Page 1

Technical

Publications

2234976

Revision 2

CT Sytec/Sytec i Series

Functional Check /Adjustment

Copyrighte 1999 by General Electric Company

Operating Documentation

Page 2

Page 3

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

WARNING

AVERTISSEMENT

2234976

D THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

D IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A LANGUAGE OTHER

THAN ENGLISH, IT IS THE CUSTOMER’S RESPONSIBILITY TO PROVIDE

TRANSLATION SERVICES.

D DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS SERVICE

MANUAL HAS BEEN CONSULTED AND IS UNDERSTOOD.

D FAILURE

PROVIDER,

OR OTHER HAZARDS.

D CE MANUEL DE MAINTENANCE N’EST DISPONIBLE QU’EN ANGLAIS.

D SI LE TECHNICIEN DU CLIENT A BESOIN DE CE MANUEL DANS UNE AUTRE

LANGUE QUE L’ANGLAIS, C’EST AU CLIENT QU’IL INCOMBE DE LE FAIRE

TRADUIRE.

D NE PAS TENTER D’INTERVENTION SUR LES ÉQUIPEMENTS TANT QUE LE

MANUEL SERVICE N’A PAS ÉTÉ CONSULTÉ ET COMPRIS.

D LE NON-RESPECT DE CET AVERTISSEMENT PEUT ENTRAÎNER CHEZ LE

TECHNICIEN, L’OPÉRATEUR OU LE PATIENT DES BLESSURES DUES À DES

DANGERS ÉLECTRIQUES, MÉCANIQUES OU AUTRES.

T

O HEED THIS W

OPERATOR OR PATIENT FROM ELECTRIC SHOCK, MECHANICAL

ARNING

MA

Y RESUL

T IN INJUR

Y T

O THE SER

VICE

WARNUNG

AVISO

D DIESES KUNDENDIENST–HANDBUCH EXISTIERT NUR IN

ENGLISCHER SPRACHE.

D FALLS EIN FREMDER KUNDENDIENST EINE ANDERE SPRACHE BENÖTIGT,

IST ES AUFGABE DES KUNDEN FÜR EINE ENTSPRECHENDE ÜBERSETZUNG

ZU SORGEN.

D VERSUCHEN SIE NICHT, DAS GERÄT ZU REPARIEREN, BEVOR DIESES

KUNDENDIENST–HANDBUCH

WURDE.

D WIRD

D ESTE MANUAL DE SERVICIO SÓLO EXISTE EN INGLÉS.

D SI

D NO SE DEBERÁ DAR SERVICIO TÉCNICO AL EQUIPO, SIN HABER

D LA NO OBSERVANCIA DEL PRESENTE AVISO PUEDE DAR LUGAR A QUE EL

DIESE W

DES KUNDENDIENSTTECHNIKERS, DES BEDIENERS ODER DES PATIENTEN

DURCH ELEKTRISCHE SCHLÄGE, MECHANISCHE ODER SONSTIGE

GEFAHREN KOMMEN.

ALGÚN PROVEEDOR DE SER

QUE NO SEA EL INGLÉS, ES RESPONSABILIDAD DEL CLIENTE OFRECER UN

SERVICIO DE TRADUCCIÓN.

CONSULTADO Y COMPRENDIDO ESTE MANUAL DE SERVICIO.

PROVEEDOR DE SERVICIOS, EL OPERADOR O EL PACIENTE SUFRAN

LESIONES

NATURALEZA.

ARNUNG NICHT BEACHTET

PROV

OCADAS POR CAUSAS ELÉCTRICAS, MECÁNICAS

NICHT

ZU RA

TE GEZOGEN UND VERST

, SO KANN

VICIOS AJENO A GEMS SOLICIT

ES ZU VERLETZUNGEN

ANDEN

A UN

IDIOMA

O DE OTRA

a

Page 4

GE MEDICAL

REV

0

ATENÇÃO

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

2234976

D ESTE MANUAL DE ASSISTÊNCIA TÉCNICA SÓ SE ENCONTRA

DISPONÍVEL EM INGLÊS.

D SE QUALQUER OUTRO SERVIÇO DE ASSISTÊNCIA TÉCNICA, QUE NÃO A

GEMS, SOLICITAR ESTES MANUAIS NOUTRO IDIOMA, É DA

RESPONSABILIDADE

D NÃO TENTE REPARAR O EQUIPAMENTO SEM TER CONSULTADO E

COMPREENDIDO ESTE MANUAL DE ASSISTÊNCIA TÉCNICA.

DO CLIENTE

FORNECER OS SER

VIÇOS DE TRADUÇÃO.

AVVERTENZA

D O NÃO CUMPRIMENTO DESTE

DO TÉCNICO, OPERADOR OU PACIENTE DEVIDO A‘ CHOQUES ELÉTRICOS,

MECÂNICOS OU OUTROS.

D IL PRESENTE MANUALE DI MANUTENZIONE È DISPONIBILE

SOLTANTO IN INGLESE.

D SE

UN ADDETT

MANUALE IN UNA LINGUA DIVERSA, IL

DIRETTAMENTE ALLA TRADUZIONE.

D SI PROCEDA ALLA MANUTENZIONE DELL’APPARECCHIATURA SOLO DOPO

AVER CONSULTATO IL PRESENTE MANUALE ED AVERNE COMPRESO IL

CONTENUTO.

D NON TENERE CONTO DELLA PRESENTE AVVERTENZA POTREBBE FAR

COMPIERE OPERAZIONI DA CUI DERIVINO LESIONI ALL’ADDETTO ALLA

MANUTENZIONE, ALL’UTILIZZATORE ED AL PAZIENTE PER

FOLGORAZIONE ELETTRICA, PER URTI MECCANICI OD ALTRI RISCHI.

O ALLA MANUTENZIONE ESTERNO ALLA GEMS RICHIEDE

A

VISO PODE POR EM PERIGO A SEGURANÇA

CLIENTE È TENUT

O A PROVVEDERE

IL

b

Page 5

CT SYTEC/SYTEC I SERIES

GE MEDICAL

REV

0

SYSTEMS

FUNCTIONAL

CHECK /

ADJUSTMENT

2234976

IMPORTANT! . . . X-RAY PROTECTION

X-ray equipment if not properly used may cause injury. Accordingly, the instructions herein contained

should be thoroughly read and understood by everyone who will use the equipment before you attempt to

place this equipment in operation. The General Electric Company, Medical Systems Group, will be glad to

assist

and cooperate in placing this equipment in use.

Although this apparatus incorporates a high degree of protection against

practical design of equipment can provide complete protection. Nor can

take adequate precautions to prevent the possibility of any persons carelessly exposing themselves or others to

radiation.

It

is important that everyone having anything to do with x-radiation be properly trained and fully acquainted with the

recommendations

available from NCRP Publications, 7910 Woodmont Avenue, Room 1016, Bethesda, Maryland 20814, and of the

International

The

equipment is sold with the understanding that

and representatives have no responsibility for injury or damage which may result from improper use of the equipment.

Various

protective material and devices are available. It is urged that such materials or devices be used.

of

the National Council on Radiation Protection and Measurements as published in NCRP Reports

Commission on Radiation Protection, and take adequate steps to protect against injury

the General Electric Company

x-radiation other than the useful beam, no

any practical design compel the operator to

.

, Medical Systems Group, its agents,

All electrica

performed by l

b

y l

icense

b

e p

highly sophisticated

d e

erforme

l i

nstallation

icense

lectrica

d b

y q

d e

l c

ualifie

, a

ontractors

nd specia

s that are p

lectrica

l c

d GE M

edica

l e

reliminar

ontractors

. O

the

ngineering competenc

r c

onnection

l p

ersonnel

y t

. I

o p

ositionin

n a

ddition

. The p

s b

g o

, e

lectrica

etwee

roduct

e i

f the e

quipmen

l f

eed

n p

iece

s o

s i

nvolve

s required.

t a

t the site p

s into the P

f e

lectrica

l e

d (and the a

repare

owe

r D

istributio

quipment

ccompanyin

d for the e

n Unit s

, c

alibrations

g e

lectrica

quipmen

hal

l b

e p

, and t

estin

l i

nstallations

t s

hal

l b

erformed

g s

hall

) a

re

e

In performin

work

The purchaser of GE equipment shall only utiliz e qualified personnel (i.e., GE’s field engineers, personnel of thir d-party

service companies wit

on t

hes

g all e

e p

roducts wil

lectrica

h e

l work o

l c

omply wit

quivalen

n t

hes

t t

raining

e p

roducts, GE will use its own s

h the r

equirements o

, o

r l

icense

f the a

d e

lectricians) t

c

peciall

pplicabl

o p

e e

erfor

y t

raine

lectrica

m e

lectrica

d f

l c

iel

d e

odes.

l s

ngineers

ervicin

. All o

g on the e

f GE’s e

quipment.

lectrical

Page 6

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2234976

DAMAGE IN TRANSPORTATION

All packages should be closely examined at time of delivery. If damage is apparent, have notation “damage in

shipment”

Electric representative or a hospital receiving agent. Whether noted or concealed, damage

carrier immediately

for inspection by the carrier

within

Call Traf

this time be ready to supply name of carrier, delivery date, consignee name, freight or express bill number, item

damaged

Complete instructions regarding claim procedure are found in Section “S” of the Policy & Procedure Bulletins.

written on

this 14 day period.

fic and T

and extent of damage.

all

upon discovery

ransportation, Milwaukee, WI (414) 827–3449

copies of the freight or express bill

, or in any event, within 14 days after receipt, and the contents and containers held

. A transportation company will

not

before

delivery is accepted or

pay a claim for damage if an inspection is not requested

/ 8*285–3449

immediately

“signed for” by a General

MUST

be reported to the

after damage is found. At

OMISSIONS & ERRORS

GE

personnel, please use the GEMS CQA Process to report all omissions, errors, and defects in this documentation.

Customers,

please contact your GE Sales or Service represenatives.

