Page 1

CAM-14 Acquisition Module

field service manual

PN 421315-001

Revision A

Page 2

T-2

Page 3

CAM-14 Acquisition Module

field service manual

PN 421315-001 Revision A

3

2

1

Page 4

NOTE

Due to continuing product innovation,

specifications in this manual are subject to

change without notice.

MD1320-005

Copyright GE Marquette Medical Systems, Inc. 1998. All rights reserved.

Trademarked names appear throughout this document. Rather than list the names and entities that own the

trademarks or in sert a trademark s y mbol with each mentio n of the trademarked n am e, the publisher stat es that

it is using the names only for editorial purposes and to the benefit of the trademark owner with no intention of

improperly using the tra d emark.

900 SC, ACCUSKETCH, AccuVision, APEX , AQUA-KNOT, ARCHIVIST, Autoseq, BABY MAC, C Qwik Connect,

CardioServ, CardioSmart, CardioSys, CardioWindow, CASE, CD TELEMETRY, CENTRA, CHART GUARD, CINE

35, COROLAN, CORO, COROMETRICS, Corometrics Sensor Tip, CRG PLUS, Digistore, Digital DATAQ, E for M,

EAGLE, Event-Link, FMS 101B, FMS 111, HELLIGE, IMAGE STO RE , INTE LLIMOTION, LASER SXP, MAC, MACLAB, MACTRODE, MARQUETTE, MARQUETTE MAC, MARQUETTE MEDICAL SYSTEMS, MARQUETTE UNITY

NETWORK, MARS, MAX, MEDITEL, MEI, MEI in the circle logo, MEMOPORT, MEMOPORT C, MINISTORE,

MINNOWS, Monarch 8000, MULTI-LINK, MULTISCR IPTOR, MUSE, MUSE CV, Neo-Trak, NEUROSCRIPT,

OnlineABG, OXYMONITOR, Pres-R-Cuff, PRESSURE-SCRIBE, QMI, QS, Quantitative Medicine, Quantitative

Sentinel, RAMS, RSVP, SAM, SEER, SILVERTRACE, SOLAR, SOL ARV IEW, Spectra 400, Spectra-Overview,

Spectra-Tel, ST GUARD, TRAM, TRAM-NET, TRAM-RAC, TRAMSCOPE, TRIM KNOB, Trimline, UNITY logo,

UNITY NETWORK, Vari-X, Vari-X Cardiomatic, VariCath, VARIDEX, VAS, Vision Care Filter, are trademarks of

GE Marquette Medical Systems, Inc., registered in the United States Patent and Trademark Office.

2SL, 15SL, Access, AccuSpeak, ADVANTAGE, BAM, BODYTRODE, Cardiomatic, CardioSpeak, CD TELEMETRY®

-LAN, CENTRALSCOPE, Corolation, DASH, EK-Pro, EDIC, Event-Link Cumulus, Event-Link Cirrus, Event-Lin k

Nimbus, HI-RES, ICMMS, IMAGE VAULT, IMPACT.wf, INTER-LEAD, IQA, LIFEWATCH, Managed Use,

MARQUETTE PRISM, MARQUETTE® RESPONDER, MENTOR, MicroSmart, MMS, MRT, MUSE CardioWindow,

NST PRO, NAUTILUS, OCTANET, O2 SENSOR, OMRS, PHi-Res, Premium, Prism, QUIK CONNECT V. QUICK

CONNECT, QT Guard, RAC, SMARTLOOK, SMART-PAC, Spiral Lok, Sweetheart, UNITY, Universal, Waterfall,

Walkmom are trademarks of GE Marquette Medical Systems, Inc.

T-2

CAM-14 Acquisition Module

421315-001

18 December 1998

Revision A

Page 5

Contents

1 Introduction ................................................. 1-1

Manual Information .................................................................. 1-3

Revision History ................................................................................. 1-3

Manual Purpose ................................................................................. 1-3

Intended Audience ............................................................................. 1-3

Safety Information .................................................................... 1-4

Definitions .......................................................................................... 1-4

Messages ........................................................................................... 1-4

Responsibility of the Manufacturer .................................................... 1-5

Intended Use ...................................................................................... 1-5

General .............................................................................................. 1-5

Equipment Symbols ........................................................................... 1-6

Service Information .................................................................. 1-7

Service Requirements ........................................................................ 1-7

Equipment Identification .................................................................... 1-7

2 Equipment Overview ...................................... 2-1

Technical Characteristics ........................................................... 2-3

General Description ......................... ....................................... ........... 2-3

Power Requirements ......................................................................... 2-4

Operation ...................................................................... 2-5

Operating Controls ............................................................................. 2-5

Leadwire Attachments ....................................................................... 2-5

Leadwire Adapters ................................................................ 2-6

Lead Configurations ............................................................. 2-7

Revision A

CAM-14 Acquisition Module

421315-001

i

Page 6

3 Maintenance ................................................ 3-1

Recommended Maintenance ....................................................... 3-3

General .............................................................................................. 3-3

Cleaning ............................................................................................. 3-3

Exterior Surfaces .................................................................. 3-3

Electrodes ............................................................................. 3-3

Visual Checking ................................................................................. 3-4

Built-In Diagnostic Tests .................................................................... 3-4

Domestic Electrical Safety Tests ................................................... 3-5

AC Line Voltage Test .......................................................................... 3-5

120 VAC, 50/60 Hz ...............................................................3-5

240 VAC, 50/60 Hz ...............................................................3-5

Leakage Tests .................................................................................... 3-6

Leakage Test Diagrams ...................................................................... 3-7

Test #1 Ground-wire-leakage-to-ground ........................................... 3-7

Test #2 Chassis-leakage-to-ground ................................................... 3-7

Test #3 Patient-cable-leakage-to-ground ......................................... .3-8

Test #4 Patient-cable-leakage-into-patient Leads-from 120 VAC ...... 3-8

Ground Continuity 3-9

Disassembly ..................................................................... 3-10

4 Parts Lists and Drawings ................................. 4-1

Ordering Parts ...................................................................... 4-3

Introduction ....................................................................................... 4-3

900995-001A Acquisition Module Assembly ................................. 4-4

420101-001B 14 Leadwire Kit .................................................. 4-7

417483-9XXA Leadwire, Multi-Link, Universal ............................. 4-8

900179-201 Leadwire Adapter Kit - Banana .............................. 4-10

900179-202 Leadwire Adapter Kit - Mactrode .................... .... .... 4-11

900179-203 Leadwire Adapter Kit - Grabber .............................. 4-12

ii

CAM-14 Acquisition Module

421315-001

Revision A

Page 7

5 PCB Assemblies ........................................... 5-1

8001280-001A Data Acquisition Module ....................................... 5-3

SD8001280-001ASchematic, Main Board .................... ... .... ............. 5-8

Appendix A: Abbreviations ...............................A-1

Standard Abbreviations .............................................................. A-3

Revision A

CAM-14 Acquisition Module

421315-001

iii

Page 8

iv

CAM-14 Acquisition Module

421315-001

Revision A

Page 9

1 Introduction

Manual Information ..................................................................... 3

Revision History ..................................................................................... 3

Manual Purpose ..................................................................................... 3

Intended Audience ................................................................................. 3

Safety Information ....................................................................... 4

Definitions .............................................................................................. 4

Messages ............................................................................................... 4

Responsibility of the Manufacturer ........................................................ 5

Intended Use .......................................................................................... 5

General .................................................................................................. 5

Equipment Symbols ............................................................................... 6

Service Information ..................................................................... 7

Service Requirements ............................................................................ 7

Equipment Identification ........................................................................ 7

Revision A

CAM-14 Acquisition Module

421315-001

1-1

Page 10

1-2

CAM-14 Acquisition Module

421315-001

Revision A

Page 11

Manual Information

Introduction: Manual Information

Revision History

Manual Purpose

Each page of the document has the document part number followed by

a revision letter located at the bottom of the page. This letter identifies

the document’s update level. The latest letter of the alphabet

corresponds to the most current revision of t he document.

The revision history of this document is summarized in the table below.

Table 2-1. Revision History

Revision Date Comment

A 18 December 1998 Initial release.

This manual suppl ies technical infor mation for service representative

and technical personnel so they can maintain the equipme nt to the

assembly level. Use it as a guide for maintenance and electrical repairs

considered field repairable. Where necessary the manual identifies

additional sources of re levant information and or t echnical assistance.

See the host operator manual for instructions necessary to operate the

equipment safely in accordance with its function and intended use.

Intended Audience

This manual is inten ded for the person who uses, maintains, or

troubleshoots this equipment.

