Page 1

SmartCommand Thermostat

Installation Manual

g

Page 2

Copyright Copyright © 2007 GE Security. All rights reserved.

This document may not be copied in whole or in part or otherwise reproduced without prior

written consent from GE Security except where specifically permitted under US and

international copyright law.

Document number/revision: 1060018A (July 2007).

Disclaimer The information in this document is subject to change without notice. GE Security (“GE”)

assumes no responsibility for inaccuracies or omissions and specifically disclaims any

liabilities, losses, or risks, personal or otherwise, incurred as a consequence, directly or

indirectly, of the use or application of any of the contents of this document. For the latest

documentation, contact your local supplier or visit us online at www.gesecurity.com.

This publication may contain examples of screen captures and reports used in daily operations.

Examples may include fictitious names of individuals and companies. Any similarity to names

and addresses of actual businesses or persons is entirely coincidental.

Trademarks and patents GE and the GE monogram are registered trademarks of General Electric Company.

Other trade names used in this document may be trademarks or registered trademarks of the

manufacturers or vendors of the respective products.

Intended use Use this product only for the purpose it was designed for; refer to the data sheet and user

documentation. For the latest product information, contact your local supplier or visit us online

at www.gesecurity.com.

FCC compliance This equipment has been tested and found to comply with the limits for a Class B digital device,

EMC directive The European Union directive on electromagnetic compatibility (2004/108/EC) requires non-

pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a residential environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

European manufacturers to designate an authorized representative in the Community.

Our European representative is GE Security, Kelvinstraat 7, 6003 DH Weert, Nederland.

The European directive Waste Electrical and Electronic Equipment (WEEE) aims to minimize the

impact of electrical and electronic equipment waste on the environment and human health. For

proper treatment, recovery, and recycling, return the equipment marked with this symbol to

your local supplier upon the purchase of equivalent new equipment, or dispose of it in

designated collection points. For more information, visit www.recyclethis.com.

Page 3

Contents

iii

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conventions used in this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety terms and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wall display unit (WDU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Thermostat control screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Temperature display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Setpoint display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Clock display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Up and down buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Menu button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mode button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fan button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Run/Hold button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

LED display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Communication error display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Main menu screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Messages screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Schedule setup screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Heat and cool schedule screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Copy schedule screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

User settings screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Set clock screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Sensor calibration screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Backlight display screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Thermostat information screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installer settings screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Freeze protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Wall display unit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Control unit installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control unit to WDU wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Control unit to HVAC wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Retrofit wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

HVAC system wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard HVAC system wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Heat pump HVAC system wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Control unit connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Serial communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

System checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Thermostat bench test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Page 4

SmartCommand Thermostat

iv

Installation Manual

Serial communication test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

HVAC system testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Control unit wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Serial network command and variable list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Network commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Network variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Contacting technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Online publication library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Page 5

Preface

This is the GE SmartCommand Thermostat Installation Manual for model CC-SCSTAT. This document

includes an overview of the product and detailed instructions explaining:

• how to install; and

• how to operate the thermostat.

There is also information describing how to contact technical support if you have questions or concerns.

To use this document effectively, you should have the following minimum qualifications:

• a basic knowledge of HVAC control components; and

• a basic knowledge of electrical wiring and low-voltage electrical connections.

1

Read these instructions and all ancillary documentation entirely before

installing or operating this product.

The most current versions of this and related documentation may be found on our website. Refer to Online

publication library on page 39 for instructions on accessing our online publication library.

Note: A qualified service person, complying with all applicable codes, should perform all required hardware installation.

Conventions used in this document

The following conventions are used in this document:

Bold Menu items and buttons.

Italic Emphasis of an instruction or point; special terms.

File names, path names, windows, panes, tabs, fields, variables, and other GUI elements.

Titles of books and various documents.

Blue italic (Electronic version.) Hyperlinks to cross-references, related topics, and URL addresses.

Monospace Text that displays on the computer screen.

Programming or coding sequences.

Safety terms and symbols

These terms may appear in this manual:

CAUTION: Cautions identify conditions or practices that may result in damage to the equipment or other property.

WARNING: Warnings identify conditions or practices that could result in equipment damage or serious personal injury.

Page 6

SmartCommand Thermostat

y

2

Installation Manual

Product overview

The SmartCommand thermostat (model CC-SCSTAT) provides typical thermostat functions as well as the

capability to send and receive information via serial communications. This capability allows the thermostat’s

setpoint, mode, and fan operation to be changed remotely. In addition, the remote systems can request status of

the thermostat’s temperature, setpoints, modes, and other system information.

The thermostat consists of two parts, a wall display unit (WDU) and a HVAC control unit. The wall display

unit looks like a traditional thermostat and is the wall-mounted user interface for the control unit. It provides a

display screen, control buttons, and the temperature sensor. The wall display unit connects to the control unit

by a four-wire cable. The control unit connects to the HVAC system in place of a standard thermostat and

provides thermostatic control of the system. In addition, the control unit sends and receives data and

commands via a twisted-pair serial communication connection for remote control of the system. The control

unit can be used with up to three remote temperature sensors.

