GE AZ85H18DAC, AZ85H12DAC, AZ85E09DAC, AZ85H09DAC Architect and Engineering Manual

ZONELINE®

Single Packaged

Vertical Units

ARCHITECTS & ENGINEERS

DATA MANUAL

WHY VERTICAL

ZONELINE® ?

As the first manufacturer to introduce packaged terminal air conditioners (PTACs) to the

market, GE Appliances led the way in improving comfort and efficiency in lodging properties,

assisted living facilities and apartments. With the single packaged vertical units (SPVUs),

we’re doing it again. The SPVU offers an excellent alternative to standard PTACs for cooling

and heating a variety of rooms—giving guests and travelers home-like comfort wherever they go.

Addressing common complaints, like noise level and precision, the SPVU offers quieter

operation with greater temperature control. Closet installation allows for a more home-like

appearance with extra room for versatile design. Most importantly, it provides the cost

benefits of PTACs with the added flexibility of a central system, as the SPVU can serve a

single room or multiple rooms.

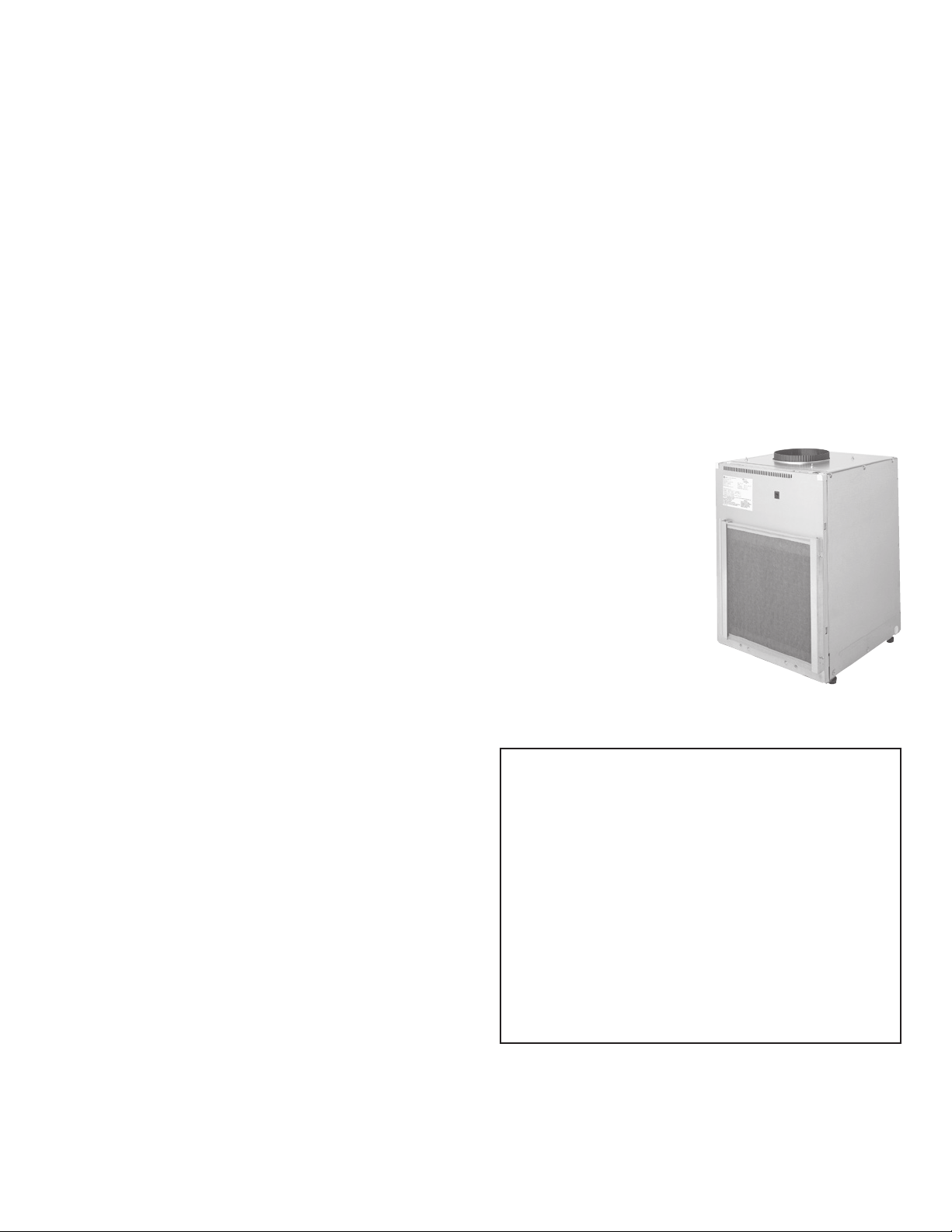

THE GE APPLIANCES ZONELINE® SINGLE

PACKAGED VERTICAL AIR CONDITIONER

The GE Appliances Zoneline® vertical air conditioner is available in ~9,000 BTUh, 12,000 BTUh or

18,000 BTUh cooling capacity, with either resistance heat or heat pump units with resistance heat

backup. Each cooling capacity is available in a dual-rated unit that operates on either 230 volts or 208

volts, and in a unit designed to operate on 265 volts. All units are equipped with a 3-element universal

heater that provides electric heat backup when connected with the appropriate 9-pin power connection

kit to 208-volt, 230-volt or 265-volt power. See page 11 for information on the power connection kits.

SYSTEM FEATURES

The single packaged vertical unit, (SPVUs), have a number of

features that help distinguish

them as the leader in the vertical unit industry. Each feature

is discussed in detail in the features and benefits section.

• Excellent efficiency and dehumidification

• Unique sleeve design for easier installation and service

