Page 1

GE Consumer & Industrial

Technical Service Guide

February 2009

GE Café™

Radiant Range

31-9182

CS980SN1SS

1

2

3

4

5

S

ta

rt

6

7

8

9

0

GE Appliances

General Electric Company

Louisville, Kentucky 40225

Page 2

IMPORTANT SAFETY NOTICE

!

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the

in ter pre ta tion of this in for ma tion, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this prod uct. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2009

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2 –

Page 3

Table of Contents

Component Locator Views ...........................................................................................................................................10

Control Features ................................................................................................................................................................ 7

Control Panel .....................................................................................................................................................................13

Convection Fan Assembly ............................................................................................................................................ 18

Cooling Blower ................................................................................................................................................................. 18

Diagnostics and Service Information .....................................................................................................................23

Door Lock Assembly .......................................................................................................................................................21

Electronic Range Control (ERC) ..................................................................................................................................13

Electronic Range Control (ERC) Pin Locator ..........................................................................................................20

ERC Failure Codes ............................................................................................................................................................. 23

Griddle Operation ............................................................................................................................................................17

Ground Strap Installation for 3-Wire Power Cord ........................................................................................... 6

Introduction ......................................................................................................................................................................... 4

Lower Oven Bottom Element ..................................................................................................................................... 14

Lower Oven Control ........................................................................................................................................................15

Lower Oven Drawer ........................................................................................................................................................12

Lower Oven Operation .................................................................................................................................................. 16

Lower Oven Top Element .............................................................................................................................................14

Nomenclature .................................................................................................................................................................... 5

Range Components ........................................................................................................................................................ 12

Range Lockout Relay .....................................................................................................................................................17

Rangetop ............................................................................................................................................................................. 12

Schematic.............................................................................................................................................................................24

Thermal Switch ................................................................................................................................................................. 19

Warranty .............................................................................................................................................................................. 25

– 3 –

Page 4

Introduction

*The new

GE Café™

Extra Large Capacity (5.0 cu. ft.) Self-Clean •

Convection Oven.

PreciseAir™ Convection System ― Features •

an innovative fan that reverses direction for

optimal air and heat circulation, providing

even cooking and precise baking and roasting

results.

Single/Multi-Rack Convection Bake ― Provides •

ideal convection airfl ow throughout the oven

cavity, using True European convection, to

deliver consistent heat and optimal results on

both racks.

Lower Oven ― Offers an additional 1.0 cu. ft. •

of capacity for convenient baking from 150

degrees to 450 degrees.

Dual Size Ribbon Element ― Offers a convenient •

choice of using a 9" or 12" heating element,

depending on the size of the pan.

Radiant Ranges have the following features:

Warming Zone ― Provides low heat capability •

for foods, making meal coordination simple.

Pre-seasoned Cast Iron Griddle ― Provides •

an extra-large cooking surface for meats,

pancakes or other food usually prepared in a

frying pan or skillet. Integral feet attached to

the bottom of the Griddle allow it to be placed

on the rangetop and heated by one or both of

the left side elements. The Griddle can be used

in the oven.

Range Lockout ―Allows consumer to lock out •

surface units, oven burners and control panel

so they cannot be activated.

* Features may vary by model.

Griddle Bottom

Griddle Top

Foot (1 of 4 shown)

