Page 1

GE Consumer & Industrial

TECHNICAL SERVICE GUIDE

Portable Room Air Conditioner

MODEL SERIES:

APN08

APN10

APH10

PUB # 31-9126 11/04

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2004

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2 –

Page 3

TABLE OF CONTENTS

Air Filter ................................................................................................................................ 7

Circulation Pump ................................................................................................................ 18

Components ........................................................................................................................11

Component Locator Views ................................................................................................. 10

Compressor ....................................................................................................................... 15

Condenser Fan Assembly .................................................................................................. 17

Control Features .................................................................................................................. 8

Control Panel ......................................................................................................................11

Drainage .............................................................................................................................. 7

Evaporator Fan Assembly .................................................................................................. 16

Factory Test Mode ............................................................................................................. 21

Filter Drier ......................................................................................................................... 20

Illustrated Parts List ...........................................................................................................23

Installation Information ......................................................................................................... 7

Introduction .......................................................................................................................... 4

Key Function Chart ............................................................................................................ 21

Louver Motor and Louvers .................................................................................................18

Nomenclature ....................................................................................................................... 5

Operation/Smart Board .......................................................................................................11

Outer Cover ........................................................................................................................11

Power Supply Board .......................................................................................................... 12

Schematics and Wiring Diagrams ...................................................................................... 22

Technical Data ..................................................................................................................... 6

Thermistors ........................................................................................................................ 14

Warranty .............................................................................................................................26

– 3 –

Page 4

Introduction

The new Portable Room Air Conditioner can be easily

moved from room to room with minimal set-up time. It

utilizes a water pump system that uses stored condensate

to effi ciently cool the condenser, helping to dissipate heat

quickly and reduce operating costs.

Features:

• 4.0 Dehumidifi cation (pints/hr).

• Electronic thermostat.

• 24-hour delay.

• 3 cooling / 3 fan only speeds.

• Available with 8,000 or 10,000 BTUH (cooling).

• The DRY MODE provides dehumidifi cation only.

• The power outage recovery feature automatically restarts the unit in the last settings used after the

power is restored.

– 4 –

Page 5

Model Number

Brand

A=GE

Product Type

P=Portable

Supplier

K=Medea

N= Kelon

P=Kelon

Capacity

Nominal BTU’s

in 1000’s

Nomenclature

A P N 10 A A G 1

Engineering

Revision

Compressor

T=Toshiba

G=Goldstar

Commercial Change

A=Original

Voltage 60Hz

L=115V < 7.0 Amps

A=115V > 7.5 Amps

F=115V 7.0 - 7.5 Amps

Nomenclature

The mini-manual is located under the

front cover. The nomenclature tag is

located on the left side of the unit. It

contains important information such as:

• Model/serial number

• Refrigerant charge

• Voltage rating

• Cool amperes

• BTU/h

R

Serial Number

The fi rst two characters of the serial number

identify the month and year of manufacture.

Example: AG123456 = January, 2004

A - JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MAY 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

The letter designating

the year repeats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

– 5 –

Page 6

Technical Data

A

T

T

A

DISC ONNE CT POWER B EF OR E SE R VICING

IMPOR TAN

T - RECONNECT ALL GROUNDING DEVICES

ll parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, nuts or washers used to

complete a path to ground are removed for service,

they must be returned to their original position and

properly fastened.

WAR NING

DISCONNECT UNIT FROM ELECTRICAL POWER SUPPLY

BEFORE MAKING ANY ELECTRICAL CHECKS.

MAX IMUM C UR R E NT LEA K AG E : 0.5 MILLIAMP

MAX IMUM G R OUN D PATH R E S IS TANC E : 0.1 OHM

POWER SUPPLY

RATEDVOLTAGE VOLTAGE LIMITS

115 103-

REPLACEMENT PARTS

D SCRIPTION CAT.NOE

IRFILTER

COMPRESSOR

CONDENSER FAN

EVAPORATOR FAN

COMPRESSOR CAPACITOR

FAN CAPACITOR

TRANSFORMER

POWER CNTRL ASM

WATER PUMP SWITCH

POWER SUPPLY PCB

CONDENSER FAN MTR

EVAPORATOR MTR

LOUVER MTR

WATER PUMP MTR

PCB BRD OPERATION

CAPILLARY TUBE 22” LONG

CONDENSER ASM

127

WJ85X10126

WJ98X10172

WJ94X10204

WJ87X10154

WJ20X10123

WJ73X10135

WJ01X10243

WJ26X10199

WJ26X10201

WJ26X10200

WJ94X10205

WJ87X10153

WJ95X10010

WJ95X10011

WJ26X10197

WJ53X0188

WJ88X10143

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and properly damage. The manufacturer or

seller cannot be responsible for the interpretation of

this information, nor can it assume any liability in

connection with its use.

APN08AAG1

CURRENT-TEMPERATURE CHECK DATA

AIR TEMPERATURE COOLING CURRENT

CONDENSER IN ˚F MIN. MAX.

70 7.3 7.6

80 8.7 9.2

EMPERATURE DIFFERENTIAL CHECK DATA

EVAPORATOR EVAP AIR TEMP

AIR TEMP IN OUT ˚F

˚F

N. MAX.MI

70 42 48

80 49 55

90 61 6

APN10AAG1, APH10AAG1

CURRENT-TEMPERATURE CHECK DATA

AIR TEMPERATURE COOLING CURRENT

CONDENSER IN ˚F MIN. MAX.

