Page 1

Dual Cavity Gas, Free Standing Ranges

Café, Profile & GE

JGB870DET

JGB870SET

PGB900DET

PGB900SET

PGB910DET

PGB910SET

PGB915SET

PGB930DET

PGB930SET

PGB935SET

P2B930DET

P2B930SET

PGB980SET

PGB995DET

PGB995SET

CGS990SET

CGS985SET

Café Profile & GE

C2S985SET

Copyright General Electric 2011

Page 2

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, &

mechanical experience. Any attempt to repair a major appliance may

result in personal injury & property damage. The manufacturer or seller

cannot be responsible for the interpretation of this information, nor can it

assume any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this product.

If electrical power is required for diagnosis or test purposes, disconnect

the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position & properly fastened.

Page 3

GE Factory Service Employees are required to use safety glasses with

side shields, safety gloves & steel toe shoes for all repairs.

Plano Type Safety Glasses

Electrically Rated Glove

Dyneema® Cut

Resistant Glove

Steel Toe Work

Boot

and Dyneema® Cut

Resistant Glove Keeper

Prescription Safety Glasses

Safety Glasses must be

ANSI Z87.1-2003 compliant

Brazing Glasses

Page 4

Copyright General Electric 2011

11/28/2011

4 /

Page 5

The Mini Manual is located in the control panel area on GE & Profile units. Back top left

rear corner on Café models.

The Nomenclature Tag is on the bottom left side front frame of the main oven.

Mini Manual Profile & GE

Mini Manual Cafe

Model Tag

Copyright General Electric 2011

5 /

11/28/2011

Page 6

Overview-Product Info

Café, Profile, and GE Brands

Cooktop

•Tri-Ring Burner

•Tri-Bridge Burner

•Tri-Bridge Griddle

Double Oven

• Upper Oven 2.5 cuft

• Lower Oven 4.0 cuft

• Both Self Clean

2x Lighting

Full Visibility Door (Glass

Liner)

Black Enameled Cavity

New Doors & SS trims

Copyright General Electric 2011

11/28/2011

6 /

Page 7

Overview-Feature Detail

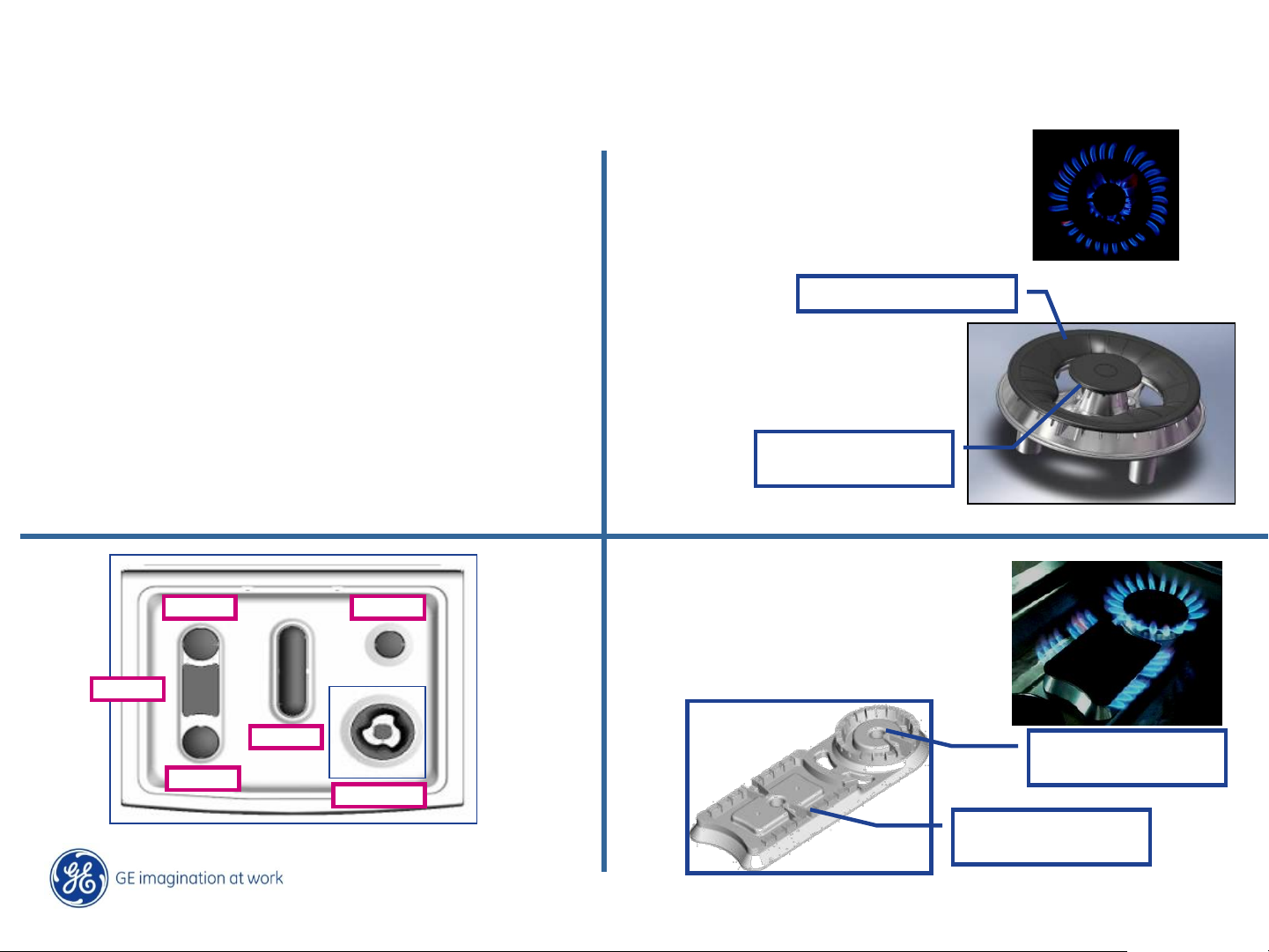

Cooktop Burners

3 Ring = 19/20K BTUs

• Tri Ring 20K BTUs- Café / 19K Profile

• Tri Bridge 23K BTUs

• New cooktop configurations

• New Griddles / Double-Bridge Griddle

9.1K

5.0K

9.5K

9.1K

5.0K

20/19K

17000 btu/h Max.

3000 btu/h Max.

400 btu/h Min.

3 Bridge = 24K BTUs

5000 btu/h Max.

1000 btu/h Min.

9100 btu/h Max.

850 btu/h Min.

