Page 1

GE Healthcare

ApexPro™ Antenna Infrastructure, Transmitter,

and Receiver

Technical Manual

ApexPro™

English

2028341-019 (cd)

2028340-042A (paper)

© 2008 General Electric Company.

All rights reserved.

Page 2

NOTE

Due to continuing product innovation, specifications in this manual are subject to change without notice.

NOTE

The information in this manual only applies to ApexPro software version 3A and later, ApexPro CH software version 1A

and later, and the ApexPro, ApexPro CH, and CARESCAPE telemetry T14 transmitters hardware. It does not apply to

earlier software versions. Due to continuing product innovation, specifications in this manual are subject to change

without notice.

NOTE

For technical documentation purposes, the abbreviation GE is used for the legal entity name, GE Medical Systems

Information T echnologies.

Listed below are GE Medical Systems Information Technologies trademarks. All other trademarks contained herein are the

property of their respective owners.

APEX, ApexPro, CARESCAPE and DINAMAP Pro are trademarks of GE Medical Systems Information Technologies

registered in the United States Patent and Trademark Office.

CIC is a trademark of GE Medical Systems Information Technologies.

T-2 ApexPro™ 2001989-351A

15 October 2008

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ordering manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Responsibility of the manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Equipment symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety statements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Service information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Service requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Equipment identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

2 Equipment Overview . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Interface with ApexPro receiver subsystem . . . . . . . . . . . . . . . . . . . . . . . 2-3

Interface with multiple ApexPro receiver subsystems . . . . . . . . . . . . . . . . 2-3

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Unity Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

ApexPro antenna system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Enterprise Access antenna system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

ApexPro and CARESCAPE transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Transmitter controls, indicators and labels. . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Transmitter interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

DINAMAP PRO series monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

SpO2 oximeter modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Apex oximeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Interconnection cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

ApexPro receiver system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3 Installation and configuration . . . . . . . . . . . . . . . . . 3-1

Infrastructure installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Install coaxial cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Install antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

2001989-351A ApexPro™ i

Page 4

Install antenna amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Install attenuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Install power supplies and bias tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Install notch/bandpass filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

ApexPro receiver installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Mounting options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Setup antenna fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setup the receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Transmitter installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Programming the transmitter for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Transmitter configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Program code storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Error log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Manually view/program TTX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

ApexPro CH Telemetry Tune-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Visual inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Inspect for damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Verify transmitter features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Verify labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Cleaning products to avoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Transmitter/device cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

ECG cable/leadwire cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Transmitter calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Receiver calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Troubleshooting tree 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Troubleshooting tree 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

ApexPro transmitter troubleshooting tree . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

System troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

RF drop-out determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Yellow drop-out condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Quick antenna system checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

ii ApexPro™ 2001989-351A

Page 5

Antenna system troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

ApexPro transmitter carrier impairment meas urement procedure. . . . . . . 5-9

Rationale for test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Equipment needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Rohde & Schwarz FSH3 test procedure . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Receiver subsystem troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Receiver Subsystem LED status chart . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

General fault isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Verify connectivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

AC line voltage test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Event logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Before calling service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

System dropout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Apex oximeter and Nonin Xpod oximeter . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Apex oximeter short battery life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Power shutdown during leads fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

ApexPro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

ApexPro CH and T14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

6 Replaceable parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Mounting hardware and labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Optional antenna mounting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Bias tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Bias tee & power supply mounting kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Antenna amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Coaxial cabling - RG-6 and RG-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Block and terminator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

75-Ohm terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

DC-power block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Splitters/combiners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

DC passing attenuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Notch filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

2001989-351A ApexPro™ iii

Page 6

Bandpass filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

ApexPro bandpass filter 608-614 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Cavity bandpass filter 608-614 MHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

International bandpass filter 433.05-434.75 MHz . . . . . . . . . . . . . . . . . . 6-18

International bandpass filter 458.5-459.1 MHz . . . . . . . . . . . . . . . . . . . . 6-19

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Ordering parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Ordering parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Field replaceable units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Label kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Interconnect cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

ApexPro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

ApexPro CH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

T14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Optional components and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

ApexPro CH transmitter parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

T14 transmitter parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Receiver subsystem disassembly guidelines. . . . . . . . . . . . . . . . . . . . . . . 6-24

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Replace the fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Open the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Remove a quad receiver module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Add a quad receiver module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Remove/replace the power supply assembly . . . . . . . . . . . . . . . . . . . . . 6-27

Remove/replace receiver subsystem pcb (backplane) . . . . . . . . . . . . . . 6-27

Close and reconnect unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Receiver system drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Receiver assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Quad receiver module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

7 Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Antenna checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Infrastructure equipment checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Receiver subsystem checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Checkout procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

iv ApexPro™ 2001989-351A

Page 7

Additional system tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Transmitter checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Checkout procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Additional system tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Oximeter operational tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Apex oximeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Nonin Xpod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Accutracker DX NIBP operational tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Pressure calibration check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Over-pressure release check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Hardware time-out and system leak check . . . . . . . . . . . . . . . . . . . . . . . 7-22

Communication test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Repair log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

A Technical specifications . . . . . . . . . . . . . . . . . . . . . . A-1

ApexPro and ApexPro CH transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Analog/digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

T14 transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

FCC compliance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Apex oximeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Nonin Xpod oximeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Accutracker DX noninvasive blood pressure monitor. . . . . . . . . . . . . . . . A-9

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

2001989-351A ApexPro™ v

Page 8

ApexPro receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Antenna specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Warranty information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Power supply specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-15

Bias tee specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-15

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-15

Device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-15

Bias tee & power supply mounting kit specifications . . . . . . . . . . . . . . . A-16

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

Antenna amplifier specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

Device specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

B Electromagnetic compatibility . . . . . . . . . . . . . . . . .B-1

ApexPro and CARESCAPE transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Guidance and manufacturer’s declaration – electromagnetic emissions . B-2

Guidance and manufacturer’s declaration – electromagnetic immunity . .B-3

Recommended separation distances . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

Compliant cables and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

ApexPro receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-7

Guidance and manufacturer’s declaration . . . . . . . . . . . . . . . . . . . . . . . . B-7

Recommended separation distances . . . . . . . . . . . . . . . . . . . . . . . . . . .B-10

Compliant cables and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-11

vi ApexPro™ 2001989-351A

Page 9

2001989-351A ApexPro™ vii

Page 10

viii ApexPro™ 2001989-351A

Page 11

1

Introduction

2001989-351A ApexPro™ 1-1

Page 12

Introduction

Manual Information

Revision history

Each page of this manual has the document part number and revision letter at the

bottom of the page. The revision letter identifies the document’s update level. The

revision history of this document is summarized below.