Revision A 1-3

CAM-14 Acquisition Module

421315-001

Page 12

Introduction: Safety Information

Safety Information

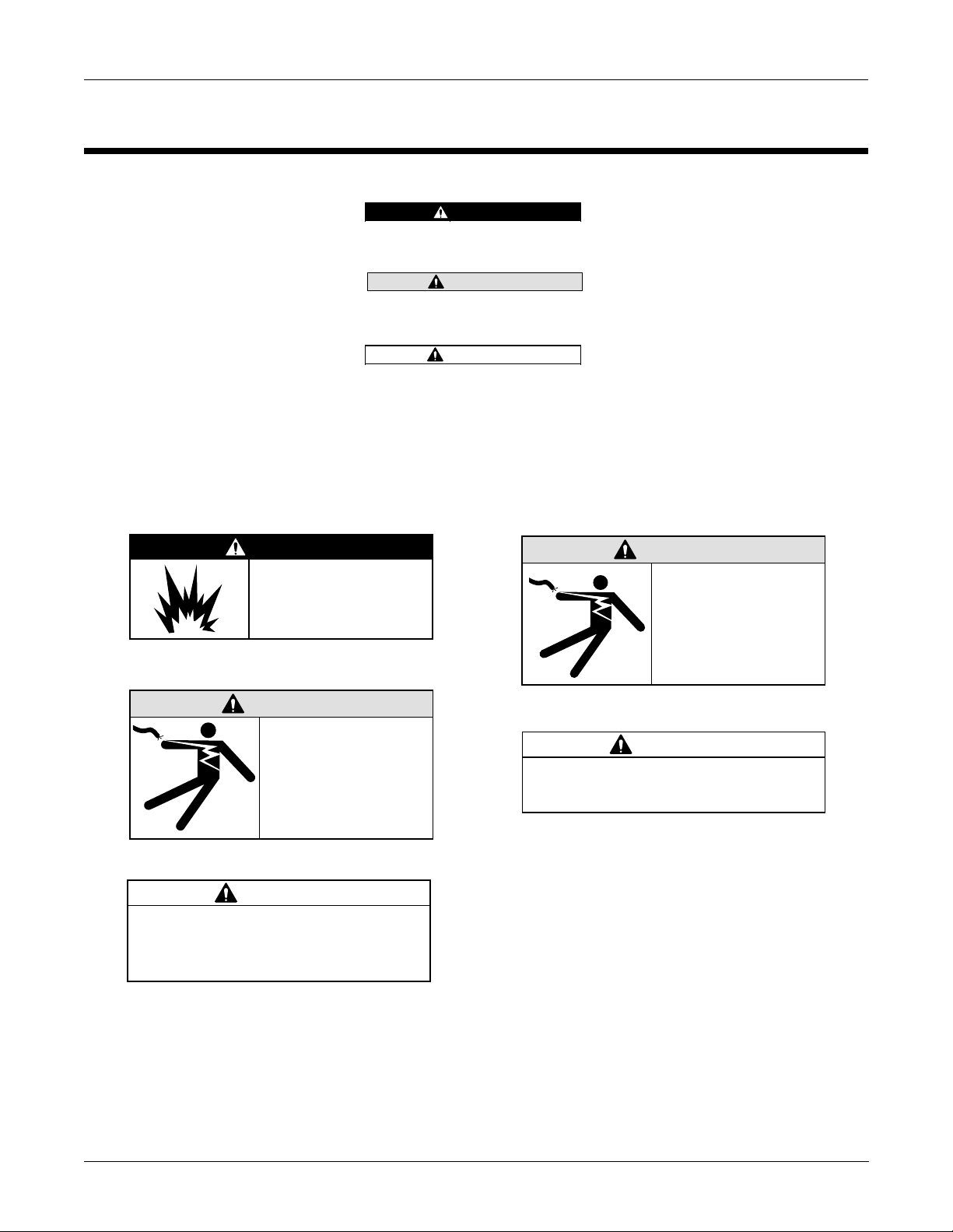

Definitions

Messages

DANGER

Do NOT use in the

presence of flammable

anesthetics.

DANGER

Indicates an imminently hazardous

situation which, if not avoided, WILL

result in death or serious injury.

WARNING

Indicates a potentially hazardous

situation which, if not avoided, COULD

result in death or serious injury.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided may result

in minor or moderate injury.

Additional safety messages may be found throughout this manual that

provide appropria te safe operation inform ation.

WARNING

Keep the conductive

parts of lead electrodes

and associated parts

M15287-1B

away from other

conductive parts,

including earth.

M15287-4C

WARNING

Do NOT contact unit or

patient during

defibrillation.

CAUTION

This equipment contains no user

serviceable parts. Refer servicing to

qualified service personnel.

M15287-8C

M15287-38A

CAUTION

Federal law restricts this device to sale by

or on the order of a physician.

M15287-17A

CAM-14 Acquisition Module

421315-001

Revision A1-4

Page 13

Introduction: Safety Information

Responsibility of the

Manufacturer

Intended Use

General

GE Marquette Medical Sy stems is responsible for th e effects of safety,

reliability, and perfor mance only if:

■ Assembly operations, extensions, readjustments, modifications,

or repairs are carried out by persons authorized by Marquette.

■ The electrical installation of the relevant room complies with

the requirements of the appropriate regulations.

■ The equipment is used in accordance with the instructions for use.

The CAM-14 acquistion module is intended to acquire analog ECG

signal, digitize it and t ransmit the signal t o a host unit. The circuitry is

designed to protect the host unit against the effects of cardiac

defibrillator discharge to ensure recovery.

This device is inten ded for use u nder t he di rect supervi sion of a lice nsed

health care pr actitioner.

This equipment is protected against the effects of cardiac defibrillator

discharge to ensure re covery, as required by test standards.

This equipment will not cause abnormal operation of the patient’s

cardiac pacemaker or other electrical stimulator.

This device uses a computerized ECG analysis program which can be

used as a tool in ECG tracing interpretation. This com puterized

interpretatio n is only significant when used in co njunction with clinical

findings. All computer-generated tracings should be overread by a

qualified physicia n.

To ensure accuracy, use only computer-generated tracings and not the

display for physician int erpretation.

To ensure pati en t safety, use only parts an d a cce ssories manufact ured

or recommended by GE GE Marquette Medical Systems.

Contact GE Marquette Medical Systems for information before

connecting any device s to this equipment that a re not recommended in

this manual.

If the installation of this equipment, in the USA, will use 240 V rather

than 120 V, the source must be a center-tapped, 240 V, single-phase

circuit.

Parts and accessories used must meet the requirements of the

applicable IEC 601 series safety standards, and/or the system

configuration must meet the requirements of the IEC 601-1-1 medical

electrical systems standard.

The use of ACCESSORY equipment not complying with the equivalent

safety requirements of this equipment may lead to a reduced level of

Revision A 1-5

CAM-14 Acquisition Module

421315-001

Page 14

Introduction: Safety Information

safety of the resulting sy st em. Consideration relating to the choice shall

include:

■ use of the accessory in the PATIENT VICINITY; and

■ evidence that the safety certification of the ACCESSORY has

been performed in accordance to the appropriate IEC 601-1

and/or IEC 601-1-1 harmonized national standard.

Equipment Symbols

M13932

The following symbols appear on the equipment.

Type BF equipment. Type BF equipment is suitable for intentional external and

internal application to the patient, excluding a direct conductive connection to the

patient’s heart. Type BF equipment has an F-type applied part. The paddles indicate

that the equipment is defibrillator proof.

CAM-14 Acquisition Module

421315-001

Revision A1-6

Page 15

Service Information

Introduction: Service Information

Service Requirements

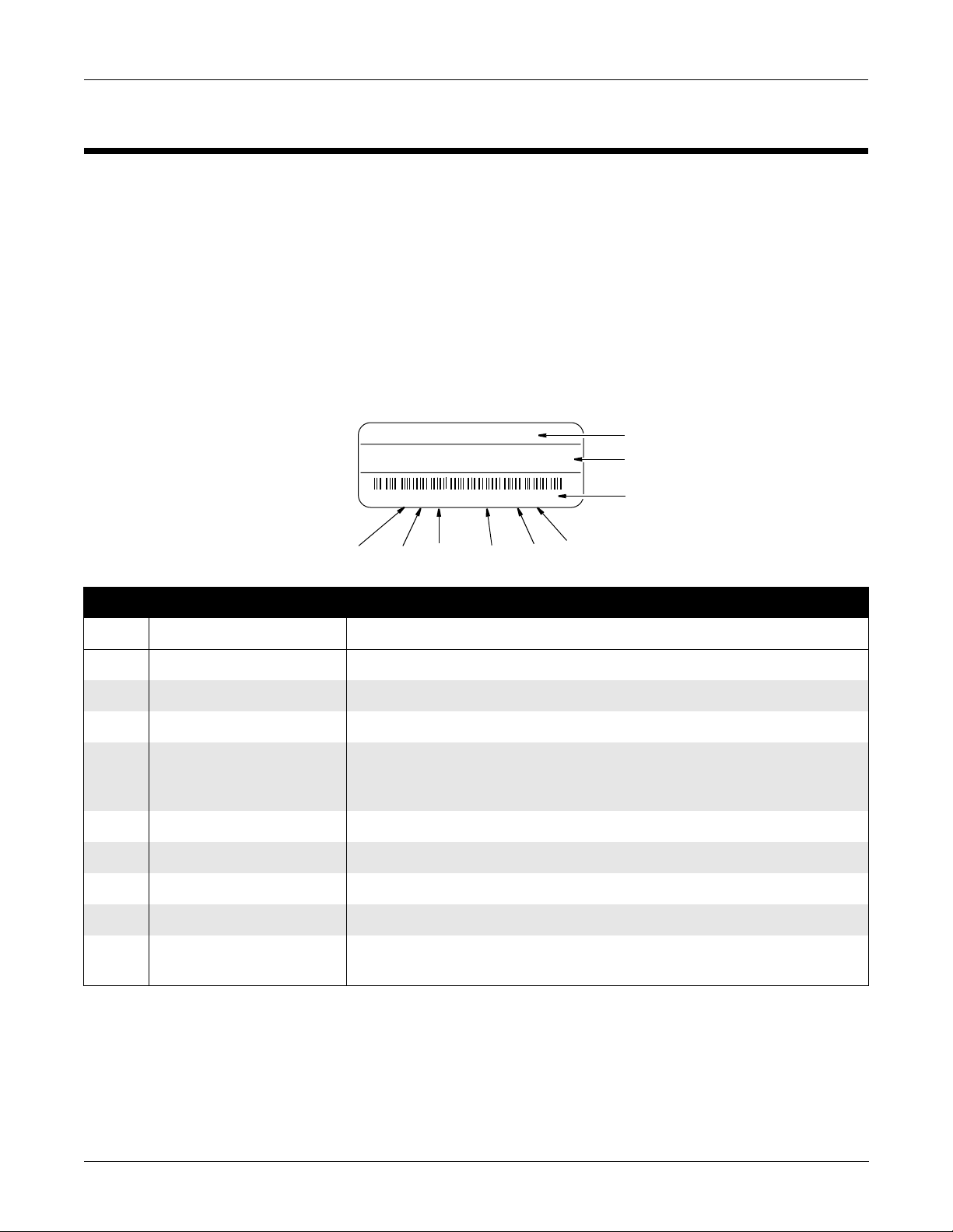

Equipment Identification

Refer equipment servicing to GE Marque tte Medical Systems’

authorized service per sonnel only. Any unauthorize d attempt to repair

equipment under warranty voids that warranty.

It is the user’s responsibility to report the need for service to GE

Marquette Medical Systems or to one of their authorized agents.

Every GE Marquette Medical Systems device has a unique s erial numbe r

for identification. The serial number appears on the product label on

the base of each unit.

XXXXXXXXX

XXXXXXXX XXXXXXX XXXXXXX XXX

XXXXXXXXX XX XXXX XX XXXXX

J6XX0415FXX

I

Table 2-2. Equipmen t Identifications

Item Name Description

G

H

F

D

E

A

B

C

MD1113-022B

A name of device AM-114 Acquisition Module

B manufacturer GE Marquette Medical Systems, Inc.

