Page 1

Guide to Ultrasonic Inspection

of Fasteners

Part No. 021-002-175

Rev . B

©2003 STRESSTEL

50 Industrial Park Road

Lewistown, PA 17044

Phone (866)243-2638

Fax (717) 242-2606

www.stresstel.com

Page 2

Page 3

Guide to Ultrasonic

Inspection of Fasteners

Copyright 2003 StressTel

Page 4

Page 5

Important Notice

Important Notice

The following information must be read and understood

by any user of a StressTel measurement instrument.

Failure to follow these instructions can lead to errors in

stress measurements or other test results. Decisions

based on erroneous results can, in turn, lead to property damage, personal injury or death. StressT el assumes

no responsibility for the improper or incorrect use of this

instrument.

General Warnings

Proper use of ultrasonic test equipment requires three

essential elements:

• Selection of the correct test equipment

• Knowledge of the specific “test application require-

ments”

• Training on the part of the instrument operator

This operating manual provides instruction in the basic

set-up and operation of the StressTel BoltMike III measurement instrument. There are, however, additional factors which affect the use of ultrasonic test equipment.

Specific information regarding these additional factors

is beyond the scope of this manual. The operator should

refer to textbooks on the subject of ultrasonic testing for

more detailed information.

Operator Training

Read the information in this manual prior to use of a

StressT el instrument. Failure to read and understand the

following information could cause errors to occur during

use of the instrument. Failure to follow these instructions can lead to error in stress measurement or other

test results. Decisions based on erroneous results can,

in turn, lead to property damage, personal injury or death.

Operators must receive adequate training before using

ultrasonic test equipment. Operators must be trained in

general ultrasonic testing procedures and in the set-up

required before conducting a particular test. Operators

must understand:

• Soundwave propagation theory

• Effects of the velocity at which sound moves

through the test material

More specific information about operator training, qualification, certification and test specifications is available

from various technical societies, industry groups, and

government agencies.

Testing Limitations

Information collected as a result of ultrasonic testing represents only the condition of test-piece material that is

exposed to the sound beam. Operators must exercise

great caution in making inferences about the test material not directly exposed to the instrument’s sound beam.

When a less-then-complete inspection is to be performed, the operator must be shown the specific areas

to inspect. Inferences about the condition of areas not

inspected, based on data from evaluated areas, should

only be attempted by personnel fully trained in applicable techniques of statistical analysis.

Sound beams reflect from the first interior surface encountered. Operators must take steps to ensure that the

entire thickness of the test material is being examined.

Calibrating the instrument/transducer combination is

particularly important when the test piece is being ultrasonically tested for the first time or in any case where

the history of the test piece is unknown.

Transducer Selection

The transducer used in testing must be in good condition without noticeable wear of its contact surface. Badly

worn transducers will have a reduced effective measuring range. The temperature of the material to be tested

must be within the transducer’s temperature range. If

the transducer shows any signs of wear it should be replaced.

• Soundwave propagation theory

• Effects of the velocity at which sound moves

through the

test material

• Behavior of the sound wave

• Which areas are covered by the sound beam

More specific information about operator training, qualification, certification and test specifications is available

from various technical societies, industry groups, and

government agencies.

• Behavior of the sound wave

• Which areas are covered by the sound beam

Guide to Ultrasonic Inspection of Fasteners Page iii

Page 6

Important Notice

Testing Limitations

Information collected as a result of ultrasonic testing represents only the condition of test-piece material that is

exposed to the sound beam. Operators must exercise

great caution in making inferences about the test material not directly exposed to the instrument’s sound beam.

When a less-then-complete inspection is to be performed, the operator must be shown the specific areas

to inspect. Inferences about the condition of areas not

inspected, based on data from evaluated areas, should

only be attempted by personnel fully trained in applicable techniques of statistical analysis.

Sound beams reflect from the first interior surface encountered. Operators must take steps to ensure that the

entire thickness of the test material is being examined.

Calibrating the instrument/transducer combination is

particularly important when the test piece is being ultrasonically tested for the first time or in any case where

the history of the test piece is unknown.

Transducer Selection

The transducer used in testing must be in good condition without noticeable wear of its contact surface. Badly

worn transducers will have a reduced effective measuring range. The temperature of the material to be tested

must be within the transducer’s temperature range. If

the transducer shows any signs of wear it should be replaced.

Page iv Guide to Ultrasonic Inspection of Fasteners

Page 7

Contents

Important Notice

Chapter 1: Ultrasonic Measurement of

Fasteners................................................................. 1

1.1 Important Concepts....................................... 1

1.1.1 Acoustic Velocity ................................. 1

1.1.2 The Use of Ultrasound ........................ 1

1.1.3 Initial Pulse and Multi-Echo

Measurement Modes .......................... 2

1.1.4 Time of Flight and Ultrasonic Length .. 2

1.1.5 Tensile Load........................................ 3

1.1.6 Stress .................................................. 4

1.1.7 Elongation ........................................... 4

1.1.8 Modulus of Elasticity (Eo) ................... 4

1.1.9 Stress Factor (K) ................................ 5

1.1.10 Temperature Coefficient (Cp) ............6

1.1.11 Calibration-Group Correction

Factors — Stress Ratio and Offset .... 6

1.1.12 Fastener Geometry ........................... 6

1.2 Principles of BoltMike Operation................... 7

1.3 Practical Limitations Of Ultrasonic

Measurement ................................................ 8

1.3.1 Material Compatible with Ultrasonic

Inspection............................................ 8

1.3.2 Significant Fastener Stretch ............... 8

1.3.3 Fastener End-Surface Configuration . 9

1.3.4 The Limitations of I.P. and M.E.

Measurement Modes .......................... 9

Chapter 4: Temperature Compensation .......... 17

4.1 Measuring Fastener Temperature .............. 1 7

4.2 Limits of Accurate Temperature

Measurement .............................................. 17

4.3 Adjusting the Temperature Coefficient ....... 1 8

Chapter 5: Selecting Phase ............................... 19

Chapter 6: Fastener Geometry.......................... 21

6.1 Approximate Length .................................... 21

6.2 Determining Effective Length...................... 21

6.3 Fastener Cross-Sectional Area .................. 2 4

Chapter 7: Material Constants .......................... 25

7.1 Standard Material Constants ...................... 25

7.2 Custom Material Constants......................... 2 5

7.3 Selecting a Material Constant..................... 25

7.4 Material Variations....................................... 26

Chapter 8: BoltMike Formulas........................... 27

Appendix: Tabular Data ....................................... 29

Chapter 2: Fastener Preparation ...................... 11

2.1 Fastener End-Surface Machining ............... 11

2.2 Methods Of Transducer Placement ............ 12

2.2.1 Practical Methods .............................12

2.2.2 Fixtures for Non-Magnetic Fasteners14

Chapter 3: Transducer Selection ...................... 15

3.1 General Acceptability .................................. 1 5

3.2 Transducer Frequency ............................... 15

3.3 Transducer Diameter .................................. 15

Purpose of Instrument and Transducer

Zeroing ........................................................ 15

Guide to Ultrasonic Inspection of Fasteners Page v

Page 8

Important Notice

Page vi Guide to Ultrasonic Inspection of Fasteners

Page 9

Chapter 1: Ultrasonic Measurement of Fasteners

Chapter 1: Ultrasonic Measurement of Fasteners

When threaded fastening systems (comprised of a bolt

or stud and a nut) are tightened, the threaded fastener

is said to be tensioned. The tensioning force in the fastener (identified in the BoltMike as its load) is equal to

the fastening system’s clamping force.

The BoltMike determines the load on a fastener by measuring the amount of time it takes for a sound wave to

travel along a fastener’s length, before and after a

tensioning force is applied to the fastener. The fastener

material’s acoustic velocity, together with difference in

the measured times, allows the instrument to calculate

the change in fastener length under the tensile load.

Provided the fastener’s dimensional and material properties are known, and the constants that represent the

material properties are entered into the instrument, the

BoltMike will calculate the load and stress present when

the fastener is in its tensioned state.

1.1 Important Concepts

To best understand exactly how ultrasonic sound waves

are used to determine loads, stress, and elongation of

threaded-fasteners, it is necessary that you understand

the concepts described in this section. Chapter 8 lists

the actual formulas used by the BoltMike to calculate

many of the quantities described below.

1.1.1 Acoustic Velocity

Applying a large electric pulse to a piezoelectric element

in a transducer creates an ultrasonic shock wave. This

type of shock wave, known as longitudinal wave, travels

through a fastener at a speed equal to the fastener

material’s acoustic velocity. A material’s acoustic velocity represents the speed with which sound moves through

it. All materials have a representative acoustic velocity

but true velocity can vary from one sample to another

(of the same material type) and even throughout the

material in a particular sample. It is important to realize

that the actual acoustic velocity is not truly a constant.

Instead, it varies between fasteners of like material, even

when the fastener’s material composition is tightly

controlled.