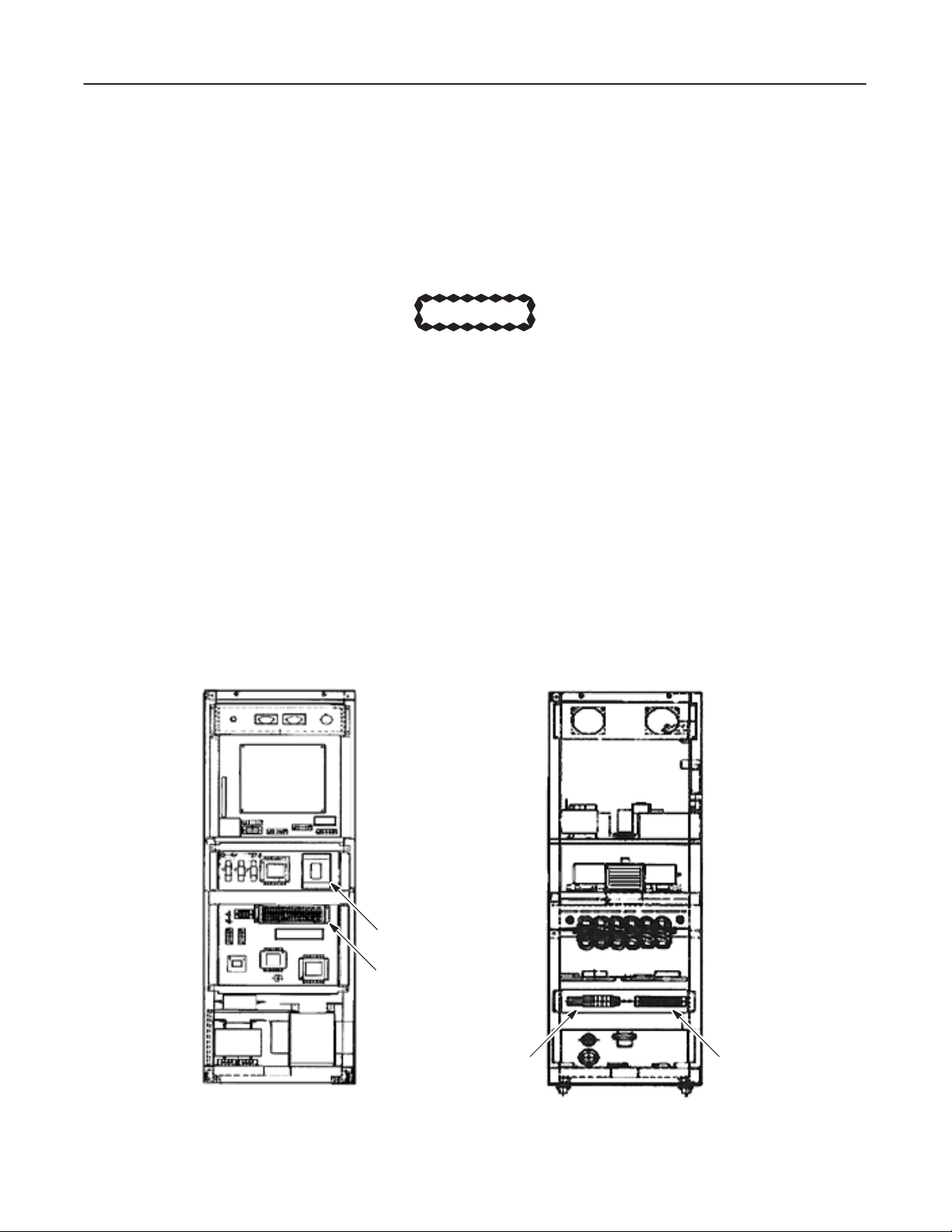

CAUTION

Do not use the following devices near this equipment. Use of these devices near this equipment could cause

this equipment to malfunction.

Devices not to be used near this equipment:

Devices

radio–controlled toy

Keep power to these devices turned of

Medical staf

which intrinsically transmit radio

, etc.

f in charge of this equipment is required to instruct technicians, patients an

waves such as; cellular phone, radio transceiver

f when near this equipment.

, mobile radio transmitter

,

d

Page 7

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 2

2234976

REVISION HISTORY

REV DATE PRIMARY

0 Jan. 6, 1999 Initial release..

1 May. 28, 1999 Added V/R 4.02 software Loading.

2 Dec. 20, 1999 DAS Count.

. . . . .

. . .

. . .

. . .

. . .

. . .

REASON FOR CHANGE

LIST OF EFFECTIVE PAGES

PAGE REV PAGE REV PAGE REV PAGE REV PAGE REV

Title page 2.

Title page rear blank.

a to d 0.

A2

. . . . . . . . . . . . . . . .

B blank

. . . . . . . . . . . . .

i0

. . . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

Tab 1 (Introduction)

i0.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–3 0.

1–4 blank

Tab 2 (System)

i1.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–15 0.

. . . . . . .

. . . . . . . . . . .

. . . . . . .

. . . . . . . . . . .

. . . . . .

1–16 blank

. . . . . . . . . .

2–1 to 2–35 0.

2–36 to 2–37 1.

2–38 blank

3–1 to 3–21 0.

3–22 blank

4–1 to 4–5 0.

4–6 blank

. . . . . . . . . . .

5–1 to 5–5 0.

5–6 blank

. . . . . . . . . . .

5–7 to 12 0.

Tab 3 (OC)

i0.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–8 0.

2–1 to 2–11 0.

2–12 blank

. . . . . .

. . . . .

. . . . . . . . . .

. . . . . .

. . . . . . . . . .

. . . . . . .

. . . . . . .

. . . . . . . .

. . . . . . .

. . . . . .

. . . . . . . . . .

Tab 4 (Gantry)

i0.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–2 0.

2–1 to 2–14 0.

3–1 to 3–9 0.

3–10 blank

4–1 to 4–8 0.

5–1 to 5–5 0.

5–6 blank

6–1 to 6–13 0.

6–14 blank

Tab 5 (Table)

i0.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–7 0.

1–8 blank

. . . . . . .

. . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . .

. . . . . . .

. . . . . . . . . . .

. . . . . .

. . . . . . . . . .

. . . . . . .

. . . . . . . . . . .

2–1 to 2–11 0.

2–12 blank

3–1 0

. . . . . . . . . . . . . .

3–2 blank

. . . . . . . . . . .

Tab 6 (DAS/Detector)

i0.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–12 0.

2–1 to 2–3 0.

2–4 blank

. . . . . . . . . . .

3–1 to 3–12 0.

Tab 7 (XG)

i0.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–23 0.

1–24 blank

. . . . . .

. . . . . . . . . .

. . . . . .

. . . . . . .

. . . . . .

. . . . . .

. . . . . . . . . .

2–1 to 2–9 0.

2–10 2

2–11 to 2–12 0.

T

ab 8 (Switch/Jumper

Setting )

i0.

. . . . . . . . . . . . . . . .

ii blank

. . . . . . . . . . . . .

1–1 to 1–48 0.

2–1 to 2–4 0.

3–1 to 3–2 0.

4–1 to 4–6 0.

Tab APPENDIX

A–1 to A–4 0.

Blank/Rear cover –.

. . . . . . .

. . . . . . . . . . . . .

. . . . .

. . . . . .

. . . . . . .

. . . . . . .

. . . . . . .

. . . . . .

.

A

Page 8

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

blank

2234976

B

Page 9

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

INTRODUCTION (T

General

SYSTEM (T

OPERATOR CONSOLE (T

GANTR

AB 2)

Checks during System Installation

Software Loading

X–ray Alignment

System Calibration

Image Performance V

OC Components

OC Operation

Y (T

AB4)

DC Power Supplies

Gantry Mechanism

Rotational Operation

T

ilt Operation

Collimator

T

able and Gantry

AB 1)

2234976

CONTENTS

erification

AB 3)

TABLE (TAB5)

Elevation Function

Longitudinal Function

T

able Accessories

DAS / DETECT

DAS Components

Detector Related Devices

DAS Operation

X–RA

Y GENERA

XG Components

Generator Output Check

SWITCH / JUMPER SETTING (T

Operator Console

Gantry

DAS

X–Ray Generator

OR (TAB6)

TOR (TAB7)

AB8)

i

Page 10

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

blank

2234976

ii

Page 11

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

INTRODUCTION

TABLE OF CONTENTS

SECTION PAGE

SECTION

1 – GENERAL

1-1 GENERAL WARNING/CAUTION/NOTICE 1–2.

1-1-1 Gantry 1–2

1-1-2 Operator Console 1–3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1.

2234976

INTRODUCTIONi

Page 12

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

blank

2234976

INTRODUCTIONii

Page 13

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

SECTION 1 – GENERAL

Use

of This Manual

Use this ‘Functional Check/Adjustment’ for the following purposes:

D

A during– and post–installation check to ensure that the entire system operates properly

D

As a reference source for Periodic Maintenance which mainly contains abbreviated lists.

D

A post–FMI (Field Modification Instruction) check to verify system.

D

A pre–diagnostic check to verify or determine failure symptoms before of during troubleshooting.

D A

post–diagnostic check to verify system operation after repairs, before returning it to the customer to use.

2234976

.

INTRODUCTION1–1

Page 14

GE MEDICAL

REV

0

1-1

GENERAL W

1-1-1 Gantry

ROTATION HAZARD !

TURN

INSERTING

SYSTEMS

ARNING/CAUTION/NOTICE

WARNING!

OFF THE ‘SCAN’ BREAKER LOCA

ANY OBJECT INT

O OR WORKING ON THE GANTRY.

WARNING!

FUNCTIONAL

TED A

T THE REAR OF THE GANTR

CT SYTEC/SYTEC I SERIES

CHECK /

Y BASE BEFORE

ADJUSTMENT

2234976

ROTATION HAZARD !

ALWAYS INSERT THE GANTRY AZIMUTH LOCK PIN BEFORE REPLACING THE TUBE, DAS

OR

DETECT

OR.

WARNING!

ELECTROCUTION !

DANGEROUS VOLTAGES ARE PRESENT ON UNSHIELDED TERMINAL.

INTRODUCTION1–2

Page 15

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-1-2

Operator Console

WARNING!

ELECTRICAL SHOCK HAZARD !

DANGEROUS

WORKING

Rotation Fan Assemblies !

