Page 1

GE Industrial Systems

TM

AV - 30 0

AV - 30 0

Quick Start Up Guide

i

i

1

Page 2

This book is referred to SW version 1.X00

This book replaces the Instruction Book Rev. 1.0c (09/98)

These instructions do not purport to cover all details or variations in equipment, nor to provide every possible contingency to be met during installation, operation, and maintenance. If further information is desired or if particular problems arise that are not covered sufficiently for the purchaser’s purpose, the matter should be referred to GE Industrial

Systems.

This document contains proprietary information of General Electric Company, USA and is furnished to its customer

solely to assist that customer in the installation, testing, operation, and/or maintenance of the equipment described.

This document shall not be reproduced in whole or in part nor shall its contents be disclosed to any third party without

the written approval of GE Industrial Systems.

© 1999 by General Electric Company, USA. All rights reserved.

2

Page 3

Table of Contents

1. Safety Precautions - Precautions de securité ......................................................................................................... 4

Functional connection diagram...................................................................................................7

2. Overview ......................................................................................................................................................................... 8

3. Control Terminals .......................................................................................................................................................... 9

3.1 Maximum cable cross section for regulator terminals ........................................................ 10

4. Power terminals .......................................................................................................................................................... 10

4.1 Maximum cable cross section for power terminals ............................................................ 10

5. Encoder terminals (XE connector)............................................................................................................................ 11

5.1 Encoder type connection .................................................................................................... 11

5.2 JUMPERS setting ............................................................................................................... 12

␣␣␣␣␣List of jumpers and dip-switch............................................................................................. 12

␣␣␣␣␣List of dip-switch .................................................................................................................. 13

5.3 Maximum cable length for encoder terminals..................................................................... 13

6. Keypad operation......................................................................................................................................................... 14

Keypads (on right the optional LED module) ............................................................................ 14

LEDs .......................................................................................................................................... 15

Moving inside a menu ............................................................................................................... 16

7. Pre Power Checks ....................................................................................................................................................... 17

8. Quick tuning ................................................................................................................................................................. 18

9. Options........................................................................................................................................................................... 22

10. Quick Tuning Guide for Factory Configured Drives ............................................................................................... 22

11. Troubleshooting ........................................................................................................................................................... 23

Overflow list .............................................................................................................................. 23

List of Self-tuning Errpr Messages ............................................................................................ 24

Failure alarms in the keypad display ......................................................................................... 25

Other faults ................................................................................................................................ 27

3

Page 4

1. Safety Precautions - Precautions de securité

WARNING/ATTENTION!

According to the EEC standards the AV300i should be used

only after checking that the mechanical equipment uses

safety devices required by the 89/392/EEC set of rules.

Drive systems cause mechanical motion. It is the

responsibility of the user to insure that any such motion

does not result in an unsafe condition. Factory provided

interlocks and operating limits should not be bypassed or

modified.

Selon les normes EEC, les drives AV300i et leurs

accessoires doivent être employés seulement après avoir

verifié que la machine ait été produit avec les même

dispositifs de sécurité demandés par la réglementation 89/

392/EEC concernant le secteur de l’industrie.

Les systèmes provoquent des mouvements mécaniques.

L’utilisateur est responsable de la sécurité concernant les

mouvements mécaniques. Les dispositifs de sécurité

prévues par l’usine et les limitations operationelles ne

doivent être dépassés ou modifiés.

WARNING - ELECTRICAL SHOCK AND BURN

HAZARD / ATTENTION – DÉCHARGE ÉLECTRIQUE ET

RISQUE DE BRÚLURE :

When using instruments such as oscilloscopes to work

on live equipment, the oscilloscope’s chassis should be

grounded and a differential input amplifier should be used.

Care should be used in the selection of probes and leads

so that accurate readings may be made. See the

instrument manufacturer’s instruction book for proper

operation and adjustments of the oscilloscope.

Lors de l’utilisation d’instruments (par example

oscilloscope) sur des systémes en marche, le chassis de

l’oscilloscope doit être relié à la terre et un amplificateur

différentiel devrait être utilisé en entrée.

Les sondes et conducteurs doivent être choissis avec soin

pour effectuer les meilleures mesures à l’aide d’un

oscilloscope. Voir le manuel d’instruction pour une

utilisation correcte des instruments.

WARNING - FIRE AND EXPLOSION HAZARD /

ATTENTION – RISQUE D’INCENDIES ET

D’EXPLOSIONS:

Fires or explosions might result from mounting drives in

hazardous areas such as locations where flammable or

combustible vapors are present. Drives should be installed

away from hazardous areas, even if used with motors

suitable for use in these locations.

L’utilisation des drives dans des zônes à risques (présence

de vapeurs ou de poussières inflammables), peut provoquer

des incendies ou des explosions. Les drives doivent être

installés loin des zônes dangeureuses, et équipés de

moteurs appropriés.

WARNING - STRAIN HAZARD / ATTENTION À

L’ÉLÉVATION:

Improper lifting practices can cause serious or fatal injury.

Lift only with adequate equipment and trained personnel.

Une élévation inappropriée peut causer des dommages

sérieux ou fatals. Il doit être élevé seulement avec des

moyens appropriés et par du personnel qualifié.

WARNING - ELECTRICAL SHOCK / ATTENTION – CAS

DE DECHARGE ELECTRIQUE:

Drives and motors must be grounded according to NEC.

Tous les moteurs et les drives doivent être mis à la terre

selon le Code Electrique National ou équivalent.

WARNING / ATTENTION:

Replace all covers before applying power to the drive.

Failure to do so may result in death or serious injury.

Remettre tous les capots avant de mettre sous tension le

drive. Des erreurs peuvent provoquer de sérieux accidents

ou même la mort.

WARNING / ATTENTION:

Adjustable frequency drives are electrical apparatus for

use in industrial installations. Parts of the drives are

energized during operation. The electrical installation, tuneup and troubleshooting should therefore only be carried

out by qualified personnel. Improper installation of motors

or drives may cause the failure of the drive as well as

serious injury to persons or equipment. The drive is not

equipped with motor overspeed protection logic.

Follow the instructions given in this manual and observe

the local and national safety regulations applicable.

Les drives à fréquence variable sont des dispositifs

électriques utilisés dans des installations industriels. Une

partie des drives sont sous tension pendant l’operation.

L’installation électrique et l’ouverture des drives devrait être

executé uniquement par du personel qualifié. De mauvaises

installations de moteurs ou de drives peuvent provoquer

des dommages materiels ou blesser des personnes.

Le convertisseur n’est pas pourvu de protection contre

vitesse de fuite du moteur. On doit suivir les instructions

donneés dans ce manuel et observer les régles nationales

de sécurité.

CAUTION / PRECAUTION:

Do not connect power supply voltages that exceeds the

standard specification. If excessive voltage is applied to

the drive, damage to the internal components will result.

Ne pas raccorder de tension d’alimentation dépassant la

fluctuation de tension permise par les normes. Dans le cas

d’ une alimentation en tension excessive, des composants

internes peuvent être endommagés.

4

Page 5

CAUTION / PRECAUTION:

Do not operate the drive without a ground wire being

connected. The motor chassis should be grounded to

earth through a ground lead separate from all other

equipment ground leads to prevent noise coupling.

The grounding connector shall be sized in accordance with

the NEC or Canadian Electrical Code. The connection shall

be made by a UL listed or CSA certified closed-loop

terminal connector sized for the wire gauge involved. The

connector must be attched to the wire using the crimp

tool specified by the terminal manufacturer.

Ne pas faire fonctionner le drive sans prise de terre. Le

chassis du moteur doit être mis à la terre à l’aide d’un

connecteur de terre separé des autres pour éviter le

couplage des perturbations. Le connecteur de terre devrait

être dimensionné selon la norme NEC ou le Canadian

Electrical code. Le raccordement devrait être fait par un

connecteur certifié et mentionné à boucle fermé par les

normes CSA et UL et dimensionné pour l’épaisseur du

cable correspondant. Le connecteur doit être fixé a l’aide

d’un instrument de serrage specifié par le producteur du

connecteur.

CAUTION / PRECAUTION:

Do not perform a megger test between the drive terminals

or the control circuit terminals.

Ne pas exécuter un test megger entre les bornes du drive

ou entre les bornes du circuit de contrôle.

CAUTION / PRECAUTION:

Because the ambient temperature greatly effects drive life

and reliability, do not install the drive in any location that

exceeds the allowable temperature. Leave the ventilation

cover attached for temperatures of 104° F (40° C) or below.

Étant donné que la température ambiante influe sur la vie

et la fiabilité du drive, on ne devrait pas installer le drive

dans des places ou la temperature permise est dépassée.

Laisser le capot de ventilation en place pour températures

de 104°F (40°C) ou inférieures.

CAUTION / PRECAUTION:

If the drive’s Fault Alarm is activated, consult the

TROUBLESHOOTING section of this instruction book.

Correct the problem before resuming operation, automatic

reset of faults is

not recommended.

Si la Fault Alarm du drive est activée, consulter la section

du manuel concernant les défauts et après avoir corrigé

l’erreur, reprendre l’opération. Ne pas réiniliatiser l’alarme

automatiquement par une séquence externe, etc….

