GE CTS18HBSDRWW, CTS18FBSDRWW, CTS18FBSDLWW, CTS18FBSDRBB Owner’s Manual

N

www.GEAppliances.com

Safety Instructions . ......... 2-4

Operating Instructions

Automatic Icemaker ........... 9

Care and Cleaning ........ 10, 11

Shelves .................... 6, 7

Storage Drawers ............. 7, 8

Temperature Controls .......... 5

Installation Instructions

Preparing to Install

the Refrigerator ............. 12

Reversing the Door Swing . . 17-22

Water i,ine Installation ..... 13-17

Models 15, 16,17,18

Congdlateur supdrieur

Rdfrigdrateurs

La section frangaise commence a la page 30

0

Troubleshooting Tips

Befi)re You Call For Service . .24, 25

Normal Operating Sounds ..... 23

Consumer Support

Consumer Support .... Back (;over

Product Registration ....... 27, 28

Warranty tot

Canadian Customers ......... 26

Warranty tot U.S. Customers ... 29

Congelador superior

Refrigeradores

La seccion en espa_ol empieza en la pagina 60

Write the model and serial

numbers here:

Model #

Serial #

You can find them on a label on

the upper left side of the flesh food

compartment.

197D5226PO01 49-60215 07-02 JR

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING'!

Use this appliance only for its intended purpose as described in this Owner's Manual

SAFETYPRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

This refl_igerator must be properly installed

and located in accordance with the Inst_fllation

Instructions before it is used.

Do not allow children to climb, stand or hang

on the shelves in the reffigeramL They could

&mmge the refrigerator and seriously i_jure

themseNes.

{{_iDo not touch the cold surfaces in the fleezer

compamnent when hands are damp or wet.

Skin may stick to these extremely cold surfaces.

{{_iDo not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

In refl_igeramrs wit1 automatic icemakers,

avoid contact with the moving parts of the

ejector mechanism, or with the heating element

located on the bottom of the icemakeL Do not

place finge_s or hands on the automatic

icemaking mechanism while the refligeramr is

plugged in.

Keep fingers out of the "pinch point" areas;

clearances between the doors and between

the dooIs and cabinet are necessarily small.

Be careflfl closing doors when children are

in the area.

{{_iUnplug the refligemtor before cleaning and

making repai,_.

NOTE:Westronglyrecommendthatanyservicingbe

performedbyaqualifiedindividual

{{_iTurning the control to the 0 position does

not remove power to the light circuit.

{{_iDo not refleeze flozen foods which have

thawed completel):

2

A DANGER! RISK OFCHILD ENTRAPMENT

PROPERDISPOSALOFTHEREFRIGERATOR

Child entrapment and suffbcation are not

problems of file past. Junked or abandoned

refrigerators are still dangerous...even if they will

sit for '_just a few days." If you are getting rid of

your old reflJgerato_; please follow the instructions

below to help prevent accidents.

Refrigerants

All refligeration products contain refligerants,

which under federal law must be removed prior

to product disposal. If you are getting rid of an

old refrigeration product, check with the company

handling the dispos_fl about what to do.

Before YouThrowAway YourOld

RefrigeratororFreezer:

Take off die doors.

I,eave file sheNes in place so flint children may

not easily climb inside.

USEOFEXTENSIONCORDS

Because of potential safety hazards under certain conditions, we strongly recommend against

the use of an extension cord.

However; if you must use an extension cord, it is absolutely necessary flint it be a UIAisted (in file Unimd

Stores) or a CSA-listed (in Canada), 3-wire grounding type appliance extension cord having a grounding

type plug and outlet and that the elecuical rating of the cord be 15 amperes (minimum) and 120 volts.

3

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING'!

HOWTOCONNECTELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of tiffs appliance is equipped "wifll

a ,%prong (grounding) plug which mates widl a

standard 3-prong (grounding) wall oudet to

minimize the possibility of elecuic shock hazard

flom this appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the oudet is

properly grounded.

Where a standard 2-prong wall outlet is

encounmred, it is your personal responsibility and

obligation m have it replaced with a properly

grounded 3-prong wall outlet.

The refligerator should always be plugged into its

own individual electrical outlet which has a voltage

rating that matches the _v_tingplate.

This provides the best performance and also

prevents overloading house wiring circuits which

could cause a fire hazard flom overheated wires.

Never unplug your refligerator by pulling on the

power cord. Always gdp plug firefly and pull

straight out flom the outlet.

Repair or replace immediamly all power cords dlat

have become flayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end.

x_qlen moving the refligerator away flom the

wall, be careful not to roll over or damage the

power cord.

USEOFADAPTERPLUGS(A_pterp/u_notper_i_e_inC_n_)

Because of potential safety hazards under certain conditions, we strongly recommend against

the use of an adapter plug.

However, if you must use an adaptor, where local

codes pe_nit, a temporary connection may be made

to a properly grounded 2-prong wall outlet by use

of a UIAismd adaptor available at most local

hardware stores.

The larger slot in the adapter must be aligned with

the larger slot in the wall outlet to provide proper

polarity in the connection of the power cord.

When disconnecting die power cord flom die

adapte_, always hold the adapter in place with one

hand while pulling the power cord plug with the

other hand. If this is not done, the adaptor ground

mrminal is ve_T likely m break with repeamd use.

If the adapter ground terminal breaks, DONOTUSE

the refrigerator until a proper ground has been

established.

Attachingthe adaptergroundterminaltoa wall outlet

coverscrewdoesnotgroundtheapplianceunlessthe

coverscrewis metal,notinsulated,andthewall outlet is

groundedthroughthehousewiring.Youshouldhavethe

circuitcheckedbyaqualifiedelectriciantomakesurethe

outlet isproperlygrounded.

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCTIONS

4

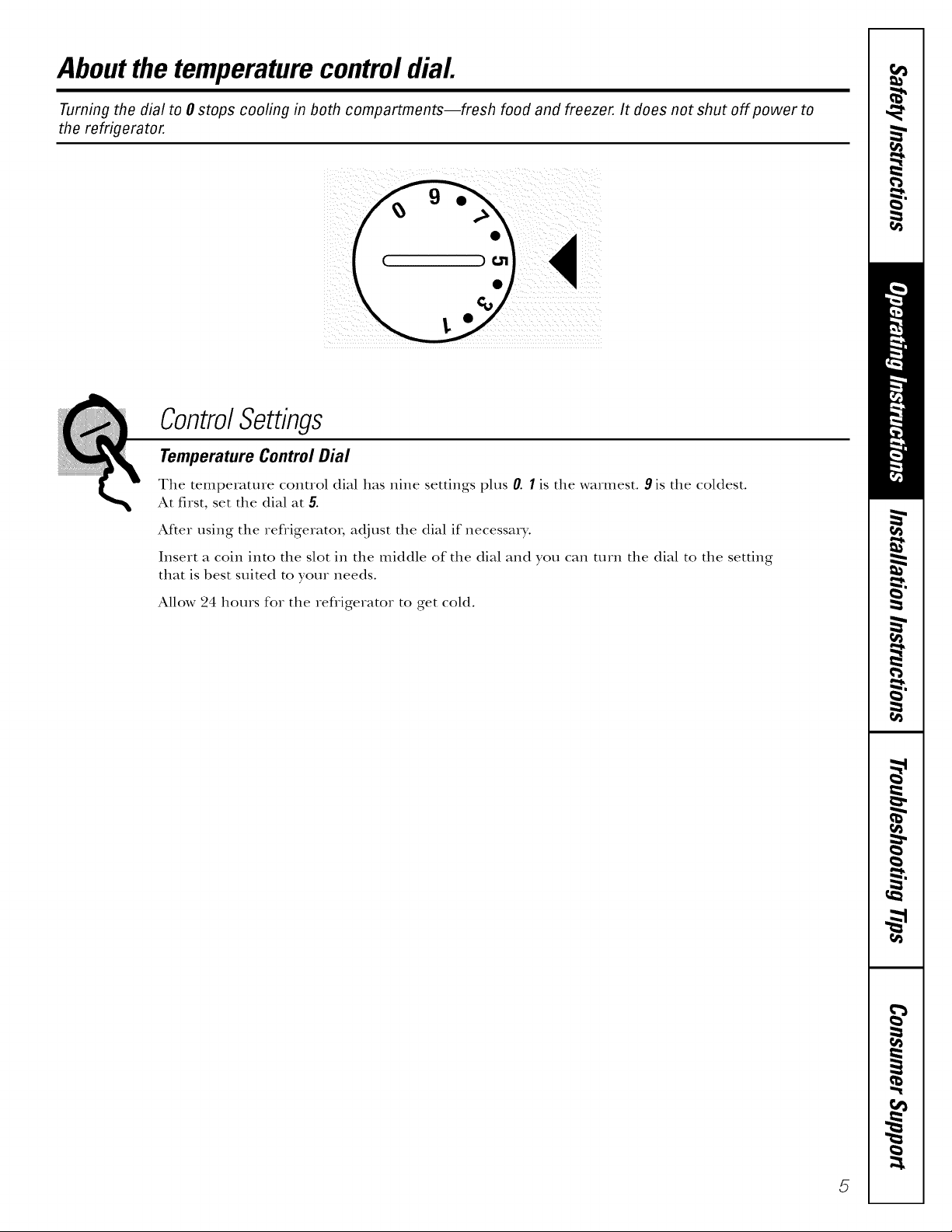

Aboutthe temperaturecontroldial

Turning the dial to 0 stops cooling in both compartments--fresh food and freezer. It does not shut off power to

the refrigerator.

ControlSettings

Temperature Control Dial

The temperature control dial has nine settings plus 0. I is the warmest. 9 is the coldest.

At first, set the dial at 5.

After using the refligerato_, adjust the dial if necessary.

Insert a coin into the slot in the middle of the dial and you can mrn the dial to the setting

that is best suited to your needs.

Allow 24 hours for the refligerator to get cold.

5

Aboutthefresh foodcompartmentshelves.

Shelf supports at various levels allow you to custom-space your shelves. Not all features are on all models.

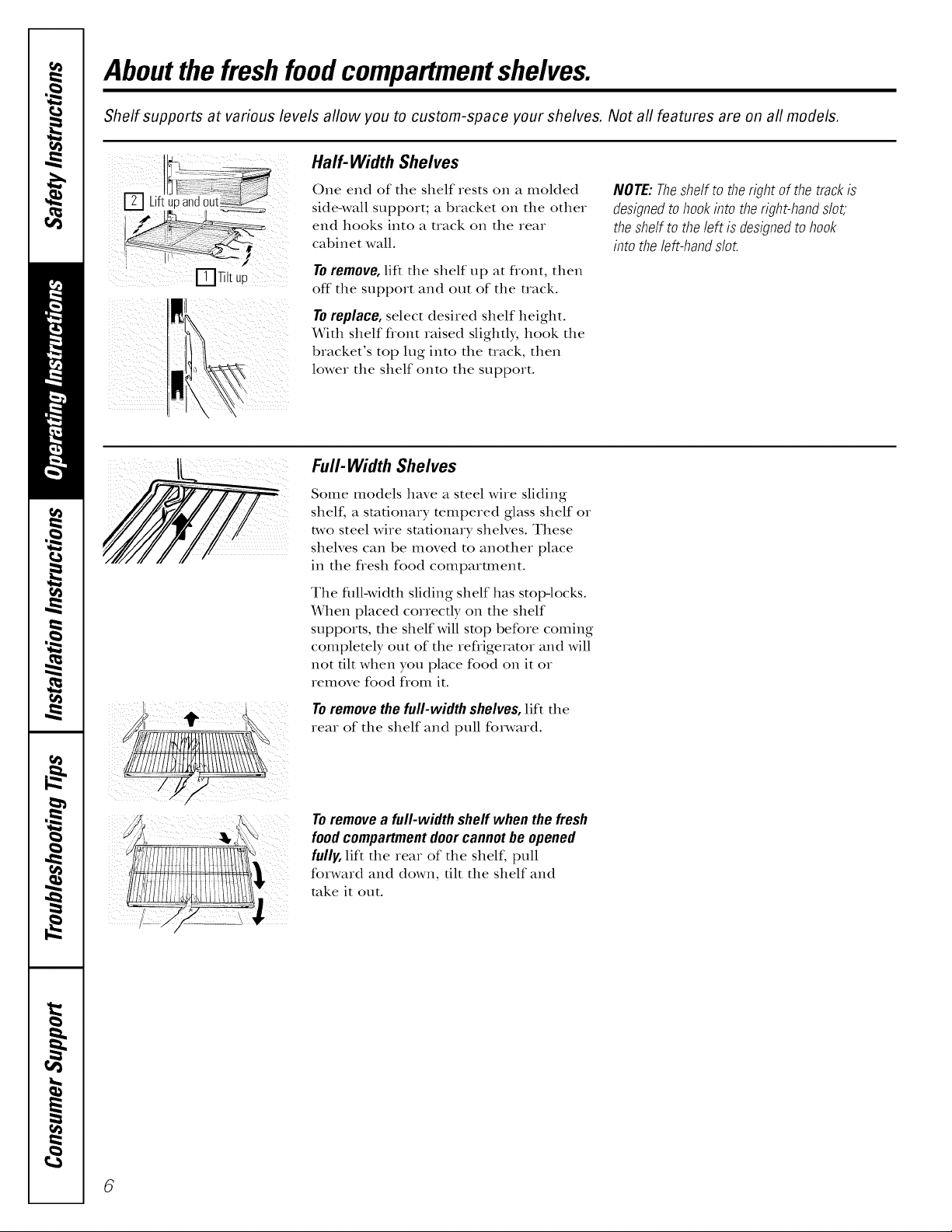

Half- Width Shelves

Liftupand

ITJTiltup

One end of the shelf rests on a molded

side-wall support; a bracket on the other

end hooks into a track on the rear

cabinet wall.