Do

not place any item into rotating blades. Use extra care when working near Fan

VOLTAGES EXIST ON EXPOSED SURF

ON LIVE EQUIPMENT

.

CAUTION

NOTICE

ACES. USE EXTREME CAUTION WHEN

2234976

assemblies.

Turn OFF power before removing or inserting any board of plug.

INTRODUCTION1–3

Page 16

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

blank

2234976

INTRODUCTION1–4

Page 17

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 1

SYSTEM

TABLE OF CONTENTS

SECTION PAGE

SECTION

1 – CHECKS DURING SYSTEM INST

1-1 CHECK PRIOR TO APPLYING POWER 1–1.

1-2 GROUND CONTINUITY CHECK 1–4.

1-3 TEMPERATURE 1–5

1-4 POWER LINE VOLTAGE 1–6.

1-5 LOAD DISTRIBUTION 1–8.

1-6 EMERGENCY OFF TEST 1–10.

1-7 FILTER 1–10

1-8 CUSTOM PARAMETER 1–10.

1-9 X–RAY TUBE OVERHEAT SAFETY 1–11.

1-10 SCAN TEST 1–12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALLATION 1–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

2234976

SECTION

SECTION

SECTION

SECTION

2 – SOFTW

2-1 GENERAL 2–1.

2-2 FD FOR SYSTEM/OPTION SOFTWARE 2–3.

2-3 PRE–ATINST PROCEDURE 2–5.

2-4 ATINST 2–11

2-5 POST–ATINST PROCEDURE 2–17.

2-5-1 Loading Version 3.02 System Software 2–25.

2-5-2 Loading Version 4.00 System Software 2–27.

2-5-3 Loading V/R 4.01 System Software 2–34.

2-5-4 Loading V/R 4.02 System Software 2–36.

3 – X–RA

3-1 GENERAL 3–1.

3-2 PLANE OF ROTATION 3–3.

3-3 DETECTOR BEAM ON WINDOW 3–6.

3-4 GRAVITY SAG 3–9.

3-5 ISO CENTER ALIGNMENT 3–14.

3-6 FILTER CENTER ALIGNMENT 3–18.

4 – SYSTEM CALIBRA

4-1 GENERAL 4–1.

4-2 CALIBRATION 4–2

4-3 CT NUMBER ADJUSTMENT 4–4.

5 – IMAGE PERFORMANCE VERIFICA

5-1 GENERAL 5–1.

5-2 IMAGE PERFORMANCE 5–2.

5-3 QUALITY ASSURANCE 5–5.

ARE LOADING 2–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y ALIGNMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TION 4–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TION 5–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1.

SYSTEMi

Page 18

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

blank

2234976

SYSTEMii

Page 19

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

SECTION 1 – CHECKS DURING SYSTEM INSTALLATION

1-1 CHECK

This

section assumes all wiring and cabling is complete, equipment is installed, and that the following circuit

and switches are OFF.

PRIOR T

O APPL

YING POWER

CAUTION

Leave all power to the System OFF and tagged until power is called for in a specific step.

D

BREAKER IN P

D

6 BREAKERS (CB 1 – 6) in XG cabinet

D

4 REAR BREAKER SWITCHES (SW 1 – 4) and 1 BREAKER (NFB) in Gantry

.D.B (Power Distribution Box) for hospital supply

(NFB is only for System with T

able P9155AF)

2234976

breakers

D SER

D

D

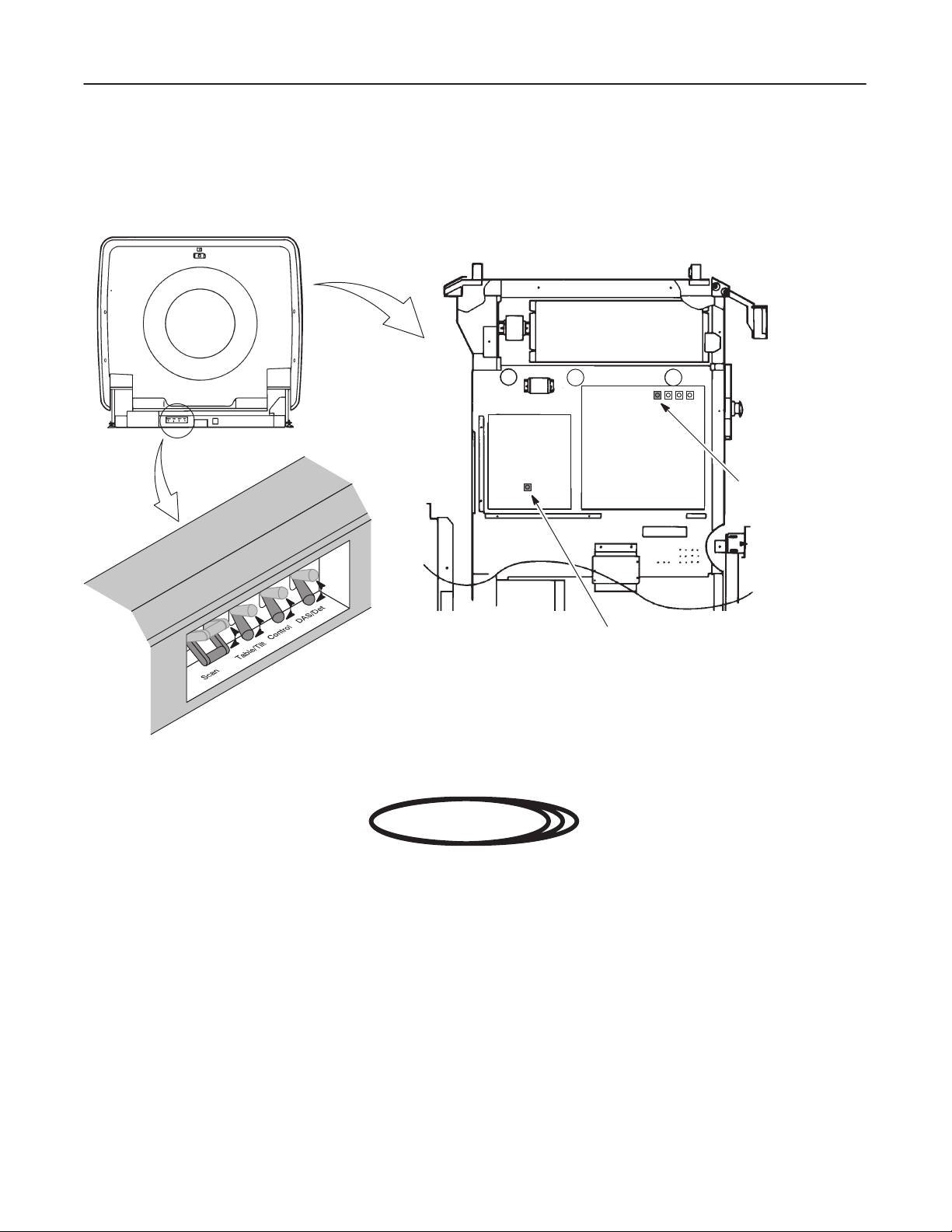

Illustration 1–1

VICE SWITCH in Gantry

SYS–OFF–MNL SWITCH in Gantry

2 BREAKERS (NFB1, 2) in OC

XG Cabinet

CB6

CB1∼CB5

TM1 TM2

SYSTEM1–1

Page 20

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-1

CHECK PRIOR T

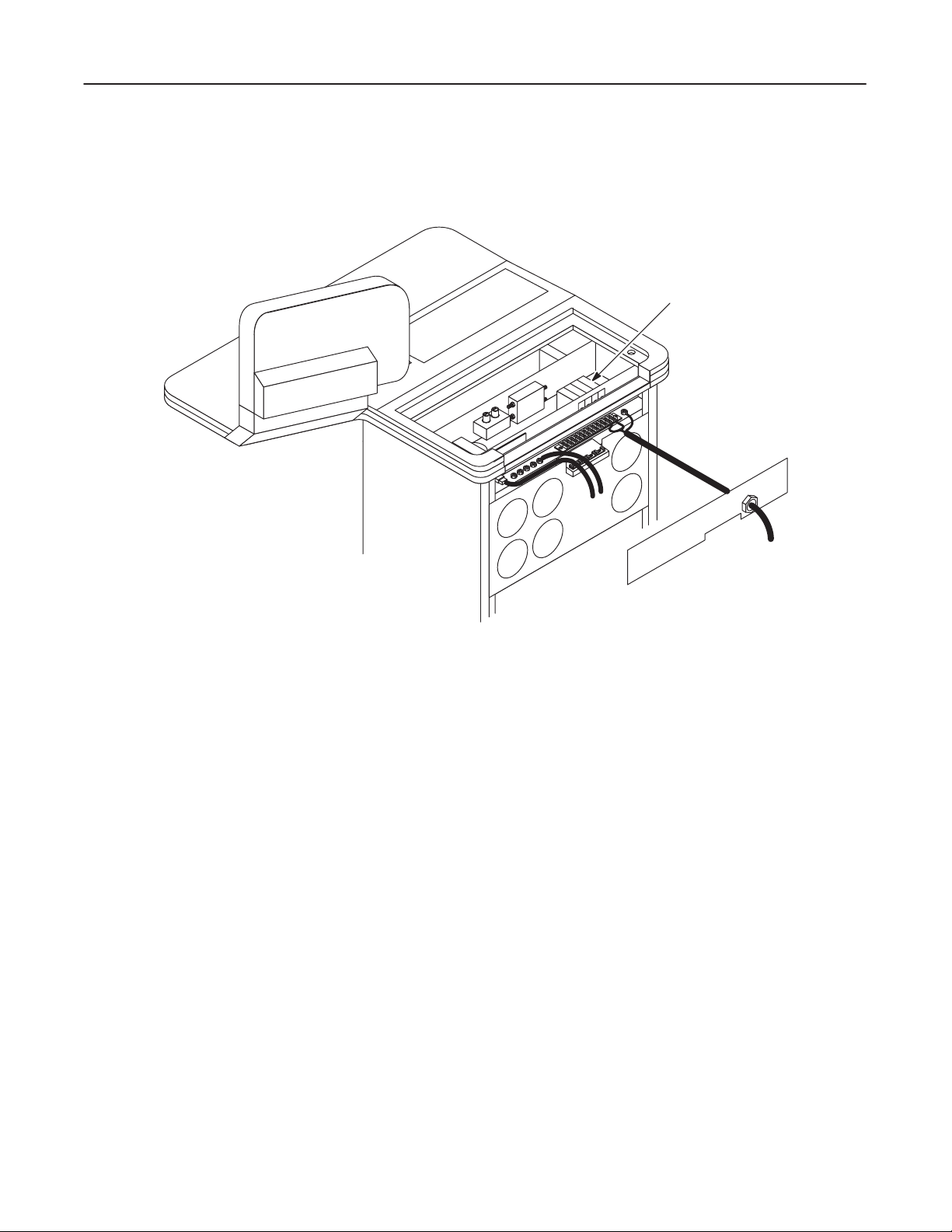

Illustration 1–2

O APPL

Gantry

2234976

YING POWER (continued)

Servo Amp

Sub Board

TGP Board

Service Switch

(SYS/OFF/MNL)

Service Switch

DANGER!!