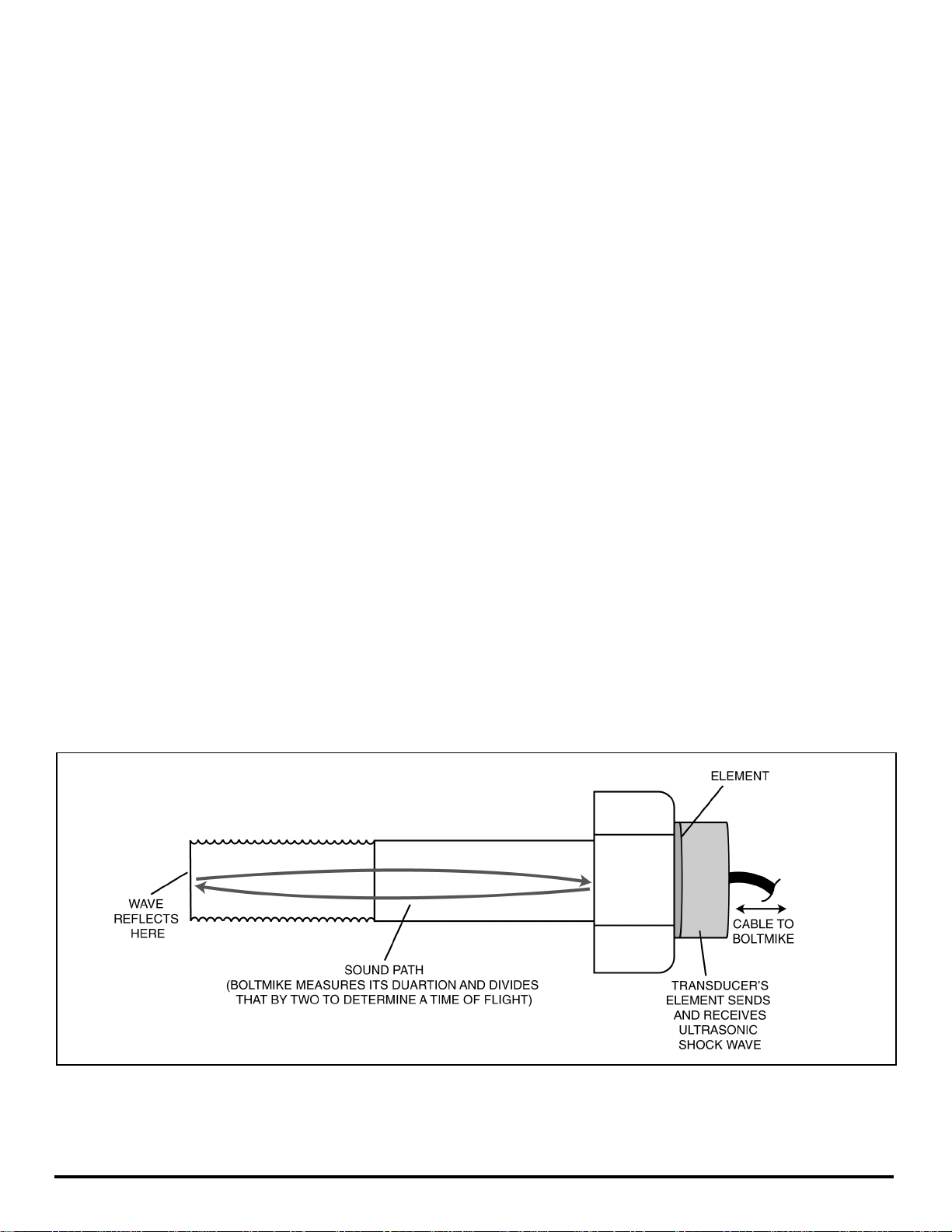

1.1.2 The Use of Ultrasound

The ultrasonic wave is transmitted from a transducer into

the end of a fastener . When the ultrasonic wave encounters an abrupt change in density, such as the end of the

fastener, most of the wave reflects. This reflection travels back the length of the fastener and back into the

transducer. When the shock wave re-enters the piezoelectric element a small electrical signal is produced. This

signal is represented on the BoltMike’s display panel by

the triggering of a measurement gate. This signal is used

by the BoltMike to indicate the returning wave.

(Figure 1-1)

FIGURE 1-1—The BoltMike determines the length of a fastener by measuring how long it takes for sound to travel its

length.

Guide to Ultrasonic Inspection of Fasteners Page 1

Page 10

Chapter 1: Ultrasonic Measurement of Fasteners

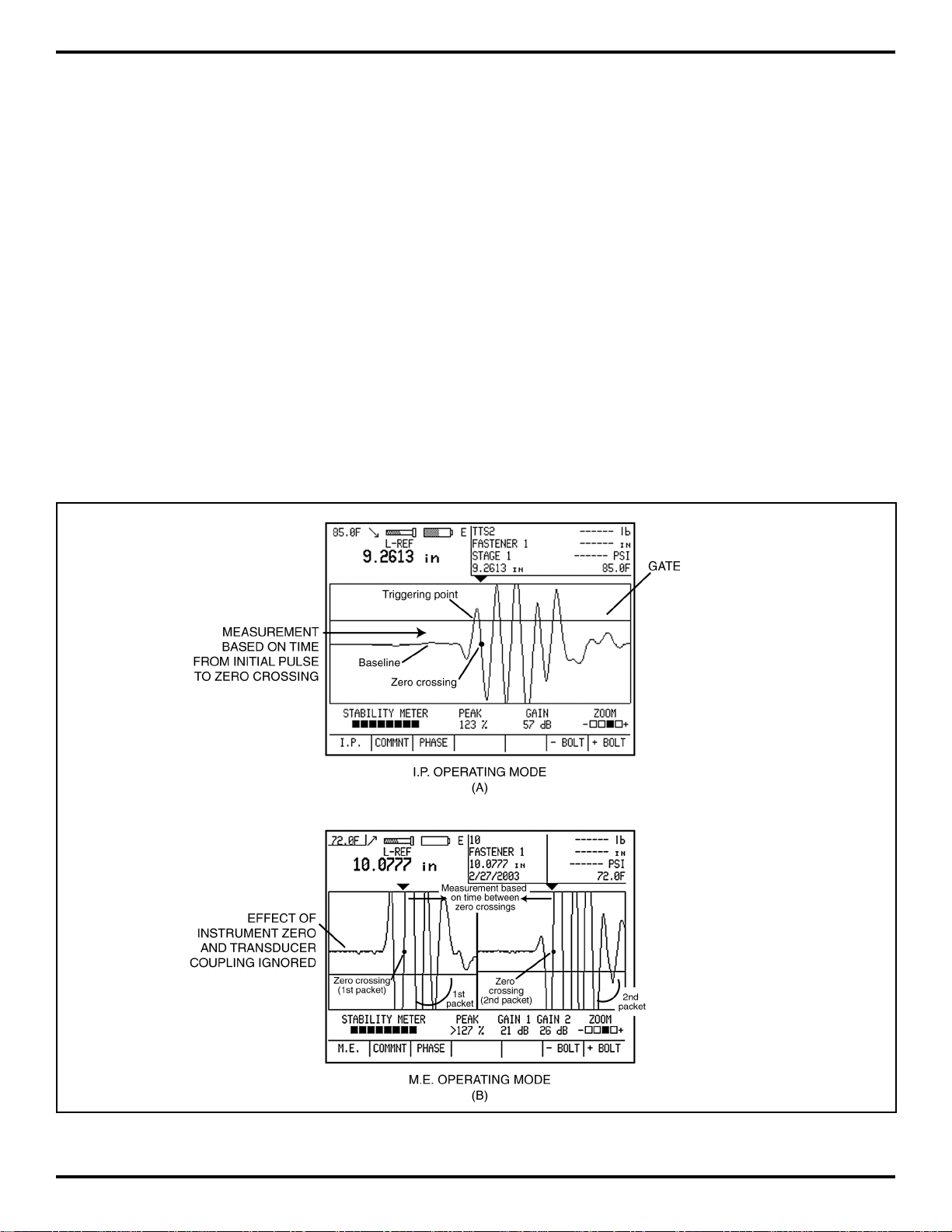

1.1.3 Initial Pulse and Multi-Echo Measurement Modes

The BoltMike III can be operated in one of two ultrasonic

measurement modes: initial pulse (I.P.) and multi-echo

(M.E.). In I.P . mode, as illustrated in Figure 1-2A, a sound

pulse is sent through the fastener. The BoltMike’s

triggering gate is positioned (based on the userinputted value of the fastener’s approximate length) to

detect this sound pulse’s first returning echo. The

BoltMike measures the time duration between transmitting and receiving the sound pulse, and uses this value

as the basis for its calculations.

In M.E. measurement mode, a sound pulse is again transmitted into the fastener. This time, however, the BoltMike

utilizes two triggering gates. These gates are positioned

so that the first returning echo triggers the first gate,

and the second returning echo triggers the second gate.

The gates are again positioned based on the user-in-

putted value of the fastener’s approximate length. In this

mode the BoltMike measures the time duration between

triggering of the two gates by two consecutive echoes. It

is critical, however, that similar features on the two consecutive packets be used to trigger the gates.

An advantage of operating in M.E. mode is that all measurements are taken between the first and second returning echoes. This means that variations in transducerto-fastener coupling (caused, for instance, by varying

couplant thickness) and instrument zeroing are factored

out of the BoltMike’s measurement. This is shown in

Figure 1-2B.

1.1.4 Time of Flight and Ultrasonic Length

The elapsed time between transmitting and receiving the

shock wave is known as the sound-path duration. Of

course, as shown in Figure 1-1, the sound-path duration actually represents the elapsed time taken by the

FIGURE 1-2—In Initial Pulse (I.P.) mode, the BoltMike measures the time to the first gate triggering. In Multi-Echo

mode the time between two consecutive gate crossings is measured.

Page 2 Guide to Ultrasonic Inspection of Fasteners

Page 11

Chapter 1: Ultrasonic Measurement of Fasteners

wave to travel the length of the fastener two times. This

duration is divided by two to find the time of flight (TOF),

which represents the time it takes for the shock wave to

travel once down the length of the fastener. The BoltMike

then determines the

ultrasonic length

by first correcting

the measured TOF for any changes in temperature, and

then multiplying by the fastener’s acoustic velocity . Acoustic velocity is represented in the BoltMike with the variable V and is determined by the fastener’s material type).

Further corrections (as described below) are then made

to this ultrasonic length to determine a measured physical length.

Because the actual acoustic velocity is not truly a constant, the uncorrected ultrasonic length is not exactly

the same as the physically measured length. Even if two

identical fasteners’ physical lengths are very tightly controlled, the measured time of flight through each fastener may vary by as much as one percent. Because of

this variability, the

change

in measured time of flight (recorded before and after each fastener is tensioned) must

be used to accurately determine the tensile stress in a

fastener. As you will learn shortly, acoustic velocity also

varies with factors other than material type including

stress (sections 1.1.9) and temperature (section 1.1.10).

