Page 1

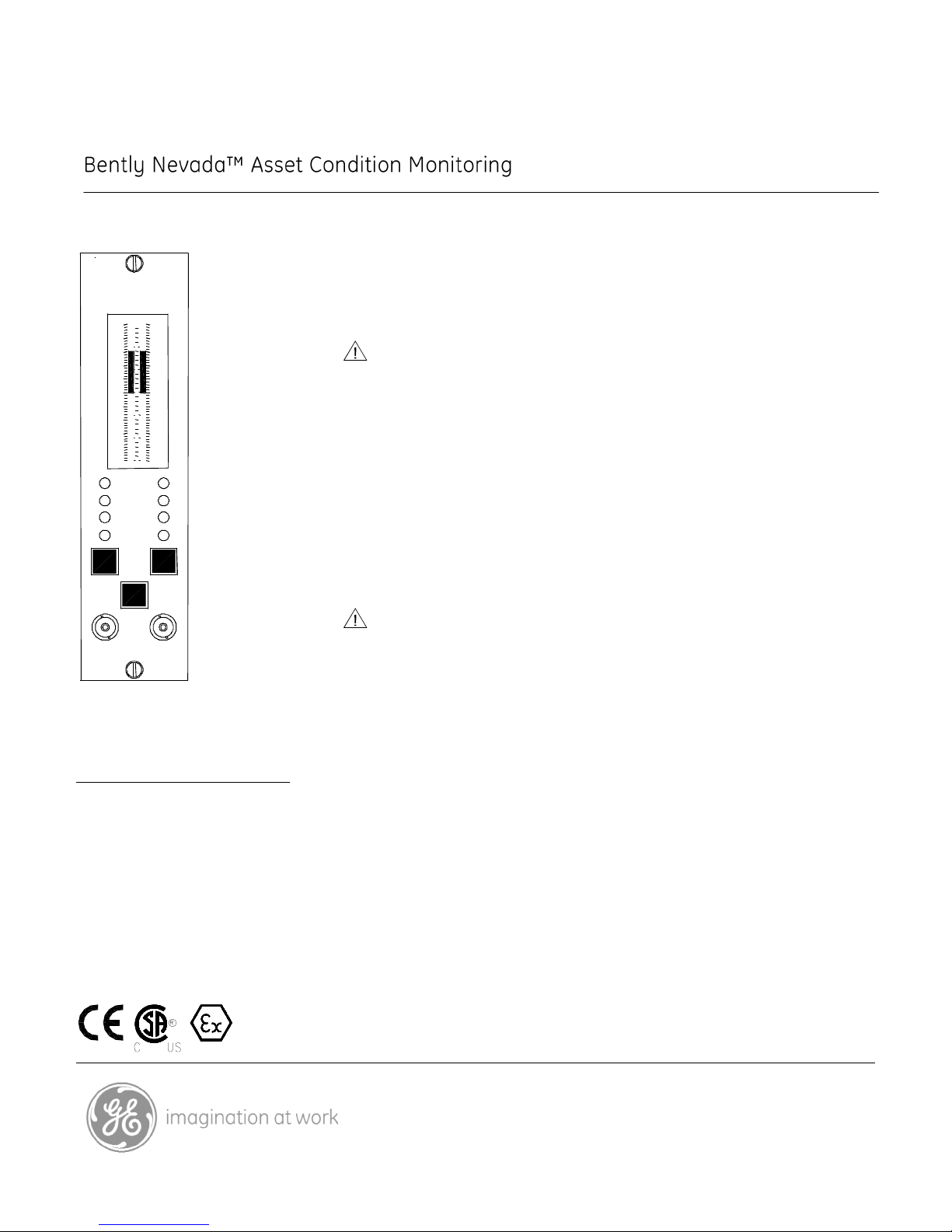

3300/20 Dual Thrust Position Monitor

BUFFERED TR ANSDUCER S

DANGER

A

GAP

ALERT

B

BYPASS

ALERT

DANGER

A B

OK

3300/20

D D

12

4 R

N

T

0 25

20

S

P

A

C

E

M

E

L

15

10

U N

T

E

C

O

8

5

I 0

R

N

25

20

T

A

10

15

U

E

N

T

O

C

M

E

E

C

0

5

S

L

P

I

vdc

16

N 20

M

S

L

I

/

5

10

15

M

O

R 20

25

24

20 N

10

5

L

/

S

I

M

15

M

R

O

25

DUAL THRUST

MONITOR

Description

The 3300/20 Dual Thrust Position Monitor provides early warning of thrust

bearing failure. It continuously measures and monitors two independent

channels of shaft axial position relative to the axial clearances within the

machine. Ideally, the axial probes are installed to observe the thrust collar

directly, so the measurement represents the position of the collar relative to the

thrust bearing clearance.

Caution

Because thrust measurements are made by observing the gap voltage of the

proximity probe used as an input, a transducer failure (gap out of range) can be

interpreted by the monitor as thrust position movement and result in a false

thrust alarm. For this reason, Bently Nevada LLC. does not recommend the use

of a single probe for thrust position applications. Instead, these applications

should use two proximity probes observing the same collar or shaft and

configure the monitor as AND voting whereby both transducers must

simultaneously reach or exceed their alarm setpoints for the monitor’s alarm

relays to actuate. This 2-out-of-2 voting scheme (also known as AND voting)

provides optimum protection against both false trips and missed trips. While the

3300/20 monitor can be programmed for either single voting (OR) or dual voting

(AND), dual voting is strongly recommended for all thrust position applications.

Caution

Probe adjustment and range is critical in this monitor for machinery protection.

Improper adjustment of the transducer may prevent the monitor from alarming

(no machinery protection). For proper adjustment, follow instructions in the

manual.

Specifications and Ordering Information

Part Number 141500-01

Rev. J (06/07)

