GE Appliances JV936, JV966, CV936, CV966 Owner's Manual And Installation Instructions

GEAppliances.com

Safety Instructions ........... 2

Operating Instructions

Fan Control ...................... ]

Light Control ..................... 4

Care and Cleaning

Grease Filters .................... 5

Hood Lights ...................... 6

Stoinless Steel Surfoces .......... 5

JV936

JV966

CV936

CV966

0

0

Installation Instructions.. 6-17

Troubleshooting Tips ....... 18

Consumer Support

Consumer Support .............. 22

Owner Registrotion ........... 19, 20

Warranty ....................... 21

Write the model and serial

numbers here:

Model #

Serial #

You can find them on (] label

on the inside of the hood.

LI275B 49-80520-3 08-11GE

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

SAFETY PRECAUTIONS

A WARNING- ToREDUCETHERISKOFFIRE,

ELECTRICSHOCKORINJURYTOPERSONS,OBSERVETHE

FOLLOWING:

A. Usethis unitonlyinthe manner intendedby the manufacturer.

Ifyou have questions,contact themanufacturer.

B. Beforeservicingor cleaningunit,switch power off at service

paneland lockthe servicedisconnectingmeansto prevent

powerfrom beingswitchedon accidentally.Whenthe service

disconnectingmeanscannot belocked,securelyfastena

prominent warningdevice,suchasa tag,to the servicepanel.

C. Donot usethis unitwith anysolid-statespeedcontrol device.

D. Thisunit mustbe grounded.

A CAUTION- FORGENERALVENTILATINGUSEONLY

DONOTUSETOEXHAUSTHAZARDOUSOREXPLOSIVEHATERIALS

AND VAPORS.

WARNING- TOREDUCETHERISKOFINJURYTO

PERSONSIN THEEVENTOFA RANGETOPGREASEFIRE,OBSERVE

THEFOLLOWING*:

A. SHOTHERFLAMESwith a close-fittinglid,cookiesheetor metal

tray,then turnoffthe burner.BECAREFULTOPREVENTBURNS.If

theflames do notgo out immediately,EVACUATEANDCALLTHE

FIREDEPARTMENT.

B. NEVERPICKUPAFLAMINGPAN-Youmaybeburned.

C. DONOTUSEWATER,includingwet dishclothsor towels-a

violentsteamexplosionwill result.

D. Usean extinguisherONLYif:

1. Youknowyou haveaClassABCextinguisher,andyou

alreadyknow how to operate it.

2. Thefire issmalland contained inthe areawhere itstarted.

3. Thefire department is beingcalled.

4. Youcanfight the fire with your backto an exit.

*Basedon "KitchenFireSafety"publishedby NFPA.

^_WARNING- TOREDUCETHERISKOFARANGE

TOPGREASEFIRE:

A. Neverleavesurface unitsunattended at highsettings.Boilovers

causesmokingand greasyspilloversthat may ignite.Heatoils

slowlyon low or medium settings.

B. Alwaysturn hood ONwhen cookingon high heatorwhen

flamb_ingfood (i.e.CrepesSuzette,CherriesJubilee,Peppercorn

BeefFlamb_).

Co

Cleanventilatingfans frequently.Greaseshouldnot beallowed

to accumulateon fan or filter.

D.

Useproper pansize.Alwaysusecookware appropriatefor the

sizeof the surfaceelement.

^._WARNING- TOREDUCETHERISKOFFIRE,

ELECTRICSHOCKORINJURYTOPERSONS,OBSERVETHE

FOLLOWING:

Ao

Installation work and electrical wiring must be doneby

qualifiedperson(s)in accordance with all applicable codes

and standards, including fire-rated construction.

Bo

Sufficient air is neededfor proper combustion and exhausting

ofgases through the flue(chimney)of fuel burning equipment

toprevent back drafting. Follow the heating equipment

manufacturer's guideline and safety standards suchas

thosepublished by the National FireProtection Association

(NFPA_,the American Societyfor Heating,Refrigeration and

Air Conditioning Engineers(ASHRAE)and the local code

authorities.

C. When cutting ordrilling into wallor ceiling,do notdamage

electricalwiring andother hiddenutilities.

D. Ductedfans mustalwaysbeventedto the outdoors.

^,..WARNING- TOREDUCETHERIsKOFnREANDTO

PROPERLYEXHAUSTAIR,BESURETODUCTAIROUTSIDE-DONOT

VENTEXHAUSTAIRINTOSPACESWITHINWALLSORCEILINGSOR

INTOATTICS,CRAWLSPACESORGARAGES.

,&WARNING- TOREDUCETHERISKOFFIRE,USE

ONLYMETALDUCTWORK.

Donot attempt to repairor replaceany partof yourhoodunless

it is specificallyrecommendedin this guide.Allother servicing

shouldbe referredto a qualifiedtechnician.

READAND FOLLOW THISSAFETYINFORMATIONCAREFULLY.

READAND SAVETHESEINSTRUCTIONS

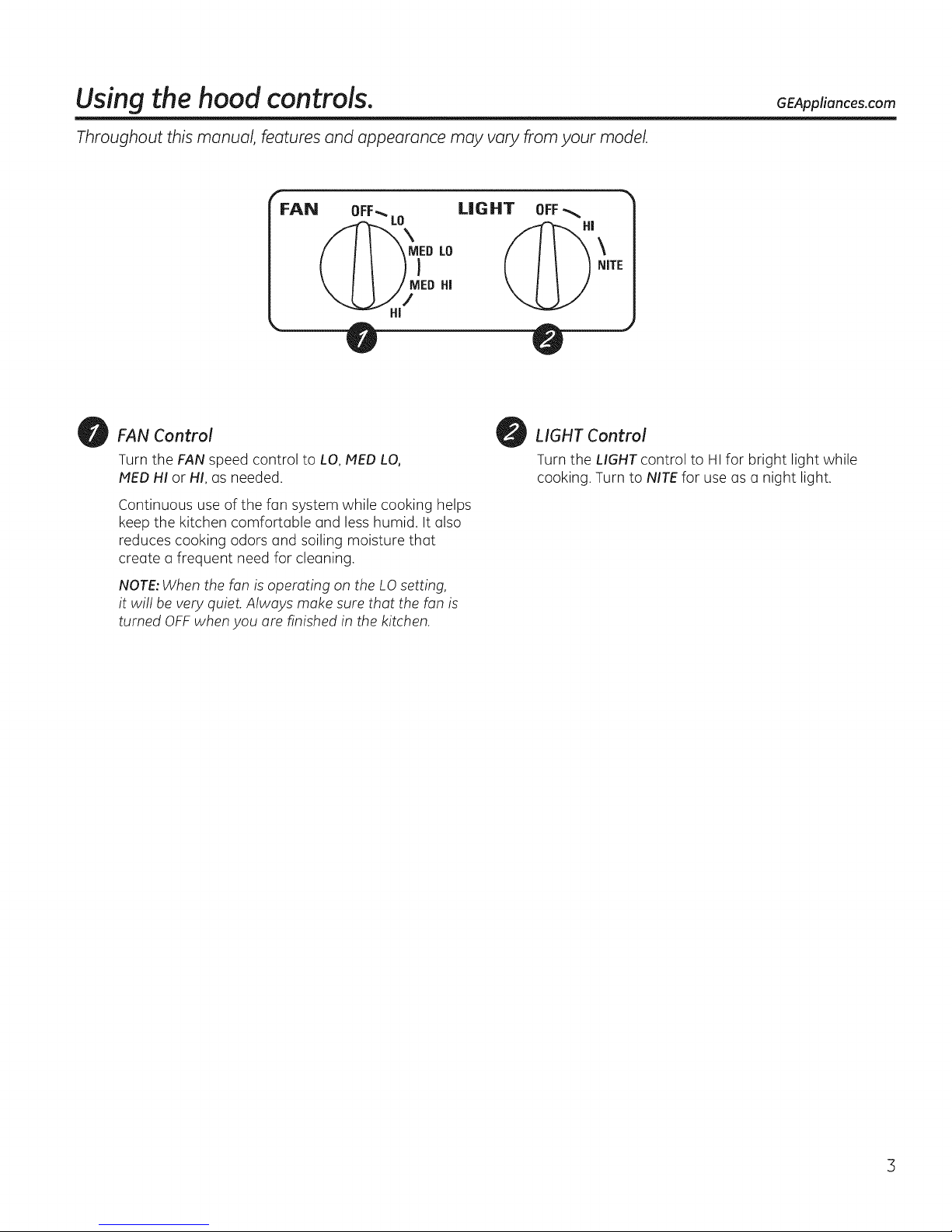

Using the hood controls.

Throughout thismanual, featuresand appearancemay vary fromyour model.