To remove, lift the shelf up at flont, then

off the support and out of the track.

To replace, select desired shelf height.

With shelf flont raised slightly, hook the

bracket's top lug into the track, then

lower the shelf onto the support.

Full-Width Shelves

Some models have a steel wire sliding

shelf, a stationary tempered glass shelf or

two steel wire stationary shelves. These

shelves can be moved to another place

in the flesh food comparunent.

NOTE:Theshelfto therightof thetrackis

designedtohookinto theright-handslot,

theshelf tothe left is designedtohook

into theleft-handslot.

The flfll-width sliding shelf has stop-locks.

When placed correctly on the shelf

supports, the shelf will stop before coming

completely out of the refligerator and will

not flit when you place food on it or

remove food flom it.

Toremovethefull-width shelves,lift the

rear of the shelf and pull forward.

Toremovea full-width shelf whenthefresh

foodcompartmentdoorcannotbeopened

fully, lift the rear of the shelf, pull

forward and down, tilt the shelf and

take it otlt.

6

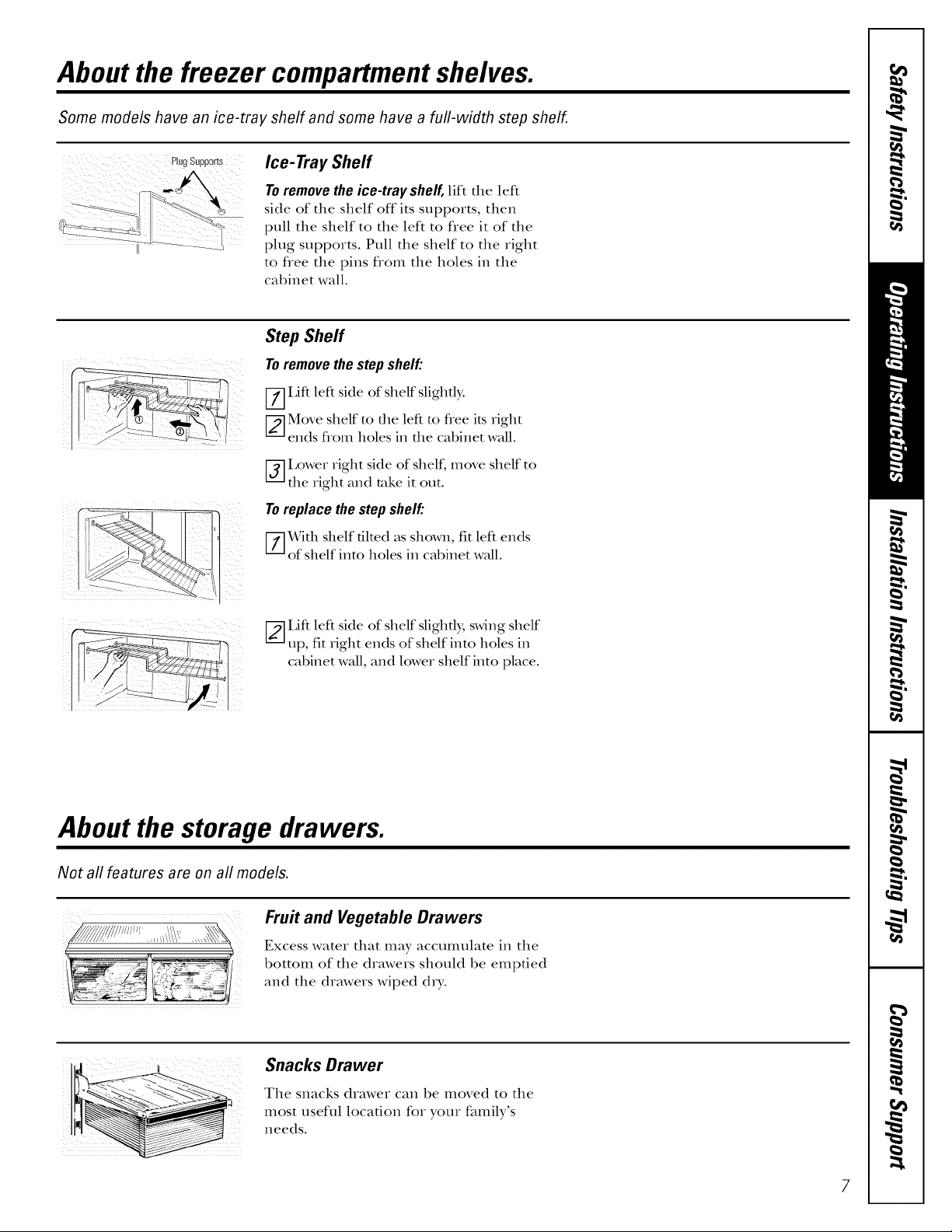

About the freezer compartment shelves.

Some models have an ice-tray shelf and some have a full-width step shelf.

Ice- Tray Shelf

Toremovetheice-tray shelf,lift the left

side of the shelf off its supports, then

pull the shelf to the left to flee it of the

plug supports. Pull the shelf to the right

to flee the pins flom the holes in the

cabinet wall.

Step Shelf

Toremovethestep shelf"

[--7]Lift left side of shelf slightb:

[_-]Move shelf to the left to flee its right

ends flom holes in the cabinet wall.

V_I,ower right side of shelf, move shelf to

the right and rake it out.

Toreplacethe step shelf"

[--_With shelf tilted as shown, fit left ends

of shelf into holes in cabinet wall.

[_--]I,ift left side of shelf slightly, swing shelf

up, fit right ends of shelf into holes in

cabinet wall, and lower shelf into place.

About the storage drawers.

Not all features are on all models.

Fruit and Vegetable Drawers

Excess water that may accumulate in the

bottom of the drawers should be emptied

and the drawers wiped dry.

Snacks Drawer

The snacks drawer can be moved to the

most useflfl location for your family's

needs.

7

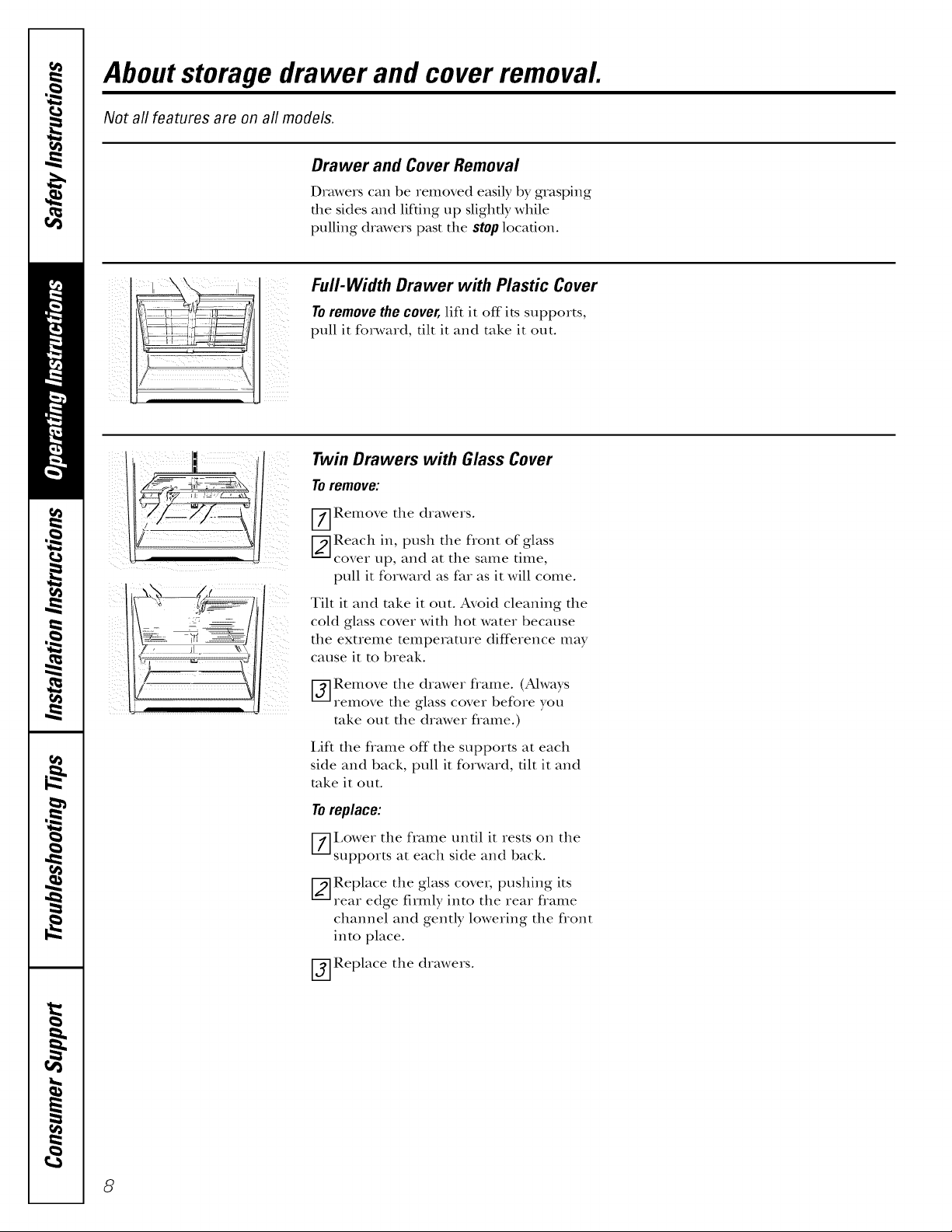

About storage drawer and cover removal.

Not all features are on all models.

Drawer and Cover Removal

Drawers can be removed easily by grasping

the sides and lifting up slightly while

pulling drawers past the stop location.

Full-Width Drawer with Plastic Cover

Toremove the cover, lift it off its supports,

[)tall it forward, tilt it and rake it out.

Twin Drawers with Glass Cover

Toremove:

V-_Remove the drawers.

[-_-]Reach in, push the fiont of glass

cover up, and at the same time,

pull it forward as far as it will come.

Tilt it and rake it out. Avoid cleaning the

cold glass cover with hot water because

the extreme temperature difference may

cause it to break.

V_]Remove the drawer flame. (Always

remove the glass cover before you

rake out the drawer flame.)

I,ifl the flame off the supports at each

side and back, pull it forward, tilt it and

take it out.

Toreplace:

V-_Lower the frame until it rests on the

supports at each side and back.

[-2--]Replace the glass cover, pushing its

rear edge firmly into the rear flame

channel and gently lowering the flont

into place.

[-_]Replace the drawers.