Page 1 of 6

Page 2

Specifications

• 0 to -10 Vdc: ±1.1% of

signal, ±15 mV offset.

Inputs

Signal:

Accepts one or two proximity

probe signal inputs.

Input

Impedance:

10 k Ω.

Sensitivity:

User-programmable for 200

mV/mil (8 V/mm) or 100 mV/mil (4

V/mm).

Power:

Nominal consumption of 1.5

watts.

Signal Conditioning

Accuracy:

Within ±0.33% of full-scale

typical, ±1% maximum. All

specified at temperature of +25°C

(+77°F).

Outputs

Recorder:

User-programmable for +4 to +20

mA, 0 to -10 Vdc, or +1 to +5 Vdc.

Voltage or current outputs are

proportional to programmed

monitor full-scale. Independent

recorder outputs are provided for

each channel. Monitor operation

is unaffected by short-circuits on

recorder outputs.

Recorder

Accuracy (in

addition to

signal

conditioning

accuracy) at

+25°C (+77°F):

• +4 to +20 mA: ±0.7% of

signal, ±0.09 mA offset.

• +1 to +5 Vdc: ±1.1% of

signal, ±10 mV offset.

Output

Impedance

(voltage

outputs):

100 Ω. Minimum load resistance

is 10 k Ω.

Voltage

Compliance

(current

outputs):

0 to +12 Vdc range across load.

Load resistance is 0 to 600 Ω

when using +4 to +20 mA option.

Buffered

Transducer

Outputs:

There is one coaxial connector

per channel on the front panel

and one terminal connection per

channel on the rear panel. All are

short-circuit protected.

Output

Impedance:

100 Ω.

Transducer

Supply Voltage:

User-programmable in power

supply for -24 Vdc or -18 Vdc.

Current limited on individual

monitor circuit board.

Note: Contact your nearest sales professional if 3000 series

transducers are to be used in the monitoring system which also

uses 3300 and/or 7200 series transducers.

Alarms

Alarm

Setpoints:

Both alarms (Alert and Danger)

are bi-directional (normal and

counter), digitally adjustable from

0 to 100% of full-scale and can be

set within LCD resolution (±1.6%)

to desired level. Once set, alarms

are repeatable within 0.39% of

full-scale.

Specifications and Ordering Information

Part Number 141500-01

Rev. J (06/07)

Page 2 of 6

Page 3

Displays

Meter:

Nonmultiplexing vertical bargraph

type Liquid Crystal Display (LCD).