CAUTION / PRECAUTION:

Be sure to remove the desicant dryer packet(s) when

unpacking the drive. (If not removed these packets may

become lodged in the fan or air passages and cause the

drive to overheat).

Lors du déballage du drive, retirer le sachet déshydraté.

(Si celui-ci n’est pas retiré, il empêche la ventilation et

provoque une surchauffe du drive).

CAUTION / PRECAUTION:

The drive must be mounted on a wall that is constructed

of heat resistant material. While the drive is operating, the

temperature of the drive's cooling fins can rise to a

temperature of 194° F (90°C).

Le drive doit être monté sur un mur construit avec des

matériaux résistants à la chaleur. Pendant le

fonctionnement du drive, la température des ailettes du

dissipateur thermique peut arriver à 194°F (90°).

Note:

The terms “inverter”, “controller” and “drive” are sometimes

used interchangably throughout the industry. We will use

the term “drive” in this document

Les mots “inverter”, “controller” et “drive” sont

interchangeables dans le domaine industriel. Nous

utiliserons dans ce manuel seulement le mot “drive”.

1. Never open the device or covers while the AC Input power supply

is switched on. Minimum time to wait before working on the

terminals or inside the drive is listed in section 4.11 in the Instruction

manual .

Ne jamais ouvrir l’appareil lorsqu’il est suns tension. Le temps

minimum d’attente avant de pouvoir travailler sur les bornes ou bien

à l’intérieur de l’appareil est indiqué dans la section 4.11 (Instruction

manual).

2. Be careful not to the damage any components when handling the

drive. Changing of the isolation gaps or removing the insulation or

covers is not permissible. If the front cover has to be removed

because of a room temperature, higher than 40°C, the user has to

ensure that no occasional contact with live parts may occur.

Manipuler l’appareil de façon à ne pas toucher ou endommager

des parties. Il n’est pas permis de changer les distances d’isolement

ou bien d’enlever des matériaux isolants ou des capots. Si la plaque

frontale doit être enlevée pour un fonctionnement avec la

température de l’environnement plus haute que 40°C, l’utilisateur

doit s’assurer, par des moyens opportuns, qu’aucun contact

occasionnel ne puisse arriver avec les parties sous tension.

3. Protect the drive from extreme environmental conditions

(temperature, humidity, shock etc.)

Protéger l’appareil contre des effets extérieurs non permis

(température, humidité, chocs etc.).

4. No voltage should be connected to the output of the frequency

inverter (terminals U2, V2 W2). The parallel connection of several

drives via outputs nor the direct connection of inputs and outputs

(bypass) are not permissible.

Aucune tension ne doit être appliquée sur la sortie du convertisseur

(bornes U2, V2 et W2). Il n’est pas permis de raccorder la sortie de

plusieurs convertisseurs en parallèle, ni d’effectuer une connexion

directe de l’entrée avec la sortie du convertisseur (Bypass).

5. When engaging a running motor, the Auto capture function (Auto

capture in the ADD SPEED FUNCT menu) must be activated (not

applicable to Regulation mode=sensorless vect).

Pour reprendre des moteurs en rotation, la fonction suivante doit

être activée : “Auto capture” dans le menu ADD SPEED FUNCT.

5

Page 6

6. A capacitative load (e.g. variable power factor capacitors) should

not be connected to the output of the drive (terminals U2, V2, W2).

Aucune charge capacitive ne doit être connectée à la sortie du

convertisseur (bornes U2, V2 et W2) (par exemple des condensateurs

de mise en phase).

7. Always connect the drive to the protective ground (PE) via the

marked connection terminals (PE2) and the housing (PE1).

Adjustable Frequency Drives and AC Input filters have ground

discharge currents greater then 3.5 mA. EN 50178 specifies that

with discharge currents greater than 3.5 mA the protective conductor

ground connection (PE1) must be a fixed type and doubled for

redundancy.

Effectuer toujours des connexions de terre (PE) par le biais des

bornes (PE2) et du chassis (PE1). Le courant de dispersion vers la

terre est supérieur à 3,5 mA. Selon EN 50178 il faut prévoir dans

ces cas une double connexion à terre.

8. The electrical commissioning should only be carried out by qualified personnel, who are also responsible for a suitable ground

connection. The power supply feeder must be in accordance with

the local and national regulations. The motor must be protected

against overloads.

La mise en service électrique doit être effectuée par un personnel

qualifié. Ce dernier est responsable de l’existence d’une connexion

de terre adéquate et d’une protection des câbles d’alimentation

selon les prescriptions locales et nationales. Le moteur doit être

protégé contre la surcharge

9. No dielectric tests should be carried out on parts of the drive. A

suitable measuring instrument (internal resistance of at least 10

kΩ/V) should be used for measuring the signal voltages.

Il ne faut pas éxécuter de tests de rigidité diélectrique sur des

parties du convertisseurs. Pour mesurer les tensions, des signaux,

il faut utiliser des instruments de mesure appropriés (résistance

interne minimale 10 kΩ/V).

10. If the drives have been stored for longer than three years, the

operation of the DC link capacitors may be impaired. Therefore,

before commissioning, connect them to a power supply for two

hours with no load connected in order to regenerate the capacitors

(the input voltage has to be applied without enabling the drive).

En cas de stockage des convertisseurs pendant plus de trois ans, il

faut tenir compte du fait que les condensateurs du circuit

intermédiaire gardent leurs caractéristiques d’origine seulement s’ils

sont alimentés avant trois ans, à partir de leur date de fabrication.

Avant la mise en service des appareils, qui sont restés stockés aussi

longtemps, il est conseillé d’alimenter les convertisseurs pendant

au moins deux heures, pour récupérer les caractéristiques d’origine

des condensateurs : appliquer une tension d’entrée sans activer le

convertisseur (Disable).

11. The drive may start accidentally because of a failure, even if

disabled, unless it has been disconnected from the AC input feeder.

L’appaeil peut rédémarrer de façon accidentel en cas d’anomalie,

sauf s’il a été déconnecté du reseau.

6

Page 7

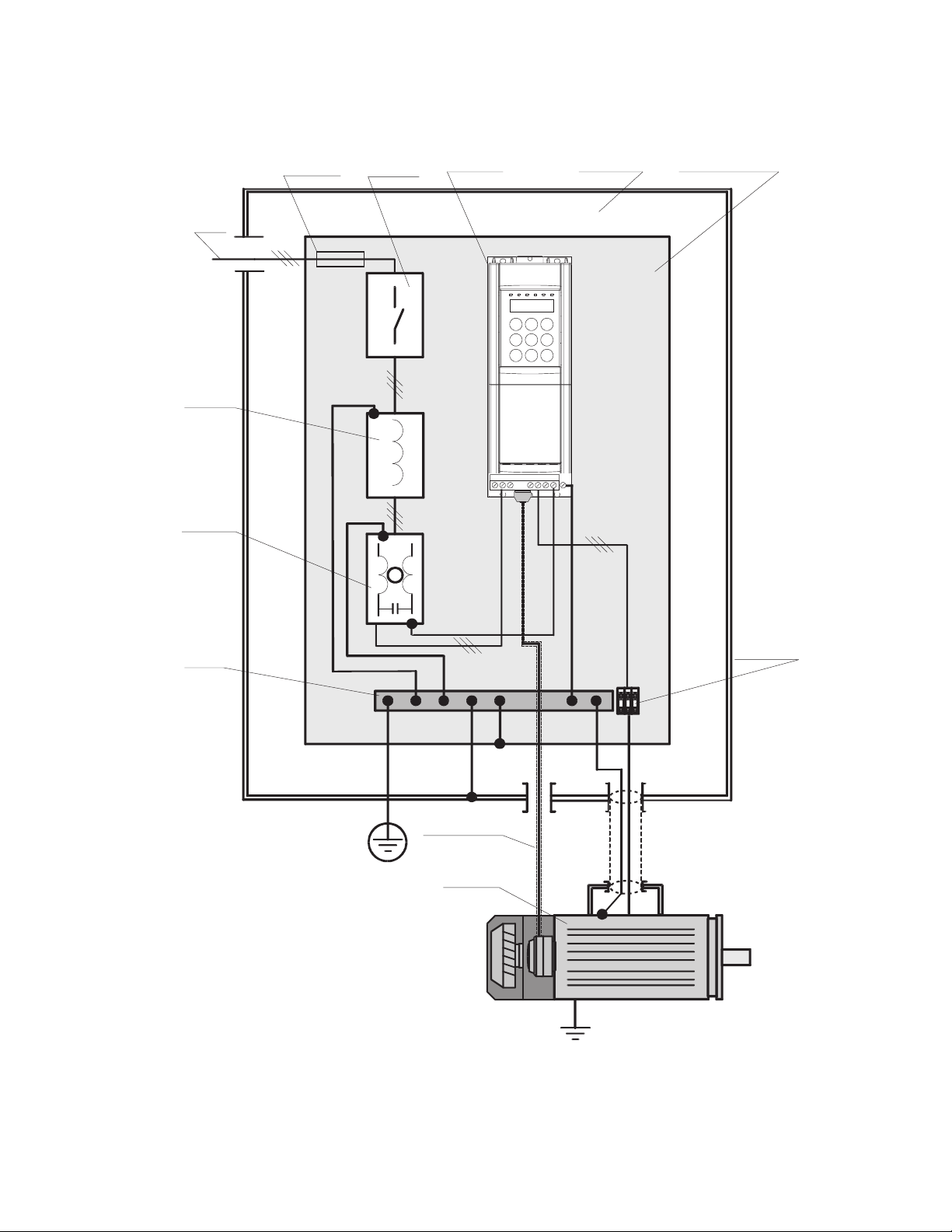

Functional connection diagram

AC

Power

Supply

AC

Line

Reactor

EMI filter

AC fuses

AC Voltage

Contactor

ACDrive

U1V1W1

U2V2W2PE2 PE1

Cabinet

Mounting panel

Ground

Bus

Motor

cable

terminals

Encoder cable

AC Motor

Note:

PE1 is the drive safety ground. If PE2 is used to connect the motor ground, EMC filter ground must connected to PE1.

