Page 1

Title pageMULTILIN B95

Pl

LISTED

52TL

IND.CONT. EQ.

E83849

GE Energy

us

BUS

Instruction manual

Plus

B95

firmware revision: 1.00

GE publication code: GEK-113629

GE Digital Energy

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.gedigitalenergy.com

*1601-0015-A1*

GE Multilin's Quality

Management System is

registered to ISO 9001:2008

QMI # 005094

UL # e83849

Page 2

PROTECTION SYSTEM –

Copyright © 2012 GE Multilin Inc. All rights reserved.

Multilin B95

Multilin, Multilin B95

FlexLogic, and FlexAnalog are trademarks or registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The manual is for informational use only and is subject to change without

notice.

Part number: 1601-0015-A1 (April 2012)

Plus

Bus Protection System Instruction Manual for product revision 1.00.

Plus

Bus Protection System, EnerVista, EnerVista B95

Plus

Setup,

Page 3

INSTRUCTION MANUAL

GENERAL SAFETY PRECAUTIONS - B95

Plus

• The use of Omega-level safety shoes, safety gloves, safety glasses, and protective clothing are

recommended during equipment installation, maintenance, and service.

• Failure to observe and follow the instructions provided in the instruction manual can cause

damage to the equipment and can lead to property damage, personal injury, and/or death.

• Before attempting to use the equipment, review all danger and caution indicators.

• If the equipment is used in a manner not specified by the manufacturer or functions

abnormally, proceed with caution. Otherwise, the protection provided by the equipment can be

impaired and can result in damage and/or injury.

• Hazardous voltages can cause shock, burns, or death.

• Installation/service personnel must be familiar with general device test practices and

electrical awareness. Safety precautions must be followed.

• Before performing visual inspections, tests, or periodic maintenance on this device or

associated circuits, isolate or disconnect all live circuits and sources of electric power.

• Failure to power equipment off prior to removing the power connections can lead to exposure

to dangerous voltages causing injury or death.

• All recommended equipment that can be grounded should be and must have a reliable and

uncompromised grounding path for safety purposes, protection against electromagnetic

interference, and proper device operation.

• Equipment grounds should be bonded together and connected to the facility’s main ground

system for primary power.

• Keep all ground leads as short as possible.

• The equipment ground terminal must be grounded at all times during device operation and

service.

• In addition to the safety precautions mentioned, all electrical connections made must respect

the applicable local jurisdiction electrical code.

• LED transmitters are classified as IEC 60825-1 Accessible Emission Limit (AEL) Class 1M. Class

1M devices are considered safe to the unaided eye. Do not view directly with optical

instruments.

• Before working on current transformers (CTs), short-circuit them.

FCC/Industry Canada

This device complies with Part 15 of the FCC Rules and Industry Canada rules. Operation is

subject to the following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

L’appareil conforme aux CNR d'Industrie Canada applicable aux appareils radio exempts de

licence. L'exploitation est autorisé aux deux conditions suivantes: (1) l'appareil ne doit pas

produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radiolectrique

subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Page 4

Page 5

GE Energy

Plus

Multilin B95

Bus Protection

System

Table of contents

GETTING STARTED Safety words and definitions........................................................................................1

Unpacking and inspection checklist ...........................................................................1

Quick start .......................................................................................................................2

For further assistance ...................................................................................................2

PRODUCT

DESCRIPTION

INSTALLATION Installing the unit in a rack.........................................................................................19

Device overview..............................................................................................................3

FlexLogic equations ........................................................................................................................................6

HardFiber overview........................................................................................................7

Order codes .....................................................................................................................8

Specifications..................................................................................................................9

Remote resources specifications..............................................................................................................9

Protection specifications ........................................................................................................................... 10

Communications specifications ............................................................................................................. 12

Digital fault recorder specifications...................................................................................................... 13

Front panel interface ................................................................................................................................... 14

Security specifications ................................................................................................................................14

Hardware specifications ............................................................................................................................14

Test specifications.........................................................................................................................................16

Environmental specifications .................................................................................................................. 17

Approvals and certification ......................................................................................................................17

Rear terminal and port layout ...................................................................................21

Typical wiring diagram................................................................................................22

Dielectric strength .......................................................................................................23

Power supply card (slot A)...........................................................................................23

Communications card (slot C) ....................................................................................25

Main processor card (slot D).......................................................................................25

Ethernet port ................................................................................................................................................... 25

IRIG-B port ........................................................................................................................................................ 26

Process cards (slot J and optionally slot F)..............................................................27

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL v

Page 6

TABLE OF CONTENTS

ENERVISTA

SOFTWARE

Introduction...................................................................................................................29

Installing the EnerVista software ..............................................................................30

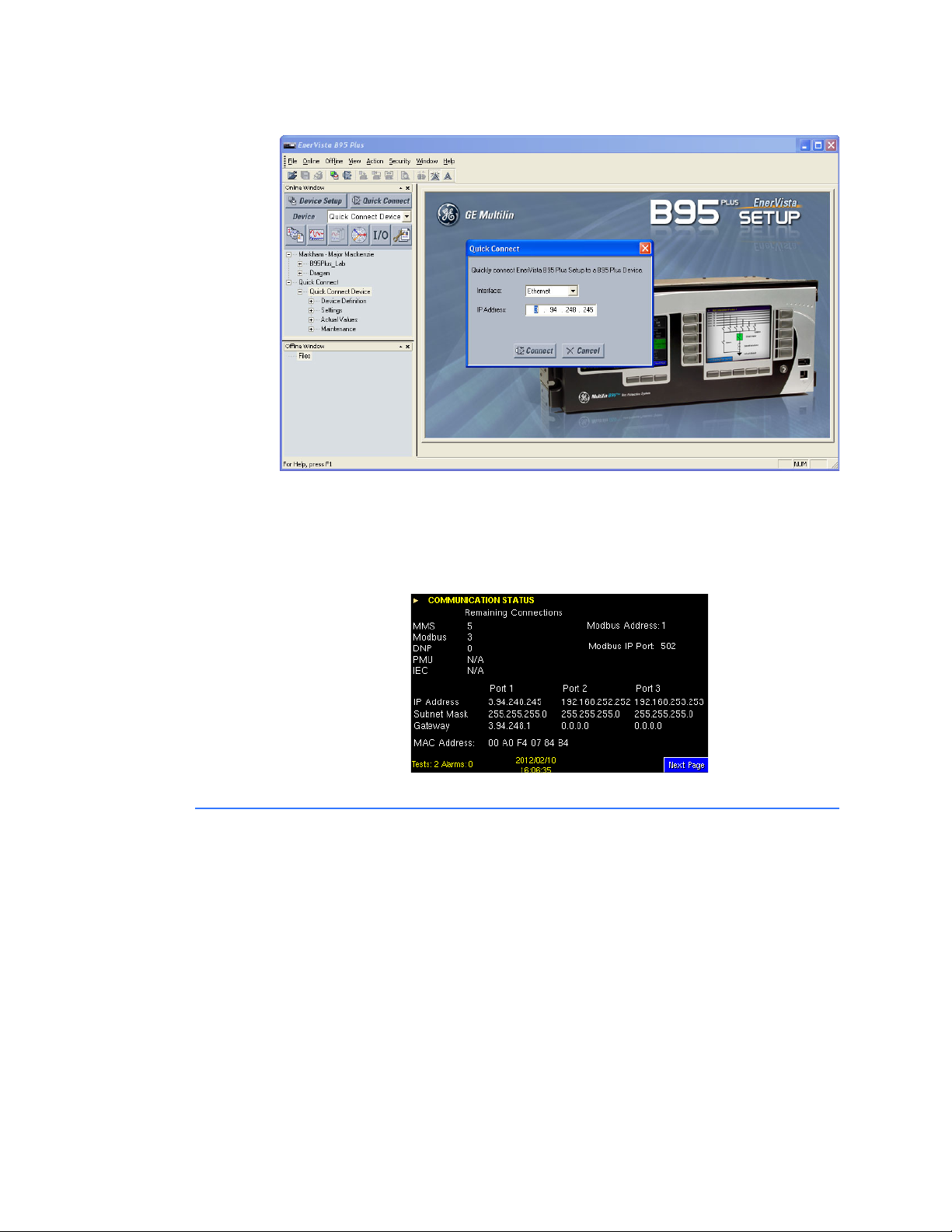

Establishing communication via USB .......................................................................31

Establishing communication via Ethernet...............................................................33

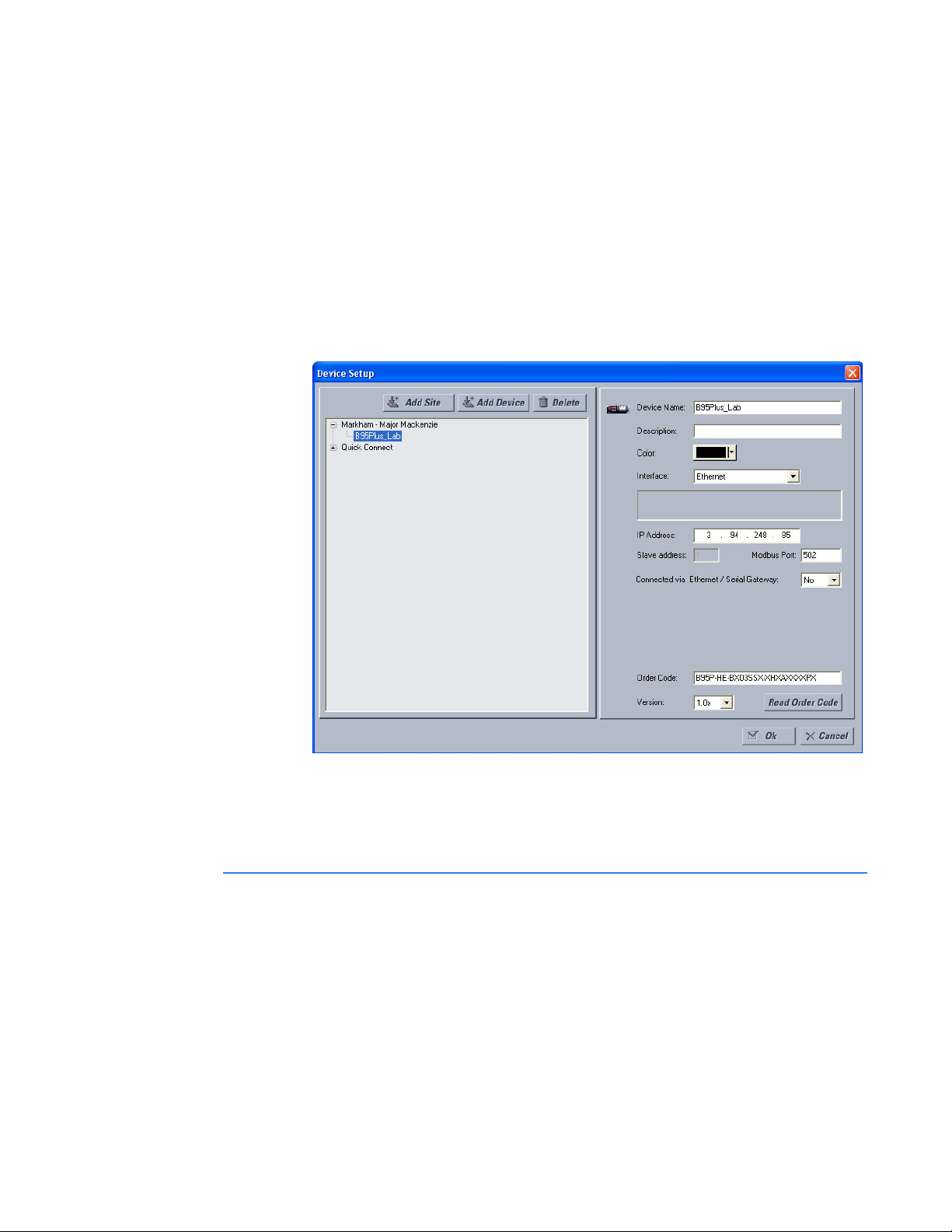

Adding sites and devices.............................................................................................34

Connecting to a device................................................................................................35

Accessing settings........................................................................................................36

Operand quick select ...................................................................................................................................36

Navigating long lists .....................................................................................................................................37

Expanding/collapsing table rows...........................................................................................................38

Viewing actual values..................................................................................................38

Viewing event records .................................................................................................38

Viewing transient records...........................................................................................39

