Page 1

Installation

Refrigerator

Instructions

Questions? Call 800.GE.CARES (800.432.2737) or visit our Website at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit our Website at: www.GEAppliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

WARNING

Built-in style models (model PYE, CYE, and PWE) are

top heavy, especially with any doors open. These

models must be secured with the anti-tip floor

bracket to prevent tipping forward, which could

result in death or serious injury. Read and follow

the entire installation instructions for installing the

anti-tip floor bracket packed with your refrigerator.

IMPORTANT ³

and ordinances. Save these instructions for local

inspector’s use.

Note to Installer – Be sure to leave these instructions with

the Consumer.

1RWHWR&RQVXPHU² Keep these instructions for future

reference.

6NLOOOHYHO²Installation of this appliance requires basic

mechanical skills.

&RPSOHWLRQWLPH²

Water Line Installation 30 minutes

3URSHULQVWDOODWLRQLVWKHUHVSRQVLELOLW\RIWKHLQVWDOOHU

3URGXFWIDLOXUHGXHWRLPSURSHULQVWDOODWLRQLVQRWFRYHUHG

under the Warranty.

Refrigerator Installation can vary

Tip Over Hazard.

Observe all governing codes

TOOLS YOU MAY NEED

Adjustable Wrench

1/4” Outer Diameter

Compression Nut

and Ferrule (sleeve)

1/8”, 3/32”, 1/4” & 5/32”

Allen Wrenches

1/8” Drill Bit and

Electric or Hand Drill

Pencil

GE Café™ models

Ȓµ Socket Ratchet/Driver

Phillips-Head Screwdriver

Flat-Head Screwdriver

Tape Measure

1/4” Nut Driver

PREPARATION

MOVING THE REFRIGERATOR INDOORS

If the refrigerator will not fit through a doorway, the

refrigerator door and freezer drawer can be removed.

7RUHPRYHWKHUHIULJHUDWRUGRRUVHHWKH,QVWDOOLQJWKH

Refrigerator section.

7RUHPRYHWKHIUHH]HUGUDZHUVHHWKH5HPRYLQJWKH

Freezer Drawer section.

WATER SUPPLY TO THE ICE MAKER AND DISPENSER

If the refrigerator has an ice maker, it will have to be

connected to a cold water line. A GE water supply

kit (containing tubing, shutoff valve, fittings and

instructions) is available at extra cost from your dealer,

by visiting our website at GEAppliances.com (in Canada

at www.GEAppliances.ca) or from Parts and Accessories,

800.626.2002 (in Canada 1.800.661.1616).

21

Pliers

Torx T20, T25

Level

Page 2

Installation Instructions

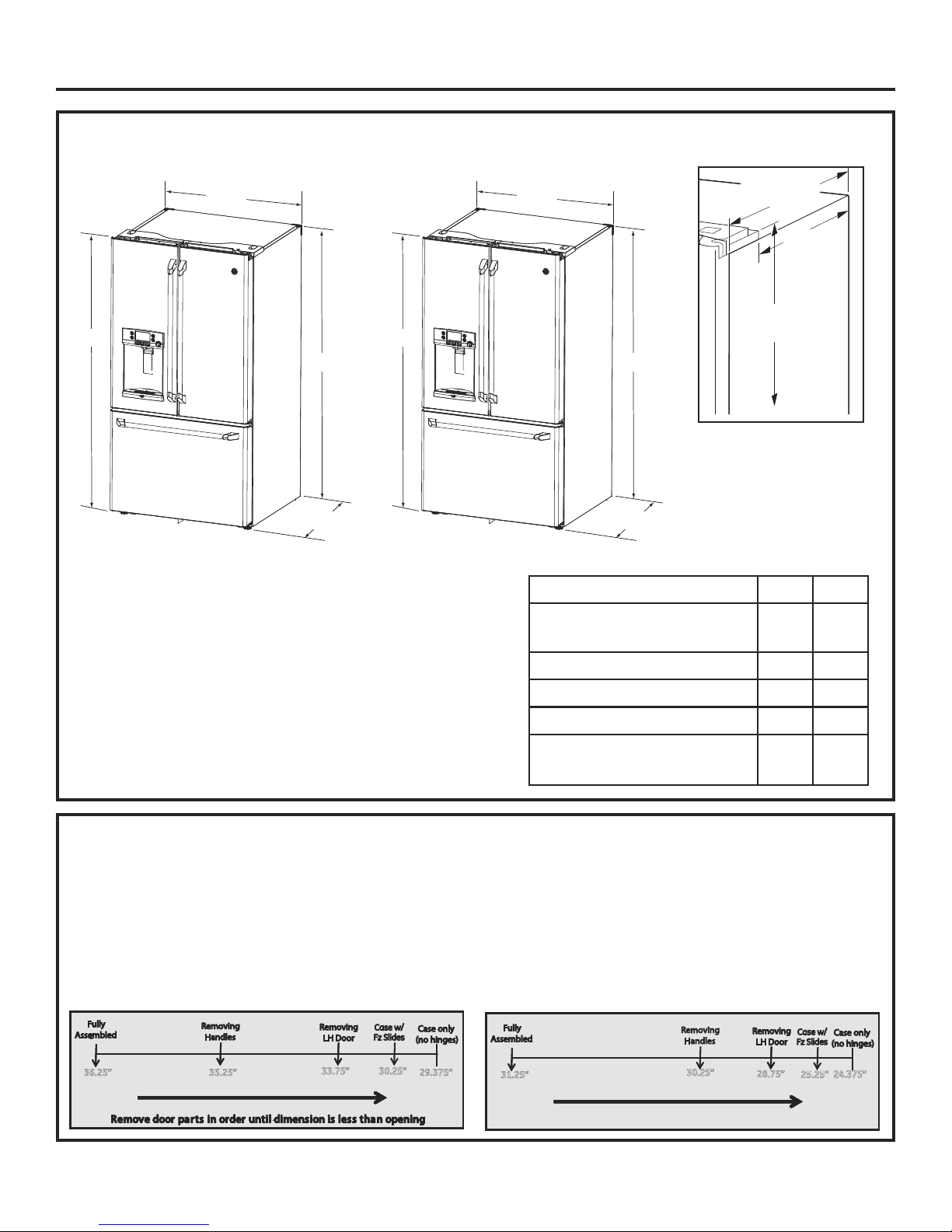

DIMENSIONS

7

ø8

”

All measurements are given with leveling leg fully retracted.

CFE OnlyCYE Only

353ø4”353ø4”

7

ø8

69

”69

Case Depth w/o

Doors 29 3ø8

Height from

floor to hinge

cover top 69

69”69”

Additional Dimensions

361ø4”311ø4”

”

231ø4” CFE

181ø4” CYE

7

ø8”

MOVING THE REFRIGERATOR

8VLQJWKHFKDUWEHORZGHWHUPLQHLIWKHZLGWKRI\RXUSDVVDJHZD\FDQDFFRPPRGDWHWKHGHSWKRIWKHUHIULJHUDWRU

Ensure you have clearance to prevent damage to the refrigerator before safety moving it to the final location.

,ISDVVDJHZD\VDUHODUJHHQRXJKWRDFFRPPRGDWHWKHUHIULJHUDWRUZLWKRXWUHPRYLQJWKHKDQGOHVVNLSWR6WHS/HDYH

tape, film and all packaging on doors until the refrigerator is in the final location.

NOTE: Use a padded hand truck or moving straps to move this refrigerator. Place the refrigerator on the hand truck

with a side against the truck. We strongly recommend that two people move and complete this installation.

If your model number starts with CFE

Overall Height to Top of

Hinge Cover

Height to Top of Cabinet

Case Depth without Doors

Overall Exterior Case Width

Overall Exterior Depth

Doors/Drawers with Handles

If your model number starts with CYE

CFE CYE

69

7

ø8

7

”69

ø8

69” 69”

29

3

ø8

3

”24

353ø4”353ø4”

36¼” 31¼”

”

ø8

36.25” 35.25” 29.375”

33.75” 30.25”

22

31.25”

30.25”

28.75”

25.25”

24.375”

Page 3

Installation Instructions

INSTALLING THE REFRIGERATOR

REFRIGERATOR LOCATION

'RQRWLQVWDOOWKHUHIULJHUDWRUZKHUHWKHWHPSHUDWXUHZLOO

go below 60°F (16°C) because it will not run often enough

to maintain proper temperatures.

'RQRWLQVWDOOWKHUHIULJHUDWRUZKHUHWKHWHPSHUDWXUHZLOO

go above 100°F (37°C) because it will not perform properly.

