Page 1

O

Zoneline Series

Heat Pump Model 3200

Heat/Cool Model 2200

Zoneline

Owner's Manual

Important Safety information

Operating Instructions

The OontroL_ on Yo_r ZoneH_m

Oa_ o{ Predator

Installation Instructions

Helpful Information

Thi_gs Tha__Are

If SomethingGoesWrong

BeZoye Yow ...... _oywce

GE Serdce _w_mness

GEAnswer Center ®

800.626.2000

GEAppliances

49-7359

Page 2

we believe in dependable service.

You'll see it in this easy-to-use

manual and you'll hear it in the

friendly voices of our customer

service department.

the comff)rt of your Zoneline.

That's important, because your

new Zoneline will be part of your

family for a long time.

Before using

yo_g

Zoneline

Staple your receipt to the inside back

cover of this manual You will need it

to obtain service under warranty.

Write down the model and serial

numbers here. They are on a label

behind the room cabinet on the

base pan.

Model number

Serial number

Date of purchase

ii _ il

Hglp 1is

help you

800.626.2000

2

Befi)re you call for service,

there are a few things you can

do to help us serve you better.

Read this manual It contains

instructions to help you use and

maintain your Zoneline properly.

Save time and money. Check the

section titled ff Something Goes

Wrong before calling. This section

was designed to solve common

problems that might occur.

If you do need service, you can

relax knowing help is only a phone

call away. Toll-free customer service

numbers are included in the back

of this manual. Or call the GE

Answer Center ® at 800.626.2000,

24 hours a day, 7 days a week.

Page 3

READ ALL SAFE TY INFORMA TION

BEFORE USING

• This Zoneline must be properly • Unplug or disconnect the

installed in accordance with the Zoneline at the fuse box or

Installation Instructions before it circuit breaker before making

is used. See pages 10-12.

any repairs.

• Repair or replace immediately

all electric service cords that have

become ficayed or otherwise

damaged.

SAVE

THE SE INS TR UCTI ONS

For details see the Installation

Instructions in the back of this

manual.

NOTE:We strongly recommend

that any servicing be pertbrmed

by a qualified individual.

3

Page 4

The

controls

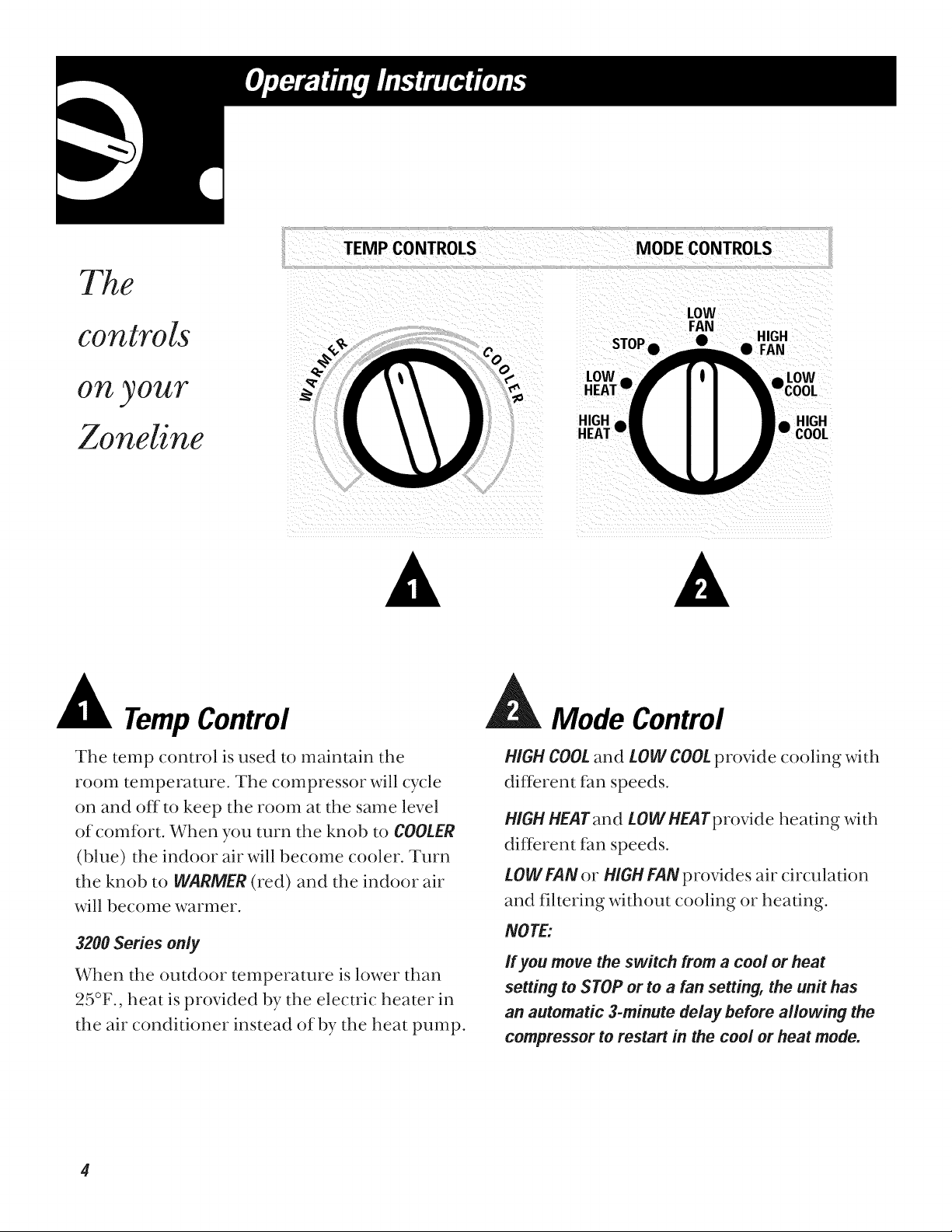

TEMP CONTROLS MODE CONTROLS

LOW

FAN

STOPt

HIGH

• FAN

On yO! T

Zoneline

A TempControl

The temp control is used to maintain the

room temperature. The compressor will cycle

on and off to keep the room at the same level

of comfort. When you turn the knob to COOLER

(blue) the indoor air will become cooler. Turn

the knob to WARMER (red) and the indoor air

will become warmer.