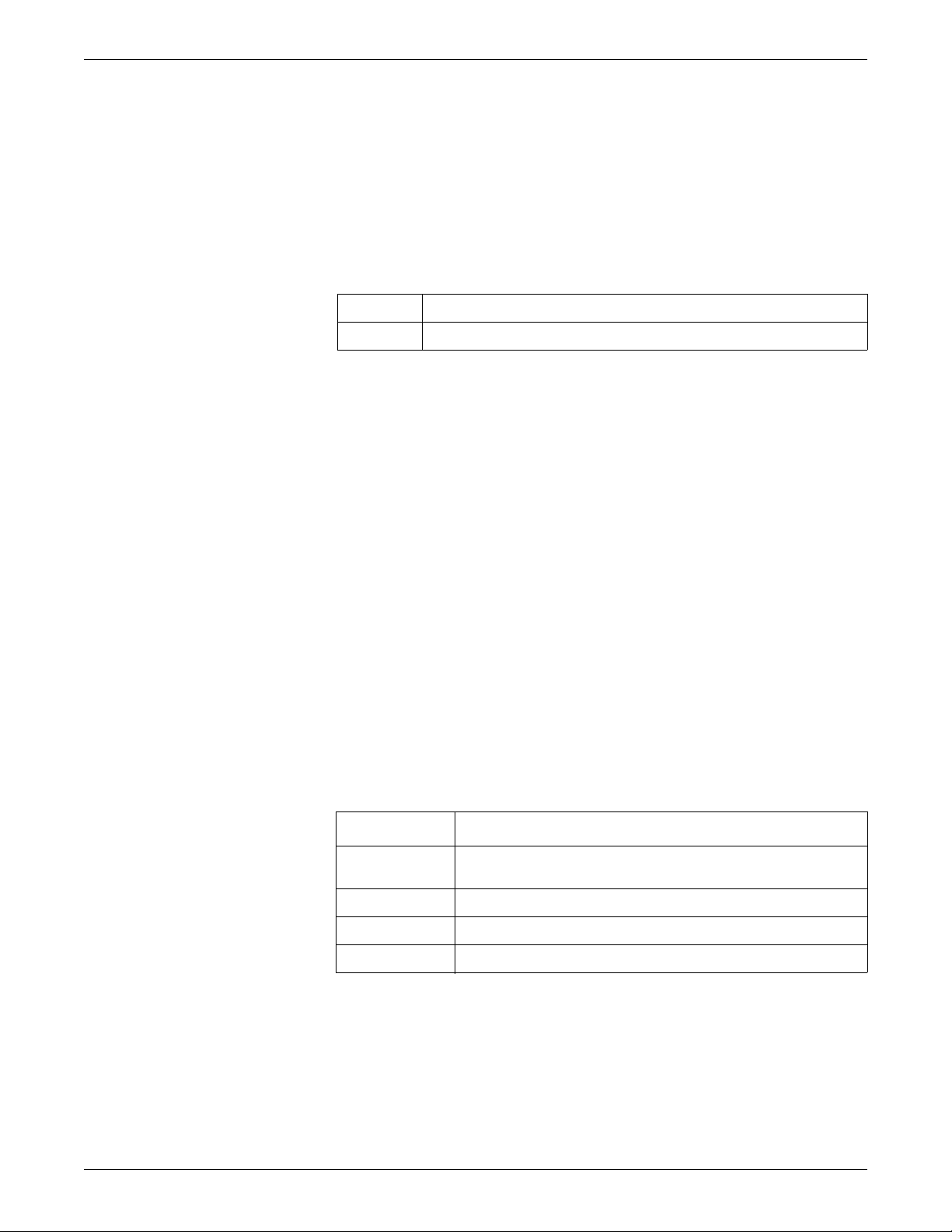

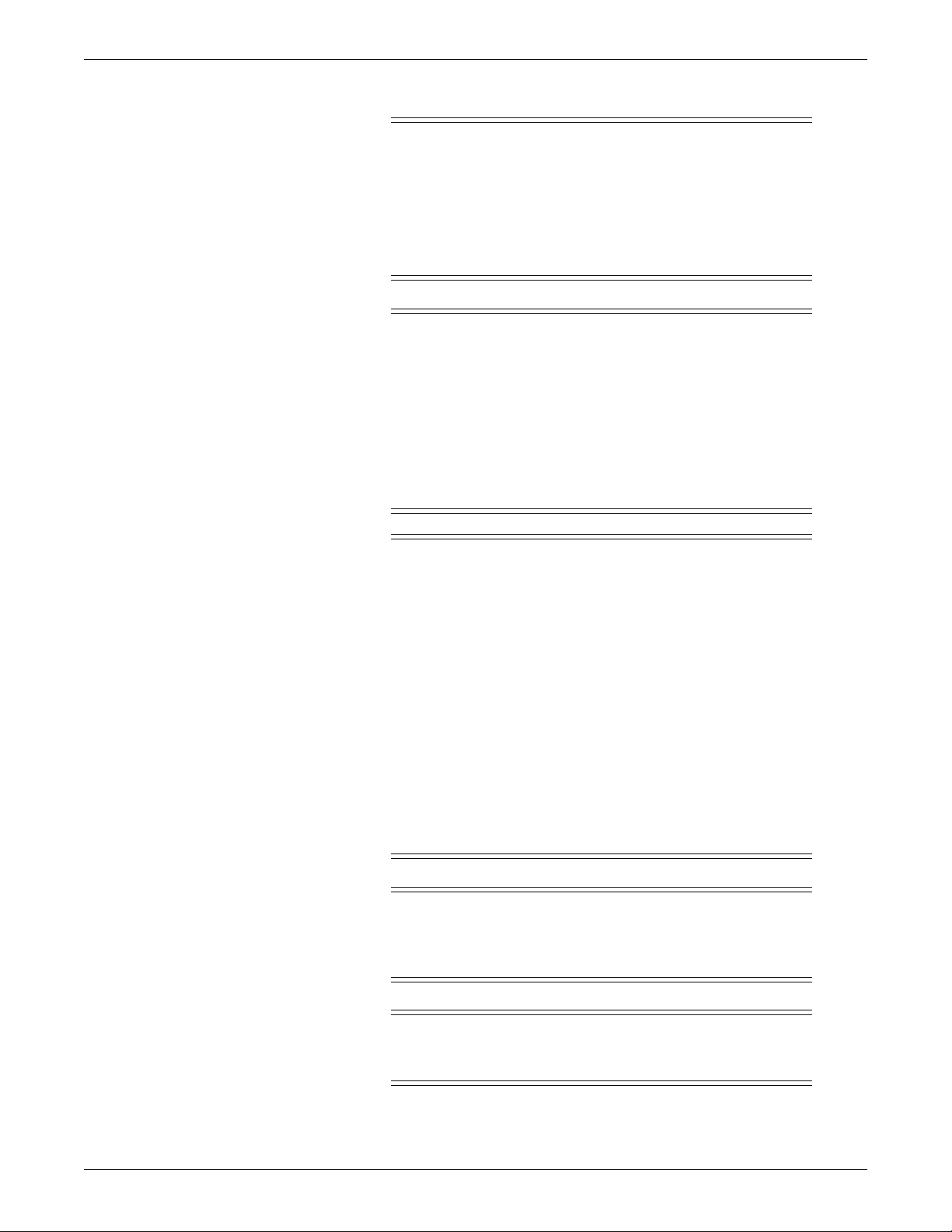

Revision Comment

Purpose

This manual provides technical information for maintaining the ApexPro, ApexPro

CH and CARESCAPE T14 transmitters, ApexPro receiver subsystem, ApexPro

antenna infrastructure equipment and GE equipment that connects to the transmitter.

A Initial release

Intended audience

Ordering manuals

Conventions

Users of this manual are expected to have a background in electronics, including

analog and digital circuitry, RF, and microprocessor architectures. It is intended for

service representatives and technical personnel who maintain, troubleshoot or repair

this equipment.

A paper copy of this manual will be provided upon request. Contact your local GE

representative and request the part number on the first page of the manual.

Style Definition

bold Indicates hardware items such as keys, labels, or text entered by the

user.

bold italic Indicates software terms such as menu items or screen text.

+ Indicates keyboard keys to select simultaneously.

> Indicates menu options to select consecutively.

1-2 ApexPro™ 2001989-351A

Page 13

Safety information

Intended use

The ApexPro Telemetry System is intended for use under the direct supervision of a

licensed healthcare practitioner. The system is designed to acquire and monitor

physiological data for ambulating adult and pediatric patients within a defined

coverage area. The system processes this physiological data to detect various ECG

arrhythmia events and select physiological parameter limit violations.

The ApexPro Telemetry System is intended to be installed in the hospital or clinical

environment in order to provide clinicians with patient physiological data, while

allowing for patient mobility. These systems are typically deployed in sub acute care

areas in hospitals or clinical sites where patient mobility can enhance the

effectiveness of the medical procedures administered.

The physiological parameters monitored include ECG, non-inv a si ve blood pressure,

non-invasive temperature and SpO2. The ApexPro Telemetry System is intended to

provide ECG data via Ethernet to the computer platform for processing. The ApexPro

is also intended to provide physiologic data over the Unity network to clinical

information systems for display.

Introduction

Responsibility of the manufacturer

GE is responsible for the effects of safety, reliability, and performance only if:

assembly operations, extensions, readjustments, modifications, or repairs are

carried out by persons authorized by GE;

the electrical installation of the relevant room complies with the requirements of

the appropriate regulations; and

the device is used in accordance with the instructions for use.

Equipment symbols

NOTE

Some symbols may not appear on all equipment.