,QVWDOOLWRQDIORRUVWURQJHQRXJKWRVXSSRUWLWIXOO\ORDGHG

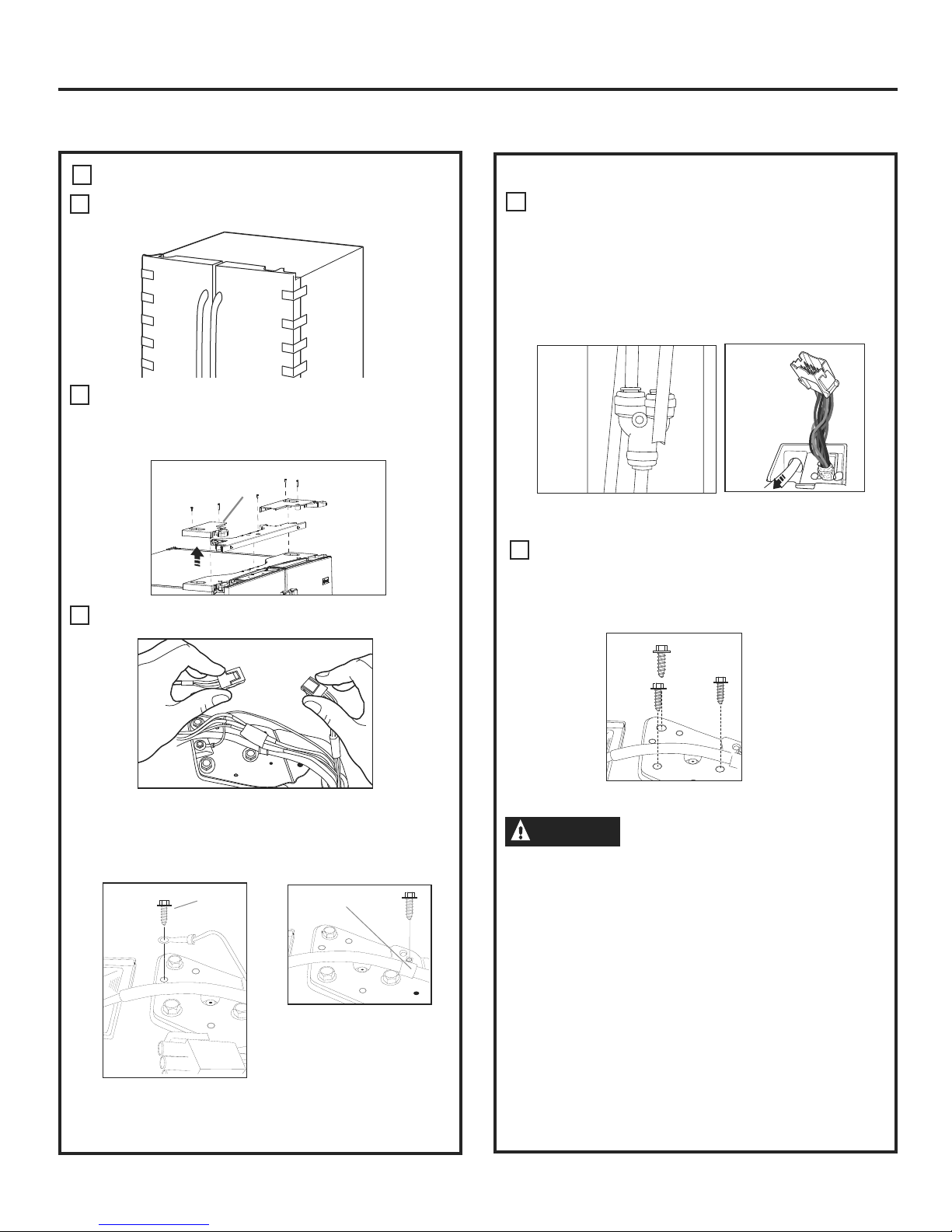

REMOVE THE FRESH FOOD

1

DOOR HANDLE

Handle Design varies based on models, however

Installation is same.

Stainless steel and plastic handles:

Loosen the set screws with the 1/8” Allen wrench and

remove the handle.

NOTE: If the handle mounting fasteners need to be tightened or

removed, use a 1/4” Allen wrench.

CLEARANCES

Allow the following clearances for ease of installation, proper

air circulation and plumbing and electrical connections.

Sides 1/8” (3 mm)

Top 1” (25 mm) Cabinet/Hinge Cover

Back 2” (50 mm)

REMOVING THE REFRIGERATOR DOORS

IMPORTANT NOTE: This refrigerator is 361/4” deep (311/4”

for CYE models). Doors and passageways leading to the

installation location must be at least 36

leave the doors and handles attached to the refrigerator

while transporting it into the installation location. If

passageways are less than 36

1

/4”, the refrigerator doors and

handles can easily be scratched and damaged. The top cap

and doors can be removed to allow the refrigerator to be

safely moved indoors. If passageways are less than 31

start with Step 1.

,ILWLVQRWQHFHVVDU\WRUHPRYHGRRUVVNLSWR6WHS/HDYH

tape and all packaging on doors until the refrigerator is in the

final location.

NOTE: Use a padded hand truck to move this refrigerator.

Place the refrigerator on the hand truck with a side against

the truck. We strongly recommend that TWO PEOPLE move

and complete this installation.

1

/4” wide in order to

1

/4”,

Mounting

Fasteners

Leave film

on until after

installation

REMOVE THE FREEZER DOOR HANDLE

2

Handle Design varies based on models, however

Installation is same.

Stainless steel and plastic handles:

Loosen the set screws with the 1/8” Allen wrench and remove the

handle.

NOTE: If the handle mounting fasteners need to be tightened or

removed, use a 1/4” Allen wrench.

Mounting

Fasteners

Leave film

on until after

installation

Reinstall the handles using the same

procedure as removing.

23

Page 4

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

REMOVE THE REFRIGERATOR DOORS

3

Securely tape the door shut with masking tape or have

A

a second person support the door.

Start with left-hand door first: Remove the hinge cover

B

on top of the left refrigerator door by removing all hex

screws and pulling it up. Do the same for the

right-hand door and the middle cover.

Hinge

Cover

REMOVE THE REFRIGERATOR DOORS (cont)

D

Disconnect the water line from the back of the unit by

pressing down on the dark grey collar while pulling up

on the water line.

Pull waterline through case conduit from the top to free

the line for door removal. The water line is more than 4’

long and may need to be taped to Door for accessibility

when reinstalling.

C

Disconnect both electrical connectors at the top cover.

Remove the 1/4” hex head screw to disconnect the

ground wire from the hinge.

Remove the 1/4” hex head screw to remove the strain

relief from the water line.

Ground

screw

Strain

Relief

Using a 3/8” socket ratchet/driver, remove the screws

E

securing the top hinge to the cabinet,

then lift the hinge straight up to free the hinge pin from

the location in the top of the door.

CAUTION

Single person lift could cause injury. Use assistance

when handling, moving or lifting the refrigerator doors.

Note: when removing door, to prevent damage to door

and electronics, carefully place the door in a proper

location.

Note: The lower door hinge pin and hinge are keyed and

must be matched correctly for the door to self close

properly. Please follow the directions carefully.

Lifting Hazard.

24

Page 5

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

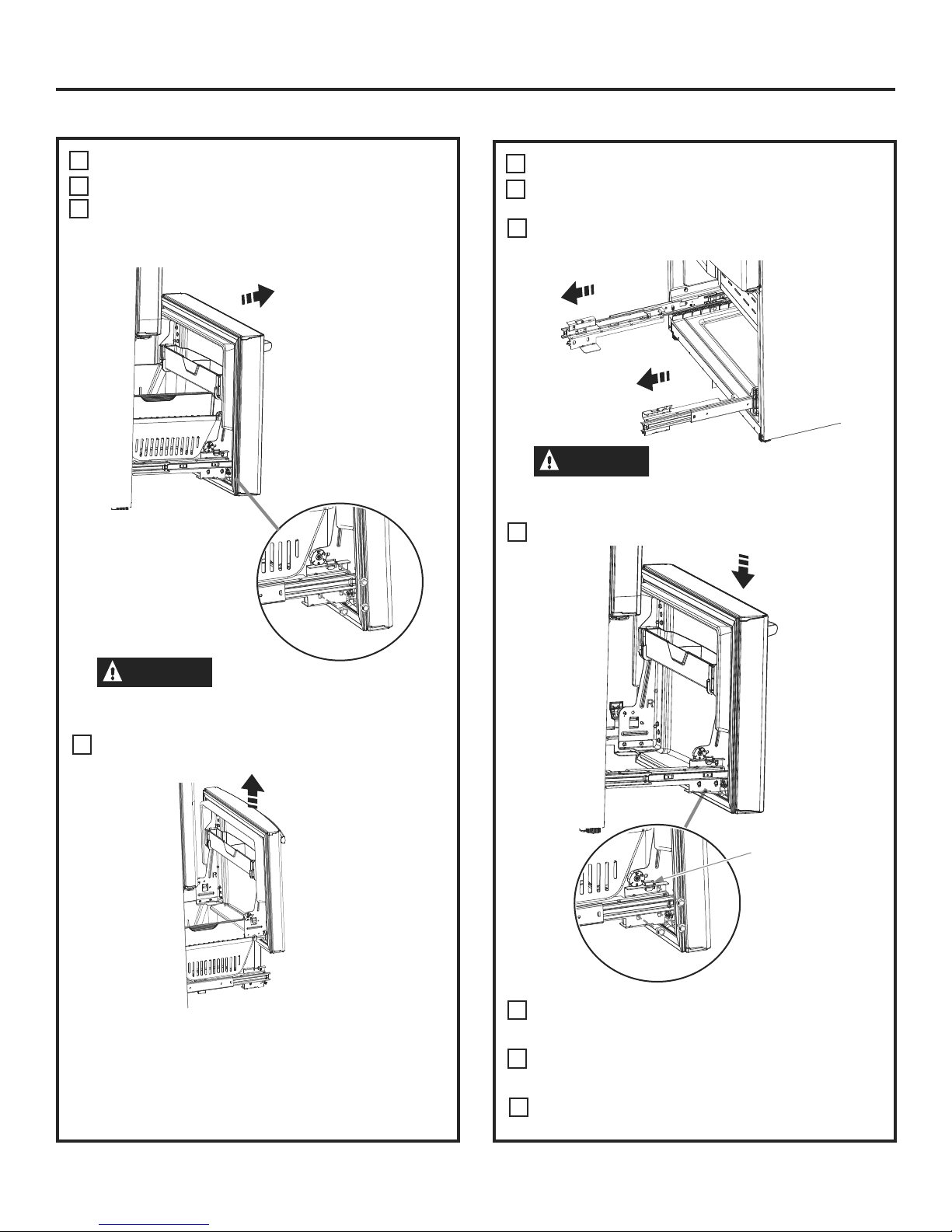

REMOVE THE REFRIGERATOR DOORS (cont)

Note: for proper installation later, please follow the next step

carefully.

