Page 1

BOLT TENSION MEASUREMENT BOLTMIKE III

The StressTel BoltMike III ultrasonically measures

tension and clamp load of threaded fasteners. A large,

bright, easy-to-read display; rapid calibration and setup; and automatic temperature compensation ensure

fast, repeatable, and accurate fastener tension measurements in many diverse applications.

Aerospace - Control tightening of bolted engine

joints and aircraft wheel assemblies.

Automotive - Confirm tension of installed engine

headbolts, connecting rod bolts, and main bearing

bolts PLUS monitor tor que and tensioning tools.

Injection Molding Machines - Measure elongation

on tiebars and tierods.

Power Generation - Verify tension on manway studs

and confirm uniform loading of gasketed flange bolts.

Oil/Petrochemical - Measure tension in leg fasteners

of offshore platforms, confirm uniform loading of

gasketed flange bolts in pipelines, and verify tension

of vessel, reactor, and heat exchanger bolts.

Critical fastener and bolting applications require

easy, repeatable, and accurate tension measure-

ments. Verify your loads with the BoltMike III.

View our products and specifications at

http://www.stresstel.com

Page 2

BOLTMIKE III SPECIFICATIONS

The StressTel BoltMike III ultra-

sonically measures tension and

clamp load of threaded fasteners.

A large, bright, easy–to–read

display; rapid calibration and set–

up; and automatic temperature

compensation ensure fast, repeatable, and accurate fastener tension

measurements.

Key BoltMike III features include:

Simultaneous display of fastener

•

load, stress, and elongation.

• Long 40 hour life with five standard

“AA” alkaline batteries.

• High resolution 1/4 VGA LCD

display to verify signal and optimize

probe placement.

• LARGE DIGIT and bargraph

display with limits for fast testing.

• Automatic temperature compensation.

• Built–in probe zero block allows

easy exchange of transducers.

• Regression analysis for custom

material calibration.

• WINDOWS™ software to download

measurements, create reports, and

upload test parameters.

• Direct to printer reports.

ULTRASONIC MEASUREMENT OF FASTENER LOAD

An ultrasonic pulse, generated in the transducer, is transmitted

into the fastener. The pulse travels down the length of the fastener

and is reflected back from the end. The BoltMike III measures

the total pulse transit time.

Fastener Length=(total pulse transit time / 2) X (material constants)

F astener Elongation=(fastener length AFTER tensioning)–(fastener length BEFORE tensioning)

Fastener Load=(fastener elongation) X (geometric and material constants)

PHYSICAL DESCRIPTION

Width: 7.5 in (191 mm)

Height: 5.5 in (140 mm)

Depth: 2.2 in (56 mm)

Weight: 2.5 lbs (1.14 kg) with batteries

Shock resistant plastic case

Weather resistant key pad

DISPLAY

Graphic Waveform LCD: 1/4 VGA

Viewing Area (w x h): 3.8 x 2.8 in/ 96 x 71 mm

Pixel Density (w x h): 320 x 240

Update Rate: 4 Hz

Adjustable contrast and backlight

Four level ZOOM for signal enlargement

StressTel offers a complete

range of transducers for fastener

tension measurement.