7

Page 8

2. Overview

This guide assumes a standard start up using the keypad

for a drive and motor that is to be run in either sensorless

vector or flux vector (with digital or sinusoidal encoder)

mode. It is also assumed that a standard scheme is to be

used for control. In other words, that the drive will be run

from pushbuttons (or contacts) and the speed will be set

from a pot input (or a 0 to 10 VDC source). While the drive

has more modes of operation, this guide will cover most

applications. The manual can be used to help adjust more

complicated configurations.

Standard Wiring: see the manual for the standard wiring

configuration. Note that if this is a system designed and

wired by our factory, the set up of the drive (aside from

minor tuning) has already been done.

NOTE:

Memory: There are two memories for set-up parameters.

One is the active memory which is always the one currently

in use by the drive. The other is the permanent memory

which is the one the drive will use if power is lost and then

restored. Note: power up is the ONLY time when the drive

looks at permanent memory. All file uploads and

downloads, all changes, etc. are made only to the active

memory and read from the active memory. The only time

permanent memory is used in any way is when it is booted

into active memory on power up, and when it is changed

to new values by the “Save Parameters” command. When

parameters are changed during set-up, the drive will use

those parameters but unless the “SAVE

PARAMETERS”command is used these changes will not

be permanent. This is an advantage if you are “trying”

something to see how it works and don’t intend to change

your permanent set-up.

Underline: When words are underlined, they refer to a

key on the keypad.

Quotes: Quote marks are put around words which will be

seen in the display window of the keypad.

Menu Navigation: In the instructions, you will be directed

to press keys to get to certain menu items. In many cases,

the same key will have to be pressed more than once to

get to a value. Note that the display has two lines, the top

line always shows the next HIGHER level of the menu. All

of the menu items referred to in this start up will be shown

in the SECOND LINE of the display. The display on the top

line is for information only and has nothing to do with

entering data. If the instructions say to press the

arrow] to “Regulation Mode” it means keep pushing the

[Down arrow] until the “Regulation Mode” is displayed in

the second line. If you get confused, refer to the manual

as it shows the complete menu structure.

I/O Connections: the drive WILL NOT OPERATE unless

the hardware enable (I/O terminal 12) and the other

interlocks are made. It is suggested to make things simple,

to temporarily connect the terminal board inputs as follows:

Jumper 16 to 18, jumper 19 to 15, jumper 15 to 14, jumper

12 to 13, and connect a simple switch between 13 and 14.

Turning the switch on and off will now enable and disable

the drive (and start and stop it at the same time). If you

have control over the I/O with the connected logic and

can make the same connections with pushbuttons/

contacts, the drive can be enabled with those.

[Down

8

Page 9

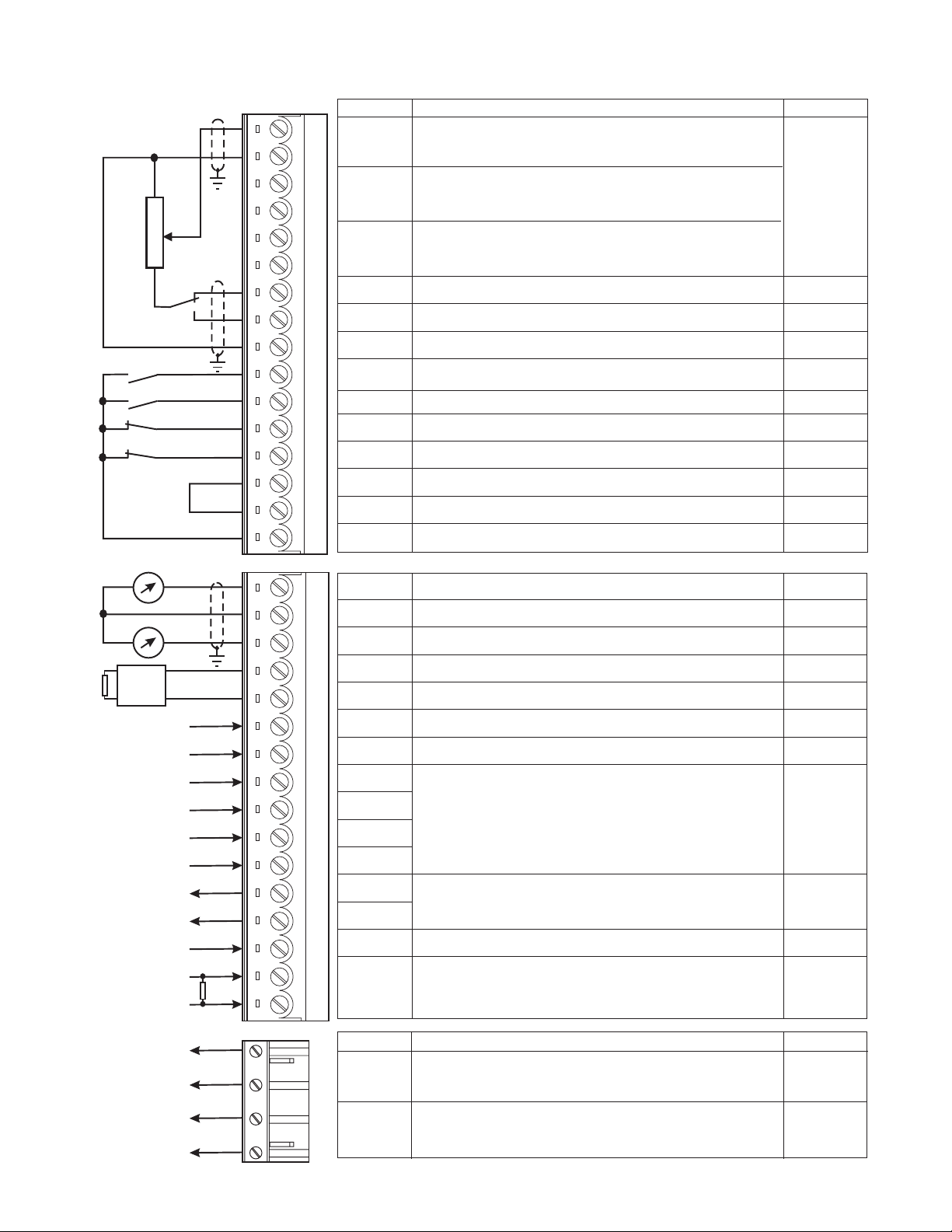

3. Control Terminals

1

2

3

4

5

6

7

8

9

12

13

14

15

16

18

19

Strip X1

Analog input 1

Analog input 2

Analog input 3

+10VDC

-10VDC

0V

Enable drive

Start

Fast stop

External fault

COMD I/O

0V24

+24VDC

F unction

Programmable / configurable analog differential input. Signal: terminal 1.

Reference point: terminal 2. Default setting: Ramp ref 1

Programmable / configurable analog differential input. Signal: terminal 3. @ 0.25mA

Reference point: terminal 4. Default setting: none (20 mA when

Programmable / configurable analog differential input. Signal: terminal 5.

Reference point: terminal 6. Default setting: none. (1)

Reference voltage +10V; Reference point: terminal 9 +10V/10 mA

Reference voltage -10V ; Reference point: terminal 9 -10V/10 mA

Internal 0V and reference point for ± 10V -

Drive enable: 0V or open; drive disabled; +15…+30V: Drive enabled

Drive start command: 0V or open: No start; +15…+30V: Start 3.2 mA@15V

OV or open: Fast stop. +15…+30V; No Fast stop.