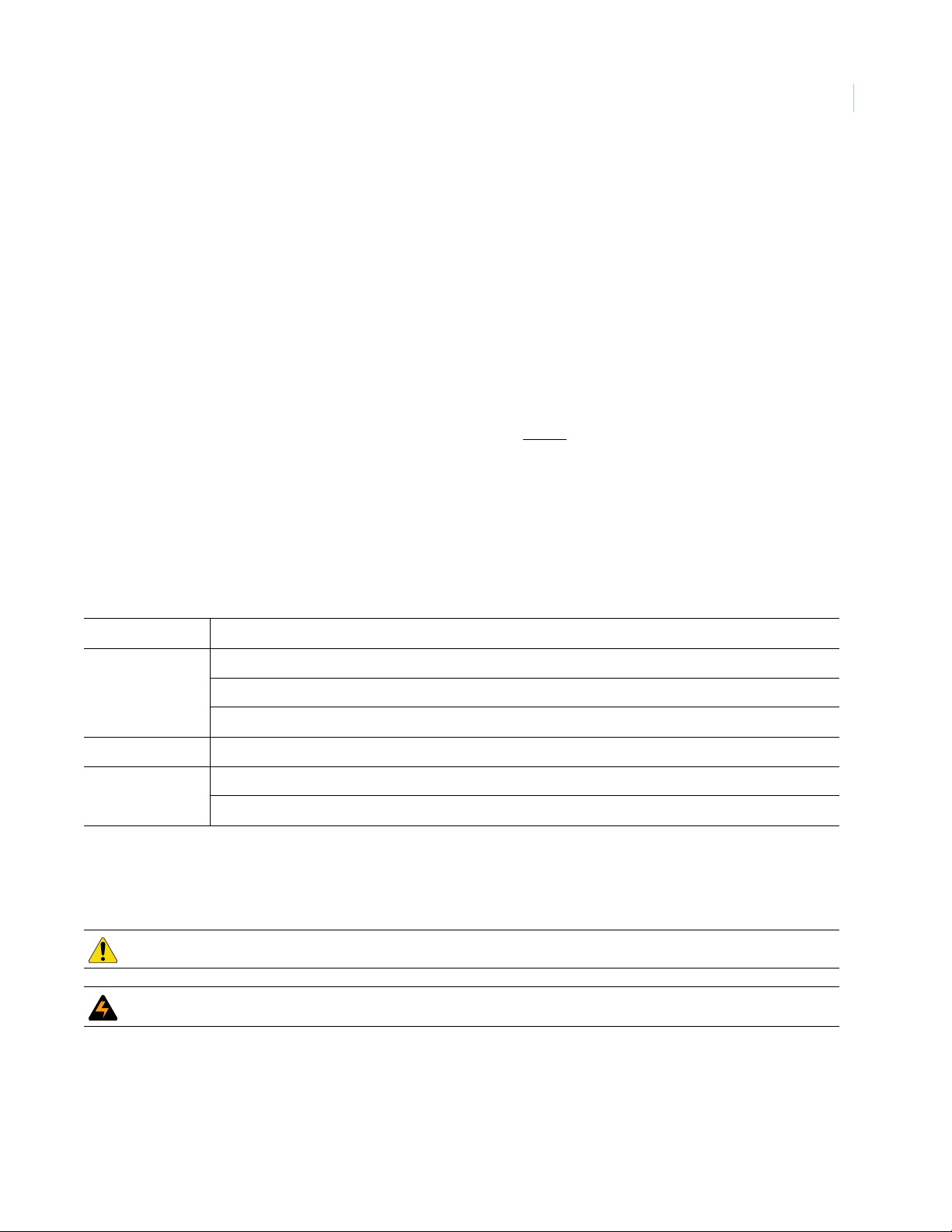

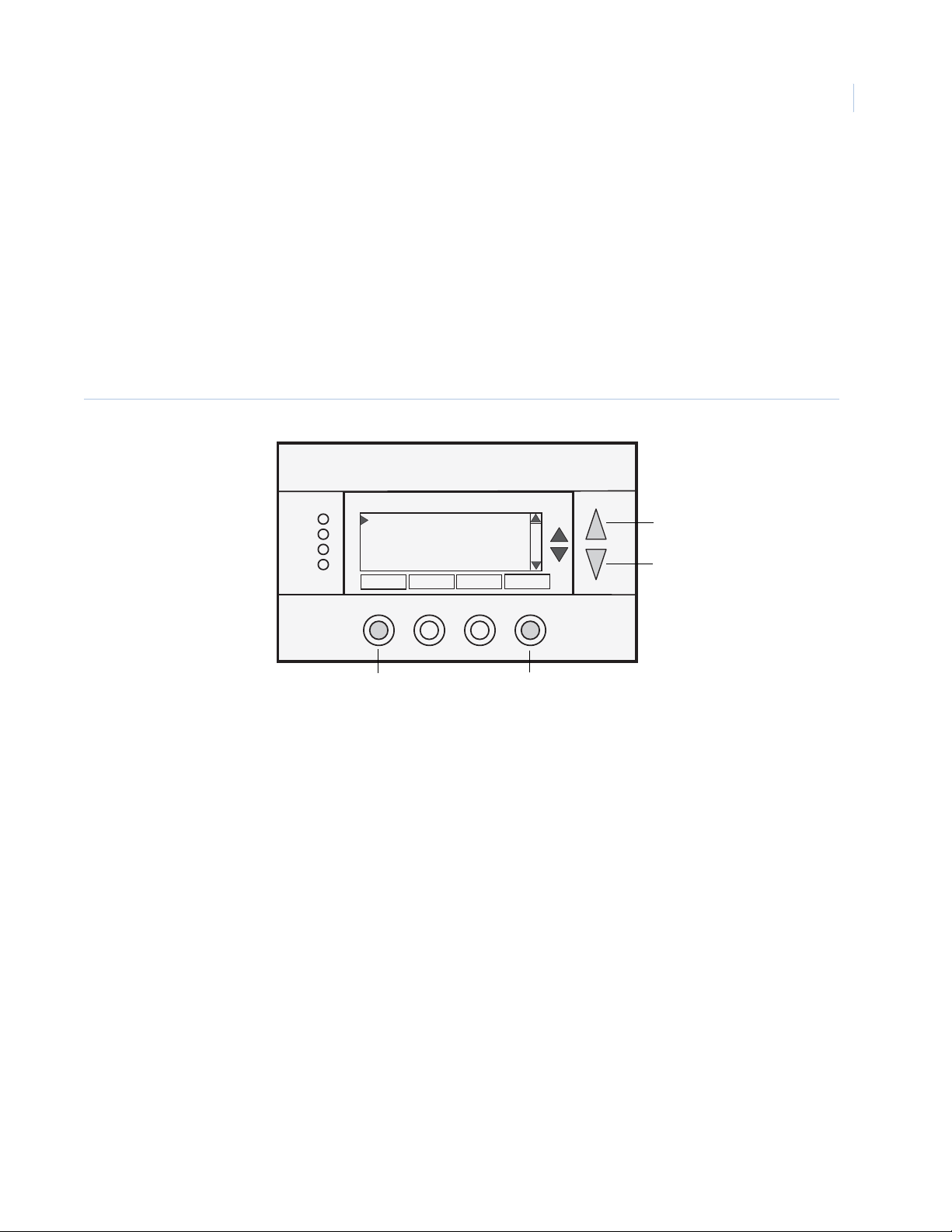

Wall display unit (WDU)

The WDU has a backlit LCD graphical display capable of both text and graphics, control buttons, LEDs, and a

digital temperature sensor. The unit can display multiple screens. In the default Thermostat control screen

(Figure 1) it shows the current temperature, setpoints, mode and manual fan mode, time, outside temperature

and other information.

Figure 1. Wall display unit default screen

WDU screen

LEDs

10:25 AM

s Off

S

Econ

Run

No Msg

MENU

Outside 60

75

MODE

Control buttons

FAN

76 H

74 C

Up button

Down button

Any changes in temperature, or control button operations, are transmitted to the control unit. Updates are

received from the control unit and displayed by the WDU.

WDU control buttons

Both the four control buttons and the up and down buttons on the WDU change functions when you change

screens. The function of the buttons is defined by on-screen labels that are dynamic and change when you

change screens.

Page 7

WDU LEDs

The four LEDs on the WDU display various status information. The LEDs have dynamic on-screen labels that

can change when you change screens.

WDU screens

One of the unique features of the WDU graphical display is the ability to have multiple display screens. In

addition to a main Thermostat control screen, menus and other control screens for special functions are

provided. This makes an intuitive and easy to use user interface and allows the many functions of the

thermostat to be easily navigated.

The WDU screens include:

Thermostat control screen. The Thermostat control screen on page 4 screen is the only screen needed

for basic thermostat operation. All other screens will automatically timeout and return to this screen after

120 seconds of no activity.

Minimized thermostat screen. The Thermostat control screen will go to a minimized screen after a 30

second timeout period. This screen presents a simple, uncluttered display of the current room temperature.

You can disable the Minimized screen if desired.

3

Note: You can press any button when the Minimized screen is displayed to restore and display the Thermostat

control screen.

Menu selection screen. Press the Menu button on the Thermostat contr ol screen to access the Main menu

screen on page 7. This screen presents a list of the other functions or setup screens that you can select.

Messages screen. The unit is capable of receiving messages from the RS485 network. Messages received

are displayed in the Messages screen on page 8.

Schedule setup screen. Use the Schedule setup screen on page 9 to setup and select schedules for the

thermostat.

User settings screen. Use the User settings screen on page 12 for the initial setup of the thermostat. From

this screen, you can set the clock, minimized screen timeout, Fahrenheit or Centigrade selection, sensor

calibration, and display settings.

Thermostat information screen. This is a quick reference list of the thermostat firmware versions and

setup. (See Thermostat information screen on page 16.)

Page 8

SmartCommand Thermostat

y

4

Installation Manual

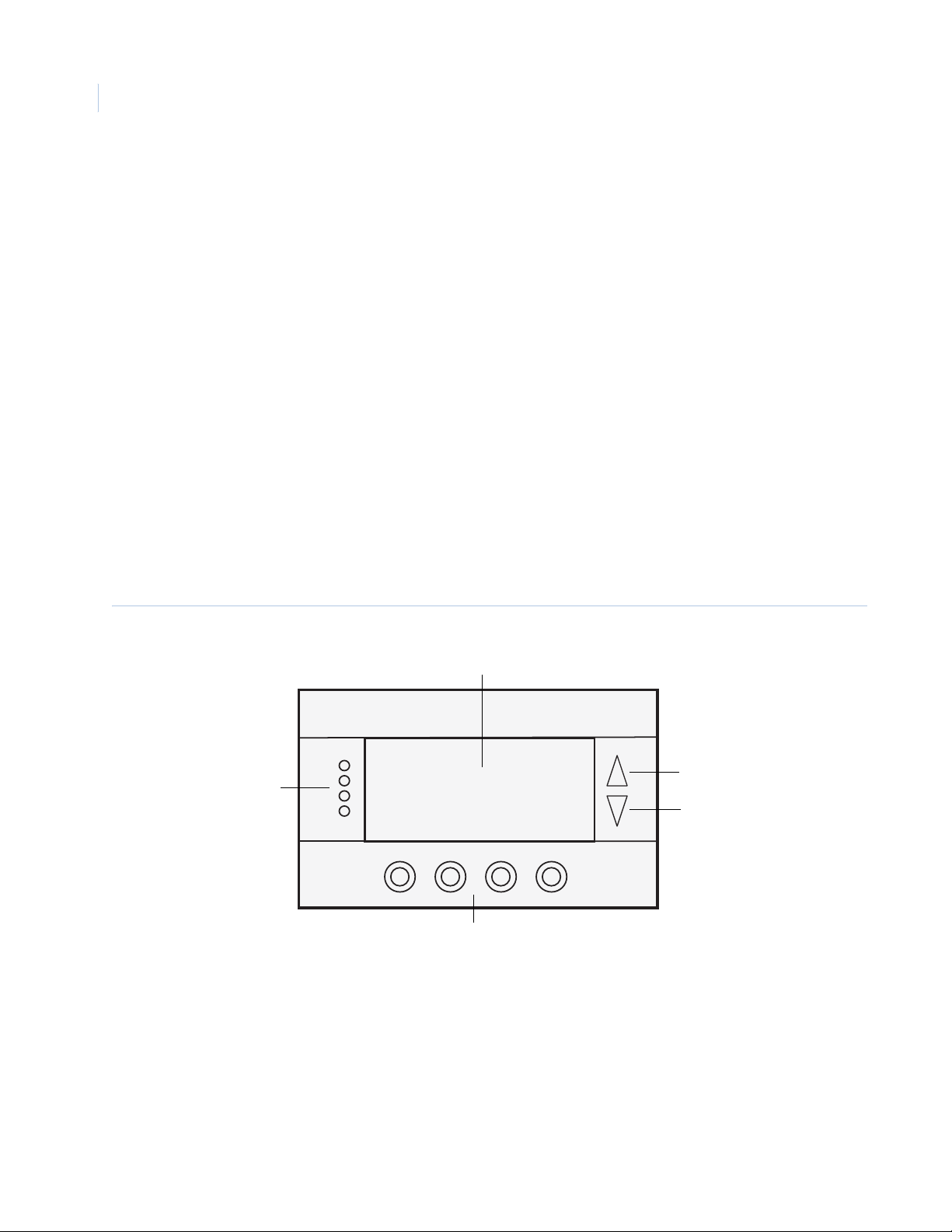

Thermostat control screen

The Thermostat control screen (Figure 2) is the default display screen normally displayed on the WDU.

Figure 2. Thermostat control screen

Clock display

Setpoint Display

LED

Display

10:25 AM

s Off

S

Econ

Run

No Msg

MENU

Menu

Outside 60

75

MODE

Mode

FAN

Fan

76 H

74 C

Run/Hold

Up

Down

Temperature display

The WDU will normally display the current temperature from the internal digital temperature sensor or a

remote sensor. The sensors have an accuracy of ± 1°F (± 0.5°C). The WDU will display temperatures from -40

to 190°F (-40 to 88°C). If averaging remote sensors are attached, the display will show the average temperature

of all attached averaging sensors.