For this reason the BoltMike incorporates logic to compensate for these effects on ultrasonic length.

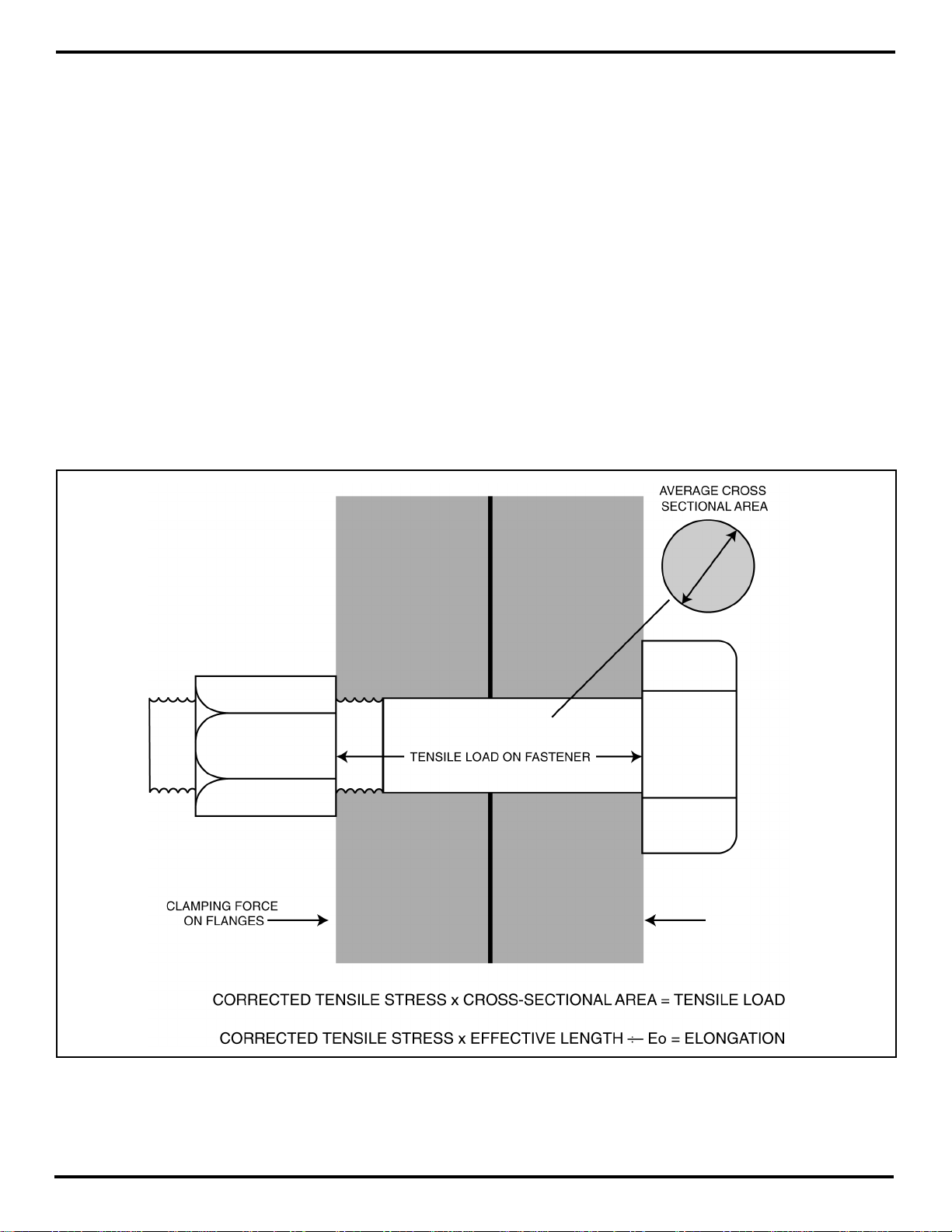

1.1.5 Tensile Load

As you may be aware, when the nut in a threaded fastening system is tightened, the clamping force the fastening system (nut and bolt or stud) places on the joint

is equal to the tensile load placed on the fastener. This

effect is shown in Figure 1-3. The BoltMike calculates

Load (L) by first determining tensile stress (as described

below), then multiplying by the fastener’s cross-sectional

area.

FIGURE 1-3—As the threaded fastening system is tightened, tensile loads are applied to the bolt or stud and

elongation occurs.

Guide to Ultrasonic Inspection of Fasteners Page 3

Page 12

Chapter 1: Ultrasonic Measurement of Fasteners

1.1.6 Stress

Stress occurs when load is applied to a fastener. When

a tensile load (like the one shown in Figure 1-3) is applied to a fastener, the tensile stress is equal to the tensile load divided by the fastener’s average cross-sectional area (see the Appendix for average cross-sectional areas). The BoltMike calculates tensile stress in

units of pounds per square inch (psi) or mega Pascal

(MPa). This calculation is performed using the change

in ultrasonic length, the effective length, acoustic velocity (described in section 1.1.1), the material’s stress factor (a property that is described below), and stress compensation parameters known as Stress Ratio and Stress

Offset. These are instrument correction parameters that

are described in section 1.1.11.

1.1.7 Elongation

As a tensile load is applied, a fastener stretches in the

same way a spring would. The amount of stretch, known

elongation

as

, is proportional to the tensile load as long

as the load is within the fastener’s working range (which

means at loads that are less than the fastener’s yield

strength – a term we’ll describe shortly). Using the effective length, the material’s modulus of elasticity, and the

calculated value for corrected stress the BoltMike calculates elongation. (Figure 1-3)

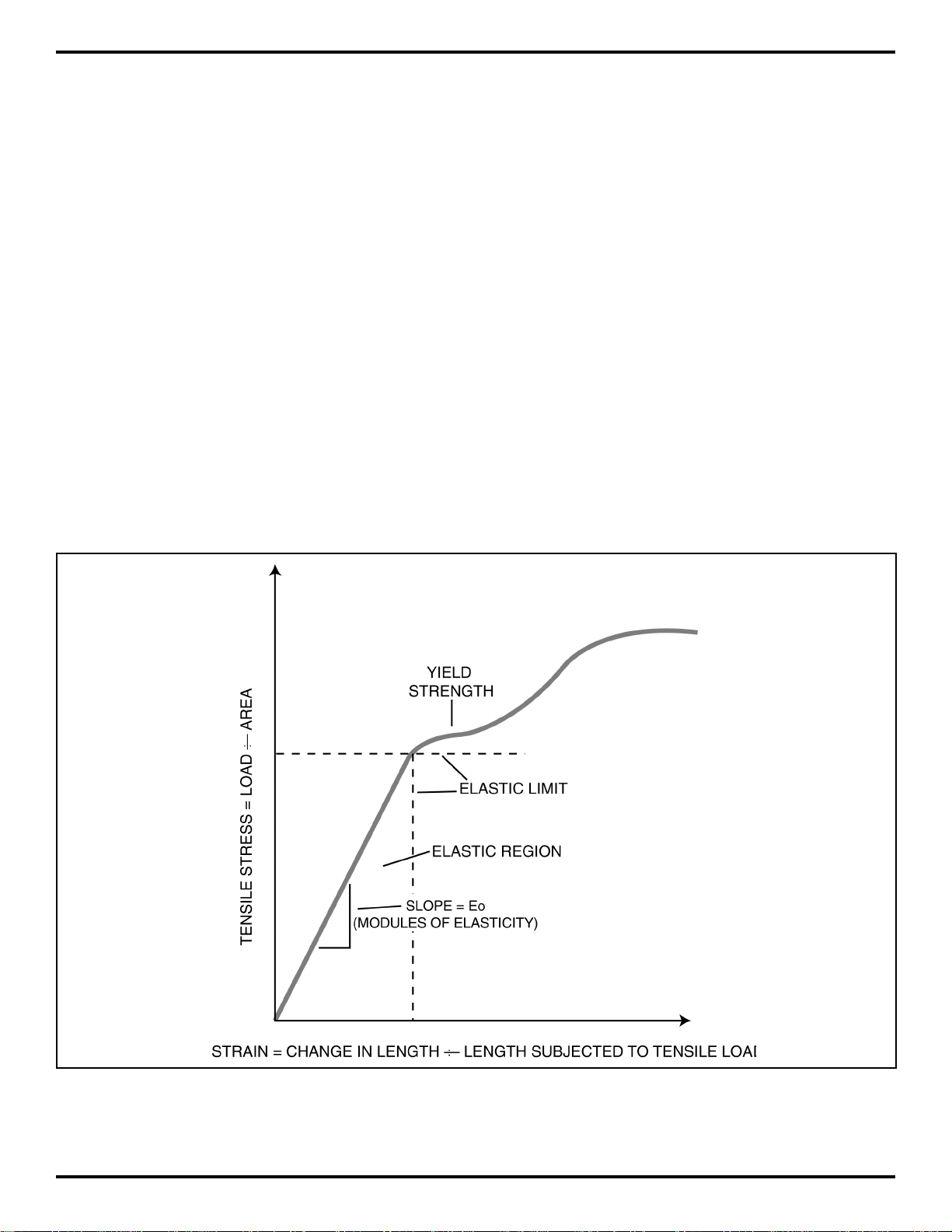

1.1.8 Modulus of Elasticity (Eo)

When a fastener is loaded with a tensile force, its length

increases. As long as the loading does not approach

the fastener’s

yield strength

(defined as the loading point

beyond which any change in material shape is not completely reversible), the relationship between the tensile

stress and elongation is linear. By this we mean that if

the stress level increases by a factor of two, the amount

of elongation also increases by a factor of two. For load

levels in the fastener’s elastic region (meaning that the

loads are less than the yield strength of the fastener),

the relationship between stress and elongation is described by a material constant known as the

elasticity

. The variable Eo in the BoltMike represents the

modulus of

modulus of elasticity . The concepts of tensile stress, elongation, modulus of elasticity, and yield strength are illustrated in Figure 1-4.