OV or open: External fault. +15…+30V; No External fault

Reference point for digital inputs and outputs, term.12...15, 36...39, 41...42

Reference point for +24V OUT supply, terminal 19 -

+24V supply output. Reference points: terminals 18 or 27 or 28

max

±10V

current ref

input)

+30V

5 mA@24V

6.4 mA@30V

-

+22…28V

120 mA@24V

BU-

External braking

unit (optional)

R1K

Analog output

21

22

23

26

27

28

29

36

37

38

39

41

42

46

78

1

0V

Analog output

2

BU comm.

output

0V24

RESERVED -

RESERVED

Digital input1 +30V

Digital input2 3.2 mA@15V

Digital input3 5 mA@24V

Digital input4 6.4 mA@30V

Digital output

1

Digitaloutput

2

Supply DO

Motor PTC

Program. analog output; def. setting: Motor speed. Ref. point: term. 22

Internal 0V and reference point for terminals 21 and 23

Program. analog output; def. setting: Motor current. Ref. point: term. 22

VeCon controlled BU-... braking units command. Ref. point: term. 27.

Reference point for BU-...command ,terminal 26

Programmable digital input; default setting: none

Programmable digital output; default setting: none

Supply input for digital outputs on terminals 41/42. Ref. point: term.16.

Motor PTC sensing for overtemperature (cutoff R1k if used)

79

±10V/5 mA

-

±10V/5 mA

+28V/15 mA

-

+30V/40 mA

+30V/80 mA

1.5mA

80

82

83

85

Strip X2

OK relay

contact

R elay 2

contact

F unction max curr.

Potential-relay contact OK relay (closed=OK)

Potential-relay contact configurable (relay2).

Default: open 0 drive stopped

250VAC

1A, AC11

250VAC

1A, AC11

9

Page 10

3.1 Maximum cable cross section for regulator terminals

Maximum Permissible Cable Cross-Section Tightening

Terminals

[mm

2

]

AWG

flexible multi-core [Nm]

1...79 0.14...1.5 0.14...1.5 28...16 0.4

80...85 0.14...1.5 0.14...1.5 28...16 0.4

NOTE:

Terminal board points are intended for 1 wire/point.

Daisy chains and multiple wires/point are better done with a panel mounted terminal board.

4. power terminals

3Ph~

Braking resistor (optional)

U1/L1

V1/L2

W1/L3

BR1

C

D

Braking unit resistor command (braking resistor

must be connected between BR1 and C)

DC Bus circuit connection

F unction

AC line voltage

torque

Ai4090

max volts/curr.

480 VAC

+10% 3Ph

See table 2.4.2.1

770 VDC/ 1.65 X

output current

U2/T1

M

V2/T2

W2/T3

PE2/

PE1/

Motor ground connection

Grounding (protective earth) conductor

4.1 Maximum cable cross section for power terminals

Hp 3/4 1 2 3 5 7.5 10 15 20 25 30

U1, V1, W1, U2, V2, W2, C, D

terminals

Tightening torque

PE1, PE2 terminals

Tightening torque

Hp 40 50 60 75 100 125 150 200

U1, V1, W1, U2, V2, W2 ,C ,D

terminals

Tightening torque

PE1, PE2 terminals

Tightening torque

AWG

[mm2]

[Nm]

AWG

[mm2]

[Nm]

AWG

[mm2]

[Nm]

AWG

[mm2]

[Nm]

3

14

2

0.5 to 0.6

14

2

2

35

6

16

1/0 2/0 4/0 300* 350* 4xA WG2 *=kcmils

50 70 95 150 185 4x35

4 12 10-30

Motor connection

12 8 4

4

12 8 6

4

10

4

2

50

AC line volt 3Ph

1.36 X output

current

8 101625

1.2x1.5

8 101616

1.2x1.50.5 to 0.6

610

23

6

23

ai4040

10

Page 11

5. Encoder terminals (XE connector)

Designation Function I/O max.voltage max.current

PIN1

PIN2 -

PIN3

PIN4

PIN5

PIN6

PIN7

PIN8

PIN9

PIN10

PIN11

PIN12

PIN13

PIN15 I

Channel B - 5V digital or 10 mA digitalor

For B- digital or B-COS incremental signal 1V pp analog 8.3 mA analog

Channel C+ 5V digital or 10 mA digital or

For C+ digital or analog zero pulse or index 1V pp analog 8.3 mA analog

Channel C- 5V digital or 10 mA digital or

For C-digital or analog zero pulse or index 1V pp analog 8.3 mA analog

Channel A+ 5V digital or 10 mA digital or

For A+ digital or A+SIN incremental signal 1V pp analog 8.3 mA analog

Channel A - 5V digital or 10 mA digital or

For A+ digital or A+SIN incremental signal 1V pp analog 8.3 mA analog

Reference point for +5V encoder supply voltage

Channel B+ 5V digital or 10 mA digital or

For B+ digital or B+COS incremental signal 1V pp analog 8.3 mA analog

+5V encoder supply voltage

Channel E+ 5V digital or 10 mA digital or

For E+ digital commutation or SIN+ absolute position signal 1V pp analog 8.3 mA analog

Channel E- 5V digital or 10 mA digital or

For E- digital commutation or SIN- absolute position signal 1V pp analog 8.3 mA analog

Channel F+ 5V digital or 10 mA digital or

For F+ digital commutation or COS+ absolute position signal 1V pp analog 8.3 mA analog

Channel F- 5V digital or 10 mA digital or

For F- digital commutation or COS- absolute position signal 1V pp analog 8.3 mA analog

Channel G+ 5V digital or

For G+ digital commutation signal 1V pp analog

Channel G- 5V digital or

For G- digital commutation signal 1V pp analog

I

I

I

I

I

O

I

O

I

I

I

I

I

––

+5V 200 mA

10 mA digitalPIN14

10 mA digital

ai3140

5.1 Encoder type connection

XEC ONNECTORPIN

ai3160

Encoder type

DE 8 pole

SE 8 pole

SESC 12 pole

DEHS 14 pole

Shielded

cable

123456789101112131415

B- C+ C- A+ A- 0V B+ +5V E+ E - F+ F- G+ G -

• •••••••

• •••••••

• •••••••••••

• •••••••••••••

- DE: 5V digital incremental encoder with A /A, B / B, C / C

- SE: 5V sinusoidal incremental encoder with A /A, B / B, C / C

- DEHS: 5V digital incremental encoder with A /A, B / B, C / C and three Hall sensor digital position signals

(for AC Brushless motors)

- SESC: 5V sinusoidal incremental encoder with A /A, B / B, C / C and and two sin/cos traces for absolute

position (for AC Brushless motors or positioning)

11

Page 12

5.2 JUMPERS setting

Encoder/Jumpers setting S11 S12 S13 S14 S15 S16 S17 S18 S19 S20 S21 S22 S23

DE OFF OFF OFF OFF OFF OFF ON(*)

SE ON ON ON ON ON ON

SESC ON ON ON ON ON ON

DEHS OFF OFF OFF OFF OFF OFF ON(*) BBBBBB

----

- ----

AAAAAA

-

-BB

ai3150

- DE: 5V digital incremental encoder with A /A, B / B, C / C

- SE: 5V sinusoidal incremental encoder with A /A, B / B, C / C

- DEHS: 5V digital incremental encoder with A /A, B / B, C / C and three Hall sensor digital position signals (for AC

Brushless motors)

- SESC: 5V sinusoidal incremental encoder with A /A, B / B, C / C and and two sin/cos traces for absolute position

(for AC Brushless motors or positioning)

(*) If the encoder is not provided with the zero channel, S17=OFF

List of jumpers and dip-switch

Designation Function Factory setting

S0 The setting must not be changed OFF

S1 The setting must not be changed OFF

S5-S6 Terminating resistor for the serial interface RS485 ON

ON=Termination resistor IN

OFF=Noterminationresistor

S8

S9

S10

S11-S12-S13 Encodersetting OFF

S14-S15-S16 ON= Sinusoidal SE or SESC encoder (see above)

S17 Monitoring of the C-channel of the digital encoder OFF

S18-S19 Encodersetting B

S20-S21 Pos.A=digital DEHS encoder (see above)

S22-S23 Analog input 3 enabling (alternative with SESC encoder) A

S24 Jumper to disconnect 0V (of 24V) from ground ON

S25 Jumper to disconnect 0V (regulation section) from ground ON

Adaptation of the input signal of analog input 1 (terminals 1 and 2)

ON=0...20mA/4...20mA

OFF=0...10V/-10...+10V

Adaptation of the input signal of analog input 2 (terminals 3 and 4)

ON=0...20mA/4...20mA

OFF=0...10V/-10...+10V

Adaptation of the input signal of analog input 3 (terminals 5 and 6)

ON=0...20mA/4...20mA

OFF=0...10V/-10...+10V

OFF=Digital DE or DEHS encoder (see above)

ON=C-Channel monitored

OFF=C-Channel not monitored (required for single-ended channels)

Pos.B=sinusoidalSESCencoder (see above)

Pos.A=enabled

Pos.B=disabled

ON=0V connected to ground

OFF=0V disconnected from ground

ON=0V connected to ground

OFF=0V disconnected from ground

OFF

OFF

OFF

ai4060

12

Page 13

List of dip-switch S3

Hp 3/4 1 2 3 5 7.5 10 15 20

S1

S2

S3

S4

S5

S6

S7

S8

Hp 25 30 40 50 60 75 100 125 150 200

S1

S2

S3

S4

S5

S6

S7

S8

ON OFF ON OFF OFF ON OFF ON OFF

OFF ON ON OFF OFF OFF ON ON OFF

OFF OFF OFF OFF ON OFF OFF OFF ON

OFF OFF OFF OFF OFF OFF OFF OFF OFF

ON ON ON OFF ON OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF OFF

ON OFF ON OFF ON OFF ON OFF ON OFF

OFF ON ON OFF OFF ON ON OFF OFF ON

ON ON ON OFF OFF OFF OFF ON ON ON

OFF OFF OFF ON ON ON ON ON ON ON

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

ai4080

The drives are factory set, but when installing a space regulator card, remember to set dip-switch S3 according to the

above table.