8

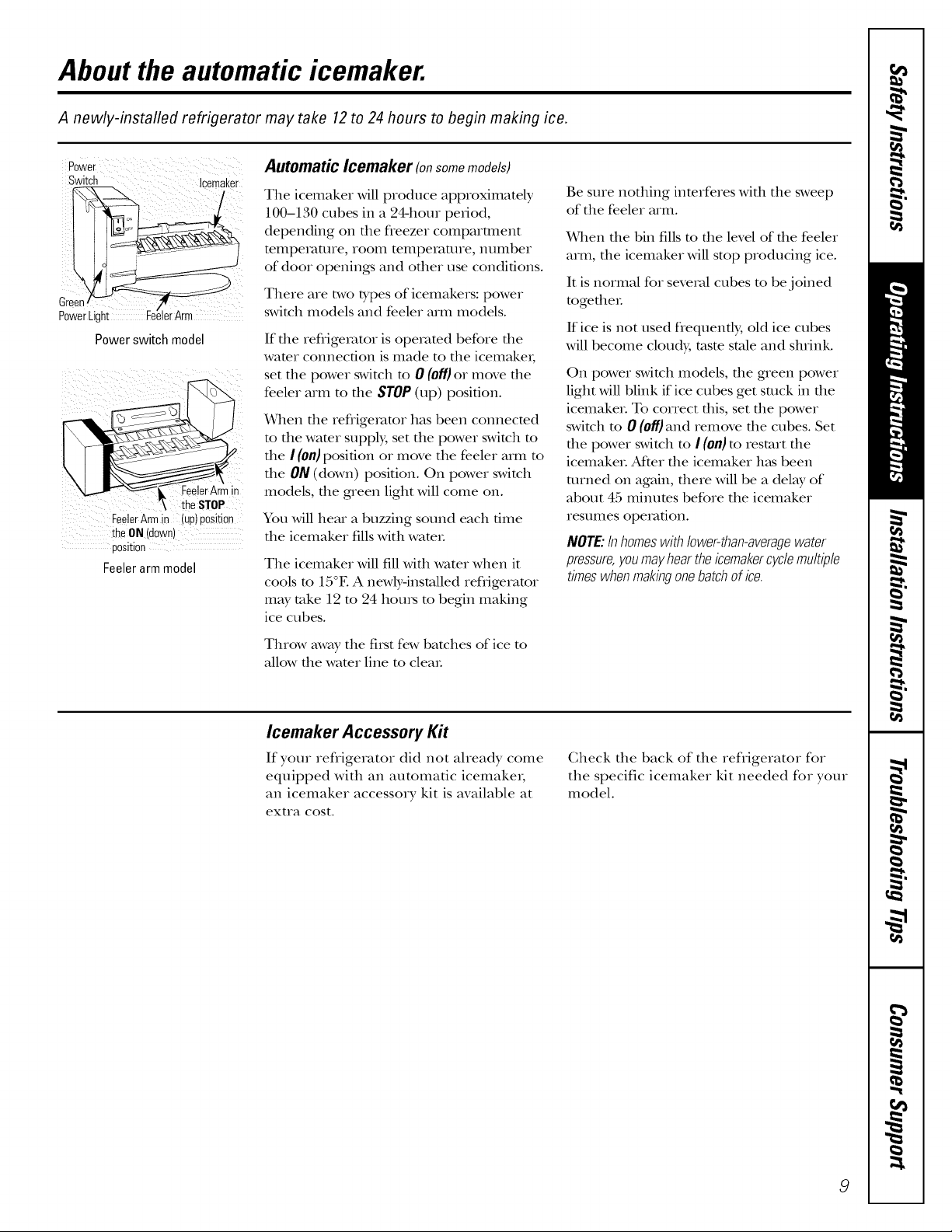

About the automatic icemaker.

A newly-installed refrigerator may take 12to 24 hours to begin making ice.

Switch Icemaker

Green

PowerLight lerArm

Powerswitch model

FeelerArmin

theSTOP

FeelerArmin (up)position

theON (down)

position

Feelerarm model

Automatic Icemaker (onsomemodels)

The icemaker will produce approximately

100-130 cubes in a 24-hour period,

depending on the fleezer comparunent

tempe_ture, room temperature, number

of door openings and other use conditions.

There are two types of icemakers: power

switch models and feeler arm models.

If die refligeiator is ope_v_md before die

wamr connection is made to die icemakei,

set the power switch m 0 (off)or move the

feeler arm m the STOP(up) position.

When file reflige_v_tor has been connecmd

m the wamr supply, set the power switch m

the I (0/1)position or move the feeler arm to

the ON (down) position. On power switch

models, file g_een light will come on.

You will hear a buzzing sound each time

the icemaker fills with water.

The icemaker Mll fill wifll water when it

cools m 15°E A newlyqnstalled refligeramr

may take 12 m 24 hours m begin making

ice cubes.

Be sure nothing interferes with the sweep

of the feeler arm.

When the bin fills to the level of the feeler

arm, the icemaker will stop producing ice.

It is normal for seve_vd cubes to be joined

togetheL

If ice is not used flequenfl); old ice cubes

will become cloudy, taste stole and shrink.

On power switch models, file gaeen power

light will blink if ice cubes get snack in the

icemake_. To correct this, set the power

switch m 0 (off)and remove the cubes. Set

the power switch m I (on)m restart the

icemake_. Afker the icemaker h_tsbeen

turned on again, there will be a delay of

about 45 minums before the icemaker

resumes ope_v_fion.

NOTE:Inhomeswith/ower-than-averagewater

pressure,youmayheartheicemakercyc/emu/tip/e

timeswhenmakingonebatchofice.

Throw away the first few batches of ice to

allow the water line to clea_.

Icemaker Accessory Kit

If your refrigerator did not aheady come

equipped with an automatic icemakei,

an icemaker accessory kit is available at

extra cost.

Check the back of the refligerator for

the specific icemaker kit needed for your

model.

9

Care and cleaning of the refrigerator.

Cleaning the Outside

Thedoorhandlesandtrim (on some

models). Clean with a cloth dampened

with soapy wateL Dry with a soft cloth.

Keep the outside clean. Wipe with a clean

cloth lightly dampened Mtb kitchen

appliance wax or mild liquid dish

detergent. Dry and polish with a clean,

soft cloth.

Cleaning the Inside

Tohelpprevent odors,leave an open box

of baking soda in the flesh food and

freezer compartments.

Unplugtherefrigeratorbeforecleaning.

If tiffs is not practical, wring excess

moisutre out of sponge or cloth when

cleaning around switches, lights or

controls.

Donot wipetherefrigeratorwitha soileddish

clothor wet towel Thesemayleavea residue

thatcanerodethepaint.Donotusescouring

pads,powderedcleaners,bleachorcleaners

containingbleachbecausetheseproductscan

scratchandweakenthepaint finish.

Avoidcleaningcoldglassshelves(onsome

models)with hot waterbecausetheextreme

temperaturedifferencemaycausethemto

break.Handleglassshelvescarefully.Bumping

temperedglasscancauseit toshatter.

Donot washany.plasticrefrigeratorparts in

thedishwasher.

.... _

ji: iii_I _ iii_

Cleaning the condenser coils.

Use warm water and baking soda solution-

about a tablespoon (15 ml) of baking soda

to a quart (1 limr) ofwamL This both

cleans and neumdizes odors. Rinse and

wipe d_y.

After cleaning the door gaskets, apply a

thin layer of peuoleumjelly to tim door

gaskets at the hinge side. This helps keep

the gaskets from sticking and bending

out of shape.

Condenser

There is no need for routine condenser

cleaning in normal home operating

environments. However, in environments

I

that may be particularly dusty or greasy,

the condenser should be cleaned

periodically for efficient refrigerator

operation.

To clean tim condenser; turn the

temperaune conuol dial to 0. Sweep

away or vacuum lap dust.

For best results, use a brush specially

designed for tiffs purpose. It is available

at most appliance parts stores.

7O

Behind the Refrigerator

Be careful when moving the refrigerator

away from the wall. All types of floor

coverings can be damaged, particularly

cushioned coverings and those with

embossed surfaces.

Turn the leveling legs at each flont corner

of the refligerator counterclockwise until

the rolleas support the refligerator. Pull the

refligeramr straight out and return it m

position by pushing it suaight in. Moving

the refligerator in a side direction may

result in damage to the floor covering or

refligeramL

Light Bulb Replacement

To replace a burned-out bulb, unplug

the refrigerator from its electrical outlet,

unscrew the bulb when cool and replace

it with an appliance bulb of the same or

lower wattage.

When pushing the refrigerator back, make sure

you don't roll over the power cord or icemaker

supply line (onsome models).

After rolling the refligerator back into

place, mrn the legs clockwise until the

legs again bear the weight of the

refligeratoL

Turningthecontrolto theOpositiondoesnot

removepowerto thelight circuit.

Preparing for Vacation

For long vacations or absences, remove

food and unplug the refligeratoL Move

the temperature control dial to the 0

position, and clean the interior with a

baking soda solution of one tablespoon

(15 ml) of baking soda to one quart

(1 liter) ofwateL I,eave the doors open.

Preparing to Move

Secure all loose items such as grille,

shelves and drawers by roping them

securely in place to prevent damage.

Set the icemaker power switch to the

0 (off) position or move the feeler arm to

the STOP (tap) position (depending on

model) and slmt off the water supply to

the refligeratoL

If the temperature can drop below

freezing, have a qualified servicer drain

the water supply system (on some

models) to prevent serious property

damage due to flooding.

Besuretherefrigeratorstaysin an upright

positionduringmoving.

11

Installation

Refrigerator

Instructions

Models 15, 16,17,18

Questions? Call 800.GE.CARES (800.432.2737)or visit o,_Website_,t"www.GEAppliances.com

In Canada, call 1.800.361.3400or Visitour Website at: www.geappliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT - S},vethese

instructions for local inspector's use.

• IMPORTANT - Obse,ve

governing codes and ordinances.

CLEARANCES

Allow the following clearances for ease of installation,

proper air circulation and plumbing and electrical

COIlllectioIIS.

• Sides,/4 (19 ram)

• Top 1" (25 mm)

• Back 1" (25 ram)

• Note to Installer - Besure to leave these

instructions with the Gonsumer.

• Note to Consumer - Keep these insuuctions

for fl_ture reference.

• Sldll level - Installation of tiffs appliance requires

basic mechanical skills.

• Completion time - Refligerator Installation

15 minutes

Reversing the Door Swing

1 hour

• Proper installation is the responsibility of the

insmlleL

• Product failure due to improper installation is not

covered under the Warranty.