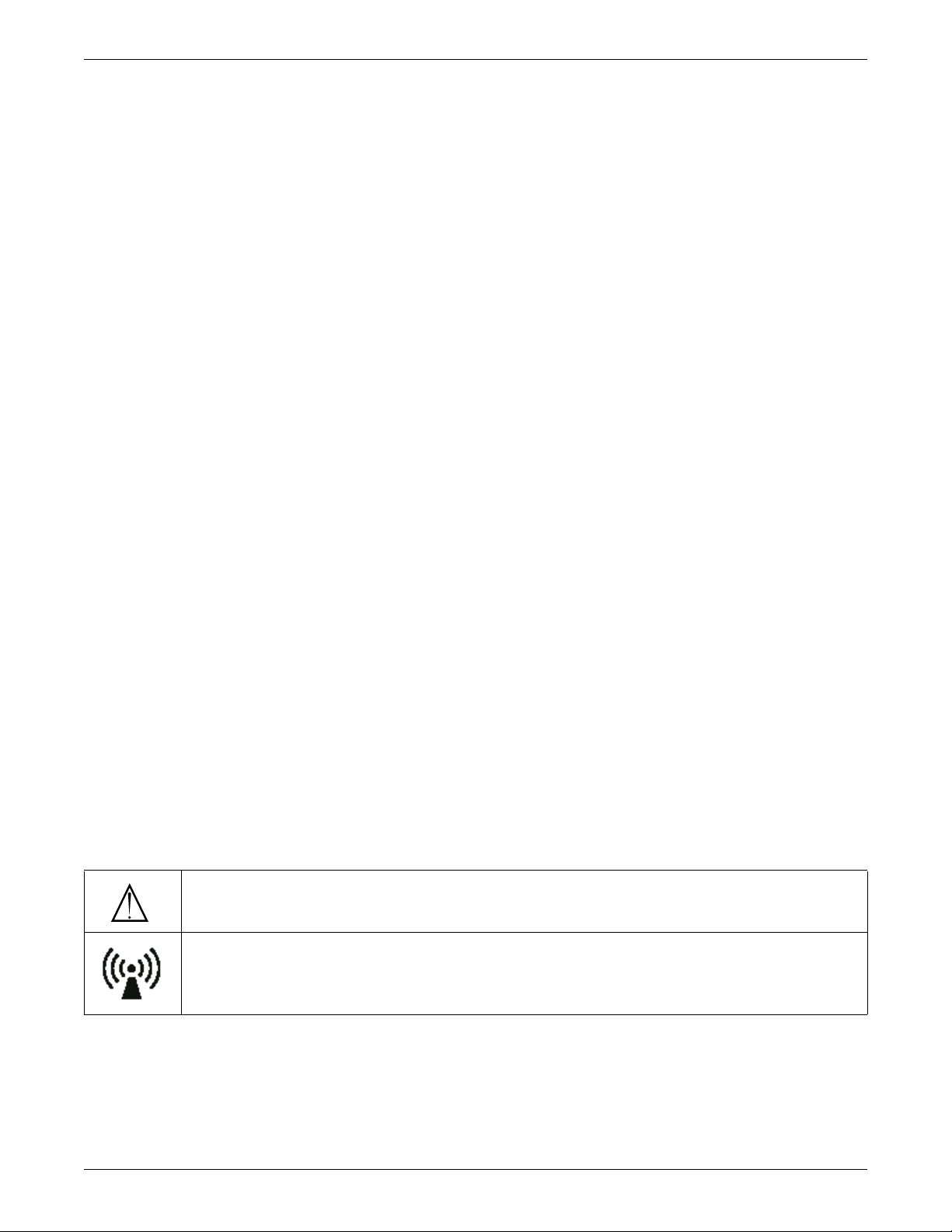

ATTENTION: Consult accompanying documents.

Non-ionizing electromagnetic radiation: T o indicate elevated, potentially dangerous, levels of non-ionizing radiation. Note In case of application in a warning sign the rules according to ISO 3864-1 shall be adhered to.

IEC 60878 note: See safety sign ISO 7010 - W005 “Warning, non-ionizing radiation”.

2001989-351A ApexPro™ 1-3

Page 14

Introduction

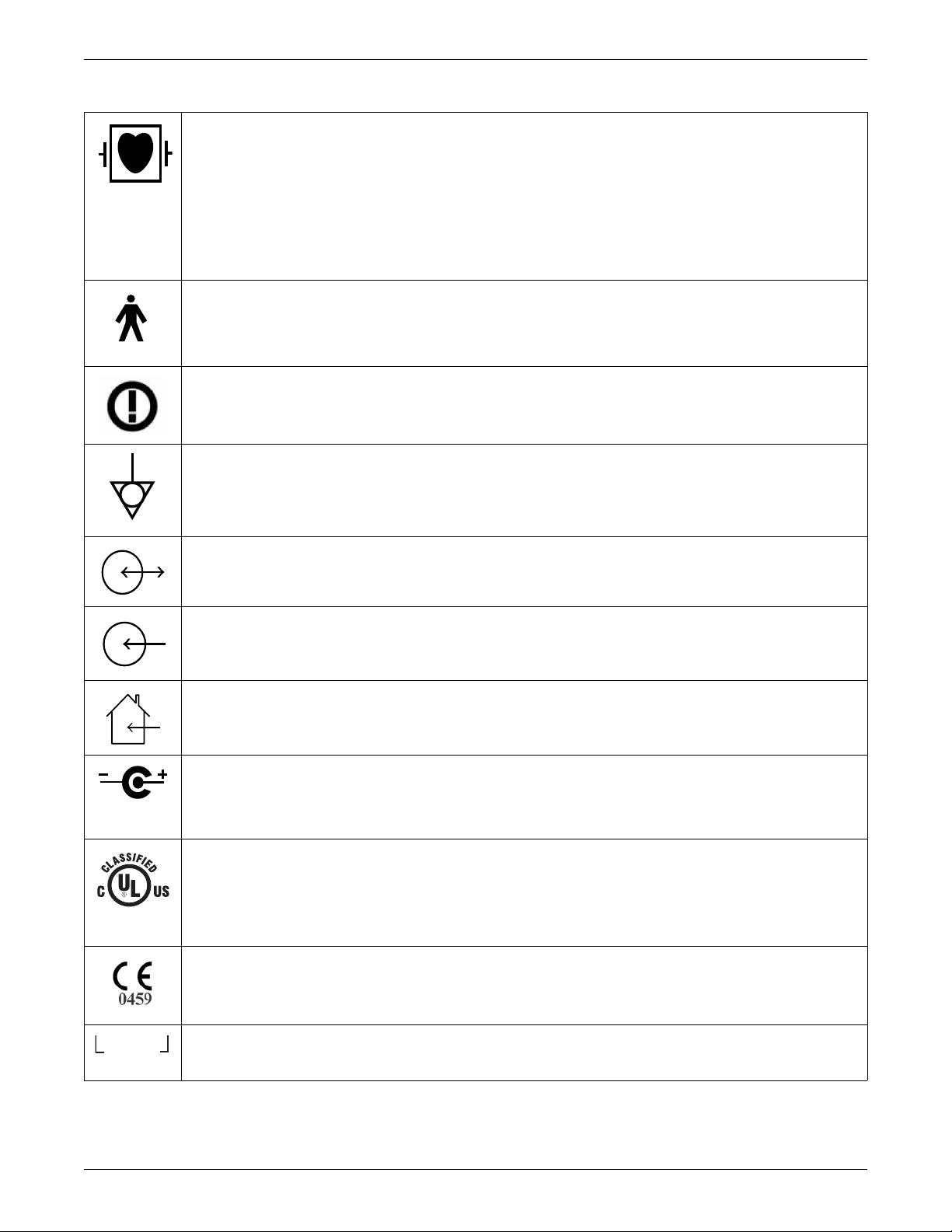

INTFC.