Copyright General Electric 2011

11/28/2011

7 /

Page 8

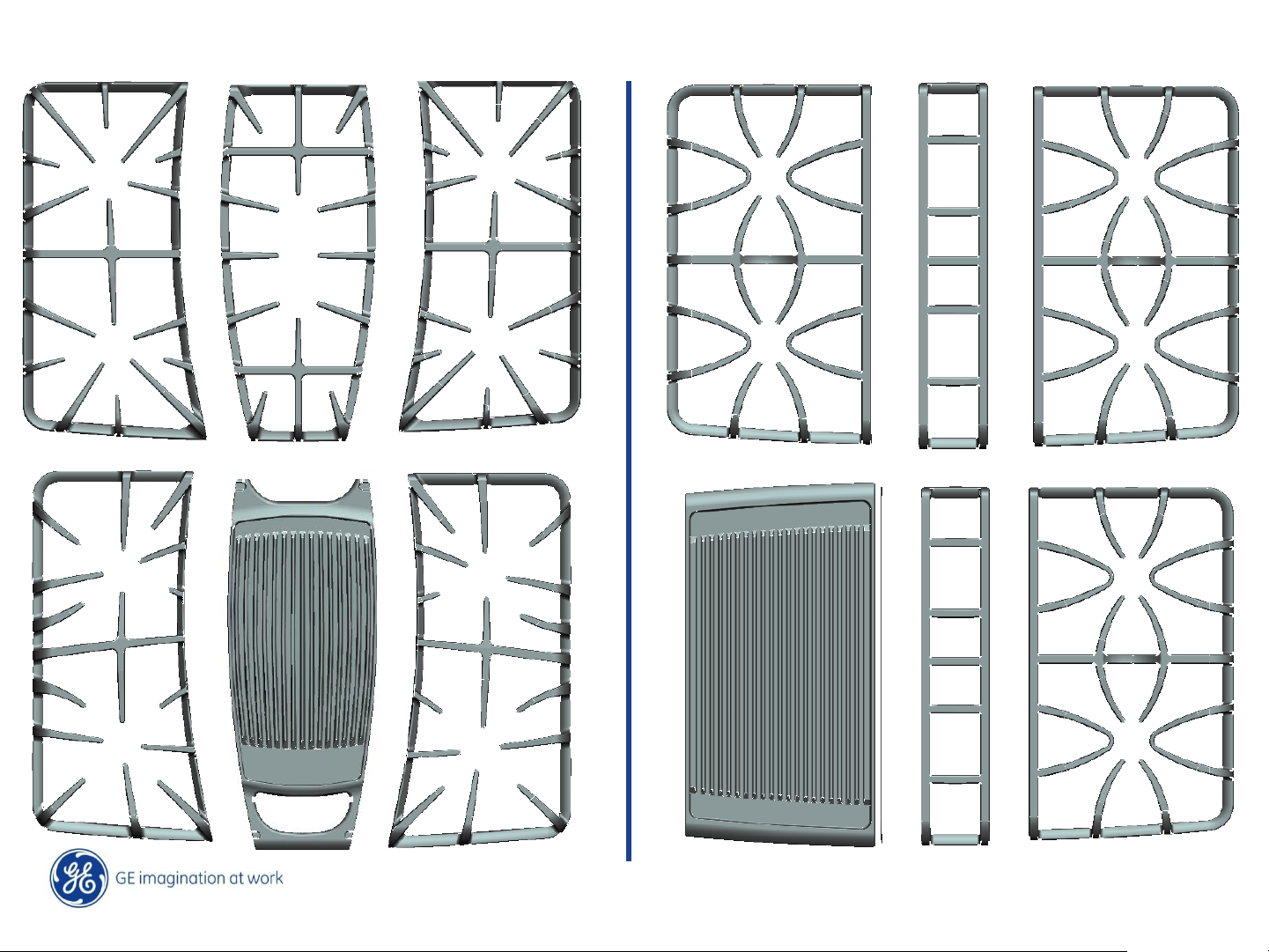

Cooktop Grates & Griddle Designs

Copyright General Electric 2011

11/28/2011

8 /

Page 9

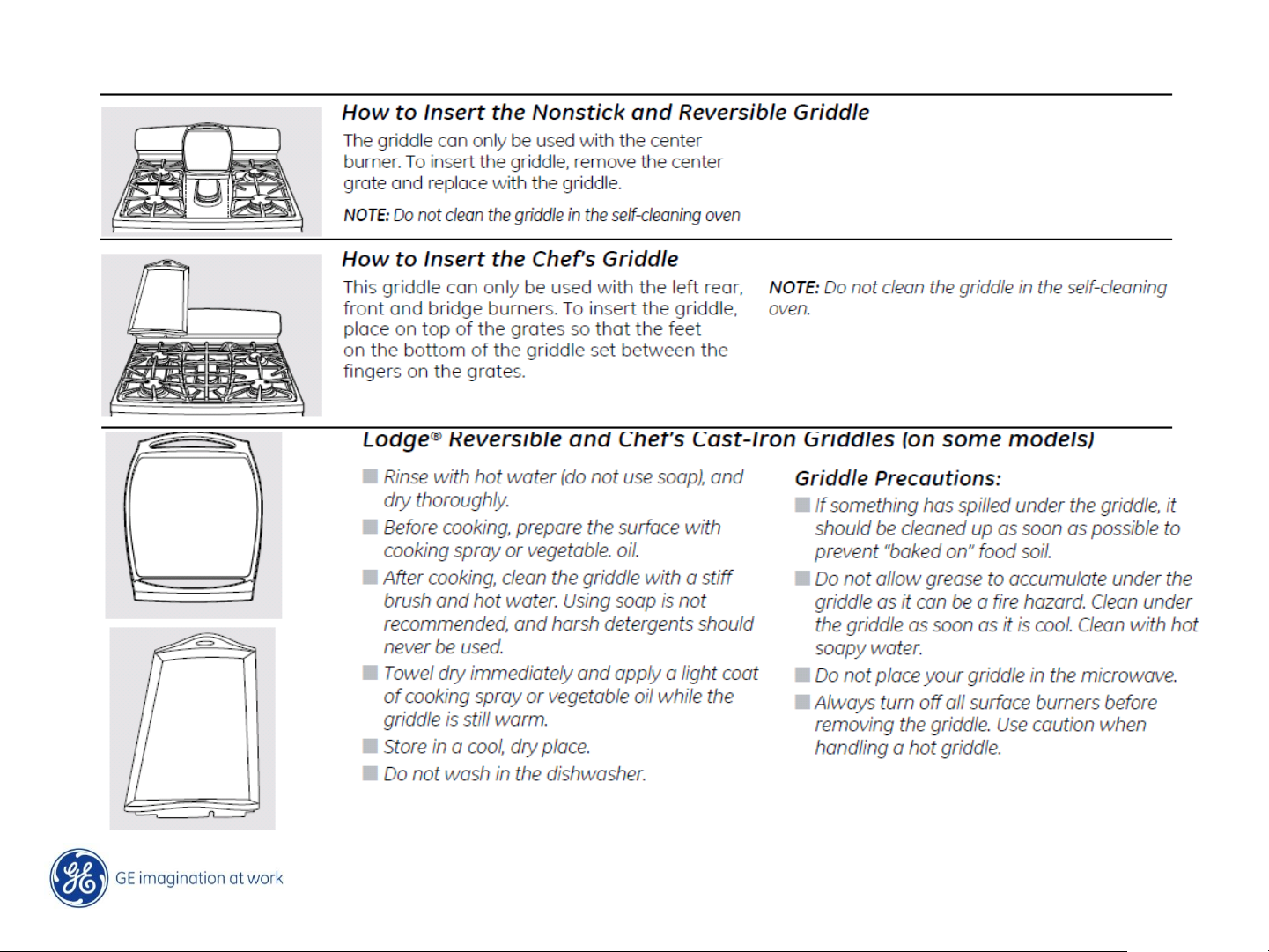

Note: The center griddle is used without the center grate installed, the Chef griddle is

installed on top of the left grate.