Setpoint display

The heating and cooling setpoints are displayed next to the Up and Down buttons. In heat mode, the Up and

Down buttons change the heat setpoint. In cool mode, they change the cooling setpoint. When in auto mode,

the buttons change the last call’s heating or cooling setpoint. The setpoints will push each other if they are

adjusted to within the minimum heat/cool separation (delta T) setting. This setting is default set to 4 degrees,

but can be changed in the installer settings.

Clock display

The current time is displayed in the upper left corner of the main screen. Set the clock from the User settings

screen on page 12.

Page 9

Up and down buttons

The Up and Down buttons adjust the setpoint temperature. Press Up to increase the setpoint value by one

degree and press Down to decrease the setpoint one degree. Pressing and holding a button down will cause the

setpoint to continuously change until the button is released. The setpoints can be set from 6 to 109° (F or C),

unless limited in the installer settings.

You cannot lower the cooling setpoint below the heating setpoint. The thermostat will push the heating setpoint

lower if you try to lower the cooling below the heating setpoint. It maintains a setpoint delta separation

between heating and cooling setpoints. The same is true for raising the heating setpoint above the cooling

setpoint. Again, the thermostat will push the cooling setpoint up to maintain the setpoint delta separation.

Menu button

The Menu button changes the screen display to the Main menu screen that shows other functions available on

the thermostat. These are dynamic and can change with the version of the thermostat you have, but the standard

ones include:

• Messages screen on page 8

• Schedule setup screen on page 9

• User settings screen on page 12

• Thermostat information screen on page 16

5

Mode button

The Mode button controls the HVAC system mode. The current mode selected is displayed above the button.

Pressing the Mode button will cause the mode and display to change to the next mode. The mode cycles

through the following modes with each press of the Mode button.

Off mode. The system is off. No heating or cooling will come on. If it was on, the system will turn off.

Heat mode. Only heating operation will occur.

Cool mode. Only cooling operation will occur.

Auto mode. Heating or cooling will come on according to the heating and cooling setpoints. The system

will automatically switch between heating and cooling when the temperature exceeds the setpoints.

EH mode. This mode is only displayed when Heat Pump HVAC system type is selected. When there is a

compressor failure with the heat pump system, setting the mode to EH will allow the supplemental heat to

come on whenever there is a heat call to provide heating. It also disables the compressor outputs to prevent

further damage to the system.

Fan button

The Fan button controls the HVAC system’s manual fan. The current manual fan mode is displayed above the

button. Normally this button is in the Auto mode (the system fan is automatically controlled by the HVAC

system). Pressing the Fan button once will turn the manual fan operation on. Pressing it again will turn the

manual fan off and return to the Auto mode. Changes in the fan mode are sent to the control unit.

Page 10

SmartCommand Thermostat

6

Installation Manual

Run/Hold button

The Run/Hold button controls the automatic schedule operation. In hold mode, the current temperature is

maintained until changed by manual or remote network command. In the run mode, the schedule loaded into

the thermostat is activated and setpoints will change according to the schedule and the time and day of the

week.

Away mode.

seconds. In the away mode, the setpoints are changed to preset temperatures: 66°F heating and 80°F cooling.

There is also an away mode that you can select if you press and hold the

Run

button for three

LED display

The Thermostat control screen has the following LED labels and descriptions, numbered from top to bottom.

LED 1 green, system operation display

LED off, SYS OFF displayed. HVAC system is off.

LED off, SYS MOT displayed. Minimum off time (MOT) delay on is active.

LED on, SYS ON displayed. HVAC system is running.

LED on, SYS MRT displayed. Minimum run time (MRT) delay off is active.

LED 2 green, system Economy mode display

LED off or on, Econ displayed. Economy or first stage heating or cooling only.

LED on, 2nd Stg displayed. Stage two heating or cooling is active.

LED on, 3rd Stg displayed. Stage three heating is active.

LED on, Vent displa yed. Fresh air venting is active.

LED 3 green, Run/Hold display shows state of schedule Run/Hold mode

LED off, Run displayed. Schedule is running.

LED on, Hold displayed. Schedule is off, temperature setpoint hold in effect.

LED 4 red, alert LED used for messaging and other system alerts

LED off, No msg displayed. No text messages or alerts present.

LED on, mail icon or alert text displayed. Message waiting or specific alert text.

Communication error display

If the WDU is not properly wired or if communication to the control unit is interrupted, the LCD display will

flash

Comm Failure at the top center of the Thermostat control screen (where outside temperature is normally

displayed). Momentary display of communication failure caused by loss of data, will clear automatically when

data communication is restored. If the communication failure display stays on, check wiring or the control unit

for problems.