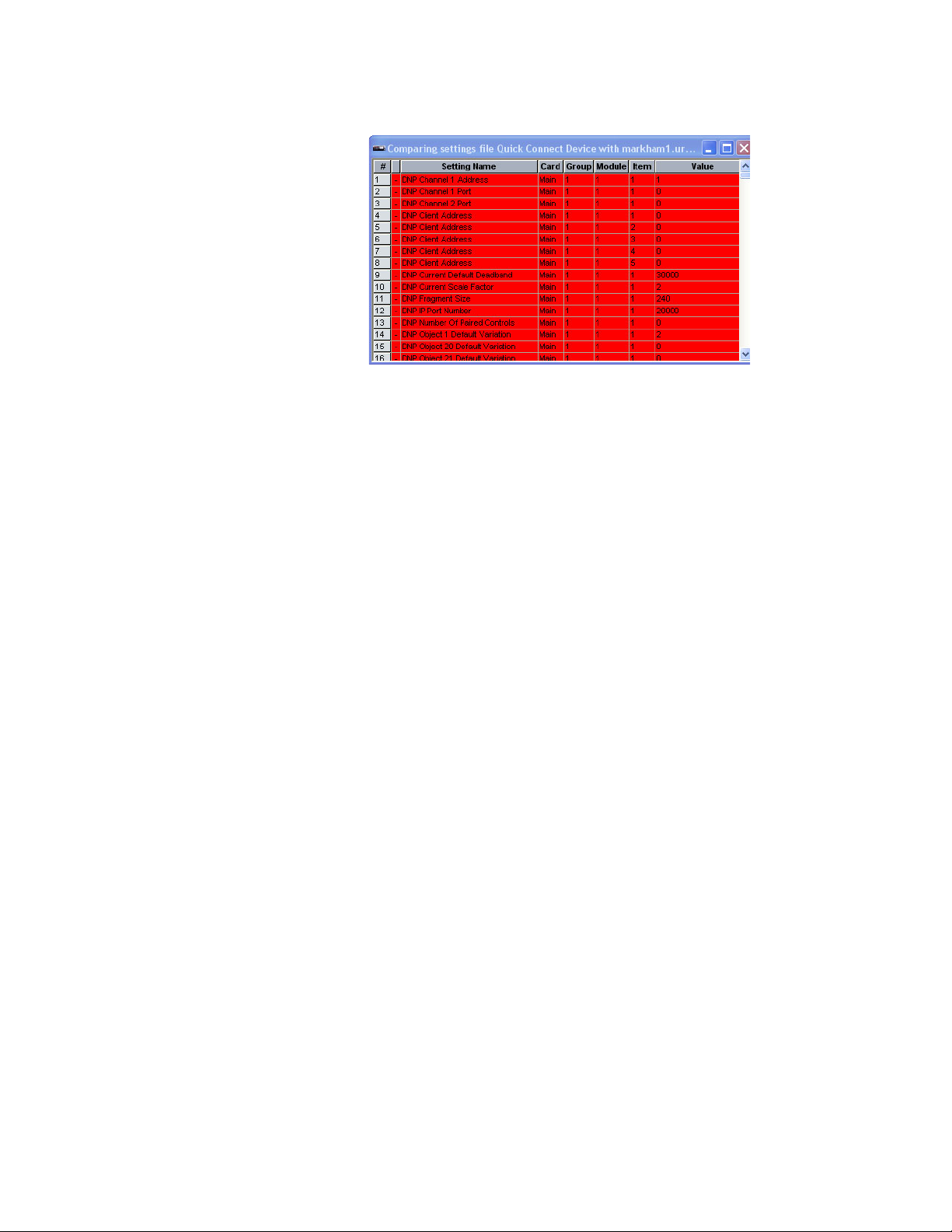

Settings files ..................................................................................................................40

Deploying settings files to multiple devices using settings templates ..............41

Enabling the settings template in offline mode...............................................................................41

Enabling the settings template in online mode...............................................................................42

Editing a settings template .......................................................................................................................42

Adding password protection to a settings template ....................................................................43

Applying a settings template....................................................................................................................44

Removing a settings template.................................................................................................................45

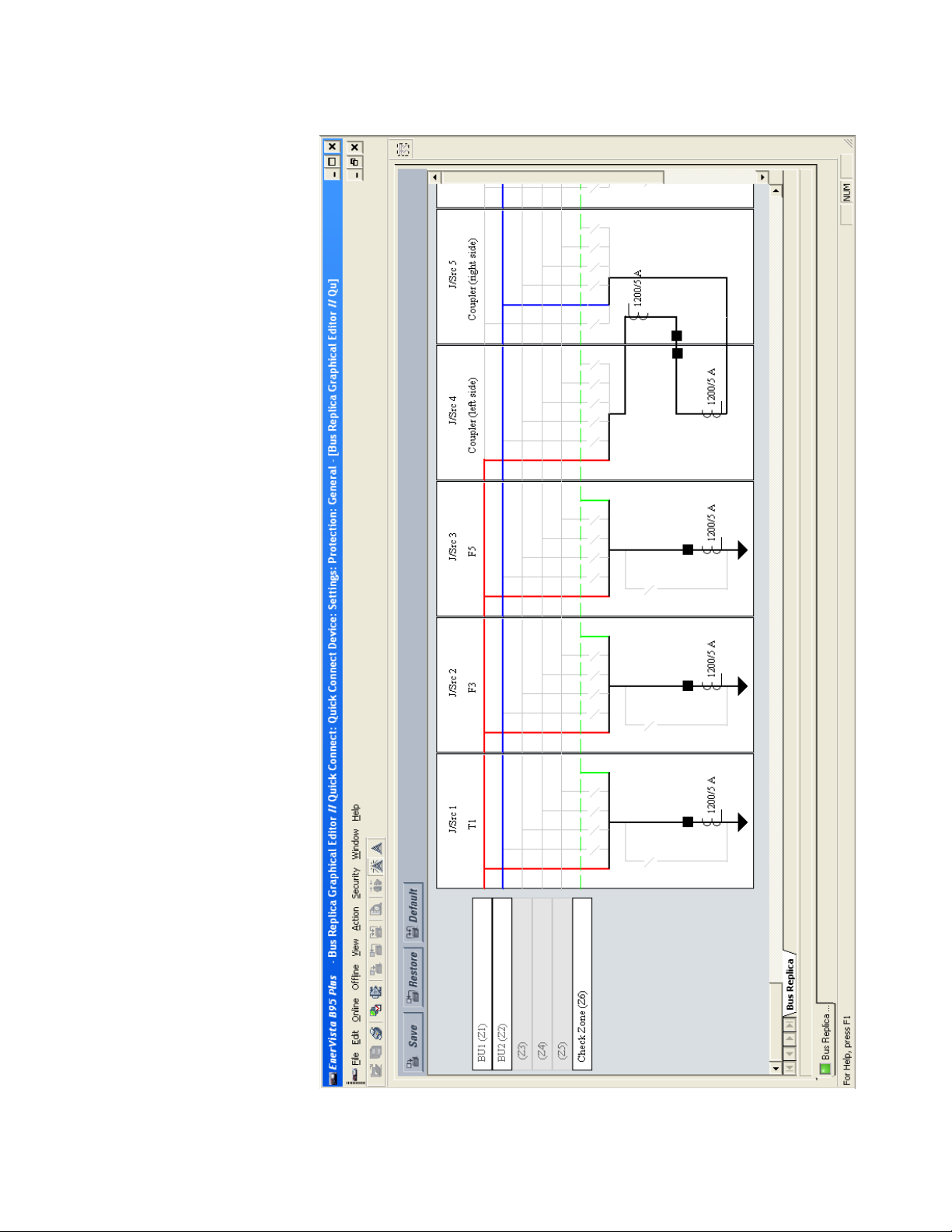

Bus replica graphical editor .......................................................................................45

Securing and locking FlexLogic equations...............................................................50

Locking FlexLogic equation entries .......................................................................................................50

Locking a settings file and FlexLogic equations to a serial number ......................................51

Settings file traceability ..............................................................................................51

SETTINGS –

GENERAL

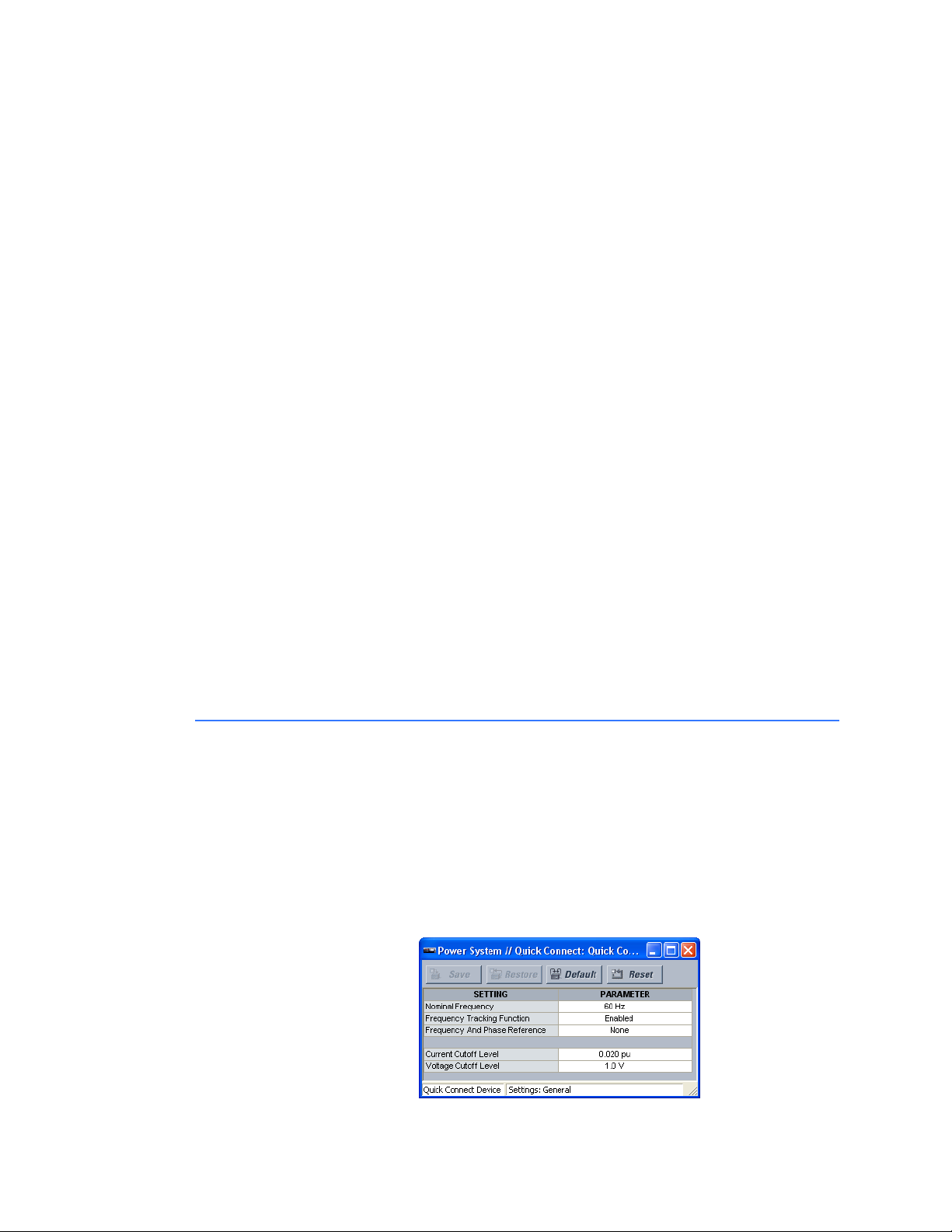

Installation.....................................................................................................................53

Power system ................................................................................................................54

User programmable self-tests...................................................................................56