– 4 –

Page 5

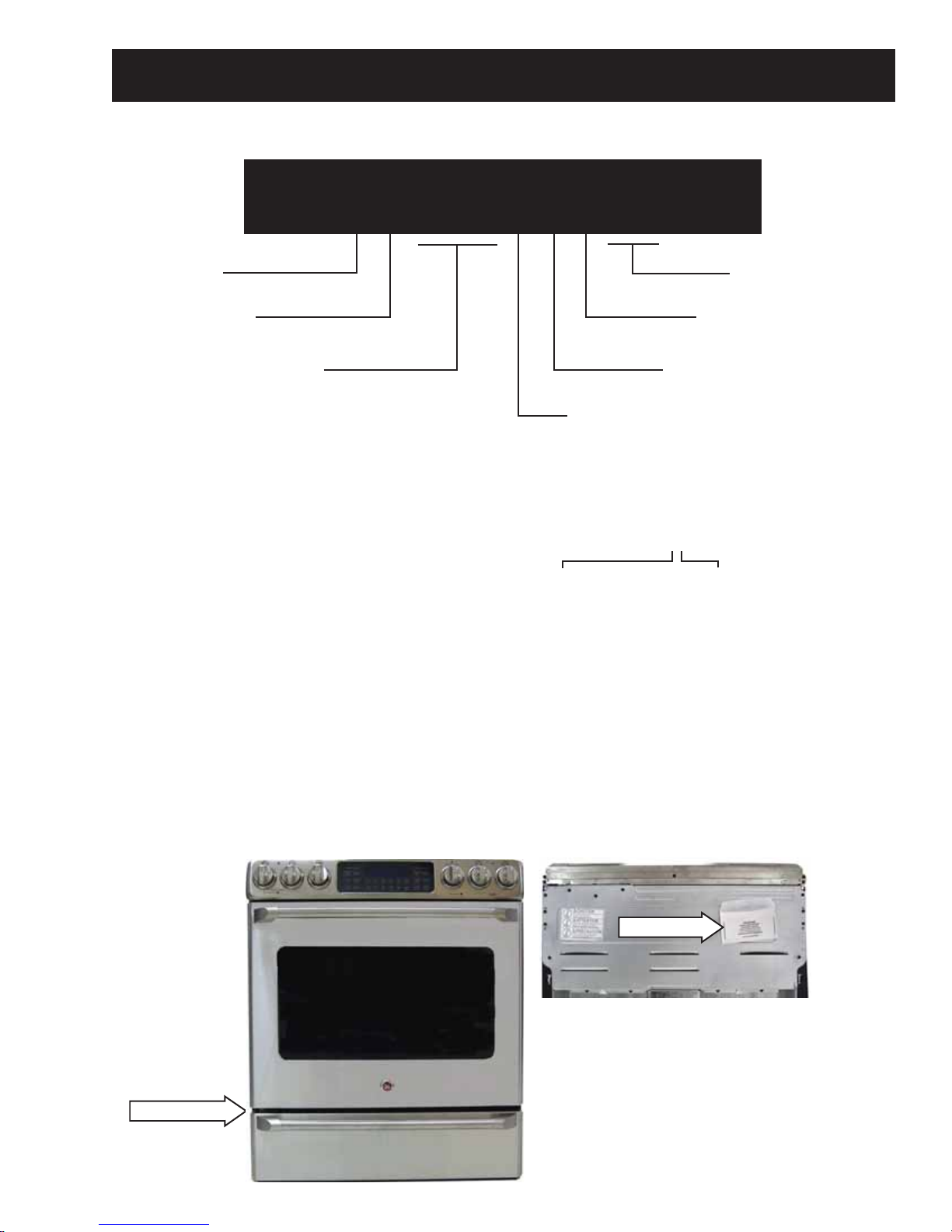

Nomenclature

C S 9 8 0 S N 1 S S

C = GE Café™

S = Slide-In

Feature Pack

The nomenclature tag of this range

is located on the oven frame behind

the lower oven drawer.

In addition to the model and serial

numbers, this tag shows the supply

voltage requirements and wattage

ratings of the elements.

The mini-manual is located behind the

range on the upper back panel.

SS = Stainless Steel

Engineering Code

Model Year

Model - Stainless

Serial Number

The fi rst two numbers of the serial number

identify the month and year of manufacture.