Copyright General Electric 2011

11/28/2011

9 /

Page 10

Copyright General Electric 2011

11/28/2011

10 /

Page 11

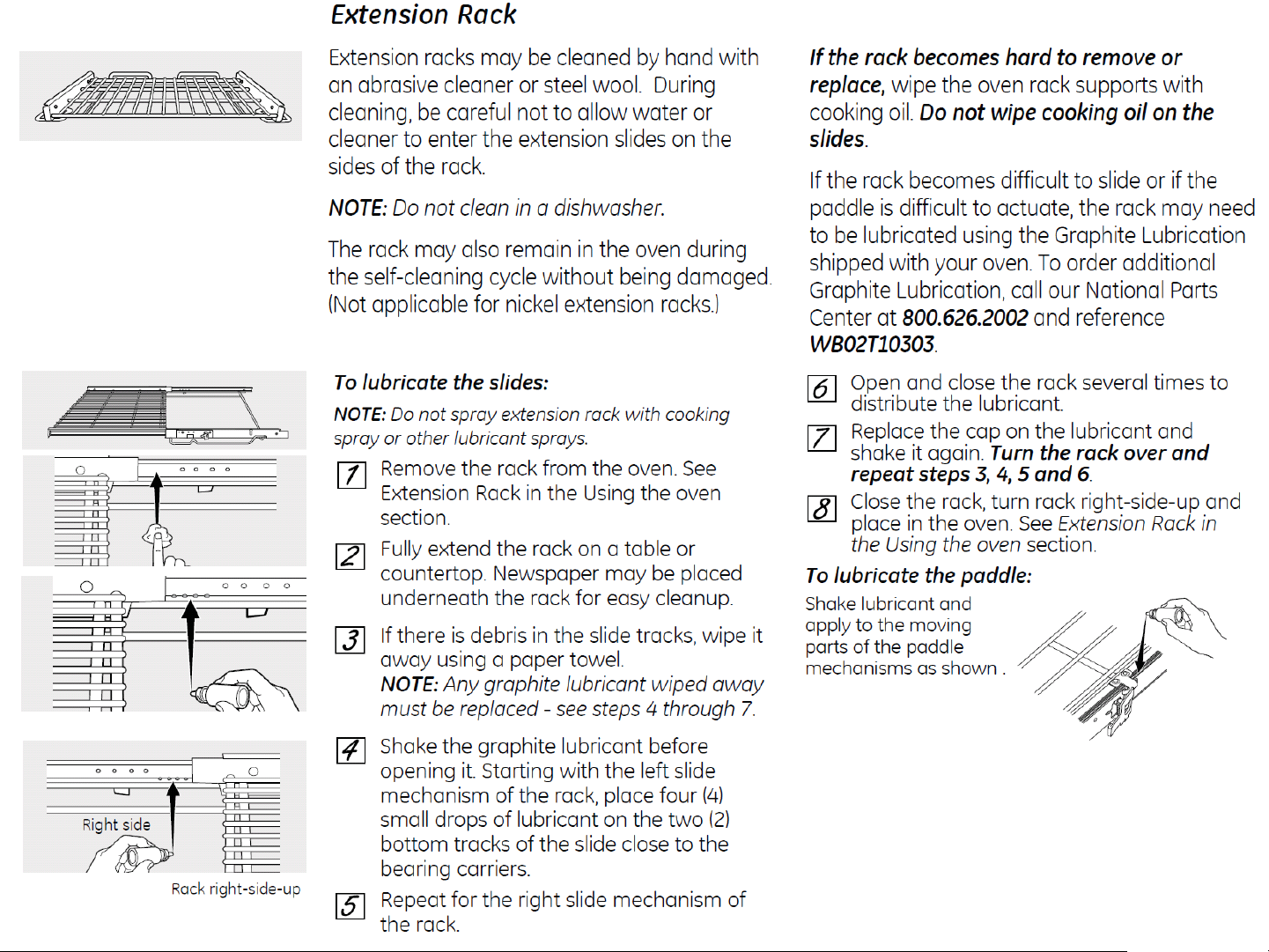

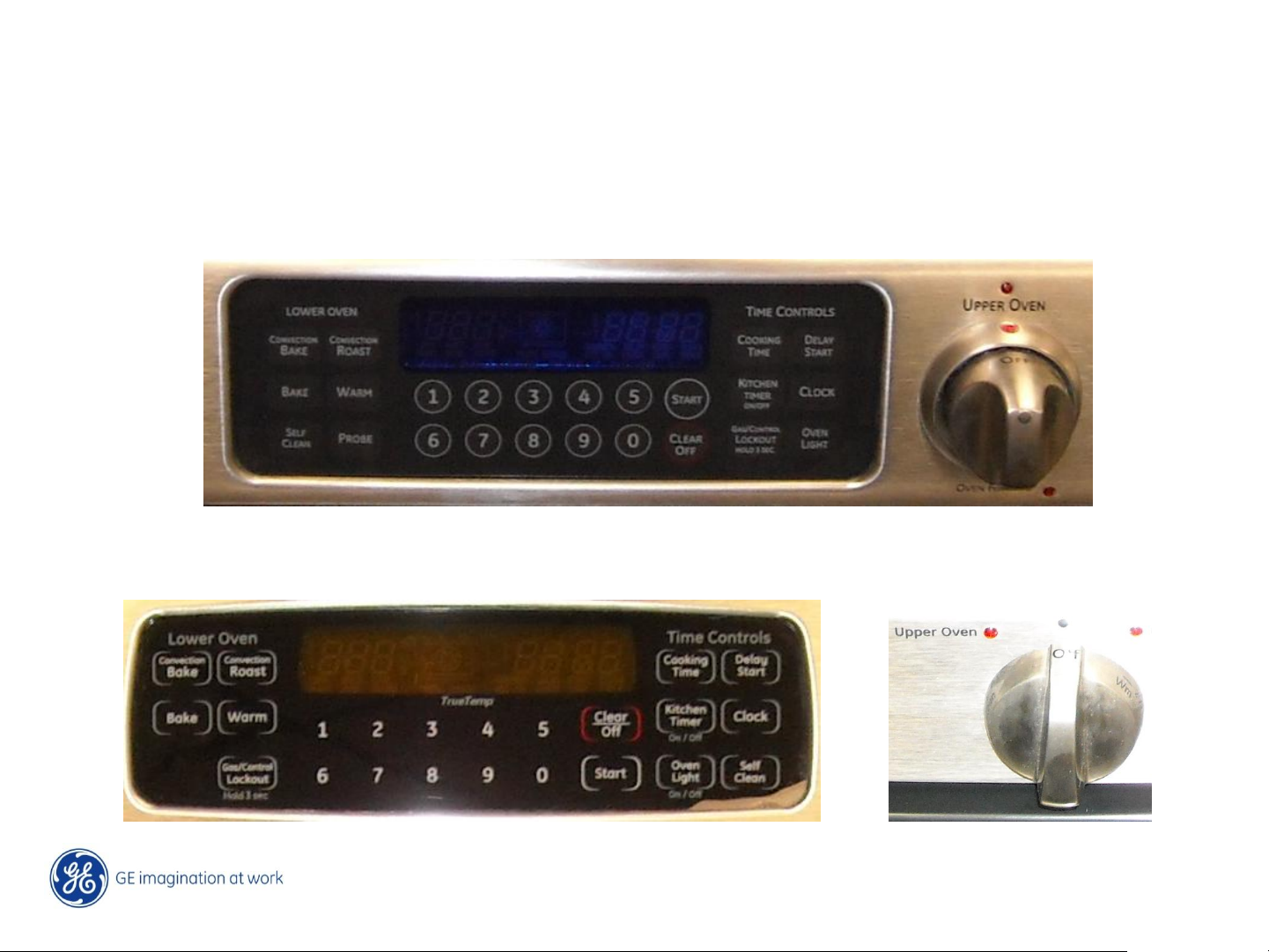

Control Overview, ERC & Thermostat

The lower oven is controlled by an (ERC) electronic control, the upper oven is controlled by

an hydraulic thermostat. Both upper and lower ovens have self clean capability.

Café Models

Profile & GE Models

Copyright General Electric 2011

11 /

11/28/2011

Page 12

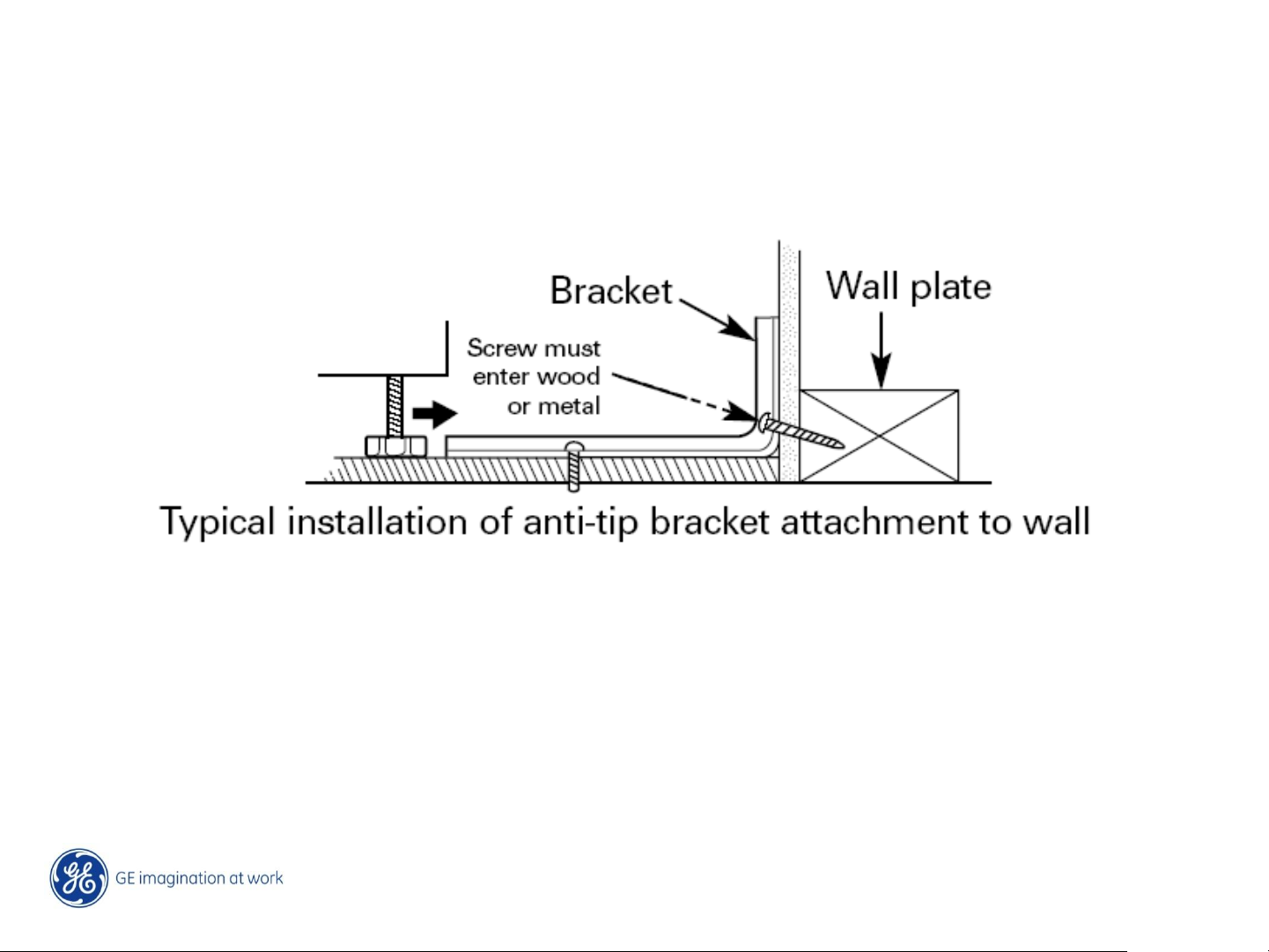

Anti-Tip Bracket

• Range must be secured by the Anti-Tip Bracket supplied.