C serial number Unique identifier

D device characteristics One or two letters that further describe the unit, for example: P = prototype not

conforming to marketing specification; R = refurbished equipment; S = special

product documented under Specials part numbers; U = upgraded unit

E division F = Cardiology G = Monitoring J = GW Labs

F product sequence number Manufacturing number (of total units manufactured)

G product code Two-character product descriptor MF = CAM-14 Acquisition Module

H year manufactured 7 = 1997, 8= 1998, 9= 1999, (and so on)

I month manufactured A = January, B = February, C = March, D = April, E = May, F = June, G = July,

H = August, J = September, K = October, L = November, M = December

Revision A 1-7

CAM-14 Acquisition Module

421315-001

Page 16

Introduction: Service Information

CAM-14 Acquisition Module

421315-001

Revision A1-8

Page 17

2 Equipment Overview

Technical Characteristics .............................................................. 3

General Description ......................... ....................................... ............... 3

Power Requirements ............................................................................. 4

Operation ................................................................................. 5

Operating Controls ................................................................................. 5

Leadwire Attachments ........................................................................... 5

Leadwire Adapters ....................................................................6

Lead Configurations .................................................................7

Revision A

CAM-14 Acquisition Module

421315-001

2-1

Page 18

2-2

CAM-14 Acquisition Module

421315-001

Revision A

Page 19

Technical Characteristics

Equipment Overview: Technical Characteristics

General Description

The acquisition module performs high resolution ECG data acquisition

for use with host equipment (resting ECG analysis systems and exercise

systems). The acquisition m o du le has the following feature s:

■ ac leadfail bias,

■ l ead off dete ct ion,

■ 4000 Hz sampling rate,

■ patient isolation,

■ software updates via floppy diskette, and

■ Hi-Res analysis on 14-lead units

■ fu nc ti on key cont rol of host equi pme nt fu nc ti ons

The acquisition module provides patient electrical isolation for the host

equipment. The minute ECG s ignal s from th e pati ent’ s skin ar e rec eived

by the electrodes and sent to the acquisition module via leadwires. The

acquisition module then amplifies, digitizes, and performs some

processing on the signals.

This whole process is contro lle d by a microprocessor in the acquisition

module. The acquisition module then sends the serial, digitized, ECG

data to the host equipment in 16 bit “words”. The host equipment

communicates to the acquisition module using this same serial line.

Table 2-1. Safety

Item Description

Certification CE Marking for Council Directive 93/42/EEC

Type of Protection Against Electrical

Not applicable

Shock

Degree of Protection Against Ingress

Ordinary

of Liquids

Handling of Disposable Supplies and

Other Consum ables

■ Use only as manufactured or recommended by Marquette.

■ Follow manufacturer’s instructions for use for disposable/consumable product.

■ Follow local environmental guidelines concerning the disposal of hazardous

materials (e.g. lead acid batteries)

Patient Mode of Operation Continuous

Patient Leakage Current less than 10µA

Degree of Protection Against Electrical

type BF applied parts

Shock

Revision A 2-3

CAM-14 Acquisition Module

421315-001

Page 20

Equipment Overview: Technical Characteristics

Table 2-1. Safety (Continued)

Item Description

Maintenance Frequency ■ Recommended user daily visual inspection and cleaning.

■ Recommended six-month routine maintenance checks and test procedures

performed by qualified technical personnel.

Repair Guidelines Calibration instructions, equi pment descriptions, and all other service informati on to

repair those parts of the equipment designated as field repairable by qualified

technical personnel is available in the service manual.

Upon request, GE Marquette Medical Systems will provide circuit diagrams and

component parts lists for printed circuit boards deemed repairable by qualified

technical personnel.

Table 2-2. Environmental

Item Description

Operating Instructions

Temperature 0°C to 50°C (32°F to 154°F)

Relative Humidity 20% to 95% noncondensing

Atmosphere Pressure 70 to 106 KPa (PRELIMINARY pending final testing)

Storage Conditions

Temperature –20°C to 60°C (–4°F to 172°F)

Relative Humidity 5% to 95% noncondensing

Atmosphere Pressure 50 to 106 KPa (PRELIMINARY pending final testing)

Power Requirements

The acquisition module draws it s power, 12 V dc, from the host unit.

(See the host equipment’s field service manual for the host equ ipment’s

power requirements.) The acquisition module provides the patient

electrical isolation for the host equipment.

CAM-14 Acquisition Module

421315-001

Revision A2-4

Page 21

Operation

Equipment Overview: Operation

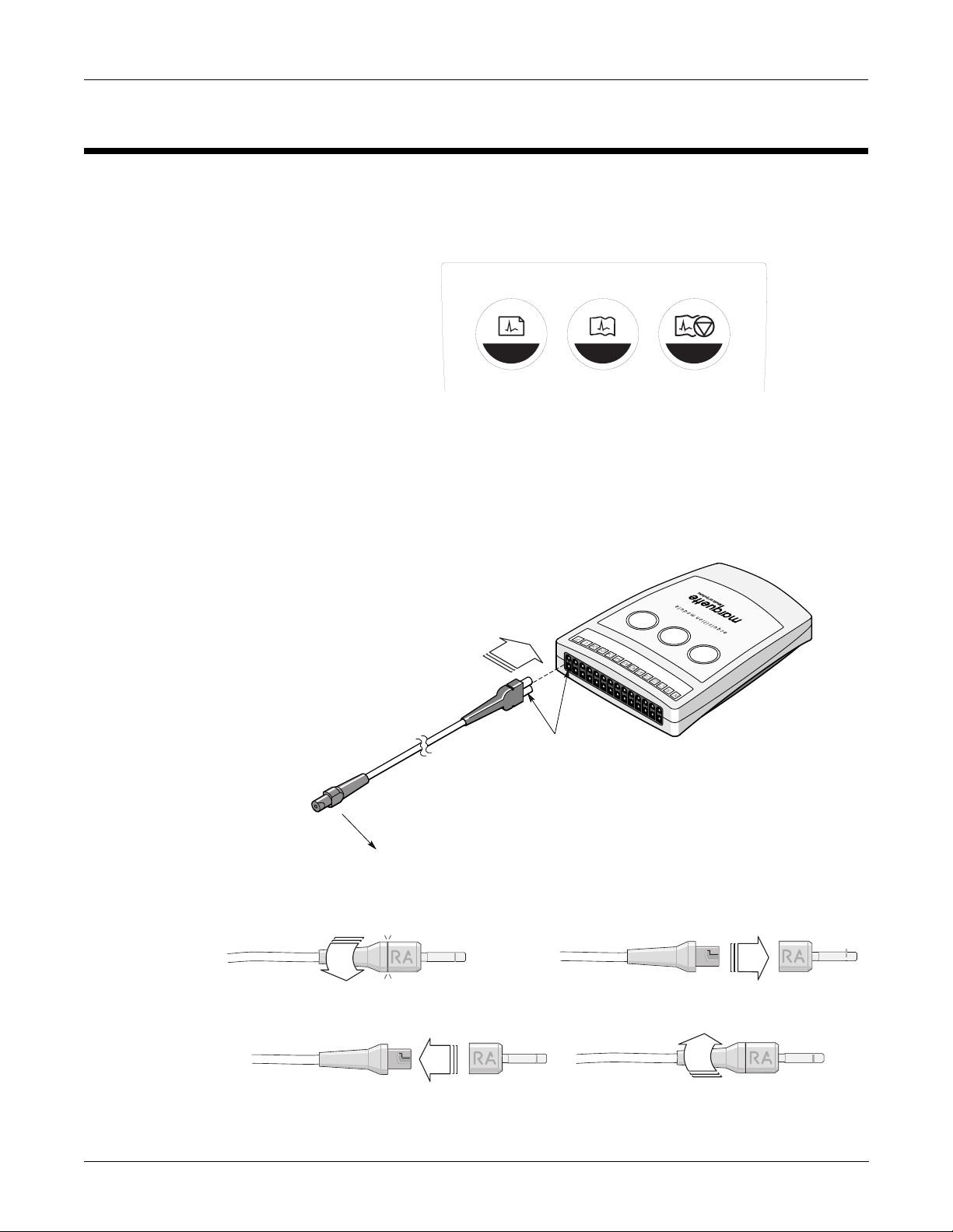

Operating Controls

Leadwire Attachments

There are three controls on the acquisition module that are

programmed by the host to record an ECG, record a rhythm, or stop the

writer. See the host equipment operator’s manual for the for specific

information on using th e a cquisition module.

2 31

MD1320-002

The leadwires are shown with 2 ends. The figure below shows how to

use both ends of the leadwires. There are various options for leadwire

adapters, the 4 mm pin, stress grabbe r, or MACTR ODE cli p. See cha pte r

5, “Parts Lists and Drawing s” for part numbers.