Example: AS123456S = January, 2009

A - JAN 2009 - S

D - FEB 2008 - R

F - MAR 2007 - M

G - APR 2006 - L

H - MAY 2005 - H

L - JUN 2004 - G

M - JUL 2003 - F

R - AUG 2002 - D

S - SEP 2001 - A

T - OCT 2000 - Z

V - NOV 1999 - V

Z - DEC 1998 - T

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

Nomenclature

Mini-manual

– 5 –

Page 6

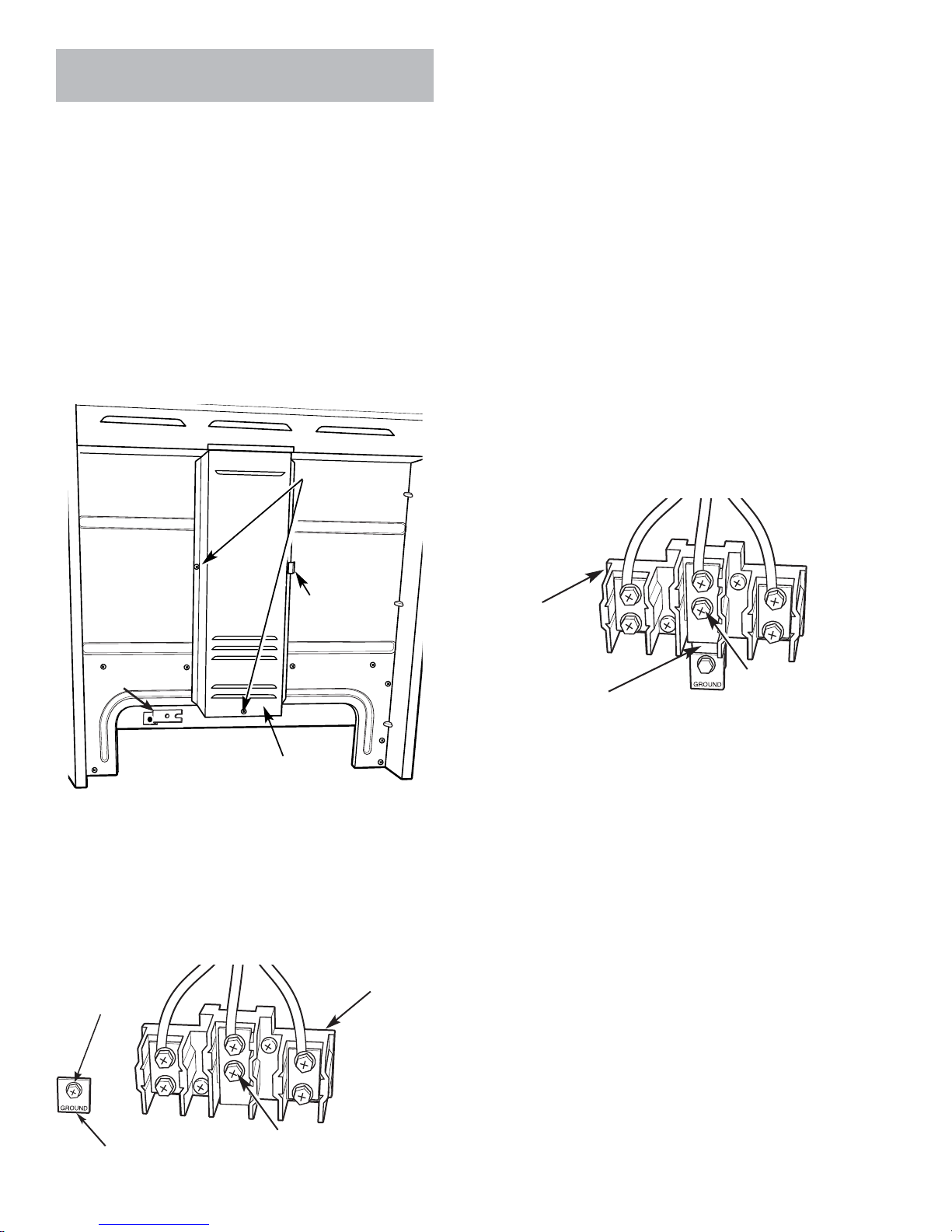

Ground Strap Installation for 3-Wire Power

Ground strap

Ground screw

Cord

Remove the two 1/4-in. hex-head screws and 1.

the wire cover from the back of the range.

WARNING: The neutral or ground wire of the power

cord must be connected to the neutral terminal

located in the center of the terminal block. The

power leads must be connected to the lower left

and the lower right terminals of the terminal block.

2. Remove the 1/4-in. hex-head screw that

attaches the copper ground strap to the lower

back of the range. Retain the copper ground

strap and return the screw to this location.

2 screws to

remove wire

cover

4. Remove the lower center screw (if present) and

loosen the upper center screw on the terminal

block.

5. Slide the open slotted end of the ground strap

under the upper center screw on the terminal

block. Make sure the ground strap is all the way

against the upper center screw and tighten it in

place.

Note: In the following step, be sure that the ground

strap does not contact any insulation that would

prevent full contact with the range frame.

6. Place the metal ground plate over the bottom of

the copper ground strap with the word GROUND

facing away from the range frame. Press strap

and plate against the range frame and attach

them with the ground screw.

7. Install the lower center screw removed in step 4.

Retaining

tab

Ground strap

Back of range

Wire cover

3. Remove the 1/4-in. hex-head ground screw,

located to the left of the terminal block, that

attaches the metal ground plate to the lower

back of the range. Retain the metal ground plate

and ground screw.

Terminal

Ground screw

block

Terminal

block

Ground strap

8. Complete the 3-wire power cord or 3-wire

conduit installation as appropriate for your

application.

Note: Wire used, location of splices, etc., must

conform to good wiring practices and local codes.

9. Place the wire cover under the retaining tab and

install the two 1/4-in. hex-head screws and the

wire cover to the back of the range.

Neutral

terminal

Neutral

Ground plate

terminal

– 6 –

Page 7

Control Features

Using the upper oven controls.

Using the upper oven controls.

(Throughout this manual, features and appearance may vary from your model)

Features and appearance may vary.

Oven Control, Clock, Timer and Features

BAKE Pad

Touch to select the bake function.

BROIL HI/LO Pad

Touch to select the broil function.

CONVECTION BAKE MULTI/1 RACK Pad

Touch to select baking with the convection

function.

CONVECTION ROAST Pad

Touch to select roasting with the convection

function.

START Pad

Must be touched to start any cooking or

cleaning function.

Display

Shows the time of day, oven temperature,

whether the oven is in the bake, broil

or self-cleaning mode, the times set for

the timer or automatic oven operations,

and if the range is locked.

SELF-CLEAN Pad

Touch to select self-cleaning function.

See the Using the self-cleaning oven section.

If “F– and a number or letter” flash in the display

and the oven control signals, this indicates a

function error code. Touch the CLEAR/OFF pad. Allow

the oven to cool for one hour. Put the oven back into

operation. If the function error code repeats, disconnect

the power to the oven and call for service.

If your oven was set for a timed oven operation

and a power outage occurred, the clock and all

programmed functions must be reset.

The time of day will flash in the display when there

has been a power outage.

OVEN LIGHT Pad

Touch to turn the oven light on or off.

DELAY START Pad

Use along with COOKING TIME or SELF

CLEAN pads to set the oven to start and

stop automatically at a time you set.

COOKING TIME Pad

Touch and then touch the number pads to set

the amount of time you want your food to

cook. The oven will shut off when the cooking

time has run out.

CLEAR/OFF Pad

Touch to cancel ALL upper oven operations

except the clock, timer and Range Lockout.

CLOCK Pad

Touch before setting the clock.

Number Pads

Use to set any function requiring numbers

such as the time of day on the clock, the

timer, the oven temperature, the internal food

temperature, the start time and length of

operation for timed baking and self-cleaning.

KITCHEN TIMER ON/OFF Pad

Touch to select the timer feature.

PROBE Pad

Touch when using the probe to cook food.

RANGE LOCKOUT Pad

Touch the RANGE LOCKOUT pad and then

touch the START pad to lock/unlock the surface

units, oven burners and control panel so they

cannot be activated.

(Continued next page)

– 7 –

Page 8

Adjust the upper oven thermostat.

Adjust the upper oven thermostat.

Using the lower oven drawer.

Adjust the lower oven thermostat.