70 8.2 8.7

80 9.3 9.8

6

– 6 –

EMPERATURE DIFFERENTIAL CHECK DATA

EVAPORATOR EVAP AIR TEMP

AIR TEMP IN OUT ˚F

˚F

N. MAX. MI

70 42 48

80 50 56

90 60 6

5

Page 7

Drain cap

Air filter

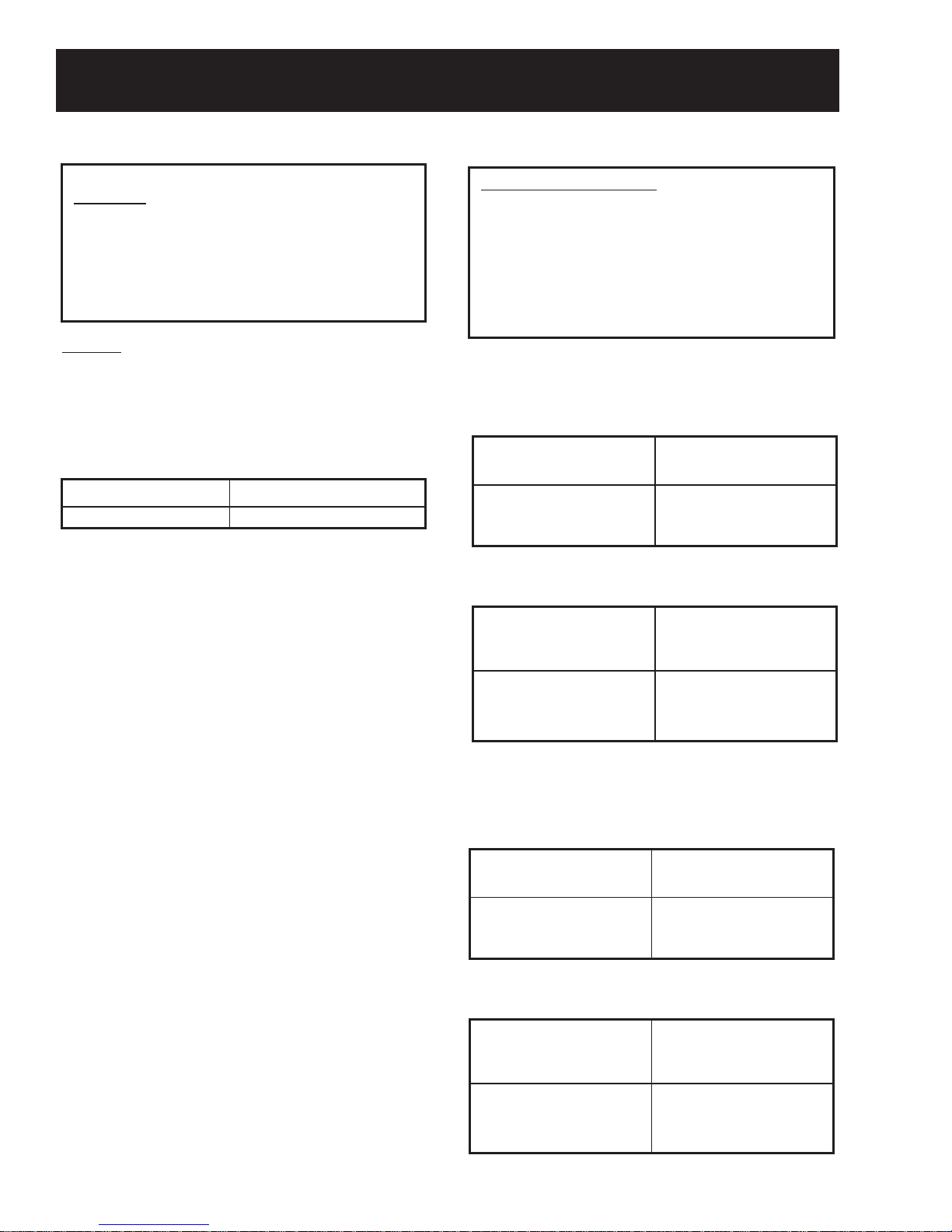

Installation Information

Back of unit

Drainage

• The air conditioner should be placed on a

smooth and level fl oor strong enough to

support the unit.

• Place the unit in an area where the

temperature will not fall below 65°F (18°C).

The coils can become covered with frost at

temperatures below 65°F (18°C), which may

reduce performance.

• Allow at least 12 inches (30 cm) of airspace

on all sides of the unit for good air circulation.

12 in. (30 cm )

12 in. (30 cm)

min.

min.

The drain cap is located at the bottom back of the

unit.

The unit is designed to automatically evaporate

water collected in normal settings. However, in

very humid settings, the unit may occasionally

need to be drained.

If the WATER FULL indicator light is blinking

and the unit is still operating, it has reached the

maximum water collection level and should be

drained. If the light stays on and the unit shuts

off, the unit will need to be drained before it will

operate again.

Note: The portable air conditioner has rollers

to aid placement, but should only be rolled on

smooth and level surfaces. Do not attempt to

roll the portable air conditioner on carpet or over

objects.

• To ensure proper cooling, do not kink or pinch

the duct. An excessive number of bends in the

exhaust hose may compromise the cooling

performance.

• To attach the exhaust hose to the back of the

air conditioner, push it into the exhaust outlet

and twist.

The unit should be drained if it is not going to

be run for an extended period of time. The unit

should also be drained prior to storage at the end

of the cooling season.