FATAL COLLISION HAZARD!!

WHEN ‘CONTROL’ SWITCH LOCATED ON THE GANTRY REAR BASE IS

TURNED ON (WITH THE ‘SCAN’ SWITCH ON), THE GANTRY WILL ROTATE

DUE TO INITIALIZATION.

Note

The ‘Scan’ and ‘TBL/Tilt’ switches must be turned ON before turning ‘Control’ switch ON. The

switches

turning ON sequence is as follows:

‘Scan’ ON ––> ‘TBL/T

ilt’ ON ––> ‘Control’ ON

The ‘DAS/Det’ switch ca be turned ON any time.

SYSTEM1–2

Page 21

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-1

CHECK PRIOR T

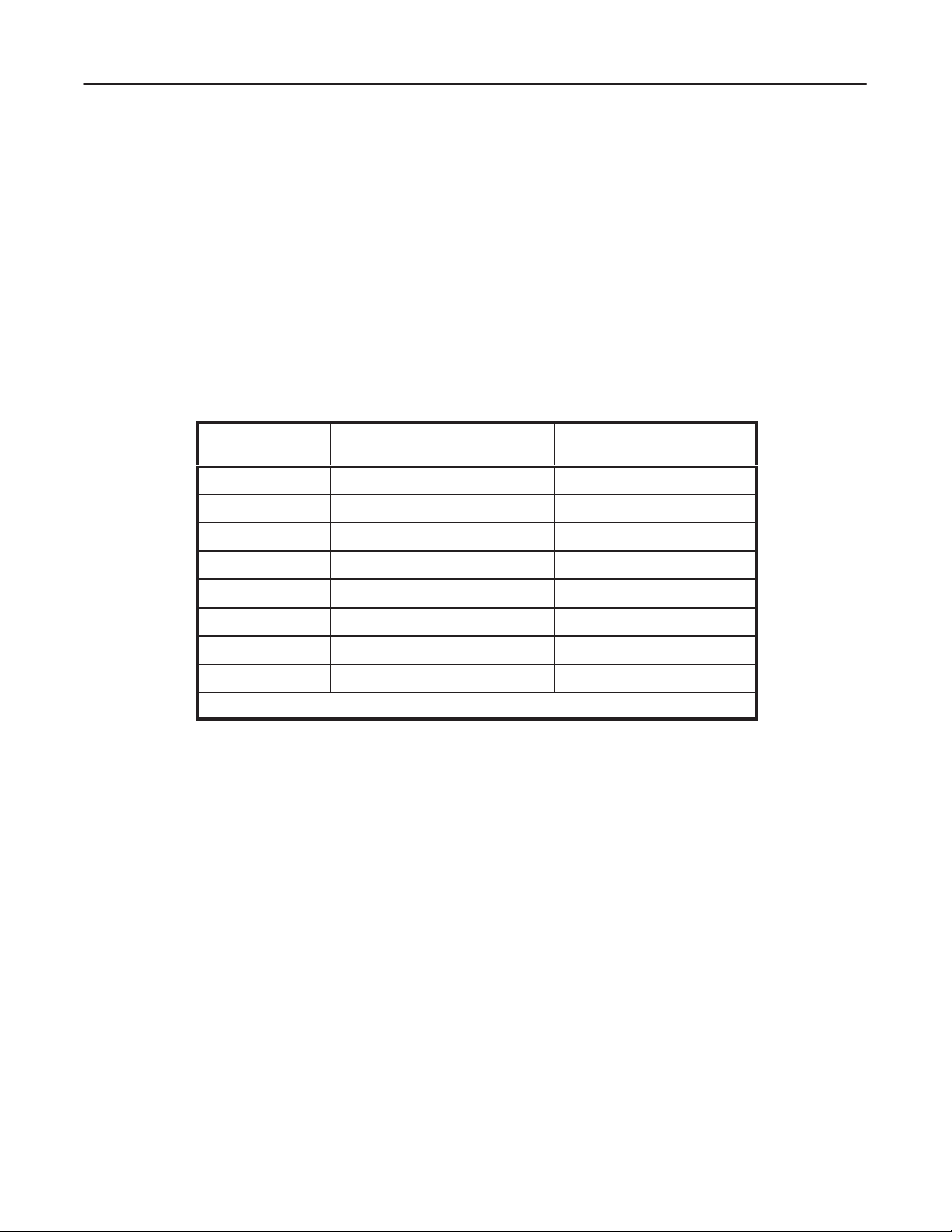

Illustration 1–3

O APPL

YING POWER (continued)

Operator Console

2234976

NFB1, NFB2

SYSTEM1–3

Page 22

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-2

GROUND CONTINUITY CHECK

V

erify that you removed the four(4) tilt lock plates and pulled out the Gantry azimuth lock pin.

1. Review illustration xxx, SYSTEM GROUNDING DIAGRAM schematics in the Installation Manual (P9018AS),

and

check that all connections are mechanically secure at both ends.

2.

Use a multimeter of equivalent device to measure the DC resistance between the following components in the

System, and verify that the resistance of each is less than

Ground specifications ≤ 0.1

T

able 1–4

GND (PDB)

GND (XG) GND (GANTRY)

GND (GANTRY) GND (TABLE)

Ground Continuity Check

FROM TO Resistance

Ω.

GND (XG)

0.1Ω.

(Ω)

2234976

GND (XG) GND (OC)

GND (OC) GND (MT)*

GND (OC) GND (MFC)*

GND (OC) GND (OD)*

GND (OC)

Note:

* indicates optional components.

GND (Advantage Windows)*

SYSTEM1–4

Page 23

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-3 TEMPERATURE

During the installation and start–up of the system you must take continuous temperature checks to make sure the

environment meets specifications listed in Section 3 of the Preinstallation manual (P9018AR). Excessive temperature,

coupled with reduced air flow from clogged filters, may overstress components and cause failures.

Filters

Check

and clean all electronic equipment dust filters. GE recommends initially doing this on a weekly basis, because

new installations

nance

interval as site environment improves.

Specifications

During installation, use the temperature/humidity recorder and thermometer to record the temperature and relative

humidity

tions.

in the scanner room. Make sure the data you collect meets the following temperature and humidity specifica

D Scanner

always have dust and dirt present at this stage. Over a period of time, you may increase the mainte

Room

–T

emperature :

20°C ∼

28

°C

2234976

-

-

Action

Contact

tions.

–

Relative Humidity :

D Operator’

the air conditioning supplier or your local GE service department when your data fails to meet any specifica

s Room and/or Equipment Room

–T

emperature :

–

Relative Humidity :

40% ∼ 70% (Non Condensing)

15°C ∼

20% ∼ 80% (Non Condensing)

30

°C

-

SYSTEM1–5

Page 24

GE MEDICAL

REV

0

1-4

POWER LINE VOL

Input Selection of 200V or 208V

V

erify that the following connections in X–Ray Generator meet the input power voltage.