5.3 Maximum cable length for encoder terminals

Cable section [mm2]

Max Length feet [m] 88 [27] 203 [62] 305 [93] 410 [125] 492 [150]

0.22 0.5 0.75 1 1.5

ai3130

13

Page 14

6. Keypad operation

The keypad is made of a LCD display with two 16-digit lines, seven LEDs and nine function keys.

Keypad LED Module

-Torque +Torque Alarm Enable Zero Speed Limit

Jog

Speed

Drive Controls

Help

Escape

Navigation

Alarm

Home

Enter

Shift

-Torque +Torque Alarm Enable Zero Speed Limit

-Torque Negative torque current

+T orque Positive

Alarm Alarm condition

Enable Drive enable status

Zero Speed Speed<=zero speed threshold

Limit Actual current >=current limit

This monitoring module can be upgraded with the keypad with

alphanumeric LCD display

torque current

Keypad is used :

- To control the drive, when keypad use has been programmed (Main commands=DIGITAL.)

- To display the speed, voltage, diagnostics etc. during operation.

- To set parameters.

LEDs

The LEDs present on the keypad and LED module are used to quickly diagnose the operating state of the drive.

Designation Color Function

-Torque yellow the LED is lit, when the drive operates with a negative torque

+Torque yellow the LED is lit, when the drive operates with a positive torque

ALARM red the LED is lit; it signals a trip

ENABLE green the LED is lit, when the drive is enabled

Zero speed yellow the LED is lit; it signals zero speed

Limit yellow the LED is lit, when the drive operates at a current limit

Shift yellow the LED is lit, when the second keypad functions are enabled

ai5010

14

Page 15

Keypad buttons

Text reference

[START]

[STOP]

Function

START button controls the Enable and Run modes of the

drive if Main commands = DIGITAL and the Stop Mode is

on. This is the default setting.

When Main commands is set as TERMINALS the button is

not active

STOP button sets the main reference to zero when Main

commands is set as DIGITAL

(Pressing this button for 2 sec will cause the drive to be

disabled, this will also cause the drive to coast stop).

When Main commands is set as TERMINALS the button is

not active.

Jog

Help

Alarm

[Increase] / [Jog]

[Decrease] / [Rotation control]

[Down arrow] / [Help]

[Up arrow] / [Alarm]

Plus button increases the speed reference for the Motor

pot function.

It is also the JOG command, when the shift button is

selected.

Minus button decreases the speed reference for the Motor

pot function.

Rotation control changes the direction in Jog mode and

Motor pot mode when the shift button is selected.

Down arrow - Used to change menu or parameter

selection. In parameter and reference setting modes, it

changes the value of the parameter or reference.

Help – Function Not available (“Help not found” displayed

when pressed with the shift button)

Up arrow - Used to change menu or parameter selection.

In parameter and reference setting modes, it changes the

value of the parameter or the reference.

Alarm - Failure register displayed ( shift selected). Use the

UP/DOWN Arrows to scroll through the last 10 alarms.

Escape

Home

Enter

Shift

[Left arrow] / [Escape]

[Enter] / [Home]

[Shift]

Left arrow-in edit mode selects the digit of the parameter

to modify. At other times it is used to exit from the setting

mode.

Escape - Used to exit from setting and Alarm displaying

mode (when shift button is pressed)

[Enter] - Used to [Enter] a new value for a parameter in the

parameter setting mode.

Home - Used to go directly to BASIC MENU (when shift

button is pressed)

Shift button enables the second keypad functions

(Rotation control, Jog, Help, Alarm, Escape, Home)

15

Page 16

Moving inside a menu

16

Page 17

7. Pre Power Checks

The following should be checked before switching ON the Drive:

Grounds / Grounding

• Verify ground connections between the drive and motor

• Verify AC Input, AC Output and control wiring aren’t grounded

Connections

• Verify AC Input (U1/L1, V1/L2, W1/L3), AC Output (U2/T1, V2/T2, W2/T3), DC link connection (C,D), Motor thermistor

(78, 79), OK Relay (80, 82), Relay 2 (83,85) and regulation board points (1.....46, XS, XE) connections.

Regulator Terminal Board Inputs:

12 ENABLE DRIVE (close to activate)

13 START (close to activate)

14 FAST STOP (open to cause a stop)

15 EXTERNAL FAULT (open to cause a stop)

16 Common for terminal board inputs

18 + 24V Common

19 +24VDC (internal power supply)

Set inputs on the regulator terminal board as follows:

• Enable drive (terminal 12) and Start (terminal 13) OPEN

• Fast stop (terminal 14) and External fault (terminal 15) CLOSED

• Record motor name plate data, encoder information, gearbox data.

MOTOR DATA

17

Page 18

8. Quick tuning

1. After a complete check of wiring, turn the power on:

• The following voltages must be present:

Terminal 7, +10V to terminal 9 (on regulation board)

Terminal 8, -10V to terminal 9 (on regulation board)

Terminal 19, +24…30V to terminal 18 (on regulation

board)

• Check DC link voltage by pressing

get “Monitor”, then

to“measurements”, then

to “DC link voltage”, then

The value should be:

275-357 VDC for 230 VAC input

480-650 VDC for 400 VAC input

550-715 VDC for 460 VAC input

If the DC Bus is not within these limits, check the AC

line voltage.

2. Default to Factory Values: If you are not certain of the

drive configuration, it will be necessary to default to factory

values or copy in a file from a PC. It is important to be

certain you are starting from a known configuration. To

default to factory values:

• Default to working memory: Push

get back to “Monitor”, then

Functions” and then

“Load Default” and

now be loaded into the working memory, the original

values are still in permanent memory.

Note:

Step 2 can be skipped if you know that the drive is loaded

with factory defaults (as it comes out of the shipping

carton).

3. Set Line Voltage:

• Press

4. Adaption to maximum ambient temperature:

• Press

5. Load Default Motor Values:

• Press

[Left arrow] to “Spec functions” then [Up

arrow] to “BASIC MENU”, then [Enter], then [Down

arrow] to “Drive type”, then [Enter] to “Mains voltage”

[Enter]. Now using the [Up arrow] / [Down

and

arrow] keys, change the voltage to your nominal AC

input rating. Then

[Down arrow] to “Ambient temp” then [Enter].

Now using the

the maximum ambient temperature value: 40°C or

50°C, then

and then

[Enter], then [Down arrow] to Motor Parameter,

[Enter], then [Down arrow] to “Load Motor Par” and

[Enter]. Use the [Up arrow]/[Down arrow] keys until

[Enter].

[Left arrow] until you are back to “BASIC MENU”

[Down arrow] to Drive Parameter, then

[Enter], then [Down arrow]

[Enter], then [Down arrow]

[Enter].

[Down arrow] to “Spec

[Enter]. Push [Down arrow] to

[Enter]. The factory values will

[Enter] to set the value.

[Up arrow] / [Down arrow] keys, set

[Down arrow] to

[Left arrow] to

the display is the correct motor voltage, then

For 460 VAC motors, select 460, and for 380/400 VAC

motors select 400.

6. Set Actual Motor Data:

• Press

then

“Nominal Voltage” then

Using the

the value and the

position. When correct press

• Press

use the

nominal speed on the motor nameplate. Press

to set data. Note, some manufacturers of vector

motors put the synchronous speed (600, 900, 1500,

1800, 3600 RPM), rather than the slip speed at 60 Hz

on the nameplate. If this is done, you MUST estimate

slip speed. Figure 20 rpm less than the synchronous

speed for these cases.

• Press

and set to the nominal frequency on the nameplate

(50 or 60 Hz) Press

• Press

and set to the nominal current on the nameplate (rated

current) by using the

Press

If the drive will “not accept” the value entered, the

most common cause is trying to

“Nominal Current” that is less than 30% of the drive

rating. This is not allowed due to parameter problems

encountered with a small motor and a large drive. Go

back to step 6 and repeat the entries. If this doesn’t

work, see the Overflow List in the troubleshooting

section of this book.

• Press

the nominal power factor on the nameplate by using

the

default if you don’t know). Press

Press

and set the base voltage by using the

[Down arrow] keys (usually rated voltage). Press

[Enter] to set data. Look in the manual for both Base

Voltage and Base Frequency when operating the motor

above normal synchronous speed.

• Press

set to the base frequency by using the

[Down arrow] keys (usually rated frequency). Press

[Enter] to set data.

• Press

and set all the motor parameters. If, when you do

this, a message saying “Over-range error XXX”

appears, there is something wrong with the data

you have entered. The drive has NOT ACCEPTED

the values you have entered. The most common cause

[Enter].