FIGURE 1-4—This graph shows the relationship between tensile stress and elongation in a fastener. The material’s

modulus of elasticity equals the slope of the straight portion of this curve (this area is known as the material’s elastic

region). The point at the top of the curve, where it is no longer linear, represents the material’s yield strength. Note

that the graph actually plots stress verses strain. Strain is simply the amount of elongation, divided by the original

length of the stressed section.

Page 4 Guide to Ultrasonic Inspection of Fasteners

Page 13

Chapter 1: Ultrasonic Measurement of Fasteners

1.1.9 Stress Factor (K)

The velocity at which a longitudinal wave moves through

an object is affected by stress. When a fastener is

stretched there are two influences on its ultrasonic length

(as determined by multiplying the sound wave’s time of

flight by the constant value of acoustic velocity). First,

the length of material through which the sound must travel

increases. Also, the fastener’s actual acoustic velocity

decreases as stress increases. In other words, even

when the stretching effect on the fastener’s physical

length is ignored, tensile stress leads to an increase in

the fastener’s ultrasonic length. In the BoltMike, a material constant known as the

Stress Factor (K)

compensates for the effect stress has on the fastener’s actual

acoustic velocity.

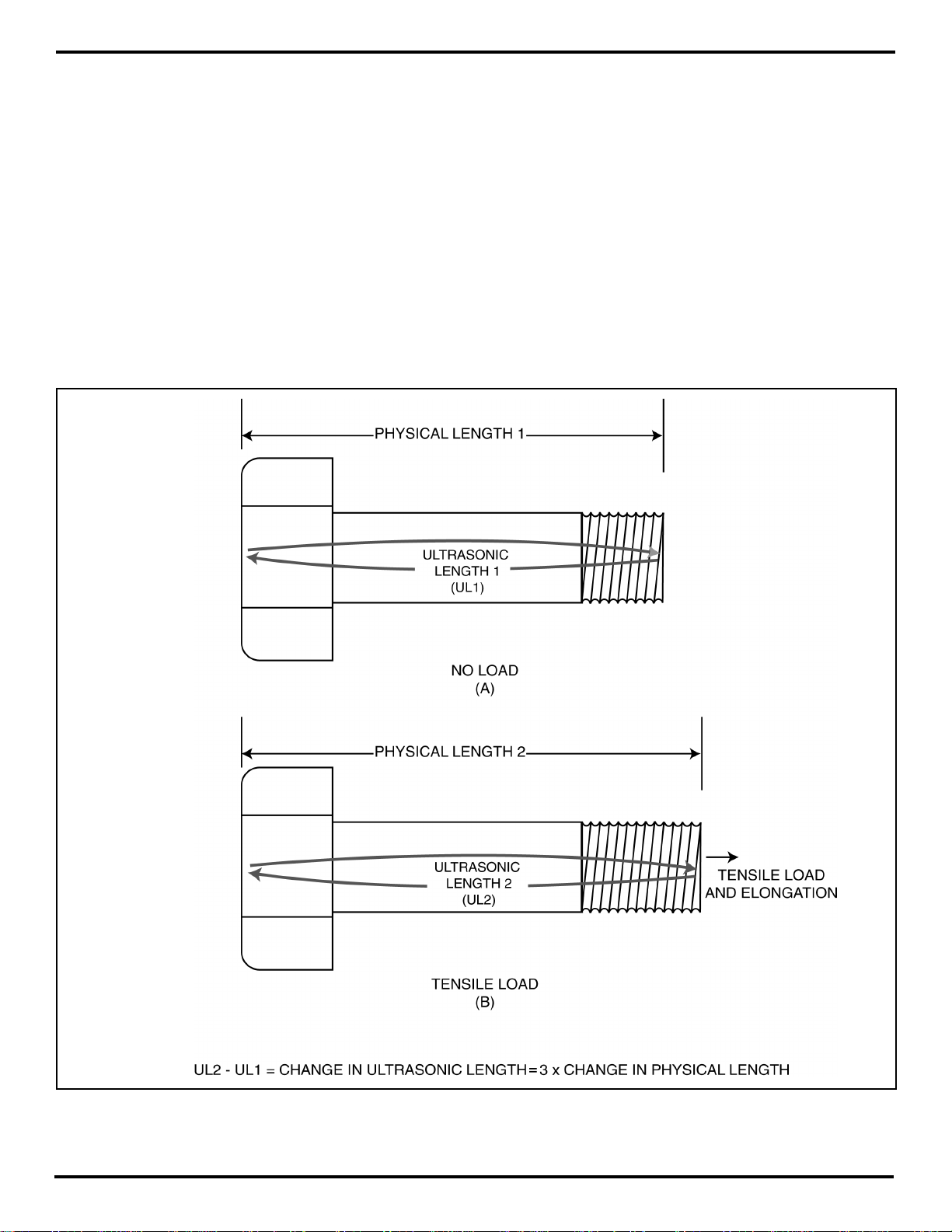

A great deal of confusion surrounds this effect. Consider the example shown in Figure 1-5 as you read the

following description. In Figure 1-5A, no load is applied

to the fastener when the reference ultrasonic length

(UL1) is recorded. In Figure 1-5B, a load is applied and

a new ultrasonic length (UL2) is recorded. Note that

Figure 1-5A and B also identify the physical length when

unloaded (Physical Length 1) and loaded (Physical

Length 2). The actual physical elongation of the fastener

equals Physical Length 1 – Physical Length 2. The difference between the ultrasonic lengths (UL1 and UL2)

is about three times the actual physical elongation of

the fastener.

FIGURE 1-5—Applied tensile stress affects the ultrasonic (measured) length of a fastener in two ways. First, it

stretches the fastener, thus increasing the actual length. Second, tensile stress reduces the fastener’s acoustic

velocity, further increasing its ultrasonic length. In the BoltMike, the material constant K (stress factor) is used to

compensate for the effect of tensile stress on acoustic velocity.

Guide to Ultrasonic Inspection of Fasteners Page 5

Page 14

Chapter 1: Ultrasonic Measurement of Fasteners

It is important to note that in order to change the acoustic velocity, stress must be applied in the same direction

traveled by the ultrasonic shock wave. Thus shear and

torsional stress have no effect on the acoustic velocity

when measured along the fastener’s length.

1.1.10 Temperature Coefficient (Cp)

The temperature of a fastener affects its physical length.

As the temperature of a fastener increases, its physical

length increases. In addition, as a fastener’s temperature increases the amount of time it takes for sound to

travel through the fastener also increases. In other words,

when a fastener is subjected to increased temperature,

its acoustic velocity decreases and, therefore, its ultrasonic length increases. In fact, temperature’s affect on

ultrasonic length is even greater than its affect on physical length. The thermal expansion of the fastener and

the ultrasonic velocity change with temperature are two

separate effects. However, for the purpose of the

BoltMike they are compensated for with a single combined factor known as the

Temperature Coefficient (Cp)

The Bolt Mike relies on a temperature compensation

system to normalize the measured time of flight (TOF)

and thus correct for temperature-caused changes in its

physical and ultrasonic length. The compensation system normalizes the TOF to the value expected at 72

degrees Fahrenheit (22 degrees C) before attempting

to calculate the fastener’s stress, load, and elongation.

This compensation greatly improves accuracy when the

temperature has changed during tightening.

1.1.11 Calibration-Group Correction Factors —

Stress Ratio and Offset

The accuracy of the BoltMike’s stress, load, and elongation calculations depends on many factors. Two major influences on the accuracy of these calculations are

the material-property constants inputted and the

fastener’s geometric characteristics.

While the material-property constants (including elasticity, acoustic velocity, and stress factor) are considered

to be standard values, actual material properties vary

widely. This variation is even found among fasteners

produced in the same manufacturer’s lot. The BoltMike’s

accuracy depends partly on the difference between the

fastener’s actual material properties and those properties represented by the standard material constants.

Similarly, variations in fastening systems’ physical characteristics affect the accuracy of load and elongation

calculations.

When BoltMike III users desire to calculate load, elongation, stress, or TOF (time of flight) values with a higher

degree of accuracy, they generally choose to create

calibration groups. During the process of creating a calibration group, the BoltMike uses inputted values of actual tensile load, as well as its own measured load data,

to calculate two correction factors: Stress Ratio and

Stress Offset. These correction factors are used to convert the BoltMike’s raw stress value into a corrected stress,

as shown in Chapter 8 of this guide.

The BoltMike uses one of two methods to determine these

correction factors. The first method, called a regression

correlation, uses a linear regression technique to determine the stress factor and offset. (Figure 1-6) The stress

factor is actually the slope of a line that represents the

relationship between actual and calculated load. The

stress offset represents the Y intercept of the actual

verses calculated load line. This value can be thought

of as the level to which actual load can increase before

the BoltMike can measure an observable load.

.

The second method used to determine correction factors is known as vector correlation. With this approach

the BoltMike calculates only a stress ratio. The value of

the stress offset is set to zero. (Figure 1-6)

When creating a calibration group, the user must decide which correction method to use. This decision should

be based on the application. If accuracy over a wide

range of loads (including low-level loads) is desirable,

the vector correction is usually preferred. If the highest

level of accuracy at a single target load is desired, the

regression method is best.

Why are two methods required? Often the relationship

between actual and measured stress is non-linear,

especially at the low end of the curve (as shown in

Figure 1-6). This can be caused by a skin effect. When

a small amount of load is applied to a fastener, most of

the stress is in the surface layers, not evenly distributed

across the cross-section. Since the longitudinal wave

travels predominantly down the center of the fastener,

less of the actual stress is observed.

1.1.12 Fastener Geometry

Several geometrical characteristics of fasteners affect

the ultrasonic measurement of load, stress, and elongation. While these characteristics are described in great

detail in Chapter 6 and the Appendix, Figure 1-7 briefly

illustrates them.

Page 6 Guide to Ultrasonic Inspection of Fasteners

Page 15

Chapter 1: Ultrasonic Measurement of Fasteners

FIGURE 1-6—When the Calibration Group feature is used, known and measured loads for a group of fasteners are

entered into the BoltMike. The correlation method chosen (vector or regression) determines if a stress ratio or a

stress ratio and offset correction factor are then calculated.