GEAppliances.com

FAN OFF.,,,,. LIGHT

LO

\

MED LO

I

NEDHI

HI

FAN Control

Turn the FAN speed control to LO, MED LO,

MED HI or HI, as needed.

Continuous use of the fan system while cooking helps

keep the kitchen comfortable and less humid, It also

reduces cooking odors and soiling moisture that

create a frequent need for cleaning.

NOTE: When the fan is operating on the LO setting,

it will be very quiet. Always make sure that the fan is

turned OFFwhen you are finished in the kitchen.

OFF

HI

\

NITE

LIGHT Control

Turn the LIGHT control to HI for bright light while

cooking. Turn to NITE for use as a night light.

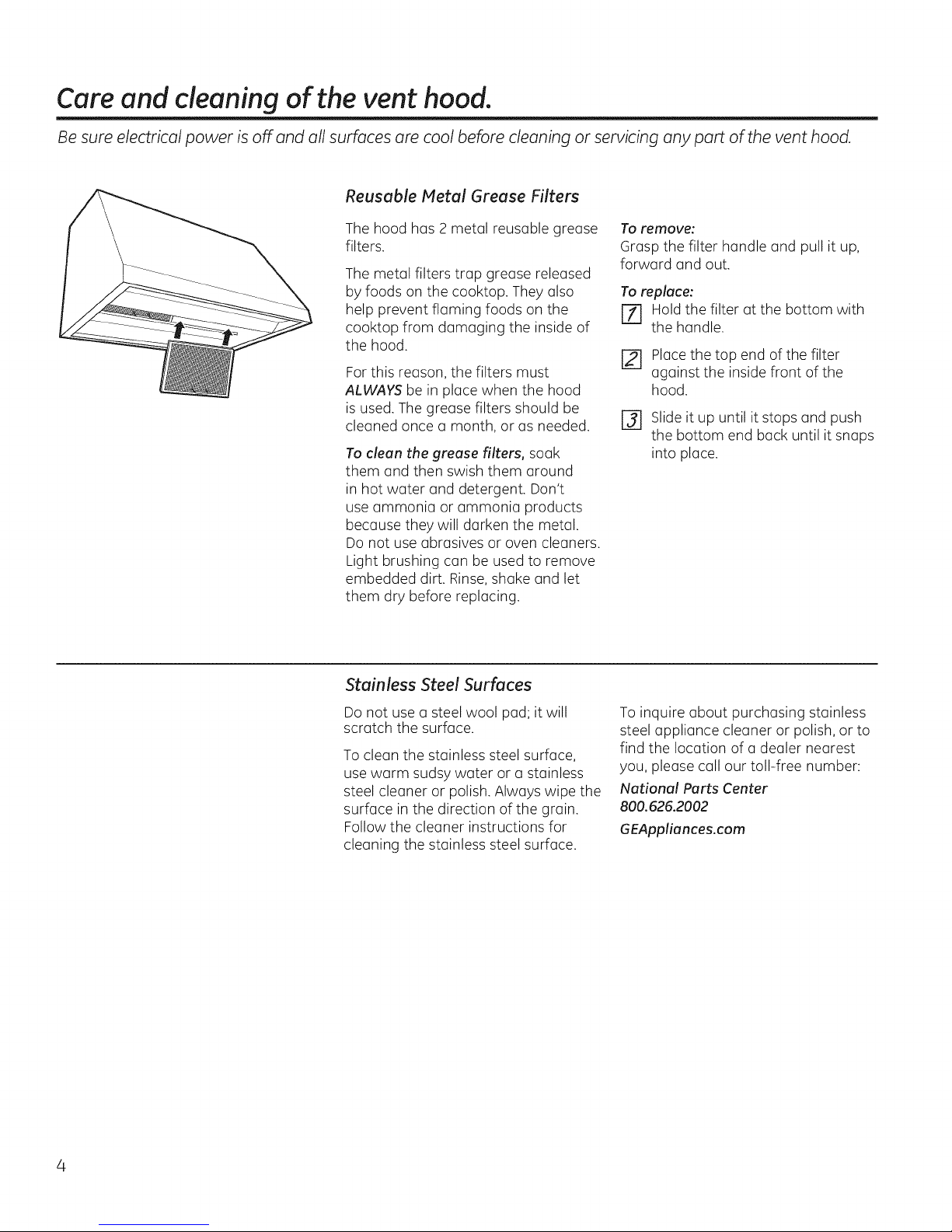

Care and cleaning of the vent hood,

Be sure electrical power is off and all surfaces are cool before cleaning or servicing any part of the vent hood.

Reusable Metal Grease Filters

The hood has 2 metal reusable grease

filters.

The metal filters trap grease released

by foods on the cooktop. They also

help prevent flaming foods on the

cooktop from damaging the inside of

the hood.

For this reason, the filters must

ALWAVSbe in place when the hood

is used. The grease filters should be

cleaned once a month, or as needed.

To clean the grease filters, soak

them and then swish them around

in hot water and detergent. Don't

use ammonia or ammonia products

because they will darken the metal.

Do not use abrasives or oven cleaners.

Light brushing can be used to remove

embedded dirt. Rinse, shake and let

them dry before replacing.

To remove:

Grasp the filter handle and pull it up,

forward and out.

To replace:

m Hold the filter at the bottom with

the handle.

[] Placethe top end of the filter

against the inside front of the

hood.

r_ Slideit up until it stops and push

the bottom end back until it snaps

into place.

Stainless Steel Surfaces

Do not use a steel wool pad; it will

scratch the surface.

To clean the stainless steel surface,

use warm sudsy water or a stainless

steel cleaner or polish. Always wipe the

surface in the direction of the grain.

Follow the cleaner instructions for

cleaning the stainless steel surface.

To inquire about purchasing stainless

steel appliance cleaner or polish, or to

find the location of a dealer nearest

you, please call our toll-free number:

National Parts Center

800.626.2002

GEAppliances.com

GEAppliances.com

Besureelectricalpower isoff and allsurfacesarecoolbeforecleaningor-servicinganypart of the vent hood.

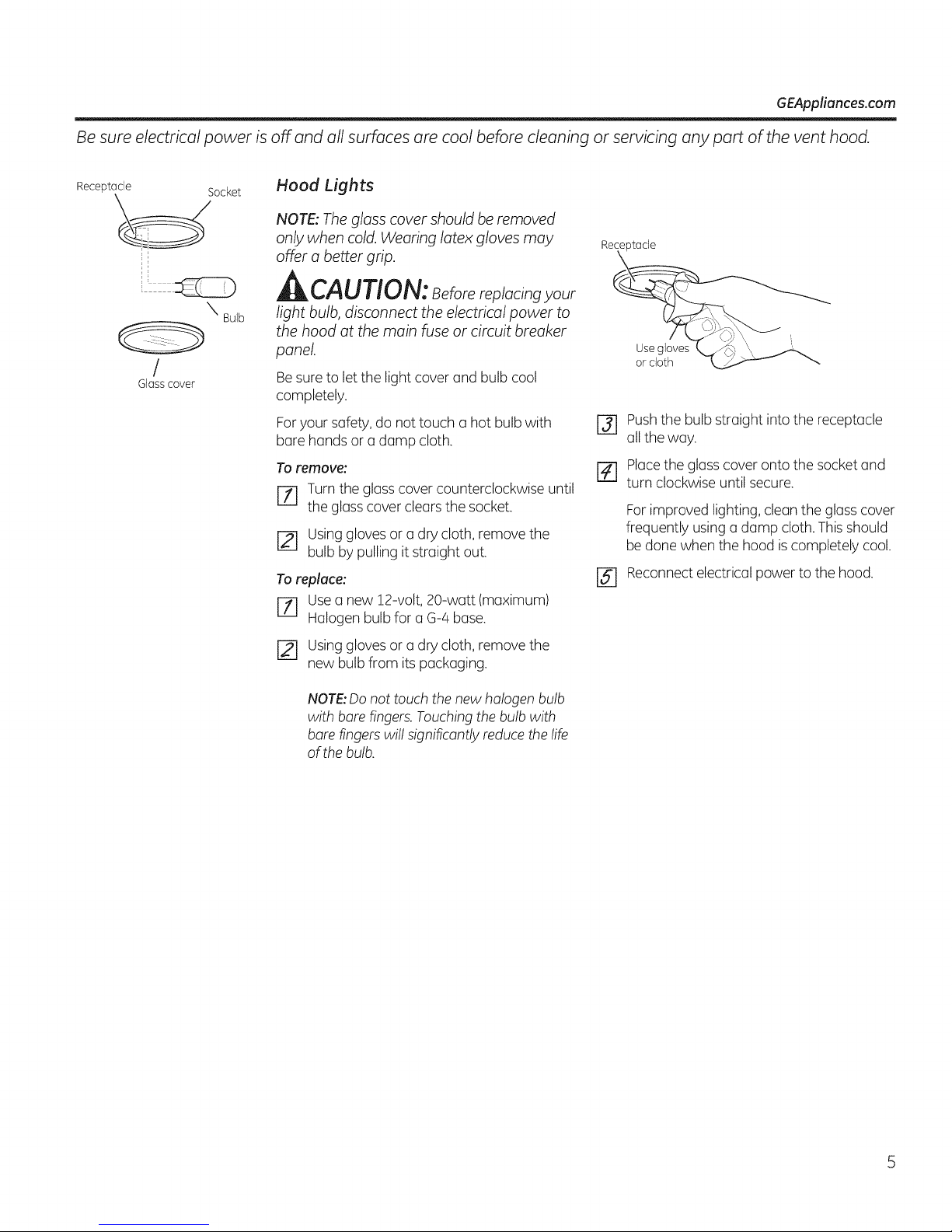

Receptacle Socket

X Bulb

/

Glasscover

Hood Lights

NOTE: Thegloss cover should be removed

only when cold. Wearing latex gloves may

offer o better grip.