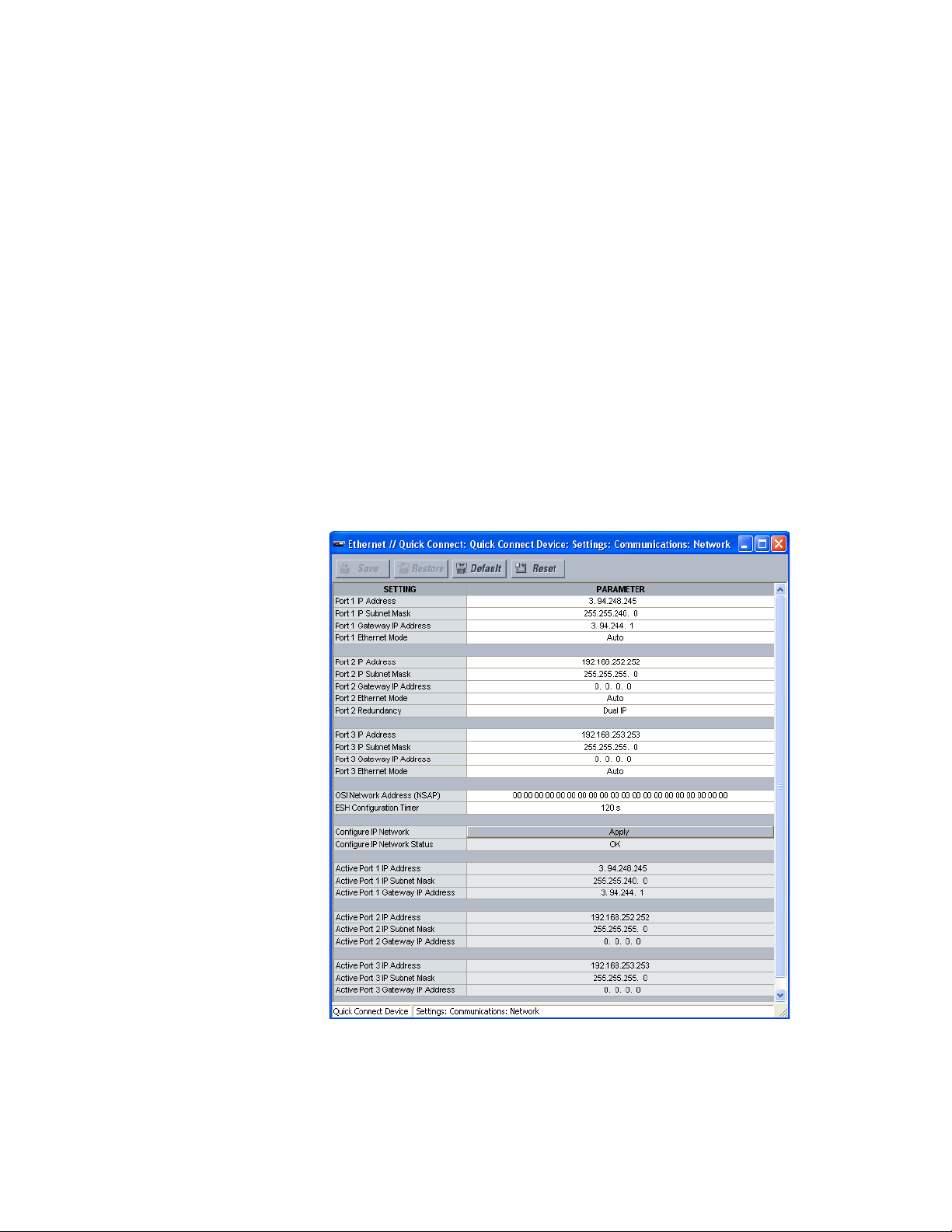

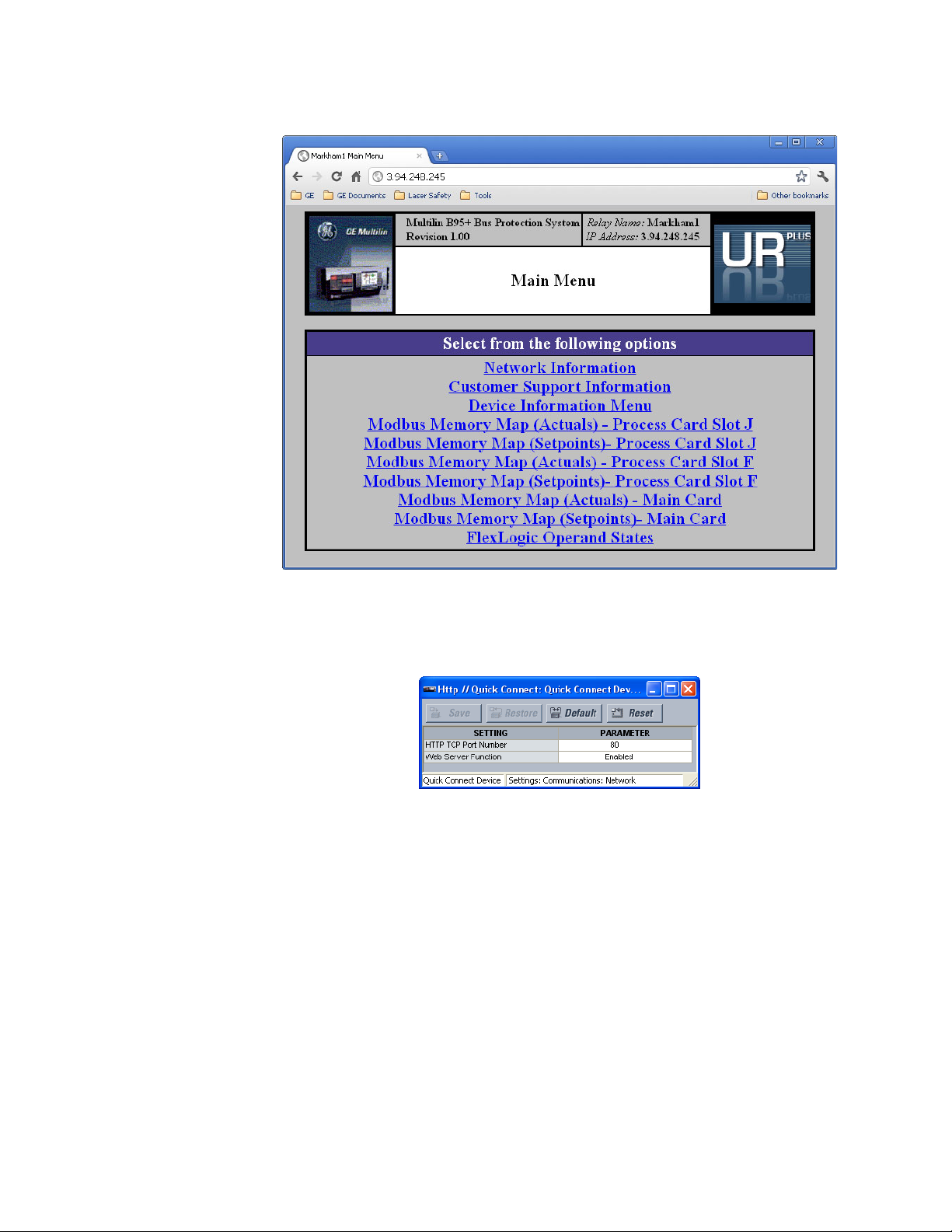

COMMUNICATIONS Communications overview .........................................................................................59

Network settings ..........................................................................................................59

Ethernet..............................................................................................................................................................59

TFTP ......................................................................................................................................................................63

SNTP .....................................................................................................................................................................64

HTTP .....................................................................................................................................................................65

Viewing Ethernet actual values...............................................................................................................67

Viewing TCP/IP connection actual values ..........................................................................................68

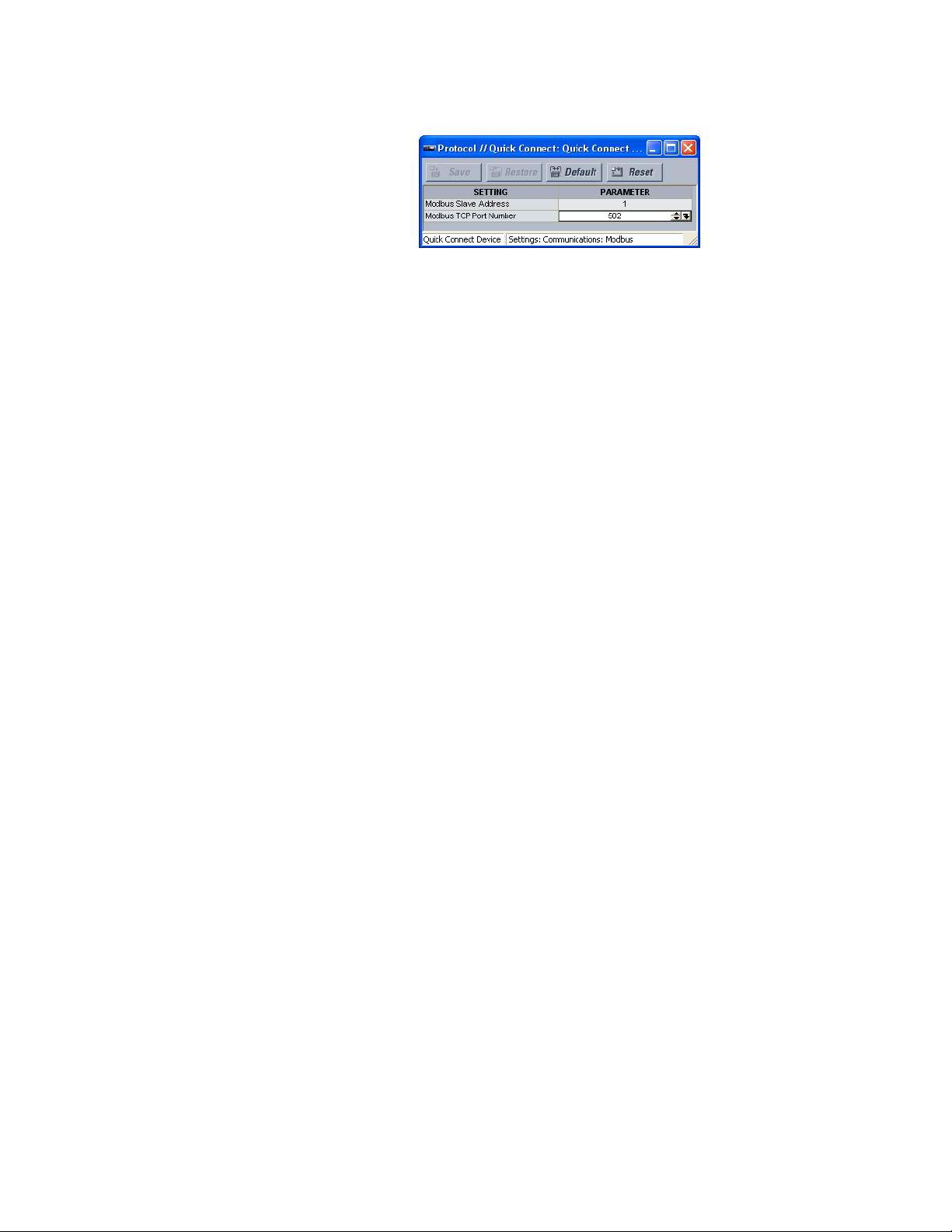

Modbus communications............................................................................................69

Protocol...............................................................................................................................................................69

User map ...........................................................................................................................................................70

DNP communications ..................................................................................................71

Protocol...............................................................................................................................................................72

User point list ...................................................................................................................................................75

IEC 60870-5-104 communications ............................................................................76

Configuring IEC 60870-5-104 settings.................................................................................................76

Configuring IEC 60870-5-104 point lists .............................................................................................77