[Left arrow] until back to “Drive parameter”,

[Enter] to get “Mot plate data” and [Enter] to

[Enter] again to see the value.

[Up arrow]/[Down arrow] keys to change

[Left arrow] to move the character

[Enter].

[Down arrow] to “Nominal speed”, [Enter], then

[Up arrow] / [Down arrow] keys to get the

[Enter]

[Down arrow] to “Nom frequency” and [Enter]

[Enter] to set data.

[Down arrow] to “Nominal current” and [Enter]

[Up arrow] / [Down arrow] keys.

[Enter] to set data.

[Enter] a value for

[Down arrow] to “Cos phi” and [Enter] and set

[Up arrow] / [Down arrow] keys (accept the

[Enter] to set data.

[Down arrow] to “Base Voltage” and [Enter]

[Up arrow] /

[Down arrow] to “Base Frequency” and [Enter],

[Up arrow] /

[Down arrow] to “Take motor par” and [Enter]

18

Page 19

of this is trying to

that is less than 30% of the drive rating. This is not

allowed due to problems encountered with a small

motor and a large drive. Try to go back to the

beginning of step 6 and repeat the entries. If this

doesn’t work, see Overflow list in troubleshooting

section or contact your service office.

7. Set Drive Base Values:

• Press

• Press

• Press

8. Set Regulation Mode: (Sensorless vect, V/f or Field

• Press

• If “Field oriented” mode is selected:

• Press

• Press

• Press

9. Speed Limit:

• Press

10. Prepare for Self Tune:

• The keypad will be used for this purpose but the

[Left arrow] until back to “drive parameter” then

[Down arrow] to “configuration”, then [Enter].

[Down arrow] to “Speed Base Value” then

[Enter] and set the nameplate rated full load speed

on the motor nameplate, press

speed related calibrations on top motor speed.

[Down arrow] to “full load current” then [Enter]

and set the DRIVE (not motor) rated full load current

on the drive nameplate by using the

[Down arrow] keys, then press [Enter] to set. This

bases all current related calibraitons on motor “Full

Load Amps” (FLA).

oriented mode )

[Up arrow] to “Regulation mode”, then [Enter]

and use

“V/f”, “sensorless vect” or “Field oriented” then

[Enter].

press

[Enter]. Use the [Up arrow]/[Down arrow] keys to

select sinusoidal encoder or digital encoder, then

[Enter].

[Enter] and set the value using the [Up arrow]/[Down

arrow] keys to the PPR (pulses per revolution) of your

encoder,

then

fdbk Loss Alarm.

arrow] to “Limits”, then [Enter] for “Speed Limits”,

then

“Speed Min Amount”. Press

Max Amount”, and

5000 RPM to the maximum speed of the motor use

the

set it to 105% of the rated motor speed). Press

[Enter].

I/O needs to be connected properly to the enable/

disable functions.

[Up arrow] / [Down arrow] keys to select

[Down arrow] until to “Motor spd fbk”, then

[Enter], [Down arrow] to “Encoder 1 type”, then

[Down arrow] to “Encoder 1 pulses”, then

[Enter].

[Down arrow] four times to “Refresh Enc 1”

[Enter], “Enable” [Enter], this enables the Speed

[Left arrow] until “Basic Menu”, then [Down

[Enter] for “Speed Amount”, then [Enter] to

[Up arrow]/[Down arrow] keys as before (for now

[Enter] a value for “Nominal Current

[Enter]. This bases all

[Up arrow] /

[Down arrow] to “Speed

[Enter]. Change the value from

11. Save Parameters:

• Press

“Basic Menu” then

“save parameters”, then

The display will read “wait” until the values are

permanently stored.

12. Self Tune:

Make sure power is on and drive not enabled.

Close the switch on terminal 12 (hardware enable has

24 Vdc on it).

• When the enable switch is made, Press

until “Basic Menu” then

Parameter”, then

“motor parameters” and

arrow] to “Self Tuning” and [Enter] to “self tune 1”.

Press

1 ?” and

“enable” led illuminated, if not, make sure that you

have the jumpers (or external switches) set so that 24

VDC exists on terminal boards 12, 13, 14, 15, with

respect to 16 or 18.

• You should now see “measuring Rs” (stator

resistance). Wait until the display says “end”, then

disable the drive (open the switch to 12) and push

[Left arrow] twice to see “self tune 1”, press [Enter],

then

and

values are stored. The motor shaft must not move

during the procedure. If necessary, the motor shaft

must be locked.

NOTE:

“xxx range error” or “timeout” messages may also occur in

some extreme parameter ranges. Repeat the tune in this

case. If error messages are persistent see troubleshooting

section.

13. Self Tune part 2:

The initial part of self tuning that can be done without

the motor rotating has been accomplished. Now, to

get the best possible tuning, the motor needs to turn

with no load attached to the shaft. For this we use

Self tune mode 2a. If, for any reason, the motor cannot

be made to rotate with no load, then a “close” level of

tuning can still be accomplished by selecting Self tune

mode 2b.

• Now press

[Down arrow] to “self tune 2a or 2b and press [Enter].

Enable the drive using the switch to terminal 12. Press

[Enter], “start part 2a ?” or “start part 2b ?” then

[Enter] and see “measure sat 2a (or b)” will appear

and the motor shaft will turn (if “self tune 2a” is select).

Wait until the display says “end”, press

to see “self tune 2a (or b)” then

[Down arrow] to see “take val part 2a (or b)”. Disable

the drive (switch off terminal 12), then

[Left arrow] to “limits”, then [Up arrow] until

[Enter], then [Down arrow] to

[Enter].

[Left arrow]

[Down arrow] to “Drive

[Enter], then [Down arrow] to

[Enter]. Press “[Down

[Enter] to “start part 1” and [Enter], “start part

[Enter] again. The keypad should show the

[Down arrow] all the way to “take val part 1”

[Enter]. The display will read “wait” until the

[Left arrow] to see “self tune 1” then

[Left arrow]

[Enter] and press

[Enter].

19

Page 20

NOTE:

“xxx range error” or “timeout” messages may also occur in

some extreme parameter ranges. Repeat the tune in this

case. If error messages are persistent see troubleshooting

section.

If there was some reason you did not want to keep these

values permanently, but only wanted to try to run the drive

with them, there is no need to save them to permanent

memory. If power is cycled however, these values will be

lost unless the “Save Parameter” function is used.

14. Self tune part 3:

The third part of self tuning (Speed regulator tuning)

identifies the total inertia at the motor shaft, the friction

value and computes the proportional and integral gains

of the speed regulator. The motor needs to be free to

turn with load attached to the shaft.

NOTE:

When regulation mode = field-oriented, the encoder needs

to be verified before running Self Tune 3. Refer to page 22

“Encoder Verification”. After this verification procedure, put

the regulation mode back to field oriented.

WARNING !

This procedure requires free rotation of the motor shaft

coupled to the load. The Start/Stop command is

ignored, therefore it can not be used on drives with

limited travel, or when free rotation presen ts a safety

problem.

CAUTION !

The test is performed using the torque limit value set

in Test T curr lim parameter. The torque is applied in a

step fashion, with no ramp profile. Therefore, the

mechanical transmission must not have significant

backlash, and it must be compatible with operation at

the torque limit set in the Test T curr lim parameter.

The user can reduce the torque limit to a suitable value

via the Test T curr lim parameter.

Note !

• Application where the system inertia coupled to the

motor shaft is much higher than the motor inertia value

, increase the Test T curr lim parameter to avoid “Time

out” error.

• This procedure is not suitable for use with “hoist”

or “elevator” drives.

• Encoder feedback is required when Field oriented mode

is selected.

• Set the current limit (BASIC MENU\ T Current lim +/-)

to a value compatible with the motor size and load.

(Example when motor is 1/3 of the Drive power, the

limit should be reduced compared to the default value).

• Select the torque current value to be used during the

test via the Test T curr lim parameter

• Now press

then

to Fwd-Rev spd tune, then

direction for this test: Forward or Reverse by using

[Up arrow] / [Down arrow] keys. Press [Enter] to

set the selection.

• Enable the drive using a switch on terminal 12 [and

close terminal 13 to terminal 19 if Speed control

function is enabled (default)]. Press

to “Start part 3” then press

then

the motor will turn. Wait until the display says “end”,

press

and press

Disable the drive, then

with the initial set up and tuning with values stored in

only in the “working memory”.

NOTE:

“xxx range error” or “timeout” messages may also occur

in some extreme parameter ranges. Repeat the tune in

this case. If error messages are persistent see

troubleshooting section.

NOTE:

If there was some reason you did not want to keep these

values permanently, but only wanted to try to run the drive

with them, there is no need to save to permanent memory.

If power is cycled however, these values will be lost unless

the next step is taken.

To save all values to permanent memory, select Save

parameters and press

15.Set up for Running:

First, before saving, let’s put the drive into the

configuration you want to run it in.

The drive is factory setting to run through the Increase

[+] and Decrease [-] keys (Enable motor pot

parameter = Enabled), see the following instruction to

run.