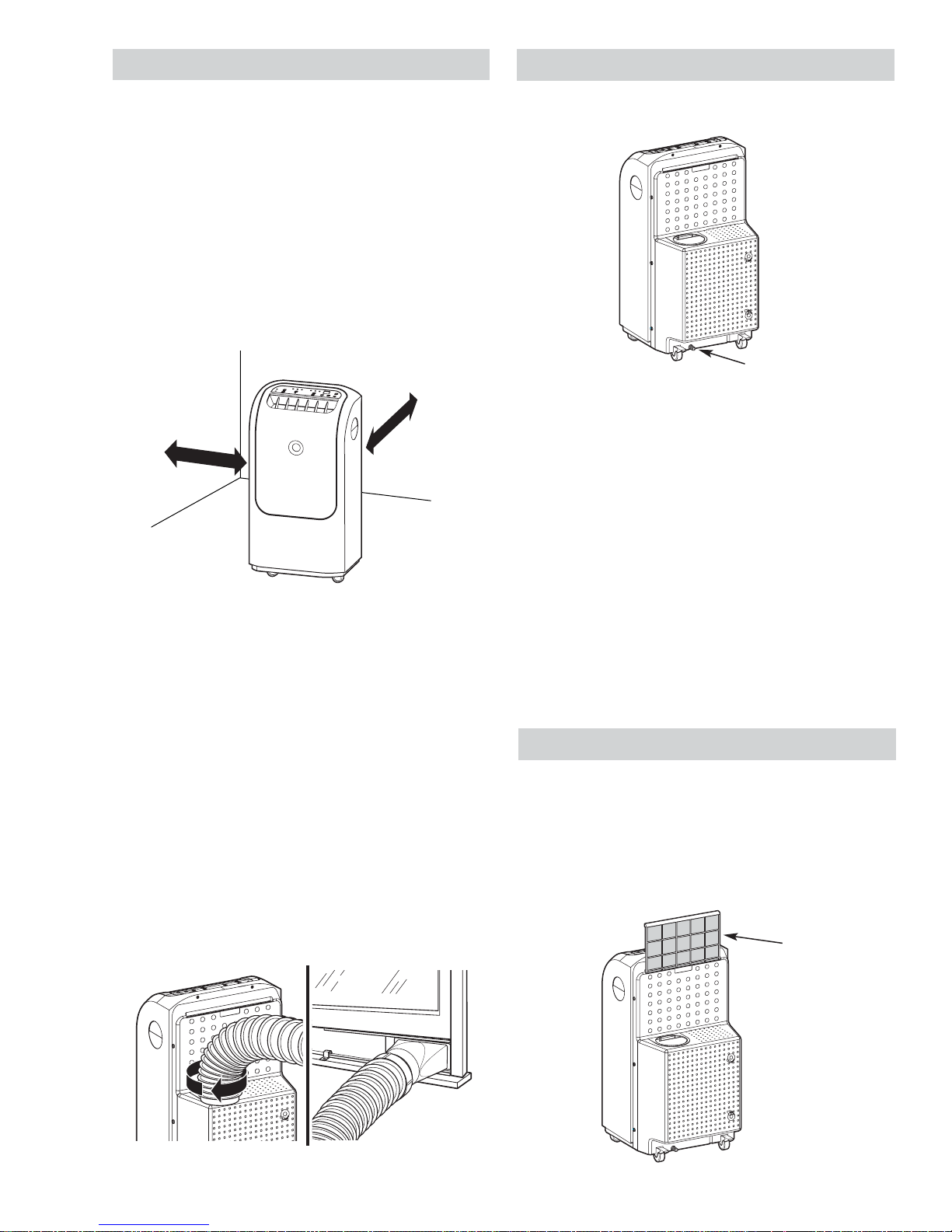

Air Filter

The air fi lter is located on the back of the air

conditioner. It should be checked and cleaned at

least every 30 days, or more often if necessary.

To remove air fi lter, grasp the tab and gently

pull the fi lter up and out. Wash it in warm soapy

water.