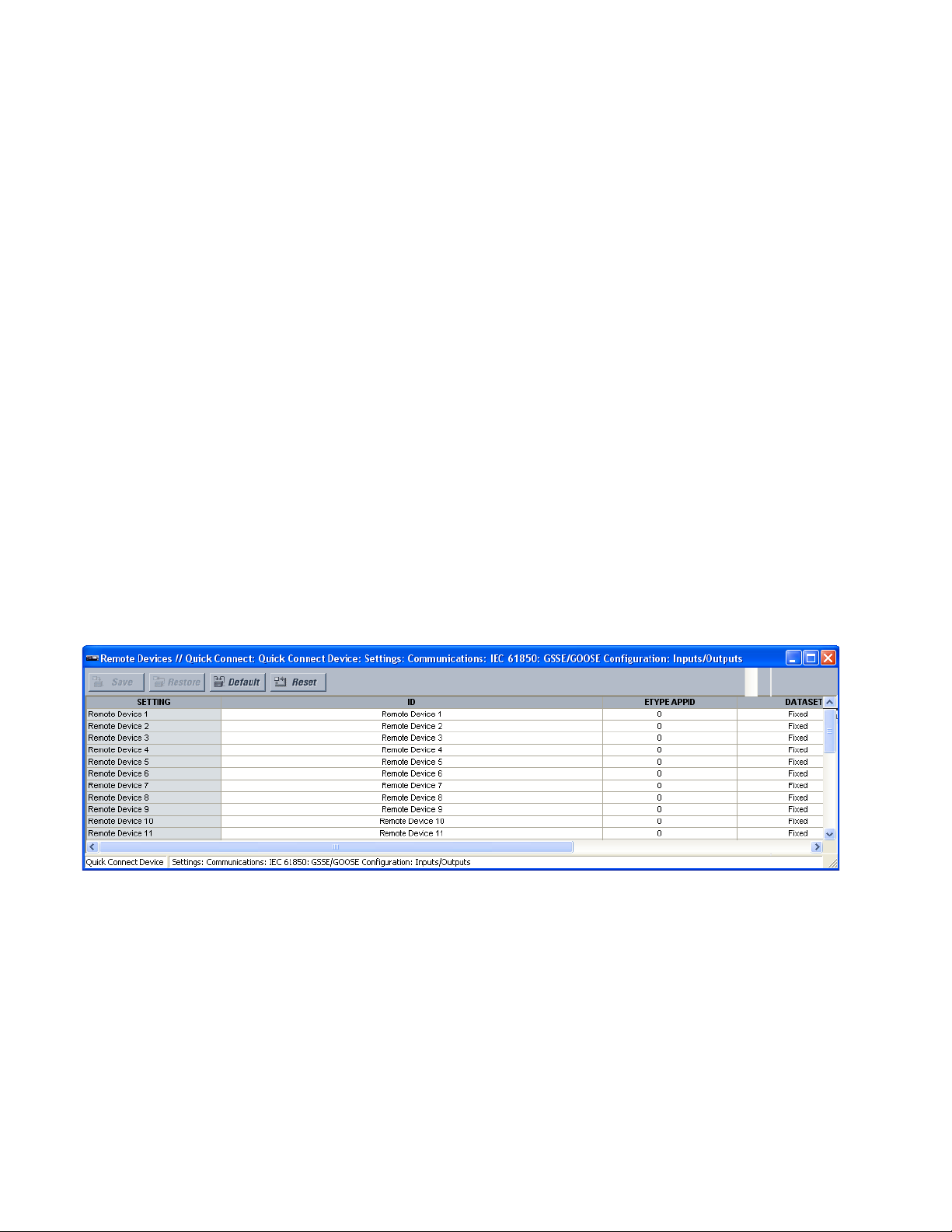

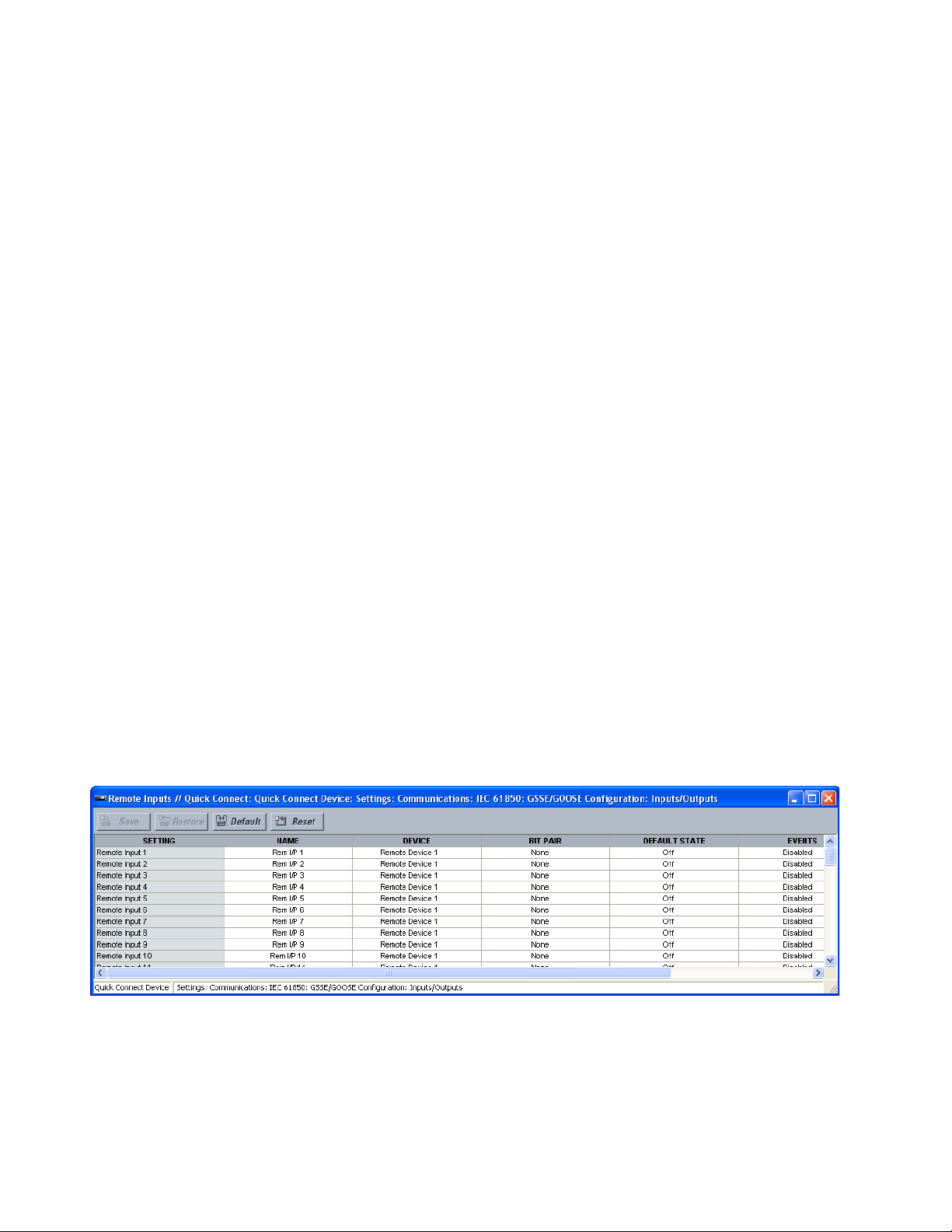

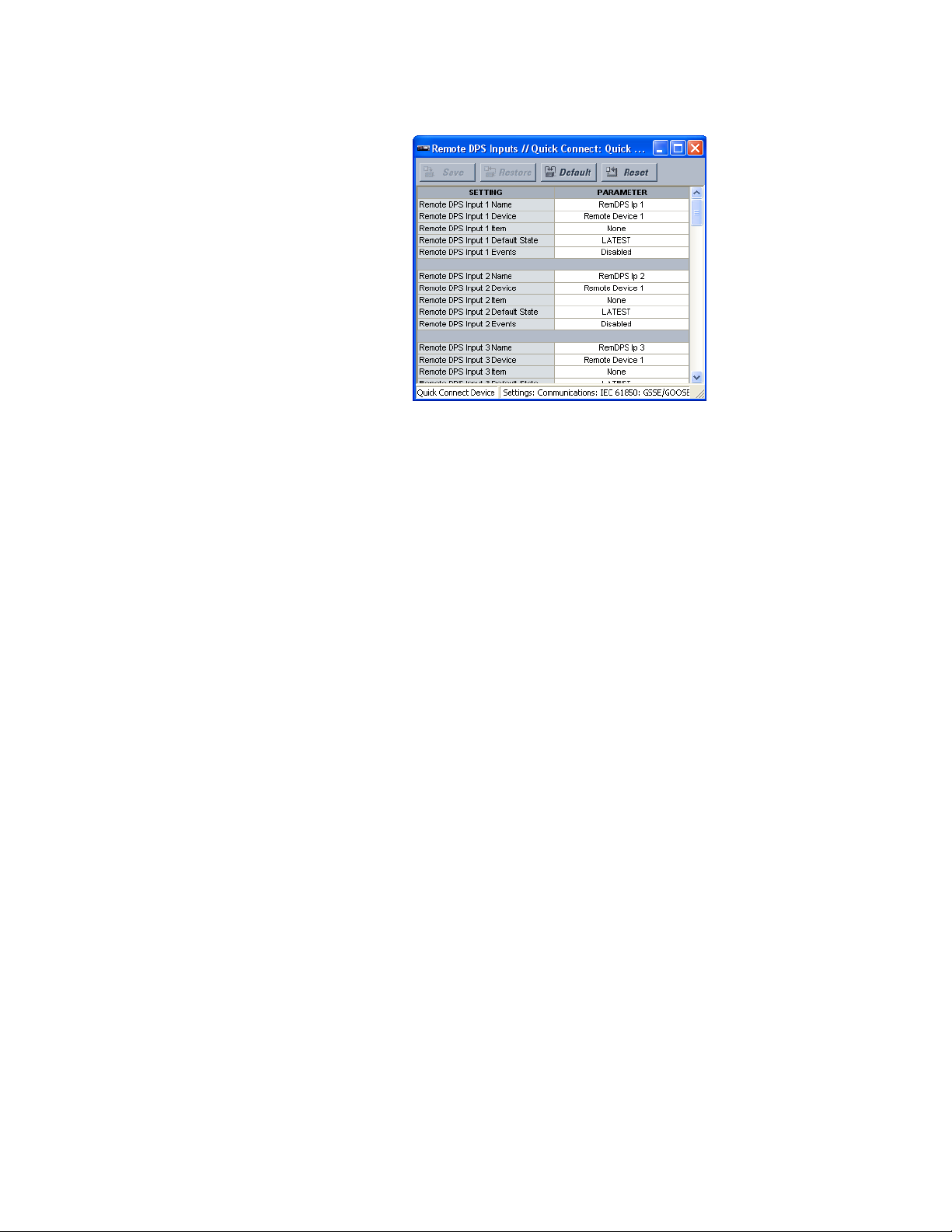

IEC 61850 communications ........................................................................................78

GSSE/GOOSE configuration.......................................................................................................................78

Server configuration.....................................................................................................................................92

vi MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 7

TABLE OF CONTENTS

GGIO1 status configuration...................................................................................................................... 93

Viewing IEC 61850 actual values........................................................................................................... 94

Real time clock and IRIG-B..........................................................................................97

Virtual inputs.................................................................................................................99

Communication logic operands ............................................................................. 100

REMOTE RESOURCES Field units.................................................................................................................... 103

Settings ........................................................................................................................................................... 104

Auto populate .............................................................................................................................................. 105

Actual values ................................................................................................................................................ 106

FlexLogic operands ................................................................................................................................... 106

Field contact inputs .................................................................................................. 107

Settings ........................................................................................................................................................... 107

Actual values ................................................................................................................................................ 108

FlexLogic operands ................................................................................................................................... 109

Field contact inputs chatter detection.................................................................. 109

Field contact outputs................................................................................................ 111

Settings ........................................................................................................................................................... 111

Actual values ................................................................................................................................................ 112

FlexLogic operands ................................................................................................................................... 113

Field latching outputs............................................................................................... 114

Settings ........................................................................................................................................................... 114

Actual values ................................................................................................................................................ 115

FlexLogic operands ................................................................................................................................... 116

Shared inputs and outputs ...................................................................................... 117

Shared input settings ............................................................................................................................... 117

Shared input actual values .................................................................................................................... 118

Shared output settings ............................................................................................................................ 119

Shared output actual values................................................................................................................. 120

FlexLogic operands ................................................................................................................................... 120

PROTECTION Bus protection overview .......................................................................................... 121

Bus source concept................................................................................................................................... 121

Bus zone concept....................................................................................................................................... 122

Bus replica concept................................................................................................................................... 123

Bus sources ................................................................................................................ 124

General settings.......................................................................................................................................... 125

CT settings ..................................................................................................................................................... 126

Bus configuration settings ..................................................................................................................... 129

Zone trip bus settings............................................................................................................................... 133

End fault protection settings................................................................................................................. 135

Breaker failure settings ........................................................................................................................... 137

Instantaneous overcurrent settings.................................................................................................. 145

Inverse time overcurrent settings ...................................................................................................... 146

Actual values ................................................................................................................................................ 147

FlexLogic operands ................................................................................................................................... 149

Analog operands ........................................................................................................................................ 150

Voltage sources ......................................................................................................... 150

General settings.......................................................................................................................................... 151

Voltage sources settings......................................................................................................................... 152

Undervoltage settings.............................................................................................................................. 155

Actual values ................................................................................................................................................ 156

FlexLogic operands ................................................................................................................................... 158

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL vii

Page 8

TABLE OF CONTENTS

Analog operands......................................................................................................................................... 158

Bus differential........................................................................................................... 158

General settings...........................................................................................................................................160

Operating characteristic settings........................................................................................................162

Supervision settings...................................................................................................................................165

Actual values.................................................................................................................................................168

FlexLogic operands....................................................................................................................................169

Analog operands......................................................................................................................................... 170

Bus replica graphical editor .................................................................................... 170

FlexLogic ..................................................................................................................... 170

FlexLogic rules..............................................................................................................................................172

FlexLogic gates and operators.............................................................................................................173

FlexLogic equation editor........................................................................................................................174

FlexLogic timers...........................................................................................................................................174

Non-volatile latches...................................................................................................................................175

Setting group control................................................................................................ 176

Isolators ...................................................................................................................... 177

Settings............................................................................................................................................................179

Actual values.................................................................................................................................................180

FlexLogic operands....................................................................................................................................182

DIGITAL FAULT

RECORDER (DFR)

Event recorder ........................................................................................................... 183

Viewing records ...........................................................................................................................................183

Transient recorder .................................................................................................... 185

Settings............................................................................................................................................................186

Viewing records ...........................................................................................................................................190

FlexLogic operands....................................................................................................................................192

FRONT PANEL Front panel overview ................................................................................................ 193

Status LED................................................................................................................... 194

Annunciator panel..................................................................................................... 194

Operation........................................................................................................................................................194

Settings............................................................................................................................................................196

Self-test summary display operation .................................................................... 200

Bus diagram operation............................................................................................. 201

Bus source template editor ..................................................................................... 201

Dynamic symbols........................................................................................................................................203

Static symbols ..............................................................................................................................................204

Pre-configured mimic diagrams..........................................................................................................205

Metering summary.................................................................................................... 205

Display properties ..................................................................................................... 207

Phasor display............................................................................................................ 208

SECURITY User and password management .......................................................................... 209

Local and remote passwords .................................................................................. 210

Access alarms ............................................................................................................ 213

CONFIGURE

Configure FlexOperands........................................................................................... 215

FLEXOPERANDS

viii MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 9

TABLE OF CONTENTS

PRODUCT

Serial number............................................................................................................. 217

INFORMATION

MAINTENANCE Test mode ................................................................................................................... 219

Self-tests ..................................................................................................................... 220

Major self-tests............................................................................................................................................ 221

Minor self-tests............................................................................................................................................ 222

FlexLogic operands ................................................................................................................................... 224

Set date and time ...................................................................................................... 226

Raw data viewer ........................................................................................................ 227

Analog inputs ............................................................................................................................................... 227

Contact and shared input/output ...................................................................................................... 228

Diagnostics.................................................................................................................................................... 230

Modbus analyzer ....................................................................................................... 232

Updating firmware.................................................................................................... 234

BUS REPLICA

APPLICATION GUIDE

Static bus arrangements ......................................................................................... 237

Dynamic bus arrangements.................................................................................... 245

Sectionalized bus........................................................................................................................................ 246

Double-bus single-breaker .................................................................................................................... 250

Main and transfer bus.............................................................................................................................. 254

Breaker bypass switches ........................................................................................................................ 259

Check zones................................................................................................................ 260

Undervoltage supervision........................................................................................ 264

Zone expansion/reduction and end fault protection ......................................... 264

Breaker failure ........................................................................................................... 265

APPENDIX Revision history ......................................................................................................... 267

Warranty..................................................................................................................... 267

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL ix

Page 10

TABLE OF CONTENTS

x MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 11

GE Energy

Plus

Multilin B95

Bus Protection

System

Chapter 1: Getting started

Getting started

This section outlines the symbols used in the document, what is in the box, and general

approach to set up the Multilin B95

Plus

Bus Protection SystemTM.

DANGER:

IMPORTANT:

CAUTION:

NOTE:

Safety words and definitions

Before attempting to install or use the device, review all safety indicators in this document

to help prevent injury, equipment damage, or downtime.

The following safety and equipment symbols are used in this document.

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Indicates practices not related to personal injury.

Unpacking and inspection checklist

Use this procedure to unpack and inspect the B95

1. Inspect the packaging for physical damage.

2. Open it and inspect the B95

3. Check that the following items have been delivered:

– Multilin B95

– GE EnerVistaTM CD (software and documentation)

– Instruction Manual (if ordered)

–Certificate of Calibration

Plus

Bus Protection System

Plus

for physical damage.

Plus

.

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 1

Page 12

QUICK START CHAPTER 1: GETTING STARTED

–Test Report

– EC Declaration of Conformity

4. View the rear nameplate of the product and verify that the correct model has been

delivered.

5. For product information, instruction manual updates, and software updates, visit the

GE Multilin website at http://gedigitalenergy.com/multilin.

6. If any of the contents listed are missing or there is physical damage to the product,

contact GE Digital Energy immediately using the contact information in the For

Further Assistance section.

Quick start

The process for installing the unit is as follows:

• Install the unit in a rack (see Installing the Unit in a Rack)

• Connect the power supply and wire the unit (see Typical Wiring Diagram)

• Install the EnerVista software on a computer (see Installing the EnerVista Software)

• Connect the computer to the unit using a USB or Ethernet cable. Use of a USB cable is

recommended for setup because of ease of use, after which you can switch to

Ethernet for faster communications. (See Establishing Communication via USB and

see Establishing Communication via Ethernet. Setup using the USB cable is

documented.)

• Configure the unit by accessing the Settings panels in the Online Window area of the

EnerVista software. Use this document for information as you work through the

settings panels.

• Configure user access (see Security)

If a device is not available, one can still familiarize oneself by installing EnerVista software

and experimenting with the Offline Window features, skipping the steps involving a device.