Page 11

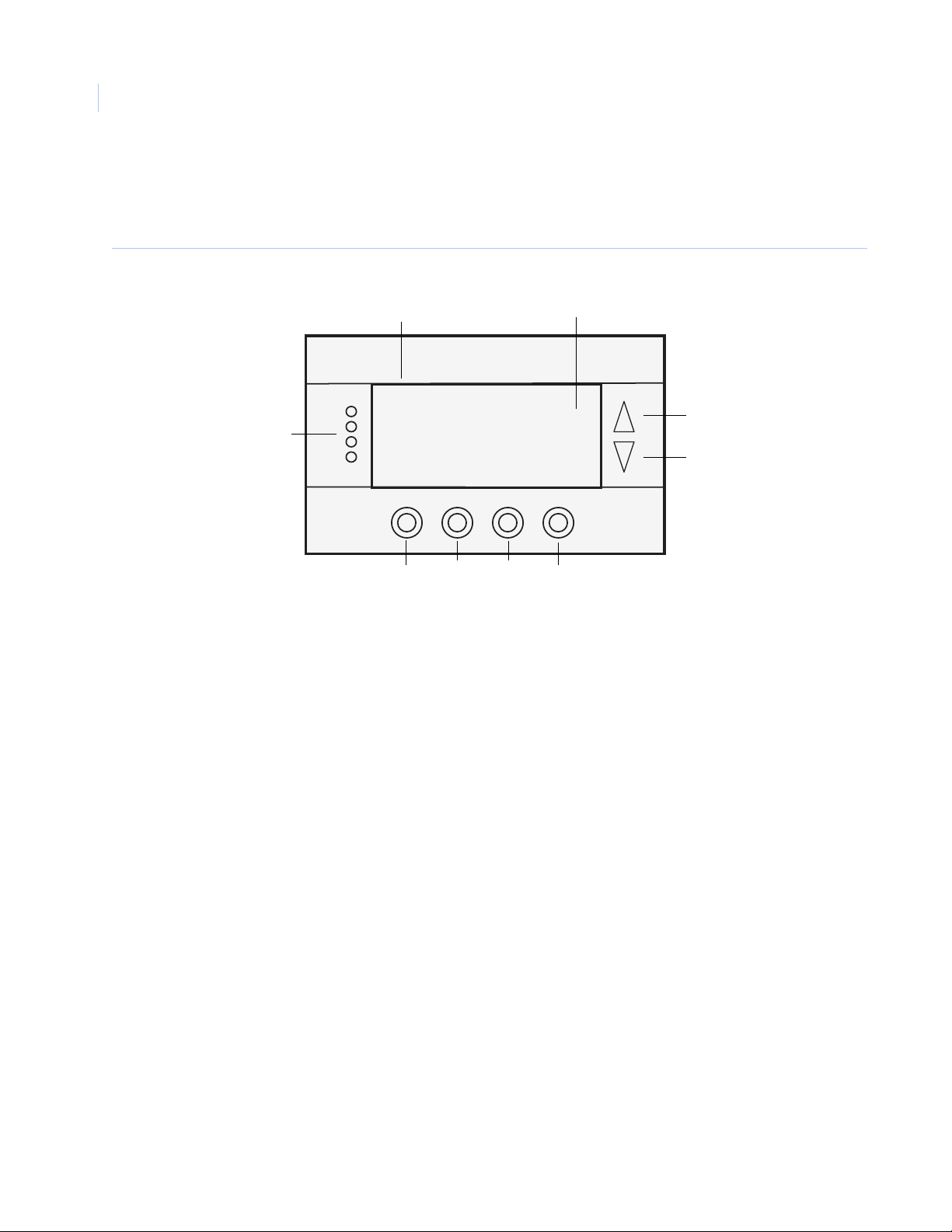

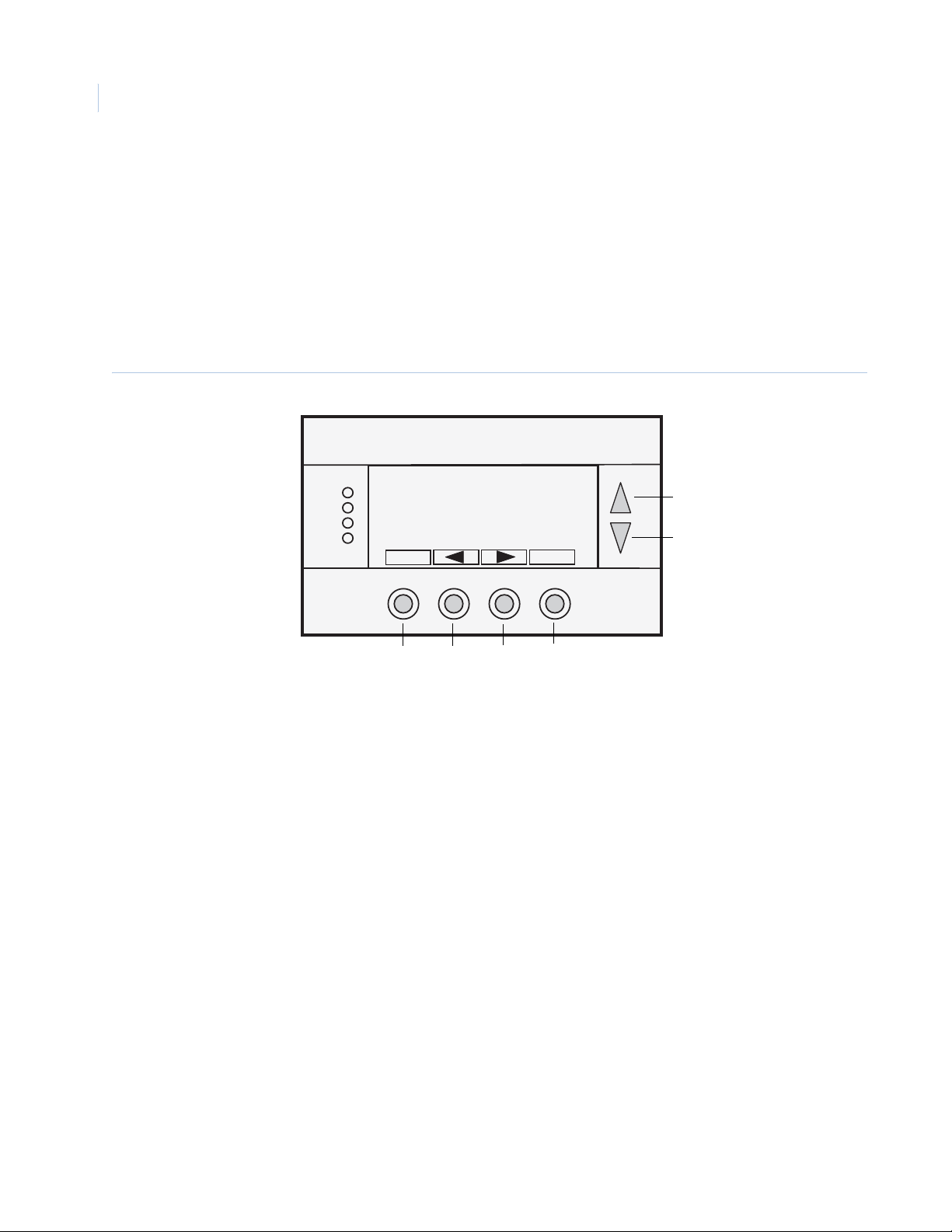

Main menu screen

The thermostat has a menu tree that can be accessed by pressing the Menu button on the main Thermostat

control screen. Various configurations of the unit can have different screen contents. The first screen that will

display is the Main menu screen (Figure 3). This is a list of the other menus or functions that you can access.

Standard screens are listed in this manual, your screen may vary with different configurations or revisions.

Figure 3. Main menu screen

Menu Selection

Messages

Schedules

User Settings

Thermostat Info

Done

Select

Up

Down

7

Done

Select

Screen options include:

Messages. Access the Messages screen on page 8. A text messaging subsystem allows messages of up to

80 characters to be sent to the thermostat. Messages received display when the message screen is selected.

The Messages menu item may or may not be displayed. It can be enabled or disabled from the installer

settings.

Schedules. Access the Schedule setup screen on page 9 to set the programmable setback schedules of the

thermostat.

User settings. Access the User settings screen on page 12 to set the clock, screen timeout, F/C mode,

sensor calibration, and backlight/display settings.

Thermostat information. Access the Thermostat information screen on page 16 that displays the

firmware versions of the WDU and control unit, the HVAC system type and equipment options, and the

network address of the thermostat.

Screen navigation buttons include:

Done. Return to Thermostat control screen on page 4.

Select. Select menu item at pointer.

Up. Move selection pointer up.

Down. Move selection pointer down.

Page 12

SmartCommand Thermostat

8

Installation Manual

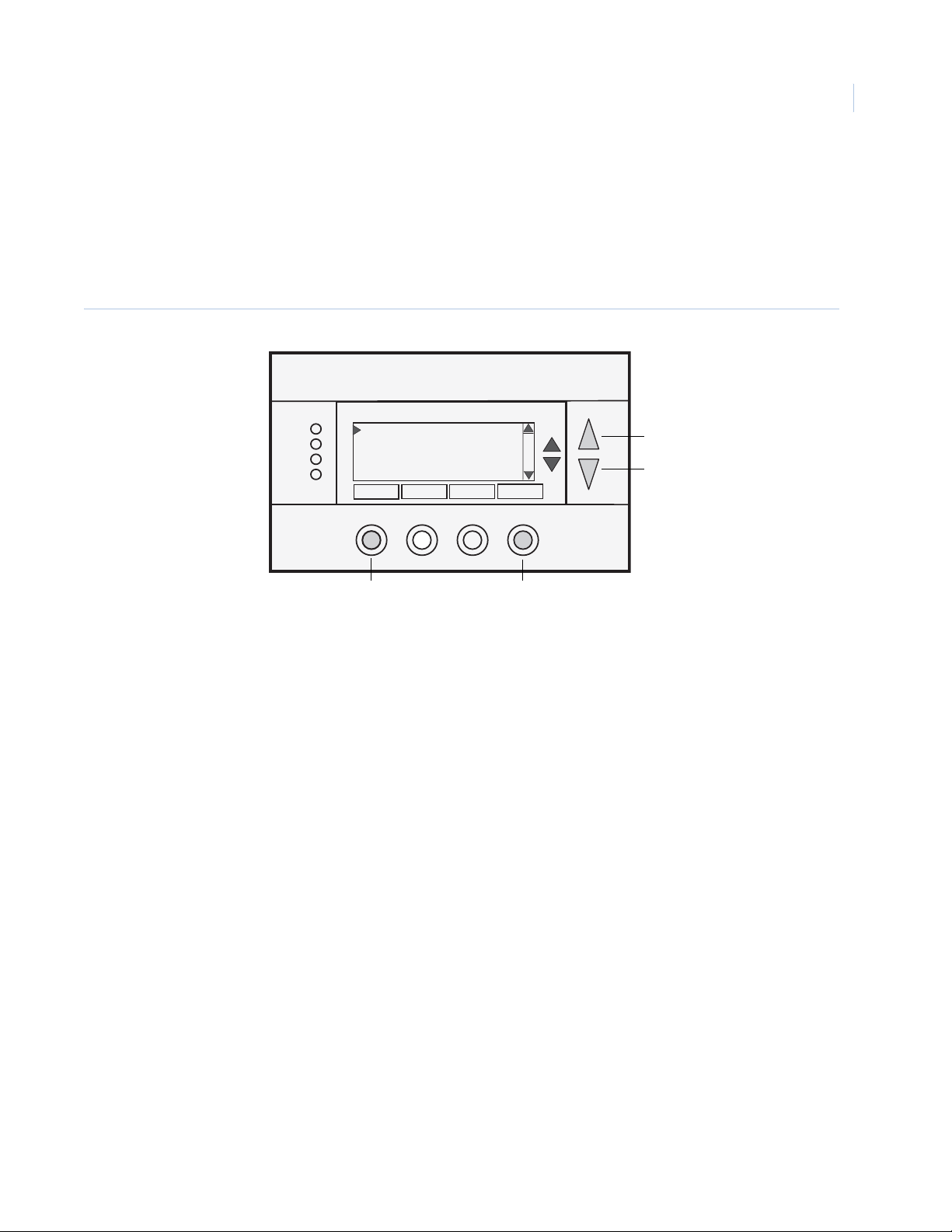

Messages screen

The Messages screen (Figure 4) allows you to retrieve text messages sent from the serial network to the

thermostat. The Messages screen features navigation buttons to read new and old messages and delete

messages.

You can store up to 16 messages. If more than 16 messages are received, the oldest is erased to make room for

the newest message.

Note: New messages will turn on and flash the red message LED and mail icon in the main Thermostat control screen.

Viewing messages makes them old and turns off the indicators. If you view some, but not all new messages, the

new message notification LED and icon will stay on. When you first select the Messages screen, the most

recently received message will be displayed as Message 1. If other messages are stored in memory, you can

recall and view or delete them by using the Messages screen navigation buttons.

Figure 4. Messages screen

Messages

Message 1 10/14 5:35 PM

The TR40 can receive 16 text

messages, each up to 80 characters

long. They are date/time stamped

Done

Done Delete Previous

Del

Prev

Screen navigation buttons include:

Done. Return to main Main menu screen on page 7.

Del. Delete the message being displayed.

Prev. Display previous messages. Scroll up in the message stack.

Next. Display the next message. Scroll down in the message stack.

Next

Next

Page 13

Schedule setup screen

The Schedule setup screen allows you to review and set the setback schedule for the thermostat. The thermostat

has a 4 by 7 schedule. Four times a day can be selected for heating and cooling setpoints. Each day of the week

can have a different schedule. Groups of days can be copied with the same schedule. When the thermostat is set

to run mode, the schedule will be executed daily, with the setpoints being changed as per that day’s schedule

stored in the thermostat. Hold mode stops the scheduled operation and holds the current setpoints until changed

manually or by network commands.

The Schedule setup screen (Figure 5) gives you the option of setting a custom setback schedule or the option to

load one of two preset schedules.