As you’ll learn in Chapter 6, the quantities inputted for

fastener geometry have varying effects on the accuracy

of the BoltMike’s calculations. In general:

• Cross-Sectional Area—Affects the calculation of

LOAD

• Effective Length—Affects the calculation of ELON-

GA TION, LOAD, & STRESS

• Approximate Total Length—Affects only the position

of the triggering gates

1.2 Principles of BoltMike Operation

NOTE: This section offers a brief description of fas-

tener elongation measurement using ultrasonics. For

more details on ultrasonic inspection techniques in

general, refer to

RIALS

, by Josef and Herbert Krautkramer, 3rd Edition

1983, (IBSN 0-318-21482-3, 324), published by the

American Society of Nondestructive Testing.

ULTRASONIC TESTING OF MATE-

FIGURE 1-7—The geometrical

characteristics of a fastener greatly

affect the results obtained by

ultrasonic inspection techniques.

Included in these important

characteristics are total length,

effective length, and average crosssectional area.

Guide to Ultrasonic Inspection of Fasteners Page 7

Page 16

Chapter 1: Ultrasonic Measurement of Fasteners

The BoltMike measures the time it takes for a sound wave

to travel through a fastener. The sound wave, more specifically known as an ultrasonic shock wave or longitudinal wave, is created in the transducer. The wave is generated when a large electric pulse is sent to the transducer from the instrument. This pulse excites a piezoelectric element in the transducer. The wave’s frequency

varies with the thickness of the piezoelectric element.

Frequencies most useful for measuring fasteners range

from 1 to 20 MHz.

This range of ultrasound will not travel in air. Couplant,

which is a dense liquid substance (usually glycerin or

oil) must be used to provide a pathway for the ultrasound

to travel from the transducer into the fastener.

When the ultrasonic wave encounters an abrupt change

in material density, such as at the end of the fastener,

most of the wave reflects. This reflection travels back

the length of the fastener, through the layer of couplant,

and back into the transducer. When the shock wave

enters the piezoelectric element a small electrical signal

is produced. The BoltMike detects this signal.

In I.P. mode (Initial Pulse mode is described in section

1.1.3), the BoltMike measures the elapsed time between

the sound entering the material and the returned signal.

This elapsed time is known as the wave’s time of flight.

Of course the time of flight actually represents the time

taken by the wave to travel the length of the fastener

two times. The TOF reported by the BoltMike equals half

of this value.

In M.E. mode (Multi-Echo mode is described in section

1.1.3), the BoltMike measures the elapsed time between

two consecutive returning signals. This elapsed time is

equal to the wave’s time of flight. As in I.P. mode this time

of flight actually represents the time taken by the wave

to travel the length of the fastener two times. The TOF

reported by the BoltMike equals half of this value.

The BoltMike then determines the

first using the temperature coefficient (Cp) to correct the

TOF for any changes in temperature. The BoltMike then

multiplies the corrected TOF by the fastener’s acoustic

velocity. Acoustic velocity is represented in the BoltMike

with the variable V and is determined by the fastener’s

material type. The stress constant (K) and effective length

are then used by the BoltMike logic to determine an uncorrected stress. As explained in Chapter 8, when the

calibration-group feature is used, the stress ratio and

offset are applied to this stress value to find a corrected

stress.

Since the actual acoustic velocity is not truly a constant,

and can vary significantly between fasteners of like material composition, the

(recorded before and after each fastener is tensioned)

change

ultrasonic length

in measured time of flight

by

must be used to accurately measure a fastener’s stress,

load, and elongation.

To determine the change in time of flight, the BoltMike

first records a

malized time of flight for a non-tensioned fastener. A

normalized time of flight measurement of the same fastener, this time while tensioned, is then recorded. The

two normalized TOF’s (which have already been corrected for the effects of temperature) are then used with

the effective length, stress factor (K), and acoustic velocity (V) to determine the uncorrected stress.

• The uncorrected stress is then corrected using the

stress offset and stress ratio (these values are

produced using a Cal group)

• Elongation is calculated using the corrected stress,

effective length, and the modulus of elasticity.

• Load is also determined using the corrected stress

and cross-sectional area.

reference length

by determining a nor-

1.3 Practical Limitations Of Ultrasonic

Measurement

Included in the list of fastening-system types that are

quite successfully inspected using ultrasonic techniques

are those where equal distribution of load is critical, such

as pipe flanges and head bolts where gaskets must be

compressed evenly for optimum performance.

Not all threaded fastening systems are suitable for measurement by ultrasonic methods, and some systems are

better suited to either multi-echo or initial pulse measurements. An understanding of ultrasonic inspection’s

practical limitations will reduce frustration and erroneous results.

1.3.1 Material Compatible with Ultrasonic

Inspection

Most metals are excellent conductors of ultrasound. However, certain cast irons and many plastics absorb ultrasound and cannot be measured with the BoltMike.

1.3.2 Significant Fastener Stretch

Since ultrasonic techniques measure a fastener’s

change in length, a significant amount of stretch is required to produce accurate measurements. Accuracy is

a significant problem in applications where the effective

length of a fastener is very short, such as a screw holding a piece of sheet metal. These applications may be

poorly suited to ultrasonic measurement because the

tensile load (and therefore tensile stress) is applied over

a very short effective length of the fastener. Because

Page 8 Guide to Ultrasonic Inspection of Fasteners

Page 17

Chapter 1: Ultrasonic Measurement of Fasteners

the stressed length is so small, little or no measurable

elongation of the fastener occurs.

In the same way, it is difficult to measure the effects of

very low loads. Negligible elongation occurs when tensile stress levels are less than about 10% of the material’s

ultimate tensile stress. The small errors in measurement

introduced by removing and replacing the transducer

(as described in section 2.2) become very significant when

trying to measure such a small amount of elongation.

1.3.3 Fastener End-Surface Configuration

The ends of bolt heads and threaded sections (bolts or

studs) must be prepared before the fastener is fit for

ultrasonic inspection. The fastener end that will be mated

with a transducer must be machined to a very flat, smooth

surface to allow for proper coupling of the transducer.

The ideal finish for the transducer coupling point is between 32 to 63 micro inch CLA (0.8 to 1.6 micro meter

Ra). Refer to section 2.1 to learn more about the requirements of fastener end-surface preparation.

Similarly, the surface at the opposite end of the fastener

(known as the

reflective surface

) must be parallel to the

surface that supports the transducer. This parallelism

allows the reflective surface to reflect the ultrasound back

to the transducer. While the finish of the reflective surface is not as critical, very rough or uneven finish can

produce errors. Problems with surfaces are indicated by

poor signal quality on the waveform display.

1.3.4 The Limitations of I.P. and M.E. Measurement Modes

Because M.E. measurement mode determines the

elapsed time between two consecutively returning echoes, it eliminates some inconsistencies introduced in I.P.

mode such as variation of couplant thickness and probe/

instrument zeroing.

However, because M.E. mode relies on the second returning echo, and the quality of ultrasonic signals diminishes substantially with each returning echo, there are

certain conditions under which the subsequent returning echoes will be distorted beyond acceptable limits and

M.E. mode will not be effective. For instance, ultrasonic

interference resulting from echoes off of the fastener’s

sidewalls increases the level of distortion present when

the second returning echo is received. To some extent

the sidewall distortion effect can be compensated for with

the use of a larger diameter transducer. Similarly, the

effects of frequency dispersion, attenuation, and sidewall

distortion can also be compensated for by using a lower

frequency transducer. In general lower transducer frequencies produce greater-amplitude returning echoes.

Ultimately , however, some small-diameter , longer-length

fastener measurements must be conducted in I.P. mode.

Guide to Ultrasonic Inspection of Fasteners Page 9

Page 18

Chapter 1: Ultrasonic Measurement of Fasteners

THIS P AGE WAS INTENTIONALL Y LEFT BLANK.

Page 10 Guide to Ultrasonic Inspection of Fasteners

Page 19

Chapter 2: Fastener Preparation

Chapter 2: Fastener Preparation

Prior to measuring a fastener, it must be properly prepared for ultrasonic inspection. The fastener ends must

be machined to be parallel and the end that will be mated

with a transducer must be machined to a controlled,

smooth surface finish. Further, to allow for proper coupling of the transducer and fastener, a suitable couplant

must be applied. Finally, consistent placement of the

transducer on the bolt head or stud end improves the

instrument’s accuracy and repeatability.

NOTE: Most fastener materials are excellent conductors of ultrasound. However, certain cast irons and

many plastics absorb ultrasound and cannot be measured with the BoltMike.

2.1 Fastener End-Surface Machining

The ends of bolt heads and threaded sections (bolts or

studs) must be prepared before the fastener is suitable

for ultrasonic inspection. The fastener end that will be

mated with a transducer must be perpendicular to the

fastener’s centerline and machined to a very flat, smooth

surface to allow for proper coupling of the transducer.

The ideal finish for the transducer coupling point is between 32 to 63 min. CLA (0.8 to 1.6 mm Ra). Inadequate

surface finishes are indicated by poor signal quality on

the A-scan display.

The reflective surface at the opposite end of the fastener must be parallel to the surface that mates with the

transducer. As shown in Figure 2-1, this parallelism allows for identical sound-path distance regardless of the

transducer’s position. The degree to which these two

surfaces are machined parallel determines the upper limit

of an ultrasonic inspection system’s accuracy.

FIGURE 2-1—Fastener ends must be uniform, parallel, and perpendicular to the fastener’s centerline to ensure

acceptable ultrasound transmission.

Guide to Ultrasonic Inspection of Fasteners Page 11

Page 20

Chapter 2: Fastener Preparation

While the surface finish of the reflective surface is not

as critical, very rough or uneven finish can produce

errors. Use care when machining fastener ends. A

common problem occurs when a small peak is left in the

center of a fastener end after facing on a lathe. This

small bump prevents the transducer from achieving

proper contact and greatly reduces the signal amplitude.