CAUTION: eforereplacingyour

light bulb, disconnect the electrical power to

the hood at the main fuse or circuit breaker

panel.

Besureto let the light cover and bulb cool

completely.

Foryour safety, do not touch a hot bulb with

bare hands or a damp cloth.

Toremove:

r_ Turn the glass cover counterclockwise until

the glasscover clears the socket.

r_ using gloves or a dry cloth, remove the

bulb by pulling it straight out.

Toreplace:

[Z] Usea new 12-volt, 20-watt (maximum)

Halogen bulb for a G-4 base.

Re_ade

or cloth __ "_-

r_ Pushthe bulb straight into the receptacle

all the way.

r_ Placethe glass cover onto the socket and

turn clockwise until secure.

Forimproved lighting, clean the glass cover

frequently using a damp cloth. This should

be done when the hood is completely cool.

rs] Reconnectelectrical power to the hood.

[] Usinggloves or a dry cloth, remove the

new bulb from its packaging.

NOTE:Do not touch the new halogen bulb

with bare fingers. Touching the bulb with

bare fingers will significantly reduce the life

of the bulb.

I stall ti

Instructi

ange Hoods

i Questions? Cull 800.GE.CARES (800.432.2737) or visit our Website ot: www.GEAppliunces.com. i

BEFORE YOU BEGIN

Read these Instrucitons completely and carfully.

"IMPORTANT- Soretheseinstructions

for local inspector's use.

" IMPORTANT- Observe oligoverning

codes ond ordinances.

, Note to Installer - Be sure to leove these

instructions with the Consumer.

, Note to Consumer - Keep these instrucitons

for future reference.

Skill Level - Instollotion of this vent hood

requires basic mechonicol and electrical skills.

Completion time - 1to 3 hours.

• Proper installation is the responsibility of the

instoller.

Product foilure clue to improper installation is

not covered under the Warranty.

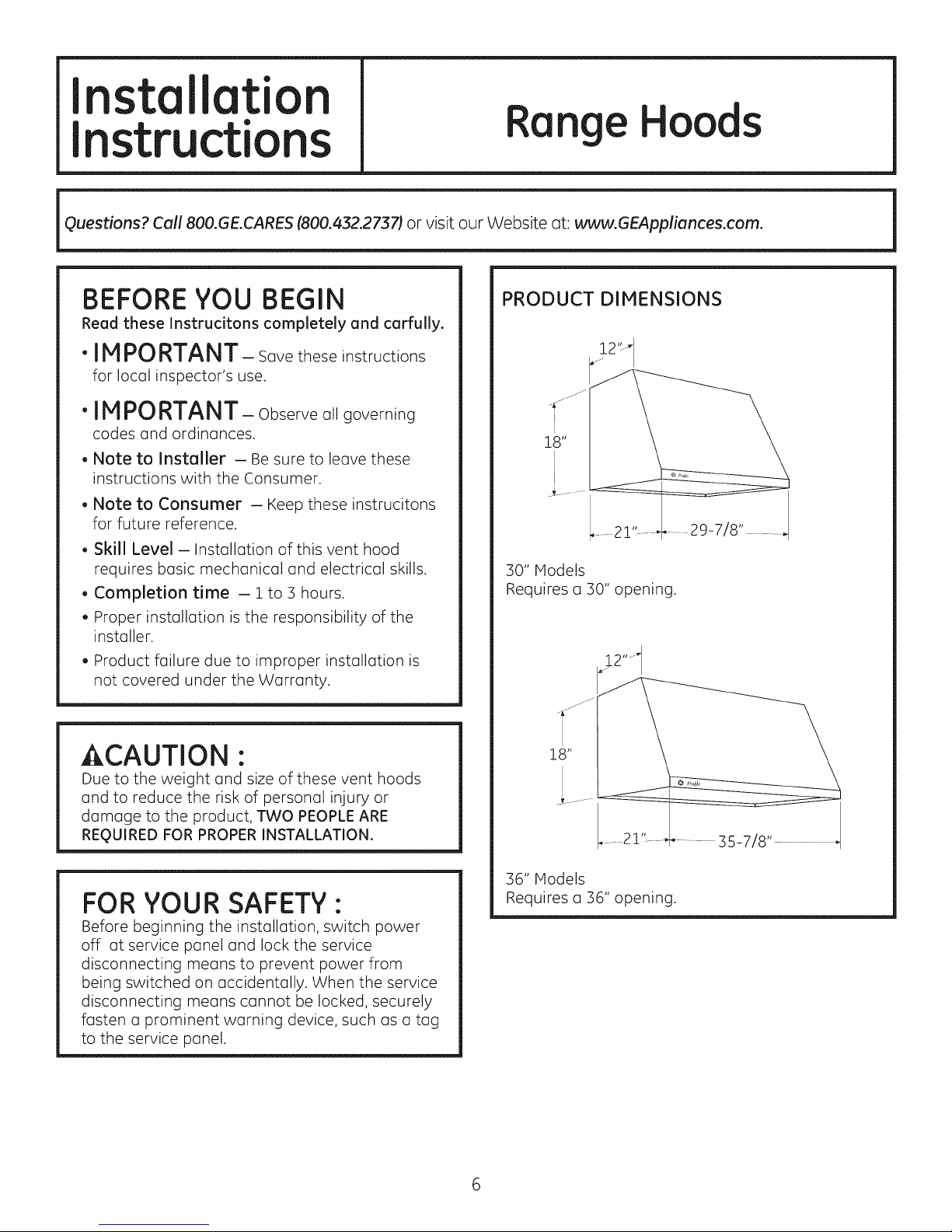

30" Models

Requires o 30" opening.

ACAUTION ."

Due to the weight ond size of these vent hoods

ond to reduce the risk of personol injury or

domoge to the product, TWO PEOPLE ARE

REQUIRED FOR PROPER INSTALLATION.

FOR YOUR SAFETY:

Before beginning the instollotion, switch power

off ot service ponel ond lock the service

disconnecting means to prevent power from

being switched on occidentolly. When the service

disconnecting meons connot be locked, securely

fosten o prominent worning device, such os o tog

to the service ponel.

18"

35-7/8" ...................

36" Models

Requireso 36" opening.