Fresh Food doors to be REMOVED and INSTALLED

F

opened at 90 with case front.

Lift up & off

center hinge

Open Door

to 90°

REMOVE OPPOSITE DOOR

Follow the same procedure on the opposite

door. There are no wires or water lines on the opposite

side

4

REMOVE CENTER HINGE (if necessary)

Remove the 3/8ļscrews securing the center hinge to the cabinet.

Use T20 driver to remove outboard screw

REINSTALLING THE REFRIGERATOR DOORS

5

Reverse steps 1 through 4 to reinstall refrigerator, follow

details below for critical alignments.

A

Reinstall center hinge first and torque the screws to

65 in-lbs. With the LH door at 90º to the front of

the case, lower the refrigerator door onto the center

hinge. Ensure that the door and hinge align correctly.

B

Rotate doors closed and make sure moveable center

sealing portion of the door aligns with the striker. If the

door will not self-close after reinstalling, remove door,

turn door upside down, check alignment mark and

arrow; (there is an alignment mark on the door closure

mechanism It corresponds to an alignment mark on

the bottom end cap. Rotate door closure mechanism to

align mark and arrow, reinstall door).

Underside OF

Fresh Food Door

Remove

center

screw

Loosen Outer screws

25

align marks

If door cannot be installed at 90° follow steps below:

1. If space or model limits opening door to less than 180°, then:

a) Remove door, carefully turn door upside down.

b) Check alignment of door closure mechanism shaft on

underside of door. The flats on the shaft should

correspond to alignment tab on plastic ring or mark

on bottom end cap.

c) If shaft is not aligned to tab/mark, using 5/32” Allen

wrench, rotate door closure mechanism shaft

counterclockwise for right door and clockwise for left

door. Then align flat with tab/mark.

d) Install the door at 90°.

Securely tape the door shut with masking tape or

have a second person support the door. Reinstall the

top hinge and torque the screws to 65 in-lbs.

Be sure to reinstall the ground wire and strain relief to

C

the top hinge.

Reinstall the hinge cover. Note: Ensure wires are not

D

pinched or under screw bosses before tightening screws.

Page 6

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

REMOVE THE FREEZER DOOR

6

A

Pull the freezer door open to full extension.

Remove 3 attachment screws, located at the bottom

B

on each side of the freezer door using 3/8” hex socket

driver.

7

A

B

REPLACING THE FREEZER DOOR

Pull the slide Mechanism to full extension using both

hands simultaneously.

Remove the basket resting on the slides.

CAUTION

Freezer door is heavy Use both hands to secure the

door before lifting.

Lift the freezer door to disengage it from the slide

C

mechanism

Lifting Hazard

CAUTION

Freezer door is heavy Use both hands to secure the

door before lifting.

Lift the freezer door and place it on the slide mechanism

C

Lifting Hazard

Align and insert

tab on freezer

door bracket

into slot on

freezer slide

bracket.

The door can safely rest on the bottom. Do not rest the

door on any other surfaces to avoid scratches.

Push the slide mechanism back completely until it self

retracts.

26

Replace the attachment screws and torque the screws

D

to 65 in-lb

For adjusting freezer door gaps, follow the instructions

E

on pg 27.

Replace the basket

F

Page 7

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

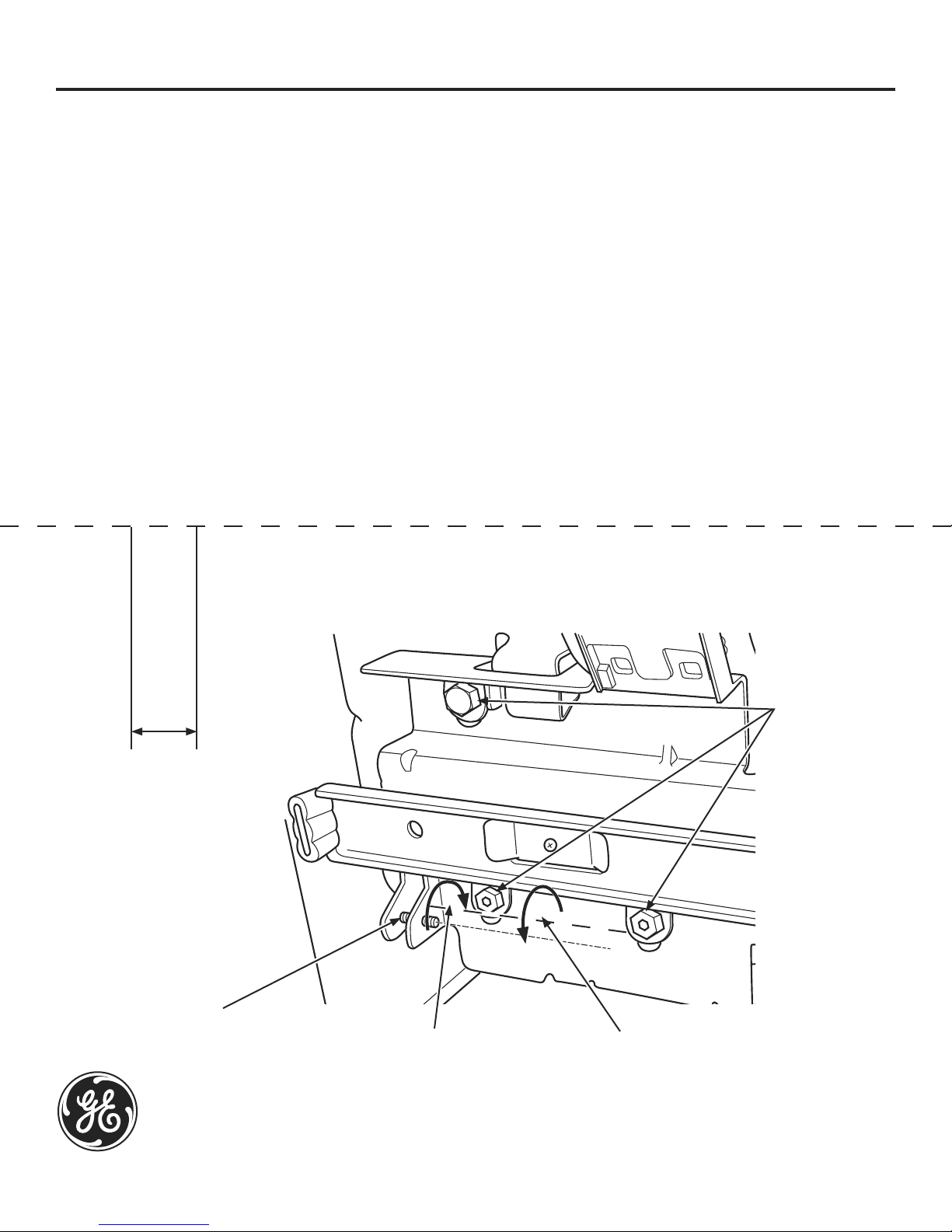

Instructions for adjusting freezer door gaps:

IMPORTANT!

The 6 mounting screws (3 on each side) are NOT interchangeable with the center or top hinge

screws. Drawer screws have flat washer heads, and other screws have lines/ribs on washer heads.

After installation of the freezer door, check for uniform gaps (top and bottom of right and left hand side)

with the template provided.

In the event of excessive gaps use the following steps to adjust the freezer door.

Step 1 - Loosen the 3 screws on each side (right and left) of the freezer door.

Step 2 - Adjust set screw clockwise if gap at the top is too big (see template). Turn the set screw using 3/32” hex

key clockwise by quarter to half a rotation

Step 3 - Adjust set screw counter-clockwise if gap at the bottom is too big (see template). Turn the set screw

using 3/32” hex key counter-clockwise by quarter to half a rotation

Step 4 - Tighten the 3 screws on each side (right and left).

Step 5 - Re-check the gaps using the template and repeat steps 1 to 4 if required and complete with step 5.

Fold here for using template

0.600”

Template for checking gaps.

Gap should be 0.6” or below.

Gabarit pour vérifier les

écarts. L’écart doit être de

0,6 po (1,5 cm) ou moins.

Plantilla para el control de

espacios. El espacio debería

ser de 0.6” o inferior.