Note: This adjustment will not affect the broiling or the self-cleaning temperatures. The adjustment will be retained in memory after a

power failure.

To Adjust the Thermostat

Touch the BAKE and BROIL HI/LO pads at the same time

1

for 3 seconds until the display shows SF.

Touch the BAKE pad. A two digit number shows in the

2

display.

Touch BAKE once to decrease (-) the oven temperature, or

twice to increase (+).

Using the lower oven drawer.

To Use the Lower Oven Drawer

Push in and turn the lower oven drawer knob to any

1

desired setting.

Allow the lower oven drawer to preheat.

2

The ON signal light is located on the upper right side of

the knob and glows when the knob is in the ON position. It

remains ON until the knob is moved to the OFF position.

The “Heating” signal light is located below the ON signal

light and glows when the heating elements are active.

Preheat is complete after the “Heating” signal has turned

off for the fi rst time with each use.

The oven temperature can be adjusted up as much as

3

35°F or down as much as 35°F. Touch the number pads

the same way you read them. For example, to change the

oven temperature 15°F, touch 1 and 5.

When you have made the adjustment, touch the START

4

pad to go back to the time of day display. Use the oven as

you would normally.

Note: The thermostat adjustment for Baking will also

affect Convection Baking or Convection Roasting.

Notes:

Always use the included drawer rack when using the

Lower Oven Drawer.

The lower oven drawer cannot be used during a self-clean

cycle of the upper oven.

Do not put food, foil or cookware directly on the bottom

of the lower oven drawer. Always use the included drawer

rack.

If foods require a cover, use only foil or lids able to

withstand baking temperatures. Do not use plastic.

Maximum height of foods that can be placed in the lower

oven drawer is 4".

Do not put liquid or water in the lower oven drawer.

Adjust the lower oven thermostat.

Note: This adjustment will not affect the broiling temperatures.

To Adjust the Thermostat

Pull the OVEN CONTROL knob off the range and look

1

at the back side. To make an adjustment, loosen

(approximately one turn), but do not completely remove,

the two screws on the back of the knob.

With the back of the knob facing you, hold the outer edge

2

of the knob with one hand and turn the front of the knob

with the other hand.

To raise the oven temperature, move the top screw toward

the right. You’ll hear a click for each notch you move the

knob.

Never place plastics, paper, canned foods or combustible

material in the lower oven drawer.

To lower the temperature, move the top screw toward the

left.

Each click will change the oven temperature

approximately 10°F. (Range is ± 60°F. from the arrow.) We

suggest that you make the adjustment one click from

the original setting and check oven performance before

making any additional adjustments.

After the adjustment is made, retighten screws so they are

snug, but be careful not to overtighten.

Re-install knob on range and check performance.

(Continued next page)

– 8 –

Page 9

Using the griddle.

Using the griddle.

Care and cleaning of the griddle.

The non-stick coated griddle provides an extra-large

cooking surface for meats, pancakes or other food

usually prepared in a frying pan or skillet.

Note: The griddle will discolor over time as it becomes

seasoned with use.

How to Place the Griddle

Caution: Place and remove the griddle only when the

griddle is cool and all surface units are turned off.

IMPORTANT: Always place and use your griddle on the

left surface units only.

Note: Do not clean the griddle in the self-cleaning oven.

Most griddled foods require cooking on a preheated

surface. Preheat griddle then switch to the desired cook

setting.

Care and cleaning of the griddle.

Cast Iron Griddle

Rinse with hot water (do not use soap), and dry

1

thoroughly.

Before cooking, prepare the surface with cooking spray

2

or vegetable oil.

After cooking, clean the griddle with a stiff brush and

3

hot water. Using soap is not recommended, and harsh

detergents should never be used.

Towel dry immediately and apply a light coat of cooking

4

spray or vegetable oil while the griddle is still warm.

Store in a cool, dry place.

5

Do not wash in a dishwasher.

6

Griddle Precautions:

If something has spilled under the griddle, it should •

be cleaned up as soon as possible to prevent “baked

on” food soil. Do not allow grease to accumulate

under the griddle as it can be a fi re hazard. Clean

under the griddle as soon as it is cool.

To turn on the surface units for the entire griddle, turn the

knob clockwise.

To turn on the surface unit for the back half of the

griddle, turn the knob counterclockwise.

Caution: The entire griddle will still become hot.

IMPORTANT NOTES:

Avoid cooking extremely greasy foods and be careful of

grease spillover while cooking.

Never place or store any items on the griddle, even when

it is not in use. The griddle can become heated when

using the surrounding surface units.

Re-Seasoning the Cast Iron Griddle

Seasoning is the process of vegetable oil absorbing

into the pores of the iron griddle. The griddle was

seasoned during manufacture. If food sticks to the

surface, or you notice a dull, gray color, the griddle

will need to be re-seasoned.

Wash the griddle with hot, soapy water and a stiff

1

brush. (It is okay to use soap this time because you

are preparing to re-season the griddle).

Rinse and dry completely.

2

Apply a thin, even coating of MELTED solid

3

vegetable shortening (or cooking oil of your choice)

to the griddle (top, sides, and bottom).

Place aluminum foil on the bottom rack of the oven

4

to catch any dripping.

Set oven temperature to 350 – 400 degrees F.

5

Do not place the griddle in the microwave.•

Always turn off all surface units before removing the •

griddle. Use caution when handling a hot griddle.