Installation Instructions

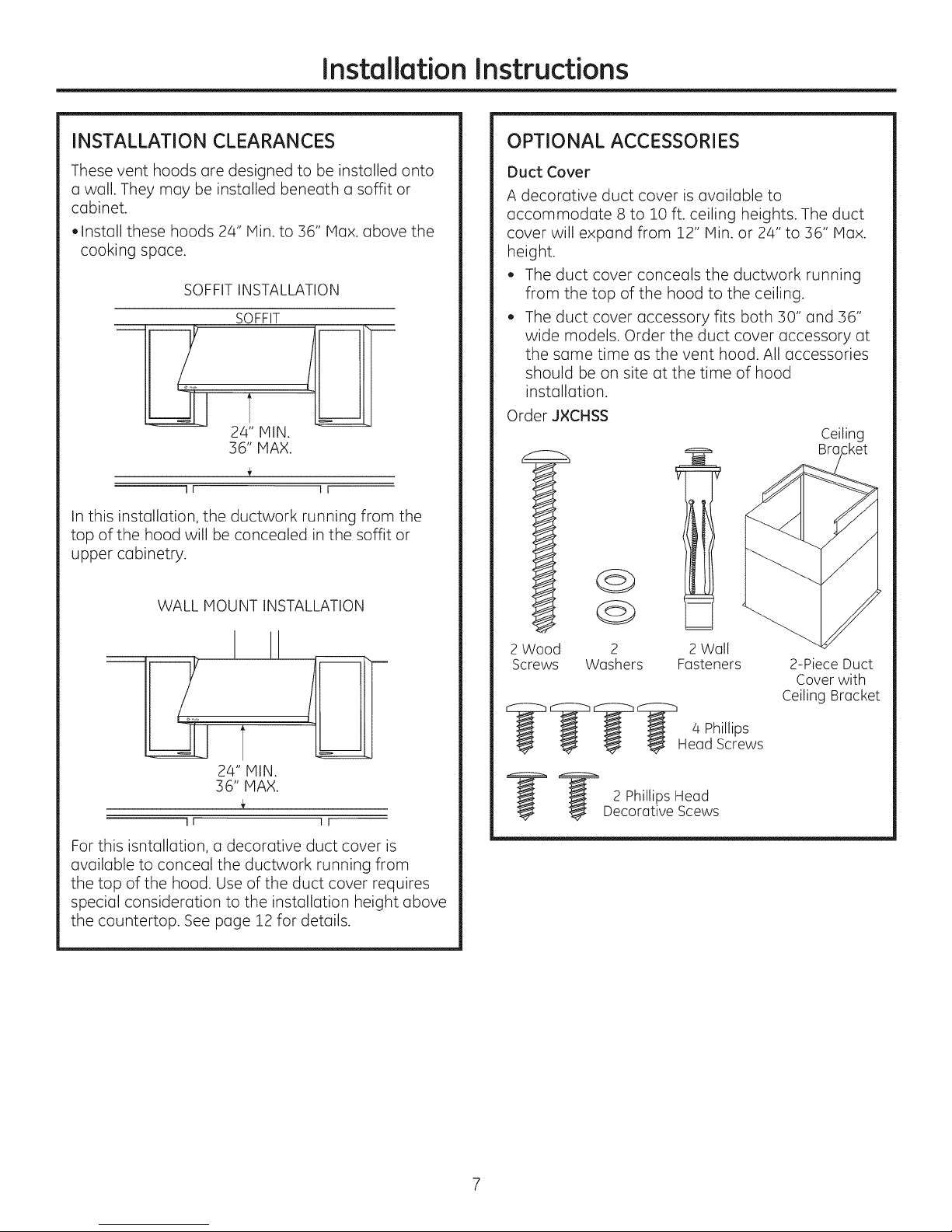

INSTALLATION CLEARANCES

These vent hoods are designed to be installed onto

a wall. They may be installed beneath a soffit or

cabinet.

,Install these hoods 24" Hin. to 36" Max. above the

cooking space.

SOFFIT INSTALLATION

SOFFIT

In this installation, the ductwork running from the

top of the hood will be concealed in the soffit or

upper cabinetry.

OPTIONAL ACCESSORIES

Duct Cover

A decorative duct cover is available to

accommodate 8 to 10 ft. ceiling heights. The duct

cover will expand from 12" Min. or 24" to 36" Max.

height.

, The duct cover conceals the ductwork running

from the top of the hood to the ceiling.

, The duct cover accessory fits both 30" and 36"

wide models. Order the duct cover accessory at

the same time as the vent hood. All accessories

should be on site at the time of hood

installation.

Order J×CHSS

Ceiling

Bra

WALL MOUNT INSTALLATION

24" MIN.

36" MAX.

11 I_

For this isntallation, a decorative duct cover is

available to conceal the ductwork running from

the top of the hood. Use of the duct cover requires

special consideration to the installation height above

the countertop. See page 12 for details.

2 Wood

Screws2Washers

_;_ _;_ _ _;_ 4 Phillips

_ 2 Phillips Head

Decorative Scews

2 Wall

Fasteners

Head Screws

2-Piece Duct

Cover with

Ceiling Bracket

Installation Instructions

ADVANCE PLANNING

Ductwork Planning

Thishoodmay be ventedverticallythrough uppercabinets,

soffit or ceiling.Aduct transitionpiece issuppliedfor vertical

exhaust.Uselocallysuppliedelbowsto vent horizontally

throughthe rearwall.Seepage 13.

Determinethe exactlocationof theventhood.

Planthe route forventing exhaustto the outdoors.

Usetheshortestand straightest duct routepossible.FFor

satisfactoryperformance,duct run should notexceed100

equivalentlengthfor anyductconfigurations.

Usemetal ductwork only.

Atransition piecefor 7" roundduct issupplied.Use7"round

duct oryou may use3-1/4" x 12" rectangular.

Installa wall capor roofcap with damperat the exterior

opening.Orderthe wall or roof cap and any transition

neededin advance.

Kit- J×DW1

Orderkit J×DW1ifyour installationrequireshorizontalducting

from the top ofthe hood throughthe backwall and:

• Youhavean 8ft. ceilingand needto use a JXCHSeries

ChimneyCover,or

• Youhavea 12"cabinet or 12" soffitthat the hoodisto be

mountedbeneath.

Thiskitprovidesa duct transitionfrom 7" round to 3-1/4"x 10"

rectangularfor through-the-wall venting.

Wall Framing for Adequate Support

• Thisvent hood isheaw. Adequate structurealsupport must

beprovided.Thehood must besecuredto verticalstuds in

thewall. Seepage 14.

• Westrongly recommendthat the vent hoodwith duct cover

beon sitebeforefinal framing and wallfinishing.Thiswill

alsohelpto accuratelylocatethe ductwork and electrical

service.

DECORATIVE DUCT COVERS

A decorativeductcoveris availabletofit bothmodelwidths.

Theduct coverconcealsthe ductwork runningfrom the top of

the hoodto theceilingorsoffit_Theduct coverwillfit 8 ft. to !0

ft.ceilingheights.Seepage!2 for details.

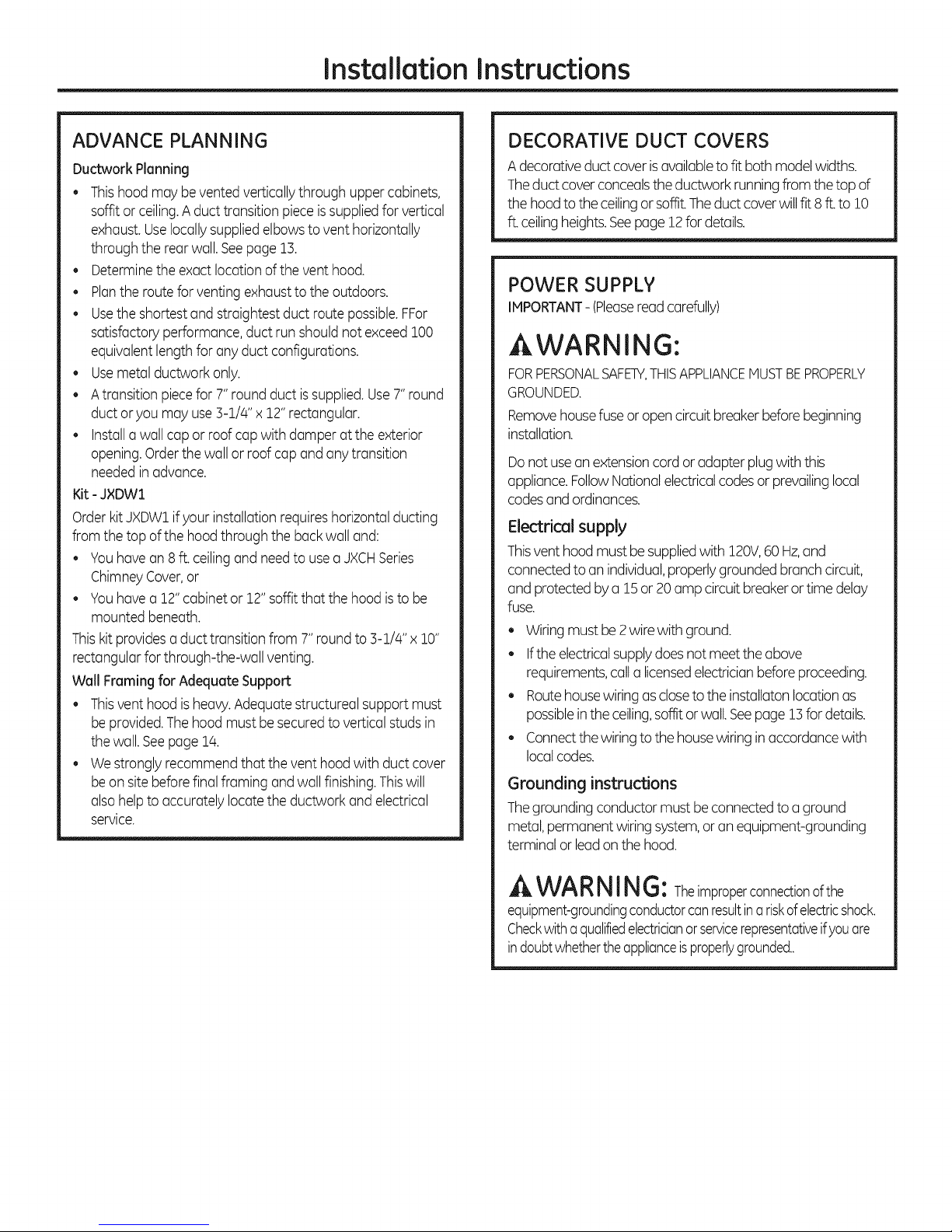

POWER SUPPLY

IMPORTANT-(Pleaseread carefully)

AWARNING:

FORPERSONALSAFETY,THISAPPLIANCEMUSTBEPROPERLY

GROUNDED.