– 7 –

Page 8

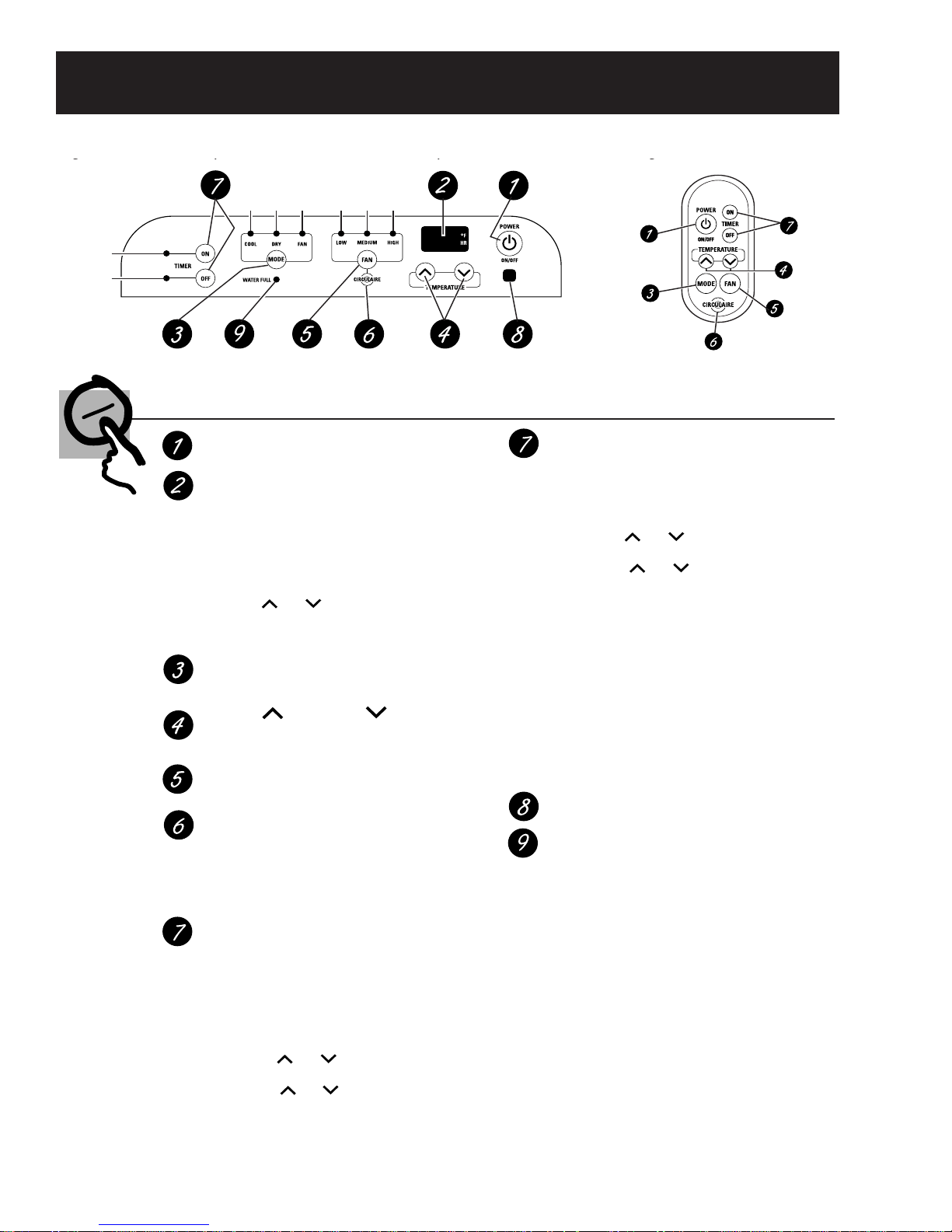

Control Features

gp p g

Cool

Dry

Fan

Low

Medium

Mode

Mode

Mode

Timer On

Timer Off

On

On

Fan

On

On

High

Fan

Fan

On

On

Air Conditioner Control Remote Control

Controls

ON/OFF Pad

Turns the air conditioner on and off.

Display

Shows the room temperature. Also shows the

set temperature while setting the temperature

in COOL mode or the set time while setting

TIMER ON or TIMER OFF.

NOTE: The display will change to show the

room temperature after settings have been

made. To recall the set cooling temperature,

press the or pad. To recall the timer

setting, press the TIMER ON pad or the TIMER

OFF pad for the timer that is set.

MODE

Use to set the air conditioner to COOL, DRY

or FAN mode.

Increase /Decrease Pads

Use to set temperature when in COOL mode

or to set a time with the timer feature.

FAN Pad

Use to set the fan speed to LOW, MEDIUM or HIGH.

CIRCULAIRE

Turn on to provide continuous side-to-side

air circulation.

For fixed side-to-side air direction, turn on

until the desired air direction is obtained,

then turn it off.

TIMER Pad

ON—The air conditioner can be set to

automatically come on in 1/2 (0.5) to 24 hours

at its previous setting. The unit must be on

while setting TIMER ON.

1. Press the POWER (ON/OFF) pad.

2. Press the TIMER ON pad. The TIMER ON

light will blink.

3. Press the or pad to set the desired

time for the unit to start. (Each time you

touch the or pads, the set time will

advance by 30 minutes between 0 and 10 hours

and by one hour between 10 and 24 hours.)

4. Press the TIMER ON pad again to start the timer.

5. Press the POWER (ON/OFF) pad to turn the

unit off.

TIMER Pad (cont.)

OFF—When the air conditioner is on, it can

be set to automatically turn off in 1/2 (0.5)

to 24 hours.

1. Press the TIMER OFF pad. The TIMER OFF

light will blink.

2. Press the or pad to set the desired

time for the unit to stop. (Each time you

touch the or pads, the set time will

advance by 30 minutes between 0 and 10

hours and by one hour between 10 and 24

hours.)

3. Press the TIMER OFF pad again to start

the timer.

After settings have been made, the display will

change back to show the room temperature.

NOTE: Both timers may be set, in combination,

to turn the unit on and off as desired.

To cancel the timer, press and hold the TIMER

ON or TIMER OFF pad (depending on the

timer(s) set) until its indicator light goes off.

Remote Control Signal Receiver

Water Full Indicator Light

When the Water Full Indicator Light begins

blinking, the unit has reached maximum

water collection level.

If water level does not lower in 40 minutes,

the unit will power off and it must be

manually drained.

1. Unplug the power cord and roll the unit

to a drain or outside.

2. Pull out the drain cap from the back

bottom edge and allow water to drain

from the unit.

3. Replace the drain cap and put the unit

back into operation.

NOTE: The unit is designed to automatically

evaporate water collected in normal settings.

However, in very humid settings, the unit may

occasionally need to be drained.