– 9 –

Place griddle upside down on the top rack of the

6

oven.

Bake the griddle for at least one hour. After the

7

hour, turn the oven off and let the griddle cool in the

oven.

Store the griddle uncovered, in a cool, dry place

8

when cooled.

Page 10

Component Locator Views

Front View (Shown with Oven Door Removed)

Control Panel

Meat Probe Outlet

Convection Fan

Broil Element

Oven Temperature Sensor

Lower Oven Drawer

Lower Oven Compartment (Shown with Lower Oven Drawer Removed)

Thermostat Capillary Tube

Bake Element

Broil Element

Bake Element

Roller Catch

(Continued next page)

– 10 –

Page 11

Rear View (Shown with Back Cover, Terminal Cover and Griddle Relay Cover Removed)

Cooling Fan

Broil Element

Convection Element

Convection Fan Motor

Range Lockout Relay

Bake Element

Griddle Relay #1

Griddle Relay #2

Rangetop (Shown with Rangetop wire harnesses and ground wire disconnected.)

Hot Surface Indicator Light Assembly

Dual Surface Element

Dual Surface Element

Single Surface Element

Single Surface Element

Cook-Warm Zone Surface Element

Thermal Switch

– 11 –

Page 12

Range Components

WARNING: Sharp edges may be exposed when servicing. Use caution to avoid injury. Wear Kevlar gloves or

equivalent protection.

Lower Oven Drawer

The lower drawer can be removed by pulling the

drawer straight out until it stops, pressing the tabs

fi rmly inward on both sides of the drawer rails and

pulling the drawer forward until disengaged from

the drawer guides.

Note: When in the closed position, the strike on the

back of the drawer is captured by the roller catch.

The strike is riveted in place and is not adjustable.

The roller catch is attached to the range fl oor with

two 1/4-in. hex-head screws that, when loosened,

can provide a small amount of adjustment.

Range Floor

Back of Drawer

Roller Catch

Strike

Rangetop

To remove the rangetop:

Pull out the range from its installation.1.

The lower drawer can be installed by placing each

drawer rail around each inner rail guide and sliding

both in slightly to hook them, then fi rmly sliding the

drawer all the way in.

Remove the three 1/4-in. hex-head screws that 2.

attach the vent trim to the rangetop.

Lift and remove the vent trim.3.

Vent Trim

4. Remove the two 1/4-in. hex-head screws that

attach the rangetop to the range.

Rangetop

5. Raise the rear of the rangetop, then slide the

rangetop toward the rear of the range about 6

inches.

– 12 –

(Continued next page)

Page 13

6. Remove the two 1/4-in. hex-head screws and

the heat shield from the range.

Heat Shield

3. Remove the 2 Phillips-head locator pins from the

top of the range.

4. Place a towel or protective item across the top

of each side panel.

5. Slide the control panel forward, rotate and place

the panel top down across the range on the

protective surfaces as shown.

Note: When installing

Locator Pin

rangetop, be sure to

engage slots in rangetop

underneath locator pins.

7. Disconnect the 2 rangetop wire harnesses.

8. Remove the 1/4-in. hex-head screw that

attaches the ground wire to the range.

Disconnect

Disconnect

9. Carefully lift the rangetop and place it on a

protective surface.

Service Position

Electronic Range Control (ERC)

The ERC is attached to a bracket that houses the

touch panel. It is necessary to remove the bracket

from the control panel to access the screws that

attach the ERC. Viewed in the service position, the

bracket is attached with 2 Phillips-head screws at

the top and 2 tabs at the bottom that lock into a fold

in the control panel.

To remove the electronic oven control (ERC):

Place the control panel in the service position. 1.

(See Control Panel.)

Mark and disconnect all wiring from the ERC.2.

Note: When installing the rangetop, be sure both

rangetop wire harnesses are positioned underneath

the heat shield.

Control Panel

To access the control panel:

Remove the rangetop. (1.

Remove the 4 Phillips-head screws from the 2.

bottom of the control panel.

See Rangetop.)

Remove the 2 Phillip-head screws from the top 3.

of the control panel.

(Continued next page)

– 13 –

Page 14

4. Carefully lift the 2 tabs out from the panel fold,

then remove the ERC from the control panel.

4. Reach behind the element and pull off the 2

element wire connectors.

5. Remove the two 1/4-in. hex-head screws that

attach the element to the oven fl oor.

Tab

Panel Fold

Tab

5. Remove the four T-15 torx screws that attach

the ERC to the bracket.

Lower Oven Bottom Element

To remove the lower oven bottom element:

Remove the lower oven drawer. (See 1. Lower Oven

Drawer.)

Remove the 2 slotted screws and the oven rear 2.

panel.

6. Remove element from the oven.

Note: When installing the element, be sure to place

element under the 3 retainers before installing

element-to-fl oor screws.

Retainers

Lower Oven Top Element

To remove the lower oven top element:

Remove the lower oven drawer. (See 1. Lower Oven

Drawer.)

Remove the 2 slotted screws and the oven rear 2.

panel. (See Lower Oven Bake Element.)

Oven Rear Panel

3. Remove the two 1/4-in. hex-head screws that

attach the bottom element terminal cover.

Place cover aside.

Remove the two 1/4-in. hex-head screws that 3.

attach the top element terminal cover. Place

cover aside.