Removehousefuse or opencircuitbreakerbeforebeginning

installation.

Donot useanextensioncordoradapterplugwith this

appliance.FollowNationalelectricalcodesor prevailinglocal

codesand ordinances.

EJectricaJ suppJy

Thisvent hoodmust besuppliedwith 120V,60Hz,and

connectedto an individual,properlygroundedbranchcircuit,

and protectedby a 15or 20amp circuitbreakeror time delay

fuse.

Wiringmust be 2wirewith ground.

Ifthe electricalsupplydoesnot meetthe above

requirements,calla licensedelectricianbeforeproceeding.

Routehousewiring ascloseto the installatonlocationas

possibleintheceiling,soffitorwall.Seepage !3 for details.

Connectthe wiringto the housewiringin accordancewith

localcodes.

Grounding instructions

Thegroundingconductor must beconnectedto a ground

metal,permanentwiring system,or an equipment-grounding

terminal or leadon the hood.

A WARNiNG:Theimproperconnectionofthe

equipment-groundingconductorcanresultinariskofelectricshock.

Checkwithaqualifiedelectricianorservicerepresentativeifyouare

indoubtwhethertheapplianceisproperlygrounded..

Installation Instructions

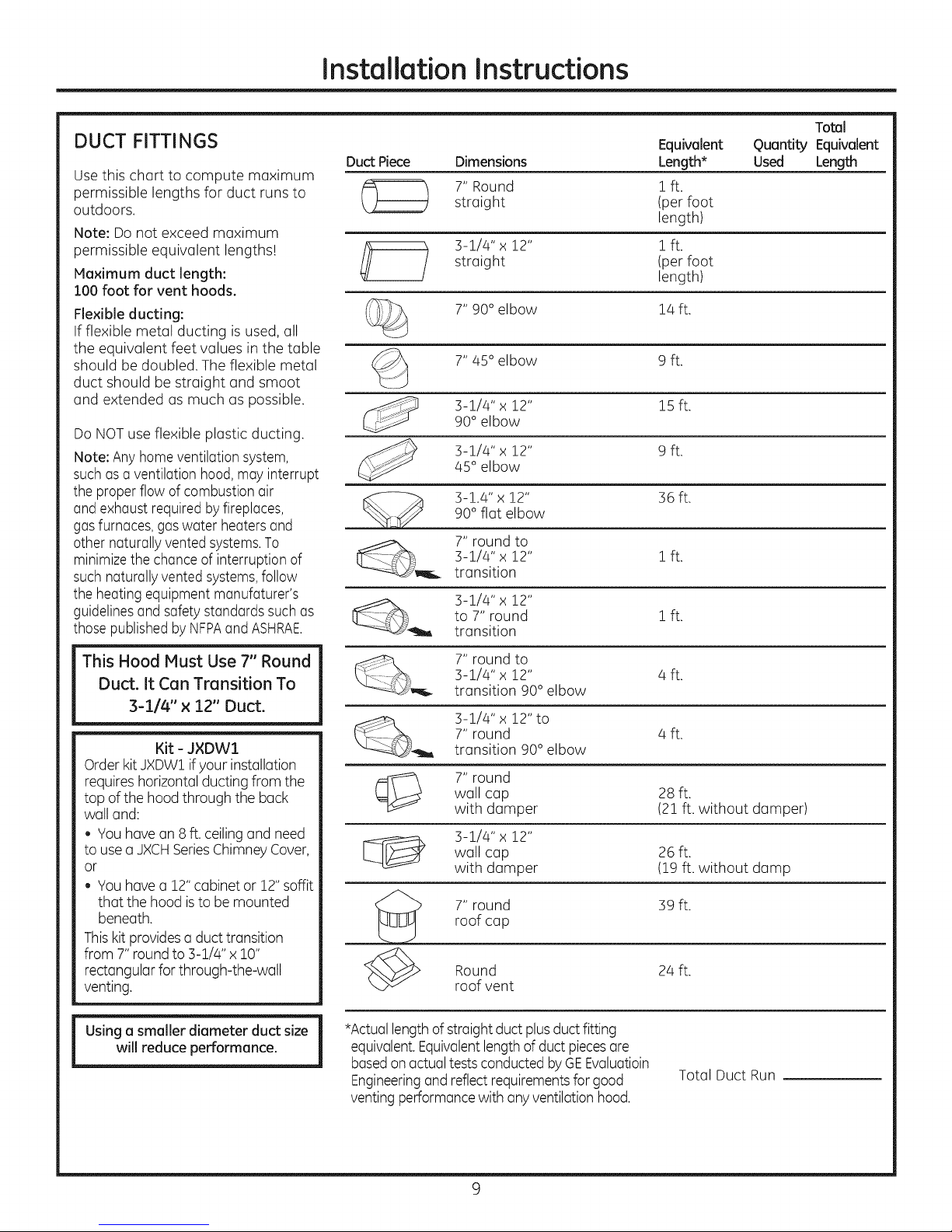

DUCT FITTINGS

Usethis chart to compute maximum

permissible lengths for duct runs to

outdoors.

Note: Do not exceed maximum

permissible equivalent lengths!

Maximum duct length:

100 foot for vent hoods.

Flexible ducting:

If flexible metal ducting is used, all

the equivalent feet values in the table

should be doubled. The flexible metal

duct should be straight and smoot

and extended as much as possible.

Do NOTuse flexible plastic ducting.

Note: Any homeventilationsystem,

such asa ventilation hood,mayinterrupt

the proper flow of combustion air

and exhaustrequired by fireplaces,

gasfurnaces,gas water heatersand

other naturally vented systems.To

minimizethe chanceof interruption of

such naturallyvented systems,follow

the heating equipment manufaturer's

guidelinesand safety standards such as

those publishedby NFPAand ASHRAE.

Equivalent

Duct Piece Dimensions Length*

7" Round 1 ft.

straight (per foot

length)

straight (per foot

3-Z/Z4"x 12" 1 ft.

7" 90° elbow lz4ft.

7" 45° elbow 9 ft.

3-!/z4" x 12" 15 ft.90° elbow

3-1/z4"x 12" 9 ft.

/45°elbow

90° flat elbow

3-1.4" x 12" 36 ft.

__ 7" round to

__j_ 3-!/Z4" x 12"

3-1/Z4"x 12" ! ft.

transition

to 7" round ! ft.

transition

length)

Total

Quantity Equivalent

Used Length

This Hood Must Use 7" Round

Duct. It Can Transition To

3-1/4" x 12" Duct.

Kit - J×DW1

Order kit JXDW1if your installation

requires horizontal ducting from the

top of the hood through the back

wall and:

. Youhave an 8 ft. ceilingand need

to use a JXCHSeriesChimneyCover,

or

Youhave a 12"cabinetor 12" soffit

that the hood is to be mounted

beneath.

Thiskit providesa duct transition

from 7" round to 3-1/4" x 10"

rectangular forthrough-the-wall

venting.

will reduce performance.

Using a smaller diameter duct size

7" round to

3-1/z4"x 12" z4ft.

transition 90° elbow

3-!/z4" x 12" to

7" round z4ft.

transition 90° elbow

wall cap 28 ft.

7" round

with damper (21 ft. without damper)

wall cap 26 ft.

3-1/z4" x 12"

with damper (19 ft. without damp

roof cap

7" round 39 ft.

Round 2z4ft.

roof vent

*Actuallength ofstraight duct plusductfitting

equivalent.Equivalentlengthof duct piecesare

basedon actualtests conducted byGEEvaluatioin

Engineeringand reflectrequirementsfor good

venting performancewith anyventilation hood.