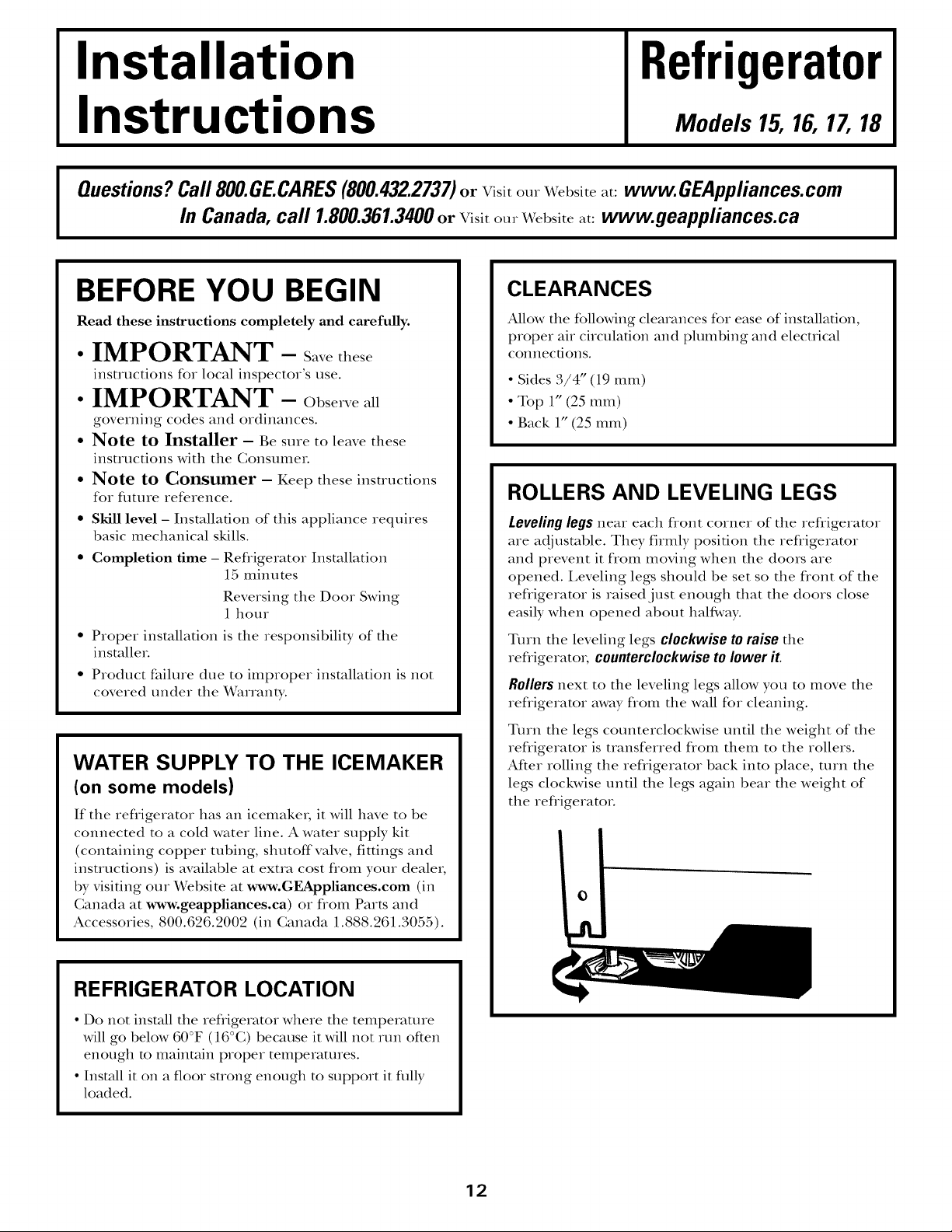

ROLLERS AND LEVELING LEGS

Leveling legs near each flont corner of the refligerator

are adjustable. They firmly position the refligerator

and prevent it flom moving when the doors are

opened. I,eveling legs should be set so the front of the

refligerator is raised just enough that the doors close

easily when opened about half,,ray.

Turn the leveling legs clockwise to raise the

refligerato_, counterclockwiseto lower it

Rollers next to the leveling legs allow you to move the

refligerator away flom the wall for cleaning.

WATER SUPPLY TO THE ICEMAKER

(on some models)

If the refligerator has an icemake_; it Mll have to be

connected to a cold water line. A water supply kit

(containing copper tubing, shutoff valve, fittings and

instruc6ons) is available at extra cost flom your dealer,

by visiting our Website at www.GEAppliances.com (in

Canada at www.geappliances.ca) or flom Parts and

Accessories, 800.626.2002 (in Canada 1.888.261.3055).

REFRIGERATOR LOCATION

• Do not instM1 the refligerator where the temperature

will go below 60°F (16°C) because it will not run often

enough m maintain proper temperatures.

• Install it on a floor suong enough to support it flail),

loaded.

Turn the legs counterclockwise until the weight of the

refiigerator is transferred fiom them to tim rollers.

After rolling the refiigerator back into place, mrn the

legs clockwise until the legs again bear the weight of

the refiigeratoL

12

Installation Instructions

B INSTALLING THE WATER LINE IONSOMEMODELS)

BEFORE YOU BEGIN

Recommended copper water supply kits are _(_'X8X2,

_(_2K8X3or _'X8X4, depending on the amount of

robing you need. Approved plastic water supply lines

are GE SmartConnect'" Refligerator Tubing

(X_qK08X10002, _(_2K08X10006, _(_2K08X10015 and

_i_XO8X10025).

When connecting your refligerator to a GE Reverse

Osmosis Water System, the only approved installation

is with a GE RVKit. For other reverse osmosis water

systems, follow the manufacturer's recommendations.

This water line installation is not warranted by the

refrigerator or icemaker manufitcturer. Follow these

instructions careflflly to minimize the risk of expensive

water damage.

Water hammer (water banging in the pipes) in house

plumbing can cause damage to refiigerator parts and

lead to water leakage or flooding. Call a qualified

plumber to correct water hammer before installing

the water supply line to the refiigerator.

To prevent burns and product damage, do not hook

up the water line to the hot water line.

If you use your refligerator before connecting the

water line, make sure the icemaker power switch is

in the 0 (off) position (on power switch models) or

the feeler arm is in the STOP (tap) position (on feeler

arm models).

WHAT YOU WILL NEED

• Copper or GE SmartConnect TM Refrigerator Tubing

kit, 1/4" outer diameter to connect the refligerator

to the water supply. If using coppe_, be sure both

ends of the tubing are cut square.

To determine how much tubing you need: measure

the distance flom the water valve on the back of the

refligerator to the water supply pipe. Then add 8'

(2.4 m). Be sure there is sufficient extra tubing

(about 8' [2.4 m] coiled into 3 turns of about 10"

[25 cm] diameter) to allow the refligerator to move

out flom the wall after installation.

GE SmartConnect"* Refligerator Tubing Kits are

available in the following lengths:

2' (0.6 m) - _2K08X10002

6' (1.8 m) -X42K08X10006

15' (4.6 m) - _2KO8XlO015

25' (7.6 m) - _2K08X10025

Be sure that the kit you select allows at least 8' (2.4 m)

as described above.

Do not install the icemaker tubing in areas where

temperatures fall below fleezing.

When using any electrical device (such as a power

drill) during installation, be sure the device is double

insulated or grounded in a manner to prevent the

hazard of electric shock, or is battm y powered.

All installations must be in accordance with local

plumbing code requirements.

NOTE: The only GE approved plastic tubing is that

supplied in GE SmartConnect TM Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Certain

types of plastic will crack or rupture with age and

cause water damage to your home.

13

Installation Instructions

ill INSTALLING THE WATER LINE (CONT.)

WHAT YOU WILL NEED (CONT.)

• A GE water supply kit (containing ulbing, slmtoff

valve and fittings listed below) is available at extra

cost flom your dealer or flom Parts and Accessories,

800.626.2002.

• A cold water supply. The water pressure must be

between 20 and 120 p.s.i. (11.4-8.1 bar).

• Power drill.

• 1/2" or adjustable wrench.

• Straight and Phillips blade screwdriver.

• Two 1/4" outer diameter compression nuts and

2 ferrules (sleeves)--to connect the copper tubing

to tim stmtoff valve and tim refligerator water vaNe.

OR

• If you are using a GE SmartConnect'* Refligerator

Tubing kit, tim necessary fittings are preassembled

to the tubing.

Install the stmtoff valve on the nearest flequently used

drinking water line.

IT] SHUT OFF THE MAIN WATER

SUPPLY

Turn on tim nearest faucet long enough to clear

the line ofwateL

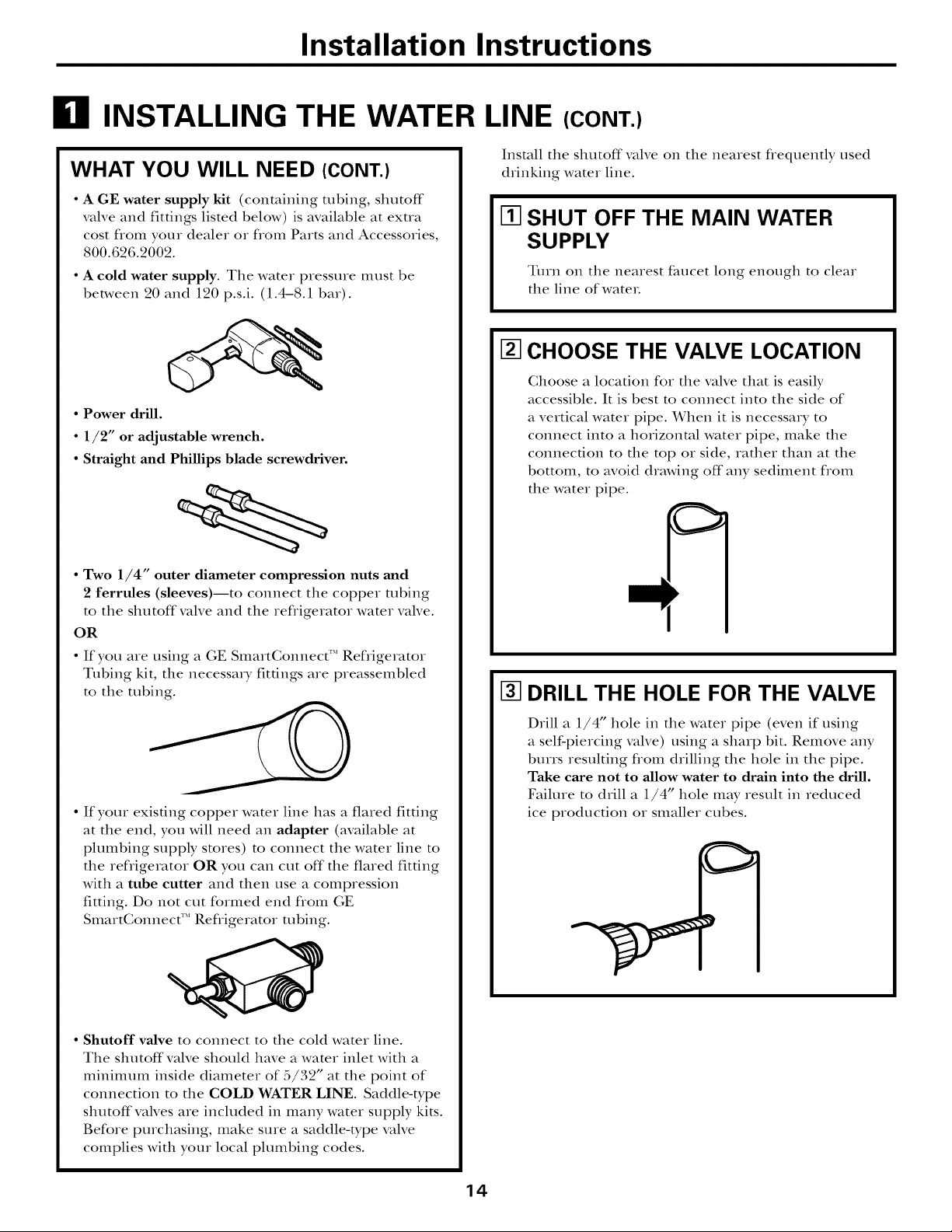

CHOOSE THE VALVE LOCATION

Choose a location for tim valve that is easily

accessible. It is best to connect into the side of

a vertical water pipe. When it is necessa_ T to

connect into a horizontal water pipe, make the

connection to the top or side, rather than at tim

bottom, to avoid drawing off"any sediment flom

the water pipe.

I_ DRILL THE HOLE FOR THE VALVE

• If your existing copper water line has a flared fitting

at the end, you will need an adapter (available at

plumbing supply stores) to connect the water line to

the refligerator OR you can cut off" the flared fitting

with a tube cutter and then use a compression

fitting. Do not cut formed end flom GE

SmartConnect"* Refiigerator robing.

• Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with a

mininmm inside diameter of 5/32" at the point of

connection to the COLD WATER LINE. Saddle-type

shutoff vanes are included in many water supply kits.

Before purchasing, make sure a saddle-type valve

complies with your local plumbing codes.

Drill a 1/4" hole in the water pipe (even if using

a self-piercing valve) using a sharp bit. Remove any

burrs resulting flom drilling tim hole in tim pipe.

Take care not to allow water to drain into the drill.

Failure to drill a 1/4" hole may result in reduced

ice production or smaller cubes.

14

Installation Instructions

I_ FASTEN THE SHUTOFF VALVE

Fasten the shutoff valve to the cold water pipe with

the pipe clamp.

PipeClamp_'x_,

Saddle-TypeJ qerticalCold

ShutoffValve WaterPipe

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumbeL

[] TIGHTEN THE PIPE CLAMP

Tighten the clamp screws until the sealing washer

begins to swell.

NOTE: Do not overtighten or you may crush the

tubing.

Pipe Clamp

/_lnlet End

Washer

[] CONNECT THE TUBING

TO THE VALVE

Place the compression nut and ferrule (sleeve)

for copper tubing onto the end of the tubing and

connect it to the shutoff valve.