3200Series on/y

When the outdoor temperature is lower than

25°F., heat is provided by the electric heater in

the air conditioner instead of by the heat pump.

LOW•

HEAT

HIGH

DLOW

COOL

HIGH

A Mode Control

HiGH COOLand LOW COOLprovide cooling with

different fan speeds.

HiGH HEATand tOW HEATprovide heating with

different fan speeds.

LOW FAN or HIGH FANprovides air circulation

and filtering without cooling or heating.

NOTE:

ff you move the switch from a cool or heat

setting to STOP or to a fan setting, the unit has

an automatic 3=minute delay before allowing the

compressor to restart in the cool or heat mode.

Page 5

EnergyTip

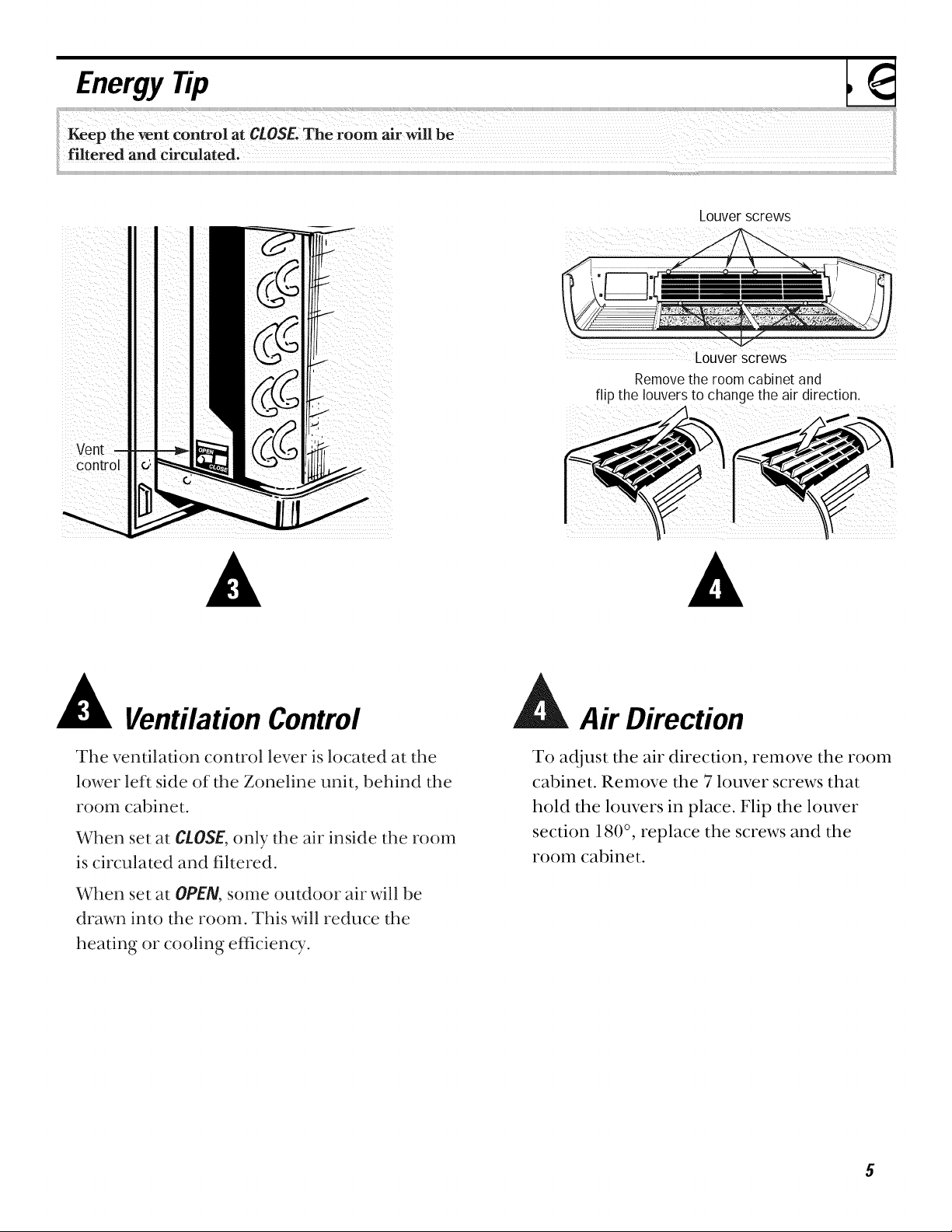

Vent

control

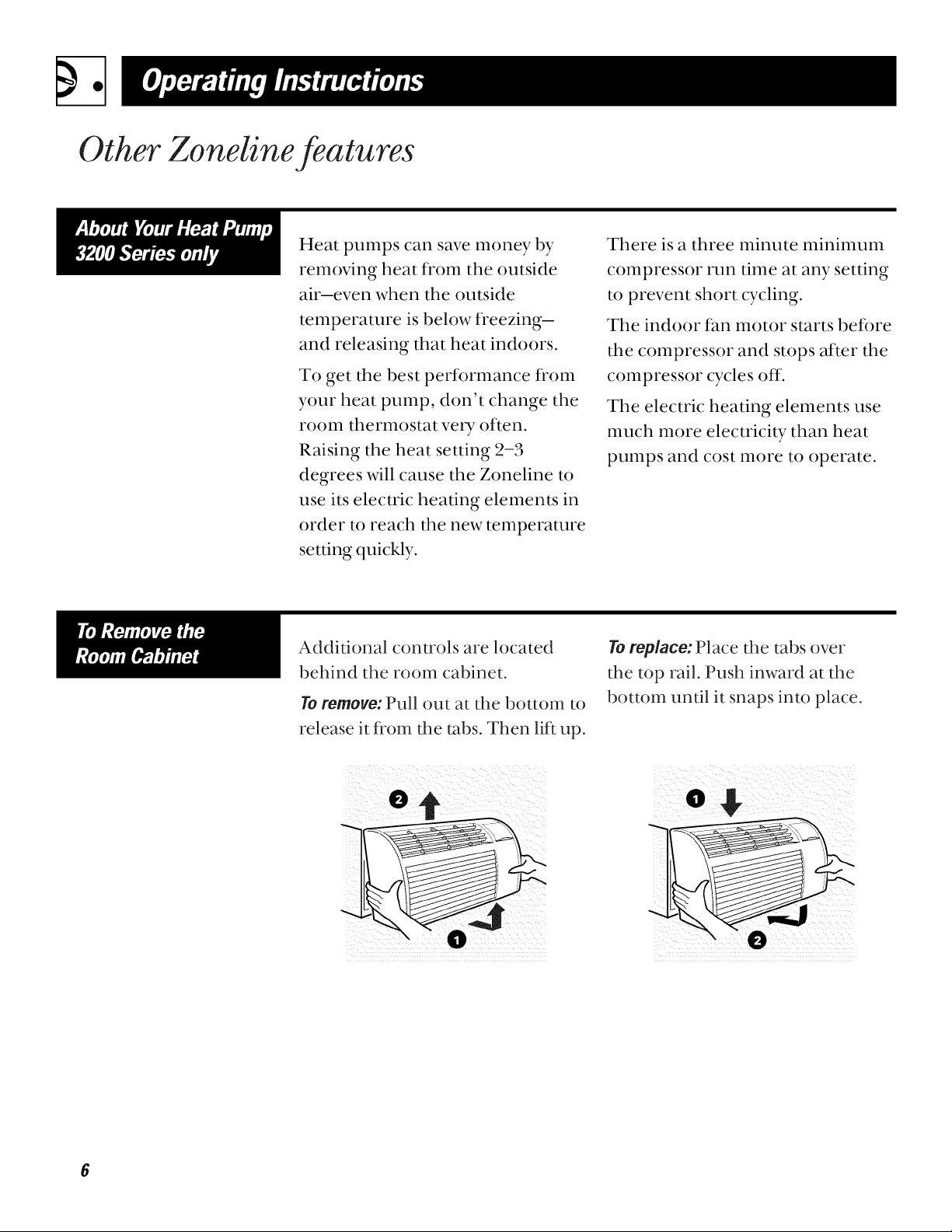

Louverscrews

Removethe room cabinet and

flip the louvers to change the air direction.

A Ventilation Control

The ventilation control lever is located at the

lower left side of the Zoneline unit, behind the

room cabinet.

When set at CLOSE, only the air inside the room

is circulated and filtered.

When set at OPEN,some outdoor air will be

drawn into the room. This will reduce the

heating or cooling egiciency.

Air Direction

To adjust the air direction, remove the room

cabinet. Remove the 7 louver screws that

hold the louvers in place. Flip the louver

section 180 °, replace the screws and the

room cabinet.

5

Page 6

Other Zoneline features

Heat pumps can save money by

removing heat from the outside

air-even when the outside

temperature is below freezing-

and releasing that heat indoors.

To get the best performance from

your heat pump, don't change the

room thermostat vet y often.

Raising the heat setting 2-3

degrees will cause the Zoneline to

use its electric heating elements in

order to reach the new temperature

setting quickly.