Plier ici pour utiliser le gabarit Dóblelo aquí para usar la plantilla

Step 1

Étape 1

Paso 1

Step 4

Étape 4

Paso 4

Set Screw

Vis d’ajustement

Tornillo del Set

GE Appliances

General Electric Company

Louisville, KY 40225

GEAppliances.com

Step 2

Étape 2

Paso 2

Step 3

Étape 3

Paso 3

Refer to 239D4144P001 Pub No. 31-45474-2 11-12 GE

27

Page 8

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

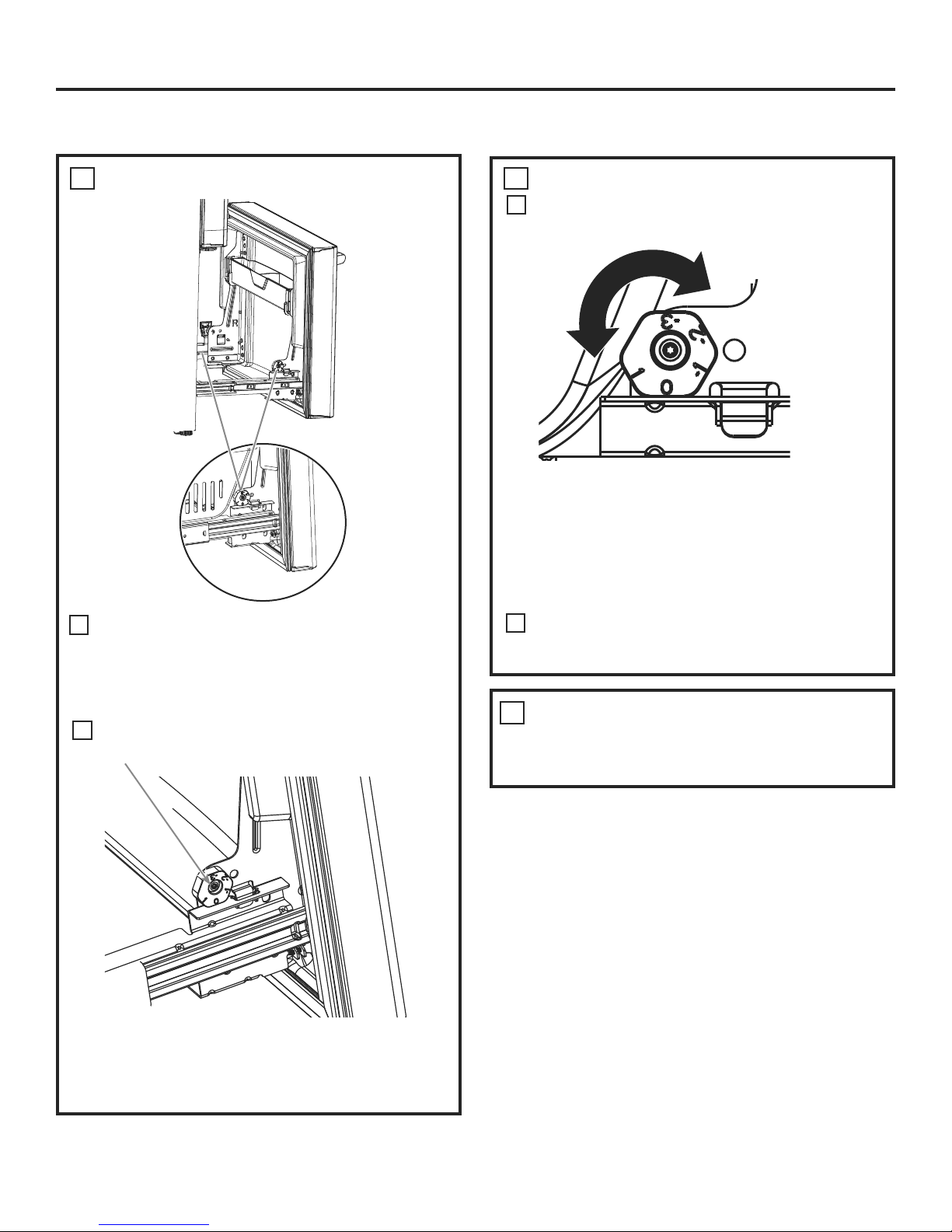

LEVEL THE FREEZER DOOR

8

9

LEVEL THE FREEZER DOOR (cont.)

A

Lift the door on the side requiring adjustment,

rotate the cam to required position.

0 - Initial position

1 - Lift by 0.050”

-1 - Lower by 0.050”

-2 - Lower by 0.100

-3 - Lower by 0.150”

Locate the height adjuster cam in the freezer

A

door. Slightly loosen the three door attachment

screws on both sides using a 3/8” hex socket

driver.

Locate and loosen the cam screw using the

B

T-27 screw driver.

After adjustment tighten the 3 attachment

B

screws using to 65 in-lb.

REMOVE PACKAGING

10

A) Remove all tape, foam and protective

packing from shelves and drawers.

28

Page 9

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

Anti-Tip Floor Bracket Installation (Models PYE, CYE, and PWE only)

WARNING

Tip Over Hazard.

Built-in style models (model PYE, CYE, and PWE) are

top heavy, especially with any doors open. These

models must be secured with the anti-tip floor

bracket to prevent tipping forward, which could

result in death or serious injury. Read and follow

the entire installation instructions for installing the

anti-tip floor bracket packed with your refrigerator.

NOTE:

If you did not receive an anti-tip bracket with your

purchase, call 1.800.626.8774 to receive one at no

cost. (In Canada, call 1.800.561.3344.)

For installation instructions of the bracket, visit:

www.GEAppliances.com.

(In Canada, www.GEAppliances.ca.)

MATERIALS YOU MAY NEED (not included)

TOOLS YOU WILL NEED

1/8” (3 mm) Drill Bit and

Electric or Hand Drill

Pencil

Tape measure

5/16” (8 mm) Nut Driver

LOCATING THE ANTI-TIP FLOOR

AT-2

BRACKET

Place the anti-tip floor bracket locator template

A

(included inside the anti-tip kit) onto the floor up

against the rear wall, within W, and in line with the

desired location of the RH side of the refrigerator

(see Figure 1).

Figure 1 – Installation Overview

Floor – Concrete

(2 Holes)

Floor – Wood

(2 Holes)

2 Wall Holes

Floor Bracket

to Install

RH Holes

Lag Bolts

1/4” (6 mm) x 1-1/2” (38 mm)

Drill Bit Appropriate for Anchors

For Anti-Tip Bracket Mounted on CONCRETE Floors Only

Anchor Sleeves

1/2” (12 mm) OD

MEASURE CABINET OPENING

AT-1

AVAILABLE VS. REFRIGERATOR WIDTH

Measure width of cabinet opening where refrigerator

will be placed, W.

Be sure to account for any countertop overhang,

baseboard thickness and any clearance desired. Width,

W, should not be less than 36”. The refrigerator will be

placed approximately in the middle of this opening.

Rear Wall

W

REFRIGERATOR

Front

Baseboard

Thickness or

Countertop

Overhang

(Whichever Is

Larger) Plus

Any Desired

Clearance

RH Side

29

15 ¼”

Rear RH

Corner of

Base Bracket

on the

Refrigerator

Place the anti-tip floor bracket onto the locator

B

RH Side of

Refrigerator

Cabinet Wall

Locator Template

Sheet

template with its RH floor holes lined up with

the floor holes indicated on the template sheet,

approximately 15 ¼” from the edge of the sheet or

the RH side of the refrigerator.

Hold down in position and use the anti-tip floor

C

bracket as a template for marking the holes based

upon your configuration and type of construction

as shown in Step 3. Mark the hole locations with a

pencil, nail or awl.

NOTE:

It is REQUIRED to use at least 2 screws to mount

the floor bracket (one on each side of the anti-tip

floor bracket). Both must be into either the wall

or the floor. Figure 2 indicates all the acceptable

mounting configurations for screws. Identify the

screw holes on the anti-tip floor bracket for your

configuration.

Refer tp 239D1142 P001 Pub# 31-45484-2

Page 10

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

Anti-Tip Floor Bracket Installation (Models PYE, CYE, and PWE only) (cont.)

LOCATING THE ANTI-TIP FLOOR

AT-2

BRACKET (cont.)

Figure 2 – Acceptable Screw

Placement Locations

Recommended Installation

Minimum Acceptable #1 –

AT-3

A

– Wood

Wall Plate Stud

Minimum Acceptable #3 –

Concrete Floor

ANTI-TIP BRACKET INSTALLATION

WOOD Wall and Floor Construction:

'ULOOWKHDSSURSULDWHQXPEHURIµPP

pilot holes in the center of each floor bracket

hole being used (a nail or awl may be used

if a drill is not available) AND remove the

locator template from the floor.

Mount the anti-tip floor bracket by fastening the

2, or recommended 4, #10-16 hex-head screws

tightly into place as illustrated in Figure 3.

Recommended Installation

– Concrete

Minimum Acceptable #2 –

Wood Floor

Figure 3 – Attachment to Wall and Floor

Rear RH

Corner of the

Refrigerator

2 Screws

Must Enter

Wood or

Metal Stud

Floor

Floor

Bracket

Wall

Wall

Plate

Stud

CONCRETE Wall and Floor Construction:

B

$QFKRUVUHTXLUHGQRWSURYLGHG

4 each 1/4” (6 mm) x 1-1/2” (38 mm) lag bolts

4 each 1/2” (12 mm) O.D. sleeve anchors

'ULOOWKHUHFRPPHQGHGVL]HKROHVIRUWKH

anchors into the concrete at the center of the

holes marked in Step 2.

,QVWDOOWKHVOHHYHDQFKRUVLQWRWKHGULOOHG

holes. Place the anti-tip floor bracket as

indicated in Step 2. Remove the locator

template from the floor.

,QVWDOOWKHODJEROWVWKURXJKWKHDQWLWLSIORRU

bracket and tighten appropriately.

WOOD Wall and TILE Floor Construction:

C

)RUWKLVVSHFLDOFDVHORFDWHWKHZDOOKROHV

identified in Fig. 1. Drill an angled 1/8” (3 mm)

pilot hole (approx. as shown in Fig. 3) in the

center of each hole.

0RXQWWKHDQWLWLSIORRUEUDFNHWXVLQJWKH

Minimum Acceptable Installation #1, as

illustrated in Fig. 2.

AT-4

POSITIONING THE REFRIGERATOR

TO ENGAGE THE ANTI-TIP FLOOR

AND BASE BRACKETS

Before pushing the refrigerator into the

opening, plug the power cord into the

A

receptacle and connect waterline (if equipped).