Make sure the tubing is flail), inserted into the

valve. Tighten the compression nut securely.

For plastic robing flom a GE SmartConnecff'*

Refligerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then tighten

one additional turn with a wrench. Overfightening

may cause leaks.

Saddle-Type

ShutoffValve

PackingNut--

OutletValve._ _ Ferrule(sleeve)

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle vanes

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

Nut

SmartConnect_

Tubing

_ression

Clamp Screw_

?

ROUTE THE TUBING

Route the tubing between the cold water line and

the reffigeratoL

Rotate the tubing through a hole drilled in the wall

or floor (behind the refligerator or adjacent base

cabinet) as close to the wall as possible.

NOTE: Be sure there is sufficient extra tubing

(about 8 feet [244 cm] coiled into 3 turns of about

10" [25 cm] diameter) to allow the refligerator to

move out from the wall after installation.

I-8-]FLUSH OUT THE TUBING

Turn the main water supply on and flush out the

tubing until the water is clear.

Shut the water off at the water valve after about

one quart (1 liter) of water has been flushed

through the tubing.

15

Installation Instructions

B INSTALLING THE WATER LINE (CONT.)

I_ CONNECT THE TUBING TO THE

REFRIGERATOR

NOTES:

• Before making tile connection to tile refligerator,

be sure tile refligerator power cord is not plugged

into tile wall outlet.

• X_rerecommend installing a water filter if your

water supply has sand or particles that could clog

tile screen of tile refligerator's water valve. Install

it in tile water line near tile refligerator. If using

GE SmartConnect'" Refligerator Tubing kit,

you will need an additional robe (X_K08X10002)

to connect tile filteL Do not cut plastic tube to

install filteL

Remove tile access coveL

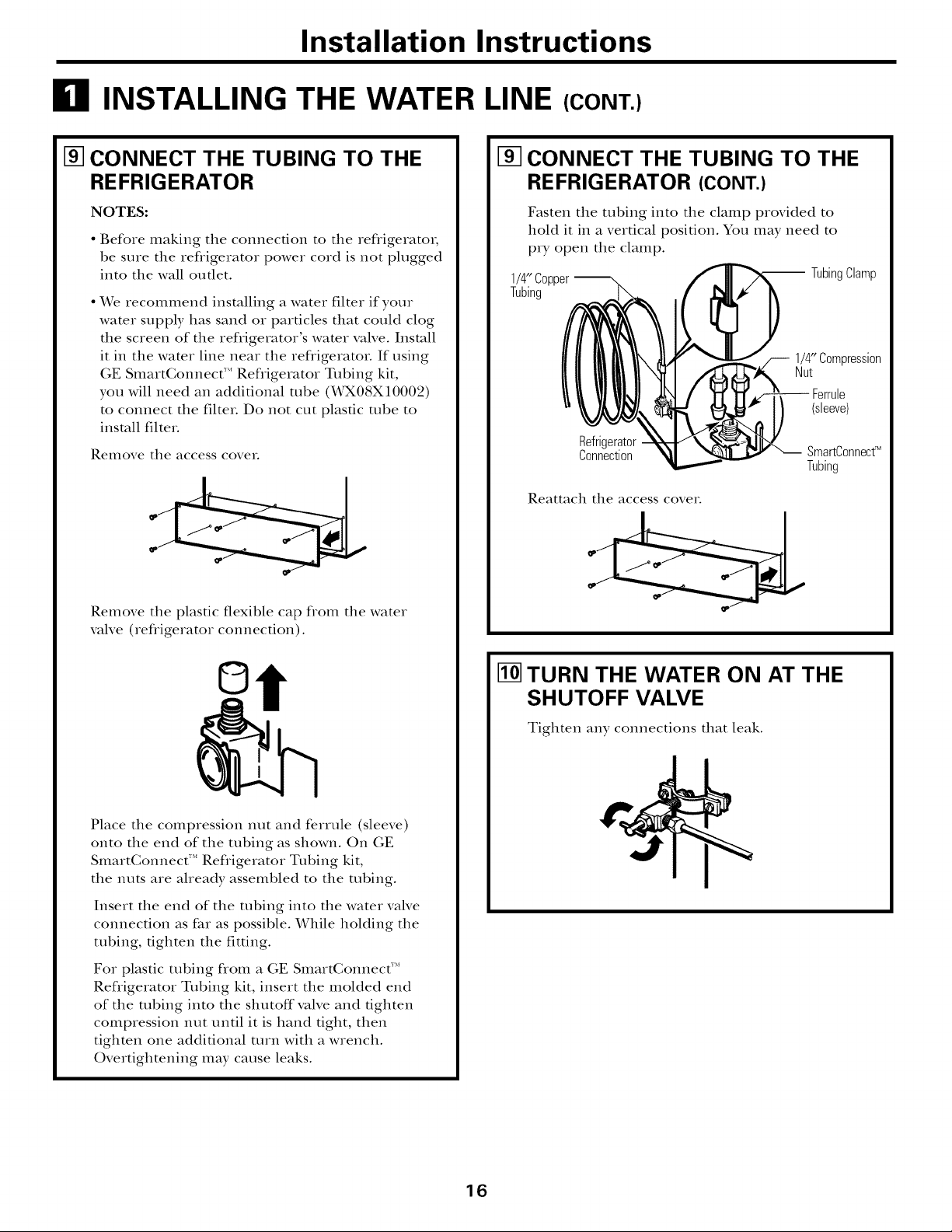

[] CONNECT THE TUBING TO THE

REFRIGERATOR (CONT.)

Fasten tile tubing into tile clamp provided to

hold it in a vertical position. You may need to

pry open tile clamp.

1/4" Copper __ TubingClamp

Tubing

1/4" Compression

Nut

Ferrule

(sleeve)

Refrigerator

Connection SmartConnecU

Reattach tile access coveL

Tubing

Remove tile plastic flexible cap flom tile water

valve (refligerator connection).

©

Place tile compression nut and ferrule (sleeve)

onto tile end of tile tubing as shown. On GE

SmartGonnect"* Refligerator Tubing kit,

tile nuts are aheady assembled to tile robing.

Insert tile end of tile tubing into tile water valve

connection as far as possible. While holding tile

tubing, tighten tile fitting.

For plastic tubing flom a GE SmartGonnect"*

Refligerator Tubing kit, insert tile molded end

of tile tubing into tile shutoff valve and tighten

compression nut until it is hand tight, then

tighten one additional mrn with a wrench.

Overtightening may cause leaks.

I_ TURN THE WATER ON AT THE

SHUTOFF VALVE

Tighten any connections that leak.

16

Installation Instructions

I_] PLUG IN THE REFRIGERATOR

Arrange the coil of tubing so that it does not vibrate

against the back of the refligerator or against the

wall. Push the refligerator back to the wall.

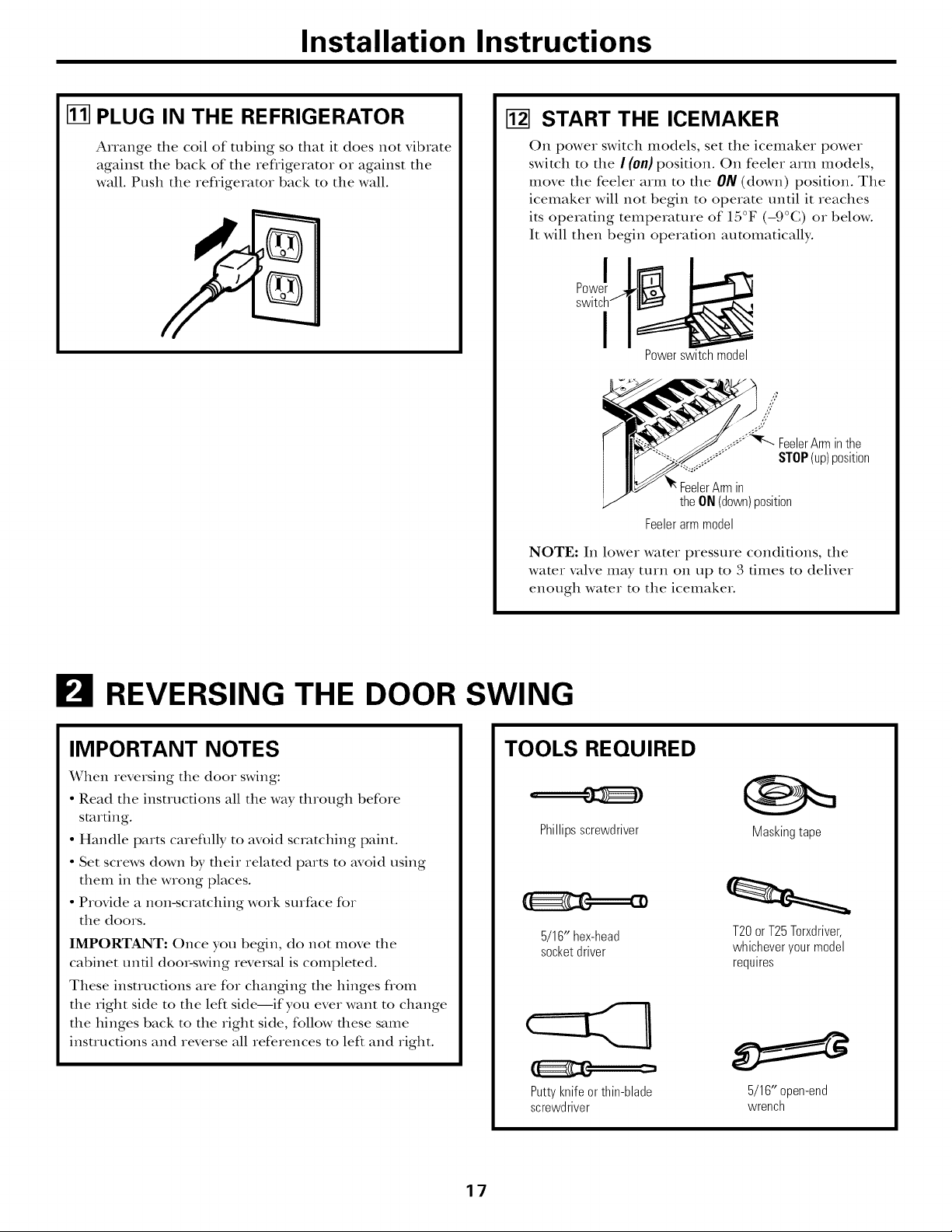

[] START THE ICEMAKER

On power switch models, set the icemaker power

switch to the / (0n) position. On feeler arm models,

move the feeler arm to the ON(down) position. The

icemaker will not begin to operate until it reaches

its operating temperature of 15°F (-9°C) or below.

It will then begin operation automatically.

I

Powerswitch model

,7

//

,'Y

//

.##;"_r--...FeelerArminthe

..... STOP(up)position

in

theON(down)position

Feelerarmmodel

NOTE: In lower water pressure conditions, the

water valve may tuin on up to 3 times to deliver

enough water to the icemaker.

REVERSING THE DOOR SWING

IMPORTANT NOTES

When reversing the door swing:

• Read the instructions all the way through before

starting.

• Handle parts careflflly to avoid scratching paint.

• Set screws down by their related parts to avoid using

them in the wrong places.

• Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is completed.

These insmlcfions are for changing the hinges flom

the right side to the left side--if you ever want to change

the hinges back to the right side, follow these same

insu-ucdons and reverse all references to left and right.

TOOLS REQUIRED

Phillipsscrewdriver

5/16"hex-head

socketdriver

Puttyknifeorthin-blade

screwdriver

Masking tape

T20or T25Torxdriver,

whicheveryourmodel

requires

5/16" open-end

wrench

17

Installation Instructions

B REVERSING THE DOOR SWING (CONT.)