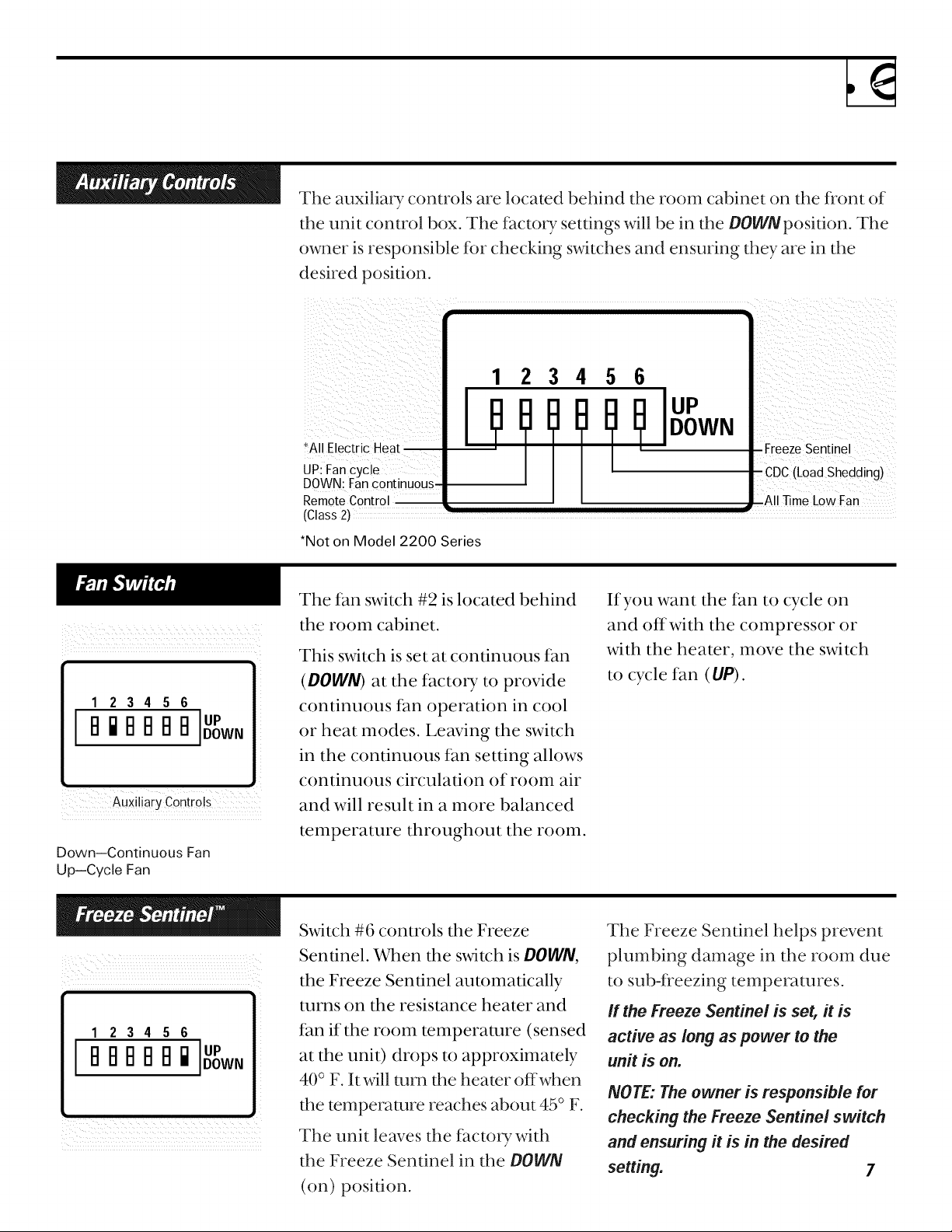

Additional controls are located

behind the room cabinet.

To remove: Pull out at the bottom to

There is a three minute minimum

compressor run time at any setting

to prevent short cycling.

The indoor fan motor starts before

the compressor and stops after the

compressor cycles off.

The electric heating elements use

much more electricity than heat

pumps and cost more to operate.

To replace: Place the tabs over

the top rail. Push inward at the

bottom until it snaps into place.

release it from the tabs. Then lift up.

Page 7

The auxilia[ T controls are located behind the room cabinet on the front of

the unit control box. The factory settings will be in the DOWNposition. The

owner is responsible for checking switches and ensuring they are in the

desired position.

123456

UP

DOWN

*All E

UP:Fan cycle

DOWN:F

RemoteCq

(Class 2)

*Not on Model 2200 Series

Load Shedding)

1B23456

IIaaaaIoow.

Auxiliary Controls

Down--Continuous Fan

Up--Cycle Fan

123456

FIBFIBFIII]oowN

UP

UP

The fan switch #2 is located behind

the room cabinet.

This switch is set at continuous fan

(DOWN) at the factory to provide

continuous fan operation in cool

or heat modes. Leaving the switch

in the continuous fan setting allows

continuous circulation of room air

and will resuh in a more balanced

temperature throughout the room.

Switch #6 controls the Freeze

Sentinel. When the switch is DOWN,

the Freeze Sentinel automatically

turns on the resistance heater and

fan if the room temperature (sensed

at the unit) drops to approximately

40 ° F. It will turn the heater offwhen

the temperature reaches about 45 ° F.

The unit leaves the factory with

the Freeze Sentinel in the DOWN

(on) position.

If you want the fan to cycle on

and offwith the compressor or

with the heater, move the switch

to cycle fan (UP).

The Freeze Sentinel helps prevent

plumbing damage in the room due

to sub-freezing temperatures.

If the Freeze Sentinel is set, it is

active as long as power to the

unit is on.

NOTE: The owner is responsible for

checking the Freeze Sentinel switch

and ensuring it is in the desired

setting. 7

Page 8

&

Cleaning

Turn the Zoneline off and discon-

nect the power supply.