(Continued next page)

– 14 –

Page 15

4. Reach behind the element and pull off the 2

element wire connectors.

5. Remove the six 1/4-in. hex-head screws that

attach the top element to the oven ceiling.

Lower Oven Control

To remove the lower oven control:

Remove the rangetop. (See 1. Rangetop.)

6. Squeeze and remove the capillary bulb clips and

remove them from the holes in the oven ceiling.

Holes in Ceiling

7. Remove the 4 Phillips-head screws and the

locator pin from the top of the left side panel.

8. Remove the six 1/4-in. hex-head screws from

the back of the left side panel.

9. Carefully spread the rear of the left side panel

out from the range approximately 10 inches.

Remove the lower oven control knob. 2.

Remove the 2 Phillips-head screws and the 3.

control from the control panel.

4. Mark and remove the wires from the control.

5. Push up and release the capillary bulb from

each capillary bulb clip.

Capillary Bulb Clip

Capillary Bulb

10. Push the capillary bulb through the entry hole

while pulling the capillary from the range.

– 15 –

Page 16

Lower Oven Operation

Note: The lower oven cannot be used during a self-clean cycle of the upper oven.

The lower oven operates in the following manner:

When the lower oven control is turned counterclockwise,

The control contacts • COM to NO close supplying L1 to the baking elements, pilot lamp and heating lamp.

The pilot lamp will be lit because neutral is not interrupted.•

The control cycling contacts • N to H close supplying Neutral to the baking elements and heating lamp.

Note: When the control is turned counterclockwise, both elements are at L1 potential regardless of the status

of contacts N to H. Neutral is cycled to control oven temperatures.

– 16 –

Page 17

Range Lockout Relay

The range lockout feature (on some models), allows

the user to lockout the surface units, upper oven,

and control panel so they cannot be activated.

When the control is set for RANGE LOCKOUT, the

control deactivates the upper oven and control

panel and energizes the lockout relay that locks out

the surface units so they cannot be activated. (See

Control Features.)

The control RY3 relay will close and complete the

circuit that supplies the voltage to the lockout relay.

Griddle Operation

The griddle, placed over the left side surface

elements, can be heated using the rear element

only or both the front and rear elements at the

same time. Two relays are used to allow only the left

rear infi nite heat switch to operate both front and

rear elements.

When the left rear control is turned clockwise to

select griddle:

P2 closes to 4, supplying L1 voltage to the left •

rear element.

The relay is also energized when the oven door is

locked (COM to NO closed). When energized, the

lockout relay will open contacts 7 to 1 and 9 to 3,

disconnecting L2 from the surface units.

EOC

SW4 LATCH

COM

NO

NC

TO LOWER OVEN

THERMOSTAT

TO SURFACE

UNITS

Relay 1 (now operating on 240VAC) simultaneously:

Disconnects the left front control element •

cycling contacts, P1 to 2, and connects both left

front elements directly to L2.

Connects L1 voltage directly to both left front •

elements.

Contacts P1 to 2, on the left rear control, now cycle

L2 voltage to both the left rear element and to relay

1, which now operates both left front elements.

P2 closes to S2, supplying L1 voltage to the left •

surface indicator light.

P2 closes to 4a, supplying L1 voltage to the •

griddle ON indicator light, relay 1 and relay 2.

Relay 2 (now operating on 120VAC) disconnects •

L1 voltage from the left front control.

Note: With the griddle turned off and the left rear

hot surface light on (glass temperature above

150°F), 27 VAC will be applied to relay 2 and 97 VAC

will be applied to relay 1. During this time, both

relays may produce a slight hum/vibration. Neither

relay will be operating. The hum/vibration will cease

once the hot light switch contacts 1b to 2b open.

– 17 –

Page 18

Cooling Blower

Convection Fan Assembly

The two-speed cooling blower is located on the rear

of the range. Air is pulled in by the blower blades

through slots below the control panel and circulated

in the space below the component compartment

and above the top of the oven liner. The air is

exhausted through the right side of the oven vent

trim.

Low speed is used for cooking functions and high

speed is used only in the self-clean mode. The

blower is operated by the ERC (a function of oven

temperature), when cooling timing parameters are

met. Blower speed is determined by the position of

door latch switch #3. (See Door Lock Assembly.)

Cooling Timing Parameters

The cooling blower will not turn on immediately

when a cooking function is set. IT WILL TURN

ON WHEN THE OVEN TEMPERATURE REACHES

APPROXIMATELY 450°F. If the oven is turned off and

the blower is running, the blower will remain on until

the oven temperature drops to below 300°F.

Cooling blower motor approximate resistance

values:

Low speed (C to L) = 20 • Ω

High Speed (C to H) = 24 • Ω

The convection fan assembly is located on the

back wall of the oven cavity and consists of the

convection cover, fan blade, and motor. The fan

motor utilizes a capacitor that can be accessed

from the back of the range. (See Component Locator

Views.) The convection fan blade can be removed

from inside the oven. The convection fan motor can

be removed from the back of the range.

The convection fan operates during the following

modes:

Preheat•

Convection Bake•

Convection Roast•

The convection fan will turn on after a short delay.

The fan may cycle on and off, and change direction

in any of these modes, to best distribute hot air in

the oven. The convection fan shuts off when the

door is opened.

The convection element is located on the upper

oven back wall and can be removed from inside the

oven cavity.