SYSTEMS

FUNCTIONAL

TAGE

CT SYTEC/SYTEC I SERIES

CHECK /

ADJUSTMENT

2234976

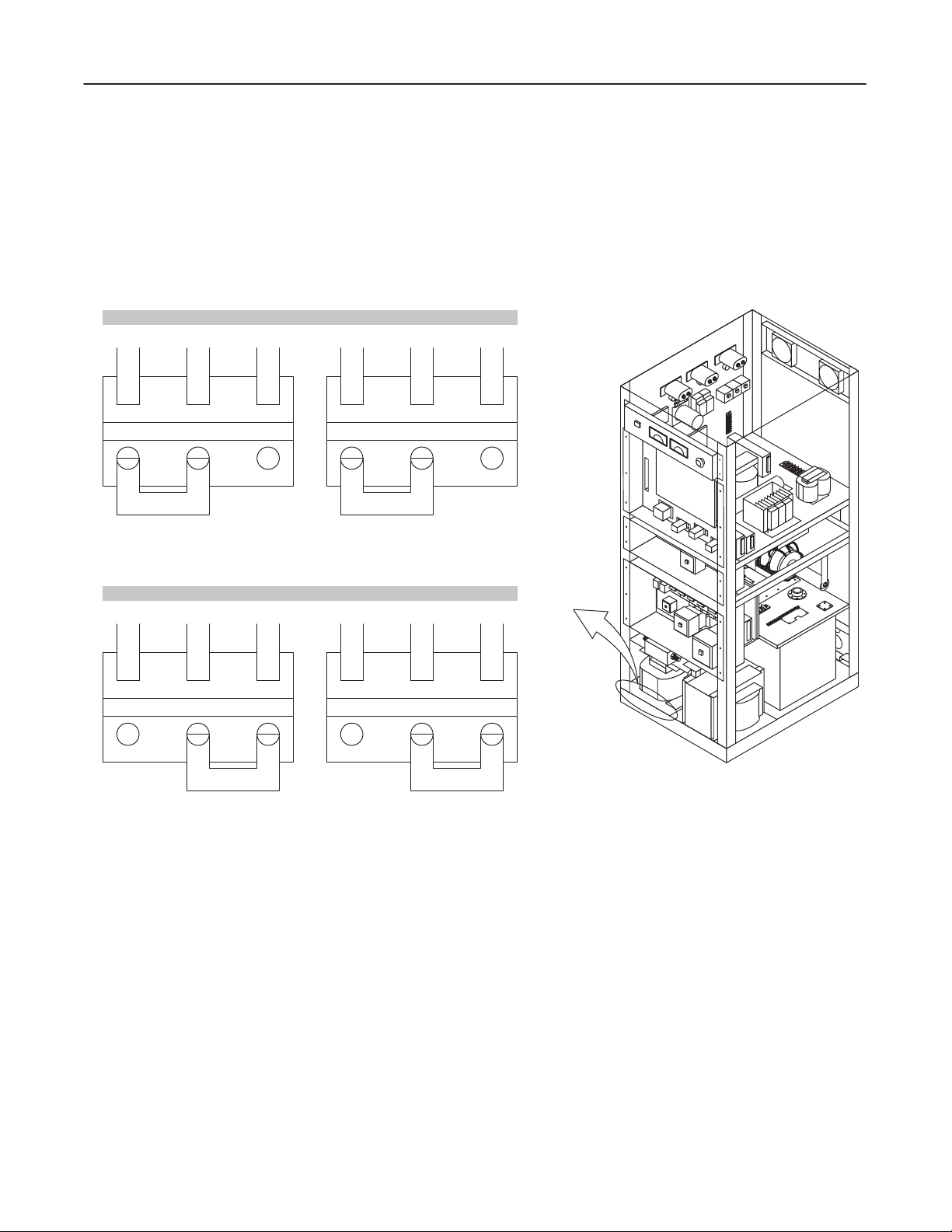

Illustration 1–5

TM3 TM4

200V C 208V 200V C 208V

TM3 TM4

200V C 208V 200V C 208V

V

oltage Selection

For 200V System

For 208V System

SYSTEM1–6

Page 25

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-4

POWER LINE VOL

The

following assumes that the power source for the system was checked for mean voltage, as well as any line

disturbance

Instrument

Use

the same instrument (Dranetz, etc.) to monitor line voltage during this check that you used during the preinstalla

tion

check. The recommended line analyzer is

or Dranetz Model line monitor plug in modules. Y

mean voltage, surges, sags, short term impulses, and frequency drift.

Check Using an Instrument

Monitor the input power lines (200V

during preinstallation site checks.

D V

erify that the current line voltage equals the voltage measured during the preinstallation check.

D Verify

that mean line voltage does not fall outside of equipment specifications during the day to day opera

tion

of other site equipment during the installation period.

TAGE (continued)

AC or 208V

the Dranetz Model 606–3 (3 channel) with the 101 frequency option,

ou can use a

AC) to the System at the System. Check in particular:

similar analyzer

, as long as it can monitor and report

2234976

voltage

-

-

D Look

From the printouts, ensure that the power supply meets the following criteria :

Check Using an Oscilloscope

Monitor

between the oscilloscope’

harmonics of the third, seventh, and eleventh derivative will be the most prevalent.

Action

Investigate any condition that falls out of spec. Identify the problem source(s) and resolve the problem.

the power lines with an oscilloscope and verify that no significant distortion, noise or transients exist. Switch

for any line voltage disturbances and check for a correlation between disturbances and system mal

functions

D

Line V

D

Daily V

D Frequency :

such as “Aborts” or component failures.

oltage :

oltage V

ariation :

s long and

200V

AC (50 Hz/60 Hz) (Normal Steady State)

208V

AC (60 Hz) for U.S.A. (Normal Steady State)

+10% to –5% from nominal steady state (50Hz)

+6% to –9% from nominal steady state (60Hz)

50Hz ± 0.5Hz, 60Hz ± 0.5Hz

short

time base to monitor for spikes, as well as line drift over time. Generally

-

,

SYSTEM1–7

Page 26

GE MEDICAL

REV

0

1-5 LOAD DISTRIBUTION

Before

attempting this power application and functional check,

instructions

SYSTEMS

given in ‘Checks prior to Applying Power

ELECTRIC SHOCK HAZARD !!

DANGEROUS

TO

PERSONNEL AND EQUIPMENT

VOLTAGES EXIST WITHIN THE UNIT

.

make sure that the breakers and switches match the

.’

WARNING!

, USE EXTREME CARE TO A

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

VOID INJUR

ADJUSTMENT

2234976

Y

Follow this procedure

Follow this sequence to protect you and the equipment from irreparable damage.

1. Preparation

a.

Remove the following covers:

D XG Covers (front and rear)

D OC Covers (front and rear)

D T

able Bottom Cover

D

Gantry Left side Cover

b. V

erify again that all breakers and switches are OFF according to ‘Checks prior to Applying Power

c. V

erify that wiring and cabling are correctly connected.

d.

2.

Switch ON the breaker on the power distribution box (hospital supply).

3.

Measure 200 (or 208) V

It should be

4.

Switch ON the ‘TRANS’ (CB1) breaker on the XG.

exactly

200 (or 208) ± 20V

in the order it was written. This procedure was developed with your safety in mind.

AC between terminals 1 and 2 (or 2 and 3) on TM1 on the XG.

AC.

.’

V

erify that the ‘Power

5.

Switch ON the ‘DAS’ (CB3) breaker on the XG.

6.

Measure 100V

7.

Push the ‘Power

Listen for the sound of contactor K1, K2 and K3 actuating in the XG. Check that the plunger indicators on K1,

K2

and K3 are pulled into the relay bodies.

AC between terminals 6 and 7 on TM2 on the XG. It should be

’ lamp in the front upper left corner of the XG turns ON.

’ switch on the OC.

100 ± 10V

AC.

SYSTEM1–8

Page 27

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-5 LOAD DISTRIBUTION (continued)

8. Switch

9. Push

On the ‘OC’ (CB5), ‘TG1

voltages:

D 100 ±

D 115 ± 11.5VAC

D 200

the ‘Power

10V

AC

(or 208) ± 20V

’ switch on the OC. V

15’ (CB4) and ‘TG200/208V’ (CB2) breakers on the XG, and

.

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

AC

.

. . . . . . . . . . . . . .

FATAL COLLISION HAZARD !!

WHEN BREAKERS LOCATED ON THE GANTRY REAR BASE ARE TURNED

ON, ALWAYS TURN THE SWITCHES ON IN THE FOLLOWING ORDER.

‘SCAN’ ON → ‘TABLE/TILT’ ON → ‘DAS/DET’ ON → ‘CONTROL’ ON

(CONTROL SWITCH MUST BE TURNED ON LASTLY.)

check the following

between terminals 10 and 1

between terminals 4 and 5 on TM2 (for TG1

between terminals 1 and 2 (2 and 3) on TM2 (for TG200/208V)

erify that the K1, K2 and K3 are turned OFF

1 on TM1 (for OC)

15V).

.

DANGER!!

2234976

FAILURE TO HEED THIS WARNING MAY LEAD TO GANTRY ROTATION AND

RESULT IN PERSONAL HARM, HARM TO OTHERS OR DEATH.

10. Switch

ON all breakers and switches according to ‘Checks prior to Applying Power

FATAL COLLISION HAZARD !!

VERIFY

THA

T NO PEOPLE ARE IN THE SCAN ROOM. THE GANTR

AUTOMATICALLY IMMEDIATELY AFTER THE OC POWER SWITCH IS

TURNED

ON. WHEN THE GANTR

CAN BE CAUGHT IN THE GANTRY. FAILURE TO HEED THIS WARNING MAY

RESULT IN PERSONAL HARM, HARM TO OTHERS, OR DEATH.

11. Push

the ‘Power

V

erify that the ‘OC Power

V

erify that the 16 Fans rotate properly

’ switch on the OC.

.’

DANGER!!

Y ROT

Y COVERS HA

’ lamp turns ON, and ‘System Preparation’ is displayed on the CR

.

VE BEEN REMOVED,

ATES

PEOPLE

T monitor

.

D Six(6) Fans

D Nine(9) Fans

D One(1) Fans

.

. . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . .

upper rear part

bottom side of the nest chassis

behind power supplies

SYSTEM1–9

Page 28

GE MEDICAL

REV

0

1-6

EMERGENCY OFF TEST

1.

Press the emergency switch on the OC.

Verify

tector).

SYSTEMS

that contactor K1, K3 and K4 in the XG turn OFF

FUNCTIONAL

, and cut the power to the T

CT SYTEC/SYTEC I SERIES

CHECK /

able/Gantry (except DAS/De

ADJUSTMENT

2234976

-

2. Press

There are two emergency switches on the Gantry and one emergency switch on the XG. Perform this emergency

OFF

1-7 FILTER

There are on Filter in the OC and two in the XG.

1.

2.

3.

4.

1-8 CUST

the ‘Power

test on each on the three emergency switches.

D

OC : Horizontal. one on the bottom of OC –– housed within a gold mesh filter enclosure.

D

XG : V

Slide the filter at the bottom of the OC forward until it is removed from the OC.

Remove the front and rear covers of the XG and gentry pull the the foam out of each enclosure.

Suck up any dust on the filters with a vacuum cleaner

Slide or fit each filter back into its enclosure.

OM P

’ switch twice to reset emergency OFF

ertical, one each on the front and rear cover –– foam held in place by a white mesh enclosure.

ARAMETER

, and re–apply power

.

.

Run

the Custom Parameter program to set the correct system configuration. Y

you

change the system configuration (adding the option, etc.).

Refer to Functional Check/Adjustment manual, System, Section 2.

Note

No image data must exists on the system hard disk if you set or change the following parameters.

–

Optical Disk Option

–

Magnetic T

– Frequency

–

Machine Number

–

Hospital Name

BOOT floppy must be in the floppy disk drive to change the parameters.

ape Option

Note

ou must also

run this program any time

SYSTEM1–10

Page 29

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-9 X–RA

Check the overheat detection function by performing the following:

1.

2.

3.

4.

5. T

Y TUBE OVERHEA

Switch OFF the ‘Scan’ switch at the Gantry rear base

Remove the both side covers from the Gantry

Disconnect the rotor cable.

If the connector is not accessible, perform the following:

a.