Total Duct Run

9

Installation Instructions

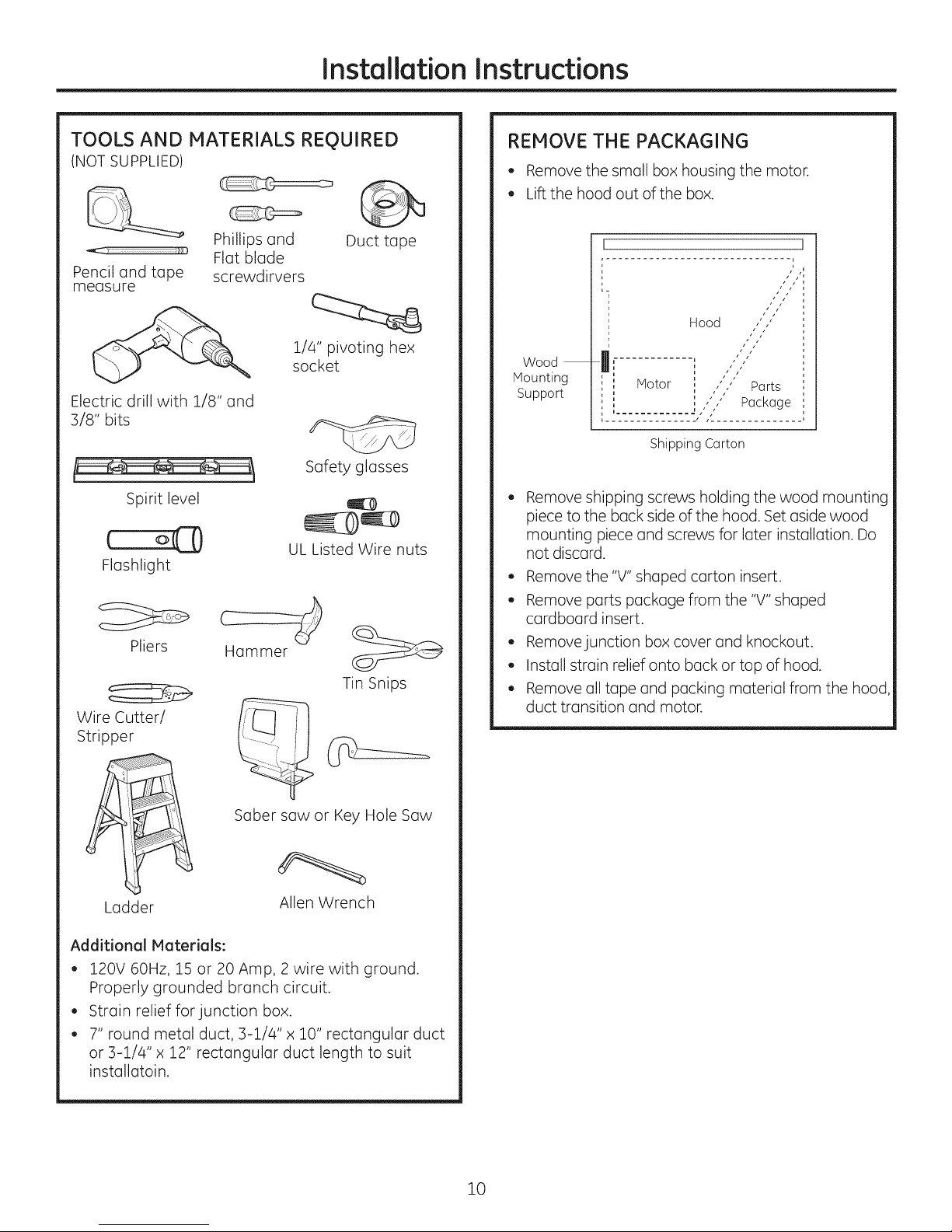

TOOLS AND MATERIALS REQUIRED

(NOT SUPPLIED)

Phillips and

Flat blade

Pencil and tape

measure

screwdirvers

Electric drill with 1/8" and

3/8" bits

Spirit level

€ o@

Flashlight

Pliers

Wire Cutter/

Stripper

Hammer

1/4" pivoting hex

socket

UL Listed Wire nuts

Duct tape

Safety glasses

Tin Snips

REMOVE THE PACKAGING

, Remove the small box housing the motor.

, Lift the hood out of the box.

Hood ""

, yiiS'

Wood

Mounting

Support

Notor , ,' ," Parts

u............ 2 ," t

, ............... , J_ .............. ,

Remove shipping screws holding the wood mounting

piece to the back side of the hood. Set aside wood

mounting piece and screws for later installation. Do

not discard.

, Remove the "V" shaped carton insert.

, Remove parts package from the "V" shaped

cardboard insert.

, Removejunction box cover and knockout.

, Install strain relief onto back or top of hood.

, Remove all tape and packing material from the hood

duct transition and motor.

i

u s t /

u s

i s /

I ,',,, Package

Shipping Carton

Saber saw or Key Hole Saw

Ladder

Allen Wrench

Additional Materials:

, 120V 60Hz, 15 or 20 Amp, 2 wire with ground.

Properly grounded branch circuit.

, Strain relief far junction box.

, 7" round metal duct, 3-1/4" x 10" rectangular duct

or 3-1/4" x 12" rectangular duct length to suit

instullutoin.

10

Installation Instructions

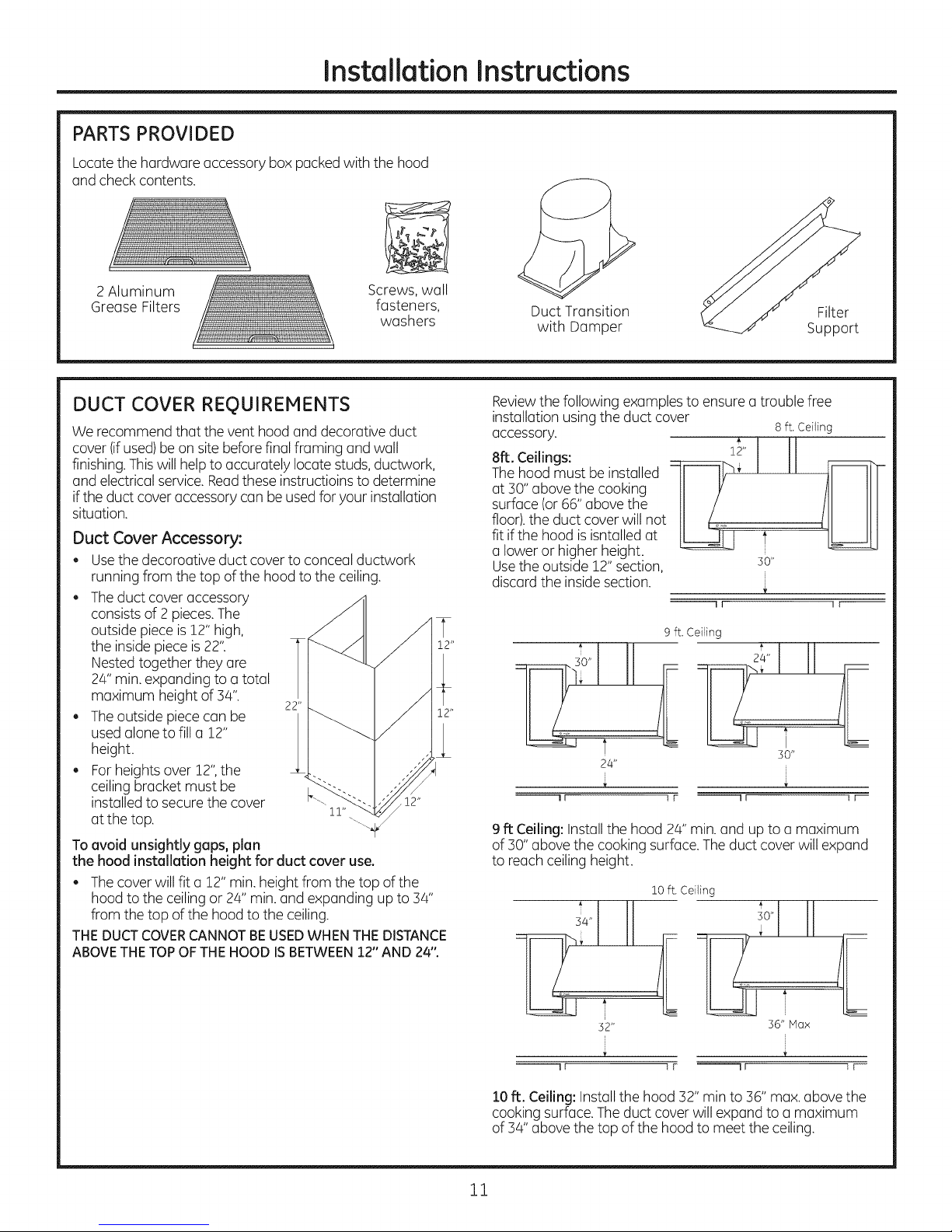

PARTS PROVIDED

Locatethe hardware accessory box packed with the hood

and checkcontents.