– 8 –

Page 9

– 9 –

Page 10

Component Locator Views

Front View

Louver Motor

Rear View

Vent Cover

Evaporator

Evaporator Fan

Evaporator Thermistor

Power Supply Board Cover

Condenser

Accumulator and Compressor

Condenser Fan

Water Switches

Power Supply Housing Shown with Cover Removed

Power Supply Board

Evaporator Fan Motor Capacitor

Condenser Fan Motor Capacitor

Water Pump

Drain

12V Transformer

Compressor Run Capacitor

– 10 –

Page 11

Components

Outer Cover

The outer cover must be removed to access the

internal components of the air conditioner. The

cover separates into 2 sections. It is held in place

by 8 Phillips-head screws, 2 on top and 3 on

each side.

Control Panel

The control panel is held in place by 8 tabs on

the inside of the outer cover. The outer cover

must be removed to access the tabs. (See Outer

Cover). Depress the tabs inward to remove the

control panel.

Operation/Smart Board

The operation/smart board is located behind the

control panel.

The operation/smart board is held in place by

9 Phillips-head screws. The outer cover must

be removed to access the screws. (See

Cover.)

Troubleshooting the operation/smart board:

If the unit is dead (no functions or indicators on

display):

• Check for 120 VAC on the power supply board

from the blue wire at CN8 (neutral) to the

brown wire on relay RLY1 (L1). If 120 VAC is

not present, check for an open in the wiring

from the power supply board to the terminal

block or the power cord.

• If 120 VAC is present between CN8 and

RLY1, check for 120 VAC at CN12 (primary

of low voltage transformer). If 120 VAC is not

present, replace the power supply board.

Outer

Note: If the brown wire is on the wrong terminal of

RLY1, the low voltage transformer will not receive

voltage.

• If 120 VAC is present at CN12, check for

12 VAC on the power supply board

at CN17. If 12 VAC is not present,

replace the low voltage transformer.

If 12 VAC is present at CN17, check

for 12 VDC at CN19, pin #1 and #5.

If voltage is not present, replace the

power supply board. If 12 VDC is

present, replace the operation/smart

board.

– 11 –

1

5

CN19

Page 12

Power Supply Board

The power supply board is located in the power supply housing behind the outer cover next to the

evaporator fan. The power supply housing cover is held in place by 7 Phillips-head screws.

Caution: Lock tabs on all low voltage wire connectors on the power supply board and operation/smart

board are fragile. Tab breakage can occur if excessive release pressure is applied.

Power Supply Board (PSB) Connector Locator

1 - Low water level switch (CN10) - 5 VDC should be measured across the two white wires in the white

connector when the low level switch is open.

2 - High water level switch (CN9) - 5 VDC should be measured across the two red wires in the white

connector when the high level switch is open.

Note: If CN9 and CN10 are reversed, the compressor will shut off after water trips the pump switch

(approximately 60 seconds). The condenser fan will continue to run for approximately 40 minutes.

3 - Thermistors (CN1). Pins #1 and #2 are the room ambient thermistor. Pins #3 and #4 are the

evaporator thermistor. The display will default to 75 F with an open connector. Output from the

board is 5 VDC between pin #1 and #2 and also between pin #3 and #4 with the connector

unplugged.

4 - Louver motor (CN5). Motor is approximately 200 Ω, 8 VDC should be measured between pin #1

and #5.

5 - CN19 to operation/smart board (CN15). CN19 is permanently attached to the PSB. 12 VDC should

be present between pin #1 and #5.

6 - CN14 to operation/smart board (CN20). CN14 is permanently attached to the PSB.

7 - Water pump (CN13 and CN2).

8 - Compressor capacitor (CN7).

9 - Terminal block (CN8 neutral).

10 - Transformer (CN12 primary). 120 VAC output from board to primary. Primary transformer

resistance is approximately 125 Ω.

– 12 –

Page 13

11 - Evaporator fan motor (CN3). Approximate resistance readings:

WH to BK - 70 Ω

WH to G - 90 Ω

WH to Y - 105 Ω

12 - Condenser fan motor (CN4). Approximate resistance readings:

WH to BK - 45 Ω

WH to Y - 80 Ω

13 - Transformer (CN17 secondary). Secondary transformer input 12 VAC. Secondary transformer

resistance is approximately 2 Ω.

14 - Compressor overload.

15 - Terminal block (L1). L1 input from the power cord.

6

5

1 2

3

4

13

– 13 –

7

12

15

11

14

7

9

8

10

Page 14

Thermistors

The air conditioner has 2 thermistors that come

as one assembly. The thermistor assembly part #

is WJ27X10065.

To check the thermistors for an open or short, run

the Factory Test Mode (see

The room temperature thermistor is located on

the front of the evaporator and positioned in place

by a plastic retainer.

Thermistor

Factory Test Mode).

The evaporator thermistor is located on the right

side of the evaporator in a copper sleeve.

Thermistor

Copper Sleeve

Check for resistance of the room temperature

thermistor at CN1 on the power supply board

between pin 1 and pin 2. Resistance will be

approximately 18 kΩ at 70°F.

Thermistor Resistance Chart

Temperature °FTemperature °CResistance

(kΩ)

10 -12 96.7

30 -1 53.4

32 0 50.7

50 10 30.6

70 21 18

90 32 11

Check for resistance of the evaporator thermistor

at CN1 between pin #3 and pin #4 on the power

supply board. Resistance will be approximately

18 kΩ at 70°F (21°C).

– 14 –

Page 15

Compressor

Check for 120 VAC on the power supply board

at RLY1 between CN7 and the black wire when

COOL or DRY is selected.

