan

1.

Perform a series of ScoutV

-

SCOUT SCAN INTER–LOCK

Tilt

the gantry away from zero degrees and make sure the software

The

VIEW MESSAGE appears as follows.

Position TILT FORWARD to 0.0 degrees Position TILT BACKWARD to 0.0 degrees

- SCOUT

a.

b.

c.

d. V

-

SCOUT SCAN [90 Gantry Angle]

a.

SCAN [0 Gantry Angle]

Select [Auto V

Perform an Gantry Angle (0_) ScoutV

Make sure you can hear and understand each auto voice.

erify that the phantom diameter (IN–OUT direction) on the image is 266 mm

Select [Auto V

oice] .

oice] .

iew scans (120KV

iew scan on a horizontal 25cm phantom, laying on cradle.

, 60mA, 42cm FOV) and verify the following:

prohibits a ScoutV

or

iew with the gantry tilted.

±

3

mm.

2208844

b.

Perform an Gantry Angle (90_) ScoutV

c.

Push the ”P

d. V

erify that the table and scan stop.

e.

Select [Resume] for re–scanning.

f. V

erify that the scanning was completed without any error

g. V

erify that you can hear and understand each auto voice.

AUSE” button on the scan box while the scan is in progress.

iew scan on a horizontal 25cm phantom using the holder

.

.

SYSTEM1–32

Page 61

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

AXIAL SCAN

Scan Parameters

120 kV, 80 mA,10 mm thickness, 10 mm interval

T

wo scans each at 2,3 and 5 sec scan times

Auto–V

a.

b. V

c. V

d. V

Scan Parameters

2 sec, 120 kV

25 cm display FOV

a.

b. Verify

oice on

Perform a series of axial scans. The scan parameter is above.

erify that the table moves to the proper location.

erify that each scan completes successfully

erify that you can hear and understand each voice.

Perform a series of axial scans. The scan parameter is above.

that the time

12 sec.

:

:

, 60 mA,10 mm thickness, 25 cm FOV

, STND Recon, Head Alg.

between the display of the first image

, and is displayed.

,

and the display of the second image

2208844

is approximately

SYSTEM1–33

Page 62

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

STOP/PAUSE

ST

P

OP button on SCAN BOX

a.

Press the ”ST

b. V

erify that the scan stops.

OP” button while an axial scan is in process. verify that the scan stops.

AUSE soft key on CR

a.

Click the ”P

b. V

erify that the scan stops.

AUSE” on CR

T

T while an axial scan is in process. verify that the scan stops.

EMERGENCY OFF

1.

Initiate an axial scan, then press the EMERGENCY SWITCH on the operator console Scan Box.

See Illustration.18.

2208844

EMERGENCY SWITCH

EMERGENCY SWITCH

ILLUSTRATION 18

SYSTEM1–34

Page 63

GE MEDICAL

REV

0

2. V

erify that the system terminates the x–ray exposure, and Gantry power is turned of

3.

Press the Emergency Stop switch again (to turn it of

4.

Perform ”Power down” of the Application software.

5.

Cycle power at the Scan T

SYSTEMS

FUNCTIONAL

f).

ower to reset the Gantry Emergency Power Of

f condition.

CT XMj/XM1500 SERIES

CHECK /

f.

ADJUSTMENT

2208844

SYSTEM1–35

Page 64

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

blank

2208844

SYSTEM1–36

Page 65

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

2208844

SECTION 2 – SOFTWARE LOADING (V2.02)

(LGT,

SRI)

1 GENERAL

This ‘Software Loading’ describes the Load–From–Cold (LFC) procedure for a full system software loading from

floppy

disks to the system hard disk. Perform this LFC procedure when:

A failure or crash corrupts the hard disk so the existing software can not be used. A Load–From–Cold

rebuilds

CT Engineering has revised the current software to incorporate improvements or correct existing problems.

The system hard disk is replaced with a new one. In this case, follow the instructions below:

the operating software on the disk and restores normal system operation.

Replace the old software by performing a Load–From–Cold with the new software.

If read operation is possible on the hard disk to be replaced, perform ‘Pre–A

and

then, replace the disk with a new one. Then, perform an LFC procedure.

If

read operation is not possible on the hard disk to be replaced, ‘Pre–A

be

performed. In this case, replace the disk with a new one, perform an LFC procedure, and then,

use the back up floppy disks saved during system installation in ‘Post–A

to Section 6–4, System Data Back Up, of the Installation tab of the Installation/Component Replacement

Latest System Software

The latest system software version/revision is

Outlines

loads

type

Formatting an FD or MOD

If a floppy disk or MOD needs to be formatted, use the Image File Management function ([Shift] + [Image Delete]).

Proceed to ‘Floppy Disks for System/Option Software.’

the software loading procedure which includes an LFC

the V/R 1.00 system software to the hard disk.

loading), and revision–up procedures (→ V/R 2.01 → V/R 2.02) are preformed.

manual (2111461 or 2121807).

V/R 2.02

.

Then, a version–up procedure (to V/R 2.00; this is an overwrite

procedure. Refer to Illustration.1. The LFC procedure

TINST Procedure’,

TINST Procedure can not

TINST Procedure.’ Refer

SYSTEM2–1

Page 66

GE MEDICAL

SYSTEMS

FUNCTIONAL

CT XMj/XM1500 SERIES

CHECK /

ADJUSTMENT

REV 0

START

SAVE CUSTOMER DATA

A

TINST Program

(to V 1.00)

DAT

A FILE SA

VE

DISK INITIALIZE

SOFTW

ARE LOADING

(SYSTEM, OPTION)

FILE ALLOCA

DAT

A FILE LOADING

TION

T–Copy Command

(to V 2.00)

RESTORE CUSTOMER DATA

(CUSTOM PARAMETERS

ONLY)

2208844

RESTORE INSITE SOFTWARE