2 Aluminum

Grease Filters

Screws, wall

fasteners, Duct Transition

washers with Damper

DUCT COVER REQUIREMENTS

We recommend that the vent hood and decorative duct

cover (ifused)be on site before final framing and wall

finishing.Thiswill helpto accurately locate studs,ductwork,

and electrical service.Readthese instructioins to determine

ifthe duct cover accessory can be usedfor your installation

situation.

Duct Cover Accessory:

. Usethe decoroative duct cover to conceal ductwork

running from the top of the hood to the ceiling.

. Theduct cover accessory

consists of 2 pieces.The

outside piece is12" high,

the insidepiece is22" 12"

Nestedtogether they are I

24"min.expanding to a total

maximum height of 34". 22"

. Theoutside piececan be _ 12"

usedalone to fill a 12"

height.

. For heights over 12",the

ceiling bracket must be <"_

installedto secure the cover •12"

at the top. 11"

To avoid unsightly gaps, plan

the hood installation height for duct cover use.

. Thecover will fit a 12" min. height from the top of the

hood to the ceiling or 24" min. and expanding up to 34"

from the top of the hood to the ceiling.

THEDUCTCOVERCANNOTBEUSEDWHENTHEDISTANCE

ABOVETHETOPOF THEHOOD ISBETWEEN12"AND 24".

Filter

Support

Reviewthe following examples to ensure a trouble free

installation usingthe duct cover 8 ft. Ceiling

accessory.

A

8ft. Ceilings: ::z_r-.12"

Thehood must be installed II I1__€

at 30" above the cooking

surface (or 66" above the

floor),the duct cover will not

fit ifthe hood isisntalled at t

a lower or higher height.

Usethe outside 12" section, so"

discard the insidesection.

--11 ] F--

9 ft. Ceiling

t so"

24"

--! I I r --I I t I_

9 ft Ceiling: Installthe hood 24" min. and up to a maximum

of 30" above the cooking surface.The duct cover will expand

to reachceiling height.

36" Max

1F --11 iF--

10ft. Ceiling: Installthe hood 32" min to 36" max.above the

cooking surface.The duct cover will expand to a maximum

of 34" above the top of the hood to meet the ceiling.

11

Installation Instructions

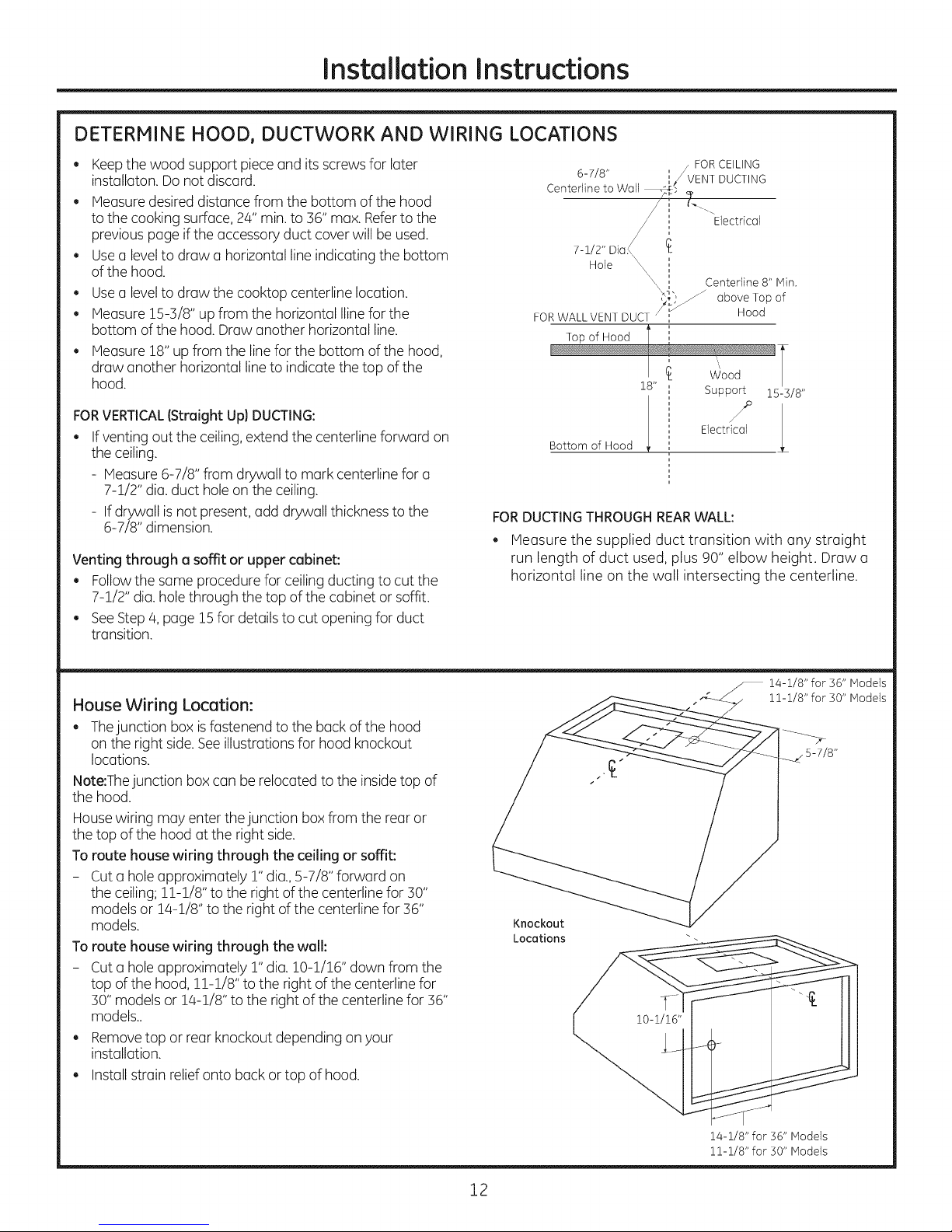

DETERMINE HOOD, DUCTWORK AND WIRING LOCATIONS

Keepthe wood support pieceand its screws for later

installaton. Do not discard.

, Measuredesired distance from the bottom of the hood

to the cooking surface, 24" min.to 56" max. Referto the

previous page ifthe accessory duct cover will be used.

, Usea levelto draw a horizontal line indicating the bottom

ofthe hood.

Usea levelto draw the cooktop centerline location.

. Measure 15-3/8" up from the horizontal Ilinefor the

bottom of the hood. Draw another horizontal line.

Measure 18"upfrom the line for the bottom of the hood,

draw another horizontal line to indicate the top of the

hood.

FOR VERTICAL (Straight Up) DUCTING:

If venting out the ceiling, extend the centerline forward on

the ceiling.

- Measure 6-7/8" from drywall to mark centerline for a

7-1/2" dia. duct hole on the ceiling.

- If drywall is not present, add drywall thickness to the

6-7/8" dimension.

Venting through a soffit or upper cabinet:

. Followthe same procedure for ceilingducting to cut the

7-1/2" dia. hole through the top of the cabinet orsoffit.

. SeeStep 4, page 15for details to cut opening for duct

transition.

, / FOR CEILING

6-7/8" _/ VENT DUCTING

Centedine to Wall /.[. _,

' ""Electrical

7-1/2" Dia.<

Hole \,

'xX Centerline 8" Min.

X_ h jJ

FOR WALL VENT DUCT '_'_"'/z

Top of Hood I

I

Bottom of Hood

€

18" i

, Support

i

i

i

i

i

', Electrical

above

Hood

Top

of

15-3/8"

FOR DUCTING THROUGH REAR WALL:

Measure the supplied duct transition with any straight

run length of duct used, plus 90" elbow height. Draw a

horizontal line on the wall intersecting the centerline.

House Wiring Locution:

. Thejunction box isfastenend to the back of the hood

on the right side.Seeillustrations for hood knockout

locations.

Note:Thejunction box can be relocated to the insidetop of

the hood.

Housewiring may enter thejunction boxfrom the rear or

the top of the hood at the right side.

To route house wiring through the ceiling or soffit:

- Cut a hole approximately r' dia.,5-7/8" forward on

the ceiling;11-!/8" to the right of the centerline for 30"

models or 14-1/8" to the right of the centerline for 36"

models.

To route house wiring through the wall:

- Cut a hole approximately r' dia. 10-1/16" down from the

top of the hood, 1!-!/8" to the right of the centerline for

30"modelsor 14-1/8" to the right of the centerline for 36"

models..

. Removetop or rear knockout depending on your

installation.

. Installstrain reliefonto back or top of hood.