Compressor resistance values:

Common to Start = 2.1 Ω

C

Common to Run = 0.7 Ω

Compressor Run Capacitor

The run capacitor is located behind the power

supply board cover. The capacitor has a value of

50 µfd.

Start to Run = 2.8 Ω

If the air conditioner is shut off and immediately

started again during the COOL or DRY mode,

it will take approximately 3 minutes for the

compressor to restart.

To direct start the compressor with the overcool

and compressor protection disabled, enter the

factory test mode (see

select COOL or DRY on the control panel.

Note: The factory test mode cannot be entered

if the unit has shut down due to high water (see

Float Switch Operation). Unplug the unit and drain

the sump before entering factory test mode.

Compressor Wiring Direct Check

WARNING: Check windings fi rst. If open or

grounded, DO NOT apply power to compressor

terminals.

Factory Test Mode) and

R

S

Run Capacitor Check

1. Replace the run capacitor with a known good

test capacitor and attempt to start compressor.

Note: Test capacitor can be 10 µfd higher than

originally specifi ed for the unit.

2. If the compressor starts, install a new run

capacitor with correct rating specifi ed for the

unit.

Brown

– 15 –

Page 16

Evaporator Fan Assembly

The evaporator fan assembly consists of a

3-speed, 120 VAC motor and fan. It is connected

to the power supply board at CN3.

Resistance Check

Disconnect CN3 and check for resistance on the

motor connector between the following wires:

• White to black wires (high speed) approximately 70 Ω.

• White to green wires (medium speed) approximately 90 Ω.

• White to yellow wires (low speed) approximately 105 Ω.

ACN (White, Neutral)

7. Remove the 5 Phillips-head screws that hold

the power suppy housing in place. Remove

the power supply housing.

Blank Pin

INFH (Black, High Speed)

INFM (Green, Medium Speed)

INFL (Yellow, Low Speed)

CN3

Evaporator Fan Assembly Removal:

1. Remove the outer cover (see Outer Cover).

2. Remove the ground wire.

3. Remove the plastic wire ties on the left and

right side of the vent cover.

4. Remove the power supply housing cover (see

Power Supply Board).

8. Remove the 7 Phillips-head screws (3 on

each side and 1 in the middle) that hold the

vent cover in place. Remove the vent cover.

Vent Cover ScrewsScrews

5. Disconnect the associated wiring from the

power supply board and the evaporator fan

capacitor.

6. Remove the evaporator thermistor from the

evaporator.

– 16 –

Page 17

9. Remove the 8 Phillips-head screws from each

side of the evaporator fan housing. Remove

the evaporator fan housing.

Evaporator Fan Housing

Evaporator Fan

The fan is held in place by a 10-mm retaining

nut. The fan motor is held in place by 3 Phillipshead screws.

Condenser Fan Motor Removal

1. Remove outer cover (see Outer Cover).

2. Remove the power supply housing cover (see

Power Supply Board).

3. Disconnect the motor wires from the power

supply board. Remove the ground wire.

4. Remove the 7 Phillips-head screws from

the condenser fan housing. Separate the

condenser fan housing.

Condenser Fan Housing

Retaining Nut

Condenser Fan Assembly

The condenser fan assembly consists of a

2-speed 120 VAC motor and fan. It is connected

to the power supply board at CN4.

Disconnect CN4 and check for resistance on the

motor connector between the following wires:

• White to black wires (high speed) approximately 45 Ω.

• White to yellow wires (low speed) approximately 80 Ω.

Condenser Fan

The fan is held in place by an 8-mm hex-head

set screw. The fan motor is held in place by 4

Phillips-head screws.

Set Screw

– 17 –

Page 18

Louver Motor and Louvers

Circulation Pump

The louver motor is a 12-VDC motor that

moves the louvers from side to side when

the CIRCULAIRE button is pressed on the

control panel. The louver motor is connected

to the power supply board at CN5 and has an

approximate resistance of 200 Ω.

Louver Motor

Check for approximately 8 VDC between pin #1

and pin #5 with the wire harness disconnected.

CN5

1

5

Note: The power supply board will interrupt full

motor voltage for 1.5 seconds to allow for motor

reversing.

To access the louver motor, separate the outer

cover (see Outer Cover). The louver motor is held

in place by 2 Phillips-head screws.

The circulation pump is located next to the

compressor. It is connected to the power supply

board at CN13 and CN2. It has a supply voltage

of 120 VAC and a resistance of 29 Ω.

Circulation Pump

The circulation pump circulates the condensate

water from the sump to the sprinkler through

a plastic hose. The sprinkler distributes the

condensate water on the condenser fi ns for

evaporation. Condensate water that is not

evaporated returns to the sump for recirculation

to the sprinkler.

Sprinkler

To remove the louvers, use a small fl at-bladed

screwdriver to lift the holding bracket past the

lock tabs.

Drive Louver

Screws

Holding Bracket

Lock Tabs

Note: The louvers and louver linkage can be

replaced separately. The drive louver must be

ordered separately, it is not interchangeable with

the remaining 5 louvers.

Water Flow

Sump

– 18 –

Page 19

Circulation Pump Float Switches

There are 2 fl oat-operated switches in the

condensate water circulation system. The lowlevel switch, CN10, controls the pump. The highlevel switch, CN9, acts as a safety to prevent

fl ooding.