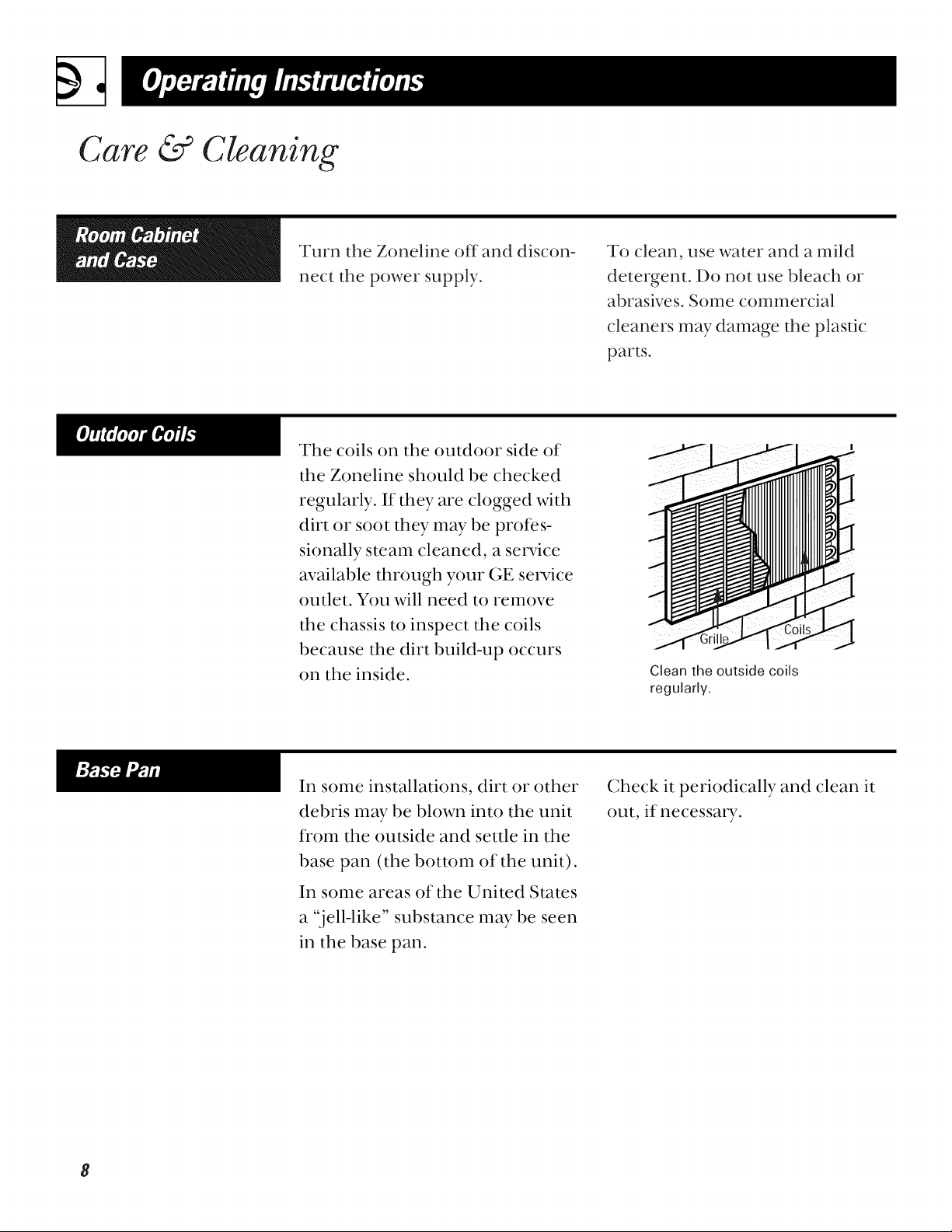

The coils on the outdoor side of

the Zoneline should be checked

regularly. If they are clogged with

dirt or soot they may be profes-

sionally steam cleaned, a seiMce

available through your GE seiMce

outlet. You will need to remove

the chassis to inspect the coils

because the dirt build-up occurs

on the inside.

To clean, use water and a mild

detergent. Do not use bleach or

abrasives. Some commercial

cleaners may damage the plastic

parts.

Clean the outside coils

regularly.

In some installations, dirt or other

debris may be blown into the unit

from the outside and settle in the

base pan (the bottom of the unit).

In some areas of the United States

a "jell-like" substance may be seen

in the base pan.

Check it periodically and clean it

out, if necessai T.

Page 9

Turnthe Zoneline off before cleaning.

The most important thing you can

do to maintain the Zoneline is to

clean the filter at least every 30

days. Clogged filters reduce cool-

ing, heating and air flow.

Keeping these filters clean will:

• Decrease cost of operation.

• Save energ T.

To remove the air filters:

2air filters

Dirty filter-Needs cleaning

clogged filter.Greatly

reduces cooling, heating ....

and airflow.

• Prevent clogged heat exchanger

coils.

• Reduce the risk of premature

component failure.

To clean the ah"filters:

• Vacuum off the heavy soil.

• Run water through the filters.

• Dry thoroughly before replacing.

To replace the air filters:

Push

down

CAUTION:

DO NOT operate the Zoneline without

the filters in place, ff a filter becomes

torn or damaged it should be

replaced immediately.

Operating without the fibers in

place or with damaged filters will

allow dirt and dust to reach the in-

door coil and reduce the cooling,

heating, airflow and efficien W of

the unit.

Replacement filters are available

from your salesperson, GE dealer,

GE Se_vice and Parts Center

or authorized Customer Care ®

servicers.

9

Page 10

Read carefully

Ifyou have any questions, call the GEAnswer Center at 800.620.2000.

Check the "Essential

Elements" label for

important information.

• Use the correct wall case.

This chassis is designed to be installed in a GE

plastic or insulated metal wall case. This mini-

mizes condensation from forming on the room

side of the case. If the current wall case is not

insulated, you can reduce the possibility of

condensation forming by installing insulation

kit RAK901L, available where you purchased

the chassis.

Any vertical deflectors in the existing rear grille

should be removed to decrease condenser air

recirculation which can cause the unit to

"short-cycle" and lead to premature compo-

nent failure.