Copyright General Electric 2011

12 /

11/28/2011

Page 13

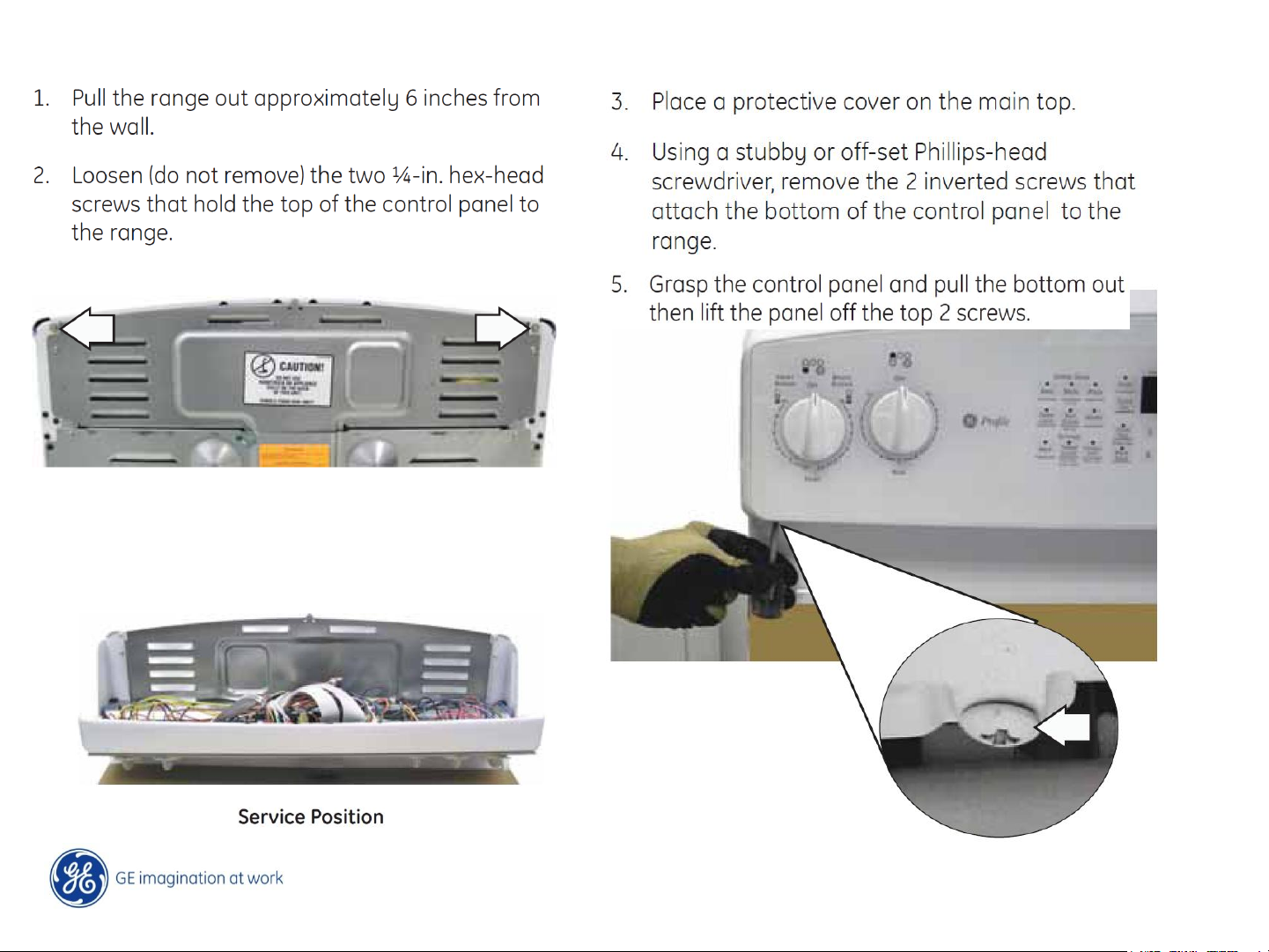

Control Panel Removal – GE & Profile

Copyright General Electric 2011

11/28/2011

13 /

Page 14

Lower Oven Door Removal

Copyright General Electric 2011

11/28/2011

14 /

Page 15

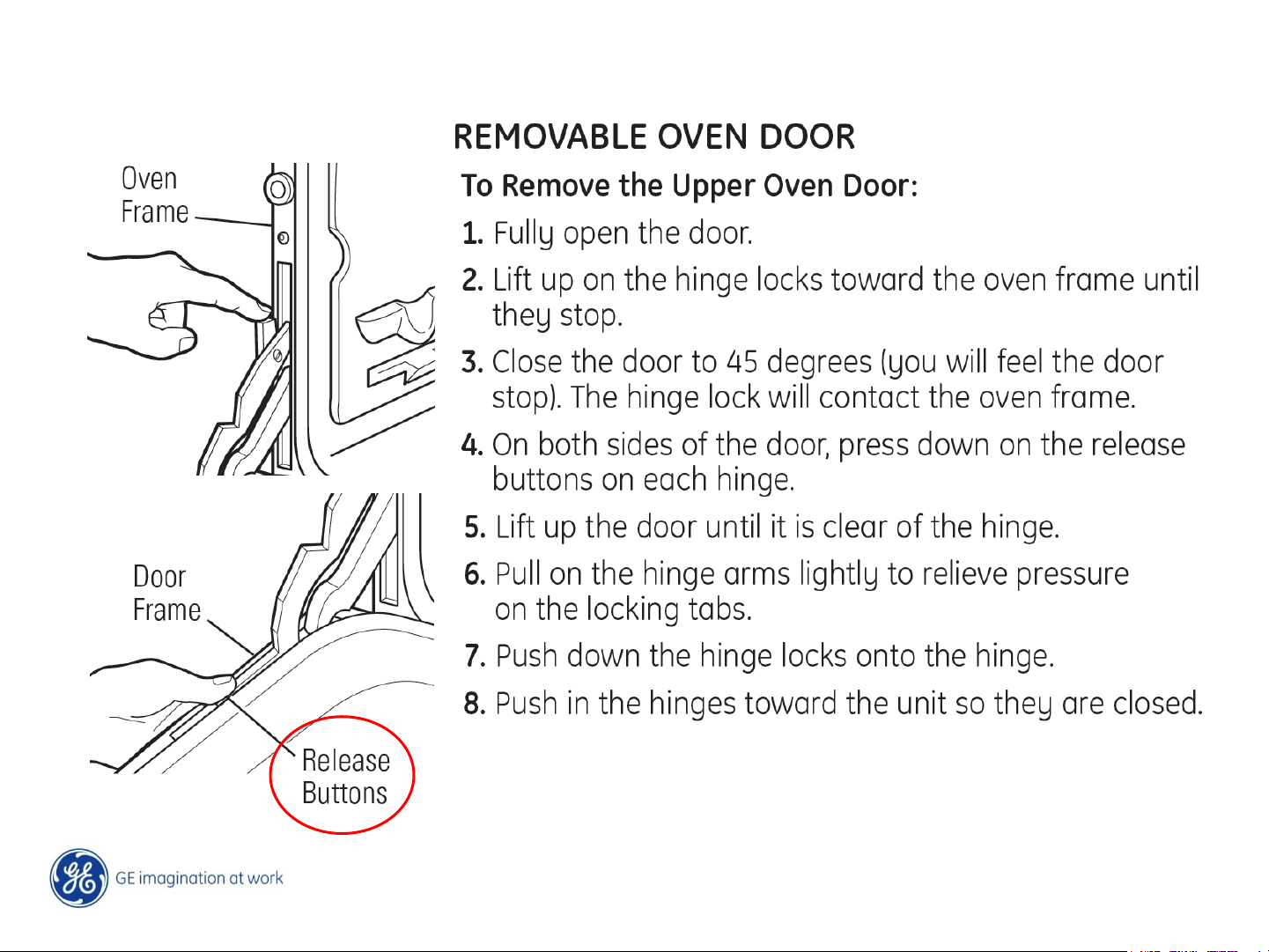

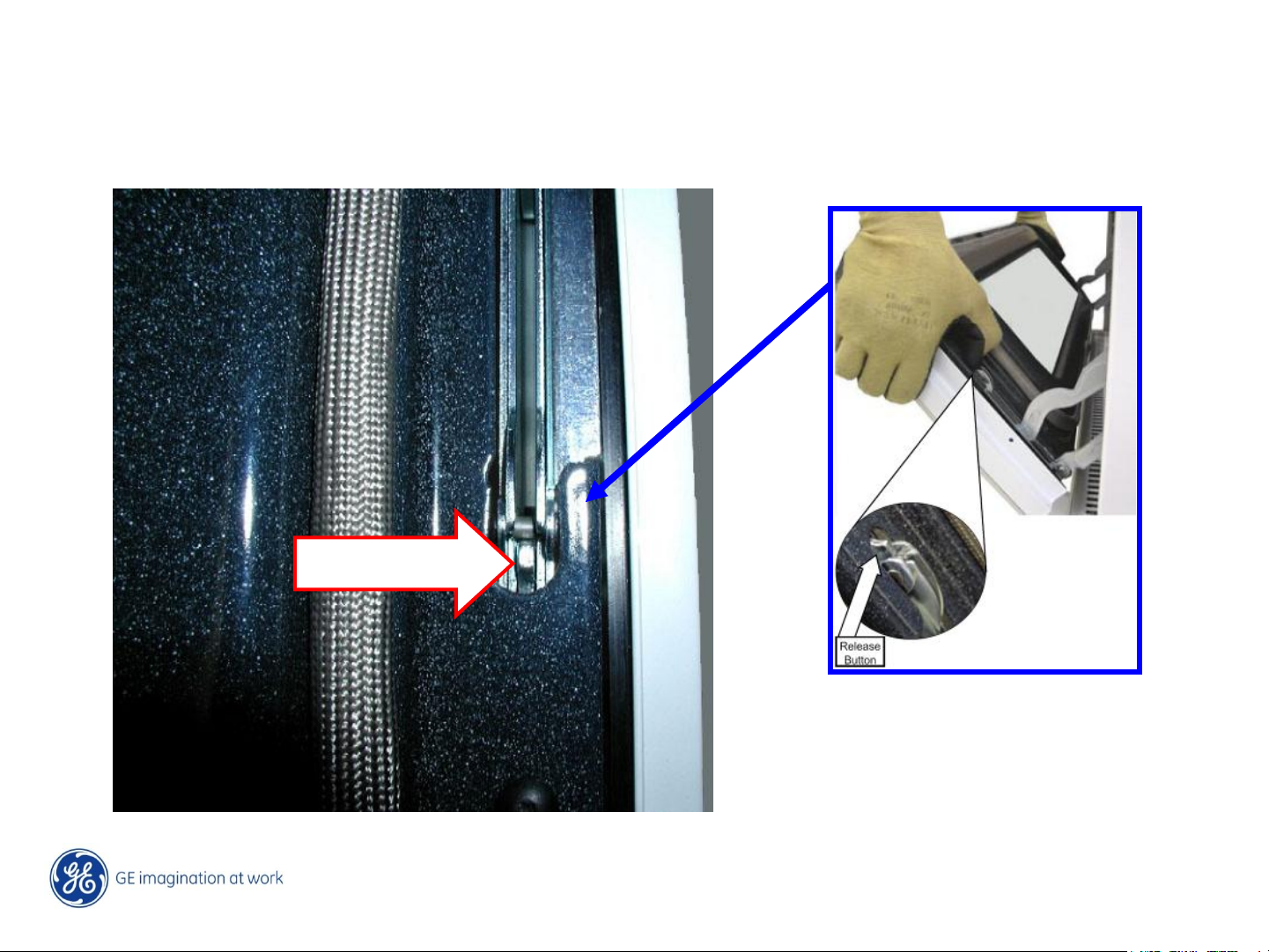

Upper Oven Door Removal – Hinge Release

Copyright General Electric 2011

11/28/2011

15 /

Page 16

Upper Oven Door Removal

Open the oven door to a 45 degree angle from the oven frame, press in on both release

buttons and lift the door off of the door hinges.