Figure 5. Schedule setup screen

Select Schedule

Heat and Cool

Preset: Comfort

Preset: EnergyMiser

Done

Select

Up

Down

9

Done

Select

Screen options include:

Heat and cool. Change the individual day/hour and setpoints for the heating and cooling schedule (see

Heat and cool schedule screen on page 10).

Preset: Comfort. Load the comfort schedule into the thermostat. This is a preset schedule with mild

setbacks.

Preset: EnergyMiser. Load the EnergyMiser schedule into the thermostat. This is a preset schedule with

deeper setbacks.

Screen navigation buttons include:

Done. Return to Main menu screen on page 7.

Select. Select the schedule to view or modify.

Up. Move selection pointer up.

Down. Move selection pointer down.

Page 14

SmartCommand Thermostat

10

Installation Manual

Heat and cool schedule screen

When you select the Heat and cool schedule menu item, the Heat and cool schedule screen (Figure 6) opens

and the schedule for the current day will be displayed. Use the scroll buttons to highlight the data to be

modified. Once the data has been highlighted, use the Up (+) and Down (-) buttons to change the value of the

data.

To copy a day’s schedule to another day or group of days, move the cursor to C on the bottom right of the

screen. When you highlight C, the button below will change from Next to Copy. Press this button to access the

Copy schedule screen on page 11.

Figure 6. Heat and cool schedule screen

Monday Schedule

Time Heat Cool

Morn 6:00 A 72 82

Day 9:00 A 68 84

Eve 5:00 P 74 76

Nite 10:00 P 70 78 C

Done

Next

+

_

Up (+)

Down (-)

Done

Left

Right

Next/Copy

Screen navigation buttons include:

Done. Return to the Main menu screen on page 7.

Left. Scroll back.

Right. Scroll forward.

Next/Copy. When the button shows Next, select the next day’s schedule. When the button shows Copy,

go to the Copy schedule screen on page 11.

Up (+). Increase time or temperature.

Down (-). Decrease time or temperature.

Page 15

Copy schedule screen

The Copy schedule screen (Figure 7) is a sub screen of the Heat and cool schedule screen on page 10. The

Copy schedule screen allows you to copy a day’s schedule to another day or group of days.

To copy a day’s schedule, do the following:

1. Select the day to be copied in the Heat and cool schedule screen. Scroll to the C at the bottom of the

Heat and cool schedule screen to highlighted it. The Next button will change to the Copy button. Press

Copy to open the Copy schedule screen (see Heat and cool schedule screen on page 10).

2. Scroll through the days in the Copy schedule screen and select the days the schedule is to be copied to

by setting the N under each day to Y, using the Up (Yes) and Down (No) buttons.

3. After selecting all the days desired, press Copy.

4. Press Back to exit the Copy schedule screen.

Figure 7. Copy schedule screen

11

Copy Monday Schedule

to

Sun Tue Wed Thu Fri Sat

N Y Y Y Y N

Back

Back

Left Right

Screen navigation buttons include:

Back. Return to the Heat and cool schedule screen on page 10.

Left. Move the selection bar back.

Right. Move the selection bar forward.

Copy. Copy the schedule to the selected days.

Up (Yes). Copy the schedule to this day.

Down (No). Do not copy to this day.

Copy

Copy

Yes

No

Up (Yes)

Down (No)

Page 16

SmartCommand Thermostat

12

Installation Manual

User settings screen

The User settings screen (Figure 8) allows you to set or change various user options of the thermostat such as

the clock, minimized screen timeout, Fahrenheit/Centigrade mode, sensor calibration, and backlight settings.

Figure 8. User settings screen

User Settings

Set Clock

Screen Timeout 30

F/C Mode F

Sensor Calibration

Done

+

-

Select

Up

Down

Done Plus

Minus

Select

Screen options include:

Set clock. Access the Set clock screen on page 13.

Screen timeout. Set the screen timeout time in seconds. Options are 0 or 15 to 127 (default is 30 seconds).

This is the time before any screen reverts to the Minimized screen after you stop pushing buttons. You can

disable the Minimized screen feature by setting this time to 0. If this is disabled, all screens revert to the

main Thermostat control screen on page 4 after 120 seconds.

F/C select. Select which temperature display mode you desire, Fahrenheit (F) or Centigrade (C) with the

+ and - buttons.

Sensor calibration. Access the Sensor calibration screen on page 14.

Backlight/Display. Access the Backlight display screen on page 15.

Screen navigation buttons include:

Done. Return to the Main menu screen on page 7.

Plus. Increase the selected value.

Minus. Decrease the selected value.

Select. Select the function to be set.

Up. Move selection pointer up.

Down. Move selection pointer down.

Page 17

Set clock screen

The Set clock screen (Figure 9) is a sub screen of the User settings screen. The Set clock screen allows you to

set the thermostat’s internal clock.

To set the time and day , do the following:

1. Move the cursor with the navigation arrows until the data you want to change is highlighted.

2. Press Up (+) or Down (-) to increase or decrease the value to the desired setting.

3. Press Set to set the time and return to the main Menu screen or wait for the screen to timeout.

Note: If the clock has been reset by an extended power outage, the clock display on the Thermostat control screen will be

blinking. Pressing Menu button will take you directly to this screen to set the clock.

Figure 9. Set clock screen

Set Clock

Time 12:00 PM

Date 7/13/07

Day Thu

Back

+

_

Set

Up (+)

Down (-)

13

Back

Left

Right

Screen navigation buttons include:

Back. Cancel and return to the User settings screen on page 12.

Left. Move the selection box backward.

Right. Move the selection box forward.

Set. Set the time and return to the User settings screen on page 12.

Up (+). Increase the selected value.

Down (-). Decrease the selected value.

Set

Page 18

SmartCommand Thermostat

14

Installation Manual

Sensor calibration screen

The Sensor calibration screen (Figure 10) is a sub screen of the User settings screen on page 12. The Sensor

calibration screen allows you to change the temperature calibration for the internal and any external remote

temperature sensors attached to the thermostat. You can change the temperature calibration by ± 7 degrees.

When the Sensor calibration screen is selected it will show the internal and all detected remote sensors. Each

sensor found will show the current temperature and the current number of degrees of offset being applied. In

the screen, n/a indicates that the remote sensor is not attached.

T o change the temperature calibration, press Up or Down to select the internal or remote sensor . Once selected,

press Plus (+) or Minus (-) to change the temperature calibration to the desired setting.

Press Refresh (right blank button) to update the information on this screen.

Note: When you change a temperature calibration and exit this screen, it may take a few seconds for the new temperature to

be displayed on the Thermostat control screen on page 4.

Figure 10. Sensor calibration screen

Internal (75) 1

Remote 1 n/a 0

Remote 2 n/a 0

Remote 3 n/a 0

Done

Done Plus

Screen navigation buttons include:

Done. Return to the Main menu screen on page 7.

Plus. Increase the temperature by one degree.

Minus. Decrease the temperature by one degree.

Refresh. Blank button. Refresh screen temperatures.

Up. Move selection pointer up.

Down. Move selection pointer down.

Sensor Calibration

+

-

Minus

Up

Down

Refresh

Page 19

Backlight display screen

The Backlight display screen (Figure 11) is a sub screen of the User settings screen. The Backlight display

screen allows you to set the backlight on and off brightness levels and contrast.

Figure 11. Backlight display screen

Backlite/Display

Backlite Timeout 0

ON Level 100%

OFF Level 0%

Contrast 5

Done

+

-

Select

Up

Down

15

Done

Plus Minus

Select

Screen options include:

Backlight timeout. Set the time after the last button press that the backlight will timeout and turn off. You

can adjust the time to 0 or from 20 to 40 seconds. If set to 0, the backlight will never timeout and will

always be on. If set in the 20 to 40 second range, the backlight will turn off after the selected time expires.

On level. Set the brightness of the backlight when it is on. You can adjust this setting in 10% steps, 0 to

100%. If set to 0, the backlight will never be on. Typically this setting is set to 100%.

Off level. Set the brightness of the backlight when off. You can adjust this setting in 10% steps, 0 to

100%. If you do not want the backlight to go completely dark when off, you can set an off brightness to

something greater than 0%. When you select an on or off brightness, the display changes to that level for

you to observe the brightness setting.

Contrast. Set the contrast level of the LCD display. You can adjust this setting from 0 to 10. Use this

control to adjust the darkness of the display. Too light and the display looks faded, too dark and dark lines

will appear in the display. Typically 5 is the correct setting.

Screen navigation buttons include:

Done. Return to the User settings screen on page 12.

Plus. Increase the selected value.

Minus. Decrease the selected value.

Select. Select the function to be set.

Up. Move selection pointer up.

Down. Move selection pointer down.

Page 20

SmartCommand Thermostat

16

Installation Manual

Thermostat information screen

The Thermostat information screen (Figure 12) displays the current configuration of the thermostat wall

display unit and the HVAC control unit. This information is useful for quick check of firmware versions and

HVAC system setup. It also shows the network address setting

Thermostat information displayed includes:

Wall display unit. Model and firmware version number.

Control unit. Model and firmware version number.

System type setting. Standard or Heat Pump (HP) HVAC system.

Fan type setting (for standard systems). No fan with heat (gas systems) or fan with heat (electric

systems).

Changeover setting (for heat pump systems). Changeover with cool or changeover with heat.

Note: You will see a Fan type setting for standard systems or a Changeover setting for HP systems.

Network address setting. RS485 network address, 1 to 254 (default 1).

Figure 12. Thermostat information screen

Thermostat Info

TS40R Ver: 3.07.6P

HFRP Ver: 03.05.2

System Type: Standard

Fan Type: No Fan w/HT

Network Address: 1

Done

Done

Thermostat information screen has one navigation button, the Done button. Press Done to return to User

settings screen on page 12.