• Replacing a ducted chassis.

New ducted installation--ff this unit is to be

installed in a new ducted application using a

duct adaptor kit, the kit must be installed before

the chassis is placed in the wall case. The installa-

tion instructions are packed with the kit.

Mounting

plate

• Use the correct outdoor grille.

You should use the outdoor grilles shown on

the "Essential Elements" label on the top of

the chassis.

• If an existing grille is not replaced, capacity and

efficiency will be reduced and the unit may fail

to operate properly or fail prematurely. A

deflector kit, RAK40, may be used with grilles

that were not designed for your new GE

Zonelines. The RAK40 contains air deflectors

and gaskets that mount to the chassis to direct

the hot exhaust air away from the air intake to

allow the unit to fimction properly. The grille

must have a 65% minimum free area.

10

Existing ducted installation--Replacement of an

existing ducted unit may require different com-

ponents. Request this information from your

sales representative.

• Replacing 230/208 volt units.

See page 12.

• Replacing 265 volt units.

See page 13.

Page 11

Important Electrical Safety-Read Carefully

Installer: Leave these instructions with the Zoneline.

Owner: Keep these instructions for future use.

• Follow the National Electrical C(_ )de (NEC) or

local codes and ordinances.

• For personal safety, this Zoneline must be prop-

erly grounded.

• Protective devices (fllses or circuit breakers)

acceptable fi_r Zoneline installations are speci-

fied on the nameplate of each unit.

zone i.Components

,_ CAUTION:

• Do not use an extension cord with this uniL

• Aluminum building wiring may present special

problems--consult a qualified electrician.

• When the unit is in the STOP position there is still

voltage to the electrical controls.

• Disconnect the power to the unit before servicing

by:

1 Removing the power cord (if it has one) from the

wall receptacle.

or--

2 Removing the branch circuit fuses or turning the

circuit breakers off at the panel

YOU WILL NEED: • Phillips screwdriver

Exterior grille/louver**

*Shipped with the Zoneline unit

**Check the "Essential Elements" list on the unit

Wall case** Zoneline unit Room cabinet*

11

Page 12

1 Remove the room cabinet.

2 Connect to electrical power.

23_ iloIt EIectrical_ly

All wiring, including installation of the

receptacle, must be in accordance with the NEC

and local codes, ordinances and regulations.

This unit is equipped with a line cord for

appropriate amperage wall receptacle. See below.

Tandem Perpendicular Large Tandem

15 Amp. 20 Amp. 30 Amp.

3 See the special instructions below fi)r

applicable supply voltages.

4 Reinstall the room cabinet.

Electrical wiring wall outlets 230/208 volts.

/2

Page 13

,_ WARNING

Connection of this 265V product to a

branch circuit MUSTbe done by direct

connection to be in compliance with the

National Electric Code. Plugging of this

unit directly into a building mounted

exposed receptacle is not permitted

bycode.

These models must be installed using one of the

following methods:

A Electrical subbase kits are available to provide

a flexible enclosure fl)r direct connection.

Branch Circuit

and Chassis Proper GE

Amperage Rating Subbase Kit

15 RAK204E15

20 RAK204E20

30 RAK204E30

The instructions provided with the selected

subbase kit must be careflflly followed. It is

the responsibility of the installer to ensure

that connection of components is done in

accordance with these instructions and all

electrical codes.

Steps for preparing cordset for direct connection:

1 Remove the junction box cover by taking out

the front four screws.

2

Remove the junction box by taking out the top

rear screw. Note how the tab at the lower right

corner of the junction box se_wes to hold the

corner in place. This will help when the box is

being reinstalled. The cord will be coiled up

inside the junction box.

Tab on

Junction

box cover

Slot in _ I_---------------_

junction box

3 Measure 6" down the cord from the strain

relief securing the cord to the chassis and cut

the cord through at this point.

4 Careflflly split the cord insulation at the center

for 2" so as to separate into three insulated

wires. Be careflfl not to cut through the center

green ground wire insulation.

B For direct connection to branch circuit wiring

inside the provided junction box without using

a subbase kit, the cord is to be cut and the wire

ends stripped and connected as follows.

$ Strip 3/4" of the insulation away at the end

of each of the three wires (L1, Neutral and

Ground). The Neutral wire is identified by

molded rib along its entire length. The L1

(Hot) wire insulation is smooth.

n _ Neutral wireStrai (molded rib) _ 3/4'__'

relief --_

2"

6"

wire

L1wire

(smooth)

13

Page 14

Use the round knockout at the bottom of the

junction box to attach conduit coming from

the branch circuit. Remove the knockout,

attach the conduit and bring wires into the

junction box. Leave 6" of wire free at the end

of the conduit to allow connections to be made.

7 Ifa fl_se and fl_seholder are to be used, the

knockout at the top of the box is for mounting

a Buss Fuseholder. Be sure the fl_se and

fl_seholder are of the same rating as the branch

circuit. Leadwires at the fl_se can be either

soldered in place or attached using UL-listed

1/4" female (receptacle) crimp connectors.

8 Reinstall the junction box by engaging the tab

at the lower rear, aligning the screw hole at the

top and driving the one screw until secure. Be

sure that all wire leads are inside the box and

not pinched between the box and the chassis.

The identified (ribbed) Neutral wire of the

cordset MUSgbe connected to the white

Neutral wire of the branch circuit. The green

insulated ground wire from the chassis

MUSl'be connected to the branch circuit

ground wire.