Flat Surface

Step 1

Step 3

Revision A 2-5

CAM-14 Acquisition Module

421315-001

Step 2

Step 4

MD1320-003B

Page 22

Equipment Overview: Operation

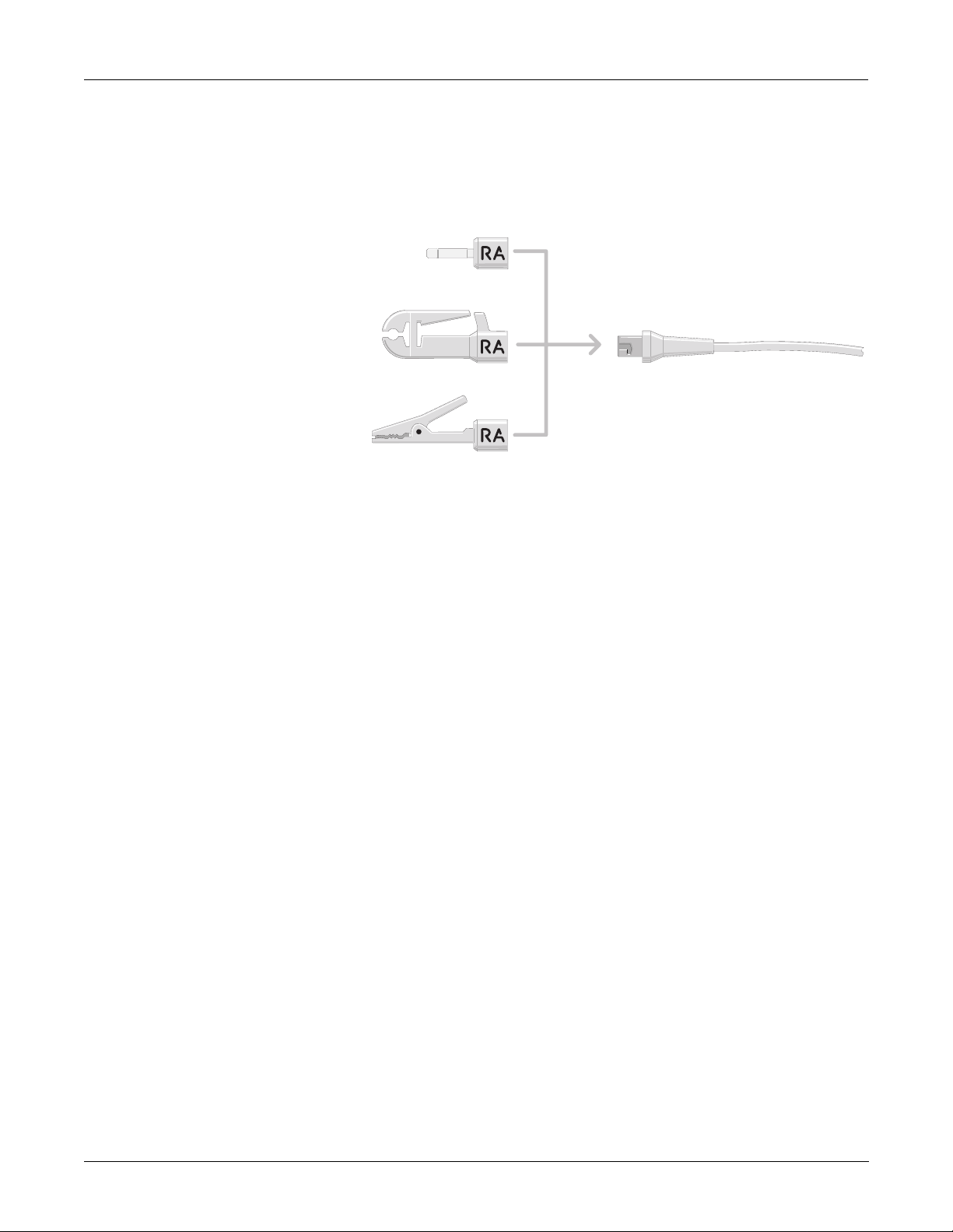

Leadwire Adapters

The acquisition module has universal leadwires which can be made into

any lead of 3 basic types by using the adapters on the ends as shown in

the figure below. The acquisition module leadwire adapters have a

variety of configuration s as shown below. (See chapter 4, “Parts Lists

and Drawings” for part numbers for the various individual leadwire

adapters.)

4 mm Pin

Stress Grabber

MACTRODE Clip

Universal Leadwire End

MD1287-004A

Refer to the figure on the next page for various labels that are affixed to

the acquisition mod ule for these configurations.

CAM-14 Acquisition Module

421315-001

Revision A2-6

Page 23

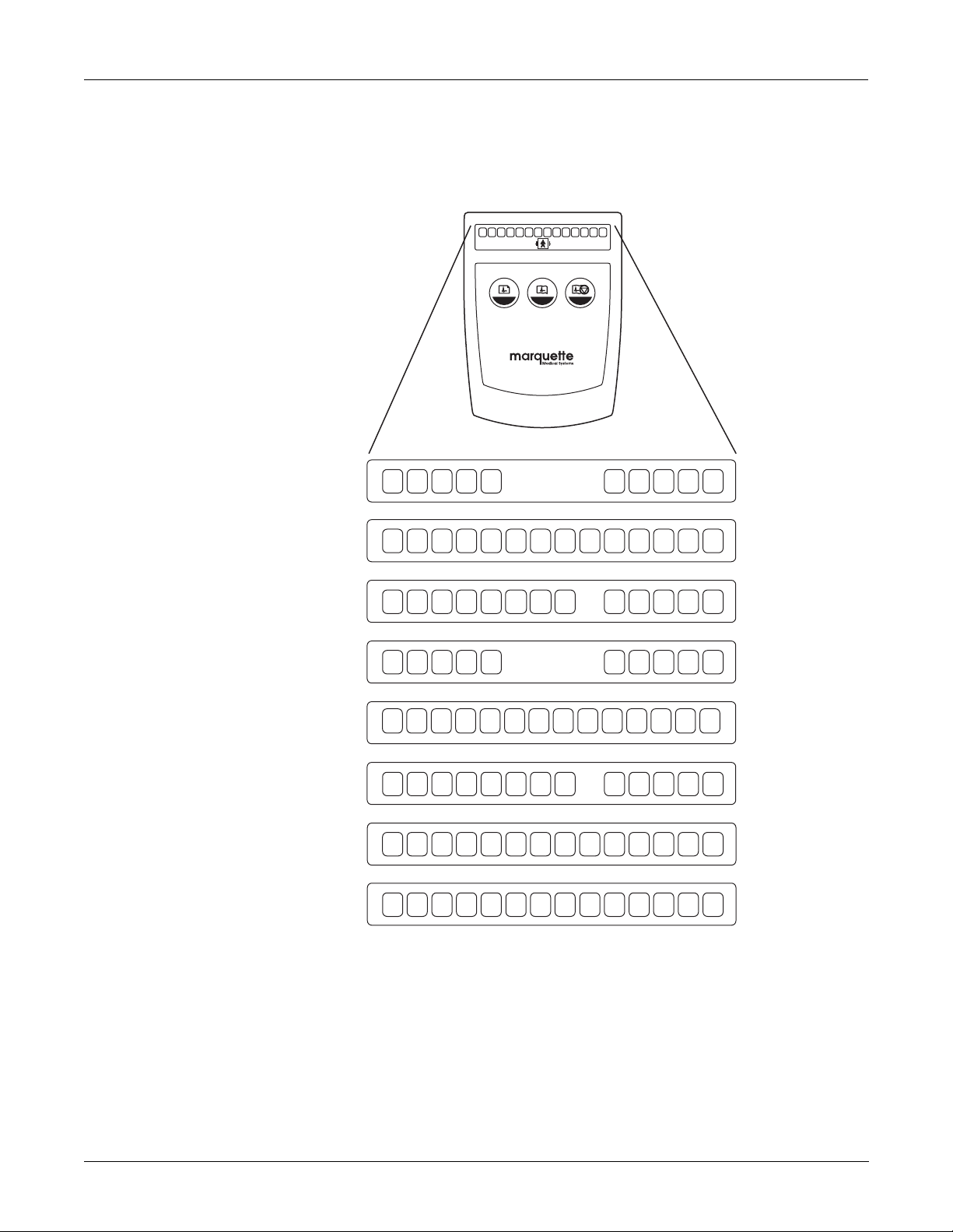

Equipment Overview: Operation

Lead Configurations

10 Lead AHA

14 Lead AHA

The various lead configurations are shown in the figure below. The

acquisition module may be configured in any one of these ways. See

chapter 5, “Parts Lists and Drawings” for part numbers.

N R C1 C2 C3 A1 A2 A3 A4 C4 C5 C6 L F

2 31

acquisition module

RL RA V1 V2 V3 V4 V5 V6 LA LL

HE MRL RA V1 V2 V3 I V4 V5 V6 LA LL

14 Lead AHA Pediatric

10 Lead IEC

14 Lead IEC

14 Lead IEC Pediatric

14 Lead AHA AUX

14 Lead IEC AUX

RL RA V1 V2 V3

V3R V4R

V7 V4 V5 V6 LA LL

N R C1 C2 C3 C4 C5 C6 L F

N R C1 C2 C3 I C4 C5 C6 L F

N R C1 C2 C3

RL RA V1 V2 V3 A1 A2

HE

C3R C4R

C7 C4 C5 C6 L F

A3 A4MV4 V5 V6 LA LL

N R C1 C2 C3 A1 A2 A3 A4 C4 C5 C6 L F

MD1320-004

Revision A 2-7

CAM-14 Acquisition Module

421315-001

Page 24

Equipment Overview: Operation

CAM-14 Acquisition Module

421315-001

Revision A2-8

Page 25

3 Maintenance

Recommended Maintenance .......................................................... 3

General .................................................................................................. 3

Cleaning 3

Exterior Surfaces ......................................................................3

Electrodes .................................................................................3

Visual Checking 4

Built-In Diagnostic Tests 4

Domestic Electrical Safety Tests ...................................................... 5

AC Line Voltage Test .............................................................................. 5

120 VAC, 50/60 Hz ...................................................................5

240 VAC, 50/60 Hz ...................................................................5

Leakage Tests 6

Leakage Test Diagrams 7

Test #1 Ground-wire-leakage-to-ground ...........................................7

Test #2 Chassis-leakage-to-ground .............................................. .....7

Test #3 Patient-cable-leakage-to-ground ..........................................8

Test #4 Patient-cable-leakage-into-patient Leads-from 120 VAC .......8

Ground Continuity 9

Revision A

Disassembly ............................................................................ 10

CAM-14 Acquisition Module

421315-001

3-1

Page 26

3-2

CAM-14 Acquisition Module

421315-001

Revision A

Page 27

Recommended Maintenance

Maintenance: Recommended Maintenance

General

Cleaning

Other than daily cleaning and occasional visual checking, the

acquisition module requires no maintena nce.

Only qualified service personnel should attemp t repairing components

and assemblies int ernal to the acquis ition module. For servic e and

repair, return the acquisition module to the factory for 48-hour turn

around service. Call Tech Support for assistance. (See the “How to

Reach Us” page in the front of the manual.)

NOTE

Unless you have an Equipment Maintenance Contract,

GE Marquette Medical Systems does not in any

manner assume the responsibility for performing the

recommended maintenance procedures. The sole

responsibility rests with the individual or institution

using the equipment. GE Marquette Medical Systems

service personnel may, at their discretion, follow the

procedures provided in this manual as a guide during

visits to the equipment site.

Exterior Surfaces

Electrodes

Disconnect the acquisition module interface cab le from the host

equipment.

■ Use a soft cloth moistened with water and a mild detergent.

Wipe the exterior of the unit, the leadwires, and the acquisition

module interface cable with the damp cloth. Dry all surfaces

with a clean, soft cloth or paper towel.