Page 21

Installer settings screen

The Installer settings screen is a hidden screen designed for installer use only. Do not change any settings in

this screen unless you are a qualified service technician. Changing these settings will affect the operation of the

heating/cooling system.

T o enter this screen, go to the Main menu scr een on page 7 and press and hold the two inner control buttons for

three seconds until the Installer settings screen (Figure 13) appears.

The Installer settings screen displays the current internal settings of the thermostat. You can view and change

the settings from this screen. Scroll to the desired function and press Plus (+) or Minus (-) to change the value.

Figure 13. Installer settings screen

Installer Settings

Display Lock N

Service Mode

Network Settings

MaxHeat SP 109

Done

+

-

Select

Up

Down

17

Done

Screen navigation buttons include:

Done. Return to the Main menu screen on page 7.

Plus. Increase value by 1 or change from N to Y.

Minus. Decrease value by 1 or change from Y to N.

Select. Select menu item to go to a submenu.

Up. Move selection pointer up.

Down. Move selection pointer down.

Plus

Minus

Select

Page 22

SmartCommand Thermostat

18

Installation Manual

Screen options include:

Display lock: Y or N (default N). Use this setting to lock or unlock the thermostat wall display unit

buttons. When the buttons are locked (Y), you can still access the Menu screen, but you will not be allowed

to select any menu options. The Installer settings screen hidden button operation is always operational,

allowing you to return to this screen and turn the display lock off.

Service mode submenu: Y or N (default N). Use this setting to turn on the service mode. When the

service mode is on (Y), it sets the thermostat to a test mode with short delays. All routine and staging

delays are reduced to 15 seconds to speed up system checkout and testing.

CAUTION: The compressor short cycle protection is lost in this mode.

Network settings submenu.

Network address: 1 to 254 (default 1). Use this setting to set the serial communication network

address (0 and 255 are reserved addresses).

Autosend: Y or N (default N). Use this setting to turn on the autosend. If autosend is on (Y), it sends

a network message when there is a change in temperature, setpoints, and mode. If autosend is off (N),

it is in polled mode and only responds to polling requests.

Maximum heating setpoint: 10 to 109 (default 109). Set the maximum heating setpoint that is allowed.

Will not ramp or accept setpoints higher than this maximum.

Minimum cooling setpoint: 6 to 110 (default 6). Set the minimum cooling setpoint that is allowed. Will

not ramp or accept setpoints lower than this minimum.

Minimum run time: 1 to 9 minutes (default 6). Set the minimum run time before a heating/cooling

cycle can turn off.

Minimum off time: 5 to 9 minutes (default 6). Set the minimum off time before another heating/cooling

cycle can begin. Five minutes minimum is the compressor short cycle protection delay.

Delta T settings submenu. This is a submenu of the delta, or dif ference between, the setpoint and current

temperature for determining when a heat or cool call comes on. Deltas are the number of degrees away

from setpoint.

H/C delta: 3 to 15 degrees (default 4). Set the minimum separation between heating and cooling

setpoints. Attempts to lower the cooling below the heating setpoint by this amount will push the

heating setpoint down to maintain this separation. In the same way , attempts to set the heating setpoint

above the cooling setpoint will push the cooling setpoint up to maintain this separation.

Heating delta stage 1 on: 1 to 8 degrees (default 1). Set the delta from setpoint that stage 1 heating

starts. Stage 1 turns off at setpoint.

Heating delta stage 2 on: 1 to 8 degrees (default 3). Set the delta from setpoint that stage 2 heating

starts. Stage 2 turns off at setpoint.

Page 23

Heating delta stage 3 on: 1 to 8 degrees (default 5). Set the delta from setpoint that stage 3 heating

starts. Stage 3 turns off at setpoint.

Cooling delta stage 1 on: 1 to 8 degrees (default 1). Set the delta from setpoint that stage 1 cooling

starts. Stage 1 turns off at setpoint.

Cooling delta stage 2 on: 1 to 8 degrees (default 3). Set the delta from setpoint that stage 2 cooling

starts. Stage 2 turns off at setpoint.

WDU settings submenu.

Messaging enable: Y or N (default N). Enable (Y) or disable (N) the network messaging function. If

you intend to use the messaging capability of the thermostat, you must enable it here by setting it to Y.

Messages will then appear as a menu item in the main Menu screen and you will be able to receive and

browse through the messages.

CAUTION: Do not change the installer settings unless you are sure of the effect these changes will make. Changing the

network address will make the thermostat not respond if the address is incorrect.

19

Page 24

SmartCommand Thermostat

20

Installation Manual

Installation overview

Before you remove an existing thermostat and install the SmartCommand thermostat, follow these guidelines:

• Record existing wiring information.

• Do the bench test.

• Check WDU wiring before applying power to the control unit.

• Be sure to install a freeze protection device as required.

Figure 14 shows the standard thermostat wiring versus retrofit applications.

Figure 14. Wiring overview

4, 5, or 6 wires

Old system

18 Ga thermostat wiring

X

Heating and cooling

system

New system

Replace existing thermostat

with SmartCommand WDU

75

SmartCommand WDU

4 wires

Insert control unit

into existing wiring

Heating and cooling

system

SmartCommand

control unit

4, 5, or 6 wires

as original installation

Page 25

Freeze protection

WARNING: Do not use this thermostat for freeze protection.

In cold climates that require the heating system to be used for building freeze protection, a mechanical backup

freeze protection device must be installed on the heating system. This can be a simple mechanical heating

thermostat or a preset thermoswitch installed in the heated area (Figure 15).

Figure 15. Freeze protection

Mechanical thermostat

or thermoswitch

40 to 45°

R

W

Red wire

White wire

Heating system

24 VAC R

Heat W

Thermostat

connections

21

Wire across heater R/W terminals

Page 26

SmartCommand Thermostat

y

22

Installation Manual

Wall display unit installation

Choose a location for the wall display unit (WDU) that best represents the temperature of the area to be

controlled. Avoid locations that are subject to drafts or areas with direct sunlight exposure.

Mounting

To mount the WDU, see Figure 16 and do the following:

1. To open the WDU case, pull from the lower corners of the case.

Figure 16. Opening and closing the WDU case

Base

J2

G

+5

C

D

J1

GND

-

+12V

+

Clock

C

Data

D

Side view

10:25

S

s Off

Econ

Run

No Msg

MENU

Front

Outside 60

75

MODE

FAN

76 H

74 C

Wiring access hole

2. Route the wires to the WDU through the access hole in the back of the case (see Wiring).

3. Mount the WDU to the wall with the screws and anchors provided. Be sure to plug any large access

hole in the wall with sealer or insulation to prevent wall drafts from affecting WDU operation.

4. To close the case hook the top of the WDU and rotate into the base. Be sure pins engage in the

connector correctly

Wiring

For new construction, we recommend you use a two twisted-pair cable, 22 Ga minimum, to the WDU from the

control unit. Category 5 wiring is preferred, but not required. In retrofit applications, the existing 18 Ga

thermostat wiring (at least four wires) is adequate and usually will work without problems. However, such

nontwisted wiring can be subject to interference due to adjacent in-wall high vo ltage wiring.

To wire the WDU to the control unit, connect the four-wire cable from the control unit to the WDU terminal

block. Two wires are for data and two are for power. WDU power is 12 VDC and provided by the control unit.

CAUTION: Do not miswire the power and data lines, damage will result. Check your wiring before applying power.

Remote sensor connection

The WDU base (Figure 16) has a remote sensor connection (J2) to connect an external remote temperature

sensor. Refer to the remote sensor documentation for the wiring diagram to connect the sensor to the WDU.

Page 27

Control unit installation

Install the control unit in a protected, convenient, indoor location near the HVAC system or in a service

accessible area such as an equipment closet or garage. Mount the control unit in a vertical position on a wall or

sturdy structural member . If you mount the control unit on the HVAC system, be careful to avoid the hot burner

section and high vibration areas.

The control unit is connected to the HVAC system and to the WDU unit as well as the serial communication

and power connections.

Control unit to WDU wiring

Connect the WDU to the control unit with existing thermostat wiring in retrofit installations. For new

installations, 22/24 Ga twisted-pair, typically CAT 3 or CAT 5 wiring is preferred (Figure 17).

Figure 17. Control unit to WDU wiring

Wall display unit

Control unit

23

J1

GND

+12 VDC

Clock

Data

CAUTION: Do not miswire the power and data lines, damage will result. Check your wiring before applying power.

GND

+12V

Clock

Data

Control unit to HVAC wiring

Electrically, the control unit looks like a standard thermostat to your HVAC system. All connections to the

HVAC system are made at the normal thermostat connections on the HVAC unit. Refer to your HV AC system’s

documentation for specific information on its thermostat connections and set up requirements. You will need to

know the following:

HVAC system type. Gas, electric, heat pump, radiant, or hydronic.

Fan requirement. No fan with heat or fan with heat.

For heat pump system. Changeover with cool or with heat (O or B connection).

Retrofit wiring

You may find that you have additional wires when you disconnect your old thermostat. Usually these wires are

for auxiliary functions such as filter o r trouble indic ators. For heat pump systems there may be emer gency heat

(EH) wiring or both O and B changeover connections. These wires are not used in the SmartCommand

installation and, in most cases, these extra wires are not required for normal HVAC system operation. See

HVAC wiring for wiring diagrams for your type of HVAC system: standard or heat pump.

Page 28

SmartCommand Thermostat

24

Installation Manual

HVAC system wiring

Wiring will differ depending on if your system is a standard gas or electric system or if your system is a heat

pump system.