Note that the chapters starting with Settings - General largely follow the structure

displayed in the software.

For further assistance

For product support, contact the information and call center as follows:

GE Digital Energy

215 Anderson Avenue

Markham, Ontario

Canada L6E 1B3

Telephone: 1-905-294-6222

Toll-free: 1-800-547-8629

Fax: 1-905-201-2098

E-mail: multilin.tech@ge.com

Website: http://www.gedigitalenergy.com/multilin/

Comments about new features or modifications for specific requirements are welcome.

2 MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 13

GE Energy

Plus

Multilin B95

Bus Protection

System

Chapter 2: Product description

Product description

This chapter provides an overview and technical specifications of the Multilin B95

Protection System.

Device overview

The Multilin B95

currents connected to the bus and when it detects a fault on the bus, it sends signals to

isolate the bus. When there is a fault on a bus, the entire bus goes down, making the

Plus

B95

Process Bus product family to provide a distributed, low impedance, current differential

protection solution for medium and high voltage large and reconfigurable buses.

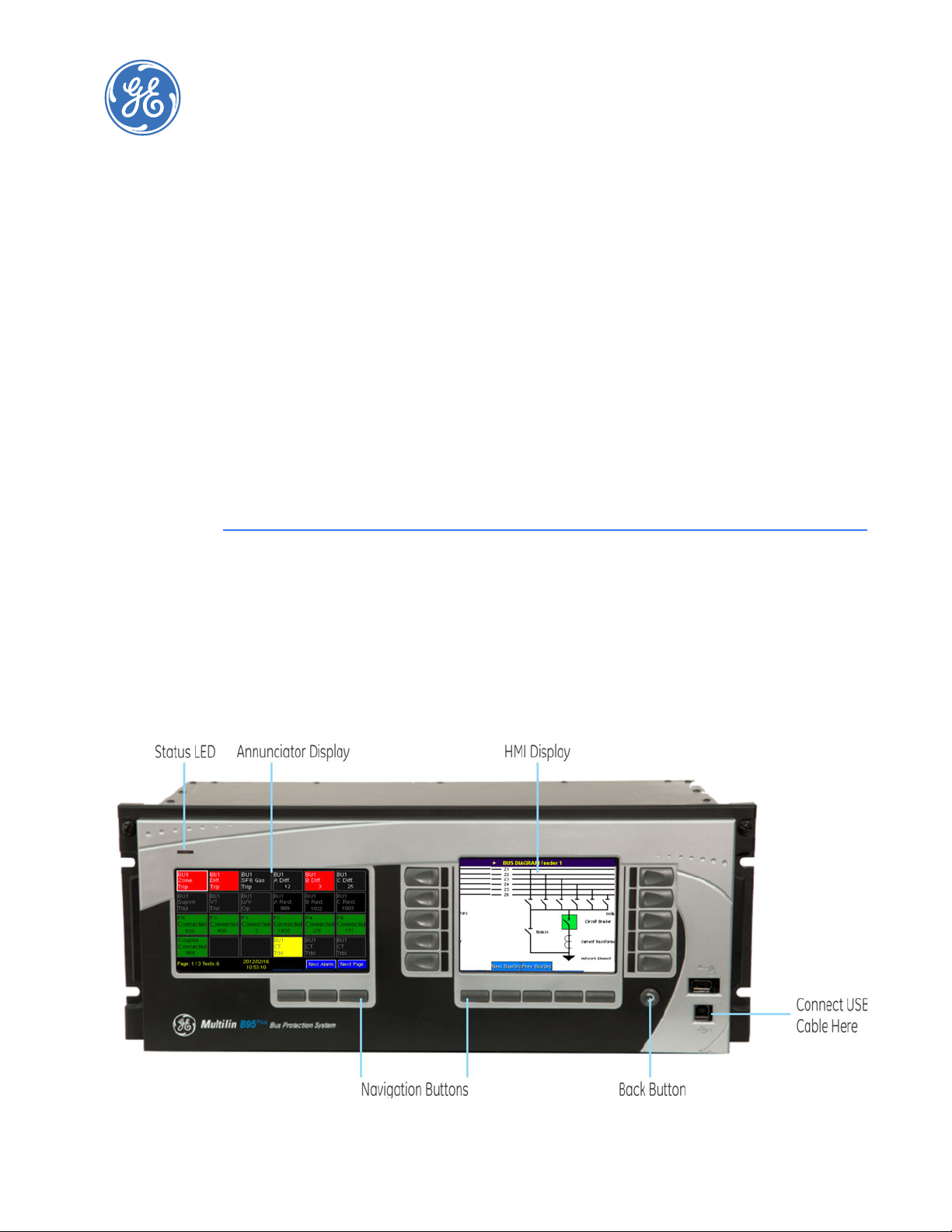

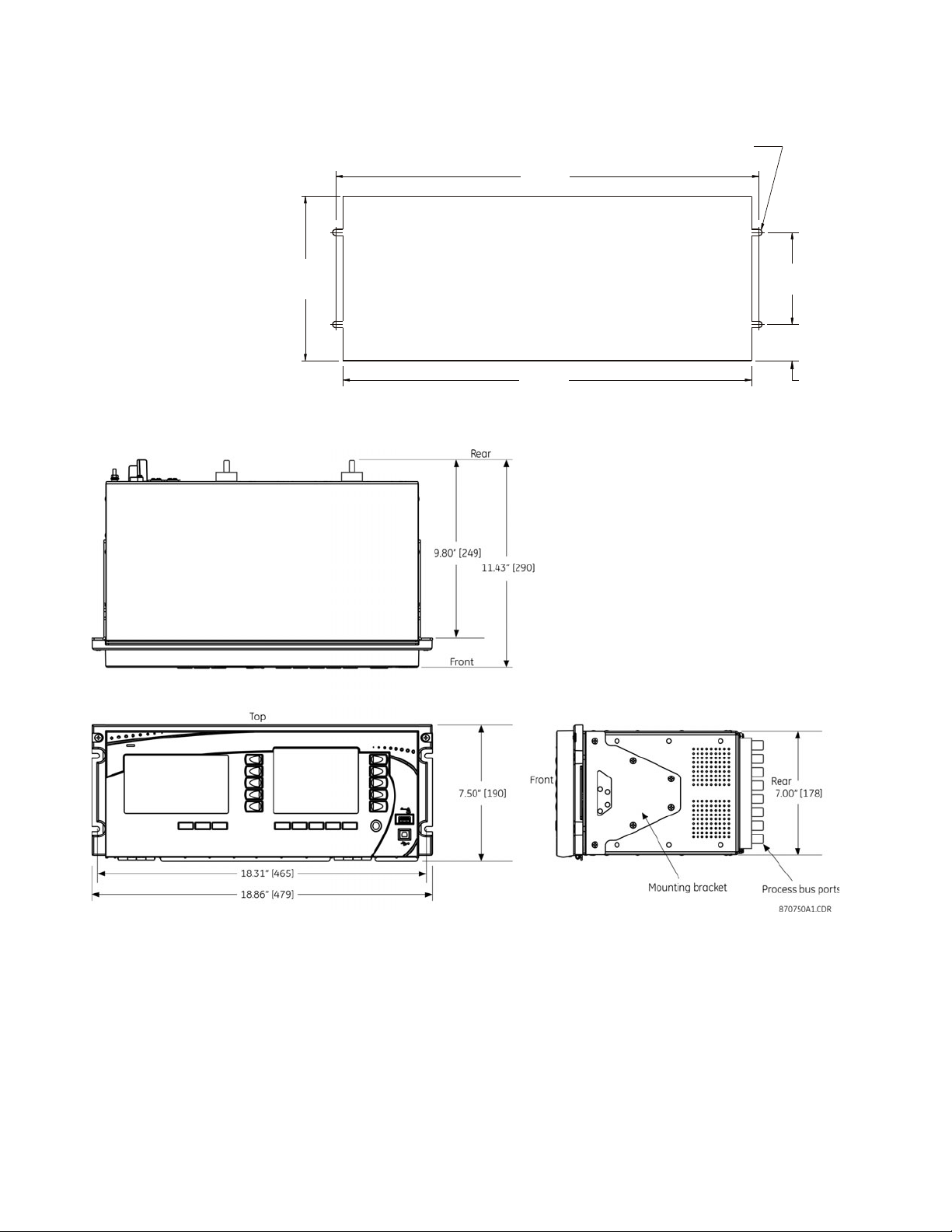

Figure 1: Front view

crucial. The B95

Plus

Plus

Bus

Bus Protection System is a relay to detect faults on a bus. It measures

Plus

extends the UR

Plus

-series product family and the HardFiberTM

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 3

Page 14

DEVICE OVERVIEW CHAPTER 2: PRODUCT DESCRIPTION

The protection system consists of a distributed process interface (data acquisition and

tripping) architecture using GE HardFiber

the B95

The functions of the B95

Plus

.

Plus

include the following:

Bricks, with centralized processing performed by

• Multi-zone differential protection with both restrained (dual-slope percent or biased)

and unrestrained (unbiased or instantaneous) functions incorporated. Differential

protection is fast and secure. Security is achieved by using a reliable current

transformer (CT) saturation detection algorithm and a directional comparison

operating principle. Security is further enhanced by support for redundant process

interface (Bricks). Three-phase tripping is supported; differential protection operands

are provided for individual phase tripping.

• Interfaces with up to eight HardFiber Bricks per process card. The B95

Plus

can contain

one or two process cards.

• Supports up to 12 bus sources per process card. A single bus source is used to

interface a network element connection to the bus, such as a feeder, line, transformer,

capacitor, or reactor. A single bus source is used to interface a bus tie disconnect. Two

bus sources are used to interface a bus tie breaker.

• Dynamic bus replica functionality and multi-zone protection is supported allowing

application of the B95

Plus

to multi-section reconfigurable buses. A zone expansion/

contraction to an open breaker feature is included.

• Check-zone functionality can be configured by programming one of the differential

zones to enclose the entire bus.

• Supports up to two undervoltage functions per process card for differential protection

supervision purposes.

• End-fault protection (dead-zone protection) is provided for each bus source.

• A breaker fail function with three-phase tripping support and fast resetting current

detectors is provided for each bus source.

• An instantaneous phase overcurrent function is provided for each bus source for

possible supervision purposes.

• An inverse time phase overcurrent function is provided for each bus source for

possible backup protection.

• An isolator position resolution and monitoring feature monitors 48 isolators per

process card.

• A CT trouble monitoring function is provided for each zone of differential protection.

Voltage and current metering are built into the relay as standard features, as fundamental

frequency-only root mean square (RMS) scaled magnitude and angle (phasor).

Diagnostic features include an event recorder capable of storing 4,096 time-stamped

events plus 4,096 time-stamped events per process card. Oscillography is userprogrammable as to sampling rate (up to 128 samples per cycle), content, writing mode,

and record length. The internal clock used for time stamping can be synchronized with an

IRIG-B signal or using the simple network time protocol (SNTP) over Ethernet. This precise

time stamping allows the sequence of events to be determined throughout the system.

Events can also be programmed using FlexLogic

TM

equations to trigger oscillography data

capture, which can be set to record the measured parameters before and after the event

for viewing on a computer. These tools significantly reduce troubleshooting time and

simplify report generation in the event of a system fault.

On the communications card, either of the two Ethernet ports can be used for supervisory

control and data acquisition (SCADA) access, the programming of settings, and the

monitoring of actual values. These two Ethernet ports have both 100Base-TX and

4 MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 15

CHAPTER 2: PRODUCT DESCRIPTION DEVICE OVERVIEW

100Base-FX interfaces, and they can be used to provide fast, reliable communications in

noisy environments. These ports support TFTP, SNTP, IEC 61850, Modbus/TCP, and IEC

60870 protocols. DNP 3.0 and IEC 60870 cannot be enabled at the same time.

A third Ethernet port supports engineering access using the EnerVista B95

Plus

SetupTM

software.

The B95

Plus

intelligent electronic devices (IEDs) use Flash memory technology that allows

field upgrading as new features are added.

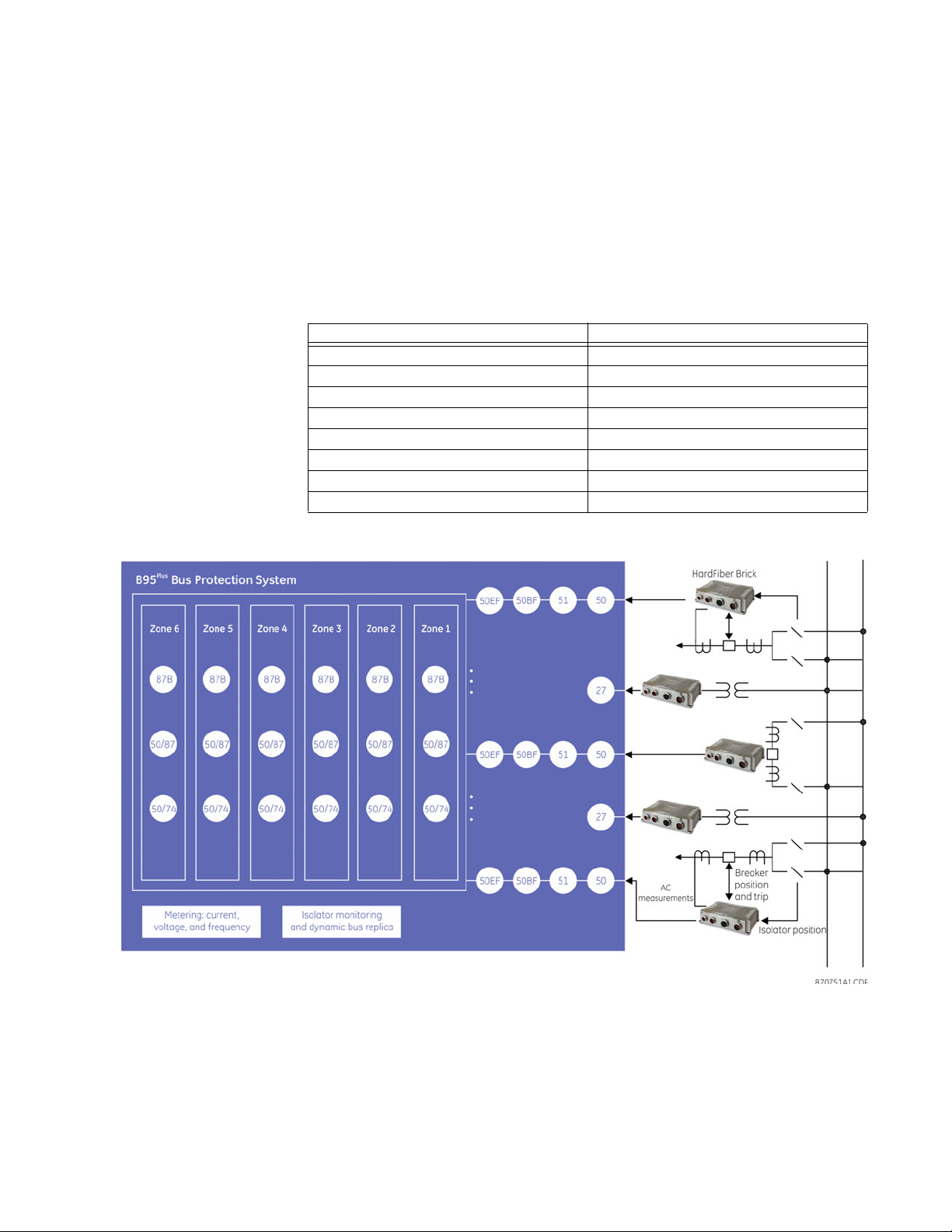

The following single-line diagram illustrates the relay functionality using American

National Standards Institute (ANSI) device numbers.