Knockout

Locations

.--- 14-1/8" for 36" Models

.4_..../ 11-1/8" for 30" Models

/

14-1/8" for 36" Models

11-1/8" for 30" Models

12

Installation Instructions

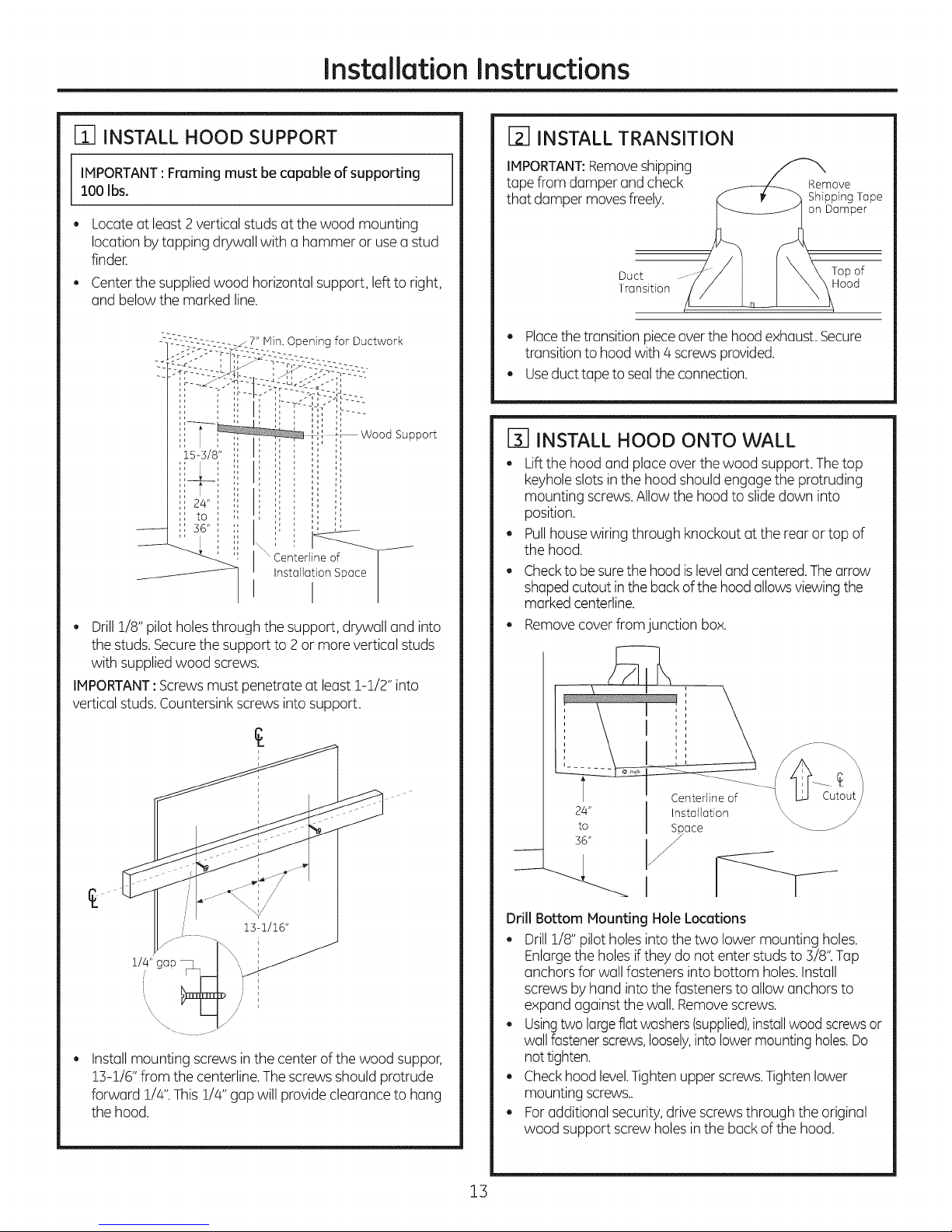

Fi] INSTALL HOOD SUPPORT

IMPORTANT:Framing must be capable of supporting

100 Ibs.

e

Locate at least 2 vertical studsat the wood mounting

location by tapping drywall with a hammer or usea stud

finder.

Centerthe supplied wood horizontal support, left to right,

and below the marked line.

Hin. Opening for Ductwork

IL_

Wood Support

Centedine of F_

Installation Space

I

. Drill 1/8" pilot holesthrough the support, drywall and into

the studs. Securethe support to 2 or more vertical studs

with supplied wood screws.

IMPORTANT:Screwsmust penetrate at least !-!/2" into

vertical studs.Countersink screws into support.

/

D INSTALL TRANSITION

IMPORTANT:Removeshipping

tape from damper and check

that damper movesfreely.

Duct Top of

Transition Hood

Remove

Shipping Tape

on Damper

. Placethe transition pieceoverthe hood exhaust.Secure

transitionto hood with 4 screws provided.

. Useduct tape to sealthe connection.

[] INSTALL HOOD ONTO WALL

. Liftthe hood and placeover the wood support. The top

keyhole slotsin the hood should engage the protruding

mounting screws.Allowthe hood to slidedown into

position.

. Pullhouse wiring through knockout at the rear or top of

the hood.

. Checkto besurethe hoodis leveland centered.Thearrow

shapedcutout inthe backof the hood allowsviewingthe

marked centerline.

. Remove cover from junction box.

l/a/',,gap

/

£

Installmounting screws in the center of the wood suppor,

13-1/6" from the centerline.The screwsshould protrude

forward 1/4".This 1/4" gap will provide clearance to hung

the hood.

°

°

24"

to

36"

Centerlin

Installation \

S/pace

L

q

Drill Bottom Mounting Hole Locutions

. Drill 1/8" pilot holesinto the two lower mounting holes.

Enlargethe holes iftheydo not enter studs to 3/8" Tap

anchors for wall fasteners into bottom holes.Install

screws by hand intothe fasteners to allow anchors to

expand against the wall. Removescrews.

. Usingtwo largeflat washers(supplied),installwood screwsor

wallfastenerscrews,loosely,intolowermounting holes.Do

nottighten.

. Checkhood level.Tighten upper screws.Tightenlower

mounting screws..

. For additional security, drive screwsthrough the original

wood support screwholes inthe buck of the hood.

13

Installation Instructions

F4-1Alternate Mounting Method

INSTALL HOOD TO SOFFIT OR

BENEATH CABINETS

SKIPTHIS STEPIF USING WALL MOUNTING METHOD

IMPORTANT: Soffit framing must be capable of

supporting 1OOibm

When necessarythe hood may be installed sothat it is

supported by the soffit.

, Thesoffit should be constructed with 2x4's,

, Determine the installation location,.

, Continuethe centerline forward on the bottom of the

cabinet or soffit.

A

IMPORTANT: For additional support and to minimize

vibration during operation, we strongly recommend

that the hood also be secured to the buck wall with wall

fastners.

30" Models

2-9/16"

7-1/16"

_,_14-i/2"

2-3/8" I

,J_ 14-1/2"

I

I

] ......... ]

€,

¢ !8-7/16

......... 4J......... I _ul

I

29-7/8"

Top View, Front Side

36" Models

2-9/16"

7-1/16"

17-1/2 "__ 17-1/2"

I

1 ,

2-3/8" _. 10_3/4._

', ¢ 8-7/16"

', i

' 2

i ........ "4 ......... J

Vue de dessus, partie avant

I

35-7/8"

2"

2"

"A .... B"

Centerline to Opening for

Center of Stud Ductwork

30" Models 14-1/2" 10-3/4" W × 8-7/16 D

36" Nideks 17-1/2" 10-3/4" W × 8-7/16 D

Mounting screws must be secured to 2 x4 studs (Dim."A")

at locations shown in the above chart.

Allow minimum opening (Dim. "B") to accommodate

the duct transition in the soffit

Rear Wall

I

1 ,

2-3/8" [,,_ , I

Cut a !0-3/4" x 8-7/16" hole through bottom of soffit or

cabinet for duct transition msshown.

5-3/8" _ 5-3/8" _

11

, ¢ 8-7/16"

I i

L ........ 4 ......... J

I

Top View, Front Side

A

Drillfour 1/8" pilot holes in locations show.

If mounting to the underside of a cabinet with a

recessed bottom, install shims to fill the gap.

I

l

',Shlmms if

114"Gap

Engage KeyholeSlots

and Push Back atWall _'

, Drive mounting screws int the studs until they

protrude 1/4".This 1/4" gap will provide clearance to

engage the keyhole slots in the top of the hood.

, Lift hood onto mounting screws, slide back against

the rear wall.

, Pull house wiring through the knockout at the rear or

top of the hood.

, Tighten mounting screws.

Bottom is

Recessed.

Add

14

Loading...

Loading...