■ DO NOT allow any excess water to get inside the acquisition

module or onto the leadwires or interface cable.

■ Do not immerse acquisition module in water.

■ Do not use alcohols, organic solvents, or abrasive cleaning

agents.

■ After each use, wipe reusable electrodes with a tissue or damp

cloth to clean them of electrode paste. At the end of each day,

wash reusable electr od es thoroughly with soap and water and

dried.

■ For suction electrodes, use a toothbrush to clean out the cups.

Revision A 3-3

CAM-14 Acquisition Module

421315-001

Page 28

Maintenance: Recommended Maintenance

Visual Checking

Built-In Diagnostic Tests

Inspect the acquisition module each time you clean it or if you suspect a

problem.

■ Check the leadwires and leadwire adapters for wear and loose

connections. Replace these parts at the first sign of wear.

■ Check the pins that the leadwires plug into. They should not be

bent or loose. Contact Tech Support for any repairs needed.

(See the “How to Reach Us” page in the front of the manual.)

■ Check the acquisition module plastic case for any damage.

Contact Tech Support for any repairs needed. (See the “How to

Reach Us” page in the front of the manual.)

The host equi pm ent gene ral ly con tain s b uil t- in di agn ost ic test s to ve ri fy

the operation of the electrocardiograph.

These built-in diagno st ic tests verify the operatio n of the acquisition

module, as well. For example, there is a test that records raw ECG data

on the thermal paper. This test checks for noise and gain in the

acquisition module . Another test is a serial link test that dete rmines if

the microprocessor in the host equipment is communicating with the

acquisition module.

For details on using these tests, see the field service manual for the host

equipment.

CAM-14 Acquisition Module

421315-001

Revision A3-4

Page 29

Domestic Electrical Safety Tests

Maintenance: Domestic Electrical Safety Tests

AC Line Voltage Test

120 VAC, 50/60 Hz

This test verifies that th e domestic wall outlet supp lying power to the

equipment is prope rly wired. For interna tion al wiring tests, refer to the

internal standards agencies of that particular country.

Use a digital voltmeter t o che ck the voltages of the 120-volt AC wall

outlet (dedicated circuit recommended). If the measurements are

significantly out of range, have a qualified electrician repair the outlet.

The voltage measurements should be as follows:

1. 120 VAC (± 10 VAC) between the line contact and neutral and

between the line contact and ground.

2. Less than 3 VAC between neutral and ground.

NEUTRAL

❶

LINE

❶❷

GROUND

MD1287-006

240 VAC, 50/60 Hz

Use a digital voltmeter, set to measure at least 300 VAC, to check the

voltages of the NEMA 6-20R, AC wall outlet (dedicated circuit

recommended). If the measurements are significantly out of range, have

a qualified electrician repair the outlet. The voltage measurements

should be as follows:

1. 120 VAC (± 10 VAC) between either “hot” contact and ground.

2. 210 to 230 VAC between the two “hot” contacts.

HOT

❶

❷

❶

GROUND

HOT

MD1287-007

Revision A 3-5

CAM-14 Acquisition Module

421315-001

Page 30

Maintenance: Domestic Electrical Safety Tests

Leakage Tests

The leakage tests are safety tests to ensure that the equipment poses no

electrical health hazards. Use the table below to determine which tests

apply to the unit under test and the maximum allowable leakage

currents. For international leakage limits, refer to the internal standards

agencies of that particular country.

If the unit under test fails the leakage tests, do not allow the customer to

use the equipment. Call Tech Support for assistance. (See the “How to

Reach Us” page in the front of the manual.)

GE Marquette Medical Systems recommends that you perform these

tests:

■ Before applying power fo r the first time

■ Every 6 months as part of routine maintenance

■ Whenever internal assemblies are serviced

You need a leakage tester to perform the leakage tests.

NOTE

The accuracy of the leakage tests depends on a

properly-wired wall outlet. Do not proceed until you

verify the integrity of the power source.

WARNING

Total system leakage

current must not

exceed 100

microamperes.

M15287-9D

Table 3-1. Leakage Tests and Maximum Allowable Leakage Currents

Test Applies To Maximum Current (µA)

1 Ground-wire-leakage-to-gro un d Host equipmen t 100

2 Chassis-leakage-to-ground Host equipment 100

3 Patient-cable-leakage-to-ground Acquisition module

(patient cable)

4 Patient-cable-leakage-into-patient-leads-from-120 V ac Acquisition module

(patient cable)

10

20

CAM-14 Acquisition Module

421315-001

Revision A3-6

Page 31

Maintenance: Domestic Electrical Safety Tests

Leakage Test Diagrams

Test #1

Ground-wire-leakage-to-ground

Tester

power

Line

Neutral

Gnd

cord

These diagrams show only a representation of how a typical leakage

current tester functions. Follow the instructions provided with the

leakage current tester that you use.

“To be tested” power connector on back of

tester (may not be labeled on some testers).

Tester

connectors

Meter

Polarity

Norm

Rvs

Neutral

1K

Line

Gnd

UUT

power

cord

Unit

under

test

(UUT)

Test #2

Chassis-leakage-to- ground

Tester

power

Line

Neutral

Gnd

cord

V

Apply line voltage to the UUT chassis for th is t est.

“To be tested” power connector on back of

tester (may not be labeled on some testers).

Tester

Meter

connectors

Polarity

Norm

Rvs

Neutral

1K

Line

Gnd

UUT

power

cord

Probe to

exposed chassis

Unit

under

test

(UUT)

MD1287-008

V

MD1287-009

Revision A 3-7

CAM-14 Acquisition Module

421315-001

Page 32

Maintenance: Domestic Electrical Safety Tests

Test #3

Patient-cable-leakage-to-ground

Line

Neutral

Gnd

Tester

power

cord

Tester

Meter

connectors

Polarity

Norm

Rvs

Line

Neutral

Gnd

1K

V

Patient

cable connectors

“To be tested” power connector on back of

tester (may not be labeled on some testers).

UUT

power

cord

Unit

under

test

(UUT)

Patient cable

MD1287-010

Test #4

Patient-cable-leakage-into-patient

Leads-from 120 VAC

Tester

power

Line

Neutral

Gnd

cord

During this test, line voltage is applied to the patient cable connectors.

To prevent errone ous readings, do not allow the leadwires to contact

conductive materials such as metal handles, and do not place the

leadwires on the floor.

“To be tested” power connector on back of

tester (may not be labeled on some testers).

Tester

Meter

connectors

Polarity

Norm

Rvs

Line

Neutral

Gnd

1K

V

Patient

cable connectors

UUT

power

cord

Patient cable

Unit

under

test

(UUT)

MD1287-011

CAM-14 Acquisition Module

421315-001

Revision A3-8

Page 33

Maintenance: Domestic Electrical Safety Tests

Ground Continuity

This test verifies that there is continuity (less than 100 mΩ resistance)

between all the exposed metal surfaces on the host equipment, which

have the potential to become energized, and the ground prong on the

mains AC power cord. If the metal surfaces are anodized or painted,

scrape off a small ar e a in an inconspicuous area for the probe to make

direct contact with the metal.

Use a digital multimeter to check all the metal surface s of the host

equipment. Make ad justments for any res istance in the test leads. (See

the host equipment field service manual for detailed information.)

If the measurements are significantly out of range, check for breaks in

the power cord or in the internal connections within the unit.

Revision A 3-9

CAM-14 Acquisition Module

421315-001

Page 34

Maintenance: Disassembly

Disassembly

Strict antistatic prec autions should be followed during disassembly/

assembly of the CAM-14.

NOTE

Use the proper ESD grounding techniques when

handling components. Wear an antistatic wrist strap

and an ESD protected mat. Store ESD sensitive

components in antistatic bags before placing them on

any surface.

Cover

Gently disconnect flex

cable from switch

before removing cover

Switch flex cable

Host cable

interface flex

#6 Torx screws

Follow the steps below when disassemblin g t he CA M-14.

1. Remove the four Torx screws holding the top and bottom of the

CAM-14 unit together us ing a #6 TORX driver.

2. Lift the top only high enou gh to allow access to the switch flex

cable from the switch as sembly.

MD1320-006

CAM-14 Acquisition Module

421315-001

Revision A3-10

Page 35

Maintenance: Disassembly

3. To avoid damage to the flex cable, gently pry the cable off the

switch at the main pcb with a small screwdriver.

NOTE

Damage to the switch flex cable connector will result in

failure of one or more of the switch functions.

■ DO NOT attempt to disconnect the switch flex

cable by pulling on it.

■ DO NOT let the main pcb hang by the cable.

4. When the main pcb has been separated from the switch flex

cable, disconnect the host cable interface flex from the main

pcb by gently prying the connectors apart.

Revision A 3-11

CAM-14 Acquisition Module

421315-001

Page 36

Maintenance: Disassembly

CAM-14 Acquisition Module

421315-001

Revision A3-12

Page 37

4 Parts Lists and Drawings

Ordering Parts ......................................................................... 3

Introduction ........................................................................................... 3

900995-001A Acquisition Module Assembly .................................... 4

420101-001B 14 Leadwire Kit ..................................................... 7

417483-9XXA Leadwire, Multi-Link, Universal ................................ 8

900179-201 Leadwire Adapter Kit - Banana ................................ 10

900179-202 Leadwire Adapter Kit - Mactrode .............................. 11

900179-203 Leadwire Adapter Kit - Grabber ................................ 12

Revision A

CAM-14 Acquisition Module

421315-001

4-1

Page 38

4-2

CAM-14 Acquisition Module

421315-001

Revision A

Page 39

Ordering Parts

Parts Lists and Drawings: Ordering Parts

Introduction

This chapter provides upper-level drawings for the standard

configurations of the acquisition module and any kit s which are

available. It includes enough detail to provide part numbers for fieldserviceable assem blies in the equipmen t.

Subassembly drawings follow the upper-le vel drawings and are

arranged in asce nding numerical order. The assembly drawings

generally include both a parts lists and an exploded view.

To order parts, contact Ser vice Pa rts at the addr ess or te lephone num ber

on the “How to Reach Us…” page at the beginning of this manual.

Revision A 4-3

CAM-14 Acquisition Module

421315-001

Page 40

Parts Lists and Drawings: 900995-001A Acquisition Module Assembly

900995-001A Acquisition Module Assembly

Item Description Part Number Qty.