Check for leaks.

Locate the refrigerator’s RH side and move back

approximately in line with the RH side of the

B

cabinet opening, W. This should position the

anti-tip floor bracket to engage the anti-tip base

bracket on the refrigerator.

Gently roll the refrigerator back into the cabinet

opening until it comes to a complete stop. Check to

C

see if the refrigerator front lines up with the cabinet

front face. If not, carefully rock the refrigerator

forward and backward until engagement occurs

and you notice that the refrigerator is fully pushed

up against the rear wall.

If Applicable: Adjust the rear (and front) wheel

height settings to fully engage the rear anti-tip

brackets, while also aligning the refrigerator

D

front with the cabinet front face.

NOTE:

If you pull the refrigerator out and away from the wall for

any reason, make sure the anti-tip floor bracket is engaged

when the refrigerator is pushed back against the rear wall.

30

Refer tp 239D1142 P001 Pub# 31-45484-2

Page 11

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

11

CONNECTING THE REFRIGERATOR

TO THE HOUSE WATER LINE

A cold water supply is required for automatic ice maker

operation. If there is not a cold water supply, you will

need to provide one. See Installing the Water Line section.

NOTES:

%HIRUHPDNLQJWKHFRQQHFWLRQWRWKHUHIULJHUDWRUEH

sure the refrigerator power cord is not plugged into the

wall outlet.

,I\RXUUHIULJHUDWRUGRHVQRWKDYHDZDWHUILOWHUZH

recommend installing one if your water supply has

sand or particles that could clog the screen of the

refrigerator’s water valve. Install it in the water line

near the refrigerator. If using GE SmartConnect

Refrigerator Tubing Kit, you will need an additional tube

(WX08X10002) to connect the filter. Do not cut plastic

tube to install filter.

%HIRUHFRQQHFWLQJWKHZDWHUOLQHWRWKHKRXVHSXUJH

the house line for at least 2 minutes.

A

If you are using copper tubing, place a compression nut

and ferrule (sleeve) onto the end of the tubing coming

from the house cold water supply.

™

If you are using the GE SmartConnect

tubing, the nuts

are already assembled to the tubing.

™

If you are using copper tubing, insert the end of the

B

tubing into the refrigerator connection, at the back of the

refrigerator, as far as possible. While holding the tubing,

tighten the fitting.

™

If you are using GE SmartConnect

tubing, insert

the molded end of the tubing into the refrigerator

connection, at the back of the refrigerator, and tighten

the compression nut until it is hand tight. Then tighten

one additional turn with a wrench. Over tightening may

cause leaks.

Fasten the tubing into the clamp provided to hold it in

C

position. You may need to pry open the clamp.

1/4” Compression

Nut

Ferrule

(sleeve)

Tubing Clamp

Bride

Abrazadera del tubo

1/4“ Tubing

Tuyau de 1/4 po

Tubería de 1/4“

SmartConnect

Tubing

Refrigerator

Connection

™

31

Page 12

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

TURN ON THE WATER SUPPLY

12

Turn the water on at the shutoff valve (house water

supply) and check for any leaks.

PLUG IN THE REFRIGERATOR

13

See the grounding information attached to the power

cord.

LEVEL THE REFRIGERATOR

14

The leveling legs have 2 purposes:

1) Leveling legs adjust so the refrigerator is

firmly positioned on the floor and does not

wobble.

2) Leveling legs serve as a stabilizing brake

to hold the refrigerator securely in position

during operation and cleaning. The leveling

legs also prevent the refrigerator from

tipping.

15

LEVEL THE REFRIGERATOR DOORS

Remember a level refrigerator is necessary for

getting the doors perfectly even. If you need

help, review the previous section on leveling the

refrigerator.

When

the left

door is

lower than

the right

door.

If you open the freezer door, you can see

A

When

the left

door is

higher

than

the right

door.

Adjustment

point

the center hinge.

Insert 1/4” Allen wrench into the shaft of the

B

center hinge.

Adjust the height by turning clockwise

C

or counterclockwise. When you turn

counterclockwise, the door will move up.

RAISE

Turn the leveling legs clockwise to raise

A

the refrigerator, counterclockwise to lower it.

Flat-Head Screwdriver

NOTICE: To avoid possible property

damage, the leveling legs must be firmly

touching the floor.

Raise

32

Page 13

Installation Instructions

INSTALLING THE REFRIGERATOR (cont.)

Refrigerator Assembly Instructions, suggested assembly.

G

G

To place bins into doors:

Match your bin with the letter shown.

Position the bin hooks over the

bin locator and push forward until

inserted fully.

Push bin down until locked into

position.

Bin locator

each side

G

Divider

(Select

models only)

Bin hook

rear each side

Refer to 239D4129P002 Pub# 31-45498

33

Page 14

Installation Instructions

INSTALLING THE WATER LINE

BEFORE YOU BEGIN

Recommended copper water supply kits are WX8X2,

WX8X3 or WX8X4, depending on the amount of tubing

you need. Approved plastic water supply lines are GE

SmartConnect

WX08X10015 and WX08X10025).

When connecting your refrigerator to a GE Reverse

Osmosis Water System, the only approved installation

is with a GE RVKit. For other reverse osmosis water

systems, follow the manufacturer’s recommendations.

If the water supply to the refrigerator is from a

Reverse Osmosis Water Filtration System (RO)

AND the refrigerator also has a water filter,

use the refrigerator’s filter bypass plug. Using

the refrigerator’s water filtration cartridge in

conjunction with an RO water filter can result in

hollow ice cubes.

This water line installation is not warranted by the

refrigerator or ice maker manufacturer. Follow

these instructions carefully to minimize the risk of

expensive water damage.

Water hammer (water banging in the pipes) in

house plumbing can cause damage to refrigerator

parts and lead to water leakage or flooding. Call a

qualified plumber to correct water hammer before

installing the water supply line to the refrigerator.

To prevent burns and product damage, do not hook

up the water line to the hot water line.

For LCD Models: If the refrigerator is operated

before the water connection is made to the ice

maker, see ICE MAKER under “settings” menu of

the LCD Operations section and follow the screen

commands to turn the ice maker OFF.

Do not install the ice maker tubing in areas where

temperatures fall below freezing.

When using any electrical device (such as a power

drill) during installation, be sure the device is double

insulated or grounded in a manner to prevent the

hazard of electric shock, or is battery powered.

All installations must be in accordance with local

plumbing code requirements.

™

Refrigerator Tubing (WX08X10006,

WHAT YOU WILL NEED

&RSSHURU*(6PDUW&RQQHFW™ Refrigerator Tubing

kit, 1/4” outer diameter to connect

the refrigerator to the water supply. If using

copper, be sure both ends of the tubing are

cut square.

To determine how much tubing you need:

measure the distance from the water valve

on the back of the refrigerator to the water supply

pipe. Be sure there is sufficient extra tubing to allow

the refrigerator to move out from the wall after

installation.

™

GE SmartConnect

available in the following lengths:

6’ (1.8 m) – WX08X10006

15’ (4.6 m) – WX08X10015

25’ (7.6 m) – WX08X10025

Refrigerator Tubing Kits are

34

Page 15

Installation Instructions

INSTALLING THE WATER LINE (cont.)

WHAT YOU WILL NEED (CONT.)

NOTE: The only GE approved plastic tubing

is that supplied in GE SmartConnect

Tubing kits. Do not use any other plastic water

supply line because the line is under pressure at all

times. Certain types of plastic will crack or rupture

with age and cause water damage to your home.

$*(ZDWHUVXSSO\NLW FRQWDLQLQJWXELQJ

shutoff valve and fittings listed below) is available

at extra cost from your dealer or from Parts

and Accessories, 800.626.2002 (in Canada

1.800.661.1616).

$FROGZDWHUVXSSO\ 7KHZDWHUSUHVVXUHPXVWEH

between 20 and 120 p.s.i. (1.4–8.1 bar).

3RZHUGULOO

1/2” or adjustable wrench.

6WUDLJKWDQG3KLOOLSVEODGHVFUHZGULYHU

™

Refrigerator

Install the shutoff valve on the nearest frequently

used drinking water line.

1

SHUT OFF THE MAIN WATER SUPPLY

Turn on the nearest faucet long enough to clear

the line of water.

2

CHOOSE THE VALVE LOCATION

Choose a location for the valve that is easily

accessible. It is best to connect into the side

of a vertical water pipe. When it is necessary

to connect into a horizontal water pipe, make

the connection to the top or side, rather than at

the bottom, to avoid drawing off any sediment

from the water pipe.

7ZR ” outer diameter compression nuts

DQGIHUUXOHVVOHHYHV³WRFRQQHFWWKHFRSSHU

tubing to the shutoff valve and the refrigerator

water valve.

OR

,I\RXDUHXVLQJD*(6PDUW&RQQHFW

Refrigerator Tubing kit, the necessary fittings

are preassembled to the tubing.

,I\RXUH[LVWLQJFRSSHUZDWHUOLQHKDVDIODUHG

fitting at the end, you will need an adapter

(available at plumbing supply stores) to connect

the water line to the refrigerator OR you can cut

off the flared fitting with a tube cutter and then

use a compression fitting. Do not cut formed end

from GE SmartConnect

6KXWRIIYDOYHWRFRQQHFWWRWKHFROGZDWHUOLQH

The shutoff valve should have a water inlet with

a minimum inside diameter of 5/32” at the point of

connection to the COLD WATER LINE. Saddle-type

shutoff valves are included in many water supply

kits. Before purchasing, make sure a saddle-type

valve complies with your local plumbing codes.