Standard HVAC system wiring

Figure 18 shows the wiring diagram for a standard gas or electric HVAC system. Wiring colors are typical

thermostat wiring color codes.

Note: For typical central heating/cooling systems, leave jumper JP1 installed. If you have separate heating and cooling

system transformers, cut jumper JP1. Wire RC to the cooling system transformer and RH to the heating system

transformer.

Figure 18. Standard HVAC system wiring

Standard HVAC systemThermostat control unit

FUSE

24V COM

24V RH

24V RC

W1 Heat 1

W2 Heat 2

G Fan

Y1 Comp 1

Y2 Camp 2

JP1

Red (RH)

Red (RC)

White

Orange

Green

Yellow

Black

Thermostat

connections

C 24 VAC common

R 24 VAC return

W1 Heat stage 1

W2 Heat stage 2

G Fan

Y1 Comp stage 1

Y2 Comp stage 2

STD 1

S2 2

SW1

HP

OFF ON

J4

HVAC system

Note: Wire R to either RH or RC for common transformer HVAC systems.

Page 29

For standard HVAC systems, follow these guidelines:

Single-stage systems. Use W1 for heating stage 1, and Y1 for cooling stage 1.

Two-stage heating systems. Use W1 for stage 1, and W2 for stage 2 heating.

Two-stage cooling systems. Use Y1 for stage 1 and Y2 for stage 2 cooling.

HVAC system 24 VAC transformer

If you have an integrated heating and cooling system with a single transformer, do not cut jumper JP1. Wire the

24V Return (red) wire to either RH or RC. This is typical of most central systems.

If you have separate heating and cooling systems with separate transformers, cut jumper JP1. W ire the heating

24V Return (red) wire to the control unit’s RH terminal and run the cooling system’s 24V Return (red) wire to

the control unit’s RC terminal. Wire the cooling system’s 24 VAC Com to the control unit’s 24 VAC Com

terminal. Do not connect the heating system’s common wire to the control unit.

DIP switches

To set the SW1 DIP switches for standard HVAC systems, do the following:

25

1. Set SW1-1 (position 1) to the Off (STD) position. This is the default setting.

2. Set SW1-2 (position 2) to the correct fan setting for your HVAC system.

• For gas furnaces that do not require fan output for heating operations, set SW1-2 to the Off

position (to the left). This is the default setting).

• For electric furnaces that do require fan output for heating operation, set SW1-2 to On position (to

the right).

Page 30

SmartCommand Thermostat

26

Installation Manual

Heat pump HVAC system wiring

Figure 19 shows the wiring diagram for a heat pump HVAC system. Wire colors are typical thermostat color

codes.

Note: Do not cut JP1 for heat pump systems. RC and RH are common for heat pumps.

Figure 19. Heat pump HVAC system wiring

Heat pump HVAC systemThermostat control unit

STD 1

S2 2

SW1

OFF ON

HP

24C COM

24V RH

24V RC

W1 Heat 1

W2/O CO

G Fan

Y1 Comp 1

Y2 Camp 2

J4

HVAC system

FUSE

JP1

Blue

Red

White

Orange

Green

Yellow

Black

Thermostat

connections

C 24 VAC common

R 24 VAC return

W1 Heat strips

O Changeover valve

G Fan

Y1 Comp stage 1

Y2 Comp stage 2

Page 31

For heat pump HVAC systems, follow these guidelines:

Single-stage compressor systems. Use Y1 for stage 1 heating/cooling, and W1 for stage 2 heating (heat

strips).

Two-stage compressor systems. Use Y1 for stage 1, Y2 for stage 2 heating/cooling, and W1 for stage 3

heating (heat strips).

DIP switches

To set the SW1 DIP switches for standard HVAC systems, do the following:

1. Set SW1-1 (position 1) to the On (HP) position (to the right).

2. Set SW1-2 (position 2) to the correct changeover (reversing valve) setting for your HVAC system:

• For systems with changeover with cooling, set SW1-2 to Off position (to the left). This is the

default setting.

• For systems with changeover with heating, set SW1-2 to On position (to the right).

Note: You must configure your changeover valve setting to work correctly with your HVAC system. Set DIP switch SW1 as

described for correct changeover operation. Changeover with cool is typical for most systems. Check your system

information to be sure. If you get cooling when you expect heating, change SW1-2 to the other position.

27

Page 32

SmartCommand Thermostat

28

Installation Manual

Control unit connection

The control unit requires 24 VAC power from the HVAC system it is controlling. Connect the 24 VAC

Common (blue wire/terminal) and 24 VAC R (red wire/terminal) from the HVAC system to the control unit’s

HVAC system terminal block J4’s 24V Com and 24V RH (or 24V RC) terminals. The RH and RC terminals

are connected together by JP1 (factory default).

Common or split transformer systems

Most HVAC systems have a common heating and cooling transformer. Connector JP1 is jumpered to common

the RH and RC inputs together for this configuration. If you have a system with separate heating and cooling

transformers, you will need to split the RH and RC jumper by cutting the JP1 jumper.

When wiring split systems, wire the heating system’ s 24VAC R (red wire) to the control unit’s RH terminal and

wire the cooling systems 24VAC R (red wire) to the control unit’s RC terminal. Wire the cooling system’s

24VAC Com to the control unit’s 24 VAC Com terminals. Do not connect the heating system ’ s common wire to

the control unit.

Page 33

Serial communication

Serial communication includes:

• RS485 com port

• RS485 address

• RS485 protocol

• Thermostat network commands

RS485 com port

The thermostat has a RS485 serial com port. This is a two-wire (plus ground), half-duplex communication

network. Typically, the thermostat will be used on the SmartCommand network and connected to the Smart

Command automation controller.

The RS485 com port communication setup is 9600 baud, 8 data bits, 1 stop bit, and no parity. Flow control is

set to None.

Transmission delay

29

The thermostat will delay responses to request messages for 5 msec to conform to the SmartCommand network

protocol. This is necessary for RS485 half-duplex devices to use send data control for automatic flow control.

RS485 address

You can check the network address setting of the thermostat by pressing Menu to open the main Menu screen.

Scroll down to the Thermostat info menu item and press Select. The Thermostat information screen on page 16

will show the current network address of the thermostat. The default network address is 1.

Changing the network address

The network address is set from the Installer settings screen on page 17 on the WDU. This is a hidden menu

and does not appear in the main Menu screen selections. To change the network address, do the following:

1. Press Menu to open the Main menu screen on page 7.

2. While in the Menu screen, press and hold the middle two control buttons on the WDU for five seconds

until the Installer settings screen on page 17 opens.

3. Scroll down to the Network menu item in the Installer settings screen and press Select. You can set the

network address from 1 to 254.

Note: Network address 0 is reserved for the host system address and 255 is reserved for global commands.

Page 34

SmartCommand Thermostat

30

Installation Manual

RS485 protocol

The thermostat has a robust serial protocol. It is based on a simple ASCII message format as described in the

Serial Communications Protocol manual, DCN: 150-00225.

Note: Not all of the commands/variables defined in the protocol document are applicable to the SmartCommand thermostat,

check Section 8 of the protocol manual for details.

Thermostat network commands

Serial commands received by the control unit can set a new setpoint or a new mode and when received, they

are sent to the WDU to update its display.

The thermostat also responds to request for status by serial commands and can provide all thermostat data and

setup information as well as the current revisions of the WDU and controller firmware.

The following thermostat information can be sent or requested from the thermostat by the serial protocol:

•Temperature

• Heating setpoint

• Cooling setpoint

• System mode

•Fan mode

•F/C mode

• HVAC output status

• Network address

• Any system variable

• System firmware revisions

Page 35

System checklist

We strongly recommend that you hook-up and run a simple bench test before installing the thermostat. Not

only will this save you time in system checkout, but will also make you familiar with the thermostat’s

operation.

Thermostat bench test

To bench test the thermostat, do the following:

1. Connect the WDU to the control unit with a short (12 to 24 in.) four-wire cable.

2. Before power up, set the control unit DIP switch, SW1 to ALL OFF.

3. Connect power to the control unit.

4. Verify the control unit status LED is blinking.

5. Verify the WDU display comes on and shows the current temperature:

• If no display and backlights are not on, check your wiring to the control unit.

• If a CommFailure display is shown on the WDU, check your wiring to the control unit.

• Do not proceed until the current temperature is displayed on the WDU.

31

With the current temperature displayed on the WDU, you have verified communication between the

WDU and the control unit. Any communication problems will result in a CommFailure

(communications failure) display on the WDU and must be fixed before proceed ing.

6. Press the Fan button on the WDU until Fan On is displayed. The control unit’s fan LED and relay

should turn on. Press the Fan button again and the fan LED and relay should turn off.

7. Press the Mode button on the WDU until Heat Mode is displayed.

8. Press the setpoint Up button until the setpoint is above the current temperature. The heat LED and

relay should come on. If they don’t come on, make sure the status LED is not flashing twice indicating

minimum off delay. Wait until the LED stops flashing twice before proceeding.

9. Press the Mode button on the WDU until Off Mode is displayed. The heat LED and relay will turn off.

10. Wait six minutes for the minimum off delay to expire. The status LED will stop flashing twice.

11. Press the Mode button on the WDU until Cool Mode is displayed.

12. Press the setpoint Down button until the setpoint is below the current temperature. The compressor and

fan LEDs and relays should turn on.

13. Press the Mode button on the WDU until Off Mode is displayed. The cool LED and relay should turn

off.

When you have successfully completed this process, you have verified that the thermostat is working correctly.