1 PCB CAM 14 MAIN BRD 801280-001 1

2 PCB CAM14 CABLE INTFC 801502-001 1

3 ASSY TOP W/ SWITCH CAM 14 422 032-001 1

4 ASSY WELD BTM BELT CL IP CAM 14 420148-001 1

5 LABEL NEW ACQ MOD LD CODES 420152-001 1

6 KIT LDWR AM11X SET 14 420101-001 1

7 LABEL CLEAR OVERLAMINATE 413608-001 1

8 LABEL CAM 14 BOTTOM 419979-001 1

9 SCREW 1 X .375 TORX T-6 FHPH 417866-002 4

10 CARTON, MAILER 11X5X3 CAM 14 421927-001 1

11 INSERT, DIE CUT CAM 14 421927-002 1

12 I-STATIC, 6.00W x 8.00 L (not shown) 9976-005 1

13 PTR 14 SET AHA BANANA 900179-201 1

1

CAM-14 Acquisition Module

421315-001

Revision A4-4

Page 41

Parts Lists and Drawings: 900995-001A Acquisition Module Assembly

5

3

2

9

Notes:

1. Model/Serial # Label to be Marked:

CAM 14

(Serial # TBD)

1

4

8

7

Revision A 4-5

CAM-14 Acquisition Module

421315-001

Page 42

Parts Lists and Drawings: 900995-001A Acquisition Module Assembly

11

11

6

Place Leadwire Kit

(Item 6) into Card

Board Insert

Place Leadwire Adapter Kit

13

(Item 13) into Card

Board Insert

LEAD

ADAPTER

KIT

LEAD

WIRE

KIT

10

5

Place unused

Labels into

Carton

CAM-14 Acquisition Module

421315-001

Revision A4-6

Page 43

Parts Lists and Drawings: 420101-001B 14 Leadwire Kit

420101-001B 14 Leadwire Kit

Item Description Part Number Qty

1 BAG, ANTISTATIC 6 X 8 9976-005 1

2 LEADWIRE UNIV/MLINK AM11X 26” 417483-905 10

3 LEADWIRE UNIV/MLINK AM11X 36” 417483-906 2

4 LEADWIRE UNIV/MLINK AM11X 40” 417483-903 2

5 INSERT/REORDER CARD 70357-001 1

Revision A 4-7

CAM-14 Acquisition Module

421315-001

Page 44

Parts Lists and Drawings: 417483-9XXA Leadwire, Multi-Link, Universal

417483-9XXA Leadwire, Multi-Link, Universal

Item Description Part Number Qty

1 TUBING FIT-221 3/32 BLK 4882-103 0.04

2 RESIN ABS NATURAL 5421-001 A/R

3 RESIN PVC 60 DURO NATURAL 5423-001 A/R

4 RESIN PVC 85 DURO NATURAL 5423-002 A/R

5 MOLD UNIVERSAL PRE MO LD AM4 58973-058 1

6 MOLD STRAIN RELIEF AM4 WIRE 58973-059 1

7 INSERT MOLDED AM4 LEADWIRE 58973-060 1

8 LDWR PLUGFACE INDV MULTILINK DGRAY 411191-004 1

9 PLUG PREMOLD INDV LDWR MULTILINK 411192-900 1

10 PLUG OVERMOLD INDV LDWR MULTILINK 411193-001 1

11 LEADWIRE CONTACT 411197-001 3

12 BAND SPLICE 412201-001 1

13 COLORANT MULTIPURPOSE DARK GRAY 412793-028 A/R

14 CABLE COAX 1 COND 26 AWG. 125 OD PVC 700136-007 A/R

CAM-14 Acquisition Module

421315-001

Revision A4-8

Page 45

Parts Lists and Drawings: 417483-9XXA Leadwire, Multi-Link, Universal

LENGTH CHART

REV SUFFIX

-901 20"/1.70 FT

A

-902 29"/2.45 FT

A

-903 40"/3.35 FT

A

-904 51"/4.25 FT

A

A

A

711

ITEM 16

DIM "A"

INCHES/FEET

26"/2.17 FT-905

36"/3.0 FT-906

5

2

13

6

3

4

13

Termination Detail

Premold Detail

Overmold Detail

13

10

13

14

12

Do Not Cover Contact

.40" Only over Shield

1

11

2

9

3

Pin No. 2

Shield

4

8

Month Lot Code

See Note 2

Pin No. 1

Center

Conductor

Dim "A" ±1.00 (See Chart)

Finished Part Detail

Notes:

1. For Overmold Mix PVC Resins Items 3 & 4 together to obtain 72 ±5 Durometer.

Color: Gray, Munsell N7.

2. Month Lot Code: One letter in alphabetical order for each month where A = January,

B = February . . . Skip letter "I".

Year Lot Code: One digit, the last digit of the year where 7 = 1997, 8 = 1998 . . .

3. Performance Specification:

Hi-Pot: Wire must withstand 5000 VDC 1 mA for 1 second between center

Conductor and Shield.

Continuity Test: Leadwire to be tested end to end between universal End & Center

Conductor.

4. Finished Assembly to be free of dirt. Discolorations or other signs of poor

workmanship. Molded Components to have Flash and Gate Marks trimed flush to

within .010 of surface.

Revision A 4-9

CAM-14 Acquisition Module

421315-001

Page 46

Parts Lists and Drawings: 900179-201 Leadwire Adapter Kit - Banana

900179-201 Leadwire Adapter Ki t - Banana

Item Description Part Number Qty

1 ASSY BANNANA RL GREEN 406554-007 1

2 ASSY BANNANA RA WHITE 406554-001 1

3 ASSY BANANA LL RED 406554-005 1

4 ASSY BANANA LA BLACK 406554-003 1

5 ASSY BANANA V1 BROWN 406554-009 1

6 ASSY BANANA V2 BROWN 406554-011 1

7 ASSY BANANA V3 BROWN 406554-013 1

8 ASSY BANANA V4 BROWN 406554-015 1

9 ASY BANANA V5 BROWN 406554-017 1

10 ASSY BANANA V6 BROWN 406554-019 1

11 ASSY BANANA E ORANGE 406554-021 1

12 ASSY BANANA H ORANGE 406554-023 1

13 ASSY BANANA I ORANG 406554-025 1

14 ASSY BANANA M ORANGE 406554-027 1

CAM-14 Acquisition Module

421315-001

Revision A4-10

Page 47

Parts Lists and Drawings: 900179-202 Leadwire Adapter Kit - Mactrode

900179-202 Leadwire Adapter Ki t - Mactrode

Item Description Part Number Qty

1 ASSY MACTRODE RL GREEN 406551-007 1

2 ASSY MACTRODE RA WHITE 406551-001 1

3 ASSY MACTRODE LL RED 406551-005 1

4 ASSY MACTRODE LA BLACK 406551-003 1

5 ASSY MACTRODE V1 BROWN 406551-009 1

6 ASSY MACTRODE V2 BROWN 406551-011 1

7 ASSY MACTRODE V3 BROWN 406551-013 1

8 ASSY MACTRODE V4 BROWN 406551-015 1

9 ASY MACTRODE V5 BROWN 406551-017 1

10 ASSY MACTRODE V6 BROWN 406551-019 1

11 ASSY MACTRODE E ORANGE 406551-021 1

12 ASSY MACTRODE H ORANGE 406551-023 1

13 ASSY MACTRODE I ORANG 406551-025 1

14 ASSY v MACTRODE M ORANGE 406551-027 1

Revision A 4-11

CAM-14 Acquisition Module

421315-001

Page 48

Parts Lists and Drawings: 900179-203 Leadwire Adapter Kit - Grabber

900179-203 Leadwire Adapter Kit - Grabber

Item Description Part Number Qty

1 ASSY GRABBER RL GREEN 406552-007 1

2 ASSY GRABBER RA WHITE 406552-001 1

3 ASSY GRABBER LL RED 40655 2- 005 1

4 ASSY GRABBER LA BLA CK 406552-003 1

5 ASSY GRABBER V1 BROWN 406552-009 1

6 ASSY GRABBER V2 BROWN 406552-011 1

7 ASSY GRABBER V3 BROWN 406552-013 1

8 ASSY GRABBER V4 BROWN 406552-015 1

9 ASY GRABBER V5 BROWN 406552-017 1

10 ASSY GRABBER V6 BROWN 406552-019 1

11 ASSY GRABBER E ORANGE 406552-021 1

12 ASSY GRABBER H ORANGE 406552-023 1

13 ASSY GRABBER I ORANG 406552-025 1

14 ASSY v GRABBER M ORANGE 406552-027 1

CAM-14 Acquisition Module

421315-001

Revision A4-12

Page 49

5 PCB Assemblies

8001280-001A Data Acquisition Module .......................................... 3

SD8001280-001A Schematic, Main Board ........................................... 8

Revision A

CAM-14 Acquisition Module

421315-001

5-1

Page 50

5-2

CAM-14 Acquisition Module

421315-001

Revision A

Page 51

PCB Assemblies: 8001280-001A Data Acquisition Module

8001280-001A Data Acquisition Module

Item Description Part Number Qty.