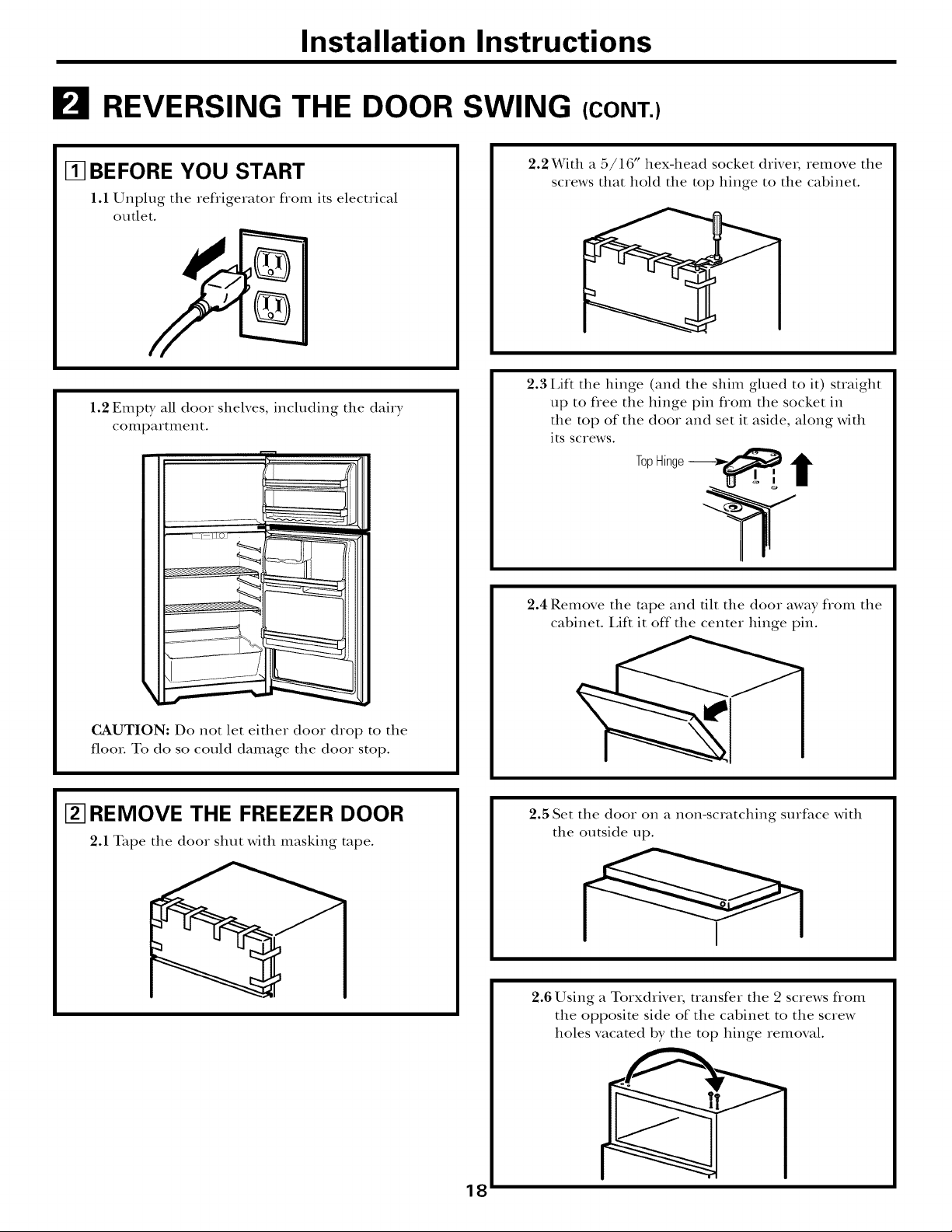

Ill BEFORE YOU START

1.1 Unplug the refrigerator from its electrical

outlet.

1.2 Empty all door shelves, including the dairy

compartment.

2.2 With a 5/16" hex-head socket drive_, remove the

screws that hold the top hinge to the cabinet.

2.3 I,iff the hinge (and the shim glued to it) suaight

up to flee the hinge pin flom the socket in

the top of the door and set it aside, along with

its screws.

TopHinge-_a___

2.4 Remove the rope and tilt the door away flom the

cabinet. I,ift it off"the center hinge pin.

CAUTION: Do not let either door drop to the

flooL To do so could damage the door stop.

[] REMOVE THE FREEZER DOOR

2.1 Tape the door shut with masking rope.

2.5 Set the door on a non-scratching surface with

the outside up.

2.6 Using a Torxdrive,, transfer the 2 screws flom

the opposite side of the cabinet to the screw

holes vacated by the top hinge removal.

18

Installation Instructions

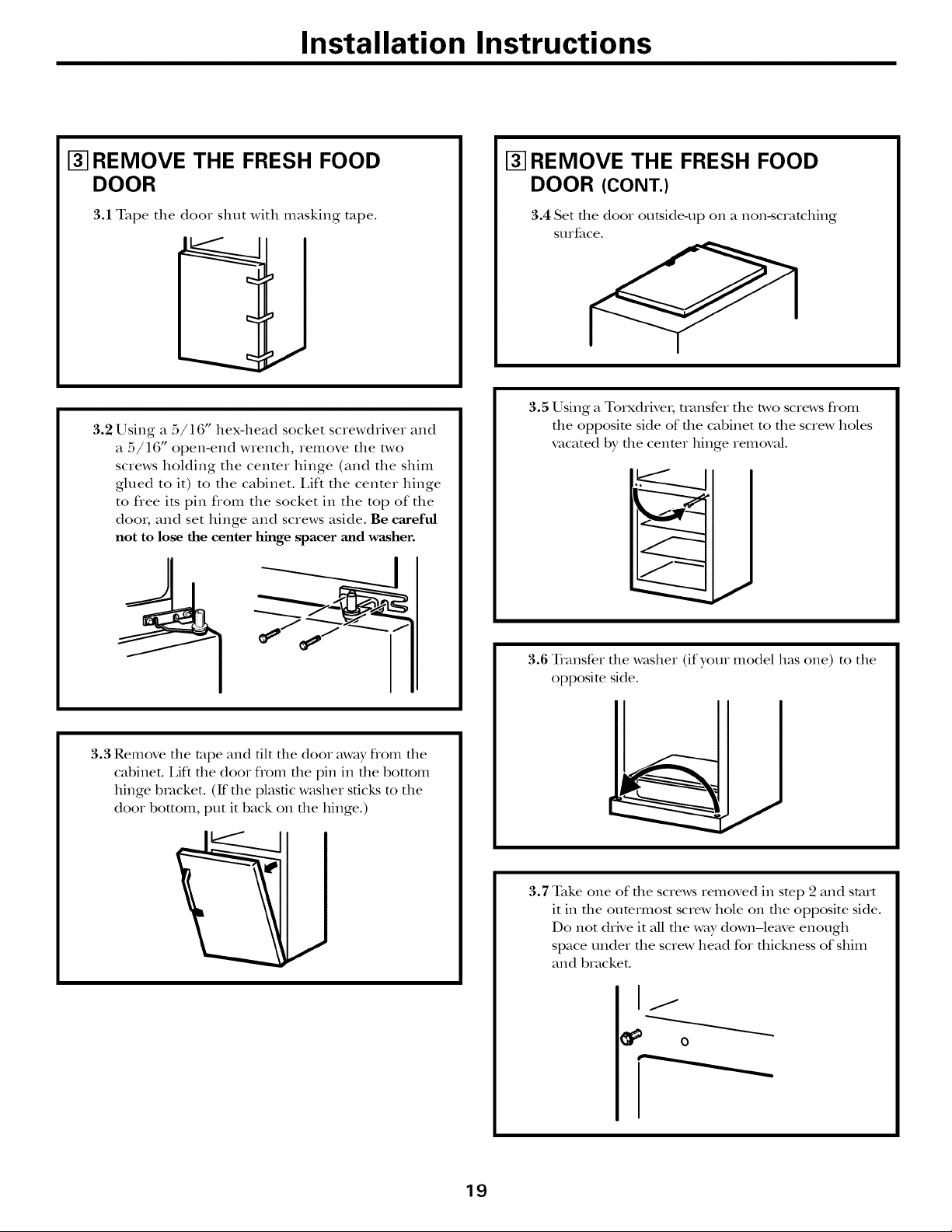

I_ REMOVE THE FRESH FOOD

DOOR

3.1 Tape the door shut with masking rope.

3.2 Using a 5/16" hex-head socket screwdriver and

a 5/16" open-end wrench, remove the two

screws holding the center binge (and the shim

glued to it) to the cabinet. I,ift the center hinge

to flee its pin flom the socket in the top of the

door, and set hinge and screws aside. Be careful

not to lose the center hinge spacer and washer.

[_] REMOVE THE FRESH FOOD

DOOR (CONT.)

3.4 Set file door outside-,up on a non-scratching

StlIface.

3.5 Using a Torxdrive_; uansfer the two screws flom

the opposim side of the cabinet to the screw holes

vacated by the cenmr hinge removal.

3.3 Remove dm tape and flit die door away flom file

cabinet. I,ift die door flom file pin in die bottom

hinge bracket. (If file plastic washer sticks to the

door bottom, put it back on file hinge.)

/

3.6 Transfer file washer (if your model has one) m the

opposite side.

3.7 Take one of file screws removed in stop 2 and start

it in the oumrmost screw hole on the opposite side.

Do not drNe it all the way down-le_,e enough

space under the screw head for thickness of shim

and bracket.

0

19

Installation Instructions

B REVERSING THE DOOR SWING (CONT.)

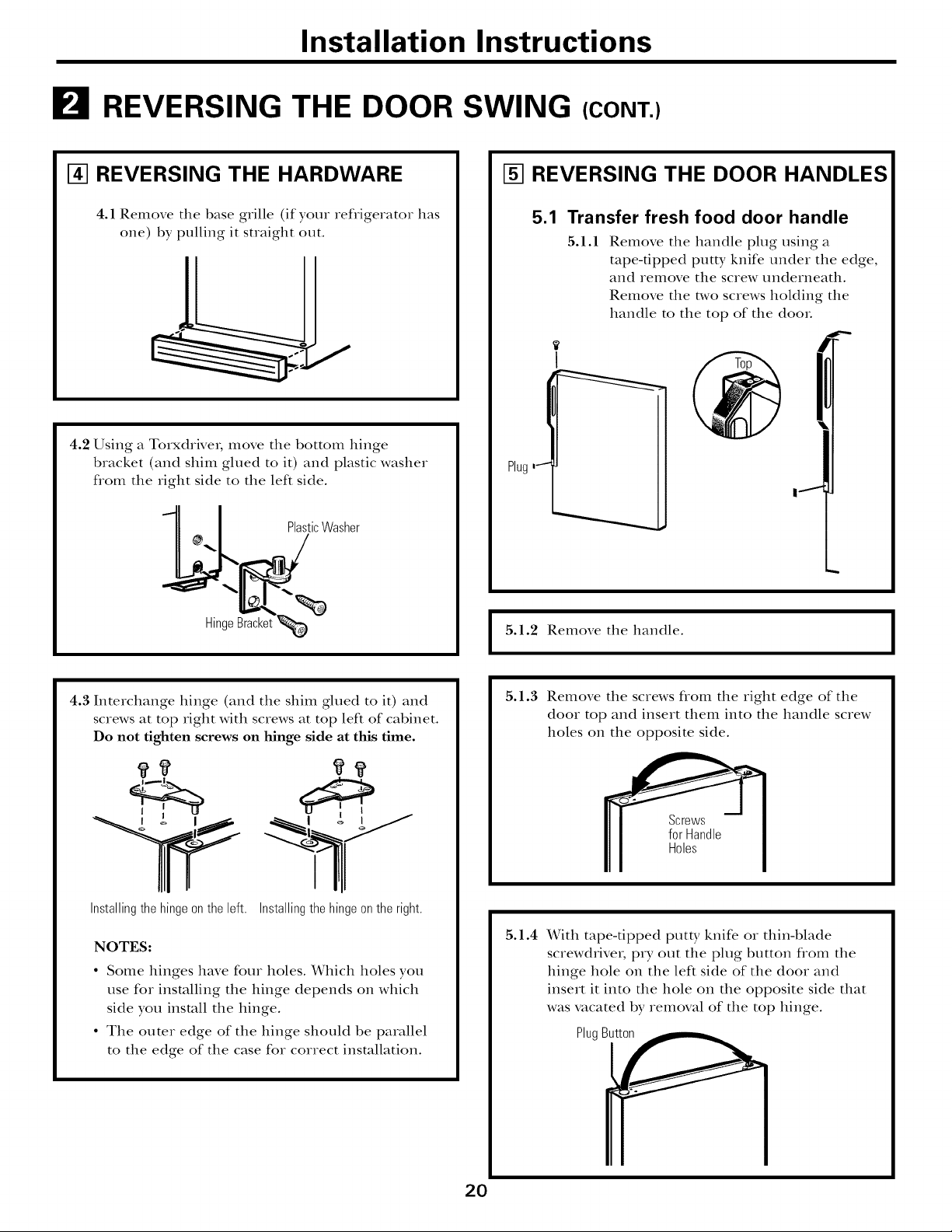

141REVERSING THE HARDWARE

4.1 Remove the base grille (if your refrigerator has

one) by pulling it straight out.