Individual 63 segment LCD per

channel. Probe Gap indicated on

a third, center scale. LCD also

displays error codes and monitor

ADJUST mode.

Resolution:

Within ±1.6% of monitor fullscale.

Size:

83 mm (3.25 inches), vertical

dimension.

LED Indicators

OK:

One constant ON green LED per

channel indicates OK condition of

monitor, transducers, and field

wiring. Constant OFF indicates

NOT OK condition or Channel

Bypassed (red Bypass LED will be

ON). OK LED flashing at 5 Hz

indicates error code(s) stored in

memory.

Alarm:

Two red LEDs per channel

indicate alarm status (individually

for Alert and Danger). Flashing

alarm LED indicates First Out

(independent for Alert and

Danger).

Bypass:

Two red LEDs indicate status of

Danger Bypass and Rack/

Channel Bypass functions

(individually per channel).

Environmental Limits

Operating

Temperature:

0°C to +65°C (+32°F to +150°F).

Storage

Temperature:

Relative

Humidity:

To 95%, noncondensing.

CE Mark Directives

EMC Directive

Certificate of Conformity: 158710

Low Voltage

Directive

Certificate of Conformity: 135300

Hazardous Area Approvals

CSA/NRTL/C

Class I, Div 2

Groups A, B, C, D

T4 @ Ta = +65 °C

Certification

Number

150368 – 1002151 (LR 26744)

ATEX

II 3 G

EEx nC[L] IIC

T4 @ Ta = -20°C to +60°C

When installed per document

number 132577-01.

Certification

Number

BN26744C-55A

Physical

Space

Requirements:

One rack position (any position

except 1 and 2, which are

reserved for Power Supply and

System Monitor, respectively).

Weight:

1 kg (2.2 lbs.).

-40°C to +85°C (-40°F to +185°F).

Specifications and Ordering Information

Part Number 141500-01

Rev. J (06/07)

Page 3 of 6

Page 4

Ordering Information

For spares, order the complete catalog number as

described below. This includes a front panel

assembly, monitor PWAs with sheet metal, and

appropriate relay module. This unit is optioned,

tested and ready to install in your system. Spare

relay modules can be ordered separately.

Dual Thrust Position Monitor

3300/20-AXX-BXX-CXX-DXX-EXX

Option Descriptions

A: Full-scale Range Option

0 1 25-0-25 mils

0 2 30-0-30 mils

0 3 40-0-40 mils

0 5 50-0-50 mils

0 6 75-0-75 mils

1 1 0.5-0-0.5 mm

1 2 1.0-0-1.0 mm

1 3 2.0-0-2.0 mm

B: Transducer Input Option

0 1 3300 or 7200 Proximitor®

systems, 200 mV/mil (Ranges

01, 02, 03, 11, and 12 only.)

0 2 7200 11 mm (not 3300XL)

Proximitor system, 100 mV/mil

0 3 7200 14 mm or 3300 HTPS

Proximitor systems, 100

mV/mil

0 4 3000 Proximitor® 200 mV/mil

(Transducer Output Voltage in

power supply must be set for –

18 Vdc or use power converter. Ranges 01 and 11 only.)

0 5 3300XL NSv and 3300 RAM

Proximitor Sensor, 200 mV/mil

(Ranges 01 and 11 only).

Note:

1. For 3300 XL 11mm transducers, use mod 146300-01.

2. Contact your nearest sales professional if 3000 series

transducers are to be used in a monitoring system

which also uses 3300 and/or 7200 Series transducers.

C: Alarm Relay Option

0 0 No Relays

0 1 Epoxy-sealed

0 2 Hermetically-sealed

0 3 Quad Relay (Epoxy-sealed

only)

0 4 Spare Monitor-No SIM/SIRM

Notes:

1. AND voting logic is not available with Quad Relays.

2. At least one relay module must be ordered with each

3300 System. If one common relay module per system

has been ordered, all monitors of this type must be

jumper programmed at the factory to activate a relay

bus. Order SCK (Special Configuration Kit) 157520-119

& -120 for bus one or 157520-121 & -122 for bus two.