™

Refrigerator tubing.

™

DRILL THE HOLE FOR THE VALVE

3

Drill a 1/4” hole in the water pipe (even if using

a self-piercing valve), using a sharp bit. Remove

any burrs resulting from drilling the hole in

the pipe.

Take care not to allow water to drain into

the drill.

Failure to drill a 1/4” hole may result in reduced

ice production or smaller cubes.

35

Page 16

Installation Instructions

INSTALLING THE WATER LINE (cont.)

4

FASTEN THE SHUTOFF VALVE

Fasten the shutoff valve to the cold water pipe

with the pipe clamp.

Pipe Clamp

Saddle-Type

Shutoff Valve

Vertical Cold

Water Pipe

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR shall be adhered to.

Saddle valves are illegal and use is not permitted

in Massachusetts. Consult with your licensed

plumber.

TIGHTEN THE PIPE CLAMP

5

Tighten the clamp screws until the sealing

washer begins to swell.

NOTE: Do not over tighten or you may crush

the tubing.

Washer

Pipe Clamp

Inlet End

7

CONNECT THE TUBING TO THE VALVE

Place the compression nut and ferrule (sleeve)

for copper tubing onto the end of the tubing

and connect it to the shutoff valve.

Make sure the tubing is fully inserted into

the valve. Tighten the compression nut securely.

For plastic tubing from a GE SmartConnect

Refrigerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then

tighten one additional turn with a wrench. Over

tightening may cause leaks.

Saddle-Type

Shutoff Valve

Packing Nut

Outlet Valve

Ferrule (sleeve)

Compression Nut

SmartConnect

Tubing

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR shall be adhered to.

Saddle valves are illegal and use is not permitted

in Massachusetts. Consult with your licensed

plumber.

™

™

Clamp

Screw

ROUTE THE TUBING

6

Route the tubing between the cold water line

and the refrigerator.

Route the tubing through a hole drilled in the

wall or floor (behind the refrigerator or adjacent

base cabinet) as close to the wall as possible.

8

FLUSH OUT THE TUBING

Turn the main water supply on and flush out

the tubing until the water is clear.

Shut the water off at the water valve after about

one quart (1 liter), or 2 minutes, of water has

been flushed through the tubing.

To complete the installation of the refrigerator, go back

to Step 11 in Installing the Refrigerator.

36

Page 17

Normal operating conditions.

Newer refrigerators sound different from older refrigerators.

Modern refrigerators have more features and use newer technology.

Do you hear what I hear? These sounds are normal.

HUMMM...

WHOOSH...

The new high efficiency compressor may run faster and longer

than your old refrigerator and you may hear a high-pitched hum

or pulsating sound while it is operating.

You may hear a whooshing sound when the doors close. This is

due to pressure equalizing within the refrigerator.

After dispensing ice, a motor will close the ice chute to keep

warn room air from entering the ice bucket, maintaining ice at a

freezing temperature.

The hum of the motor closing the ice chute is normal, shortly after

dispensing ice.

You may hear the fans spinning at high speeds. This happens

when the refrigerator is first plugged in, when the doors are

opened frequently or when a large amount of food is added to

the refrigerator or freezer compartments. The fans are helping to

maintain the correct temperatures.

The fans change speeds in order to provide optimal cooling and

energy savings.

CLICKS, POPS,

CRACKS and SNAPS

You may hear cracking or popping sounds when the refrigerator

is first plugged in. This happens as the refrigerator cools to the

correct temperature.

Expansion and contraction of cooling coils during and after

defrost can cause a cracking or popping sound.

On models with an ice maker, after an ice making cycle, you may

hear the ice cubes dropping into the ice bucket.

On models with a dispenser, during water dispense, you may

hear the water lines move at initial dispense and after dispenser

button is released.

START UP COOLING

It can take up to 24 hours for the refrigerator and freezer

temperatures to match the display. During that time refrigerator and

freezer door openings should be minimized.

TIPS

Freezer cools first.

Refrigerator compartment cools last; it may take several

hours after the freezer.

Turning off ice maker makes both fresh food and freezer

food cool faster.

WATER SOUNDS

The flow of refrigerant through the cooling coils may make a

gurgling noise like boiling water.

Water dropping on the defrost heater can cause a sizzling,

popping or buzzing sound during the defrost cycle.

A water dripping noise may occur during the defrost cycle as ice

melts from the evaporator and flows into the drain pan.

Closing the door may cause a gurgling sound due to pressure

equalization.

37

Page 18

Before you call for service…

Troubleshooting Tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

Problem Possible Causes What to Do

Water filter indicator light

remains lit after replacing filter

Water filter indicator light is not lit This is normal. This indicator will turn

Handle is loose/handle has a gap. Handle needs adjusting See Attach Fresh Food Handle and

Refrigerator beeping This is door alarm Turn off or disable with door closed.

Not cooling The cooling system is off See About Controls.

Water has poor taste/odor Water dispenser has not been used

Water in glass is warm Normal when refrigerator is first

Water dispenser does not work Water supply line turned off or not

Water filter indicator must be reset On the LCD screen select

system SETTINGS, then WATER FILTER.

Select RESET.

See About the Water Filter for more

on to tell you that you need to replace

the filter soon.

for a long time

installed

Water dispenser has not been used

for a long time

Water system has drained Allow several hours for replenished

connected

Water filter clogged or filter/bypass

plug not installed

Air may be trapped in the water

system

information.

Attach the Freezer Handle sections for

detailed instructions.

If door open and alarm is sounding, you

can only snooze the alarm.

Dispense water, until all water in system

is replenished.

Wait 24 hours for the refrigerator to

completely cool down.

Dispense water, until all water in system

is replenished.

supply to chill.

See Installing the Water Line.

Replace filter cartridge or remove filter

and install bypass plug.

Press the dispenser arm for at least 5

minutes.

Water spurting from dispenser Newly installed filter cartridge Run cold water from the dispenser for

Water in reservoir is frozen because

the controls are set too cold

38

Set the refrigerator control to a warmer

setting and wait 24 hours. If the water

does not dispense after 24 hours, call for

service.

5 minutes (about 2 gallons)..

Page 19

GEAppliances.com

Troubleshooting Tips (cont)

Problem Possible Causes What to Do

No water or ice cube production Supply line or shutoff valve is clogged Call a plumber

Water filter is clogged Replace filter cartridge or remove filter and

install bypass plug

Filter cartridge not properly installed Remove and reinstall filter cartridge,

being certain that it locks in place.

Ice maker is turned off Check that the ice maker is turned on. See

About the Automatic Ice Maker.

Water is leaking from dispenser Air may be present in the water line

system, causing water to drip after

being dispensed

Photos not found Photos not in root directory of USB Make sure the photos are in the root direc-

Photos not in JPEG format Photos must be in JPEG format

Camera/PC used with USB cord Must use a USB drive

PRECISE FILL will not fill container Normal, PRECISE FILL requires use of

dispenser paddle

Freezer cooling, fresh food not cooling Normal, when refrigerator first

plugged in or after extended power

outage

Ice dispenser opens after closing

freezer drawer

Hot water does not work Operation disabled Make sure “Hot Water Disabled” is not

Hot water continues to dispense for a

short time after releasing the knob

Normal The ice dispenser door may open after

Low water pressure Make sure water line is not kinked

Water supply line turned off or not

connected

Water filter clogged or filter/bypass

plug not installed

Water filter is partially clogged or low

water pressure (<40 psi)

Dispense water for at least 5 minutes to

remove air from system

tory in your USB

For a specific amount of water, select PRE-

CISE FILL to dispense water

Wait 24 hours for temperature in both

compartments to reach selected

temperatures.

closing freezer door to allow access

selected

See Installing the Water Line

Replace filter cartridge or remove filter and

install bypass plug

Replace filter cartridge or remove filter

and install bypass plug or increase water

pressure

39

Page 20

Before you call for service, review the detailed troubleshooting tips in the Owner’s

SERVICE

manual. If needed, service can be scheduled by visiting us online GEAppliances.

com or calling 800.ge.CARES 800.432.2737

Truth or Myth

Truth or Myth? Answer Explanation

The refrigerator water filter may require replacement,

even though the filter indicator has not turned red, or

reads “Filter Expired.”

The automatic ice maker in my refrigerator will

produce ice when the refrigerator is plugged in to a

power receptacle.

After the refrigerator has been plugged in and

connected to water, I will immediately have unlimited

chilled water available from the water dispenser.

After water dispenses, a few drops of water are

normal.

I will never see frost inside the freezer compartment. MYTH Frost inside the freezer typically indicates that the door is not properly

When the refrigerator is installed, or after replacing the water filter, I must dispense water for five

minutes.

To fill the ice bucket to the maximum capacity, I

should dispense 12 and 18 hours after installation.

I can use the water filter bypass plug to determine if

the filter requires replacement.

The top of the refrigerator doors will always be

aligned.

Refrigerator door handles can be easily tightened. TRUE If door handles are loose or have a gap, the handle can be adjusted using

There may be odor and taste problems with your ice. TRUE After starting the ice maker throw away 24 hours of ice production to

I can make fine adjustments to the fresh food doors

to align them.

Door handles should always be removed for

installation.

TRUE The water filter indicator will indicate the need to replace the water filter

every six months. Water quality varies from city to city; if water flow from

the dispenser slows, or ice production decreases, the water filter should

be replaced, even though the filter indicator may not indicate the need for

replacement.

MYTH The refrigerator must be connected to water, and the ice maker must be

turned on. Make sure the ice maker is turned on, only after the water line

is connected and water is turned on. The ice maker can be turned on/

off from the controls and ensure the ice maker is on, as indicated on the

refrigerator control panel. See About the Automatic Ice Maker.