Type CF applied part: Isolated (floating) applied part suitable for intentional external and internal application to the patient

including direct cardiac application. “Paddles” outside the box indicate the applied part is defibrillator proof.

[Medical Standard Definition:] F-type applied part (floating/isolated) complying with the specified requirements of IEC

60601-1/UL 60601-1/CSA 601.1 Medical Standards to provide a higher degree of protection against electric shock than

that provided by type BF applied parts.

NOTE

The rating of protection against electric shock (indicated by symbol for CF) is achieved only when used with patient

applied parts recommended by GE.

TYPE B APPLIED PART: Non-isolated applied part suitable for intentional external and internal application to the patient

excluding direct cardiac application.

[Medical Standard Definition:] Applied part complying with the specified requirements of IEC 60601-1/UL 60601-1/CSA

601.1 Medical Standards to provide protection against electric shock, particularly regarding allowable leakage current.

R&TTE equipment class 2 identifier: An alert sign, indicating that transmitting radio equipment operates in nonharmonized frequency bands and can cause interference.

Equipotential

4P41

DC In/RF Out or DC Out/RF In

DC In or RF In

For indoor use only.

Power supply cable configuration.

+ = Power

– = Return

Medical Equipment

With respect to electric shock, fire and mechanical hazards only in accordance with UL 60601-1, and CAN/CSA C22.2 NO.

601.1 and if applicable, IEC 60601-2-27, IEC 60601-2-30, and IEC 60601-2-49.

CE mark CE-0459 indicating conformity with the provisions of the Council Directive 93/42/EEC concerning medical

devices, and fulfills the essential requirements of Annex I of this directive.

Interface Connector(s)

1-4 ApexPro™ 2001989-351A

Page 15

Introduction

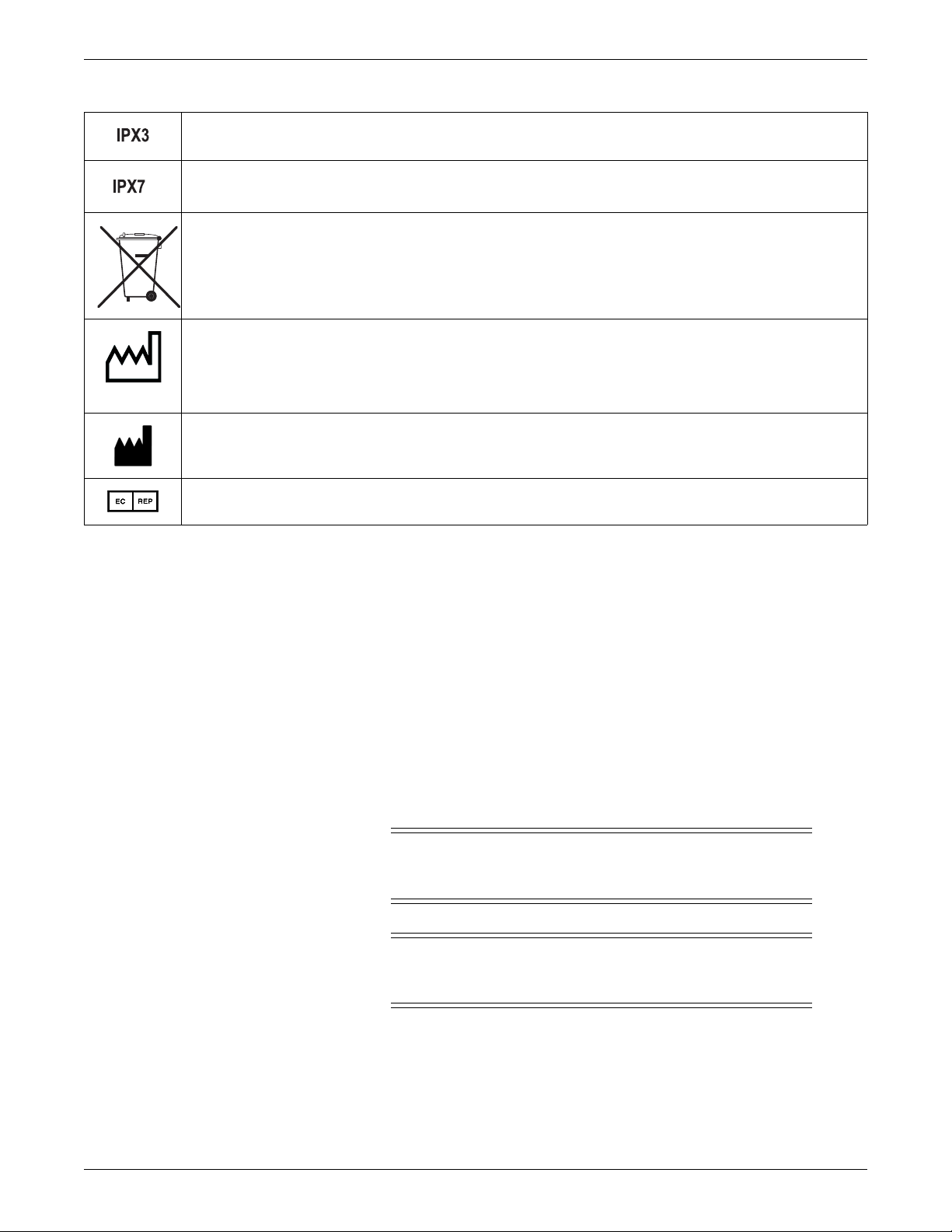

2005-08

Complies with IPX3 standards for water ingress

Complies with IPX7 standards for water ingress

This symbol indicates that the waste of electrical and electronic equipment must not be disposed as unsorted municipal

waste and must be collected separately. Please contact an authorized representative of the manufacturer for information

concerning the decommissioning of your equipment.

This symbol indicates the date of manufacture of this device. The first 4 digits identify the year and the last 2 digits identify

the month.

Manufacturer name and address.

European authorized representative.

Safety statements

Dangers

Warnings

Danger statements identify an imminent hazard which, if not avoided, will result in

death or serious injury. No danger statements apply to this product.

Warning statements identify a potential hazard or unsafe practice which, if not

avoided, could result in death or serious injury. The following warnings apply to this

product.