The element is rated at 1200 watts, has an

approximate resistance value of 12 Ω, and draws

approximately 10 amps.

To remove the cooling blower, it is necessary to

remove the rangetop (See

Rangetop.), and rear

panel. The cooling blower assembly is attached with

six 1/4-in. hex-head screws.

L

H

C

OPERATING CHARACTERISTICS

Convection Bake - Single Rack preheats with

bake element and broil element operating (cycling)

alternately. Heat maintained with bake element.

Fan alternates CW and CCW rotation.

Preheat

Red box indicates cycling contacts

(Continued next page)

– 18 –

Page 19

Heat Maintained

Red Box indicates cycling contacts

Convection Bake - Multi Rack preheats with bake

element and broil element operating (cycling)

alternately. Heat maintained with convection

element only. Fan alternates CW and CCW rotation.

Preheat

Convection Roast preheats with bake element and

broil element operating (cycling) alternately. Heat

maintained with bake element and broil element

operating (cycling) alternately. Fan rotates CCW.

Preheat and Heat Maintained

Red Box indicates cycling contacts

Thermal Switch

The thermal switch is located under the rangetop

on the burner box fl oor and protects the electronics

from damage should a high temperature condition

occur when the range is in the self-clean mode.

Red Box indicates cycling contacts

Heat Maintained

Red Box indicates cycling contacts

Thermal Switch

The thermal switch is wired in series with the lock

motor switches. The thermal switch opens at 265°F.

The switch closes when temperatures cool below

approximately 220°F. If the thermal switch opens

during the following conditions:

Oven Temperature Below 600°F (315°C). •

Program is cancelled when thermal switch

opens. Lock motor will run and the word

LOCKED will be fl ashing in the display.

Oven Temperature Above 600°F (315°C). Any •

mode of operation control will go to -F2- failure

code. When this condition exists, check the

fan operation (look for obstructions), inspect

oven installation (make sure grill areas are not

blocked), oven insulation, and lock circuit.

– 19 –

Page 20

Electronic Range Control (ERC) Pin Locator

TB640

TB102

TB101

TB650

TB655

TB630

TB620

RY 500A1

RY 540B

RY 502A1

RY 501A1

TB660

TB661

CN2 - Sensor, Thermal Switch, Door Lock,

Switch, Door Unlock Switch, Probe

Switch, Door Unlock Switch, Probe

CN950 - Glass Touch Board

RY500A1 - Broil

RY501A1 - Bake

RY502A1 - Convection Element

RY540B - Double Line Break

CN2

CN950

TB101 - L1

TB102 - Neutral

TB620 - Oven Light

TB630 - Door Lock Switch

TB640 - Door Lock Switch, Lock Out Relay

TB650 - Convection Motor CW

TB655 - Convection Motor CCW

TB660 - Door Lock Motor

TB661 - Door Lock Common

– 20 –

Page 21

Door Lock Assembly

The door lock assembly consists of a lock motor

cam and switch assembly (switches #1, #2, #3, and

#4), lock hook, and mounting plate.

The lock motor is energized when the control is set

for CLEAN and START is selected. The RY1 relay

contacts will close and complete the circuit that

supplies the voltage to the lock motor.

UNLOCKED

DOOR LATCH OUTPUT PIN

DOOR LATCHED INPUT PIN

DOOR UNLATCHED INPUT PIN

DOOR LATCH OUTPUT PIN

DOOR LATCHED INPUT PIN

DOOR UNLATCHED INPUT PIN

CN2

CN2

5

4

3

5

4

3

LOCKED

DOOR LOCK DOOR UNLOCK

SW1 LATCH

THERMAL

SWITCH

DOOR LOCK DOOR UNLOCK

SW1 LATCH

THERMAL

SWITCH

SW2 LATCH

SW2 LATCH

• CAM – The cam on the motor performs two

functions:

Positions the lock hook in the door to prevent 1.

opening during clean operation.

Operates the lock switches which tell the control 2.

if the door is unlocked or locked and ready for

clean operation.

Note: When the door is either being locked or

unlocked, both lock switches will be in the open

position.

Switch #3 controls cooling fan motor speed. Hi

speed is used when the self-clean cycle is selected

and the door is locked and low speed for other oven

selections when the door is unlocked.

COOLING FAN

The lock switch circuit “tells” the control if the

lock motor is in the unlocked or locked position or

somewhere in between. There are two lock switches

mounted to and operated by the lock motor.

The lock switch circuit is from the control, through

one of the lock switches (switch #2 for unlocked or

switch #1 for locked), back to the control. If neither

switch is closed, and the oven temperature is below

600°F (315°C), control will energize the lock motor

circuit until the correct switch closes to complete

the circuit. (If circuit to the correct switch is open,

lock motor will run continuously with the oven

below 600°F [315°C].)

Note: If initiating a clean cycle with the door switch

in the “C” to “NC” position (door open), the control

display will fl ash “LOCKED” and will sound a series

of beeps, followed by cancellation of the clean

selection.

• The word “LOCKED” will fl ash on and off in the

display while the lock motor is in motion. When

the door is locked, the word “LOCKED” will remain

illuminated in the display.

Switch #4 locks out the lower oven and all surface

units when the self-clean cycle is selected and the

door is locked.

LOCKOUTS IN CLEAN CYCLE

The door lock motor has an approximate resistance

value of 2K Ω.