9 Make all wire connections by using

appropriate UL-listed electrical connectors

and techniques (black to black, white to white

and green to green).

10 Careflflly rock all wires and connections back

inside the junction box. Be sure there are no

loose connections or stray uninsulated wires

exposed.

11 Place the junction box cover in place. Replace

the fimr screws removed earlier and tighten

securely.

12 Discard the unused portion of the plug and

the cordset.

14

Page 15

The RAB71 or RAB77 wall case must be

Insulated Wall Case

properly installed per instructions packed

with the case.

2 Remove the corrugated stiffener and the

outdoor protective panel. Use the slit in the

outdoor panel as a handhold and push out.

Protective Slit

panel

Stiffener

3 Install the exterior grille from the room side

following instructions packed with the grille.

This chassis is designed to be installed in a

GE plastic or an insulated steel wall case. This

minimizes condensation from forming on the

room side of the case.

The RAB71 wall case is insulated. Insulation kit

RAK901L is available for use with RAB77 or

existing uninsulated wall cases when needed.

NOTE:For installation with a subbase or duct

adapter, see the instructions packed with those kits.

1 Careflllly remove shipping tape, if there is any,

from the room cabinet and vent door.

Shipping tape

2

Remove the room cabinet by pulling it out at

the bottom to release it, then lift it up to clear

the rail along the unit top.

O

15

Page 16

Slide the unit into the wall case and secure with

four screws through the unit flange holes.

If an insulated wall case is needed, see Install the

Wall Case and Exterior Grille section on the

previous page.

Reinstall the room cabinet by hooking the top

over the rail along the unit top, then pushing it in

at the bottom.

16

Page 17

Low Voltage Connectors & Auxiliary Controls

NOTE: The owner is responsible for checking all switches and ensuring they are set in the desired setting.

The Electric Heat Option switch #1 increases

the Zoneline air temperature by using electric

heat only. The heat pump is not used to produce

any heat.

Using the Electric Heat Option is much more

expensive than heating with the heat pump only.

i! Temperature Limiting

Temperature limiting can reduce energy costs by

limiting the lowest temperature that can be set

fl)r cooling and the highest temperature that can

be set fi)r heating.

To set the Electric Heat Option, move switch to

the O/V (up) position.

123456

UP

BBB BB lDowN

Auxiliary controls

®

®

®

Limiting the maximum and minimum settings

prevents users from turning the control to the

extreme heat or cool positions.

The normal fifll range of the temp control is

approximately 62 ° F to 85 ° F. The control range

may be narrowed by the use of the temperature

limiting screws located behind the control panel.

@

Limits

heat

temp

®

temp

Eachposition equals

approximately 3° F

17

Page 18

To operate the Remote Control/Wall

Thermostat ((;lass 2) switch #3, you must use

an Optional Interface Module kit. See the

Installation Instructions with accesso_ T kit

RAKOIM.

To operate Central Desk Control (C C),

switch #5, you must have an Optional Interface

Module kit. See the Installation Instructions with

123456

BBWBBBl."o"wN

Auxiliary Controls

123456

accessoi T kit RAKOIM.

Switch #4 controls the All-Time Low Fan and is

only effective with a Remote Control Thermostat.

This flmction causes the indoor fan to operate at

low speed. If the switch is DOWN (off) the fan will

run in high speed. If the switch is lip (on) the fan

will mn in low speed.

IBBBB BI o" .

123456

IBBB BBI o" .

18

Page 19

Things That Are Normal

You may hear a pinging or popping noise caused by water being

PING! POP!

picked up and thrown against the condenser on rainy days or

when the humidity is high. This design feature helps remove

moisture and improve efficiency.

"CLICK"

DRIP

6

You may hear relays click when the controls cycle on and offor are

adjusted to change the room temperature.

Water will collect in the base pan during high humidity or on rainy

days. The water may overflow and drip from the outdoor side

of the unit.

The indoor fan runs continuously when the unit is operating in the

cooling mode, unless the fan switch behind the room cabinet is set

at fan cycle (up). This will cause the fan to cycle on and offwith the

compressor. You may also hear a fan noise stop and start.

You may notice a few minutes delay in starting if you tU to restart the

Zoneline too soon after turning it off or if you adjust the thermostat

right after the compressor has shut off. This is due to a built-in

restart protector for the compressor that causes a 3-minute delay.

COMPRESSOR

PROTECT

The compressor shuts off during the defrost cycle. Full resistance

heat comes on during the defrost cycle to maintain room comfort.

To protect the compressor and prevent short cycling, the unit is

designed to run for a minimum of 3 minutes, after the compressor

starts at any thermostat setting.

19

Page 20

Before You Call For Service

Problem Possible Causes What to Do

The unit is unplugged

The fuse is blown/circuit

breaker is tripped

The unit is waiting for the

compressor overload

protector to reset

Power failure

Indoor airflow

is restricted

• Make sure the Zoneline plug is

pushed completely into the outlet.

• Check the house fuse/circuit breaker

box and replace fuse or reset the breaker.

• This is normal. The Zoneline will start

again after it resets.

If power failure occurs, set the mode

control to STOP. When power is restored

set the mode control to the desired setting.

There is a protective time delay (up to

3 minutes) to prevent tripping of the

compressor overload. For this reason, the

unit may not start normal heating or

cooling fi)r 3 minutes after it is turned

back on.

• Make sure there are no curtains, blinds

or furniture blocking the front of the

Zoneline.

2O

Outdoor airflow

is restricted or

recirculated

The temp control may

not be set high or low

enough

The air filter is dirty • Clean the filter at least evei y 30 days.