WARNING

BEFORE USE —Periodically, and whenever the integrity of the

device is in doubt, test all functions.

WARNING

EXPLOSION HAZARD —Do not use this equipment in the

presence of flammable anesthetics, vapors or liquids.

2001989-351A ApexPro™ 1-5

Page 16

Introduction

WARNING

FALSE CALLS—False low heart rate indicators or false asystole

calls may result with certain pacemakers because of electrical

overshoot.

WARNING

INTERFACING WITH OTHER EQUIPMENT —Contact GE for

information before connecting any devices to the equipment that are

not recommended in this manual.

WARNING

LOSS OF DATA — Notify the affected users relying upon this data

flow before shutting down the ApexPro™ antenna infrastructure

components for any reason.

WARNING

MONITORING PACEMAKER PATIENTS —Monitoring of

pacemaker patients can only occur with the pace program activated.

WARNING

PACEMAKER SPIKE —An artificial pacemaker spike is displayed

in place of the actual pacemaker spike. All pacemaker spikes appear

uniform. Do not diagnostically interpret pacemaker spike size and

shape.

WARNING

P ATIENT HAZARD —A pacemaker pulse can be counted as a QRS

during asystole in either pace mode. Keep pacemaker patients under

close observation.

WARNING

RATE METERS—Keep pacemaker patients under close

observation. Rate meters may continue to count the pacemaker rate

during cardiac arrest and some arrhythmias. Therefore, do not rely

entirely on rate meter alarms.

Cautions

Caution statements identify a potential hazard or unsafe practice which, if not

avoided, could result in minor personal injury or produ ct/property damage. The

following cautions apply to this product.

1-6 ApexPro™ 2001989-351A

Page 17

Introduction

CAUTION

ACCESSORIES (SUPPLIES) —To ensure patient safety, use only

parts and accessories manufactured or recommended by GE.

Parts and accessories used must meet the requirements of the

applicable IEC 60601 series safety standards, and/or the system

configuration must meet the requirements of the IEC 60601 medical

electrical systems standard.

CAUTION

ACCESSORIES (EQUIPMENT) —The use of accessory equipment

not complying with the equivalent safety requirements of this

equipment may lead to a reduced level of safety of the resulting

system. Consideration relating to the choice shall include:

use of the accessory in the patient environment; and

evidence that the safety certification of the accessory has been

performed in accordance to the appropriate IEC 60601-1 and/or

IEC 60601 harmonized national standard.

CAUTION

FDA POSTMARKET SAFETY ALERT—The United States FDA

Center for Devices and Radiological Health issued a safety bulletin

October 14, 1998. This bulletin states “that minute ventilation rateadaptive implantable pacemakers can occasionally interact with

certain cardiac monitoring and diagnostic equipment, causing the

pacemakers to pace at their maximum programmed rate.”

The FDA further recommends precautions to take into

consideration for patients with these types of pacemakers. These

precautions include disabling the rate responsive mode and

enabling an alternate pace mode. For more information contact:

Office of Surveillance and Biometrics, CDRH, FDA

1350 Piccard Drive, Mail Stop HFZ-510

Rockville, MD 20850

U.S.A.

CAUTION

POWER REQUIREMENTS —If the installation of the equipment,

in the USA, uses 240V rather than 120V, the source must be a

center-tapped, 240V, single-phase circuit.

CAUTION

RESTRICTED SALE —Federal law restricts this device to be sold

by or on the order of a physician.

2001989-351A ApexPro™ 1-7

Page 18

Introduction

Notes

CAUTION

SUPERVISED USE —This system is intended for use under the

direct supervision of a licensed health care practitioner.

Note statements provide application tips or other useful information to assure that you

get the most from your equipment. The following notes apply to this product.

NOTE

ECG monitoring with patients on non-invasive transcutaneous pacemakers may

not be possible due to large amounts of energy produced by these devices.

Monitoring ECG with an external device may be needed.

NOTE

This device is not intended for home use.

NOTE

Service information

Service requirements

Follow the service requirements listed below.

Refer equipment servicing to GE authorized service personnel only.

Any unauthorized attempt to repair equipment under warranty voids that

It is the user’s responsibility to report the need for service to GE or to one of their

Failure on the part of the responsible individual, hospital, or institution using this

Regular maintenance, irrespective of usage, is essential to ensure that the

Patient environment is any volume in which intentional or unintentional cont act

can occur between patient and parts of the system or between patient and other

persons touching parts of the system. (IEC 60601-1-1)

warranty.

authorized agents.

equipment to implement a satisfactory maintenance schedule may cause undue

equipment failure and possible health hazards.

equipment will always be functional when required.