NOTE: The use of Multi-Echo measurement mode reduces some types of variation and measurement inaccuracies, especially those that are due to couplant

thickness and instrument/probe zeroing. However,

errors introduced by inconsistent transducer placement or surface preparation techniques are not eliminated with the use of M.E. mode.

2.2 Methods Of Transducer Placement

Unless fastener ends and transducer surfaces are perfectly parallel, as discussed in section 2.1 of this manual,

the reflected ultrasonic signal will vary with changes in

the transducer’s orientation, with respect to the fastener.

This condition is illustrated in Figure 2-2. Optimal repeatability and accuracy are achieved by leaving the

transducer attached to the fastener, in exactly the same

location and angular orientation, throughout the

tensioning process. As this ideal approach is often not

possible or practical, the next best practice is to consistently return the transducer to the same location and

angular orientation, with respect to the fastener. This

practice improves the chances that the path followed by

the shock wave when the reference length was measured is identical (or close to identical) to the path followed after the fastening system is tightened.

2.2.1 Practical Methods

Several practical methods are used to ensure consistent transducer placement. The most common method

utilizes a magnetic transducer, which is placed in the

center of the bolt’s head. When inspecting bolts with diameters above one inch, refer to Figure 2-3 and follow

these steps:

Step 1:

First measure the reference (non-tensioned)

length by coupling the transducer to the fastener end

and adjusting its orientation, while observing the A-scan

display. Position the transducer in the center of the fastener end and identify the angular transducer position

that returns the A-scan waveform of greatest amplitude.

At this point consider the accuracy of the selected measurement mode. M.E. mode can increase repeatability

and improve accuracy if the subsequent returning echoes are free enough of distortion to be measured properly.

Step 2:

Mark the transducer location and angular orien-

tation on the fastener end.

Step 3:

Continue with the fastener tightening procedure.

If possible, the transducer should remain connected to

the fastener end in exactly the same position and orientation. If this is not possible, proceed to step 4.

Step 4:

Before proceeding, reconfirm that the position

marked on the fastener end remains the location that

returns the greatest-amplitude waveform and the shortest length and/or lowest load or stress reading. This step

is important because in some cases, as the fastener is

tensioned, a small amount of bending occurs. When

bending occurs, the angular orientation that returns the

FIGURE 2-2—Changing the transducer’s position with respect to the fastener’s end can change the shape and/or

amplitude of the returned waveform. This effect is especially significant when inspecting long or large-diameter

fasteners.

Page 12 Guide to Ultrasonic Inspection of Fasteners

Page 21

Chapter 2: Fastener Preparation

FIGURE 2-3—A consistent approach to transducer placement ensures accurate results.

Guide to Ultrasonic Inspection of Fasteners Page 13

Page 22

Chapter 2: Fastener Preparation

maximum-amplitude waveform may change. If the

maximum-response location has changed, adjust the

position of the transducer to the new location on the bolt

head. This assures the optimum sound path is being

used, both before and after tightening.

Step 5:

Position the transducer in the marked location

(or at the newly identified maximum-amplitude location)

to continue recording tensioned readings.

2.2.2 Fixtures for Non-Magnetic Fasteners

When fasteners are made of non-magnetic materials,

fixtures are sometimes used to hold the transducer in

place. Note that the fit between the transducer and the

head of the bolt is extremely critical, and some provision

must be made in the fixture to allow the transducer to

“float” while finding the position where contact is at its

best.

NOTE: Ultrasonic inspection techniques evaluate the

change in length of a fastener. Fastener elongation

occurs when a significant portion of the fastener

(known as the effective length) is exposed to tensile

loading. However, ultrasonic techniques are not effective when only a small percentage of the fastener’s

length experiences tensile loading (such as a screw

holding a piece of sheet metal) or where load levels

are below 10% of ultimate tensile stress.

Page 14 Guide to Ultrasonic Inspection of Fasteners

Page 23

Chapter 3: Transducer Selection

Chapter 3: Transducer Selection

A wide variety of ultrasonic transducers are available.

Suitability for a specific application is determined based

on the transducer’s center frequency, diameter, and

damping. However, because there is often a broad range

of applications for which transducers are suitable, and

these ranges often overlap, it can be difficult to pick the

“best” transducer for a specific job.

NOTE: It is a generally accepted practice that the

same style and model probe be used when taking nontensioned (L-Ref) and tensioned-fastener measurements of a fastener group. Further, it is preferable

that the same probe be used to make tensioned and

non-tensioned measurements of a fastener group.

3.1 General Acceptability

There is no single rule of thumb to follow when selecting

a transducer for a specific application. For some fastening systems, many different types of transducers will

measure with acceptable results. In the case of a hardto-inspect fastener, transducer selection becomes more

critical. The best way to evaluate an application is to use

the Bolt Mike’s waveform display and an assortment of

transducers. Try making readings on a fastener that’s

similar or identical to the ones you’ll be inspecting. Use

several different transducers and observe the waveform

display and the stability of the reading produced with

each transducer. While you’re using a transducer, observe the effects of removing and replacing it. Select

the transducer that provides a large-amplitude signal and

stable, repeatable readings.

energy to reach the end of the fastener, making the noise

that reflects off the thread and shank areas less of an

issue.

However, as frequency increases, the absorption of the

ultrasound by the material also increases. Absorption

refers to the material’s ability to absorb (rather than reflect) ultrasonic sound energy. It interferes with the

shockwave, reducing the received signal’s resolution.

Lower-frequency ultrasound travels around small flaws

or air bubbles in the fastener’s without significant interference to the shock wave. Absorption is an especially

significant problem when inspecting more granular material such as is found in castings.

In conclusion, lower transducer frequencies are better

suited as fastener lengths increase.

3.3 Transducer Diameter

A transducer’s rated diameter actually refers to the diameter of its crystal. A transducer’s diameter affects the

efficiently with which it transmits sound as well as the

beamwidth of the transmitted ultrasound. Remember,

beamwidth identifies how dispersed the shock wave becomes as it travels over a specific distance. Beamwidth

decreases (that is, the wave becomes more tightly focused) and transmitting efficiency increases as the diameter of the transducer’s crystal increases. Again, a

tightly focused beam is desirable since it allows more

energy to reach the end of the fastener, making the noise

that reflects off the thread and shank areas less of an

issue.

3.2 Transducer Frequency

A transducer’s frequency rating refers to the resonant

frequency of the piezoelectric crystal. This is determined

by the thickness of the crystal material. A thin crystal

has a higher resonant frequency than a thick crystal.

The BoltMike will work with transducers in the 1 to 15

MHz (megahertz) range.

The frequency of the transducer affects the transmission of ultrasound in two different ways, beamwidth and

absorption. The

ity

) identifies how dispersed the shock wave becomes

as it travels over a specific distance. Beamwidth decreases (that is, the wave becomes more tightly focused)

as transducer frequency increases. This means that a

10 MHz transducer has a tighter beam (with a lower

beamwidth) than a 5 MHz version of the same transducer.

A tightly focused beam is desirable since it allows more

Guide to Ultrasonic Inspection of Fasteners Page 15

beamwidth

(also referred to as

directiv-

It’s generally preferable to select the largest-diameter

transducer available that will still fit on the fastener to be

measured. Note that external diameter of a transducer

equipped with a built-in magnet is much larger than the

piezoelectric crystal size. For example, a 1/4 inch 5 MHz

non-magnetic transducer has a case with a 3/8-inch

outside diameter. However, when a transducer with the

same 1/4-inch crystal is mounted in a magnetic housing,

the transducer’s outside diameter is 3/4 inch.

Purpose of Instrument and Transducer Zeroing

The BoltMike’s zeroing procedure occurs whenever the

user presses the Inst Zero key and follows the steps as

prompted. The procedure compensates for the actual

delay that occurs while the transmitted pulse travels

through the instrument’s circuitry, the probe cable, and

the probe’s head and contact surface. Variations in different probes and cables, as well as changes in the trans-

Page 24

Chapter 3: Transducer Selection

ducer cable length, affect the necessary amount of timedelay compensation.

Repeat the transducer calibration whenever changing

transducers or cables. As the probe’s contact surface

wears with use, the instrument should be periodically rezeroed to compensate for any change in time delay.

NOTE: When operating in multi-echo measurement

mode, the transducer and instrument zero do not affect the instrument’s accuracy.

Page 16 Guide to Ultrasonic Inspection of Fasteners

Page 25

Chapter 4: Temperature Compensation

Chapter 4: Temperature Compensation

The temperature of a fastener affects its physical length.

As the temperature of a fastener increases, its physical

length increases. In addition, as a fastener’s temperature increases the amount of time it takes for sound to

travel through the fastener also increases. In other words,

when a fastener is subjected to increased temperature,

its acoustic velocity decreases and, therefore, its ultrasonic length increases. In fact, temperature’s effect on

ultrasonic length is even greater than its effect on physical length. The thermal expansion of the fastener and

the ultrasonic velocity change with changing temperature are two separate effects. However , in the BoltMike’s

logic they are compensated for with a single combined

factor known as the

The BoltMike relies on its temperature compensation

system to normalize the time of flight of a fastener and

thus correct for temperature-caused changes in its physical and ultrasonic length. The compensation system

normalizes the TOF to the value expected at 22.22 degrees C (72 degrees F) before attempting to calculate

the change in the fastener’s ultrasonic length. This

compensation greatly improves accuracy when the temperature has changed during the time period between

recording a reference length and a tensioned length.

Temperature Coefficient (Cp)

.

NOTE: The range of the BoltMike temperature sensor is -55 degrees to 150 degrees C (-67 to 302 degrees F). Use of the sensor outside of these ranges

will damage the sensor.

NOTE: Large accuracy problems can occur from handling the temperature sensor. Body heat conducted

into the housing of the sensor will greatly increase

the temperature reading. After holding the sensor in

a bare hand, allow approximately ten to fifteen minutes for the temperature probe to stabilize. If while

fastener measurement is underway a temperature

sensor must be moved, handle it only while wearing a

thick glove. Alternatively, you may carefully remove

the temperature sensor by pulling on and handling

only its cable.