3. Agency approval places limitations on the relay

module. Refer to the Relay Module data sheet for

information.

4. Quad Relays are not available with the Internal Safety

Barriers option.

D: Agency Approval Option

0 0 Not required

0 1 CSA/NRTL/C

0 2 ATEX self certification

Note: ATEX approval requires the monitor rack be installed in a

weatherproof housing.

E: Safety Barrier Option

0 0 None

0 1 External

0 2 Internal

Spare Relay Module Assemblies

(Order the option in parenthesis for ATEX approved

spares)

81544-01(02)

No Relays

81545-01(02)

Dual Epoxy Relays

81546-01(02)

Dual Hermetic Relays

84152-01(02)

Quad Relays

88984-01(04)

Dual Hermetic, Internal Barriers

88984-02(05)

Dual Epoxy, Internal Barriers

88984-03(06)

No Relay, Internal Barriers

Notes:

1. External Safety Barriers must be ordered separately.

Specifications and Ordering Information

Part Number 141500-01

Rev. J (06/07)

Page 4 of 6

Page 5

2. Quad Relays are not available with Internal Safety

Barriers option.

Field-programmable Options

These options are field-programmable via plug-in

jumpers.

Bold text indicates options as shipped from the

factory.

First Out Option

Enabled

Disabled

OK Mode Option

Nonlatching

Latching

Alarm Time

Delay Option

0.1 second

1 second

3 seconds

6 seconds

Alert Reset

Mode Option

Latching

Nonlatching

Danger Reset

Mode Option

Latching

Nonlatching

Alert Relay

Mode Option

Normally de-energized

Normally energized

Danger Relay

Mode Option

Normally de-energized

Normally energized

Recorder

Outputs Option

+4 to +20 mA

+1 to + 5 Vdc

0 to -10 Vdc

Danger Relay

Voting Option

AND voting for relay drive

OR voting for relay drive

Note: For Quad Relays, AND voting logic must be done externally

by wiring the contacts in series.

Normal Thrust

Direction

Option:

(programmable

per channel)

Toward probe

Away from probe

Accessories

89634-01

-24V to -18V Proximitor Power

Converter

128112

Galvanic Isolator Kit

02245002

External Barrier

02200214

Surge Protector

Specifications and Ordering Information

Part Number 141500-01

Rev. J (06/07)

Page 5 of 6

Page 6

Alert

5 5

25 0 25

20

15 E

R 4

10

O U

N

T

C 8

20

15

10

0 12

5

10

16

0

5

10

15

20

20 M R

N

O

25 vdc 24

M

15

O

N

R

20

25

C

T

N

U O

R

E

Field wiring diagram

3300/20 Dual Thrust Position Monitor

DUAL THRUST

MONITOR

M

L

S

/

D

I

S

P

L

A

C

E

M

E

N

T

OK

DANGER

A

ALERT

BYPASS

DANGER

GAP

A

BUFFERED TRANSDUCERS

3300/20

Shielded Cable

M

I

L

S

/

D

S

P

L

A

C

E

M

E

N

T

Channel A

B

ALERT

To Channel A

Recorder

B

Relay

Contacts

Proximitor

3 Conductor

Output

ALERT

Channel A

Probe

R

Channel B

Probe

CH B

CH A

PWR

COM

IN

BUF

COM

REC

Channel B

Shield (Green)

(To single earth

point ground) 4 pl.

To Channel B

Recorder Output

DANGER

NC

ARM

NO

NC

ARM

NO

Danger

Relay

Contacts

Thrust Collar

Shaft

-V

T

COM

OUTPUT

Dual Relays Shown

Quad Relays also available

Bently Nevada and Proximitor are trademarks of General Electric Company.

Copyright 1999. Bently Nevada LLC.

1631 Bently Parkway South, Minden, Nevada USA 89423

Phone: 775.782.3611 Fax: 775.215.2873

www.ge-energy.com/bently

All rights reserved.

Specifications and Ordering Information

Part Number 141500-01

Rev. J (06/07)

Page 6 of 6

Loading...

Loading...