Table 1: ANSI device numbers and functions

Device Function

87B Percent bus differential

27 Undervoltage

50 Instantaneous overcurrent

50/74 CT trouble

50/87 Unrestrained bus differential

50EF End fault protection

51 Time overcurrent

50BF Breaker failure

Figure 2: ANSI device number schematic

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 5

Page 16

DEVICE OVERVIEW CHAPTER 2: PRODUCT DESCRIPTION

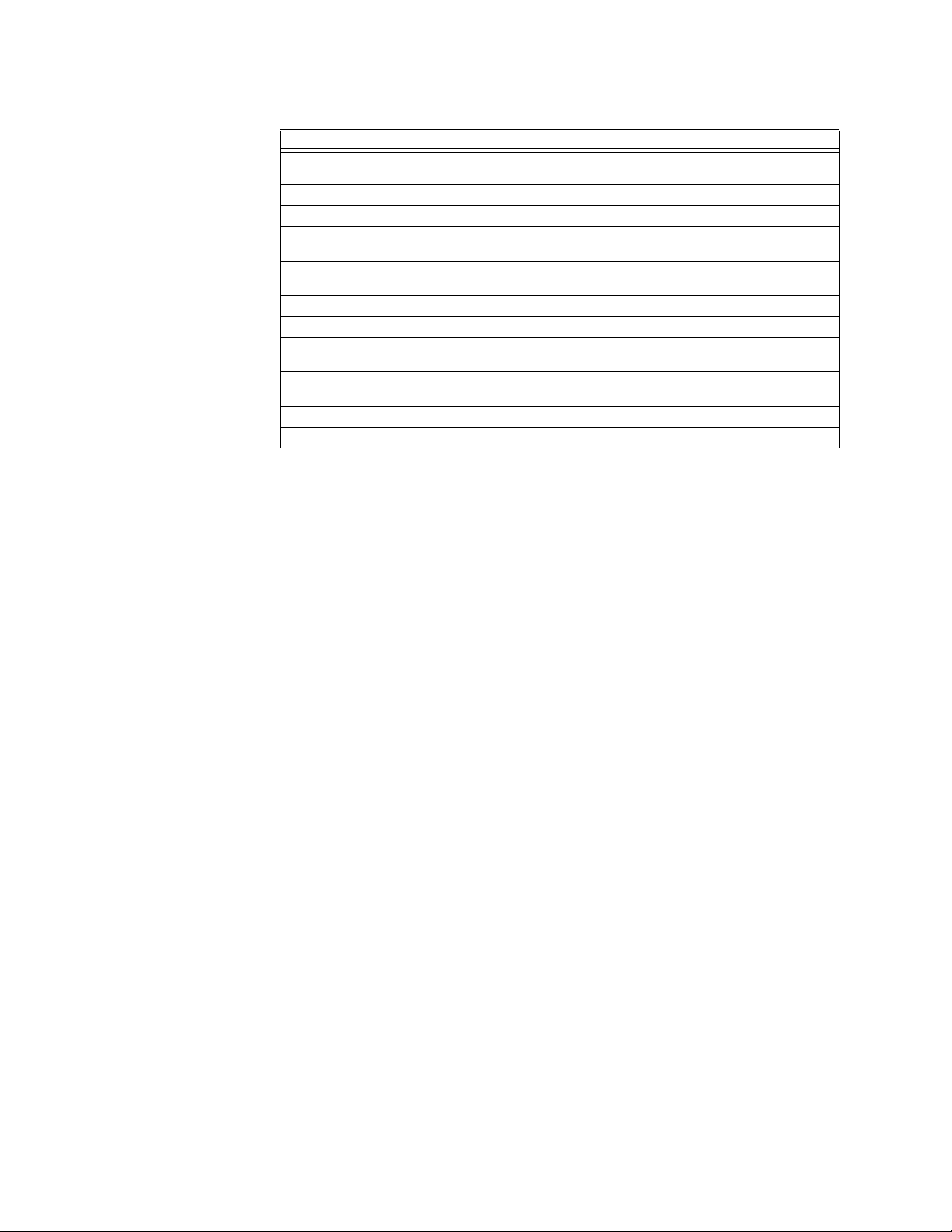

Table 2: Other device functions

Function Function

HardFiber Brick interface (8 Bricks per process

card)

Field contact inputs (144 per process card) Event recorder

Field contact outputs (48 per process card) Transient recorder (oscillography)

Current AC banks (12 per process card)

Voltage AC banks (2 per process card)

Dynamic bus replica User-definable mimic, metering, and annunciator

End-fault protection User-programmable self-test

DNP 3.0 or IEC 60870-5-104 communications Virtual inputs (64)

IEC 61850 communications, including GOOSE

and sampled values

Metering: current, voltage, tracking frequency FlexLogic equations (512 lines plus 512 lines per

Modbus communications Non-volatile latches (16 plus 16 per process card)

Modbus user map Setting groups (2)

Differential zone expansion/contraction

Time synchronization via SNTP or IRIG-B

displays

Virtual outputs (96 plus 96 per process card)

process card of protection speed code)

Advanced functionality allows the user to access comprehensive information without

having to navigate through conventional displays and keypads. Information displays on

two graphical display panels on the front panel. One serves as a digital annunciator and

the other, called the HMI, displays mimic diagrams, phasor plots, and other information.

The configurable, color LCD annunciator on the front panel eliminates the need for LEDs

and separate annunciator devices. Any contact input, remote input, or internally

generated logic operand can be assigned to each indicator, as well as any analog

operand. Up to 288 indicators can be assigned. The display can be configured for 12, 24, or

48 indicators per page. A separate self-test message page on the annunciator panel

displays error messages about device health.

The HMI panel provides easy access and visualization of device information, ranging from

the graphical and numeric display of bus source current phasors, voltage source phasors,

differential and restraint phasors, and tracking frequency, as well as a display of sequence

of events and a transient records list. The HMI can display a mimic diagram that provides

the status of each bus source’s breaker and isolators. Many bay configurations can be

realized through the setting of the device.

FlexLogic equations

FlexLogic refers to executable code developed by GE or you for use with the device. You

can create or edit FlexLogic

subsequently view automatically generated logic diagrams.

6 MULTILIN B95

equations in order to customize the relay’s behavior. You can

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 17

CHAPTER 2: PRODUCT DESCRIPTION HARDFIBER OVERVIEW

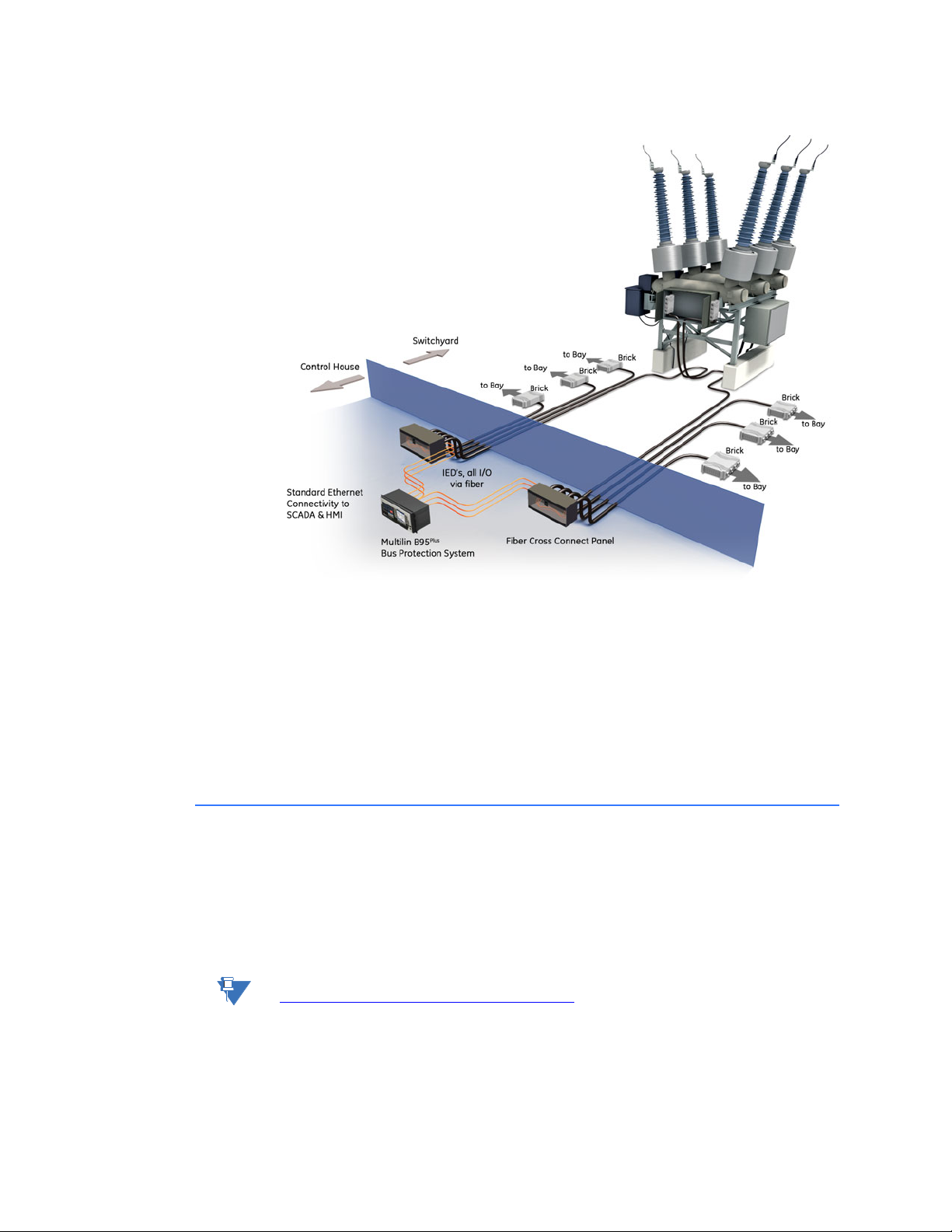

HardFiber overview

The GE HardFiber Process Bus System allows copper wiring to be replaced in substation

switchyards with optical fiber. The system includes all physical components required for its

installation: relays; factory pre-terminated fiber cables; fiber crossconnect panels; factory

connectorized copper cables; and switchyard I/O interface devices known as Bricks. The

Bricks implement the concept of an IEC 61850 merging unit, expanded to optically connect

relays with all types of input and output signals in the switchyard, not just instrument

transformers. The relays are the proven GE Multilin Universal Relay (UR) series devices with

a decade-long field record, and they incorporate all major applications from a simple

feeder relay to a sophisticated generator protection package. With the release of the

Plus

, the HardFiber system can also be used for the protection of large and dynamic

B95

buses.

Figure 3: GE HardFiber Brick top view

The HardFiber system replaces copper wiring between power apparatus in the switchyard

and protection and control devices in the control house with off-the-shelf components that

use standard physical and logical interfaces. As such, it shortens deployment time, reduces

labour requirements, facilitates work transfer, improves quality, simplifies procurement,

and improves safety.

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 7

Page 18

ORDER CODES CHAPTER 2: PRODUCT DESCRIPTION

NOTE

Figure 4: B95

Plus

in control house and HardFiber Bricks in switchyard

Bricks, cables, and crossconnect panels can simultaneously connect to the B95

and UR-series relays. For example, a Brick located in a feeder bay can be used by a D60

Line Distance Protection System protecting the feeder and a B95

The B95

manual refer to HardFiber

Details of the HardFiber Bricks, cables, crossconnect panels, and protocols are contained in

the HardFiber

HardFiber

Plus

is designed to work with GE HardFiber Bricks. Any references to Bricks in this

Process Bus System Reference Manual. Chapters 5 and 6 of the

manual do not apply to the B95

Bricks.

Plus

because the B95

Plus

protecting the bus.

Plus

has its own process

Plus

relays

card, settings, actual values, and self-test errors.