4.2 Limits of Accurate Temperature Measurement

Errors in temperature compensation can have several

causes including:

• Manual input of air (rather than) fasten tempera-

ture

4.1 Measuring Fastener Temperature

In some applications, significant differences in temperature exist from one portion of the fastener to another.

Compensating for these temperature gradients is

extremely difficult. Instead, the fastener’s average temperature is used for temperature compensation. While

the BoltMike allows manual input of temperature, it is

preferable to input fastener temperature using the temperature probe.

The BoltMike’s temperature sensor provides a convenient way to input fastener temperature. Because it

magnetically couples to the metal of the fastener joint, it

provides a very accurate temperature reading.

Typically, the temperature sensor is attached to the

superstructure or frame that is being fastened, not each

individual bolt. The probe is then left in place while the

lengths of all fasteners in the area are ultrasonically

measured.

NOTE: In most cases, air temperature has very little

effect on fastener temperature and should not be

entered as the temperature of the fastener. For optimum accuracy, use the temperature sensor and automatic temperature compensation.

• Contact between the operator ’s hand and the

temperature sensor

• Variation of the material’s temperature coefficient

• Materials’ non-linear response to changes in

temperature

The last two of these sources of error should be further

explained. If a sample of physically identical bolts is tested

for temperature coefficient, some bolt-to-bolt variation

will be found. The amount of variation will depend on the

type of material, and the uniformity with which the fasteners were manufactured. One way to compensate for

this variation is to determine the range of actual temperature coefficients in the sample then decide of the

difference between the actual and average values is too

significant. Alternatively, a temperature calibration can

be preformed for each fastener.

A materials actual response to changes in temperature

(as represented in the BoltMike by the temperature coefficient) is not necessarily linear over a large range of

temperatures. Although the thermal expansion of a fastener, when plotted against change in temperature, is

very nearly linear, non-linearity is present in all materials. When trying to compensate for a large variation in

temperature (in the range of fifty degrees Centigrade or

Guide to Ultrasonic Inspection of Fasteners Page 17

Page 26

Chapter 4: Temperature Compensation

more), the nonlinear thermal reaction becomes a factor

and significant errors may occur. When temperature

variations are relatively large and increased accuracy is

desired, the temperature coefficient may be adjusted to

the specific temperature range.

4.3 Adjusting the Temperature Coefficient

If measurements are to be made over a large temperature range (50 degrees C or greater), the best results

will be obtained by adjusting the temperature coefficient

to the particular bolt and the specific temperature range.

Select at least two temperature levels that fall within the

temperature range anticipated during the actual ultrasonic measurement. For example, the extremes of the

temperature range may be 20 degrees C (representative of the shop temperature when the fasteners’ reference length is recorded) and 70 degrees C (the temperature of the structure to which the bolt will be connected). In this case you might wish to examine the fastener at 20, 40, 50 and 70 degrees C.

Proper temperature calibration requires a means of controlling the bolt temperature such as a temperature oven.

Place the bolt to be measured in the oven (set to the

lower

of your two target temperatures) with a transducer

and temperature sensor attached. It is not necessary to

load the bolt to determine the temperature coefficient.

In preparation for temperature calibration, create a group

containing enough fasteners to store one L-REF for each

of the fasteners you wish to sample. Measurements made

(as described below) will only be stored as L-REFs.

Create a custom material type (with the correct acoustic

velocity) then assign it, along with a temperature

coefficient of 0 (zero) to the group.

Allow plenty of time for the bolt in the oven to reach the

target temperature. One way to tell when the internal

temperature of the fastener has stabilized is to watch

the L-REF change on the BoltMike. When the L-REF

has been stable for two minutes, the temperature in the

fastener is constant. This occurs because the displayed

L-REF is temperature compensated. Record the

fastener’s measured length and the probe’s temperature reading. Identify these as L1 and T1.

Change the oven setting to the higher temperature,

monitor the bolt length until it again stabilizes, and repeat the process described above. Identify the second

measured length and temperature as L2 and T2.

You should now have recorded at least two ultrasonic

length measurements at different temperatures. Two

measurement points will allow you to calculate a value of

Cp. These calculated values of Cp must be averaged

over a temperature range to find the best value of Cp in

the temperature range of your test. In the following formula, L1 and T1 are the reference length and temperature for data point 1, and L2 and T2 the reference length

and temperature for data point 2.

If readings are taken across a temperature range (for

example, at four temperatures) you can calculate a Cp

for T1 and T2, as well as a Cp for T3 and T4. Then,

average the two calculated values for Cp to produce an

average Cp over the temperature range.

Page 18 Guide to Ultrasonic Inspection of Fasteners

Page 27

Chapter 5: Selecting Phase

Chapter 5: Selecting Phase

When recording a reference (non-tensioned) fastener

length, the operator must first select a measurement

phase. This setting determines if the triggering gate is

positioned above or below the A-scan zero level and,

therefore, if the gate detects positive or negative heading portion of the signal.

Once the measurement phase is selected, and an L-Ref

is recorded, the phase may not be changed again for

that fastener. Therefore, it is critical that the user first

examine the A-scan shape in non-tensioned and

tensioned loading conditions. As shown in Figure 5-1,

there are often low-amplitude half-cycle features visible

on the A-scan. These echoes should not be used to trigger the gate as they are not valid representations of a

returning echo. However, the first valid echo available

should be used to trigger the gate (especially in MultiEcho mode) as later echoes may be substantially affected by sidewall distortion. Sidewall distortion results

from sound energy reflecting off of the fastener’s

sidewalls, into the primary sound path, and back towards

the transducer.

FIGURE 5-1—Select the PHASE to trigger off of the first valid echo available in both the non-tensioned and

tensioned condition. Note that invalid echoes before the first valid echo and distortion-affected later echoes should

not be used to trigger gates.

Guide to Ultrasonic Inspection of Fasteners Page 19

Page 28

Chapter 5: Selecting Phase

THIS P AGE WAS INTENTIONALL Y LEFT BLANK.

Page 20 Guide to Ultrasonic Inspection of Fasteners

Page 29

Chapter 6: Fastener Geometry

Chapter 6: Fastener Geometry

As explained throughout Chapter 1 of this guide, many

of the calculations made by the BoltMike rely directly on

user-input fastener dimensions. A fastener’s material

type, nominal length, average diameter, and effective

length (also known as working or grip length) must be

input in order for the BoltMike to perform all calculations.

While material types and the constants that define their

properties are described in Chapter 7, this chapter deals

with the geometric properties that define a fastener’s

shape. Some of a fastener’s geometric properties have

little effect on certain BoltMike calculations, while others

have a significant effect. It is important to understand

how each geometric property affects the BoltMike’s output.

6.1 Approximate Length

In the BoltMike, the approximate length is the total length

of the fastener. In terms of ultrasonics, this is the distance from the ultrasonic transducer to the opposite (reflecting) end of the fastener. The approximate length is

used to determine the distance at which the BoltMike’s

receiver is enabled.

While the accuracy of the quantity entered for total fastener length does not directly affect the accuracy of the

BoltMike readings, entering a significantly incorrect value

for total length may result in unstable or no readings at

all. If the value entered for approximate length is too

large, the first echo that returns from the bolt will be ignored. If the value entered for approximate length is too

short, the BoltMike will not detect the correct returning

echo. These two cases are shown in Figure 6-1.

6.2 Determining Effective Length

When a fastening system is tensioned, the length of the

fastener to which the tensile load is applied is known as

its effective length. When considering a constant applied

load, the amount of fastener elongation is directly proportional to a fastener’s effective length. In other words,

if two fastening systems are identical in all ways, including the tensile load on the fastener, except that the effective length of the first fastener is twice the effective

length of the second, then the elongation of the first fastener will be twice the elongation of the second.

The effective length must be entered into the BoltMike

in order to make any measurement other than the reference length. However, the accuracy of the value entered as the effective length has almost no influence on

the accuracy of the elongation measurement. And then,

the affect on elongation measurement is only noticeable

at very high tensile loads, approaching the material’s

yield strength. Because the measurement of elongation

is virtually independent of the effective length, tension

loading is specified in terms of elongation in applications

where the ability to accurately determine effective length

is questionable.

However, the accuracy of the value entered for effective

length has a direct influence on the accuracy of measured stress and load. If the value entered for effective

length is ten percent less than the actual value, the error in load and stress measurements will be ten percent.

FIGURE 6-1—The value of approximate total length is used only to set the position of the gate(s) on the A-scan

display screen.

Guide to Ultrasonic Inspection of Fasteners Page 21

Page 30

Chapter 6: Fastener Geometry

The effective length is calculated differently depending

on the fastener application. The directions for calculating the effective length in four different cases are outlined in Figures 6-2 through 6-5. Note that the resulting

values for effective length are approximate and may vary

due to certain other factors. For example, consider an

application using a bolt in a blind hole. Suppose the

material strength of the bolt is greater than the threaded

hole. The weaker threads in the hole will flex more than

the threads of the bolt, and the effective length will be

longer than if the materials were of the same material.

For the best accuracy of load or stress readings, calibrate the BoltMike for the specific application. This will

cancel errors due to effective length uncertainty. In this

approach a calibration group is formed (using fasteners

that are the same or similar to the ones being tested).

The fasteners are inserted in a fixture that loads them at

the same effective length with a known quantity of load.

Refer to Figures 6-2 through 6-5 to identify the fastening system closest to the one you are evaluating. Then

follow the instructions in the applicable figure to calculate effective loading. The figures show:

• Stud fastening system (Figure 6-2)

• Through bolt fastening system (Figure 6-3)

• Bolt (screw) turned into a threaded hole

(Figure 6-4)

• Stud turned into a threaded hole (Figure 6-5)

FIGURE 6-2—This is a typical stud configuration. The effective length of a stud with nuts on each end is found by

adding the stud diameter to the clamp length.