Set the Service switch to ON on the SUB Board.

b.

Rotate the Gantry until the X–ray tube reaches the 3 o’clock position.

c.

Set the Service switch to OFF

Switch ON the ‘Scan’ switch.

ry to perform a scan.

V

erify that a scan can not be performed and the “XG Fail” error message is reported on the status screen.

T SAFETY

.

.

2234976

V

erify that the ‘OH’ LED on the Power CONT Board in the XG is illuminated.

6.

Switch OFF the ‘Scan’ switch.

7.

Reconnect the connector

.

SYSTEM1–11

Page 30

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-10

SCAN TEST

This

check assumes successful completion of all functional checks for XG, Gantry T

tec

i series Operator Manual for scanning operation instructions.

DANGER!!

X–RAY EXPOSURE !!

IN

THIS SECTION, THE X–RA

THAT

Warm

Up Scan

1.

Make sure system power is ON an the ‘New Patiant’ and the ‘W

NO PEOPLE IS IN

‘W

arm Up’ should blink just after power up or system reset.

THE SCAN ROOM WHENEVER SCAN IS PERFORMED.

Y EXPOSURE IS PERFORMED. ALWAYS VERIFY

arm UP’ arear are blinking on LCD screen.

Note

2234976

able and OC. Check CT Sytec/Sy

-

2.

Make sure mothing is in the scan arear in the Gnatry room.

3. T

ouch the ‘W

Make sure all warm up scans complete without error

aum Up’ prompt to start the tube warm up program.

.

SYSTEM1–12

Page 31

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-10 SCAN TEST (continued)

Scoutview Scan

4.

Perform a series of scout scans to check scout scan operations:

Use the following scan parameters:

FOV

mA

Tilt

a.

Make sure that each scan is completed successfully

b. T

ilt the Gantry to any angle.

Make sure the software prohibits a scout scan with the Gantry tilted.

c.

Release the ‘Scan ’ button during a scout scan.

V

erify it aborts X–ray radiation, rotor rotation and cradle movement.

: 42 cm

: 40, 60 or 80 mA

: 0

°

2234976

.

d.

Select Auto V

Lay the water phantom horizontally on the cradle.

Perform an AP (0°) scout scan on the phantom.

Make sure that you can hear and understand each voice.

V

erify that the phantom diameter (In–Out direction) on the image is

e.

Select Auto V

Set the QA phantom on the phantom holder

Perform a L

Make sure that you can hear and understand each voice.

Release the ‘Scan’ button before the whole image is displayed and verify that the scan continues.

Push the ‘Abort’ key and verify that the cradle and scan stop.

oice S1 and Auto V

oice S2 and Auto V

T (90°) scout scan on the phantom.

oice E1.

oice E1.

.

266mm ± 3mm

.

SYSTEM1–13

Page 32

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-10 SCAN TEST (continued)

Localize

5.

Perform a Localize function:

a.

Display a scout image (use the image acquired at step 4).

b.

Select the Localize function.

c.

Prescribe and confirm an axial scan plan.

Make sure theat the ‘T

d.

Press the ‘T

Check that the cradle advances to the prescribed position.

Axial Scan

able Set’ button.

2234976

able Set’ button blinks.

6.

Perform an axial scan to check axial scan opreation:

Use the following scan parameters:

Interval : +10.0mm

Scan T

a.

Select each of the Auto V

V

erify that each scan completes with no error occurred.

V

erify that you can hear and understand each voice.

Recon Time

7.

Perform an axial scan using the following scan parameters:

Scan T

Scan FOV

Recon FOV

Recon Mode

Anatomic Region

ime : 3.6 sec

2.7 sec

1.8 sec

ime : 3.6 sec

(CT Sytec 2000i, S)

(CT Sytec, 3000i)

(CT Sytec 4000i, Plus)

oice messages (S1, S2, S3, S4, S5 or S6).

2.7 sec

1.8 sec

:

25 cm

:

25 cm

: STND

: Head

(CT Sytec 2000i, S)

(CT Sytec, 3000i)

(CT Sytec 4000i, Plus)

V

erify that the time between the scan end and the image appearance on the CR

T monitor is within

15 sec

SYSTEM1–14

.

Page 33

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

1-10 SCAN TEST (continued)

KV and mA Meter

8.

Perform a series of axial scans (mA : 40, 60, 80, 100, 130 and 160).

V

erify that the KV meter on the XG read

Also verify that the mA meter on the XG reads the expected value ± 5%

Abort

9.

Perform an axial scan and press the ‘Abort’ button before the scan completes.

V

erify that the scan is terminated.

120KV ± 3KV

.

2234976

.

SYSTEM1–15

Page 34

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

blank

2234976

SYSTEM1–16

Page 35

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-1 GENERAL

Save

existing patient data any time you perform the LFC procedure or you will lose this data.

The saving procedure is described in section 2-3 Pre–ATINST Procedure, Saving Customer

Data.

For DC–X, the system must be running on at least version 5.00 software. If the customer ’s

DC–X

system is older than version 5.00, perform FMI (FM91015 or 91016) must be performed

(version

2234976

SECTION 2 – SOFTWARE LOADING

NOTICE

NOTICE

5 upgrade) first.

This

section describes the

Disk)

to system hard disk. Perform this LFC procedure when:

D A failure or crash corrupts the hard disk so the existing software can not be used. A Load–From 0Cold

rebuilds

D CT Engineering has revised the current software to incorporate improvements or correct existing prob-

lems.

Replace the old software by performing a Load–From–Cold with the new software.

Load–From–Cold (LFC) procedure for a full system software loading from some FD (Floppy

the operating software on the disk and restores normal system operation.

SYSTEM2–1

Page 36

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-1 GENERAL (continued)

Illustration 2–1

•

‘Acq Reverse’ Data

•

Communication Data

•

Ethernet Data

•

Station Data

•

Raw Data Files

•

Patient Image Data

•

Error Message Help

•

Record the Custom Parameters –––––

Load–From–Cold Standard Procedure

Start

Save Customer Data

– Start Study No.

– Direction of Scout Image (Apex / Lateral)

– Gantry Direction from Operator

Set CPW Boot Dip Switch

Insert Boot Floppy

Pull Reset Switch

A

TINST Program

2234976

•

Data File Save –––––––––––––––––––––

•

Disk Initialize

•

Software Loading (Standard, Option)

•

File Allocation

•

Data File Loading

Starting Up System

•

Remove Floppy Disk

•

Reset CPW Dip Switch

•

Pull Rest Switch

Restore Custom Parameters

•

Including Additional Option Software Loading

•

Custom Parameter Change

(It is necessary to manually restore the parameters due to a software bug.)

– Start Study No.

– Direction of Scout Image (Apex / Lateral)

– Gantry Direction from Operator

Restore Customer Data

•

‘Acq Reverse’ Data

•

Communication Data

•

Ethernet Data

•

Station Data

•

Raw Data Files

•

Patient Image Data

•

Error Message Help

– Calibration Files

– Station No. Information

– Preset Patients Information

– Scan Parameter

– System Parameters (Custom Parameters, etc...)

End

SYSTEM2–2

Page 37

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-2

FD FOR SYSTEM/OPTION SOFTW

Prepare the following, prior to starting the LFC procedure.

T

able 2–1

System Software Diskettes

V

olume Name

ARE

BOOT 0

KEY0 1

LO00 2

LO10 3

LO20 2

LO21 2

LO30 3

LO31 2

LO40 2

2234976

Revision

LO41 2

LO42 2

LO43 3

HO00 4

CT00 3

CT10 2

VC00 2

TD00 3

OP00 0

OP01 0

OP02 0

OP03 0

OP04 0

PL00 (for CT Sytec 4000i, Plus)

ST00 (for CT Sytec, 3000i)

BS00 (for CT Sytec 2000i, S)

4

4

4

V400 (1/5 ∼ 5/5)

V400 (for CT Sytec 4000i, Plus)

V400 (for CT Sytec, 3000i)

V400 (CT Sytec 2000i, S)

0

0

0

0

SYSTEM2–3

Page 38

GE MEDICAL

N

Volume

R

N

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-2

FD FOR SYSTEM/OPTION SOFTW

T

able 2–2

Volume

o.

Name

1 PZ00 1

2 PG10 1 Paging F F f

3 CVRF 2

4 RTRF 2

5 DIND 1

6 DIM3 1

7 CD00 2 Coordinate f f f

8 DENT 2

9 ELNK 1

Option Software Diskettes

ev.

Pan / Zoom

Curved Reformation

Real T

ime Reformation

Display in Display

3D Imaging

Denta Scan

Ethernet Link

ARE (continued)

ame

Sytec 4000i, Plus

F F f

F F f

F F f

F f f

f f f

f f f

f f f

Option or Standard

Sytec, 3000i

Sytec 2000i, S

2234976

10 INST 0 InSite f f f

11 BMD0 1 BMD f f f

12 CCI0 0 CCI f f f

13 FI00 0

F

: Standard

f

: Option

Normally, option software disks and also some application software disks included in the system software (‘PG00’

disk,

‘PZ00’ disk, ....) are

if the A

TINST program (described later) failed, or when the system hard disk drive is replaced with a new one.

Functional Image

: The system includes the software.

: The system does not include the software.

not required in a version up or a re–loading procedure. However

f f f

, these disks are required

SYSTEM2–4

Page 39

GE MEDICAL

REV

0

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

2234976

2-3 PRE–A

Save Customer Data before proceeding. You must load Customer Data onto floppy diskette, tape or optical disk

cartridge because the LFC (Load–From Cold) procedure destroys any information on the system disk. Refer to the

Operator Manuals to complete the following steps.

1.

Record ‘Acq Reverse’ user setting parameter

a. After displaying an image on the CRT screen, write down ‘Acq Reverse’ data (ON or OFF) in ‘Set

2.

Save Communication Data.

For any system on which ELINK is installed, save Communication Data, Station No. and Ehternet Data on a

floppy

a.

TINST PROCEDURE

Note

Alphanumeric letters you must enter at the keyboard are underlined. ‘CR’ means press the ‘Enter

.

function.