• Three-way slide-out chassis service/maintenance flexibility

• Electronic Temperature Limiting (requires room

air temperature sensor accessory - RAVRMS)

• Freeze Sentinel (requires room air temperature

sensor accessory - RAVRMS)

• Constant ON fan (required in nursing homes in some states)

• Permanently lubricated fan motors

• Standard size air filter (20" x 20" x 1")

• Central desk control capability

• Occupancy sensor interface

• HI and LOW fan speeds controlled by remote thermostat

• 3-speed indoor fan motor for selectable HI and

LOW speeds

• Corrosion protection treatment standard

• Slinger ring condensate removal

• Indoor frost control

• Automatic compressor random restart

• Compressor restart delay

• Quick heat recovery (on heat pump units)

• Extended heat pump operation

• Reverse cycle heat pump defrost

SYSTEM ESSENTIAL COMPONENTS

• Installation platform (field supplied)

• Wall plenum

• Exterior grille

• Chassis

• Case

• Power connection kit

• Remote thermostat

• Filter (field supplied)

• Return air grille

• Ductwork (field supplied)

• Supply register

(field supplied)

IMPORTANT NOTICE

Equipment used as a primary source for heating or

cooling is an integral part of the building in which it is

installed. Proper application is essential for satisfactory

performance over a wide range of operating conditions.

It is strongly recommended that a professional engineer

determine proper application.

If this unit is a replacement unit, its specifications

and performance may differ from those of the unit it

is replacing. For that reason, we again strongly

recommend that a professional engineer determine

proper application.

• Warranty (including both parts and labor)

3

3

FEATURE S & BENEFITS

EXCELLENT EFFICIENCY

AND DEHUMIDIFICATION

GE Appliances recognizes the importance of energy

efficiency and dehumidification in an air conditioning

system and uses EER (Energy Efficiency Rating) as a means

of reporting the relative cooling efficiency of the unit.

EER is the cooling rating system used for single packaged

vertical air conditioners and heat pumps.