The resistance of the door lock motor can be

checked on the ERC. Place the control panel in the

service position. (See

Control Panel.)

With the door closed, test between TB660 (MDL) and

N on the ERC for the approximate resistance value.

– 21 –

(Continued next page)

Page 22

Lock Assembly Removal

The lock assembly is attached to the front of the range by two T-15 Torx screws. To replace the door lock it

is necessary to place the control panel in the service position (See

Control Panel.), remove the lock assembly

insulation, and two 1/4-in. hex-head screws and the lock assembly cover.

Door Lock Assembly (top view shown with insulation and cover removed)

Door Lock Assembly (removed, rear view shown)

Switch #2

C

NC

NC

NO

NO

NO

Switch #3

C

Switch #4

C

Lock Motor

Switch #1

C

NO

Switch Function Door UnLocked Door Locked C NO NC

1 Door Lock C - NO open C - NO closed Yellow Gray N/A

2 Door Unlock C - NO closed C - NO open Yellow Orange N/A

3 Cooling Fan Motor Speed

Hi speed in clean, Low speed

in other modes

4 Lower oven and all surface

unit lockout in Clean cycle

C - NO closed

C - NC open

C - NO closed

C - NC open

C - NO open

C - NC closed

C - NO open

C - NC closed

Gray/Red Black Blue

Red Violet Brown

Caution: It is possible to reconnect the switch wiring incorrectly to the lock assembly. When reconnecting

the wiring, make sure it is properly connected to the lock assembly before turning the power back on.

– 22 –

Page 23

Diagnostics and Service Information

ERC Failure Codes

The oven may stop operating but not give an F code on the display immediately. F codes are stored in non

volatile eeprom memory until 2 of the same fault occur consecutively. After that, it will be displayed. They

can be recalled by pressing together: TIMER, CLOCK, 9. While displayed, pressing 8 and 6 together will clear

them. A fault must exist continuously for 5 minutes before an F code is recorded (F2, F8 are sooner).

FAILURE

CODE

-F0- Shorted OFF key Determine if problem is with Key Panel or control by disconnecting

-F2- Over temperature inside

oven cavity as measured

by sensor over 600°F

unlatched or 915°F

latched.

-F3- Open oven sensor (over

2900 ohms)

-F4- Shorted oven sensor

(under 950 ohms)

MEANING CORRECTION

ribbon cable and measuring fl at cable pins 13 to 14. Should be open.

Should be 100-150 ohms while pressing OFF key.

- Welded relay contacts

- Cooling fan stalled or blocked

- Airfl ow to rear of unit

- High resistance in oven sensor leads/connectors

- (especially at sensor in rear)

- Disconnect power.

- Disconnect sensor harness from control. Measure sensor resistance

(white leads) to be -1080 ohms at room temperature with 2 ohms per

degree change.

- Look for damaged harness terminals if not a bad sensor.

- Disconnect power.

- Disconnect sensor harness from control. Measure sensor resistance

(white leads) to be -1080 Ω at room temperature with 2 ohms per

degree change.

- Look for damaged harness terminals if not a bad sensor

-F5- A to D system fault Replace control

-F6- Range Lockout - Switch

issues

-F7- Shorted matrix or START

key

-F8- EEPROM data shift failure If repeated, replace control

-F9- Door Lock false while

above Runaway

Setpoint, Unlatched Door

Lock temperature. OR

Thermal switch device

setpoint exceeded.

Check connections on lockout motor and CN6 of control.

Determine if problem is with Key Panel or control by disconnecting

ribbon cable and measuring fl at cable using pinout chart. Allow up to

1000 ohms when pressing key.

“Unlock” Latch Changing status to “Lock” while cooking or “Lock”

Latch of Motor changing to “Un-Lock” while above run away set point

– 23 –

Page 24

Schematic

WARNING: Disconnect electrical power before servicing.

Caution: Label all wires prior to disconnection. Wiring errors can cause improper and dangerous operation.

Verify operation after servicing.

Schematic Diagram

– 24 –

Page 25

Warranty

GE Electric Range Warranty. (For customers in the United States)

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule

service, on-line, 24 hours a day, visit us at ge.com, or call

800.GE.CARES (800.432.2737). Please have serial number

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

and model number available when calling for service.

For The Period Of: GE Will Replace:

One Year Any part of the range which fails due to a defect in materials or workmanship. During this

From the date of the limited one-year warranty, GE will also provide, free of charge, all labor and in-home service

original purchase to replace the defective part .

Five Years A replacement glass cooktop if it should: crack due to thermal shock; discolor; crack at the

From the date of the rubber seal between the glass cooktop and the porcelain edge, or if the pattern wears off.

original purchase

A replacement radiant surface unit if it should burn out.

During this limited additional four-year warranty, you will be responsible for any labor or

in-home service.

What GE Will Not Cover:

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused,

or used for other than the intended purpose or

used commercially.

■ Damage to the glass cooktop caused by hardened

spills of sugary materials or melted plastic that

are not cleaned according to the directions in

the Owner’s Manual.

■ Damage to the glass cooktop caused by use of cleaners

other than the recommended cleaning creams.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

■ Damage caused after delivery.

■ Product not accessible to provide required service.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. If the product is located in an area where service by a GE Authorized Servicer is not available,

you may be responsible for a trip charge or you may be required to bring the product to an Authorized GE Service

location for service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

– 25 –

Loading...

Loading...