Note

Usually

matically in the A

be

Press the [Mgt] key

the parameter setting data does not need to

TINST program (Data File Save Function). However

recorded due to a software bug.

disk. Otherwise, these data will be deleted during LFC.

.

be recorded, since the data will be saved auto

, only ‘Acq Reverse’ data

must

’.

Display’

-

D

Select Communication Data Load/Save → Save

D

Select Ethernet Data Handling → Save to FD

D

Select Dump Parameters → Station Number Information File

Note

When saving all information above, use on floppy disk.

SYSTEM2–5

Page 40

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-3 PRE–ATINST PROCEDURE (continued)

NOTICE

If

you intend to save raw data on MOD, e sure to start with a blank cartridge, or one that does

not

need to be preserved. This procedure erase all previous data contained on

tridge.

3. Save

Raw Data Files:

Archive

wise,

Use the ‘Maintenance’ function to save the Raw Data as follows:

a.

b.

c.

d. V

Raw Data Files to a MOD, floppy

these files are destroyed during LFC.

Select

Select

Record the ID number of the Raw Data Files which you want to save.

Support

FD Dump/Load, MT Dump/Load

erify that the MOD should be set “write enable”.

from the Maintenance menu.

disks, tape, or optical disk if the customer wants to save them. Other

, or

MOD Dump/Load.

the MOD car

2234976

-

-

e.

Select

f.

Select

g.

Enter all the Raw Data File ID numbers. Then press the [End] key

4.

Save Patient Image Data:

Archive Patient Image Data to a MOD, floppy disks, tape, or optical disk if the customer wants to save them.

Otherwise,

Data. (Refer to Operator Manual.)

5.

Check if the service maintenance menu includes ‘

If

the system contains ‘Error Message Help’ function, it must be reinstalled since version–up or reloading proce

dures

Initialize

Dump (Disk –> MOD)

these files are destroyed during LFC. Use the ‘Image File Management’ function to save the Image

delete it.

to initialize the MOD.

.

.

Error Message Help

’.

-

SYSTEM2–6

Page 41

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-3 PRE–ATINST PROCEDURE (continued)

6.

Record Customer Parameters.

Usually the Customer Parameter Data does not need to be recorded, since the data will be saved

automatically

rameters

D

Start Study No.

D Direction of Scout Image (Apex)

D

Direction of Scout Image (Lateral)

D

Gantry Direction from Operator

Also,

it is recommended to check which option software are currently installed

you

can confirm later that those option software have been correctly retrieved. In addition, if you nave

all

the records, they con serve as backup in the event there is trouble with the A

a.

Select

in the A

must be recorded due to a software bug.

Custom Parameters

TINST program (Data File Save Function). However

from the Maintenance menu.

Note

Note

, at least the following pa

on the system, so that

TINST program.

2234976

-

b.

Select

Custom

ters.

Custom

Therefore, enter the

Display Parameters

Parameters will be displayed

Parameters include Function Menu which noes not show in the Display Parameters mode.

.

one by one, as listed in T

Change Parameters

able 2–3. Use this table to record the parame

mode and record the parameters in T

-

able 2–4.

SYSTEM2–7

Page 42

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-3 PRE–ATINST PROCEDURE (continued)

T

able 2–3

Current Model Name

Auxiliary

Optical Disk

Magnetic Optical Disk

Magnetic T

Frequency

Machine No.

Hospital Name

Start Study No.

Disk Size

ape

Custom Parameters (Display)

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

50 . 60

2234976

vailable

vailable

vailable

vailable

Direction of Scout Image

Apex Lateral

Kind of Base

Gantry . Head

Gantry Direction from Operator

Head T

Postfossa T

Neck T

Thorax T

Abdomen T

Pelvis T

Extremities T

Thickness 2/3mm

Note1

: For Sytec 2000i and Sytec S system, this parameter is NOT displayed.

Picture Direction

Upper . Lower

Left . Right

Direction of Axial Image (from)

op . Bottom

op . Bottom

op . Bottom

op . Bottom

op . Bottom Infant – Abdomen

op . Bottom

op . Bottom

Infant – Head

Infant – Postfossa

Infant – Neck

Infant – Thorax

Infant – Pelvis

Infant – Extremities

2mm . 3mm

Kind of Base

Gantry . Head

Picture Direction

Upper . Lower

T

op . Bottom

T

op . Bottom

T

op . Bottom

T

op . Bottom

T

op . Bottom

T

op . Bottom

T

op . Bottom

(see Note1)

SYSTEM2–8

Page 43

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-3 PRE–ATINST PROCEDURE (continued)

T

able 2–3

P

AN & ZOOM

PAGING

3D IMAGING

REAL–TIME REFORMA

CUR

VED REFORMA

BMD

COORDINATE

CALCULATOR

DENTA

DISPLA

NETWORK

Y IN DISPLA

Custom Parameters (Display) (continued)

TION

TION

Y

Option

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

Unavailable . A

2234976

vailable

vailable

vailable

vailable

vailable

vailable

vailable

vailable

vailable

vailable

vailable

SET LANGUAGE TYPE

INSITE

No. of Raw Data

Note2

: This parameter is displayed at the system o version 3.01 or later

T

able 2–4

Auto Store Device Option

OD Special Store Option

Auto Delete Option

Min. V

acant Image Space for Scan

FD Packing Option

MT Packing Option

OD Packing Option

FD System No.

MT System No.

OD System No.

Custom Parameters (in Change Mode)

Function Menu

Unavailable . YMS E–LINK

English . French (see

OD . MT . MOD

NON . AUT

ON . OFF

DPCM . ORIGINAL

DPCM . ORIGINAL

DPCM . ORIGINAL

Note2)

.

O

MT Image Max. No.

Device T

Note3

ype of Optional Disk

: This parameter appears only if both OD and MOD are installed.

128 . 256 . 384 . 512 . 640 . 768

OD . MOD

(see Note3)

SYSTEM2–9

Page 44

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-3 PRE–ATINST PROCEDURE (continued)

7.

Save data files (Preset Patient Information, Series Description, ....)

Note

Usually

in

trouble with the A

D

D Series

D Calibration

D Station

the sets of information below do not need to be saved since they will be automatically saved

the A

TINST program. However

, if you save them, they can serve as backup in the event there is

TINST program.

Preset Patient Information

Description

Files

No. Information

.

. . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . .

.

. . . . . . . . . .

Select

Select

Select

Select

Dump Parameters

Dump Parameters

Dump Parameters

Dump Parameters

Note

Do not save the System

has

been retried, system might hang–up.

Parameter

. If the backup system parameter will be restored after ATINST

2234976

from the Management menu.

from the Management menu.

from the Management menu.

from the Management menu.

SYSTEM2–10

Page 45

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

0REV 0

2-4 ATINST

Introduction

ATINST

BOOT

program performs the following operations on after another automatically

floppy performs the most of the LFC procedures, as described below:

D

Data File Save

The

following data is automatically saved to the floppy disks. Prepare a few (1 ∼ 4) blank floppy diskettes

before

starting A

–

–

–

–

–

–

TINST.

Calibration Files

Station Number Information

Preset Patient Information

Series Description

Scan Parameter

System Parameters

Custom Parameters

Window / Level Key Settings

W/L Menu Settings

Set Display Settings

Image Sequence Settings

. The program A

2234976

TINST included in

D

Disk Initialize

D Software Loading (Standard, Option)

Additional option software will be installed during the ‘Restore Custom Parameters’ procedure.

D

File Allocation

File

Allocation create variable files for the system hard disk, such as image directory

image

data files. If consists of two phases as follow:

–V

ariable File Allocation (VRALCT)

Create blank image file directory and blank calibration files.

–

Image / Raw Data File Reserve (DFRSV)

Reserves contiguous sectors on the disk for image data and raw data.

D Data File Loading

The data stored on the FD at the first stage of the A

TINST in automatically loaded to the hard disk.

, calibration files and

SYSTEM2–11

Page 46

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-4 ATINST (continued)

Failure Analysis of A

Each

of the A

to

have occurred while the A

The following error could occur during the execution of the A

If either of the above error occur

TINST operations are automatically called up after the previous procedure is finished. If an error seems

D T

est LED :

D T

est LED :

D TAL

D

******************************* Displayed *******************************

T LED :

An error of the A

TINST

TINST program is running, check the following LED’

When Test LEDs lit in 7x(h), it indicates that the program is accessing the hard disk or floppy

diskette.

When T

If lit, this LED indicates that the system operating system has terminated the current

command due to some error

It shows that the system is operating normally

est LEDs lit in D0(h), it indicates that a bus error has occurred. (abnormal state)

. (Abnormal state)

TINST program itself (Program abort due to a program bug or hardware failure)

, the following menu will be displayed:

2234976

s on the CPW board:

.

TINST program:

Current Task Aborted Unexpectedly

File Name : xxxx (a program name to which an error is occurred)

1. Exit INSTALLATION

2. Retry Current Task

Select Menu No. =

************************************************************************

Menu

1 :Terminates the A

Menu 2 :

If problems are unable to be fixed, type “A

Retry of A

After terminating the A

The ATINST program will start as ‘Reloading Mode’ or ‘First Loading Mode’, depending on when the program failed.

After the ATINST program is successfully finished, restore the following data files in that order, if they were saved.

Loading

order is very important.

Calibration Files

Station Number Information

Preset Patient Information

Series Description

Scan Parameters

Option software which the customer

InSite software (if system had)

Retries the program in which the error occurred.

TINST

TINST program by selecting ‘1’ in the menu, retry A

TINST program.

TINST” to resume A

’s system contains

TINST.

TINST.

SYSTEM2–12

Page 47

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-4 ATINST (continued)

Operating ATINST

It will take approximately 40 minutes for the A

TINST program to complete all its operation.

NOTICE

Save existing patient data any time you perform a LFC procedure or you will lose this data.

The

saving procedure is described in ‘Pre–A

Prepare all of the floppy diskettes listed in T

1.

Set the SW2 and SW4 of the “BOOT” switches on the CPW Board (Slot #1) to the ON option.

Illustration 2–2

Boot Switch Setting on CPW Board

ON

TINST’ procedure.

Note

able 2–1 and T

able 2–2 before starting this procedure.