Low-Water-Level Switch

High-Water-Level

Switch

Float Switch Operation

When the drain sump is empty, both switches

are open. When the water level rises, the lowlevel switch closes and starts the pump. When

the water level drops, the switch opens and the

pump stops. At higher water levels, the low-level

switch stays closed and the circulation pump runs

continuously. If the low-level switch stays closed

for longer than 15 minutes, the condenser fan,

normally operating at high speed during COOL,

will change to low speed.

If the water level continues to rise, the highlevel switch closes and:

• After 1 minute, the WATER FULL indicator

light fl ashes.

• The compressor and evaporator fan shut

down.

• The condenser fan operates at high speed.

• The circulation pump continues to run.

If the high level switch stays closed for 40

minutes, the unit beeps twice and:

• The condenser fan and circulation pump shut

off.

• The WATER FULL indicator light stays on,

and all other indicator lights on the control

board turn off.

• The unit displays the room temperature.

Note: The low and high level switches must be

open and the unit must be manually drained and

restarted to resume operation.

WARNING: If condenser air fl ow is restricted,

condensate in the sump may become hot.

If the sump overfl ows and the pump is not

running:

• Check for 120 VAC between CN13 and CN2

on the power supply board. If voltage is

present, replace the pump.

• If 120 VAC is not present between CN13 and

CN2, check for 5 VDC at CN10. If 5 VDC is

not present, replace the board.

• If 5 VDC is present, check continuity of the

low-level switch at CN10 on the power supply

board.

• If the switch is open, check for an inoperative

fl oat or defective switch.

• If the unit has not shut down after 40 to 45

minutes during high condensate levels, check

for continuity of the high-level switch at CN9.

If the switch is open, check for an inoperative

fl oat or defective switch. If the unit still fails to

shut down, replace the board.

– 19 –

Page 20

Filter Drier

The fi lter drier should be installed anytime the

sealed system is repaired.

Caution: Brazing heat can cause the mastic to

become sticky and/or catch fi re. Remove the

mastic BEFORE installing the drier and charging

valve.

Replace the mastic after installation to help

deaden sound and reduce rattles.

Charging Valve

Mastic

Filter Drier

Parts

Charging Valve - Part # WJ56X61

Mastic - Part # WR2X9363

Drier - Part # WJ56X10003

– 20 –

Page 21

Factory Test Mode

The air conditioner has a factory mode function that allows the service technician to test various

functions.

Note: The factory test mode cannot be entered if the unit has shut down due to high water (see Float

Switch Operation under

Circulation Pump). Unplug the unit and drain the sump before entering factory

test mode.

• To enter the factory test mode, unplug the unit, then plug it back in while simultaneously pressing

and holding the ON button.

• While the ON button is still pressed, the software checks the 2 thermistors for open/short conditions.

If the thermistor is open, the power supply board beeps. After this initial test, all the functions can

then be tested. (Overcool protection and compressor protection are disabled on the compressor.)

• To exit the factory test mode, unplug the unit.

Key Function Chart

Function Key -

Electronic Mode

On/Off On

On/Off Off Nothing displayed Unit unpowered

Temperature Button

Fan Speed Button

Mode Button

Timer Button On

Timer Button Off Nothing Displayed N / A

Energy Saver On / Off On

Energy Saver On / Off Off

Circulaire

Sleep Mode

Status /

Function

Increase /

Decrease

Desired Room

Temperature

Increase /

decrease

Desired Fan

Speed

Changes

unit function

between Fan

Only and Cool

Mode

Engages

motorized

air discharge

louvres

Button activates

Sleep Mode

Display Action Notes

Appropriate symbol of Fan

or Cool and Temperature

Cool Symbol and Desired

Temperature

Fan Symbol or LED and

Desired Fan Speed (F1, F2

& F3 or Low, Med & High)

Appropriate symbol of Fan

or Cool or LED

Timer symbol or LED On

with time count (1 - 12 or 1

- 24 hrs.)

Energy Saver Symbol (or

LED) and Temperature

Standard mode and function

symbol

May have a Circulaire

symbol or LED display

Sleep symbol (or LED)

displayed for 15 seconds

after key is depressed

Unit powered up, compressor

On / fan On. When restarted,

the compressor will stay off for 3

minutes

Desired air temperature is set

& discharged from unit. Fan

and compressor cycle until set

temperature is received by temp

sensor.

Desired fan speed (RPM) is set &

fan motor speed changes

In Cool Mode, the unit fan and

compressor run and cool air is

discharged from unit. In Fan Mode,

the compressor is OFF and fan

runs at set speed to circulate

ambient temperature air in room.

Time Function is set.

In this mode the fan runs at

a reduced RPM when the

compressor shuts off. When the

compressor restarts, the fan RPMs

change back to the desired setting.

Standard Cool Cycle mode and

function

Motorized louvres begin auto swing

sequence

Unit runs for 8-hour cycle when

sleep key is pressed. One hour

after, cycle start temperature

increases a minimum 2°F to a

maximum of 4°F from the set point

for the duration of the cycle.

Temperature is not displayed in

Fan Mode.

In Fan Only mode, fan symbol

and speed will stay on display. In

Cool Mode, fan speed will briefl y

appear on display then display will

revert to temperature setting.

Time Function can be set so that

the unit can be made to run or

shut down with timer.