The GE Zoneline® single packaged vertical heat pump has

outstanding COP ratings. The measurement of the efficiency

of the heat pump output, when compared to electric

resistance heat, is called the Coefficient of Performance

(COP). This number provides a basis not only for comparing

the heat pump output to electric resistance heat, but also

the ability to directly compare heat pumps within the same

range of capacity to one another.

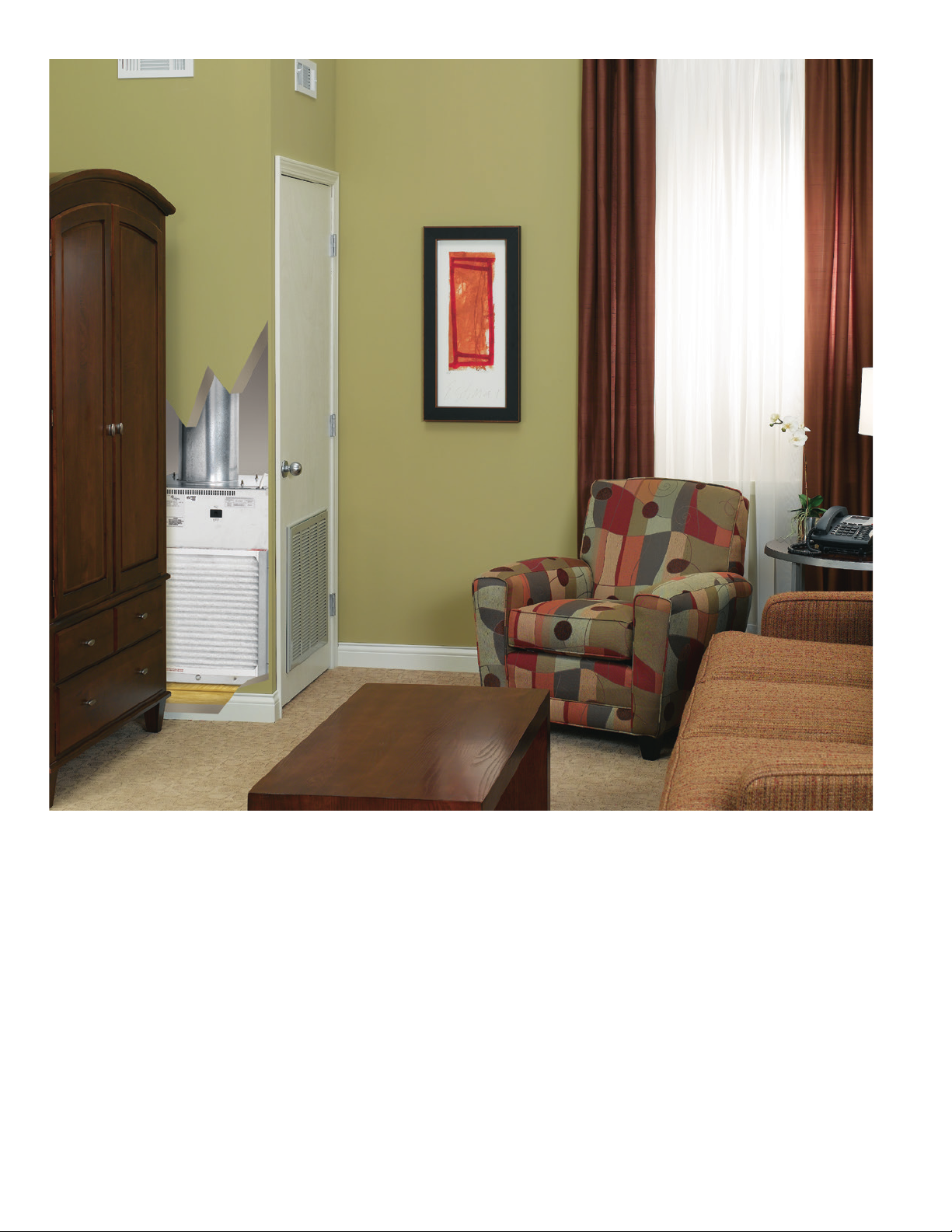

UNIQUE SLEEVE DESIGN

The SPVU case is installed on a field-supplied platform

and attached to the wall plenum with field-supplied screws.