1-8 ApexPro™ 2001989-351A

Page 19

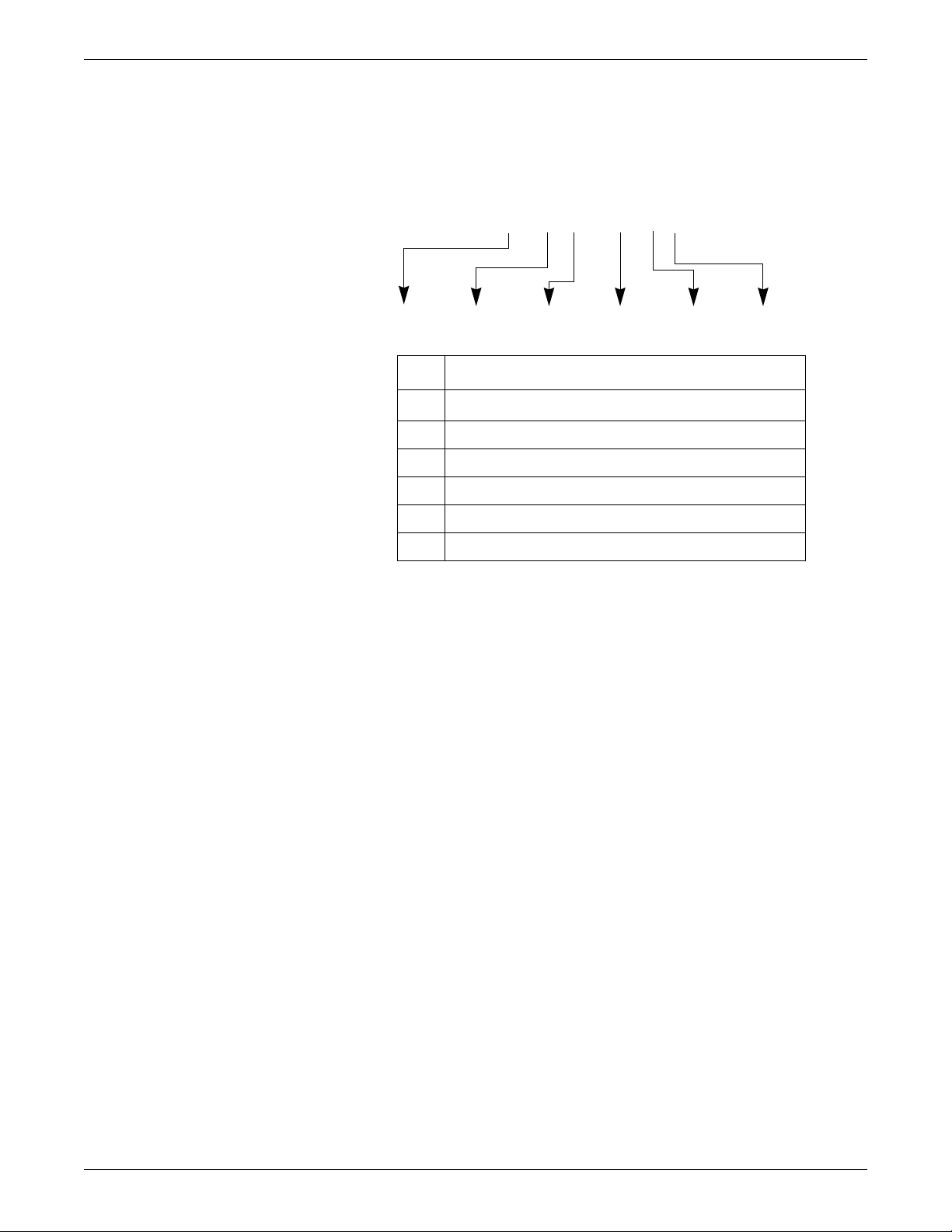

Equipment identification

### ## ## #### # #

ABCDEF

Every GE device has a unique serial number for identification. A sample of the

information found on a serial number label is shown below.

Introduction

Description

A

B year manufactured

C fiscal week manufactured

D production sequence number

E manufacturing site

F miscellaneous characteristic

product code

1

The product code is: TT for ApexPro transmitter, domestic; AM for

ApexPro transmitter, international; T9 for Ap exPro CH transmitter;

SE3 for the CARESCAPE Telemetry T14 transmitter; RTS for US

(560-614 MHz) ApexPro receiver subsystem; and RAV for

international (420-474 MHz) ApexPro receiver subsystem.

1

2001989-351A ApexPro™ 1-9

Page 20

Introduction

1-10 ApexPro™ 2001989-351A

Page 21

2

Equipment Overview

2001989-351A ApexPro™ 2-1

Page 22

Equipment Overview

System overview

Overview

A transmitter is directly connected to the patient and transmits monitored data via the

antenna to a corresponding receiver in a one-to-one correspondence between

transmitters and receivers. Up to 16 receivers (four quad receiver modules with four

receivers on each) may reside in a receiver system. Up to four quad receiver modules

connect to the receiver backplane PCB, which is responsible for managing

communications between all connected receivers and the telemetry host application

software on the PC. The communication between the PC and the receiver backplane

is 10BaseT Ethernet and is called the Receiver-Exchange (RX) network. The host

application software processes the patient data from the receivers and makes the

patient’s ECG parameter and waveform data available for display at network viewing

stations or the Clinical Information Center (CIC) central station.

The ApexPro telemetry system consists of the following components:

Patient monitoring equipment

Apex oximeter (optional)

Xpod oximeter (optional)

Accutracker DX noninvasive blood pressure monitor (optional)

DINAMAP PRO 100, 200, 300, and 400 series monitor (optional)

Transmitter (one for each monitored patient)

ApexPro transmitter, or

ApexPro CH transmitter

Antenna system

ApexPro antenna system

Receiver antenna

Attenuator

Antenna splitters/combiner

Amplifier

Bias tee

Antenna filter as needed (bandpass and/or notch)

DC power source to power the receiver antennas and antenna amplifiers

Enterprise Access antenna system.

Refer to the Enterprise Access System Service Manual for more details.

Receiver system (holds up to 4 ApexPro quad receivers)

Unity Network

ApexPro Telemetry Server (ATS) with ApexPro software

PC with CIC Pro Clinical Information Center (CIC)

2-2 ApexPro™ 2001989-351A

Page 23

Power requirements

Transmitter

Monitor(s)

Attenuator

Attenuator

Cable

Antenna

RX

RF

DC

+12 VDC

1A

Unity MC

Antenna System

Splitter

Bias

Tee

Filter,

Notch,

or

Bandpass

Combiner

ApexPro

Receiver

System

ATS

CIC Pro

Center(s)

Amplifier

Antenna

Cable

Power Supply

Equipment Overview

035B

The DC power requirements for the ApexPro antenna system depend greatly on the

configuration of each individual system. To ease the power requirements of the

ApexPro telemetry system, the power supply for the antenna system is external to the

ApexPro receiver system and separate from the antenna.

Interface with ApexPro receiver subsystem

Each receiver in the quad receiver module, located in the receiver subsystem, receives

data from the transmitters. This data is processed by the receiver system and then

transmitted via the dedicated Ethernet interface to a CIC Pro center for further

processing and display. The quad receivers and the receiver subsystem together are

known as the receiver system.

The interface between the antennas and the receiver system consists of coaxial

cabling and connectors for transferring the transmitted signal. The interface uses 75ohm cable from each antenna field and F style 75-ohm connectors as a connection

medium. The preferred cable is RG-6, but for longer lengths RG-11 may be used.