Release Button

Copyright General Electric 2011

16 /

11/28/2011

Page 17

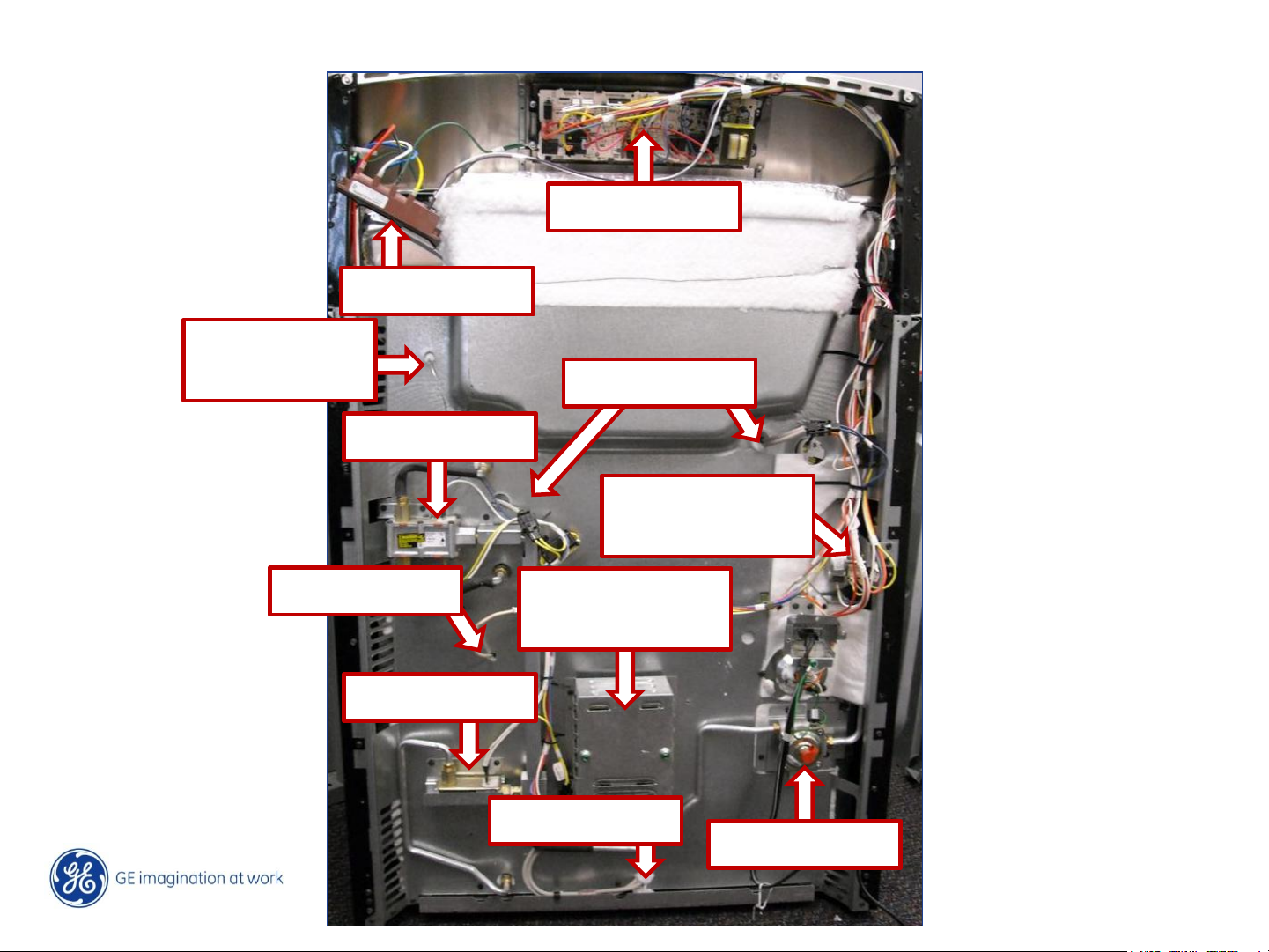

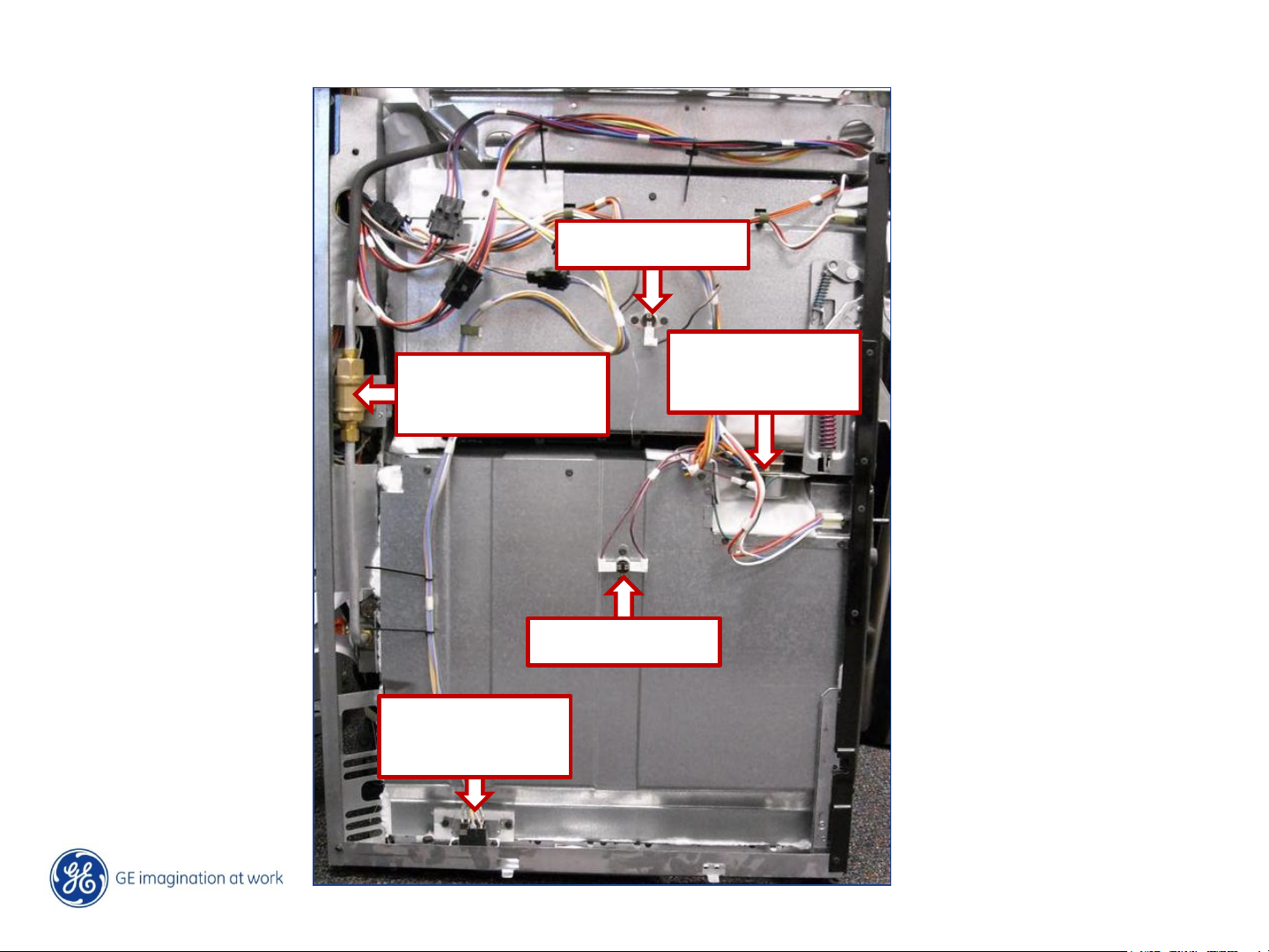

Component View, Back – Profile & GE

ERC

Spark Module

Thermostat

Capillary

Oven Sensor

Igniters UO

Gas Valve UO

Gas Lockout

Valve

Convection

Fan Motor

Gas Valve LO

Igniter LO

Regulator

17 /

Copyright General Electric 2011

11/28/2011

Page 18

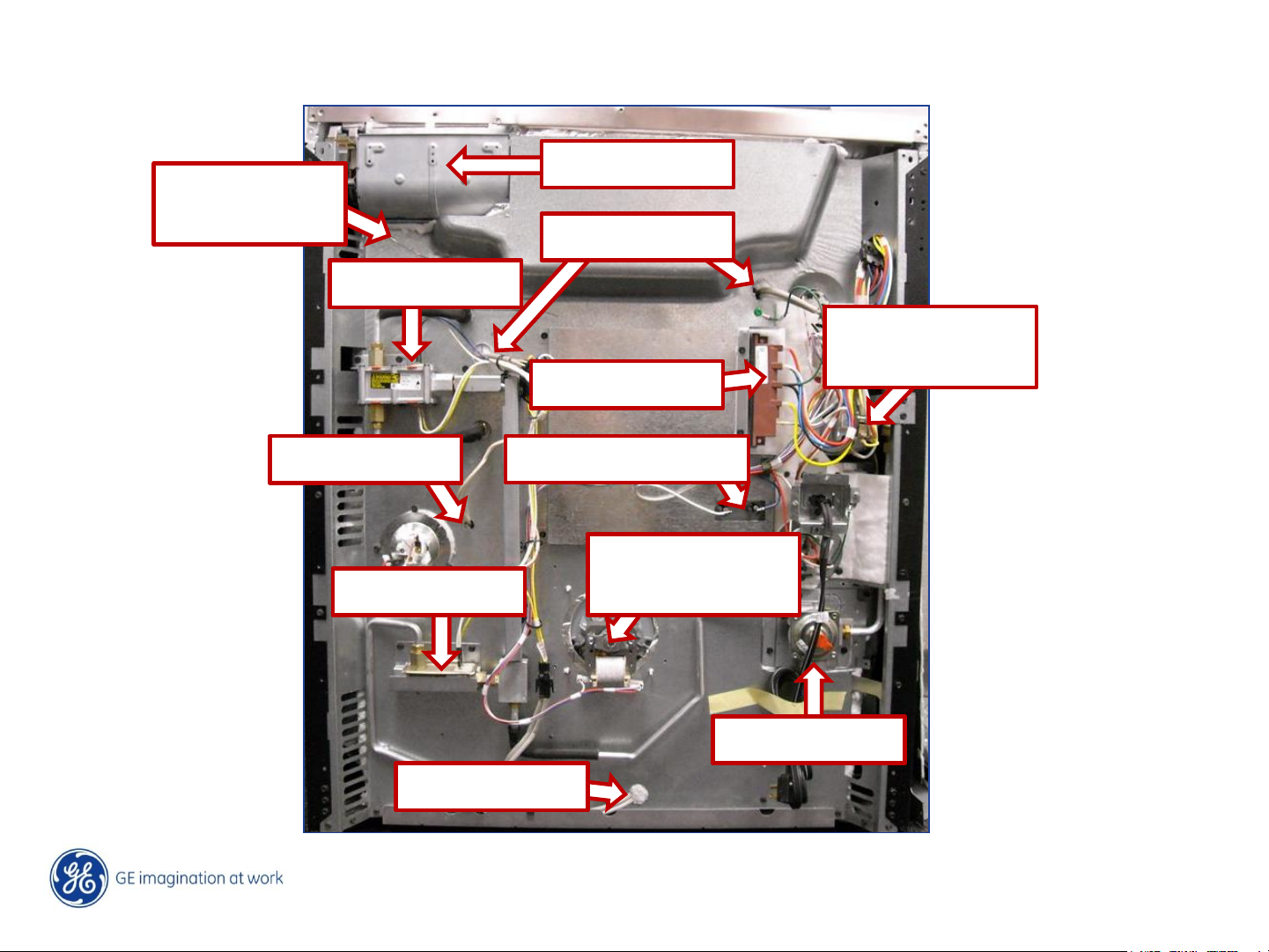

Component View, Back – Café

Thermostat

Cooling Fan

Capillary

Oven Sensor

Gas Valve UO

Gas Valve LO

Igniters UO

Gas Lockout

Valve

Spark Module

Broil Element LO

Convection

Fan Motor

Igniter LO

Regulator

18 /

Copyright General Electric 2011

11/28/2011

Page 19

Component View, LH Side – All Models

TCO UO

Gas Lockout

Valve

Self Clean

Latch Assy

Lock Out

Relay UO

TCO LO

19 /

Copyright General Electric 2011

11/28/2011

Page 20

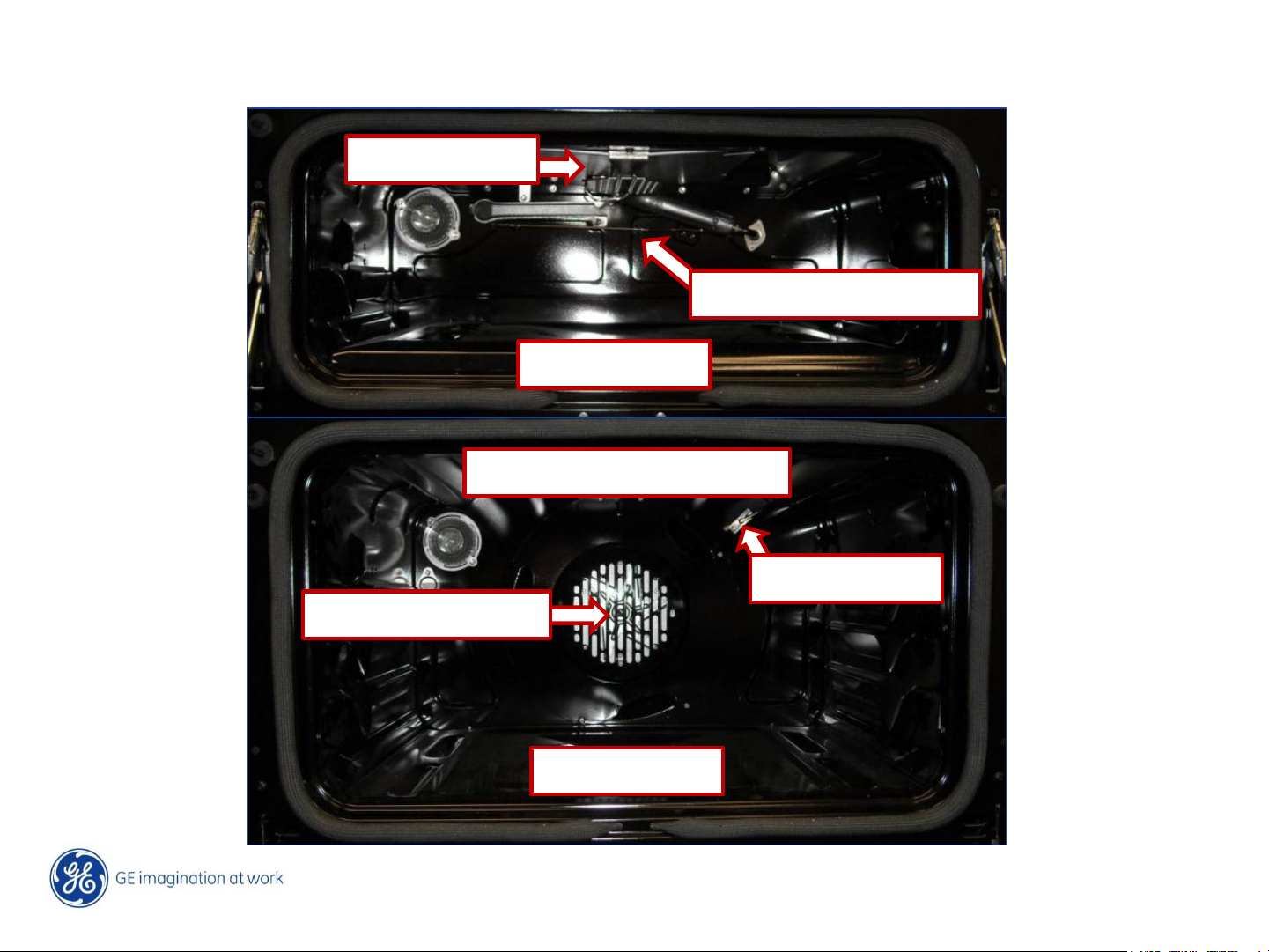

Component View, Oven Cavities

Broil Burner

Thermostat Capillary

Bake Burner

Broil Element, Café Only

Convection Fan

Sensor

Bake Burner

20 /

Copyright General Electric 2011

11/28/2011

Page 21

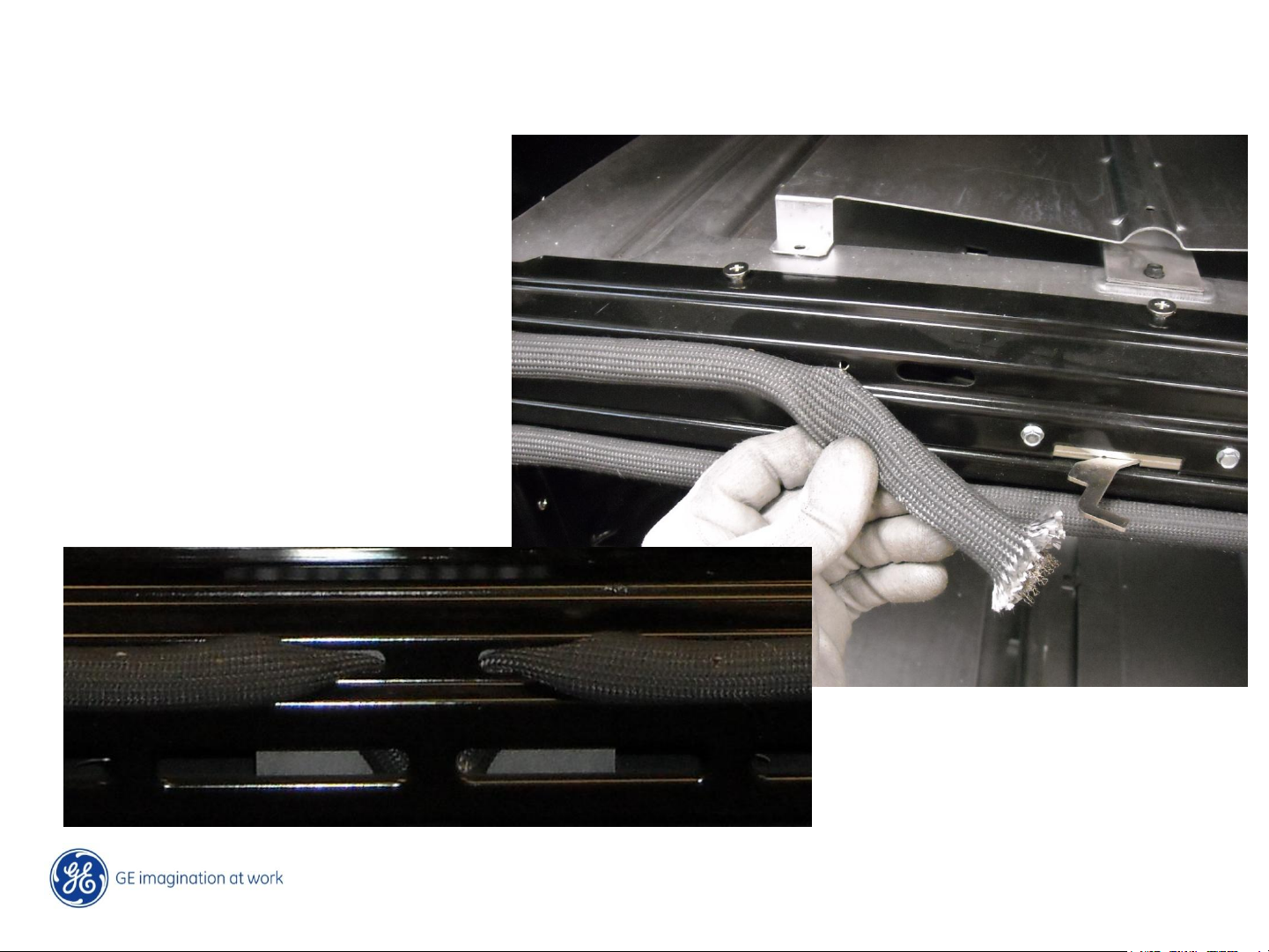

Oven Gaskets

The oven gaskets are installed with push in spring clips.

The bottom corners of the gasket

are installed in two oval slots at

the bottom without a crossover.

Copyright General Electric 2011

11/28/2011

21 /

Page 22

Cooktop Removal, GE & Profile

Copyright General Electric 2011

11/28/2011

22 /

Page 23

Cooktop Removal, Café

The first step for removal of the cooktop is to remove the oven vent trim. Remove three

¼” hex head screws from the vent trim and lift for removal.

Copyright General Electric 2011

11/28/2011

23 /

Page 24

Cooktop Removal, Café

Remove all of the T-15 Torx screws from the burners and front of the cooktop. Remove

the hex screws from the back of the cooktop and remove the spark electrodes from the

burners. Lift the cooktop off of the top of the oven.

Copyright General Electric 2011

11/28/2011

24 /

Page 25

Power Boil Tri-Burner