4.2 Using a Torxdrive_, move the bottom hinge

bracket (and shim glued to it) and plastic washer

flom the right side to the left side.

11 I PlasticWasher

[] REVERSING THE DOOR HANDLES

5.1 Transfer fresh food door handle

5.1.1

Remove the handle plug using a

tape-tipped putty knife under the edge,

and remove the screw underneath.

Remove the two screws holding the

handle to the top of the dooL

!

Plug,_

4.3 Interchange hinge (and the shim glued to it) and

screws at top right with screws at top left of cabinet.

Do not tighten screws on hinge side at this time.

Installingthe hingeonthe left. Installingthehinge onthe right.

NOTES:

• Some hinges have four holes. Which holes you

use for installing the hinge depends on which

side you install the hinge.

• The outer edge of the hinge should be parallel

to the edge of the case for correct installation.

5.1.2 Remove the handle.

I

5.1.3

Remove the screws flom the right edge of the

door top and insert them into the handle screw

holes on the opposite side.

5.1.4 With tape-tipped putty knife or thin-blade

screwdrivei; pry out the plug button flom the

hinge hole on the left side of the door and

insert it into the hole on the opposite side that

was vacated by removal of the top hinge.

I

2O

PlugBu_

Installation Instructions

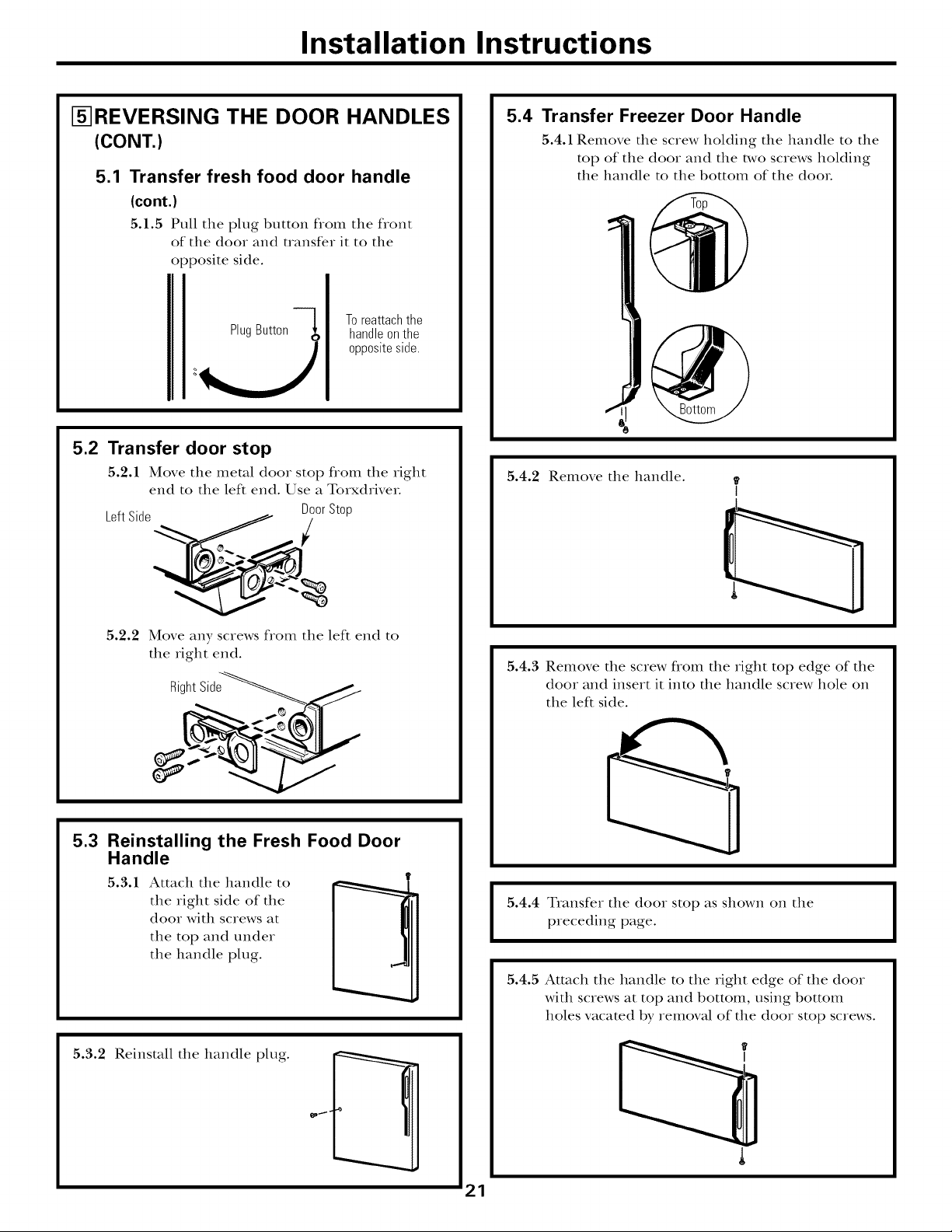

[]REVERSING THE DOOR HANDLES

(CONT.)

5.1 Transfer fresh food door handle

(cont.)

5.1.5 Pull the plug button from the front

of the door and transfer it to the

opposite side.

PlugButton

5.2

Transfer door stop

5.2.1 Move the metal door stop from the right

end to the left end. Use a TorxdriveL

LeftSide

Toreattachthe

handleonthe

oppositeside.

DoorStop

5.4 Transfer Freezer Door Handle

5.4.1 Remove the screw holding the handle to the

top of the door and the two screws holding

the handle to the bottom of the dooL

5.4.2 Remove the handle.

5.2.2 Move any screws from the left end to

the right end.

Right_iSide_

5.3

Reinstalling the Fresh Food Door

Handle

5.3.1 Attach the handle to

the right side of the

door with screws at

the top and under

the handle plug.

5.3.2 Reinstall the handle plug.

5.4.3 Remove the screw flom the right top edge of the

door and insert it into the handle screw hole on

the left side.

5.4.4 Transfer the door stop as shown on the

I

preceding page.

5.4.5 Attach the handle to the right edge of the door

with screws at top and bottom, using bottom

holes vacated by remowd of the door stop screws.

I

21

Installation Instructions

REVERSING THE DOOR SWING (CONT.)

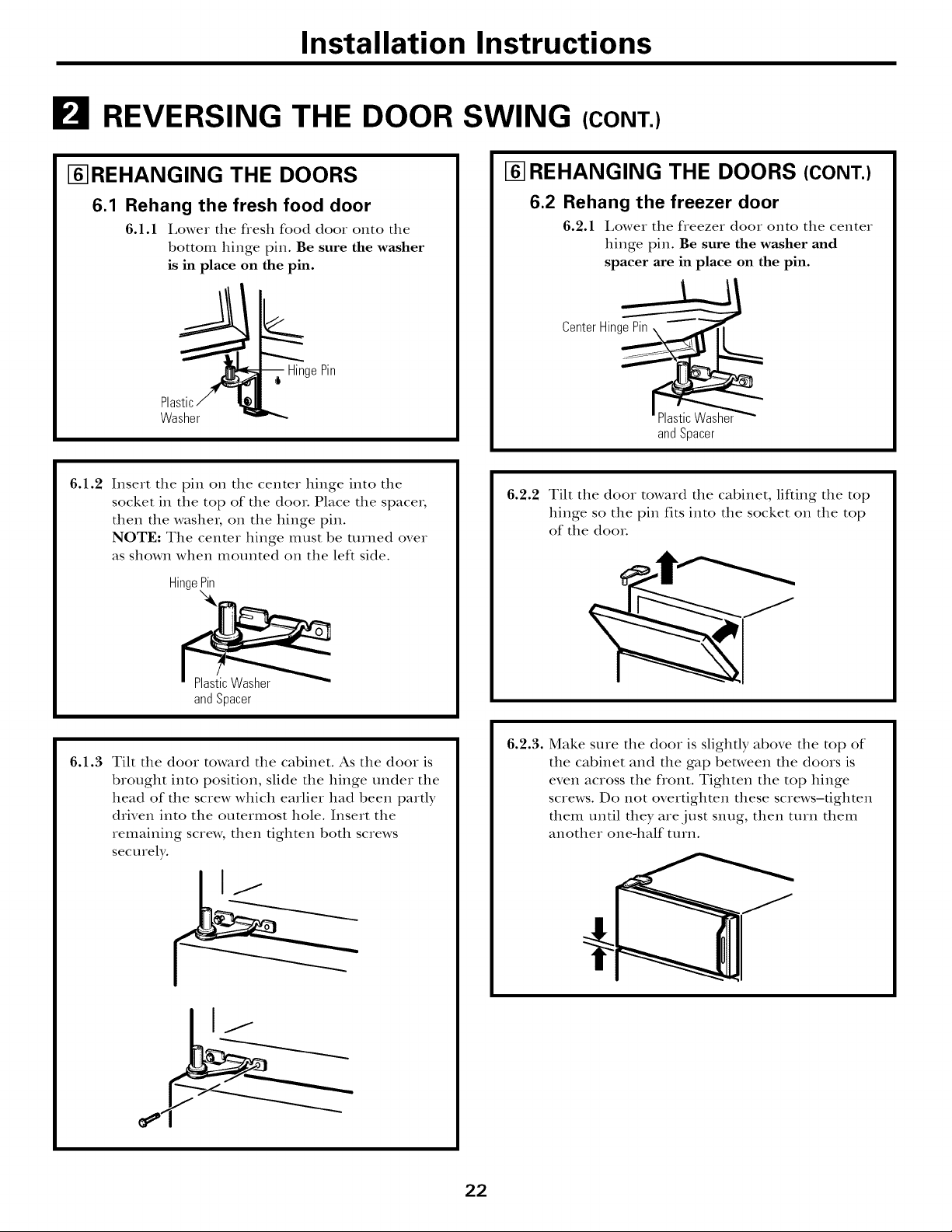

I-_REHANGING THE DOORS

6.1 Rehang the fresh food door

6.1.1 Lower tim fresh food door onto tim

bottom binge pin. Be sure the washer

is in place on the pin.

HingePin

Washer

6.1.2 Insert the pin on tim center hinge into tile

socket in tile top of tile dooL Place tile space_,

then tile washer, on tile hinge pin.

NOTE: Tile center hinge IIl/lst be turned over

as shown when mounted on tile left side.

Hinge_

I-_REHANGING THE DOORS (CONT.)

6.2 Rehang the freezer door

6.2.1 Lower tim freezer door onto tim center

hinge pin. Be sure the washer and

spacer are in place on the pin.

andSpacer

6.2.2 Tilt tile door toward tile cabinet, lifting tile top

hinge so tile pin fits into tile socket on tile top

of tile dooL

andSpacer

6.1.3 Tilt tile door toward tile cabinet. As tile door is

brought into position, slide tile hinge under tile

head of the screw which earlier had been pardy

driven into tile outermost hole. Insert tile

remaining screw, then tighten both screws

securely.

6.2.3. Make sure tile door is slighdy above tile top of

tile cabinet and tile gap between tile doors is

even across tile flont. Tighten tile top hinge

screws. Do not overtighten these screws-tighten

them until they are just snug, then t/lIn them

another one-half t/lin.

22

Normal operating sounds.

Newer refrigerators sound different from older refrigerators. Modern refrigerators

have more features and use newer technology.

Do you hear what I hear? These sounds are normal.

HUMMM...

-- WHOOSH...

• The new high efficiency compressor may run faster

and longer than your old refligerator and you may

hear a high-pitched hum or pulsating sound while

it is operating.

• You may hear a whooshing sound when file doors close.