See pages 8 and 15 for platform construction details.

The chassis slides into the sleeve, allowing for easy removal

of the unit for servicing and cleaning without the need to

remove condensate lines.

THREE-WAY SLIDE-OUT CHASSIS

The case is designed to allow the installation of the chassis

from the front or either side of the case. This provides

greater flexibility in building/room design and unit

placement. If access to the front of the unit is restricted by

a wall or furniture placement, the chassis can slide in from

either side of the case. If an alcove or offset is designed into

the building facade, the three-way slide-out chassis enables

the unit to be easily installed and removed for service.

ELECTRONIC TEMPERATURE LIMITING

Although the vertical unit is controlled by a wall-mounted

thermostat, there may be a need to prevent the temperature

from being set to extreme energy-wasting settings. The SPVU

has seven independent programmable heating and cooling

temperature limits. A wide selection of limits eliminates the

need to reset the limits seasonally. The temperature

limiting feature requires the use of the optional room

air temperature sensor, model RAVRMS. Designed to be

mounted on the room-side wall of the unit enclosure closet,

the room air temperature sensor allows any compatible

thermostat to be used with the unit and provide

temperature limiting.

The limits are set by dip switches located on the SPVU and

are not accessible by the room occupant. Location of the dip

switches are shown on page 14 and the temperature settings

are shown below.

COOLING TEMPERATURE LIMITS (DEGREES F.)

MIN 60° 64° 66° 68° 70° 72° 74° 76°

MAX 85° 85° 85° 85° 85° 85° 85° 85°

HEATING TEMPERATURE LIMITS (DEGREES F.)

MIN 60° 60° 60° 60° 60° 60° 60° 60°

MAX 85° 80° 78° 76° 74° 72° 70° 65°

FREEZE SENTINEL

To prevent damage to plumbing and room furnishings by

freezing temperatures, the SPVU includes Freeze Sentinel,

a feature which turns the resistance heaters on at 41° F.,

warms the indoor air to 46° F., and shuts the heater off. The

Freeze Sentinel feature requires the use of the optional room

air temperature sensor, model RAVRMS.

Designed to be mounted on the room side wall of the

unit enclosure closet, the room air temperature sensor

allows any compatible thermostat to be used with the

unit and provide Freeze Sentinel protection. Freeze

Sentinel protection is automatic with the installation

of the RAVRMS.

Even if the unit is connected to a central desk control

system or a room occupancy sensor system, and the unit

is turned off by the controlling system, Freeze Sentinel

is still active to provide protection. It may be defeated by

switching the unit’s ON/OFF switch to the OFF position,

removing the power supply to the unit or putting #2 dip

switch in DOW N position.

CONSTANT ON FAN

Some localities may require the indoor fan on single

packaged air conditioners to operate at all times, even

when the wall primary control would normally turn the

unit off. To accommodate this requirement and provide the

feature for use by anyone wanting to operate the unit in this

manner, GE Appliances has provided a switch on the SPVU

that will allow this mode of fan operation.

If the controlling dip switch (#3) is set in the UP setting,

the fan will run unless the unit’s ON/OFF switch is set to

the OFF position or power is removed from the unit.

PERMANENTLY LUBRICATED FAN MOTORS

The SPVU has two permanently lubricated, totally enclosed

fan motors. The motors are permanently lubricated to

reduce maintenance, and totally enclosed to keep dirt and

water out of the motor windings.

4

STANDARD SIZE AIR FILTER

A number of filters, providing varying degrees of filtering

efficiency, are available on the market today. GE Appliances

has designed the SPVU to accommodate a number of filter

placement options. All of the options designed for the unit

use a standard size 20" W x 20" H x 1" D filter. Since the

filter is field supplied, GE Appliances has allowed the owner

or property manager to decide which type of filter to use

with the unit.