The right front burner is a 4 orifice power burner. Café„ models are 20K btu‟s and the GE

& Profile models are rated at 19K btu‟s. The outer three orifices are all connected to a

common manifold and operate at the same time. The center orifice is the simmer

burner.

Copyright General Electric 2011

11/28/2011

25 /

Page 26

Power Boil Tri-Burner

The front orifice is de-rated for requirements for clothing ignition. The front flames will

be smaller than the other two burner orifices, this is normal for this type of burner.

Smaller burner flame

Copyright General Electric 2011

26 /

11/28/2011

Page 27

Power Boil Tri-Burner – Spark Igniter

To replace the Tri-Burner spark igniter requires removal of the cooktop. Remove the T-15

Torx from the igniter bracket to remove. The orifice does not need removal.

Copyright General Electric 2011

11/28/2011

27 /

Page 28

Self Clean Latch, Upper Oven – Profile & GE

The upper oven self clean latch is accessible after removing the cooktop. The latch is

held to the front frame by two ¼” hex head screws.

Copyright General Electric 2011

11/28/2011

28 /

Page 29

Self Clean Latch, Upper Oven – Café

On Café models there are additional heat barriers that need to be removed to access the

self clean latch. The first heat shield is held by two ¼ hex screws at the rear. Next a fiber

barrier needs to be pulled to the rear of the range to expose another cover over the latch

assembly.

Copyright General Electric 2011

11/28/2011

29 /

Page 30

ERC (Electronic Range Control – Café

On Café models there is limited access to the ERC for electrical testing with a VOM.

Copyright General Electric 2011

11/28/2011

30 /

Page 31

ERC (Electronic Range Control) – Café

Once the burner bracket manifold screws are removed, remove two additional Phillips

screws at the top rear of the control housing. The control housing can the be lifted for

better access to the ERC terminals for testing.

Copyright General Electric 2011

11/28/2011

31 /

Page 32

Upper Oven (DRT) Thermostat