– 21 –

Page 22

Schematics and Wiring Diagrams

1L

N

– 22 –

Page 23

Illustrated Parts List

– 23 –

Page 24

VIEW DESCRIPTION QUANTITY APN08AAG1 APN10AAG1 APH10AAG1

0001 REMOTE CONTROL 1 WJ26X10204 WJ26X10204 WJ26X10204

0002 FRONT PANEL ACCESS 1 WJ90X10085 WJ90X10085 WJ90X10085

0003 PCB BRD OPERATION 1 WJ26X10197 WJ26X10197 WJ26X10197

0004 SUPPORT PANEL PCB 1 WJ26X10198 WJ26X10198 WJ26X10198

0005 POWER CNTRL ASM 1 WJ26X10199 WJ26X10199 WJ26X10199

0006 FRONT CVR 1 WJ90X10086 WJ90X10086 WJ90X10086

0007 MNTG CLIP 2 WJ01X10241 WJ01X10241 WJ01X10241

0008 EVAPORATOR MTR 1 WJ87X10153 WJ87X10153 WJ87X10153

0010 EVAPORATOR FAN 1 WJ87X10154 WJ87X10154 WJ87X10154

0013 LOUVER MTR 1 WJ95X10010 WJ95X10010 WJ95X10010

0014 LINKAGE ROD/LVR MTR 2 WJ85X10123 WJ85X10123 WJ85X10123

0015 VERTICAL LVR A 5 WJ85X10124 WJ85X10124 WJ85X10124

0016 VERTICAL LVR B 1 WJ85X10125 WJ85X10125 WJ85X10125

0017 LINKAGE ROD 1 WJ27X10064 WJ27X10064 WJ27X10064

0018 CAVITY 1 WJ01X10242 WJ01X10242 WJ01X10242

0019 AIR OUTLET 1 WJ76X10191 WJ76X10191 WJ76X10191

0020 EVAPORATOR ASM 1 WJ87X10155 WJ87X10155 WJ87X10155

0022 POWER SUPPLY PCB 1 WJ26X10200 WJ26X10200 WJ26X10200

0023 FAN CAPACITOR 2 WJ73X10135 WJ73X10135 WJ73X10135

0024 COMPRESSOR CAPACITOR 1 WJ20X10124 WJ20X10123 WJ20X10123

0025 TRANSFORMER 1 WJ01X10243 WJ01X10243 WJ01X10243

0027 CONDENSER ASSEMBLY 1 WJ88X10145 WJ88X10143 WJ88X10143

0028 SPRINKLER 1 WJ75X10002 WJ75X10001 WJ75X10001

0030 AIR TUNNEL COND 1 WJ76X10192 WJ76X10192 WJ76X10192

0031 GRID 1 WJ01X10244 WJ01X10244 WJ01X10244

0032 CONDENSER FAN 1 WJ94X10204 WJ94X10204 WJ94X10204

0033 TERMINAL 1 WJ02X10030 WJ02X10030 WJ02X10030

0034 TERMINAL COVER 1 WJ43X10057 WJ43X10057 WJ43X10057

– 24 –

Page 25

VIEW DESCRIPTION QUANTITY APN08AAG1 APN10AAG1 APH10AAG1

0035 CONDENSER FAN MTR 1 WJ94X10208 WJ94X10205 WJ94X10205

0036 COND AIR TUNNEL 1 WJ76X10193 WJ76X10193 WJ76X10193

0037 BACK PANEL 1 WJ82X10039 WJ82X10039 WJ82X10039

0038 ROUND TIE-IN 1 WJ01X10245 WJ01X10245 WJ01X10245

0039 EXHAUST HOSE 1 WJ86X10133 WJ86X10133 WJ86X10133

0040 ADAPTER 1 WJ01X10246 WJ01X10246 WJ01X10246

0041 WINDOW INSTALLATION KIT 1 WJ86X10141 WJ86X10141 WJ86X10141

0048 AIR FILTER 1 WJ85X10126 WJ85X10126 WJ85X10126

0049 GRID ADAPTER 1 WJ01X10247 WJ01X10247 WJ01X10247

0057 TRANSVERSE 1 WJ01X10248 WJ01X10248 WJ01X10248

0060 COMPRESSOR 1 WJ98X10177 WJ98X10172 WJ98X10172

0061 OVERLOAD PROTECTOR 1 WJ23X10081 WJ23X10081 WJ23X10081

0063 GASKET NUT 3 WJ43X10055 WJ43X10055 WJ43X10055

0064 BOLT COMPRESSOR 3 WJ01X10249 WJ01X10249 WJ01X10249

0065 WATER PUMP ASM 1 WJ94X10209 WJ94X10209 WJ94X10209

0073 WATER PUMP SWITCH 1 WJ26X10201 WJ26X10201 WJ26X10201

0074 WARNING SWITCH 1 WJ26X10202 WJ26X10202 WJ26X10202

0076 FLOAT 1 WJ01X10252 WJ01X10252 WJ01X10252

0077 FLOATER FOAM 2 WJ01X10253 WJ01X10253 WJ01X10253

0078 SWITCH BASE 1 WJ01X10254 WJ01X10254 WJ01X10254

0079 ROLLER-FRNT 2 WJ01X10255 WJ01X10255 WJ01X10255

0081 ROLLER-REAR 2 WJ01X10256 WJ01X10256 WJ01X10256

0082 WATER PLUG 1 WJ43X10056 WJ43X10056 WJ43X10056

0084 WATER PLUG CVR 1 WJ79X10146 WJ79X10146 WJ79X10146

0085 WATER TANK CVR 1 WJ79X10147 WJ79X10147 WJ79X10147

0100 THERMISTOR 1 WJ27X10065 WJ27X10065 WJ27X10065

– 25 –

Page 26

Warranty

– 26 –

Loading...

Loading...