Page 36

SmartCommand Thermostat

32

Installation Manual

Serial communication test

Connect the thermostat to a PC via an RS232/485 converter to a PC serial com port.

Note: Any RS232 to RS485 adapter used with SmartCommand serial thermostats must have automatic send data control.

To use Windows HyperTerminal, do the following:

1. Set up a direct connection session to the com port you will be using on the PC.

2. Configure port settings to 9600 baud, 8 bit, no parity, 1 stop bit, and no flow control.

3. Under the Settings tab, go ASCII setup.

4. Set ASCII sending to Echo characters and No delays.

5. Set ASCII receiving to Append line feeds and Wrap lines.

Note: Serial ASCII commands are case sensitive.

Verify serial communication by typing the following command sequence:

A=1 R=1 <cr>

The Thermostat should reply with the R1 status message:

A=00 O=1 T=xx SP=xx SPC=xx SPH=xx M=xx FM=x

If you have problems communicating, check addresses and port settings.

Page 37

HVAC system testing

If you have difficulty with the HVAC system operation, you can do the following test to verify the HVAC

system is operational.

Thermostats, like the SmartCommand thermostat, are just switches to the HVAC system as shown in the

Figure 20. This is a simplified example of a thermostat and a standard HVAC wiring diagram. You can test the

HVAC system operation by duplicating the thermostat switch operation by shorting across the thermostat

terminals on the HVAC system.

Figure 20. HVAC system wiring example

33

Typical thermostat

Thermostat

connection

Fan

Heat

Comp

HVAC system (standard gas/AC)

C 24 VAC common

R 24 VAC hot

G Fan

W Heat

Y Comp

Fan relay

Gas valve

Comp relay

24 VAC

Note: The HVAC system and thermostat connection voltage is 24 VAC. This is a safe voltage to work with, but be careful to

avoid shorting the 24 VAC common (C) and 24 VAC return (R) terminals. This may blow a fuse in the HVAC system.

Page 38

SmartCommand Thermostat

34

Installation Manual

Standard HVAC system quick test

You can do a quick test of the HVAC system by shorting across the appropriate terminals on the HVAC

system’s thermostat connector. Use a short 6-in. wire to connect across the terminals shown in Table 1.

Table 1. Standard system quick test

Function test HVAC terminals Result

Fan R to G Fan should come on.

Heating R to W Heat cycle should start for heating.

Cooling R to Y and G Compressor and fan should start for cooling.

Heat pump system quick test

You can do a quick test for heat pump operation by shorting across the appropriate terminals on the heat pump

system’s thermostat connector. Note that heat pumps have an additional thermostat terminal (O) for the

changeover valve. The changeover valve determines whether heating or cooling is provided. Typical heat

pump systems have changeover with cooling and require the O terminal to be powered to get cooling

operation. Use a short 6-inch wire to connect across the terminals as shown in Table 2.

Table 2. Heat pump system quick test

Function test HVAC terminals Result

Fan R to G Fan should come on.

Heating R to Y and G Compressor and fan should start and heating occurs.

Cooling R to Y and G and O Compressor and fan should start . CO valve operates

and cooling occurs.

Note: If you have the CO selection incorrect, you will get cooling when you expect heating and vice versa. Change the DIP

switch SW1-2 changeover setting to correct this problem.

Page 39

Control unit wiring

Figure 21 shows the control unit wired to a wall display unit and the HVAC system. Wire colors are typical

thermostat wiring colors. The fuse is a mini ATO 2 amp.

Note: For heat pump HVAC systems, the orange wire (O) is the changeover valve.

Figure 21. Control unit wiring

Control unit

35

HVAC system

C-24VAC common

R-24VAC return

W1-Heat stage 1

W2/O-Heat stage 2

G-Fan

Y1-Comp stage 1

Y2-Comp stage 2

Wall display unit

GND

+12VDC

Clock

Data

GND

RS-485 Data +

RS-485 Data -

STD

S2

J1 WDU

GND

12V

C

D

GND

D+

D-

J2 RS-485

1

2

SW1

OFF ON

HP

Status

Heat 1

Heat 2

CO

Comp 1

Comp 2

Fan

Fuse

24V COM

24V RH

24V RC

W1

W2/O

G

Y1

Y2

J4 HVAC system

JP1

Blue

Red

White

Orange

Green

Yellow

Black

HVAC system transformer

Most central HVAC systems have a common heating and cooling transformer. This is the factory default

setting for jumper JP1. In some cases you may have separate heating and cooling systems, each with their own

transformer. In that case, cut jumper JP1 and wire the heating transformer red wire to the RH terminal and the

cooling system transformer red wire to the RC terminal. Wire the cooling system’ s 24 VAC Com to the control

unit’s 24 VAC Com terminal. Do not connect the heating system’s common wire to the control unit.

Page 40

SmartCommand Thermostat

36

Installation Manual

DIP switch SW1 settings

White indicates a switch is in the On position. Set the DIP switches as follows:

SW1-S1. HVAC system type selection. Standard or heat pump.

Set S1 to Off (STD) for gas/electric systems (default setting).

Set S1 to On (HP) for heat pump systems.

SW1-S2. This is a dual-use switch that depends on the switch S1 setting.

If S1 is set to Standard HVAC system type, then S2 selects the HVAC fan type.

Set S2 to Off for gas systems that normally do not require fan w/heat operation (default setting).

Set S2 to On for electric systems that normally do require fan w/heat operation.

If S1 is set to Heat pump operation, then S2 selects the changeover valve operation.

Set S2 to Off for changeover with cooling (default setting).

Set S2 to On for changeover with heating.

If the heat pump supplies heating when you expect cooling or vice versa, change the SW1-S2 switch.

Page 41

Serial network command and variable list

Refer to the Serial Communications Protocol Manual 150-00225 for format details.

Network commands

Table 3 shows the network commands and a description of each command.

Table 3. Network commands

Command Description

BF Set setback flag

CFM Set F or C temperature mode

Date Set date

DL Set display lock

DOW Set day of week

37

F Set fan mode

M Set system mode

OT Set outside air temperature data (for network supplied OT)

SC Set schedule control run/hold mode

SEd/x Set schedule entry for day and entry

SP Set setpoint (for single setpoint system)

SPC Set cool setpoint

SPH Set heat setpoint

SVx Set variable number x

Time Set time

R=1 Request status message 1: Thermostat data (temperature, setpoints, modes)

R=2 Request status message 2: HVAC operation data (heating/cooling/fan status)

R=3 Request status message 3: Temperature data only

R=4 Request status message 4: Setpoint data only

R=5 Request status message 5: Mode data only

R=6 Request status message 6: WDU/Control unit model/version data

R=7 Request status message 7: Time and DOW

R=8 Request status message 8: Not used

R=9 Request status message 9: HVAC system setup data (SW1 settings)

Page 42

SmartCommand Thermostat

38

Installation Manual

Network variables

Table 4 shows the network variables for use with the system variable, SVx command.

Table 4. Network variables

Variable

number Name Variable data Default value Notes

1 System type 0, 1 0 0 = gas/electric, 1 = heat pump

2 Fan type 0, 1 0 0 = gas (no fan w/heat), 1 = electric

3 Changeover type 0, 1 0 0 = c/o w/cool, 1 = c/o w/heat

4 C/F type 0, 1 0 0 = Centigrade, 1 = Fahrenheit

5 Network address 1 to 254 1 Reserved: 0 = host, 255 = global

9 Display lock 0, 1 0 0 = unlocked, 1 = locked

10 MOT 5 to 9 minutes 6 minutes 0 = 20-second test time

11 MRT 0 to 9 minutes 6 minutes 0 = 20-second test time

12 H delta stage 1 on 0 to 8 degrees 1 degree

14 H delta stage 2 on 0 to 8 degrees 3 degrees

16 H delta stage 3 on 0 to 8 degrees 5 degrees

18 C delta stage 1 on 0 to 8 degrees 1 degree

20 C delta stage 2 on 0 to 8 degrees 3 degrees

24 Setpoint h/c delta 3 to 15 degrees 4 degrees Minimum delta T between h/c setpoints

69 Service (test) mode 0, 1 0 1 = test mode, sets MRT/MOT = 20 seconds

74 Autosend mode 0, 1 0 0 = off, 1 = on, send temp/mode on change

The system type, fan type, and changeover type variables are determined by the controller DIP switch SW1

setting. They can be viewed by the system variable command, but cannot be changed from the network.

Page 43

Contacting technical support

For assistance installing, operating, maintaining, and troubleshooting this product, refer to this document and

any other documentation provided. If you still have questions, you may contact technical support during

normal business hours (Monday through Friday, excluding holidays, between 6 a.m. and 5 p.m. Pacific Time).

Table 5. Sales and support contact information

Sales Technical support

39

Phone:

E-mail

Fax

Note: Be ready at the equipment before calling for technical support .

Toll-free: 888.GESECURity (888.437.3287 in the US, including Alaska and Hawaii; Puerto Rico; Canada).

Outside the toll-free area: 503.885.5700.

info@gesecurity.com generaltech@ge.com

800.483.2495 541.752.9096 (available 24 hours a day)

Online publication library

Another great resource for assistance with your GE Security products is our online publication library,

available to all of our customers on our website. To access our publication library, go to our website at the

following location:

http://www.gesecurity.com

In the Tools area at the top, click the Publication Library link. After you register and log on, you may search

through our online library for the documentation you need.

1

1. Many GE Security documents are provided as PDFs (portable document format). To read these documents, you will need

Adobe Acrobat Reader, which can be downloaded free from Adobe’s website at www.adobe.com.

Page 44

SmartCommand Thermostat

40

Installation Manual

Loading...

Loading...