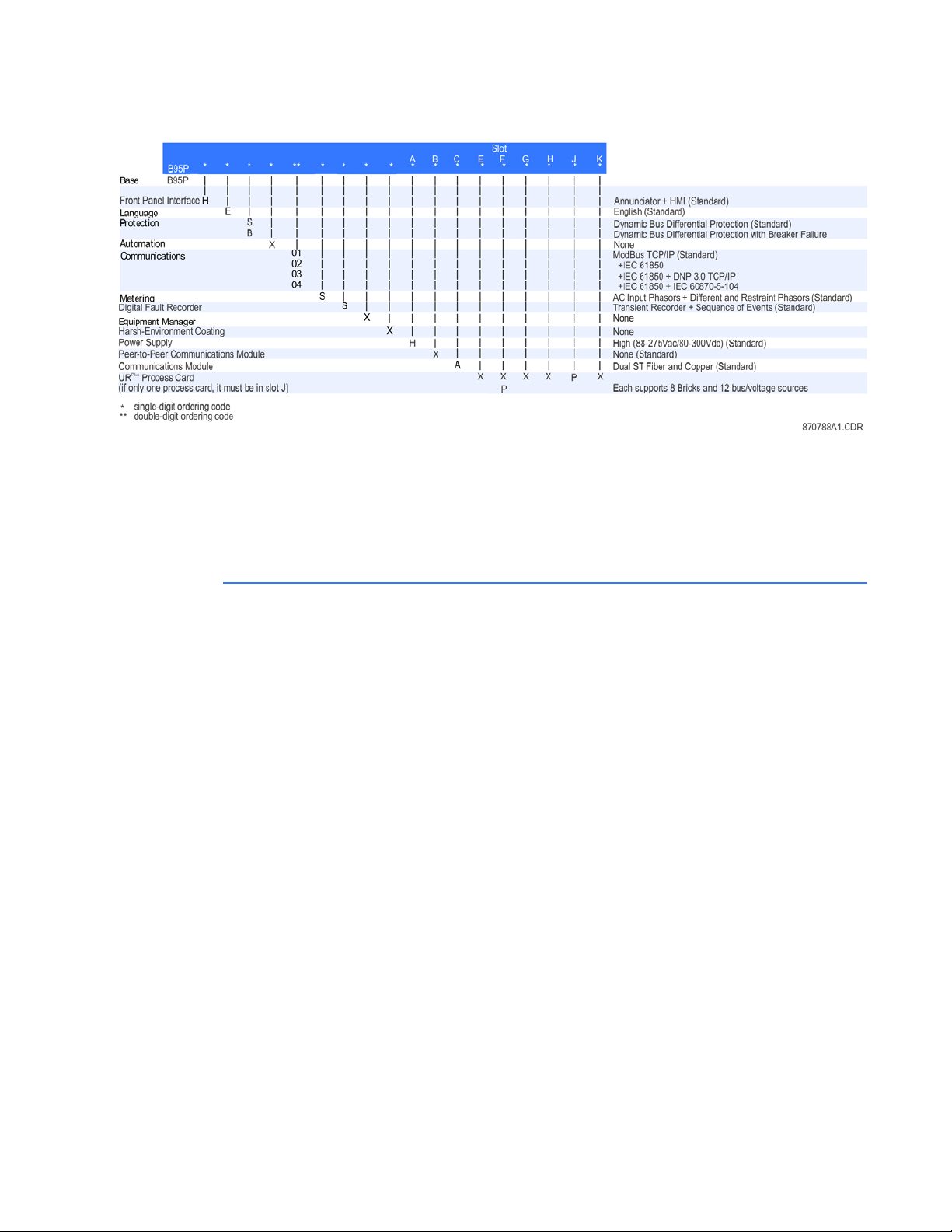

Order codes

The B95

cards. For the B95

The information required to completely specify the system is provided in the following

table. Reading across the order code table, an example of an ordering code is

B95P-HE-BX03SSX-XHXAXPXXPX.

NOTE:

Order codes are subject to change without notice. See the GE Multilin ordering page at

http://www.GEindustrial.com/multilin/order.htm

For communications, the DNP option or the IEC 60870-5-104 option is ordered, not both.

Plus

is a 19-inch horizontal rack-mount unit that consists of required and optional

Plus

, only process card F is optional.

for the latest B95

Plus

options.

8 MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 19

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

Figure 5: Order codes

After the unit is set up, the order code is viewable in the EnerVista software.

To view the order code:

1. In the Online Window area of the EnerVista software, navigate to Actual Values >

Product Information > Model Information. Or view the code on the Product

Information page on the front panel annunciator display.

Specifications

This section outlines specifications, which are subject to change without notice.

Remote resources specifications

REMOTE RESOURCE SPECIFICATIONS

Number of field units (bricks): .......................8 per process card

Number of field contact inputs: ...................18 for each brick

Number of field contact outputs:................6 for each brick

Number of field latching outputs:...............1 for each brick

Number of shared inputs:...............................16 per process card

Number of shared outputs:............................16 per process card

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 9

Page 20

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

Protection specifications

BUS DIFFERENTIAL PROTECTION

Comparator algorithm:....................................low impedance differential with through current restraint,

direction and CT saturation supervision (same as B90)

Number of differential zones: ....................... six 3-phase zones

Maximum number of currents:.................... total dynamic number of bus source to zone connections

closed at any one moment in time up to 120

CT ratio compensation range:......................32:1

Supervision:........................................................... 2 user-programmable conditions per zone

Pickup level:........................................................... 0.050 to 2.000 pu on bus base in steps of 0.001 pu

Low slope: ..............................................................15 to 100% in steps of 1%

High slope: ............................................................. 50 to 100% in steps of 1%

Low breakpoint:................................................... 1.00 to 30.00 pu on bus base in steps of 0.01 pu

High breakpoint:..................................................1.00 to 30.00 pu on bus base in steps of 0.01 pu

Dropout level: ....................................................... <98% of pickup

Level accuracy:....................................................

0.1 to 2.0 × bus base:.......................................±0.5% of reading or ±1% of bus base (whichever is greater)

>2.0 × bus base: ................................................. ±1.5% of reading

Operating time:.................................................... <1 power system cycle

High set (unbiased) level: ................................2.00 to 99.99 pu in steps of 0.01 pu

High set (unbiased) operate time:............... <1 power system cycle

CT TROUBLE MONITORING

Number of CT trouble detectors:................. 1 per bus differential zone, that is, 6

Responding to:..................................................... differential current

Pickup level:........................................................... 0.020 to 2.000 pu in steps of 0.001 pu

CT trouble operate delay: ...............................1.0 to 60.0 s in steps of 0.1 s

Supervision trouble delay:.............................. 0.00 to 5.00 cycles in steps of 0.25

BUS REPLICA

Features:.................................................................Dynamic bus source current assignment to each zone.

Dynamic zone trip assignment to each bus source. Dynamic

blocking of zones on CT bypassed. 3 user-programmable

auxiliary zone trip inputs. 3 user-programmable bus source

trip inputs. Dynamic zone expansion/reduction.

BUS SOURCES

Number of bus sources: .................................. 12 per process card included in the order code

Current inputs: .....................................................3-phase currents

CT rated primary:................................................1 to 65000 A

CT rated secondary: .......................................... 1 or 5 A

Nominal frequency:........................................... 50 or 60 Hz

10 MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 21

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

BREAKER FAILURE PROTECTION

Number of BF protections: .............................1 per bus source

Mode:........................................................................3-pole initiate only

Current supervision: ..........................................phase current

Current supervision pickup: ...........................0.01 to 30.00 pu on CT base in steps of 0.01 pu

Current supervision dropout: ........................<98% of pickup

Current supervision accuracy:......................

0.1 to 2.0 × CT rating: .......................................±0.75% of reading or ±2% of CT base (whichever is greater)

above 2 × CT rating:..........................................±2.5% of reading

Current supervision reset time:....................< 0.5 cycles

Coordination delay timers:.............................0 to 60 s in steps of 1 ms

Delay accuracy:...................................................±3% or ±4 ms, whichever is greater

Breaker position inputs:...................................advanced and final position contact inputs, each optionally

dual-redundant

Stages: .....................................................................current + advanced breaker position status + time

current + time

final breaker position + time

opening resistor protection

INSTANTANEOUS PHASE OVERCURRENT

Number of IOC protections: ...........................1 per bus source

Comparators:........................................................3 phase, sensing fundamental frequency current

Pickup level:...........................................................0.00 to 30.00 pu on CT base in steps of 0.01

Dropout level:........................................................<98% of pickup

Level accuracy: ....................................................

0.1 to 2.0 × CT:.....................................................0.5% of reading or 1% of CT base (whichever is greater)

above 2.0 × CT:....................................................1.5% of reading

Pickup delay: .........................................................0 to 60 s in steps of 1ms

Reset delay: ...........................................................0 to 60 s in steps of 1ms

Delay accuracy:...................................................±3% or ±4 ms (whichever is greater)

Operate time:........................................................<1 power system cycle at 3 x pickup

INVERSE TIME PHASE OVERCURRENT

Number of TOC protections:..........................1 per bus source

Comparators:........................................................3 phase, sensing fundamental frequency current

Pickup level:...........................................................0.01 to 30.00 pu on CT base in steps of 0.01 pu

Dropout level:........................................................<98% of pickup

Level accuracy: ....................................................

0.1 to 2.0 × CT:.....................................................0.5% of reading or 1% of CT base (whichever is greater)

above 2.0 × CT:....................................................1.5% of reading

Curve shapes:.......................................................IEEE Moderately/Very/Extremely Inverse; IEC (and BS) A/B/C

and Short Inverse; GE IAC Inverse, Short/Very/ Extremely

Inverse; I2t; Definite T ime (0.01 s base curve)

TD multiplier: .........................................................0.00 to 600.00 in steps of 0.01

Reset type:..............................................................instantaneous or timed (per IEEE)

Timing accuracy: ................................................±3% or ±40 ms (whichever is greater)

END FAULT PROTECTION

Number of EFPs:..................................................1 per bus source

IOC pickup level: ..................................................0.01 to 30.00 pu in steps of 0.01 pu

IOC dropout level: ...............................................<98% of pickup

Level accuracy: ....................................................

at 0.1 to 2.0 × CT: ...............................................0.5% of reading or 1% of nominal (whichever is greater)

above 2.0 × CT:....................................................1.5% of reading

CB open delay timer:.........................................0.10 to 60 s in steps of 1 ms

End fault dropout timer:...................................0 to 60 s in steps of 1 ms

Time accuracy: ....................................................±3% or ±8 ms (whichever is greater)

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 11

Page 22

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

VOLTAGE SOURCES

Number of voltage sources:.......................... 2 per process card included in the order code

Voltage inputs:..................................................... 3-phase voltages, wye or delta

VT ratio: ...................................................................1.00 to 24000.00

VT rated secondary: ..........................................25.0 to 240.0 V

Nominal frequency:........................................... 50 or 60 Hz

UNDERVOLTAGE PROTECTION

Number of UV protections: ............................2 per process card

Comparators: .......................................................3 phase-to-phase and 3 phase-to-ground

Pickup level:........................................................... 0.50 to 1.50 pu in steps of 0.01

Dropout level: ....................................................... >102% of pickup

Level accuracy:....................................................±0.5% of reading from 10 to 208 V

Operate time:........................................................ <1 power system cycle at 0.5 x pickup

ISOLATORS

Number of isolators:.......................................... 48 per process card

Isolator status inputs:....................................... form “a” and form “b” contact inputs, each optionally dual-

redundant

Configurable failsafe modes:........................ open, closed, last valid state

Monitoring:............................................................. alarm on inconsistent inputs persisting longer than a user

set time

FLEXLOGIC DESIGN

Programming language:................................. Reverse Polish Notation with graphical visualization

Inputs: ...................................................................... Any logical variable, contact , or virtual input

Number of timers: .............................................. 32 per process card plus 32 on main card

Timer pickup delay: ........................................... 0 to 1000 hrs in steps of 1 ms

Timer dropout delay: ........................................ 0 to 1000 hrs in steps of 1 ms

Timer accuracy: .................................................. ± the sum of 1/8 power system cycle and 1% of the timer

setting

Virtual outputs: .................................................... 96 per process card plus 96 on main card

Non-volatile latch latches: ............................. 16 per process card plus 16 on main card

Non-volatile latch modes: .............................. Set-dominant or reset-dominant

Lines of code:........................................................ 512 per process card plus 512 on main card

Supported operations: ..................................... NOT, XOR, OR (2 to 16 inputs), AND (2 to 16 inputs), NOR (2 to

16 inputs), NAND (2 to 16 inputs), latch (reset-dominant),

edge detectors, timers

Execution speed:................................................. recalculated at 8 times per power system cycle

Card-to-card operand delay:........................ up to 1/8 power system cycle

SETTINGS GROUPS

Number of settings groups:...........................2

Grouped settings:............................................... threshold type settings for bus source, voltage source, and

bus differential

Communications specifications

MODBUS USER MAP

Number: .................................................................. up to 256 Modbus addresses

Programmability: ................................................ any setting or actual value in decimal

REMOTE INPUTS (IEC 61850 GSSE/GOOSE)

Input points: ..........................................................64

Remote devices:.................................................. 32

Default states on loss of

communications:........................................... On, Off, Latest/Off, Latest/On

Remote double-point status inputs:.......... 16

12 MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 23

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

REMOTE OUTPUTS (IEC 61850 GSSE/GOOSE)

GSSE:.........................................................................32 DNA + 32 UserSt

GOOSE:.....................................................................128 status

IEC 61850 LOGICAL NODES

LLNO: ........................................................................1 logical node zero

LPHD: ........................................................................1 physical device information

GGIO:.........................................................................GGIO1, general status output

PDIF: ..........................................................................6 differential zones

PIOC:..........................................................................1 per bus source instantaneous overcurrent

PTOC:.........................................................................1 per bus source timed overcurrent

PTUV:.........................................................................1 per undervoltage

RBRF:.........................................................................1 per bus source breaker failure

PTRC:.........................................................................1 per bus source

MMXU: ......................................................................1 per bus source phase current bank

MMXU: ......................................................................1 per voltage source

IEC 61850 REPORTS

Unbuffered control blocks:.............................3 for GGIO1

3 for each PDIF

3 for each MMXU

Buffered control blocks:...................................2 for GGIO1

1 for each PDIF

1 for each MMXU

Digital fault recorder specifications

TRANSIENT RECORDER

Storage capacity:................................................five records with all channels recorded, at 128 samples per

cycle, spanning 1 second with no retriggers

Number of records:............................................up to 50

Sampling rate: ......................................................8, 16, 32, 64, or 128 samples per power cycle

AC waveform channels:...................................all enabled bus sources and voltage sources

Analog channels: ................................................magnitudes and angles of all AC waveforms recorded plus

all enabled zone differential and zone restraint phase

current magnitudes and angles

Digital channels:..................................................128 user-configurable channels on the main card and 128

user-configurable channels on each process card

Configurable digital data: ...............................any FlexLogic operand

Storage modes:....................................................automatic overwrite, protected

Triggering modes:...............................................time window from rising edge of trigger, continuous

recording as long as trigger is active

Pre-trigger window:...........................................0 to 100% of the basic record length

Data storage:........................................................non-volatile memory

EVENT RECORDER

Storage capacity:................................................4,096 events plus 4,096 events on each process card

Time tag:.................................................................to 1 µs

Triggers:...................................................................most FlexLogic operand activations

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 13

Page 24

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

Front panel interface

ANNUNCIATOR MAIN DISPLAY

Annunciator pages: ...........................................