1 RES COMP 100M 5% 1/4W 1001-107 2

2 RES SM CER 100 5% 1/8W 1081-101 1

3 RES SM CHIP 5% 1/8W 51 OHMS 1081-472 1

4 RES SM CER 26.7 1% 1/8W 1082-909 1

5 CAP SM CER COG 150PF 5% 50V 1181-151 13

6 CAP SM CER X7R .1UF 50V 1187-104 2

7 DIODE SM SERIES PR D7000 2013-201 4

8 DIODE SM SCHTKY BARRIER 2800 2412-001 1

9 DIODE SM LL FDSO1503 2414-001 14

10 IC SM HC 74HC161 3038-161 1

11 IC SM SSOP VHC04 3057-004 1

12 IC SM SSOP VHC573 3057-573 1

13 DIODE SM ZENER 5234 6.2V 401502-001 2

14 CAP SM TANT 1.0UF 10% 16V 406883-002 3

15 CAP SM TANT 10UF 10% 35V 406884-013 3

16 IC SM DUAL N-CHAN MFET SI9955 407547-001 1

17 BEAD SM 1206 600@100 200MA 408746-001 3

18 IC SM HCMOS TC7S02F 408795-001 2

19 IC SM OPTOCOUPLER CNW2611 408825-001 2

20 IC SM HCMOS AND TC7S08F 409035-001 2

21 RES SM 0603 100 1% 1/16W 410334-003 1

22 RES SM CER 0603 10K 1% 1/16W 410334-013 22

23 RES SM 0603 11.5K 1% 1/16W 410334-014 1

24 RES SM 0603 3.01K 1% 1/16W 410334-018 13

25 RES SM 0603 100K 1% 1/16W 410334-019 7

26 RES SM CER 0603 0 OHM JUMPER 410334-027 1

27 RES SM 0603 511 OHM 1% 1/16W 410334-034 1

28 RES SM 0603 47.5K 1% 1/16W 410334-036 1

29 RES SM 0603 200 OHM 1% 1/16W 410334-044 2

30 RES SM 0603 7.68K 1% 1/16W 410334-049 1

31 RES SM 0603 20.0K 1% 1/16W 410334-053 6

32 RES SM CER 0603 4.99K 1% 1/16W 410334-066 1

33 RES SM CER 0603 35.7K 1% 1/16W 410334-091 2

34 RES SM 0603 7.87K 1% 410334-098 3

35 RES SM 0603 750 1% 410334-099 3

36 RES SM 0603 1.24K 1% 410334-101 1

37 RES SM 0603 30.1 1% 1/16W 410334-109 1

38 RES SM 0603 2.49K 1% 1/16W 410334-110 7

39 RES SM CER 0603 8.06K 1% 1/16W 410334-113 2

Revision A 5-3

CAM-14 Acquisition Module

421315-001

Page 52

PCB Assemblies: 8001280-001A Data Acquisition Module

Item Description Part Number Qty.

40 RES SM 0603 1.0M 1% 1/16W 410334-120 3

41 RES SM 0603 33.2K 1% 1/16W 410334-165 1

42 RES SM 0603 249K 1% 1/16W 410334-186 2

43 RES SM 0603 15.8K 1% 1/16 410334-225 12

44 CONN BLK,CAM 14 14POS W/10K R 411305-003 1

45 CAP SM X7R 0603 .1UF 10% 16V 411575-002 80

46 CAP SM X7R 0603 1000PF 5% 50V 411575-003 2

47 CAP SM X7R 0603 390PF 5% 50V 411575-009 1

48 CAP SM X7R 0603 2700PF 5% 50V 411575-010 2

49 CAP SM X7R 0603 0.01UF 5% 50V 411575-012 2

50 CAP SM X7R 0603 .022UF 16V 5% 411575-014 4

51 CAP SM X7R 0603 220PF 5% 50V 411575-022 4

52 CAP SM X7R 0603 3300PF 5% 50V 411575-024 1

53 CAP SM NPO 0603 100PF 5% 50V 411575-025 2

54 CAP SM X7R 0603 2200PF-5% 411575-033 3

55 CAP SM NPO 0603 33PF 5% 50V 411576-004 1

56 CAP SM NPO 0603 5.6PF +/-25PF 411576-017 13

57 CAP SM NPO 0603 470PF 5% 50V 411576-018 3

58 CAP SM X7R 0805 .047UF 5% 25V 411587-004 1

59 IC SM DUAL OP AMP TLC272CD 411710-001 1

60 RES SM 0603 10M 5% 1/16W 411723-003 1

61 SM RESONATOR 4MHZ TYPE KBR 412010-001 1

62 IC SM OPTOCOUPLER CNW136 412017-001 1

63 CAP SM TANT 220UF 20% 10V 412662-002 2

64 CAP SM TANT 33UF 20% 25V 412662-003 1

65 IC SM OP AMP AD822 412753-001 1

66 IC SM OP AMP LOW POWER AD82O 412799-001 1

67 CAP SM TANT 3.3UF 10% 10V 413119-001 1

68 DIODE SM SCHTKY RECT MBR0520 413970-001 2

69 SM FERRITE BEAD 0603 BLM11A601 414061-001 5

70 CAP SM TANT 2.2UF 10V 10% 414084-001 2

71 IC SM PWM CONTROLLER UCC3806DW 414247-001 1

72 IC SM 4.85V REG MIC5201 416998-001 1

73 IC RS485/422 XCVR MAX490 SO8 417913-001 1

74 CONN SCKT SM B/B 2MM HGT 10POS 417955-001 2

75 TRANSFORMER TNI ISO T8175 418434-001 1

76 IC SM DSP TMS320F206 PQFP 419051-001 1

77 IC SM D FLIP TC7W74FU 419131-001 1

78 IC SM AV9170-02 419133-001 1

79 IC SM OP AMP TLV2221 SOT23-5P 419134-001 13

80 IC SM TPS 5904 419135-001 1

81 IC SM MAX4051 419283-001 2

CAM-14 Acquisition Module

421315-001

Revision A5-4

Page 53

PCB Assemblies: 8001280-001A Data Acquisition Module

Item Description Part Number Qty.

82 IC SM INSTR AMP INA126E SSOP 419315-002 12

83 IC SM QUAD OP-AMP 34184 TSSOP 419383-001 1

84 RES SM CHIP 0.2 5% 0.2W 419604-001 1

85 IC SM PWR SPLY MONMAX823 419699-002 1

86 IC SM ADS7809 16 BIT A/D 419952-001 1

87 POST SM 1MM MALE 2X7 420007-007 1

88 FRMWR COMMAND INTERFACE V001A 421920-001 1

89 CKT BD CAM 14 MAIN BD 801281-001 1

90 SCHEM CAM14 MAIN BRD SD801280-001 0

Drawing notes:

■ Unless otherwise specified, all resistors are 10K, 1%; all

capacitors are 0.1µF, 10%; all diodes are FDS01503; all ICs are

INA126E.

■ The bar shown on all polarized capacitors denotes the positive

terminal.

■ Parts not installed (solder side): R29, R30.

■ Trim leads of R224 and R225 in the indicated area so they do

not extend beyond edge of solder pad.

Revision A 5-5

CAM-14 Acquisition Module

421315-001

Page 54

PCB Assemblies: 8001280-001A Data Acquisition Module

Component (Top) View

CAM-14 Acquisition Module

421315-001

Revision A5-6

Page 55

PCB Assemblies: 8001280-001A Data Acquisition Module

Solder (Bottom) Side

Revision A 5-7

CAM-14 Acquisition Module

421315-001

Page 56

PCB Assemblies: SD8001280-001A Schematic, Main Board

SD8001280-001A Schematic, Main Board

1 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-8

Page 57

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-9

CAM-14 Acquisition Module

421315-001

Page 58

2 of 13

PCB Assemblies: SD8001280-001A Schematic, Main Board

CAM-14 Acquisition Module

421315-001

Revision A5-10

Page 59

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-11

CAM-14 Acquisition Module

421315-001

Page 60

PCB Assemblies: SD8001280-001A Schematic, Main Board

3 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-12

Page 61

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-13

CAM-14 Acquisition Module

421315-001

Page 62

PCB Assemblies: SD8001280-001A Schematic, Main Board

4 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-14

Page 63

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-15

CAM-14 Acquisition Module

421315-001

Page 64

PCB Assemblies: SD8001280-001A Schematic, Main Board

5 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-16

Page 65

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-17

CAM-14 Acquisition Module

421315-001

Page 66

PCB Assemblies: SD8001280-001A Schematic, Main Board

6 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-18

Page 67

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-19

CAM-14 Acquisition Module

421315-001

Page 68

PCB Assemblies: SD8001280-001A Schematic, Main Board

7 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-20

Page 69

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-21

CAM-14 Acquisition Module

421315-001

Page 70

PCB Assemblies: SD8001280-001A Schematic, Main Board

8 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-22

Page 71

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-23

CAM-14 Acquisition Module

421315-001

Page 72

PCB Assemblies: SD8001280-001A Schematic, Main Board

9 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-24

Page 73

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-25

CAM-14 Acquisition Module

421315-001

Page 74

PCB Assemblies: SD8001280-001A Schematic, Main Board

10 of 13

CAM-14 Acquisition Module

421315-001

Revision A5-26

Page 75

11 of 13

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-27

CAM-14 Acquisition Module

421315-001

Page 76

PCB Assemblies: SD8001280-001A Schematic, Main Board

CAM-14 Acquisition Module

421315-001

Revision A5-28

Page 77

12 of 13

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-29

CAM-14 Acquisition Module

421315-001

Page 78

PCB Assemblies: SD8001280-001A Schematic, Main Board

CAM-14 Acquisition Module

421315-001

Revision A5-30

Page 79

13 of 13

PCB Assemblies: SD8001280-001A Schematic, Main Board

Revision A 5-31

CAM-14 Acquisition Module

421315-001

Page 80

PCB Assemblies: SD8001280-001A Schematic, Main Board

CAM-14 Acquisition Module

421315-001

Revision A5-32

Page 81

A Appendix A:

Abbreviations

Standard Abbreviations ................................................................. 3

Revision A

CAM-14 Acquisition Module

421315-001

A-1

Page 82

A-2

CAM-14 Acquisition Module

421315-001

Revision A

Page 83

Standard Abbreviations

A

Aampere

A-ang antianginal

A-arh antiarrhythmic

A-coa anticoagulants

A-hyp antihypertensive

A1 - A4 auxiliary leadwires

AAMI American Association of Medical

Instrumentation

ABP ambulatory blood pressure

ac, AC alternating current

ACLS Advanced Cardiac Life Support

A/D analog-to-digital

Adj adjustable

AG automotive glass

Ah ampere hou rs

AHA American Heart Association

Al aluminum

AllRam all RAM

AllSec all sector

AllTrk all track

ALT alternate

Alt-Off alternate offset

am, AM acquisition module, ante meridiem

AM-1 acquisition module-1

AM-1M acquisition module-1 modified

AM-2 acquisition module-2

AM-3 acquisition module-3

AM-4 acquisition module-4

amp ampere

Ampl amplifier

AMU ambulatory monitoring unit

ANA analog

ANLG analog

AnsrTone answer tone

A/O Analog Output

ASCII American Standard Code for Information

Interchange

ASSY assembly

Attn attention

AUG August

AUST Australian

AUSTRALN Australian

Auto automatic

AutoRhym automatic rhythm

AUX auxiliary

aVF augmented left leg lead

avg average

aVL augmented left arm lead

aVR augmented right arm lead

AWG American Wire Gage

B

Bd board, baud

BDGH binding head

BetaB beta blockers

BKSP backspace

BLK black

BLU blue

Blvd boulevard

BP blood pressure

BPM beats per minute

BRIT Britain

BRN brown

BSI British Standards Institute

Btu British thermal unit

C

CalcBlk calcium blockers

CAPOC Computer Assisted Practice of

Cardiology

CASE Computer Aided System for Exercise

Catoprl Catopril

Cauc Caucasian

Cer ceramic

CFM cubic feet/minute

CGR computer graphic record

Ch, CH channel

C/L center line

CLK clock signal

Clonid Clonidine

cm centimeter

cm2 square centimeters

Cmd command number

CMMR common mode rejection ratio

CMOS complementary metal-oxide

semiconductor

c/o in care of

COM1 communications port 1

COM2 communications port 2

ComLink communications link

Comp composition

Confrmd confirmed

Cont, CONT Continent a l, continued

Coumadn Coumadin

CPR cardiopulmonary resuscitation

CPU central processing unit

CR diode

Revision A A-3

CAM-14 Acquisition Module

421315-001

Page 84

CRC cyclic redundancy check

CRD cord

crt, CRT cathode ray tube

CSA Canadian Standards Association

CTRL control

D

D/A digital to analog

DA damping relay

dac, DAC digital-to-analog converter

DAN Danish

Dat/Tim date/time

dBm decibel (referenced to 1 milliwatt into

600 ohms)