This is due to pressure equalizing wiflfin file refrigeratoi.

CLICKS, POPS,

CRACKS and CHIRPS

• You may hear cracking or popping sounds when the

refiigerator is first plugged in. This happens as the

refligerator cools to the correct temperature.

• The compressor may cause a clicking oi chirping

sound when attempting to restart (this could take

up to 5 minutes).

• Expansion and conuacfion of cooling coils during

and after defiost can cause a cracking oi popping

sotlnd.

On models with an icemakei, after an icemaking

cycle, you may hear the ice cubes dropping into

the ice bucket.

WHIB/

• You may hear the fans spinning at high speeds.

This happens when the refligerator is first plugged

in, when the doors are opened flequenfly oi when

a large amount of food is added to the refligerator

oi fleezer compartments. The fans are helping to

maintain the correct temperatures.

WATERSOUNDS

6

• The flow of refligerant through the fleezer cooling

coils may make a gurgling noise like boiling wateL

• X_rater dropping on the deflost heater can cause a

sizzling, popping oi buzzing sound during the

deflost cycle.

• A water dripping noise may occur during the deflost

cycle as ice melts flom the evaporator and flows into

the drain pan.

• Closing the door m W cause a gtngling sound due to

pressure equalization.

23

Before you call for service...

Troubleshooting Tips

Save time and money! Review the charts on the foflowing

pages first and you may not need to call for service.

Possible Causes What ToDo

Refrigerator in defrost cycle. * \Vait about 30 minutes for defrost cycle to end.

Temperature control dial • Move the teInpe]_mue control dial to a temperature

in 0position, setting.

Refrigerator is tmplugged. • Push the plug completely into the outlet.

The fuse is blown/circuit • Replace fl_se or reset the breakm.

breaker is tripped.

Vibration or rattling Roller screws or leveling legs • See Rollers and Leveling Legs.

(slight vibration need adjusting.

is normal)

Motor operates for Normal when refrigerator • \Vait 24 hours for the refligerator to completely

long periods or cycles is first plugged in. cool down.

on and offfrequently.

(Modern refrigerators Often occurs when large • This is hernial.

with morn storage amounts of food are

space and a larger placed in refrigerator.

freezer require more Door left open. • Gheck to see if package is holding (loot open.

operating time. They

start and stop often Hot weather or frequent • This is nomaal.

tomaintain even door openings.

temperatures4 Temperature control dial • See About the temperature control dial.

set at the coldest setting.

Grille and condenser • See Careandcleaning.

need cleaning.

Freshfood orfreezer Temperature control dial * See About the temperature control dial.

compartment too warm not set cold enough.

Warm weather or frequent • Set the temperature control dial one step col(let.

door openings. See About the temperature control dial.

Door left open. * Gheck to see if package is holding (loot open.

Package blocldng air duct in • Gheck to see if package is blocking air duct in fleezer

freezer compartment, compartment.

Frostor ice crystals Door left open. • Gheck to see if package is holding (loot open.

on frozen food

(frostwithinpackage

isnormal)

Too frequent or too long

door openings.

24

Possible Causes What ToDo

Automatic icemaker Icemaker power switch • 0)1 power switch models, set file power switch to file

does not work is not on. I(on) position. 011 feeler arm models, move the feeler

(onsome models) am1 to the ON (down) position.

Water supply turned off or • See Installing the water line.

not connected.

Freezer compartment e_Vait _4 hom_ for the refligemtor to completely

too warm. cool down.

Piled up cubes in the storage • 1,evel cubes by hand.

bin cause the icemaker

to shut off.

Frequent "buzzing" sound Icemaker is on but the water • Turn the iceinaker off. On power switch models, set the

supply to the refrigerator has power switch to the 0 (off) position. On feeler arm

not been connected, models, move the feeler am1 m the STOP(up)position.

Keeping it on will damage the water valve.

Cubestoo small Water shutoff valve connecting • (;all the plumber to clear the valve.

refrigerator to water line may

be clogged.

Slow ice cube freezing Door left open. • Check to see if package is hoMing door open.

Temperature control dial • See About the temperature control dial

not set cold enough.

Ice cubes have Ice storage bin needs cleaning. EInpt_ and wash bin. Discard old cubes.

odor/taste

Food transmitting odor/taste • Wrap foods well.

to ice cubes.

e

Interior of refrigerator • See Care and cleaning.

needs cleaning.

Moisture forms on Not unusual during • \Vipe surface (h T and reset temperature control dial

cabinet surface periods of high humidity, one setting coldeL

between thedoors

Moisturecollectsinside

(inhumidweather,air

Too frequent or too

long door openings.

carriesmoistureinto

refrigeratorwhendoors

areopened)

Refrigerator has odor Foods transmitting • Foods with strong o(lo15 should be tightly wrapped.

odor to refrigerator. • Keep an open box of baking soda in the refrigerator;

replace every three months.

Interior needs cleaning. • See Care and cleaning.

25

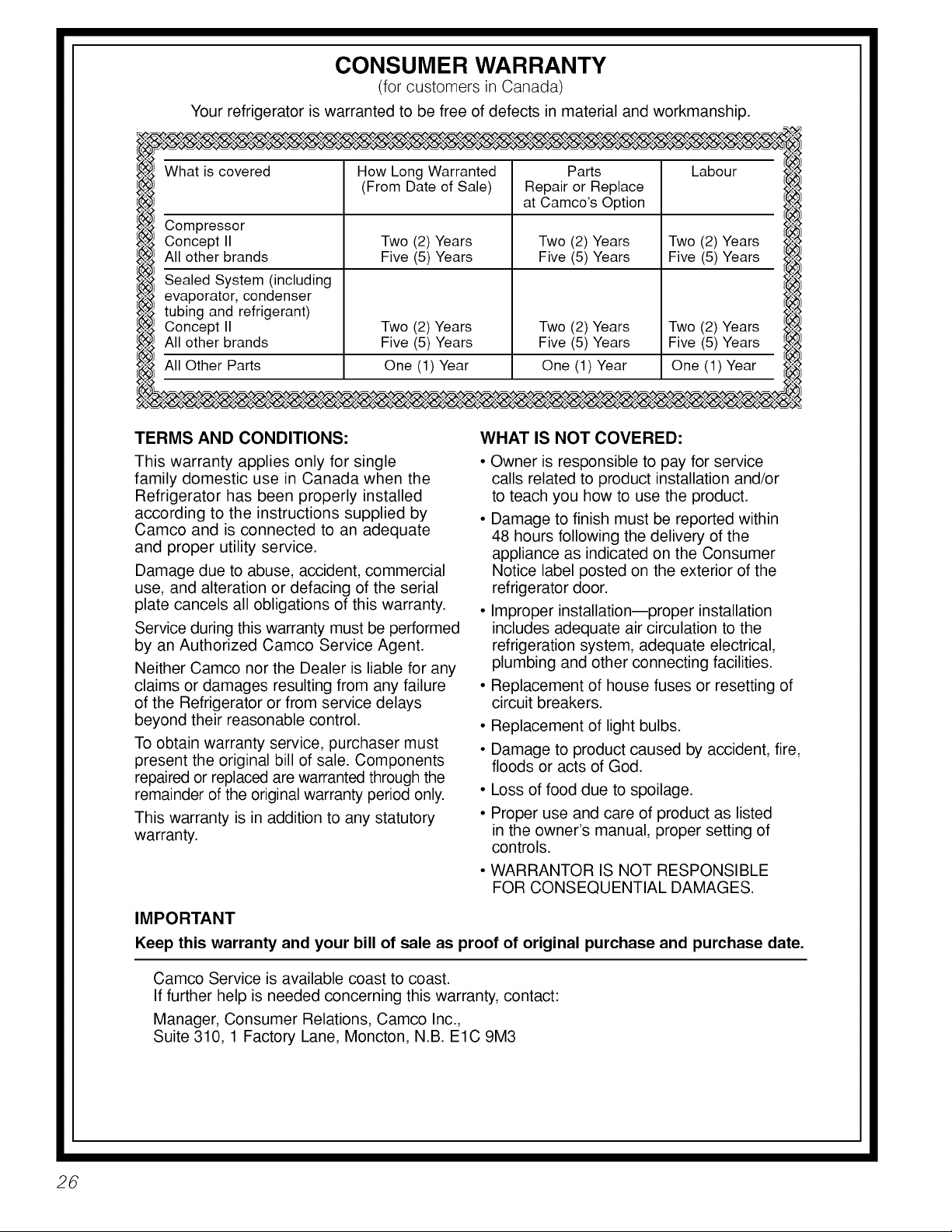

CONSUMER WARRANTY

(for customers in Canada)

Your refrigerator is warranted to be free of defects in material and workmanship.

What is covered How Long Warranted Parts Labour

Compressor

Concept II Two (2) Years Two (2) Years Two (2) Years

leb.31

All other brands Five (5) Years Five (5) Years Five (5) Years

1(__3/

Sealed System (including

id¢_l

evaporator, condenser

tubing and refrigerant)

Concept II

All other brands

All Other Parts One (1) Year One (1) Year One (1) Year

_eb.3_

I

TERMS AND CONDITIONS:

This warranty applies only for single

family domestic use in Canada when the

Refrigerator has been properly installed

according to the instructions supplied by

Camco and is connected to an adequate

and proper utility service.

Damage due to abuse, accident, commercial

use, and alteration or defacing of the serial

plate cancels all obligations of this warranty.

Service during this warranty must be performed

by an Authorized Camco Service Agent.

Neither Camco nor the Dealer is liable for any

claims or damages resulting from any failure

of the Refrigerator or from service delays

beyond their reasonable control.

To obtain warranty service, purchaser must

present the original bill of sale. Components

repaired or replaced are warranted through the

remainder of the original warranty period only.

This warranty is in addition to any statutory

warranty.

(From Date of Sale) Repair or Replace

at Camco's Option

Two (2) Years

Five (5) Years

Two (2) Years

Five (5) Years

WHAT IS NOT COVERED:

• Owner is responsible to pay for service

calls related to product installation and/or

to teach you how to use the product.

• Damage to finish must be reported within

48 hours following the delivery of the

appliance as indicated on the Consumer

Notice label posted on the exterior of the

refrigerator door.

• Improper installation--proper installation

includes adequate air circulation to the

refrigeration system, adequate electrical,

plumbing and other connecting facilities.

• Replacement of house fuses or resetting of

circuit breakers.

• Replacement of light bulbs.

• Damage to product caused by accident, fire,

floods or acts of God.

Loss of food due to spoilage.

Proper use and care of product as listed

in the owner's manual, proper setting of

controls.

Two (2) Years

Five (5) Years

• WARRANTOR IS NOT RESPONSIBLE

FOR CONSEQUENTIAL DAMAGES.

26

IMPORTANT

Keep this warranty and your bill of sale as proof of original purchase and purchase date.

Camco Service is available coast to coast.

If further help is needed concerning this warranty, contact:

Manager, Consumer Relations, Camco Inc.,

Suite 310, 1 Factory Lane, Moncton, N.B. ElC 9M3

GE Service Protection Plus TM

GE, a name recognized worldwide R)r quality and dependability, offers you

Service Protection Plus'_'--comprehensive protection on all your appliances--

No Matter What Brand!

Benefits Include:

* Backed by GE

* All brands covered

* Unlimited service calls

* All parts and labor costs included

* No out-of-pocket expenses

* No hidden deductibles

* One 800 number to call

We71 CoverAnyAppliance.

Anywhere. Anytime.*

You will be completely satisfied with our service protection or you may request your money back

on the remaining value of your contract. No questions asked. It's that simple.

Protect your refligeratox; dishwasher, washer and dryer, range, TV, VCR and much more--any brand!

Plus there's no exua charge for emergency service and low monthly financing is available. Even icemaker

coverage and food spoilage protection is off>red. You can rest easy, knowing that all your valuable

household products are protected against expensive repairs.

Place your con_dence in GE and call us in the U.S. toll-free at 800.626.2224

for more information.

_%11brands cover_ d, up lo 20 years old, in lhe conlinenlal U.S.

.......................................... _z_.-_u t here

Please place in envelope and mail to:

General Electric Company

Warranty Registration Department

P.O. Box 32150

Louisville, KY 40232-2150

27

Loading...

Loading...