MYTH The water dispenser tank located inside the refrigerator stores water

for dispensing. The water in this tank requires 24 hours to chill after

installation. High usage conditions will not allow time for the water to

chill.

TRUE A few drops of water may fall from the dispenser, after the dispenser

paddle has been released. To minimize the drops, remove the glass

slowly from the dispenser.

sealed, or has been left open. If frost is found, clear the frost using a

plastic spatula and towel, then check to ensure that no food packages

or containers are preventing the freezer door from closing. Check the

refrigerator control panel to ensure the door alarm is on.

TRUE

TRUE Dispensing 3-4 cubes 12 hours and 18 hours after installation, allows ice

TRUE Decrease in flow from the water dispenser, or decreased ice production,

MYTH Several things can affect the fresh food door alignment, including the

TRUE If the fresh food doors are not aligned, use a 1/4” Allen wrench to adjust

MYTH Check chart on reverse side of this instruction. If the doors must be

A newly installed refrigerator or water filter contains air in the water lines.

Press the dispenser paddle and dispense cold water for at least 5 minutes

to remove air from the water line, and flush the filter.

to disperse within the ice bucket, which in turns calls on the ice maker to

produce additional ice. Normal ice production = 100 cubes in 24 hours.

may indicate the need to replace the water filter. Install the water filter

bypass plug (provided with the refrigerator), and check flow from the

dispenser. If water flow returns to normal with the bypass plug in place,

replace the water filter.

floor the refrigerator is installed on, and loading of doors. If the top of

the fresh food doors are not aligned, use a 1/4” allen wrench to adjust

the right hand door. The adjustment screw is located on the bottom right

hand side of the door; open the freezer door to access the screw. The left

hand fresh food door may be raised using spacers. Call 800-GECARES to

obtain the spacers.

a 1/8” allen wrench, on set screws located on the ends of the handles.

avoid odor and taste problems.

the right hand door. The adjustment screw is located on the bottom of the

right door. Open the freezer door to access. The left hand fresh food door

may be raised using spacers. Call 800-GECARES to obtain the spacers.

removed do not remove the handles, or if the refrigerator will fit easily

through the passage way opening. Adjust handles that are loose or have

a gap, by adjusting 1/8” set screws on either end of handles.

40

Page 21

Before you call for service, review the detailed troubleshooting tips in the Owner’s

SERVICE

manual. If needed, service can be scheduled by visiting us online GEAppliances.

com or calling 800.ge.CARES 800.432.2737

Truth or Myth (cont.)

Truth or Myth? Answer Explanation

Door removal is always required for installation. MYTH Check chart on reverse side of this instruction. Doors should only be

removed when necessary to prevent damage from passage way or

access to final location.

Refrigerator doors that won’t close after installation,

can be adjusted to close properly.

There is an adjustment to rear wheels. MYTH Front leveling legs are adjustable and should be used to balance the

Check for leaks after all water connections are made. TRUE While purging the air from the water system, check all water line

My LCD display will always be on when I plug the

power cord in at installation.

Any packaging residue can be cleaned off the

refrigerator using any cleaner.

TRUE Door mechanism works best if installed at 90°+. If installed at 180°,

remove the door from the mid hinge, and swing the door 180° before

reinstalling. See Reinstalling the Refrigerator Doors.

refrigerator. Leveling legs are used to make initial fresh food door

adjustment.

connections for leaks. Check the connection to the household water

supply at back of refrigerator, and door water line connect.

MYTH If the refrigerator has been stored in a cold environment, the LCD may be

slow to give a proper display. Give the refrigerator enough time to warm

up, and the display should be okay.

MYTH Do not use wax, polish, bleach, or other products containing chlorine on

Stainless Steel panels, door handles and trim. Check this instruction under

“Cleaning the Outside” for full details.

41

Page 22

Refrigerator Warranty. (For customers in the United States)

All warranty service provided by our Factory Service Centers, or

®

an authorized Customer Care

technician. To schedule service,

visit us online at GEAppliances.com, or call 800.GE.CARES

(800.432.2737). Please have serial number and model number

available when calling for service.

Staple your receipt here.

Proof of the original

purchase date is needed

to obtain service under the

warranty.

Servicing your refrigerator may require the use of the onboard data port for diagnostics. This gives a GE

Factory Service technician the ability to quickly diagnose any issues with your appliance and helps GE

improve its products by providing GE with information on your appliance. If you do not want your appliance

data to be sent to GE, please advise your technician NOT to submit the data to GE at the time of service.

For the Period of: GE Will Replace

GE PROFILE ™ AND

GE CAFÉ™ MODELS

One Year

From the date of the original

purchase

Thirty Days

(Water filter, if included)

From the original purchase

date of the refrigerator

GE PROFILE MODELS ONLY

Five Years

(GE Profile models only)

From the date of the

purchase

Any part of the refrigerator which fails due to a defect in materials or workmanship.

During the limited one-year warranty, GE will also provide, free of charge, all labor and related

service to replace the defective part.

Any part of the water filter cartridge which fails due to a defect in materials or workmanship. During

this limited thirty-day warranty, GE will also provide, free of charge, a replacement water filter

cartridge.

Any part of the sealed refrigerating system (the compressor, condenser, evaporator an all

connecting tubing) which fails due to a defect in materials or workmanship.

During this limited five-year sealed refrigerating system warranty, GE will also provide, free of

charge, all labor and related service to replace the defective part in the sealed refrigerating system.

What GE Will Not Cover:

■ Service trips to your home to teach you how to use the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused, or used for other

than the intended purpose or used commercially.

■ Loss of food due to spoilage.

■ Replacement of house fuses or resetting of circuit breakers.

■ Damage caused after delivery.

■ Replacement of the water filter cartridge, if included, due to

water pressure that is outside the specified operating range or

due to excessive sediment in the water supply.

(;&/86,212),03/,(':$55$17,(6³<RXUVROHDQGH[FOXVLYHUHPHG\LVSURGXFWUHSDLUDVSURYLGHGLQWKLV

Limited Warranty. Any implied warranties, including the implied warranties of merchantability or fitness

for a particular purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. If the product is located in an area where service by a GE Authorized Servicer is not available,

you may be responsible for a trip charge or you may be required to bring the product to an Authorized GE Service

location for service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

■ Replacement of the light bulbs, if included, or water filter

cartridge, if included, other than as noted above.

■ Damage to the product caused by accident, fire, floods or acts

of God.

■ Incidental or consequential damage caused by possible defects

with this appliance.

■ Product not accessible to provide required service.

■ Damage caused by a non-GE Brand water filter.

Warrantor: General Electric Company. Louisville, KY 40225

42

Page 23

RPWF Water Filter Cartridge Limited Warranty.

Appliance Service

GE

Appliances

800-GE-CARES

For The Period Of: We Will Replace, At No Charge To You:

Contact us at www.geapplianceparts.com,

or call 800.GE.CARES.

Staple your receipt

here. Proof of the

original purchase

date is needed to

obtain service

under the warranty.

Thirty Days

From the date of the

Any part of the water filter cartridge which fails due to a defect in materials or

workmanship during this limited thirty-day warranty.*

original purchase

What is Not Covered:

? Service trips to your home to teach you how to use the product.

? Improper installation.

? Failure of the product if it is abused, misused, used for other than the intended

purpose or used commercially.

? Replacement of house fuses or resetting of circuit breakers.

? Replacement of the water filter cartridge due to water pressure that is outside the

specified operating range or due to excessive sediment in the water supply.

? Damage to the product caused by accident, fire, floods or acts of God.

? Incidental or consequential damage caused by possible defects with this appliance.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for

home use within the U.S.A. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

For Purchases Made In Iowa: This form must be signed and dated by the buyer and seller prior to the

consummation of this sale.

This form should be retained on file by the seller for a minimum of two years.

Buyer:

Name

Address

City State Zip

Signature Date

* If your GE part fails because of a manufacturing defect within thirty days from the date of original purchase for use, we will give you a new or, at our option, a rebuilt part without charge.

Return the defective part to the parts supplier from whom it was purchased together with a copy of the “proof of purchase” for the part. If the part is defective and shows no signs of abuse,

it will be exchanged. The warranty does not cover the failure of parts which are damaged while in your possession, are abused, or have been installed improperly. It does not cover the cost

of returning the part to the supplier from whom it was purchased nor does it cover the cost of labor to remove or install it to diagnose the fault. It does not cover parts used in products in

commercial use except in the case of air conditioning equipment. In no event shall GE be liable for consequential damages. Warrantor: General Electric Company

EXCLUSION OF IMPLIED WARRANTIES: Your sole and exclusive remedy is part exchange as provided in this Limited Warranty. Any implied warranties, including the implied warranties of

merchantability or fitness for a particular purpose, are limited to six months or the shortest period allowed by law.

GE

Appliances

Appliance Park

Louisville, KY 40225

geapplianceparts.com

Seller:

Name

Address

City State Zip

Signatur

43

eDate

© 2012 General Electric Company PC66596

Page 24

Performance Data Sheet

Model: GE RP

WF

Use Replacement Cartridge RPWF.

The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible

limit for water leaving the system as specified in NSF/ANSI Standard 42 and Standard 53. System tested and certified by NSF International against

NSF/ANSI Standard 42 and Standard 53 for the reduction of substances listed below.

Capacity 170 Gallons (643.5 Liters). Contaminant Reduction Determined by NSF testing.