dc, DC direc t current

DD double density, day

DDD Digital Diagnostic Diskette

DEC Digital Equipment Corporation,

December

Del delete

DEMO demonstration

DES designation

DevId device identification

Diag diagnostic

Digital Digitalis

Digitox Digitoxin

Digox digoxin

Digoxin Digoxin-Lanoxin

DIP dual in-line package

Dirctry directory

Diurt diuretics

DOB date of birth

DOS disk operating system

DP diametral pitch

DPST double-pole, single-throw

DRAM dynamic RAM

DR/DT digital recording/digital transmission

DSKTP desktop

Dysopyr Dysopyramide

E

EPLD electrically programmable logic device

EPROM eraseable, programmable, read-only

memory

ESD electrostatic discharge

etc, etc. et cetera

EURO Europe, European

EXP Expanded

F

F fuse, Farad, female

F1-F5 function keys 1 through 5

Fax facsimile

FCC Federal Communications Commission

FE front end

FILH fillister head

FLH flat head

FLRAM flash RAM

FR French

FrntEnd front end

FSK frequency shift keying

ft foot, feet

Furosem Furosemide

G

g gram, acceleration due to gravity

GB Great Britain

GERM German, Germany

GND ground, digital ground (dc common)

GRN green

GRY gray

H

H high, vector electrode site, vector lead

HDLC high-level data link control

Hex, HEX hexagon, hexadecimal

HH hour

HiRes high-resolution

Hr hour

Hydral Hydralazine

Hz Hertz (cycles per second)

E enable, vector electrode site, vector lead

ecg, Ecg, ECG electrocardiogram

ECO Engineering Change Order

EDIC Electrocardiograph Digital Inform ation

Center

EEPROM electrically erasable programmable ROM

e.g. for example

EGA enhanced graphics adapter

EMF electromotive force

EMI electromagnetic interference

ENG English

EOF end of file

EPIC Electronic Patient Information Chart

CAM-14 Acquisition Module

421315-001

I

I on, input, vector electrode site

I, II, III limb leads

II vector lead

IC integrated circuit

ID identification

i.e. that is

IEC International Electrotechnical Commission

in inch

IN input

inc, inc., INC incorporated

Info information

Revision AA-4

Page 85

Ins insert

I/O input/ ou tp ut

I/P input

ISA industry standard architecture

Isosorb Isosorbide

IT Italian, Italy

J

JAN January

JIS Japan Industrial Standards

K

k, K kilo, 1000, 1024

Kb, KB kilobyte

kg, Kg kilogram

kHz, KHz kilohertz

kV, KV kilovolt

Kyb keyboard

L

Lline

L1 level one

L2 level two

LA left arm

lb pound

LCD liquid crystal display

Lcl Line local line

Ld Grps lead groups

LED light-emitting diode

LH left hand

Lidoca Lidocaine

LL left leg

Loc location

LocPc Local MAC PC

LogRetry log retry

Ltd limited

M

m meter

M megabyte, metric, vector electrode site,

vector lead, male

mA milliamperes

MAC Microcomputer Augmented Cardiograph

mains voltage voltage of a supply mains between 2 line

conductors of a polyphase system or

voltage between the line conductor and

the neutral of a single-phase system

max maximum

Measure measurements

Med medications

MEM memory

MF metal film

MHz megahertz

min minutes, minimum

Misc miscellaneous

mm millimeter

MM minute

MMM month

mm/mV millimeter per millivolt

mm/s millimeter per second

MMS Marquette Medical Systems

Modem modulator/demodulator

MOS metal oxide semiconductor

MPE metallized polycarbonate expitaxial

ms milliseconds

MS-DOS Microsoft Disk Operating System

MTBF mean time between failures

mtg mounting

MTR MOTOR

MUSE Marquette Universal System for

Electrocardiography

mux multiplexer

mV millivolt

mVR minus (inverted) aVR

N

N neutral

n/a not available

NA not applicable

NC no connection

Nitrate nitrates

NLQ near letter quality

NMI non-maskable interrupt

NMOS N-channel metal-oxide semiconductor

No number

NO normally open

norm no rmal

nS nanoseconds

NSR Normal Sinus Rhythm

O

O off, original

OE other errors

OEM original equipment manufacturer

OH off-hook relay

OneSec one sector

ORG orange

Orig original

OUT output

oz ounce

P

P P wave (section of the ECG waveform)

p-p peak-to-peak

PA P wave amplitude

Params parameters

Revision A A-5

CAM-14 Acquisition Module

421315-001

Page 86

Passwds passwords

PatData patient data

PatInfo patient information

PATN patient

PC printed circuit, personal computer

PCB printed circuit board

pF picofarad

Pgm program

PgmId program identification

Phenoth Phenothiazide

Phenytn Phenytoin

PID patient identification digit

PLCC plastic leadless chip carrier

PM power module

pm, PM post meridiem, preventive maintenance

PM-2 Power Module-2

PM-3 Power Module-3

pn, PN part number

PNH pan head

PPA P wave amplitude

PR ECG signal interval

Pro-Off progressive offset

Procain Procainamide

PROM programmable read-only memory

Propran Propranolol

PSK phase shift keying

PSU power supply unit

Psych psychotropic

PUP pull-up signal

PVC polyvinyl chloride

PWM pulse-width modulation

PWR power

PWR CRD power cord

Q

Qtransistor

QA quality assurance, Q wave amplitude

QAD Quality Assurance Deviation

QAM quadrature amplitude modulatio n (phase

and amplitude modulation)

QC quality control

QD Q wave duration

QRS QRS complex (portion of ECG waveform),

interval of ventricular depolarization

QT QRS interval

QTC QRS interval

QTY quantity

Quinid Quinidine

R

R resistor, red, reset

RA right angle, right arm or R wave

amplitude

RAM random access memory

RC resistor capacitor

RD R wave duration

Ref reference, refresh

REN Ringer Equivalence Number

Reserp Reserpine

REV revision

RevdBy reviewed by

RevXmit reverse transmission

rf radio frequency

RFI radio frequency interference

RGB red, green, blue

RI ring indicate

RL right leg

RMR Rhythm and Morphology Report

ROM read only memory

RPA R wave amplitude

RPD R wave duration

rpt, Rpt report

RTC real time clock

RTI relative to patient input

RTN return

RVS reverse

R/W read/write

S

12SL 12 simultaneous leads

s, S second, select, switch

SA s wave amplitude

SB slow-blow

SCL safe current limits

SD schematic diagram, S wave duration

SE serial input/output errors

sec second

sec.s seconds

SEER Solid-state Electronic ECG Recorder

SING Singapore

SP Spanish

SPA S wave amplitude

SPDT single-pole, double-throw

SRAM static RAM

ST-T ST-T wave (section of the ECG

waveform)

standrd, Standrd standard

STD standard

STE ST segment displacement at the end

STJ ST segment displacement at the J point

STM ST segment displacement at the mid-

point between STJ and STE

stmts, Stmts statements

SumRam some RAM

supply mains permanently installed power source

SVT power cord type; 300 V

sw, SW switch, software

SW Swedish, Sweden

CAM-14 Acquisition Module

421315-001

Revision AA-6

Page 87

T

X

T Tone touch tone

TA T wave amplitude

Tant tantalum

TDML treadmill

TE timeout errors

Tech technical

Thiazid Thiazide

TM trademark

Tot total number or errors

TP test point

TPA T’ wave amplitude

TRAM Transport Remote Acquisition Monitor

Tricyli Tricylic antidepressant

TTL transistor-transistor logic, TTL levels

TVS transient voltage suppressor

U

UE undefined errors

uF microfarad

UL Underwriters’ Laboratory, Inc

Unconf unconfirmed

UUT unit-under-test

V

v, V volt, volts

V1-V6 precordial leads

V123 V1, V2, V3

V3R precordial lead

V456 V4, V5, V6

V4R precordial lead

V ac volts, alternating current

V dc voltage, direct current

VA volt-amperes

Var variable

VDE Verband Deutscher Ele ktrotechn iker

(German regulatory agency)

Vent. ventricular

VF ventricular fibrillation

VGA video graphics array

VIA versatile interface adapter

VIO violet

Volt voltage

VRAM video RAM

vs versus

x by (as in “8-1/2 x 11”)

XCV transceiver

XYZ orthogonal leads

Y

Y year, yellow

yr year

yrs years

YY year

Symbols

↑ SHIFTed or alternate function

µ micro

µFmicrofarad

µs, µsec microsecond

68K 68000

&and

#number

°C degrees Celsius

°F degrees Fahrenheit

Ω Ohm, ohm

% percent

registered

> greater than

< less than

± plus or minus

* An asterisk after a signal name indicates

the signal is active at its relatively lower

potential, or “active-low.” Signals

without the asterisk suffix are active at

their relatively higher potential, or

“active-high.”

12SL 12 simultaneous leads

W

w/ with

Wwatt

Warfar Warfarin

WHT white

WI Wisconsin

Revision A A-7

CAM-14 Acquisition Module

421315-001

Page 88

CAM-14 Acquisition Module

421315-001

Revision AA-8

Loading...

Loading...