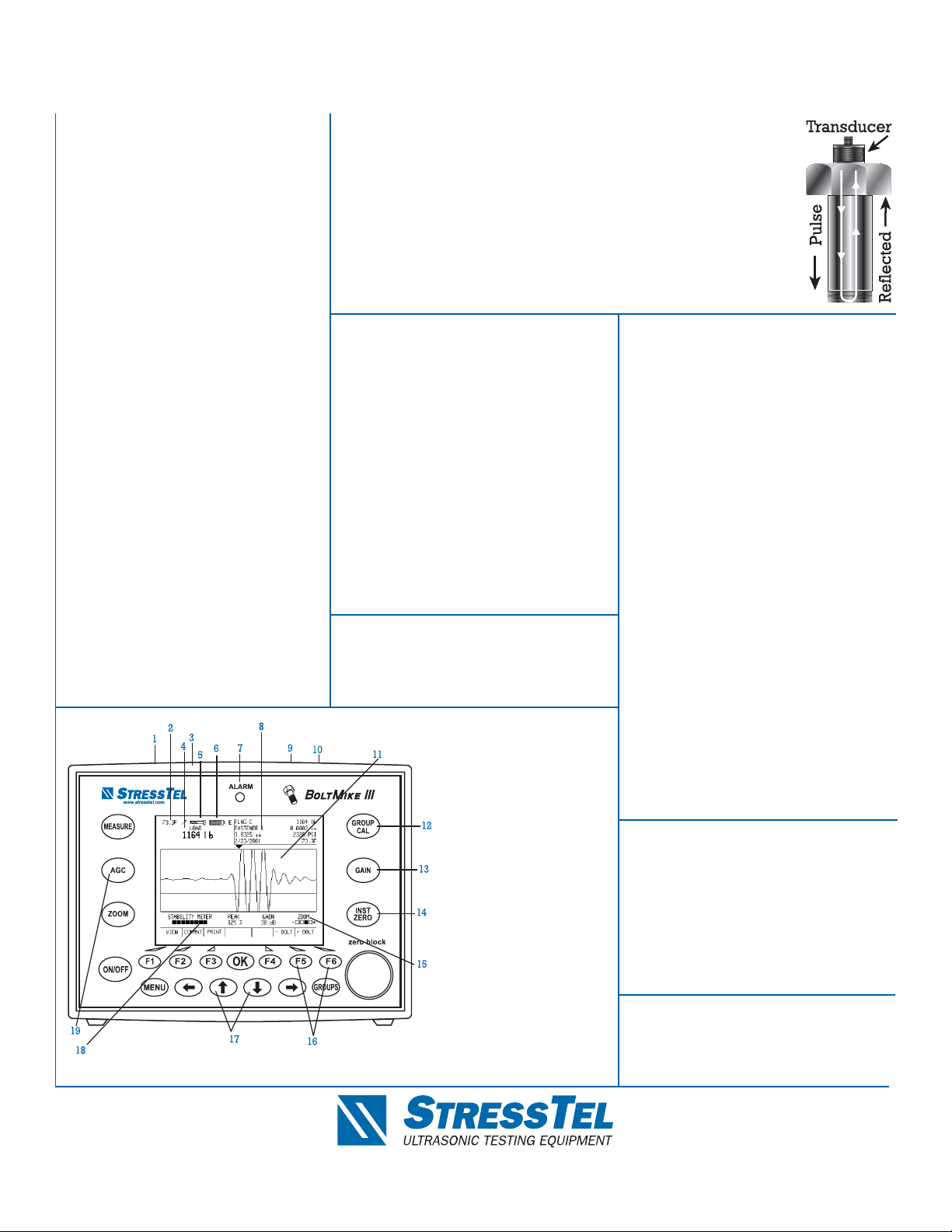

1. Temp Sensor Connector

2. Test Temperature

3. Transducer Connector

4. Measurement Value

(load, stress, or elong)

5. Coupling Indicator

6. Battery Life Indicator

7. Alarm LED

8. Measurement Window

9. RS-232 Connector

10. A.C. Power Connector

11. Measurement Signal

12. GROUP CAL for Custom

Material Calibration

13. GAIN Adjustment

14. Zero for Probe Exchange

15. ZOOM Indicator

16. BOLT Increment Keys

17. Navigation Keys

18. Stability Indicator

19. Auto Gain Adjustment

TEST SPECIFICATIONS

Measurable Fastener Length:

0.75 to 250 in/19 to 6350 mm

Fastener and Test Memory:

10,000 fasteners in 512 groups

Measurement Modes: Initial to first

pulse; multiple echo for short fasteners

Units: Load, stress, and elongation in

English and Metric units

Stored material constants:

12 common fastener materials

POWER SUPPLY

5 “AA” Alkaline or NiCad batteries

Interchangeable and easy–to–access

Operating time: 40 hours w/o backlight

A.C. Power (85 to 260 volt)

SOFTWARE

STRESSWARE (WINDOWS™ 95/98/

ME/NT/2000) to download measurements, create reports, and upload test

parameters.

OPERATING TEMPERATURE

+10 to +120 F/-10 to + 50 C

WARRANTY

The BoltMike III and StressTel fastener

transducers are manufactured in a facility

with processes conforming to ISO 9001.

All BoltMike III’s have a full two–year

warranty on parts and labor excluding

batteries, transducers, and cables.

Specifications subject to change without notice

Visit our website at

http://www.stresstel.com

2790 West College A v e nue , State College, PA 16801-2605

PH: (814) 861-6300 FAX: (814) 861-6330

www.stresstel.com

BoltMike III 06/0110K

Loading...

Loading...