Substance Tested

for Reduction Average Infl uent

Chlorine Taste and Odor 2.0 mg/L 2.0 mg/L ± 10% 97.4% 0.05 mg/L N/A ≥50% J-00102044

Nominal Particulate

Class I, , ≥0.5 to < 1.0 μm 7,633,333 pts/mL At least 10,000 particles/mL 99.0% 71,850 pts/ml N/A ≥85% J-00106249

Asbestos 109 MFL

Atrazine 0.009 mg/L 0.009 mg/L ± 10% 94.4% 0.0005 mg/L 0.003 mg/L N/A J-00102058

Benzene 0.016 mg/L 0.015 mg/L ± 10% 96.4% 0.001 mg/L 0.005 mg/L N/A J-00102065

Carbofuran 0.08 mg/L 0.08 mg/L ± 10% 98.8% 0.001 mg/L 0.04 mg/L N/A J-00102059

Cyst* 104,750 cysts/L Minimum 50,000 cysts/L 99.99% 3 cyst/L N/A ≥99.95% J-00102057

Lead pH @6.5 0.140 mg/L 0.15 mg/L ± 10% 99.3% 0.001 mg/L 0.010 mg/L N/A J-00102052

Lead pH @8.5 0.158 mg/L 0.15 mg/L ± 10% 98.3% 0.002 mg/L 0.010 mg/L N/A J-00102053

Mercury @ pH 6.5 0.006 mg/L 0.006 mg/L ± 10% 91% 0.0003 mg/L 0.002 mg/L N/A J-00102054

Mercury @ pH 8.5 0.006 mg/L 0.006 mg/L ± 10% 88.3%% 0.0007 mg/L 0.002 mg/L N/A J-00104087

Lindane 0.002 mg/L 0.002 mg/L ± 10% 99% 0.00002 mg/L 0.0002 mg/L N/A J-00102063

P-Dichlorobenzene 0.222 mg/L 0.225 mg/L ± 10% 99.8% 0.0005 mg/L 0.075 mg/L N/A J-00102067

Toxaphene 0.015 mg/L 0.015 mg/L ± 10% 93.5% 0.001 mg/L 0.003 mg/L N/A J-00102061

2, 4-D Reduction 0.218 mg/L 0.210 mg/L±10% 99.9% 0.0001 mg/L 0.07 mg/L N/A J-00102064

*Based on the use of Cryptosporidium parvum oocyst s.

NSF specifi ed

Challenge Concentration

7

10

to 108 fi bers/L; fi bers

greater than 10μm in length 99.99% <1 MFL N/A ≥99% J-00102069

Avg %

Reduction

Average Product

Water

Concentration

Max Permissible

Product Water

Concentration

NSF Reduction

Requirements

NSF

Test Report

07020100-J%59≥A/NL/gm 5100.0%7.79%01 ± L/gm 003.0L/gm 872.0COV

The following pharmaceutical reduction claims have not been certifi ed by NSF International. Claims tested and verifi ed

by independent laboratory:

Contaminant

Reduction Average Infl uent

Atenolol 1088 ng/L N/A 99.5% 5.0 ng/L N/A J-00103221

Fluoxetine 845 ng/l N/A 99.4% 5.0 ng/L N/A J-00103221

Ibuprofen 898 ng/L N/A 98.8% 9.9 ng/L N/A J-00103726

Progesterone 945 ng/L N/A 99.4% 5.5 ng/L N/A J-00103727

Trimethoprim 403 ng/L N/A 99.5% 2.0 ng/L N/A J-00103221

NSF specifi ed

Challenge Concentration

Avg %

Reduction

Average Product Water

Concentration

Max Permissible

Product Water

Concentration

NSF

Test Report

Application Guidelines/Water Supply Parameters

Service Flow 0.5 gpm (1.89 lpm)

Water Supply Potable Water

It is essential that the manufacturer’s recommended installation, maintenance and filter replacement requirements be carried ou t for the product to perform as advertised.

See Installation Manual for Warranty information.

Note: While the testing was performed under standard laboratory conditions,

actual performance may vary.

Replacement Cartridge: RPWF. For estimated costs of replacement elements

please call 1-800-626-2002 or visit our website at www.geapplianceparts.com.

WARNING

To reduce the risk associated with ingestion of contaminants:

A ytilauq nwonknu fo ro efasnu yllacigoloiborcim si taht retaw htiw esu ton oD

without adequate disinfection before and after the system. Systems certifi ed

for cyst reduction may be used on disinfected water that may contain fi lterable

cysts. EPA Establishment Number 070595-MEX-001.

Water Pressure 25-120 psi (172– 827 kPa)

Water Temperature 33º F - 100º F (0.6º C - 38º C)

exceeds 80 psi, you must install a pressure-limiting valve. Contact a plumbing

professional if you are uncertain how to check your water pressure.

K Do not install where water hammer conditions may occur. If water hammer

conditions exist you must install a water hammer arrester. Contact a plumbing

professional if you are uncertain how to check for this condition.

K Do not install on hot water supply lines. The maximum operating water

temperature of this fi lter system is 100º F (38º C).

K Protect fi lter from freezing. Drain fi lter when temperatures drop

below 33ºF (0.6ºC).

fi elbasopsid ehT Klter cartridge must be replaced every 6 months at the

rated capacity, or sooner if a noticeable reduction in fl ow rate occurs.

NOTICE

To reduce the risk associated with property damage due to water leakage:

DRead and follow use instructions before installation and use of this system.

D5stallation and use MUST comply with all state and local plumbing codes.

D Do not install if water pressure exceeds 120 psi (827 kPa). If your water pressure

GE

Appliances

Appliance Park

Louisville, KY 40225

geapplianceparts.com

For conditions of use, health claims certified by the California Department of Public

Health, and replacements, see performance data sheet. California Department

of Public Health Certification #11-2110. The contaminants or other substances

removed or reduced by this water filter are not necessarily in all users’ water.

System tested and certifi ed by NSF

International against NSF/ANSI Standard

42 and Standard 53 in model GE RPWF

for the reduction of the claims specifi ed

REPLACEMENT

on the performance data sheet.

TNEMELE

34-8708-7119-0

EPA #070595-MEX-001

© 2012 General Electric Company PC71879

44

Page 25

State of California

Department of Public Health

Water Treatment Device

Certicate Number

-

211011

Date Issued: November 16, 2011

Trademark/Model Designation

GE RPWF

Manufacturer:

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section

116830 of the Health and Safety Code for the following health related contaminants:

Microbiological Contaminants and Turbidity

Cysts

Organic Contaminants

Atrazine

Benzene

Carbofuran

Lindane

p-Dichlorobenzene

Toxaphene

2, 4-D

VOC’s by chloroform surrogate

3M Purication Inc.

Replacement Elements

RPWF

Inorganic/Radiological Contaminants

Asbestos

Lead

Mercury

CA AB1953 Low Lead Compliant

Rated Service Capacity:

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems certied

for cyst reduction may be used on disinfected waters that may contain lterable cysts.

170 gallons

Rated Service Flow:

Conditions of Certification:

45

0.5 gpm

Page 26

Consumer Support.

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances website, 24 hours a day, any day

of the year! For greater convenience and faster service, you can now download Owner’s Manuals, order parts

or even schedule service on-line. In Canada: www.GEAppliances.ca

In the U.S.: GEAppliances.com

Schedule Service In the U.S.: GEAppliances.com

Expert GE repair service is only one step away from your door. Get on-line and schedule your service at your

convenience any day of the year! Or call 800.GE.CARES (800.432.2737) during normal business hours.

In Canada, call 1.800.561.3344

Real Life Design Studio In the U.S.: GEAppliances.com

*(VXSSRUWVWKH8QLYHUVDO'HVLJQFRQFHSW³SURGXFWVVHUYLFHVDQGHQYLURQPHQWVWKDWFDQEHXVHGE\SHRSOHRI

all ages, sizes and capabilities. We recognize the need to design for a wide range of physical and mental abilities

and impairments. For details of GE’s Universal Design applications, including kitchen design ideas for people with

disabilities, check out our Website today. For the hearing impaired, please call 800.TDD.GEAC (800.833.4322).

In Canada, contact: Manager, Consumer Relations, Mabe Canada Inc.

Suite 310, 1 Factory Lane

Moncton, N.B. E1C 9M3

Extended Warranties In the U.S.: GEAppliances.com

Purchase a GE extended warranty and learn about special discounts that are available while your warranty is still

in effect. You can purchase it on-line anytime, or call 800.626.2224 during normal business hours. GE Consumer Home

Services will still be there after your warranty expires. In Canada, call 1.888.261.2133

Parts and Accessories In the U.S.: GEApplianceParts.com

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today, 24 hours every day or by phone at

800.626.2002 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing generally should

be referred to qualified service personnel. Caution must be exercised, since improper servicing may cause unsafe

operation.

Customers in Canada should consult the yellow pages for the nearest Mabe service center, or call 1.800.661.1616.

Contact Us In the U.S.: GEAppliances.com

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details including your

phone number, or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

In Canada: www.GEAppliances.ca, or write to: Director, Consumer Relations, Mabe Canada Inc.

Suite 310, 1 Factory Lane

Moncton, N.B. E1C 9M3

Register Your Appliance In the U.S.: GEAppliances.com

5HJLVWHU\RXUQHZDSSOLDQFHRQOLQH³DW\RXUFRQYHQLHQFH7LPHO\SURGXFWUHJLVWUDWLRQZLOODOORZIRUHQKDQFHG

communication and prompt service under the terms of your warranty, should the need arise. You may also

mail in the pre-printed registration card included in the packing material. In Canada: www.GEAppliances.ca

Printed in United States

Loading...

Loading...