FIGURE 6-3—This is a typical through bolt configuration. The effective length of a bolt with a single nut is found by

adding half the diameter to one-third the diameter (5/6 of the diameter total) to the clamp length.

Page 22 Guide to Ultrasonic Inspection of Fasteners

Page 31

Chapter 6: Fastener Geometry

FIGURE 6-4—This is typical of a configuration with a bolt (screw) turned into a threaded hole. When a headed

fastener is threaded into a metal block, such as an automotive head bolt, calculate the effective length by adding

half the diameter to one third the diameter (5/6 of the diameter total), then adding this amount to the clamp length.

FIGURE 6-5—This is typical of a configuration with a stud turned into a threaded hole. When a stud is threaded into

A blind hole and a nut is placed on the opposite end, find the effective length by adding the stud diameter to the

clamp length.

Guide to Ultrasonic Inspection of Fasteners Page 23

Page 32

Chapter 6: Fastener Geometry

6.3 Fastener Cross-Sectional Area

The cross-sectional area is the average area of that

portion of a fastener that is subjected to tensile loading.

In other words, it’s an average cross-sectional area taken

over only the fastener’s effective length. The crosssectional area in threaded portions of the fastener should

be calculated based on the thread’s minor diameter . The

accuracy with which cross-sectional area is entered only

affects the BoltMike load calculation. It has no effect on

the stress or elongation measurement.

The accuracy of the value entered for cross-sectional

area has a direct influence on the accuracy of measured

load. If the value entered for cross-sectional area is ten

percent less than the actual value, then the measured

value of load will be ten percent lower than the actual

value.

If a fastener’s geometry is more complex, with varying

values of cross-sectional area along its effective length,

the various areas over the effective length may be aver-

aged to arrive at an overall average cross-sectional area.

In the case of a hollow fastener, the area of the hole

must be subtracted from the overall average cross-sectional area to determine the actual cross sectional area.

To calculate the average cross-sectional area of a fastener, multiply the length of each segment along the effective length of the fastener by the cross-sectional area

of each specific segment. (Figure 6-6) Add all of the resulting values, and then divide the total by the sum of

the lengths.

In the appendix of this manual, you will find tables of

average cross-sectional areas for various types and sizes

of common fastener.

For the best accuracy of load readings, calibrate the

BoltMike for the specific application. This will cancel errors due to cross sectional area uncertainty. In this approach a calibration group is formed (using fasteners

that are the same or similar to the ones being tested).

The fasteners are inserted in a fixture that loads them at

the same effective length with a known quantity of load.

FIGURE 6-6—Follow this procedure to determine the average cross-sectional area over the effective length of an

irregular fastener.

Page 24 Guide to Ultrasonic Inspection of Fasteners

Page 33

Chapter 7: Material Constants

Chapter 7: Material Constants

As described in Chapter 1 of this guide, several constants are used by the BoltMike to represent the material properties of a specific fastener. You have the

option of using constants already stored in the BoltMike

for standard material types or defining constants for a

custom material type.

7.1 Standard Material Constants

While constants are stored in the BoltMike for twelve standard material types, as shown in Table 7-1, any other

material type and it’s related constants may be entered

using the CUSTOM material type feature.

Material constants used by the BoltMike include:

Vo—Acoustic Velocity (described in section 1.1 of this

guide)

Eo—Modulus of Elasticity (described in section 1.1.8 of

this guide)

Cp—Thermal Coefficient (described in sections 1.1.10

and 4.3 of this guide)

K—Stress Factor (described in section 1.1.9 of this guide)

Y—Yield Strength (described in section 1.1.8 of this

guide)

The material constants listed in Table 7-1 are stored in

the BoltMike for the twelve standard material types listed.

7.2 Custom Material Constants

StressT el of fers laboratory material calibration at a nominal cost. This service is highly recommended for users

of exotic material or in applications where highest accuracy is required.

7.3 Selecting a Material Constant

There are several ways to select a bolt material constant. The best way is to compare the published specifications for the material you wish to evaluate against those

of the standard material types listed in Table 7-1. First

identify the standard material type that’s closest in properties to the non-standard material type you wish to test.

Next, while creating a Group in the BoltMike, first select

the standard material type that most closely resembles

the properties of your non-standard material, and then

press

to enter the CUSTOM material mode. When

Table 7-1

Standard Material Types and Constants Stored in the BoltMike

Name

B7 ASTM A193 B7 5964.7303 0.00007 704 206206.8966 0.000000090 6299 0 655.8621

B16 ASTM A193 B16 5957.3211 .00007704 206206.8966 0.00000009468245 655.8621

8.8 ISO 8.8 6047.9915 0.00007 704 206206.8966 0.00000011457682 627.9593

9.8 ISO 9.8 5842.0000 0.00007 704 206206.8966 0.000000139997 40 720.6897

10.9 ISO 10.9 6047.2295 0.00007704 206206.8966 0.00000011162954 882.9428

11.9 ISO 11.9 5997.6995 0.00007704 206206.8966 0.00000010720853 991.0345

12.9 ISO 12.9 5739 .8895 0.00007704 206206.8966 0.00000008989307 1058.9310

304SS 304 Stainless Steel 5725.9703 0.000103 04 19310 3.4483 0.000000092 10355 209.9862

316SS 316 Stainless Steel 5690.8192 0.000103 04 19310 3.4483 0.000000088 41941 209.9862

1020S 1020 Mild Steel 5964.7303 0.00007704 200000 0.00000008105113 295.1724

MONEL MONEL 5697.9795 0.0001459 6 193103.4483 0.00000009210355 274.9821

Material

Type

Vo

(m/s)

Cp

(1/deg C)

Eo

(MPa)

K

(m/s/Pa)

Y

(MPa)

A490 A490 Structural Steel 5928.6394 0.00007704 200000 0.00000008068271 896.5517

Guide to Ultrasonic Inspection of Fasteners Page 25

Page 34

Chapter 7: Material Constants

the CUSTOM material mode is activated, you edit the

material name and any material property to match those

of your non-standard material type.

Even if you are able to obtain published constants for a

non-standard material type, it is best to perform some

amount of testing to determine the accuracy of the resulting measurements.

Another way to determine the bolt type is to measure a

group of bolts and use the built in calibration function to

determine which material type gives the minimum error.

In this approach a calibration group is formed (using fasteners that are the same or similar to the ones being

tested). The fasteners are inserted in a fixture that loads

them at the same effective length with a known quantity

of load.

7.4 Material Variations

Many materials exhibit very uniform material constants.

However, material constants in samples of some materials will vary widely .

A material’s elastic modulus has a direct effect on that

material’s acoustic velocity (Vo) and stress factor (K).

Hardening or heat treatment of the material or relaxation

of the hardening will affect the accuracy of the standard

values of these constants. In fact, the constants in some

materials can vary dramatically as a result of work hardening of the material. Therefore, it is strongly suggested

that a sample of the bolts be tested to confirm the accuracy of the material properties you’ve chosen under actual loading conditions.

Page 26 Guide to Ultrasonic Inspection of Fasteners

Page 35

Chapter 8: BoltMike Formulas

Chapter 8: BoltMike Formulas

The BoltMike uses the following collection of formulas

as a basis for all calculations and derived values. If using the formulas manually, be certain to convert all values to the units listed below, and to adhere to accepted

rounding practices and number of significant digits. Finally , keep in mind that all BoltMike calculations are performed in metric units. When English units are displayed,

the conversion from metric to English takes place after

values are calculated.

Units

Temperature: Degrees C

Thermal Coefficient (Cp): 1 / Degrees C

Time of Flight (TOF): s (Seconds)

Acoustic Velocity (Vo): m/s (Meters per sec.)

All values of length: m (Meters)

Modulus of Elasticity (Eo): Pa (Pascal)

Stress Factor (K): m/s/Pa (meters per

second per Pascal)

Yield Strength (Y): Pa (Pascal)

Uncorrected Stress: Pa (Pascal)

Corrected Stress: Pa (Pascal)

Stress Offset: Pa (Pascal)

2

Cross-Sectional Area: m

(Square meters)

Load: kN (KiloNewton)

Measured Time of Flight (TOF)

TOF measured = Sound Path Duration

2

Reference Length (LREF)

LREF = TOF

measured

* V

Temperature Normalization

TOF

normal

= TOF

* [1 + (Cp * Temp

measured

measured

– 22.22 )]

Change in Ultrasonic Length

Change in Ultrasonic Length =

(V * TOF

normal-stressed

) – (V * TOF

normal-reference

)

Stress Calculation and Correction

Stress

uncorrected

=

V * (Change in Ultrasonic Length)

K (Change in Ultrasonic Length + Effective Length)

corrected

uncorrected

=

* (1 + Stress Ratio) + Stress Offset

Stress

Stress

100

NOTE: The units of measurement listed above are

those units used in the following equations. These are

not in all cases the same units that are displayed by

the instrument, nor are they necessarily the same units

as listed in tables throughout this guide.

Load

Load = Stress

corrected

Elongation

Elongation = Stress

* Cross-Sectional Area

* Effective Length

corrected

Eo

Guide to Ultrasonic Inspection of Fasteners Page 27

Page 36

Chapter 8: BoltMike Formulas

THIS P AGE WAS INTENTIONALL Y LEFT BLANK.

Page 28 Guide to Ultrasonic Inspection of Fasteners

Page 37

Appendix: Tabular Data

µ

g

g

g

g

g

g

Appendix: Tabular Data

NOTE: The tables contained in this appendix give the

cross sectional stressed area for many standard sizes

of bolt. The operator may choose to use these tables

to determine the area of a fastener. IMPORTANT:

These tables are provided for convenience only StressTel does not assume liability for errors.

In this appendix you will find these tables:

• Material Constants – Units of measurement

(English and Metric) for each of the BoltMike’s

constant or measured values

• Metric Standard Thread

• Metric Fine Thread

• Metric Standard Thread, Waist Bolts

• Metric Fine Thread, Waist Bolts

• Extra Fine Thread Series, UNEF and NEF