A different size filter may also be used in a field-supplied

frame installed in a return air grille mounted in the closet

enclosure door or wall. If a different size filter is used,

it must be at least 20" W x 20" H x 1" D and provide

no more restriction to air flow than the standard

20"W x 20"H x 1"D filter.

The unit must not be operated without a filter in place,

even during construction.

GE Appliances provides three filter placement options

for design and installation flexibility. A filter bracket is

provided in the front panel of the Zoneline vertical unit case,

which allows the use of a louvered closet door. The bracket is

mounted to allow the filter to be inserted from

the top of the bracket rather than sliding in from the side,

where the enclosure wall may interfere with filter removal.

An access panel, accessory model number RAVRG1, for the

closet enclosure is the second filter placement option. The

access panel requires a 28" W x 48" H cutout in the unit

closet enclosure wall and provides access to the unit for

servicing and removal. The access panel should be located

in the wall such that the centerline of the access panel

matches the centerline of the case to allow for removal of the

chassis. The bottom of the access panel should be at least 1"

below the unit support platform to allow for easy removal of

the Zoneline Vertical Unit.

The third filter placement option provided by GE Appliances

is incorporated in a return air grille, accessory model

number RAVRG2, designed to be mounted in a flat closet

access door. The door must have a minimum clear opening

of 24" to allow for installation and removal of the unit.

GE Appliances recommends a 28" wide door. A 20-3/8" W

x 20 3/8" H cutout is required in the door to accommodate

the grille and filter bracket.

Only one filter is to be used in the installation. Multiple

filters will reduce the air f low and affect unit performance.

A clean filter is essential to efficient unit operation.

The filter should be checked at least every 30 days and

replaced if dirty.

CENTRAL DESK CONTROL (CDC)

Terminals are provided on the unit to allow a central desk

control system to be interfaced with the unit. The most

common installation of this type of system is a switch

mounted at the registration desk; and, upon guest check-in,

the switch is activated to allow the air conditioner to operate.

Likewise, when the guest checks out, the device is switched

to the “OFF” setting so the unit will not operate when

the room is not rented. In some resort areas, devices are

connected to sliding glass doors, and opening the doors

causes a contact to close, turning the air conditioner off.

This prevents the unit from running and wasting energy

with the sliding glass door open.

IMPORTANT CDC NOTES:

1. The unit requires the use of a normally open switch.

Closing the circuit interrupts power to the unit.

2. Both wires comprising the circuit must connect to the

CDC terminals on the unit and to the controlling switch.

Do not use a common buss (at the unit or at the switch

panel) in the wiring.

3. A 24-volt transformer is contained within the Zoneline

Vertical Unit. No external voltage may be applied to the

unit through the CDC terminals.

4. Minimum wire size for CDC wiring:

WIRE SIZE # AWG MAXIMUM ALLOWABLE LENGTH

#22 600 Ft.

#20 900 Ft.

#18 1,500 Ft.

#16 2,000 Ft.

OCCUPANCY SENSOR INTERFACE

The SPVU is equipped with a terminal connection to allow

it to interface with a field-supplied motion sensor and a

door sensor to allow a room occupancy detection system to

be connected to the unit. Various companies market and

install room occupancy systems as a means of reducing the

operating cost of the unit. GE Appliances does not market

or install these systems, but provides the interface terminals

on the unit and logic within the microprocessor controls to

permit these systems to be installed at a minimum cost to

the property owner.

HIGH AND LOW FAN SPEEDS

If the SPVU is connected to a wall thermostat without

the ability to provide two fan speeds, the fan speed will

be determined by connecting the wire controlling the fan

to either the low speed fan terminal or the high speed fan

terminal on the unit.