To replace the upper oven thermostat requires removal of the cooktop. Once the cooktop

is removed – remove the two T-15 Torx screws holding the thermostat to the control

panel. The thermostat can then be pulled out from the control panel.

Copyright General Electric 2011

11/28/2011

32 /

Page 33

Upper Oven (DRT) Thermostat

The front of the thermostat contains a switch; this switch is an input to the ERC control.

This input provides (on or off) information to the ERC so the ERC can control the Upper

Oven Lockout Control. This also provides the ERC the ability to control the hydraulic

thermostat Self Clean timing of 5 hours. This switch closes when the thermostat is off

and opens when the thermostat is in any on position. If the switch does not open the

ERC will not allow self clean.

Copyright General Electric 2011

11/28/2011

33 /

Page 34

Upper Oven (DRT) Thermostat

The thermostat capillary routing on GE & Profile units runs through an opening behind

the right rear surface burner. On Café units the capillary routing is in the right hand

side panel. The side panel does not need to be removed for thermostat replacement,

the rear panel does need removal for the oven cavity routing.

Profile & GE

Cafe‟

34 /

Copyright General Electric 2011

11/28/2011

Page 35

Upper Oven (DRT) Thermostat

The capillary tube routes into the back panel and passes through to the upper oven

cavity where it is secured to the back wall with two spring clips.

Copyright General Electric 2011

11/28/2011

35 /

Page 36

Upper Oven (DRT) Thermostat

The DRT is a hydraulic control thermostat. It receives L1 power from a jumper at the

ERC L1. Line power is sent through the RX to SX wire contact and then through the

External relay contact. The cycling contact is on the YX to VX wires. The VX to OX is

closed for bake and VX to NX for broil.

Copyright General Electric 2011

11/28/2011

36 /

Page 37

Cooktop Burner Gas Valves

The cooktop burner valves are secured to the manifold pipe with a (saddle) clamp with a

single screw for removal. The spark module switches are “D” keyed on the valve shaft.