[Left arrow] to see “self tune 2a or 2b”

[Down arrow] to “self tune 3” and press [Enter]

[Enter]. Set the motor shaft

[Down arrow]

[Enter], “start part 3 ?”

[Enter] and see “measure speed” will appear and

[Left arrow] to see “self tune 3” then [Enter]

[Down arrow] to see “take val part 3”.

[Enter]. You are now finished

[Enter] .

20

Page 21

Control buttons

Sequencing

Press START button to command the Drive to the Enable and

Run state

Press STOP button commands to stop the Drive from the

Run state

Display

Jog

Press to display the current reference value and to increase

the reference value and accelerate the drive.

Press to decrease the reference value and decelerate the drive.

Press SHIFT and [-] to change the motor shaft rotation

Shift

8.1 Motor Potentiometer function

Note!

(Main commands = DIGITAL)

Enable drive, terminal 12 connected to 24VDC

Start, terminal 13 connected to 24VDC

Resetting the speed reference value using Mot pot

function

• Press

• Press

[STOP] button to stop the motor

[Left arrow] until to “Basic menu”, then [Down

arrow] to “Functions”. [Enter] to motor pot, then

[Enter] to “enab motor pot”, press [Down arrow] to

motor pot reset, then

[Enter].

The diplay will read “ready” until the reference value

is set to zero.

Set the motor pot to “disable” (Enable motor pot

parameter = Disable) if you will want to use an analog

voltage on terminal 1 for speed reference.

Jog function

Note!

This function is enabled as a default setting (Enable jog

parameter = Enabled). Speed reference value = 100 rpm.

(Main commands = DIGITAL)

Enable drive, terminal 12 connected to to 24 VDC

Start, terminal 13 conected to to 24 VDC

Press

Press

Press

Press

Changing jog reference

Press

arrow] until “Jog reference”, [Enter], using the [Up arrow]/

[Down arrow] keys to change the value and the [Left

arrow] to move the character position, set the reference

value, then

If there are other changes you might want to make to set

up (see Options), do them now, and complete the following

step to put everything into permanent memory.

Saving all values to Permanent Memory:

• Press [Left arrow] back to “Configuration” then [Up

arrow] to “basic menu” and [Enter]. Press [Down

arrow] to “save parameters” and [Enter]. Parameters

are now stored permanently.

Motor pot oper.

+0 [rpm] POS

Motor pot oper.

-0 [rpm] NEG

[SHIFT and [+] to run, the speed will be displayed

[-] to select the motor shaft rotation

[jog] to run the other direction

[Left arrow] to exit from jog operation

[Down arrow] until “Functions”, [Enter], then [Down

[Enter].

21

Page 22

9. Options

Encoder verification: Set the Drive in V/f mode and run

the motor, enable and start the drive and set an analog

reference. If the reference is positive on terminal 1 with

respect to 2 (common) the motor should be turning

clockwise. With the motor turning clockwise (looking at

the drive end), monitor the encoder measurement by

selecting “Monitor/measurements/speed/speed in rpm/

Enc 1 speed”. The speed should be positive, not negative.

If it is negative, then A and A- or B and B- should be

interchanged on the encoder. Now return to the “Set Up

for Running” section.

Current Limit: The current limit will have been set to

approximately 136% by default in the previous setup (exact

number is a function of the power factor but the difference

is very small). The value actually set can be verified by

(from “Basic Menu”) pressing down/right arrow to “Limits”,

[Enter], then down/right arrow to “current limits”, then

then

[Enter], then down right arrow to “T current lim” and [Enter].

The value of T current limit can be changed to a higher (or

lower) number. Bear in mind that the ultimate limits are

based on the capacity of the drive, not the motor. T current

is the torque producing component of total current. Settings

in excess of 200% are possible, although the motor may

not be able to handle this current. Current Limit restricts

the magnitude of the torque current reference. The drive

has other alarms and faults to provide motor and drive

current protection.

I/O Configuration: This drive can be configured in several

ways.

The standard drive has three standard analog inputs and

two analog outputs as well as six digital inputs and two

digital outputs. These are assignable and configurable. The

drive is defaulted already to provide the analog outputs

as Actual speed and Torque current. To set up the drive

for two analog outputs (one for speed and one for load)

for metering or other purposes, do the following:

Refer to the “Control terminals” section of this guide

showing a description of the connections to the regulator.

A more detailed description and discussion of the I/O are

shown in the manual. The analog outputs are defaulted to

a scale of 1, which means 10 volts out at the max parameter

value. In other words, if analog output 1 is set to max speed

then max speed will be scaled to 10 VDC (maximum output

voltage available) at “Speed Base Value”. If you wanted 5

volts out at max speed then set the scale to 0.5. If the

output were set to Torque current then 10 VDC would be

rated current. If you wanted the output to be 10 Vdc at

150% of “Full Load Current” then the scale would be 0.66.

The standard factory default is already set up for speed

(with scale factor of 1) on analog output 1 (terminals 21

and 22) and load (Torque current, with scale factor of 1) on

analog output 2 (terminals 23 and 22). Note that terminal

22 is a common for both the outputs. This common can

be grounded, and should be grounded somewhere,

preferably at the load device (meter).

How to disable analog input 1 as ramp reference:

Analog inputs 2 and 3 are defaulted to off, #1 is defaulted

to Ramp ref 1.

• Press

[Enter].

• Press

for Analog input 1, then

[Enter] to display the setting, which will be “Ramp ref

1”.

• Press

displayed, then

How to enable analog input 2 as ramp reference

• Press

press

then

to ”analog input 2. Then

then

Use the

“Ramp ref 1” and

2 (terminals 3 and 4) will be the ramped (accel/decel)

speed reference for the drive.

The manual shows the entire configuration of other

I/O in the drive.

10. Quick Tuning Guide for Factory

Configured (or pre-configured)

Drives

When the drive configuration has already been set and

you are simply fine tuning the drive you can ignore most of

the preceding procedure. It is recommended that you go

through the steps anyway, if the data is suspect. You can

just use the

all the steps in which the entry is found to be correct. Start

with step 4 of the full procedure and do not default the

parameters to factory parameters. If there is any

question about whether the existing setup should be saved

or not, then use the configuration tool software that came

with the drive and save the file to a PC first so it can be

used later.

[Up arrow]/[Down arrow] to “I/O Config”, then

[Down arrow] to “Analog inputs”, then [Enter]

[Enter] to Select input 1, then

[Up arrow] / [Down arrow] keys until “OFF” is

[Enter].

[Up arrow]/[Down arrow] to “I/O Config” and

[Enter], then down right arrow to “analog inputs”

[Enter] for “analog input 1” then [Down arrow]

[Enter] to “select input 2”;

[Enter] again to see the set up. It says “OFF”.

[Up arrow] / [Down arrow] keys to display

[Enter]. This means the analog input

[Left arrow] key rather than the [Enter] key in

22

Page 23

11. Troubleshooting

Overflow list

CODE CAUSES

10 ; 54 The ratio between the Encoder 1 pulses[416] and the number of motor pole pairs must be

higher than 128

3 ; 4 The Stator resistance [436] value is too high. The motor is not compatible with the drive

size used.

5 ; 8 ; 9 ; 15 The Leakage inductance [437] value is too high. The motor is not compatible with the drive

size used.

16 ; 24 The Rotor resistance [166] value is too high. The motor is not compatible with the drive

size used.

17 The Nominal voltage [161] and Nom frequency [163] values produce motor nominal flux

that is too high.

- The Nominal voltage value is too high and/or the Nom Frequency value is too small.

18 The Base voltage [167] and Base frequency [168] values produce motor nominal flux

that is too high.

- The Base voltage value is too high and/or the Base frequency value is too small

23 The ratio between nominal flux (Nominal voltage, Nom frequency) and working flux (Base voltage,

base frequency) is too high.

- Verify the above parameters value.

The Magnetizing current [165] value is too high.

- Verify that this value is lower than Full load curr.

27 The Base voltage value is too high. The maximum value is 500 VAC.

28 The Base frequency value is too high. This value must be lower than 500Hz

59 The Magnetizing working curr [726] is too high.

- Verify that the nominal flux value (Nominal voltage and Nom frequency) is lower than the

working flux value (Base voltage and Base frequency). Check the parameters value.

The Magnetizing current value is too high.

- Verify that this value is lower than Full load curr.

64 The Motor cont curr [656] value, of the motor thermal protection function (menu Ovld mot contr),

produces a continuous current that is too low in comparison to the used inverter size. This error

can also be due to a too low setting of the Nominal current [164] parameter ( ≤ 0.3 x I

66 The Nominal speed [162] value is wrong.

The set value produces too small (or too high) slip value.

2N

).

23

Page 24

List of Self-tuning Error Messages

Generic messages

Description Note

“Drive disabled”: Provide enable input by setting terminal 12 high.

“Not ready”: “Take values part 1”, “Take values part 2a”, “Take values part 2b”or “Take values part 3”

can not be executed because the measurement has not been completed correctly. Repeat

self-tune procedure.

“Time out”: Measurement has not been completed in the proper time.