Indicators: ..............................................................288

Indicators per page:......................................... 12 to 48

Pages: .....................................................................up to 24

Sequence: .............................................................manual reset, locking

Off indication:...................................................... alarm inactive and reset

Flashing indication: ..........................................alarm active and not acknowledged, alarm inactive and not

acknowledged

On indication: ...................................................... alarm active and acknowledged, alarm inactive and not

reset

Priority: ...................................................................by active window and page number

Data storage: ......................................................non-volatile memory

Other annunciator displays:..........................

Product information page:............................ displays order code, serial number, relay ID, configuration

name and date, and firmware version and date

Communication status page: ......................displays remaining connections for MMS, Modbus, DNP, PMU,

IEC. Also displays Modbus slave addresses and TCP/IP port.

Also displays for Ethernet ports their MAC address, IP

addresses, subnet mask, and gateway.

Self-test summary page: ...............................displays all active or unacknowledged B95

related self-test messages in a sequence of events format

HMI DISPLAY

Mimic diagram:.................................................... mimic diagrams display bus source breaker and isolator

status

Phasors: .................................................................. digital and phasor diagram display of present voltage source

phase voltages, bus source phase currents, zone differential

currents, and zone restraint currents, both magnitudes and

angles

Sequence of events:..........................................displays the stored events record

Transient records:............................................... list of stored transient records

MULTI-LANGUAGE SUPPORT

Languages:............................................................English

Plus

device -

Security specifications

SECURITY SPECIFICATIONS

Features:.................................................................Two access levels (Command and Setting), with separate

remote and local passwords for each level. Dictionary attack

deterrence. Programmable authorization control.

Hardware specifications

PROCESS I/O

Number of process bus ports:...................... 8 per process card

Port type: ................................................................100Base-BX-D, in SFP package with LC 50/125 µm multi-

mode connector

Transceiver diagnostics: .................................per SFF-8472

Brick synch frame jitter:................................... ±1 µs

14 MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 25

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

NOTE

ETHERNET PORTS

Standard: ................................................................2 ports on the communications card supporting SNTP, TFTP,

Modbus TCP, DNP 3.0, IEC 60870-5-104, IEC 61850, or

EnerVista software. 1 port on main processor card

supporting EnerVista software.

Media types: ..........................................................100Base-FX or 10/100Base-TX

100Base-FX type:................................................

Power budget:.....................................................10dB

Maximum input power:...................................–14 dBm

Receiver sensitivity:...........................................–30 dBm

Typical distance:.................................................2.0 km

10/100Base-TX type:.........................................RJ45 connector

SNTP clock synchronization:..........................<10 ms typical

USB FRONT PORT

Standard: ................................................................type B USB connector for EnerVista software

IRIG-B INPUT

Amplitude modulation:.....................................1 to 10 V pk-pk

DC shift: ...................................................................TTL

Input impedance:................................................50 kΩ

Isolation:..................................................................2 kV

NOTE:

An internal clock free runs when neither the IRIG-B signal nor SNTP is present.

CRITICAL FAILURE RELAY

Type:..........................................................................Form-C, normally energized

Make and carry for 0.2 s:.................................10 A as per ANSI C37.94

Carry continuous: ...............................................6 A

Break at L/R of 40 ms:.......................................0.25 A DC at 125 V DC; 0.125 A DC at 250 V DC

POWER SUPPLY

Nominal DC voltage:..........................................125 to 250 V

Minimum DC voltage:........................................80 V

Maximum DC voltage: ......................................300 V

Nominal AC voltage:..........................................100 to 240 V at 50/60 Hz

Minimum AC voltage:........................................80 V at 48 to 62 Hz

Maximum AC voltage:.......................................275 V at 48 to 62 Hz

Voltage withstand: .............................................2 × highest nominal voltage for 10 ms

Voltage loss ride-through:..............................200 ms duration at nominal input voltage

Power consumption: .........................................65 VA maximum

Control power wiring:........................................14 AWG or larger

Control power protection:...............................Has internal non-user replaceable 4 Amp "slo blo" fuse.

Recommend external upstream disconnect on both sides.

Recommend external overcurrent protection of 5 to 10

Amps.

Control power terminal connection:..........Use suitable ring terminal, torque terminal to 9 in lb (1 N-m)

Grounding connection: ....................................10 AWG or larger wire or braid, independent and direct-to-

cubicle ground bus

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 15

Page 26

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

PROCESS CARD OPTICAL

Number of transceivers:.................................. 8

Transceiver type: ................................................transmit 1550 nm, receive 1310 nm, 100 Mbps, bidirectional

single-fiber 50/125 µm multimode module (complies with

IEEE 802.3 standard 100Base-BX-D)

Optical transmit power:................................... –14 to –8 dBm

Maximum optical input power: .................... –8 dBm

Optical receiver sensitivity: ............................ –30 dBm

Termination:.......................................................... LC fiber connector

Laser class:............................................................ Class 1. Class 1 devices are considered safe to the unaided

eye. Do not view directly with optical instruments.

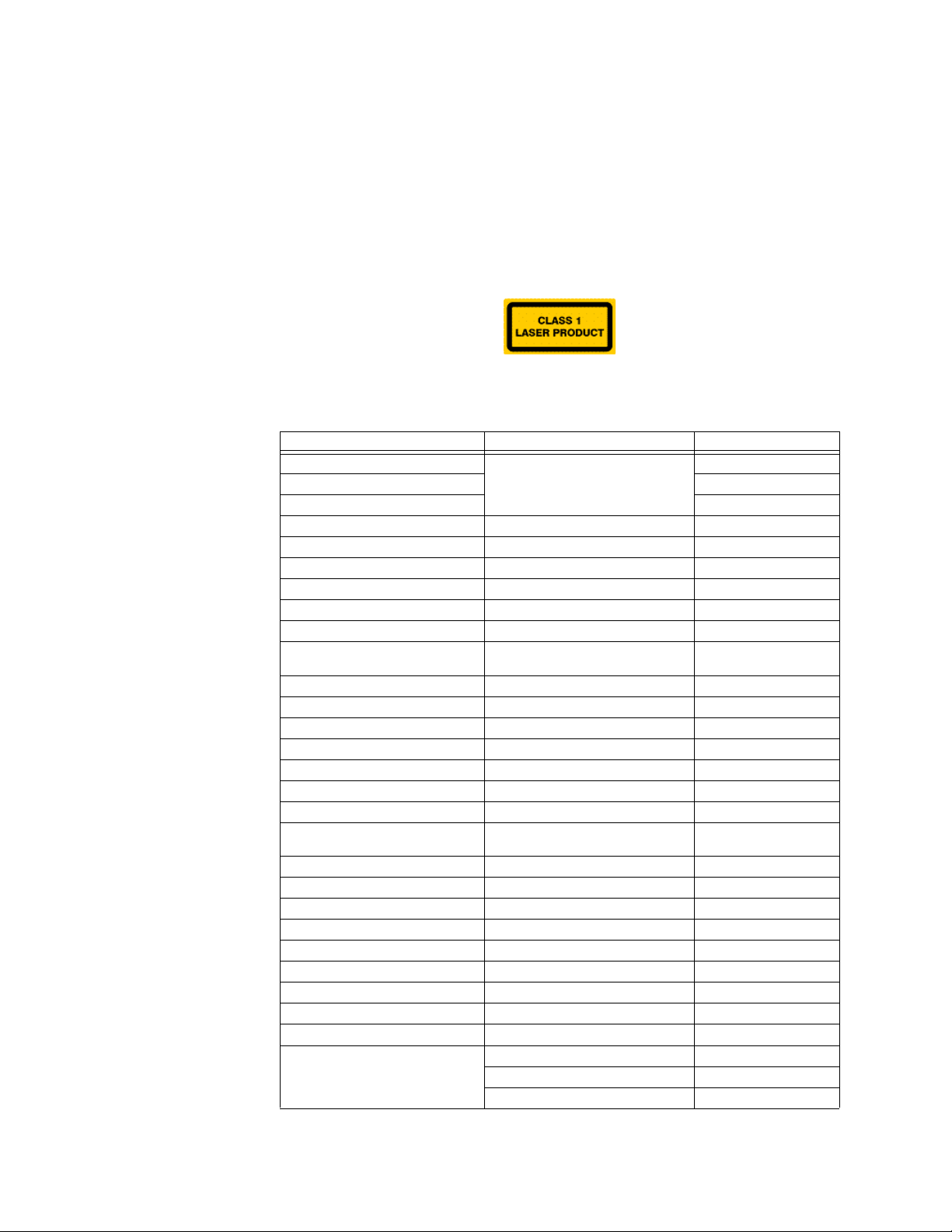

Test specifications

Test Reference standard Test level

Dielectric voltage withstand EN 60255-5 2.3 KV

Impulse voltage withstand 5 KV

Insulation resistance 500 Vdc

Damped oscillatory IEC 61000-4-18 / IEC 60255-22-1 2.5 KV CM, 1 KV DM

Electrostatic discharge EN 61000-4-2 / IEC 60255-22-2 Level 4

RF immunity EN 61000-4-3 / IEC 60255-22-3 Level 3

Fast transient disturbance EN 61000-4-4 / IEC 60255-22-4 Area B

Surge immunity EN 61000-4-5 / IEC 60255-22-5 Level 3

Conducted RF immunity EN 61000-4-6 / IEC 60255-22-6 Level 3

Voltage interruption and ripple DC IEC 60255-11 15% ripple, 200 ms

Radiated and conducted emissions CISPR 11 / CISPR 22 / IEC 60255-25 Class A

Sinusoidal vibration IEC 60255-21-1 Class 1

Shock and bump IEC 60255-21-2 Class 1

Seismic IEC 60255-21-3 Class 2

Power magnetic immunity IEC 61000-4-8 Level 5

Pulse magnetic immunity IEC 61000-4-9 Level 4

Damped magnetic immunity IEC 61000-4-10 Level 4

Voltage dip and interruption IEC 61000-4-11 0, 40, 70, 80% dips, 250/

Voltage ripple IEC 61000-4-17 15% ripple

Ingress protection IEC 60529 IP30Front

Environmental (cold) IEC 60068-2-1 -40°C / 16 hours

Environmental (dry heat) IEC 60068-2-2 85°C / 16 hours

Relative humidity cyclic IEC 60068-2-30 6 day, variant 1

Electrostatic discharge IEEE ANSI C37.90.3 8 KV contact, 15 KV air

Damped oscillatory IEEE ANSI C37.90.1 2.5 KV, 1 MHz

Fast transient disturbance IEEE ANSI C37.90.1 4 KV, 2.5 KHz

RF immunity IEEE ANSI C37.90.2 20 V/m, 80-1 GHz

Safety UL 508 e83849 NKCR

UL C22.2-14 e83849 NKCR7

UL 1053 e83849 NKCR

interrupts

300 cycle interrupts

16 MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 27

CHAPTER 2: PRODUCT DESCRIPTION SPECIFICATIONS

Environmental specifications

TEMPERATURE

Cold: ..........................................................................IEC 60028-2-1, 16 hours at –40°C

Dry heat:..................................................................IEC 60028-2-2, 16 hours at 85°C

Humidity:.................................................................Up to 95°C non-condensing at 55°C, as per IEC 60068-2-30

variant 1, 6 days

Storage temperature: .......................................-40 to 85°C

Operating temperature:...................................-40 to 60°C

OTHER ENVIRONMENTAL SPECIFICATIONS

Altitude:....................................................................up to 2000 m

Insulation class:...................................................I

Overvoltage category:......................................II

IP rating: ..................................................................IP30

Pollution degree: .................................................II

Approvals and certification

APPROVALS AND CERTIFICATION

Compliance: ..........................................................CE, CSA, UL, ISO

Compliance Applicable council directive According to

CE Low voltage directive EN 60255-27 (normative sections)

EMC directive EN 60255-26 / EN 50263

EN 61000-6-5 (Area G)

C-UL-US --- UL 508

UL 1053

C22.2 No 14

ISO --- ISO 9001:2008

MULTILIN B95

Plus

BUS PROTECTION SYSTEM – INSTRUCTION MANUAL 17

Page 28

SPECIFICATIONS CHAPTER 2: PRODUCT DESCRIPTION

18 MULTILIN B95

Plus