5

FEATURES & BENEFITS

3-SPEED INDOOR FAN MOTOR

FOR SELECTABLE HIGH AND LOW SPEEDS

Since the SPVU discharge air may be routed through

duct work for air distribution into the room and into

other rooms, the units are equipped with a 3-speed fan

that provides greater air movement to compensate for the

additional duct length. GE Appliances recommends an

HVAC engineer be consulted to determine the best fan

speed for the application.

A switch on the unit (dip switch #5-duct) adjusts the

two-speed fan system to different settings. With the

switch in the UP position, the system will operate using

high and medium fan speeds. With the switch in the

DOWN position, the system will operate using the

medium and low fan speeds.

For example, on the 9,000 BTUh unit, the three fan speeds

at 0.2" ESP provide 220 CFM on the lowest fan speed, 370

CFM on the medium fan speed, and 480 CFM on the

highest fan speed.

With the switch DOWN, the unit would provide 220 CFM

on LOW speed and 370 CFM on HIGH speed. With the

switch U P, the unit would provide 370 CFM on LOW

speed and 480 CFM on HIGH speed.

Higher CFMs tend to increase the operating sound level,

both from fan noise and from the air noise in the duct.

Higher CFMs also reduce the dehumidification rate of the

unit, while lower CFMs provide quieter operation and better

dehumidification. However, if the CFMs are not high enough

to adequately move the air through the duct system, the unit

will not be able to provide a comfortable room.

CORROSION PROTECTION

TREATMENT - STANDARD

All

SPVUs

damage from seacoast area corrosion.

Components that are in contact with

the salt air have special coatings or

are made of non-corroding materials

to help withstand the corrosive effects

of the environment. This protection

includes the use of totally enclosed fan motors with painted

casings, a special coating on the outdoor coil, use of stainless

steel screws and brackets, and additional paint on components

such as the base pan.

are protected against

SLINGER RING CONDENSATE REMOVAL

Condensate water removed from the indoor air is dispersed

into the air stream by the outdoor fan slinger ring and

deposited on the hot outdoor coil. The water helps cool the

refrigerant in the outdoor coil and increases the efficiency

of the air conditioner.

6

INDOOR COIL FROST CONTROL

Under certain operating conditions, frost can form on the

indoor coil of an air conditioner, reducing air flow and

cooling. In order to prevent frost from forming, the SPVU

has an automatic frost control on the indoor coil. When frost

begins to form on the coil, the compressor stops until the coil

temperature increases and the frost dissipates.

At this time, the compressor resumes operation and cooling

continues. The indoor fan remains running during the time

the compressor is off to help warm the coil with room

temperature air.

AUTOMATIC COMPRESSOR RANDOM RESTART

In the event of a power interruption, all compressors

attempting to restart immediately when power is restored

can result in a power surge that can cause another power

failure. The microprocessor in the SPVU has a random

restart logic system that prevents all compressors from

restarting at the same instant.

COMPRESSOR RESTART DELAY

SPVUs are designed to provide a minimum of three minutes

of compressor off time to allow refrigerant pressures to

equalize before attempting to restart. Attempting to

restart against a high head pressureshortens compressor

and overload protector life.

The units are also designed to provide a minimum of three

minutes of compressor run time to prevent short cycling

from disturbing the room occupant.

QUICK HEAT RECOVERY - ON HEAT PUMP UNITS

Heat pumps save money compared to electric resistance

heat, but if the unit cannot provide room occupant comfort,

the savings may be of questionable benefit. GE Appliances

has years of experience with designing Zoneline® heat

pumps to solve the problem of guest complaints.

The heat pump unit incorporates a two-stage heat/one-stage

cooling thermostat that utilizes the resistance heat to bring

the room temperature to the thermostat set point before

initiating heat pump operation. This method addresses the

two major complaints about heat pump operation: taking

too long to warm the room and low discharge air temperature.

Full electric resistance heat is utilized when the unit is first

turned on or when the unit is operating in heat pump mode

and the temperature in the room falls more than 4°F. b e l o w

the thermostat set point.

Loading...

Loading...