Clamp

Gasket

Switch

Copyright General Electric 2011

37 /

11/28/2011

Page 38

Copyright General Electric 2011

11/28/2011

38 /

Page 39

Cooling Fan – Café Models

On Café models – there is a squirrel cage cooling fan in the right rear corner of the

cooktop. To service the fan requires removal of the cooktop. Once the cooktop is

removed, remove the six ¼” Hex head screws that hold the fan housing and lift up to

remove the fan assembly. The fan motor is controlled by the ERC and the oven sensor

temperature. The fan is turned on when the oven cavity temperature exceeds 300

degrees.

Copyright General Electric 2011

11/28/2011

39 /

Page 40

FAD – Café Models

On Café models with the cooling fan there is also a FAD (Fan Apparent Device). This

thermostat will disable the ovens in an over temperature issue due to a cooling fan

failure. The FAD is a self resetting thermostat that opens at 265˚F and closes at 225˚F.

If either oven is terminating Self Clean before time out, check Fan and FAD operation.

Copyright General Electric 2011

11/28/2011

40 /

Page 41

Side Panel Removal

There are several components that require the side panel to be removed. The lower oven

self clean latch, cooktop gas cutoff valve, door hinge and an upper oven lockout relay.

After removing the top and rear panel screws remove the single Phillips screw on the

cavity front.

Copyright General Electric 2011

11/28/2011

41 /

Page 42

Side Panel Removal

Carefully swing the side panel away from the range, using a large blade screw driver pry

out between the panel where it snaps onto the retainer clip while pulling out on the top

front of the side panel.

Retainer clip

Pry Outward

Copyright General Electric 2011

42 /

11/28/2011

Page 43

Lower Oven Latch

If the lower oven door should lock shut due to a latch failure, the two ¼” hex screws

can be accessed and removed by opening the upper oven door. The latch catch can the

be manipulated to release the door.

Copyright General Electric 2011

11/28/2011

43 /

Page 44

Lower Oven Latch Assembly

Lower Oven Self

Clean Latch Assy

Copyright General Electric 2011

11/28/2011

44 /

Page 45

Lower Oven Latch Removal

The latch is replaced through the LH side with the side panel removed.

Disconnect the wiring to the TCO and white wire

that comes from the door switch to the latch motor,

disconnect the ground wire. Remove the wire

Bundle from the wire retainers.

Pull the latch assembly back and out of the frame.

Transfer the wires one at a time from the old

latch to the replacement latch.

Copyright General Electric 2011

45 /

11/28/2011

Page 46

Upper Oven – Lockout Relay

Lock Out Relay

Upper Oven

Copyright General Electric 2011

46 /

11/28/2011

Page 47

Upper Oven Lockout Relay

The upper oven uses a lock out relay that will

disable the upper oven from operating when

the lower oven is in self clean. When the lower

oven is placed into clean the relay is activated

by the ERC disabling the upper oven

thermostat control. The ERC also uses this

relay to terminate the upper oven self clean

cycle at a preset 5 hour cycle.

Copyright General Electric 2011

11/28/2011

47 /

Page 48

Upper Oven Lockout Relay

The ERC activates the lockout relay from the “OUT WD” terminal when in clean. When

powered the relay opens the cycling contact circuit of the thermostat (NC contact). In

the Upper Oven clean cycle the ERC powers the thermostat through the MDL terminal.

Clean Cycle

Copyright General Electric 2011

11/28/2011

48 /

Page 49

Cooktop Gas Lockout Valve

Gas Lockout

Valve

Copyright General Electric 2011

11/28/2011

49 /

Page 50

Gas Lockout Valve

These models also utilize a gas lock out valve which turns the gas off to the cooktop.

This feature can be activated by the consumer through the ERC control and it is

automatically activated during self clean.

Copyright General Electric 2011

11/28/2011

50 /

Page 51

Gas Lockout Valve

The gas lockout function is activated by the ERC when selected by the consumer or

when a Self Clean cycle is activated. The Lockout valve will NOT operate if a surface

burner is in the on position. Each burner switch must be in the open (OFF) position state

to complete the gas lockout function. The ERC AUX terminal sends power down to the

surface burner switches and when ALL are closed (burners off) the lock out motor runs.

Copyright General Electric 2011

11/28/2011

51 /

Page 52

Gas Lockout Valve

The gas lockout valve incorporates two positioning switches to allow the ERC to know

the position of the lockout valve. Yellow to Orange closes when the valve is open and

allowing gas flow to the cooktop. This switch opens and Yellow to Silver close when the

valve is closed.

ERC

Loss of the Yellow to Orange contact will cause the lockout motor to run continuously

and LOC will flash in the ERC display. Loss of the Yellow to Silver will cause the lockout

motor to run continuously when Lock Out or Clean is selected; LOC will flash in the

display. LOC will display steady when the cooktop is locked out.

Copyright General Electric 2011

11/28/2011

52 /

Page 53

Cavity TCO‟s – All Models

Both upper and lower oven cavity TCO‟s (Thermal Cut Outs) are wired in series between

the latching motors and the ERC. If either TCO opens

during a clean cycle, the cycle will terminate and the

ERC will return to TOD (Time Of Day). If either TCO is

open at the start of a clean cycle; the ERC will beep

until the cancel button is pressed, no “F” code will be

displayed. The error code will be logged into the ERC

Memory and can be retrieved in diagnostic mode.

Both TCO‟s are rated 176˚ F open, 158˚ F close.

Copyright General Electric 2011

11/28/2011

53 /

Page 54

Self Clean Sequence of Operation

When the lower oven is placed into clean mode,

1. The gas lockout valve rotates to shut off the cooktop gas, returns signal to ERC.

2. The lower oven latch locks the door , returns signal to ERC.

3. The upper oven latch locks the door , returns signal to ERC.

4. The upper oven lockout relay is activated , returns signal to ERC.

5. The cooling fan is turned on. (Café models)

Clean time can be set from 3 to 5 hours, default is 4 hours.

When the cycle is complete,

1. The lower oven unlocks , returns signal to ERC.

2. The upper oven unlocks , returns signal to ERC.

3. The gas lockout rotates to allow gas flow to the cooktop , returns signal to ERC.

The upper oven follows the same sequence, the cycle time is fixed at 5 hours.

The spark module remains active but the burners will not light during clean.

Note: if any of these sequences fail; the ovens will NOT self clean.

Copyright General Electric 2011

11/28/2011

54 /

Page 55

Spark Module Location

The spark module on the Profile & GE models is located in the control panel.

On Café models the module is located on the back of the unit adjacent to the gas

lockout valve. When any surface burner is lit all igniters spark.

GE & Profile Café

Copyright General Electric 2011

11/28/2011

55 /

Page 56

Convection Fan Motor

The convection fan motor is front

serviceable. Remove the 6 Phillips

screws from the cover.

Remove the fan blade and pull the

motor into the oven cavity. Remove

the ¼” hex screws that attach the

motor to the mounting plate.

Copyright General Electric 2011

11/28/2011

56 /

Page 57

Bake & Broil Burners

The bake and broil burner orifices no

longer allow for adjustment.

When the unit is converted for LP

gas, new orifice hoods need to be

installed.

Without an adjustment, the hood

must be replaced if there are

combustion issues. But, this change

eliminates the possibility of damage

to the orifice hood needle valve by

the installer.

Copyright General Electric 2011

57 /

11/28/2011

Page 58

Bake & Broil Burners

The bake burners utilize a non-caged glow bar igniter. Be sure to use the proper

replacement, these are NEW igniter parts, the wiring harness‟ are longer. The

igniter is secured to the burner bracket with two ¼” hex screws. To access the

harness plugs requires removal of the oven back panel. Glow bar amperage is

approximately 4 amps. The upper oven glow bar is caged since it is open to the

oven cavity.

Copyright General Electric 2011

11/28/2011

58 /

Page 59

Bake & Broil Burners

The upper oven burner is secured at the top front of the cavity and can be

removed by a single ¼” hex screw. The Igniter wiring is run behind the left hand

cover also secured by a single ¼” hex screw. .

Copyright General Electric 2011

11/28/2011

59 /

Page 60

Bake & Broil Burners

The lower oven bake burner can be removed by removing a rear wall cover and

following the same procedure for the upper oven burner.

Copyright General Electric 2011

11/28/2011

60 /

Page 61

Café Lower Oven Broil Unit

Café‟ models utilize an upper broil calrod. The ERC closes the broil relay sending 120

volts to the element. The element resistance is 12 ohms and draws approximately 10

amps.

Copyright General Electric 2011

11/28/2011

61 /

Page 62

Copyright General Electric 2011

11/28/2011

62 /

Page 63

Copyright General Electric 2011

11/28/2011

63 /

Page 64

The oven can be set for the Jewish Sabbath Holidays. The oven lights will have to be

removed on some models since they are not controlled by the ERC.

Copyright General Electric 2011

11/28/2011

64 /

Page 65

Copyright General Electric 2011

11/28/2011

65 /

Page 66

Copyright General Electric 2011

11/28/2011

66 /

Page 67

Warranty

Copyright General Electric 2011

11/28/2011

67 /

Loading...

Loading...