“Start part…?”: Press [ENTER] to confirm start of measurement.

“Tuning aborted”: Measurement aborted by user ([SHIFT] / [Escape] button has been pressed).

“Set Main cmd=Dig”: Go to CONFIGURATION menu and set Main commands = digital.

“Set Ctrl=Local”: Go to CONFIGURATION menu and set Control mode = Local.

“Reg mode NOK”: Self tune part 3 can only be executed with Regulation mode = Field oriented or Regulation

mode = Sensorless vect. Go to BASIC MENU and set Regulation mode properly.

“Inertia range”: Self-tuning part 3 procedure has found an inertia motor value too low, for this reason it

cannot calculate the speed regulator gains. Try to repeat the self-tune procedure to eliminate

accidental measurement errors.

If this error persist , do not use the “Take val part 3”command. The speed regulator will

probably be stable with the factory gains. It is possible to optimize the speed regulator by

manual tuning .

Measurement error messages

These messages may occour when extreme parameter values have been identified. It may be useful to retry the self

tune command when any of the following messages occur. If the messages persist, alternative manual tuning procedures

should be used.

Description Note

“No break point” Self-tune Part 1 failed. Check the connections between the drive and the motor and repeat

self-tune Part 1.

“Overspeed” Self-tune Part 3 detected a much higher speed than expected. Repeat Self-tune 1 or the

manual tuning that was performed.

“Drive stalled”: Increase value of parameter Test T curr lim and repeat Self tune 3

“Load applied”: Nominal zero load torque at standstill was detected. Self tune 3 is impossible for this type

of load.

“T curr too high”: Reduce value of parameter Test T curr lim for Self tune 3

“Friction null”: Value of friction is zero or lower than the accuracy limit of the control system.

24

Page 25

Failure alarms in the keypad display

Failure alarm Possible causes

BU overload The braking duty cycle is out of the allowed range

Bus loss Failure in the Bus connection (only with interface Bus option card)

Check the Bus connection

EMC compatibility problem, check wiring.

Curr fbk loss Failure in the connection between regulation card and TA transformer.

Check the connection cable on XTA connector.

DSP error Processor program error

Switch off the drive and restart

If unsuccessful there is probably an internal fault. Contact your service office.

Enable seqerr Drive is powered up or RESET* with the ENABLE input connected to 24 VAC (picked up) and

the drive in “terminal mode”. Refer to CONFIGURATION/Main Commands.

External fault External failure, reported on terminal 15

If the "External fault" message is not displayed, the connection is missing between terminals

16 and 18 (reference point) and/or 15 and 19.

If the "External fault" message is displayed:

- The signal on terminal 15 is missing (15 ... 30 V to terminal 16). With an external voltage

supply, commons must be connected together.

Failure supply Fault in the voltage supply; the voltages are below the permitted value

CAUTION: switch off voltage before removing terminal strips.

In most cases the cause is in the external wiring. Pull out the plug-in terminal strips of the

regulator card and enter the Reset command. If no other failures are reported, check your

wiring for a short-circuit, check cable shielding.

If this has not corrected the fault, try to RESET* once more.

If still unsuccessful, the fault is probably internal. Contact your service office.

Heatsink ot (For sizes from 22kW ... and higher). Temperature of the heatsink drive too high.

Failure of device fan.

Failure in the IGBT module on power section.

Fast overload current duty cycle.

Heatsink sensor Ambient temperature too high

Failure of drive fans

Dirty heatsink

Intake air ot (For sizes from 30 Hp and higher). Temperature of the cooling air too high.

Failure of drive fans

Air intake obstructed

25

Page 26

Interrupt error An unused interrupt has occurred

Switch off the drive and restart

If still unsuccessful, the fault is probably internal. Contact your service office

Module overtemp (For sizes from 1 Hp to 20 Hp). Temperature of the IGBT module is too high

Failure of drive fan

Failure in the IGBT module in the power section.

Fast overload current duty cycle.

Output stages Internal Overcurrent failure of IGBT power section

Switch off drive and restart

If unsuccessful, contact your service office

Overcurrent Overcurrent in the motor circuit

Short-circuit or ground fault at the output of the drive

Current regulator tuned incorrectly

Message appears when switching on the drive: drive is connecting to a motor

that is running. Auto capture function must be activated

Switch off drive and restart

If unsuccessful, contact your service office

Overvoltage Overvoltage on the DC Bus due to energy regenerated from motor

Lengthen deceleration ramp. If not possible:

Use a BU... braking unit to increase the energy absorption capability

Overtemp Motor Overtemperature of the motor (indicated via thermistor on terminals 78/79)

Cable between thermistor in motor and terminals 78 and 79 interrupted

Overheating of motor:

- Load cycle too extreme

- Ambient temperature at motor location too high

- Motor has an external blower and it has failed

- Motor does not have an external blower: load too large at low speeds. The cooling effect

of the fan on the motor shaft is inadequate for this load cycle. Change cycle or install an

external blower

Regulation ot Temperature of the drive regulator card is too high

Ambient temperature too high

Speed fbk loss Speed feedback loss

Encoder not connected, or incorrectly connected or not supplied:

Select the Enc 1 speed parameter in the MONITOR\ Measurement \ Speed \ Speed in rpm

menu.

- With the drive disabled, manually turn the motor clockwise (viewed from the front of the

shaft). The value indicated must be positive.

- If the indicated value does not change or random values are shown, check the power

supply and the cabling of the encoder.

- If the indicated value is negative, reverse the encoder connections. Exchange channel

26

A+ and A- or B+ and B-

Page 27

Undervoltage Line voltage parameter incorrectly set. Remedy: set parameter correctly and then acknowledge

the failure via RESET*.

The incoming voltage to the power section of the device is too low due to:

- too low an AC input voltage or extreme line dips

- poor cable connections (e.g. terminals on contactor, choke, filter ... not properly tightened).

Remedy: check connections.

* To RESET the alarms press [Escape]. If Enable and Start commands are configured for terminal mode, remove

both commands before “Reset”. To RESET remove +24V potential from these terminals.

Note:

The RESET alarm operation can be also configured for a digital input.

Other faults

Failure Possible causes

Motor not turning Failure alarm is displayed: see above

Once the error has been corrected enter the failure Reset command

Keypad display is dark: AC voltage supply to terminals U1/V1/W1 missing or an internal fuse

is faulty

Enable and/or start command missing (Check configuration of the reg. terminals)

Drive not accepting commands: incorrect or wrong operating mode

Protective device ahead of the power supply has tripped: protective device incorrectly sized

or input jumper faulty

The analog input used for the reference value was not assigned or assigned incorrectly

Motor turning in the wrong direction

Polarity of the reference signal incorrect

Motor incorrectly connected. CAUTION: if the motor rotation is reversed, two encoder cables

(A+ and A- or B+ and B-) have to be reversed also.

Motor not reaching nominal speed

Drive is encountering a speed limit. Remedy: check Speed max amount, Speed max pos

and Speed max neg parameters

Drive working at current limit (LED Ilimit) Possible causes:

- Motor overloaded

- Inverter sized too small

- Incorrect V/f characteristics set

- T current lim reduction selected via Torque reduct parameter

The entered value for the number of encoder pulses is too high. Remedy: check the parameter

“encoder 1 pulses” and set the correct value.

An override signal is reducing the main reference value.

Remedy: check the configuration

Speed base value parameter set too low

27

Page 28

Motor accelerates immediately to maximum speed

Reference set via analog input: Check whether the signal varies from min. to max.

Potentiometer used for reference: Is there a 0V (common) connection present?

Encoder not connected, or incorrectly connected.

Select the Enc 1 speed parameter in the MONITOR \ Measurement \ Speed \ Speed in rpm

menu.

- With the regulator disabled, manually turn the motor clockwise (viewed from the front of

the shaft). The value indicated must be positive.

- If the indicated value does not change or if random values are shown, check the power

supply and the cabling to the encoder

- If the indicated value is negative, reverse the encoder connections. Exchange channel

A+ and A- or B+ and B-.

Motor accelerates too slowly

Ramp value incorrectly set

Motor running at max. current

- Motor overloaded

- Drive sized too small

- Incorrect V/f characteristics set

Motor decelerates too slowly

Ramp value incorrectly set

Motor turns slowly, although reference value = Zero

Minimum speed parameter selected

Interference due to unused analog input. Remedy: set unused analog inputs to OFF

Disconnect reference on the analog input

- If drive now stands still, the effect is due to the cable resistance of the 0V (common) leg.

- Use the offset compensation on the analog input. Set Offset input xx parameter so that

the drive stands still.

Output voltage oscillates under load

The value for Rotor resistance is not correct. See section “Checking and manual tuning of

rotor resistance for field oriented mode” in the AV-300i instruction book.

Motor not supplying the maximum torque or maximum output power

The value for Magnetizing curr is less than required for the connected motor.

- The ratio Output voltage / Output frequency in the MONITOR / Measurements menu

should be approx equal to the ratio of Base voltage / Base frequency

- Drive working at current limit

- Check whether the value for Full load curr in the CONFIGURATION menu is correctly

set

- Check the value for the current limit