The room may have been

hot or cold

Outdoor air is

entering the room

• Make sure the rear grille is not restricted.

This can cause the unit to cycle off due to

the compressor overload.

• Turn the control to a lower or higher

setting. NOTE: The temperature limiter may

be limiting the temperature range.

• When the Zoneline is first turned on

you need to allow time for the room to

cool down or warm up.

• Set the vent control to the C£OSEposition.

Page 21

Before You CaU For Service

Problem Possible Causes What to Do

Dust is on the surface of

the heating element

The heat pump is not

producing hot air

The fan switch may be set

at continuous fan (down)

The heat pump alone

produces air that feels

cooler than desired

• This can cause a "burning" odor at the

beginning of the heating operation. This

odor should quickly fade.

This is normal. The heat pump will

produce warm air but not as hot as air

produced when the higher-cost electric

heat is used.

This causes the tan to blow room

temperature air even when the

compressor or heater cycles off.

The continuous air movement provides

better overall temperature control.

• Use the Electric Heat Option. This turns

off the heat pump and warms with

electric heat only.

NOTE:Use of this option will result in

increased energy consumption.

21

Page 22

Notes

22

Page 23

We'U be there!

800.626.2000

TDD

800-833-4322

Open 24 hours a day,

7 days a week.

800-GE-CARES

(800-432-2737)

800-626-2002

If for some reason you

are not happy with the

seiMce you receive, here

are three steps to follow

for fllrther help.

We provide expert repair service,

scheduled at a time that's

convenient for you.

Individuals qualified to service

their own air conditioner can have

parts or accessories sent directly

to their home.

VISA, MasterCard and Discover

cards are accepted.

First, contact the people who ser-

viced your air conditioner. Explain

why you are not pleased.

Next, if you are still not pleased,

write all the details-including

your phone number-to:

Consumer Relations

Our factory-trained technicians

know your air conditioner inside and

out-so most repairs can be handled

in just one visit.

Care and cleaning instructions con-

tained in this manual cover proce-

dures to be performed by any user.

Other servicing generally should be

referred to qualified service person-

nel. Caution must be exercised,

since improper servicing may cause

unsafe operation.

Finally, if your problem is still

not resolved, write:

Major Appliance

Consumer Action Program

20 North Wacker Drive

Chicago, IL 60606

GE Appliances,

Louisville, KY 40225

23

Page 24

Staple sales slip or cancdled check here.

Proof of original purchase date is needed

to obtain service under warranty.

All warranty service will be provided

by our Factory Service (;enters, or an

authorized Customer Care ® technician.

For service in the U.S., call

800-GE-CARES.

For service in Canada, call

1-800-361-3400.

FULL ONE-YEAR WARRANTY

For one year from date of original pur-

chase, we will provide, fiee of charge,

parts and service labor on site to repair

or replace a'rzypart of the Zo'rzeli'rzethat

fails because of a mamffacmring defect.

FULL FIVE-YEAR WARRANTY

For five years fiom the date of original

purchase, we will provide, free of

charge, parts and on-site service labor

to repair or replace a'rlypart of the seabed

r@Jgerati'ng system (the compressor, con-

denser, evaporator and all connecting

tubing) that fails because of a mamffac-

turing defect.

Service trips to your site to teach you

how to use the product.

hnproper installation.

If you have an installation problem,

or if the air conditioner is of

improper cooling capacity tiw the

intended use, contact your dealer

or installer. You are responsible fiw

providing adequate electrical

connecting facilities.

Replacement of filses or resetting of

circuit breakers.

In commercial locations, labor neces-

sary to move the unit to a location

where it is accessible fiw service by an

individual technician.

LIMITED 2ND THROUGH

5TH YEAR PARTS WARRANTY

For the second through the fifth year

fiom date of original purchase, General

Electric will provide, fiee of charge,

parts that fail as a result of a manufac-

turing defect. Parts covered are fan

motors, switches, thermostat, heater,

heater protectors, compressor over-

load, solenoids, circuit boards, auxiliary

controls, thermistors, Freeze Sentinel,

fiost controls, ICR pump, capacitors,

varistors, and indoor blower bearing.

This is a limited parts-only warranty,

and does not include labor or trans-

portation to and fiom the service shop.

Failure or damage resulting fiom

corrosion due to installation in an

environment containing corrosive

chemicals.

• Failure or damage resulting from

corrosion due to installation in a

coastal environment, except fiw

models treated with special factory-

applied anti-corrosion protection as

designated in the model number.

• Damage to product caused by

improper power supply voltage, acci-

dent, fire, floods or acts of God.

Incidental or consequential damage

to personal property caused by possi-

ble defects with this air conditioner.

Failure of the product resulting from

modifications to the product or due

to unreasonable use including failure

to provide reasonable and necessary

maintenance.

Warrantor: General Electric Company. Louisville, KY 40225

This warranty isextended to the original purchaser and any succeeding owner for products purchased for use

within the USA and Canada: In Alaska, the warranty exc!udes the CoSt Of.shipping or sepdc e ca!l s to your site i

Some states do not allow the exclusion or limitation of incidental or consequential damages2 This warranty gives you

specific legal rights; and you may also have other rights which vmy fl-om state tO state iTo know What your legal

rights arein your state, Consult your local or state consumer affhirs office or your state!s Attorney General.

i Pub. _ P_nte,JinChina

No. 49-7359

i

1

_2-97CG 2200/3200Series

Zoneline

Loading...

Loading...