2234976

1 2 3 4

OFF

2.

Insert the BOOT floppy into the disk drive.

3.

Pull the reset switch located under the right side of the Operator Console.

The system is reset and “>” will appear on the monitor

4.

Start the A

******************************* Displayed *******************************

FHS ERROR C2

> ATINST ‘CR’

Delete IMAGE & RAW Data ? <0:OK, 1:Exit> = 0 ‘CR’

** INSTALLATION START **

Please Insert <<KEY0_[ x]>> FD and Press <ENTER>

************************************************************************

TINST program by entering A

TINST:

.

SYSTEM2–13

Page 48

CT SYTEC/SYTEC I SERIES

GE MEDICAL

REV

0

2-4 ATINST (continued)

5.

Remove the BOOT floppy from the floppy drive and insert KEY0 floppy supplied with the system.

SYSTEMS

FUNCTIONAL

CHECK /

ADJUSTMENT

2234976

Press the <Enter> key

******************************* Displayed *******************************

Please Insert FD for STORE and Press <ENTR>

************************************************************************

Always

prompted

The following operations are carried out automatically in the order described:

D

D

D

D

D

If a non–initialize floppy diskette is inserted, it will be initialized automatically before saving data.

use either blank floppies to store Data Files, or answer “Y

during ST

Saving Data files

Disk Initialize

Software Loading (Standard, Option)

File Allocation

Data File Loading

.

ORE.

Note

Note

es” to “Initialize OK

?” question when

6.

Save Data Files:

Remove

the scratch

the

7.

Initialize Hard Disk:

Remove the floppy diskette that data files are saved on and insert “BOOT” floppy diskette.

Press the <Enter> key

the KEY0 diskette, then insert the scratch floppy diskette with No.1 written on it. Y

floppy

disks in order according to screen messages to save data onto these disks. Be sure to number

floppies in the order used (1–4) for later reloading.

Note

If a non–initialize floppy diskette is inserted, it will be initialized automatically before saving data.

. This starts VINIT program so that the hard disk will be initialized automatically

******************************* Displayed *******************************

Please Insert <<BOOT>> FD and Press <ENTR>

** VNINTS Start **

What Device Name (4 Characters)? 463 MB Disk

** VINITs End

************************************************************************

.

.

.

ou only have to change

.

SYSTEM2–14

Page 49

CT SYTEC/SYTEC I SERIES

GE MEDICAL

REV

0

2-4 ATINST (continued)

8.

Software Loading (Standard, Option)

Remove the “BOOT” floppy diskette and insert the system floppy requests.

Press the <Enter> key. You only have to change the floppy disks to be loaded according to screen messages

until

SYSTEMS

all the floppies are loaded.

******************************* Displayed *******************************

** FD Loading Start **

Please Insert <<xxxx_[ x]>> FD and Press <ENTR>

SELECT No. 1 2 3 4

1: COPY 2: COPY AND VERIFY

3: VERIFY 4: VERIFY WITH COMMENT

.

.

.

FD Loading End

FUNCTIONAL

CHECK /

ADJUSTMENT

2234976

************************************************************************

9. File

Allocation

Inset the “BOOT” floppy diskette and press the <Enter> key

This start the file allocation program so that the variable files are created automatically

******************************* Displayed *******************************

** VR FILE ALLOCATION **

.

.

.

** VRALCT End **

** DFRSV Start **

.

.

** DFRRV End **

************************************************************************

.

.

SYSTEM2–15

Page 50

CT SYTEC/SYTEC I SERIES

GE MEDICAL

REV

0

2-4 ATINST (continued)

10.

Data File Loading

Remove the “BOOT” floppy diskette and inset No.1 floppy diskette that includes the parameters saved during

“Saving

11.

Replace the No.1 floppy diskette with No.2 and press the <Enter> key according to screen messages. Repeat

this procedure until all parameters are loaded.

12. After all FDs have been loaded, press the <End> key to terminate the Data File Loading. Then the following

screen

SYSTEMS

Data files” procedures at the first stage of A

will appears.

******************************* Displayed *******************************

** INSTALLATION END **

*************************************************

* We will complete all works for installation *

* Put back the Dip Switch (1–4:OFF) *

* and pull the Rest Button. *

* Don’t Forget other operations as follows: *

* (*) Retrieve Image & Raw Data *

* (*) Change CUSTOM PARAMETER if necessary *

*************************************************

TINST

. Then press the <Enter> key

FUNCTIONAL

CHECK /

.

ADJUSTMENT

2234976

************************************************************************

ATINST First Loading Mode

If the ‘first Loading Mode’ is used as ATINST, you have to respond to inquiry during the ATINST operations, as described

below

. This inquiries is on Model Name.

D

Model Name

Select the appropriate Model Name.

Y

ou will be instructed insert the ‘ST00’ or ‘BS00’ floppy

:

.

SYSTEM2–16

Page 51

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-5 POST–A

Starting Up System

1.

Remove the floppy diskette that was used during data file loading.

2.

Set all bits of the “BOOT” switches on the CPW Board to the OFF position.

3.

Pull the system reset switch located under the right side of the Operator Console.

4. Check

Reinstall

If the system contains the InSite system, restore the InSite software.

TINST PROCEDURE

that the system status up normally and that the system version No. and loge appear on the CR

InSite Software

Note

The new INST floppy diskette must be prepared. Old software must not be reloaded.

Note

The system version 3 or later can not load InSite software using ‘Change Parameters’ mode of the

Customer Parameter

. Also so not use TCOPY when loading it.

2234976

T monitor

.

1.

Enter the Management menu by pressing [Mgt] key

2.

Insert the BOOT floppy disk.

3.

Enter $$

4.

Remove the BOOT floppy diskette and insert the INST floppy diskette.

5.

Enter the following at the “>” prompt:

6. Pull

7.

Check that the system starts up normally

and “>” prompt will be displayed.

******************************* Displayed *******************************

> FN INST:0.&.INSTINST.CF ‘CR’

> IC ‘CR’

************************************************************************

the system reset switch located under the right side of the Operator Console.

.

.

SYSTEM2–17

Page 52

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-5 POST–ATINST PROCEDURE (continued)

Restoring Custom Parameter

Use the CHANGE P

to change the custom parameters;

to load additional option software;

to change the number of raw data files.

The

custom parameter data will be restored automatically in the ATINST program (Data File Loading

Function). However, regarding the following, it is necessary to manually restore due to a software

bug:

1.

Insert the BOOT floppy into the disk drive.

ARAMETERS function of the CUST

– Start

–

–

–

Study No.

Direction of Scout Image (Apex)

Direction of Scout Image (Lateral)

Gantry direction from Operator

OM P

ARAMETERS program for the following purposes:

Note

2234976

2. T

ouch the [Maint] key and enter $$

3.

Select

Custom Parameters

4.

Select

Change Parameters

If a parameter is not required to be changed, press the [END] key to proceed to the next item.

V

erify or change the custom parameters which are displayed one by one as listed T

When installing addition option software, the CUST

can

not be loaded using TCOPY

5.

Remove the BOOT floppy diskette.

6.

Pull the system reset switch located under the right side of the Operator Console.

7.

Check that the system start up normally

8. Using

‘Display Parameter

are

displayed as “Installed”.

’ of the CUST

to display the Maintenance menu.

from Maintenance menu.

Note

OM PARAMETER menu must be used. Note that software

.

.

OM P

ARAMETERS menu, check if all the optional software you installed

able 2–5.

SYSTEM2–18

Page 53

GE MEDICAL

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

REV 0

2-5 POST–ATINST PROCEDURE (continued)

T

able 2–5

Set Model Name

Optical Disk

Magnetic Optical Disk

Magnetic T

Frequency

Machine No.

Hospital Name

Start Study No.

Scout Image Orientation

Gantry Direction from Operator

Axial Image Orientation (from)

ape

Custom Parameters (Change Mode)

This parameter does not appear if the hard disk contains images.

This parameter does not appear if the hard disk contains images.

see Note1

see Note2

see Note3

Press [END] to proceed to next item.

2234976

Function Menu

Thickness 2/3 mm

Option

InSite Password

No. of Raw Data Files

Note1 When

creased

Note2

rewritten

has

Note3 When

be rewritten against the original data. The indication visible in the display might be the same as the original one, but

data has been rewritten. So, enter the original data recorded during ‘Pre–A

rameter will not appear if ‘Gantry’ is selected as the kind of BASE IN SCOUT IMAGE ORIENTATION (Lateral).

by 1. So, enter the original No.

against the original data. The indication visible

been rewritten. So, enter the original data recorded during ‘Pre–A

‘Start Study No.’ is automatically saved and loaded by A

When ‘Scout Image Orientation’ is saved and loaded automatically

‘Gantry Direction from Operator

see Note4

see Note5

see Note6

Password for InSite can be changed.

see Note7 This parameter does not appear if the hard disk contains images.

TINST

, the original

. Using A

in the display might be the same as the original one, but data

TINST Procedure’ to New Data.

’ is automatically saved and loaded by A

TINST Procedure’ to New Data. This pa

study number will be in

TINST

the default data will be

TINST

, the default data will

-

-

SYSTEM2–19

Page 54

GE MEDICAL

REV

0

2-5 POST–ATINST PROCEDURE (continued)

SYSTEMS

CT SYTEC/SYTEC I SERIES

FUNCTIONAL

CHECK /

ADJUSTMENT

2234976

Note4 Function

******************************* Displayed *******************************

** FUNCTION MENU

1.AUTO STORE DEVICE OPTION = (OD or MT or MOD)

2.OD SPECIAL STORE OPTION = (NON

3.AUTO DELETE OPTION = (ON or OFF)

4.MIN VACANT IMAGE SPACE for SCAN = (XXXX)

5.FD PACKING OPTION = (DPCM

6.MT PACKING OPTION = (DPCM

7.OD PACKING OPTION = (DPCM

8.FD SYSTEM No. = (XXXXXX)

9.MT SYSTEM No. = (XXXXXX)

10.OD SYSTEM No. = (XXXXXX)

11.MT IMAGE MAX No. = (XXX)

12.DEVICE TYPE OF OPTICAL DISK = (OD

Select No.=