Interface with multiple ApexPro receiver subsystems

To interface the antenna system with multiple ApexPro receiver systems, each

antenna field in the antenna system is split into the appropriate number of tap points

using combiners/splitters before connecting to each ApexPro receiver system.

Equipment

Unity Network

2001989-351A ApexPro™ 2-3

The Unity Network is the networking system used to transmit information from one

GE product to others connected to the same Unity Network.

Page 24

Equipment Overview

ApexPro antenna system

Antenna

The antenna system is used for transmission of data from the transmitter to the

receiver system.

The antenna is a circularly-polarized array of sloping half-wave dipoles with an omnidirectional coverage pattern. The antenna is available in two versions: active and

passive. An active antenna includes an active amplifier, while a passive antenna

provides no signal amplification. The receiver antenna comes with a standard drop

ceiling T-bar mount.

Antenna amplifier

The antenna amplifier boosts the signal when losses from other antenna components

exceed the gain of the antenna. DC power for the amplifier is obtained from the

+12VDC power supply.

Coaxial cable

Splitters/combiner

Attenuators

Power supply

Coaxial cabling is used to connect the omni-directional antennas and amplifiers to the

receiving equipment. Controlled-impedance cabling is used and 75-ohm, RG-6 type

is recommended. Plenum- or riser-rated cable is used to meet NEC fire codes. RG-11

may be used if cable lengths become long and dB losses become excessive.

Passive splitters/combiners split or combine the RF signal into multiple paths. The

same splitter may also be used as a combiner to join multiple RF signals into one

path. There are two-, four-, or eight-way splitters available that are DC-passive.

Attenuators lower signals and balance antenna runs. The attenuators are DC-passive

and are available as 3 dB, 6 dB and 10 dB attenuators.

A +12VDC power supply at 1A supplies power to the antenna system. Power supplies

accept AC voltages between 90-270VAC. AC inputs have internal fuses that are not

replaceable. The output of the supply is short circuit protected.

Bias tee

The antenna bias tee allows the injection of DC power from the antenna power supply

into the antenna system cabling. The bias tee supplies RF isolation between the RF

signals on the antenna cabling and the power supply. It contains a DC block that

2-4 ApexPro™ 2001989-351A

Page 25

Notch filter

Bandpass filter

Identify antennas

Equipment Overview

blocks the conduction of DC power to the receiver system and associated hardware. A

bias tee is used with each power supply.

Notch filters are frequency or TV channel specific and notch out the TV video, audio,

or digital center of the band signals. Notch filters also filter pager signals or other

strong RF signals that can be found in a telemetry environment.

The bandpass filter rejects frequencies outside its listed bandwidth and passes

frequencies inside its listed bandwidth. It is used in place of certain notch filters to

provide wide band filtering with less in-band loss than multiple notch filters.

Identify the high-power and active antennas by the part number label and the GE logo

only on the front (bottom). The passive antenna looks identical to the high-power

antenna except it has a black cap over the LED power indicator. To visually identify

the antenna type, observe the following:

The -002, -003, -004, and -005 models have an embossed GE logo.

The -006, -007, and -008 models have a blue GE logo.

The -003, -005, and -006 passive antennas have a black cap over the LED power

indicator.

For further identification, check the part number label.

Part number

2000673-002 600 MHz ApexPro Antenna Hi-Pwr

2000673-003 600 MHz ApexPro Antenna

2000673-004 450 MHz ApexPro Antenna Hi-Pwr

2000673-005 450 MHz ApexPro Antenna

Design

frequency

Antenna type Description Status

560-614MHz

Passive 560-614MHz

420-474MHz

Passive 420-474MHz

This high-power antenna operates within 560-614MHz and has

filtering for out-of-band signals. It has >15dB rejection below

470MHz.

This passive antenna has no internal filtering or amplification,

therefore requires no DC voltage. Use this antenna with notch

filters, high- or low-pass filters, or a bandpass filter and an in-line

amplifier. Use only when other antennas do not meet design

requirements.

This high-power antenna operates within 420-474MHz and has

filtering for out-of-band signals. It has >15dB rejection below

320MHz.

This passive antenna has no internal filtering or amplification,

therefore requires no DC voltage. Use this antenna with notch

filters, high- or low-pass filters, or a bandpass filter and an in-line

amplifier. Use only when other antennas do not meet design

requirements.

Obsolete

Obsolete

Obsolete

Current

2000673-006 600 MHz ApexPro Passive

Antenna 560-614MHz

This passive antenna has no internal filtering or amplification,

therefore requires no DC voltage. Use this antenna with notch

filters, high- or low-pass filters, or bandpass filters and an in-line

amplifier. Use only when the other antennas do not meet design

requirements.

Current

2001989-351A ApexPro™ 2-5

Page 26

Equipment Overview

Part number

2000673-007 600 MHz ApexPro Active Antenna

2000673-008 450 MHz ApexPro Antenna Hi-Pwr

Design

frequency

Antenna type Description Status

This active antenna operates within 608-614MHz. This antenna

608-614MHz

420-474 MHz

also has a bandpass filter element that rejects signals outside of

608-614MHz, except for signals in channels 36 and 38.

This high-power antenna operates within 420-474MHz and has

filtering for out-of-band signals. It has >15dB rejection below

320MHz.

For technical specifications, see Antenna specifications on page A-13.

Enterprise Access antenna system

Refer to the Enterprise Access System Service Manual for details on the system.

ApexPro and CARESCAPE transmitters

CAUTION

UNINTENTIONAL RADIO FREQUENCY (RF)

INTERFERENCE—Unintentional RF interference could degrade

the reliability and performance of the wireless data link. The facility

must maintain an RF environment free from unintentional

interference.

Current

Current

The ApexPro and CARESCAPE transmitters send the patient’s ECG data to the

ApexPro receiver system for processing. Data is then transmitted via a dedicated

Ethernet interface to the CIC Pro center for viewing. The transmitter can also send

DINAMAP PRO data to the CIC Pro center via the DinaLink cable.

Additionally, the transmitter can send the patient’s SpO2 and noninvasive blood

pressure data when the interface connector ports are enabled and when the optional

oximeter and/or Accutracker DX noninvasive blood pressure monitor are connected

to it.

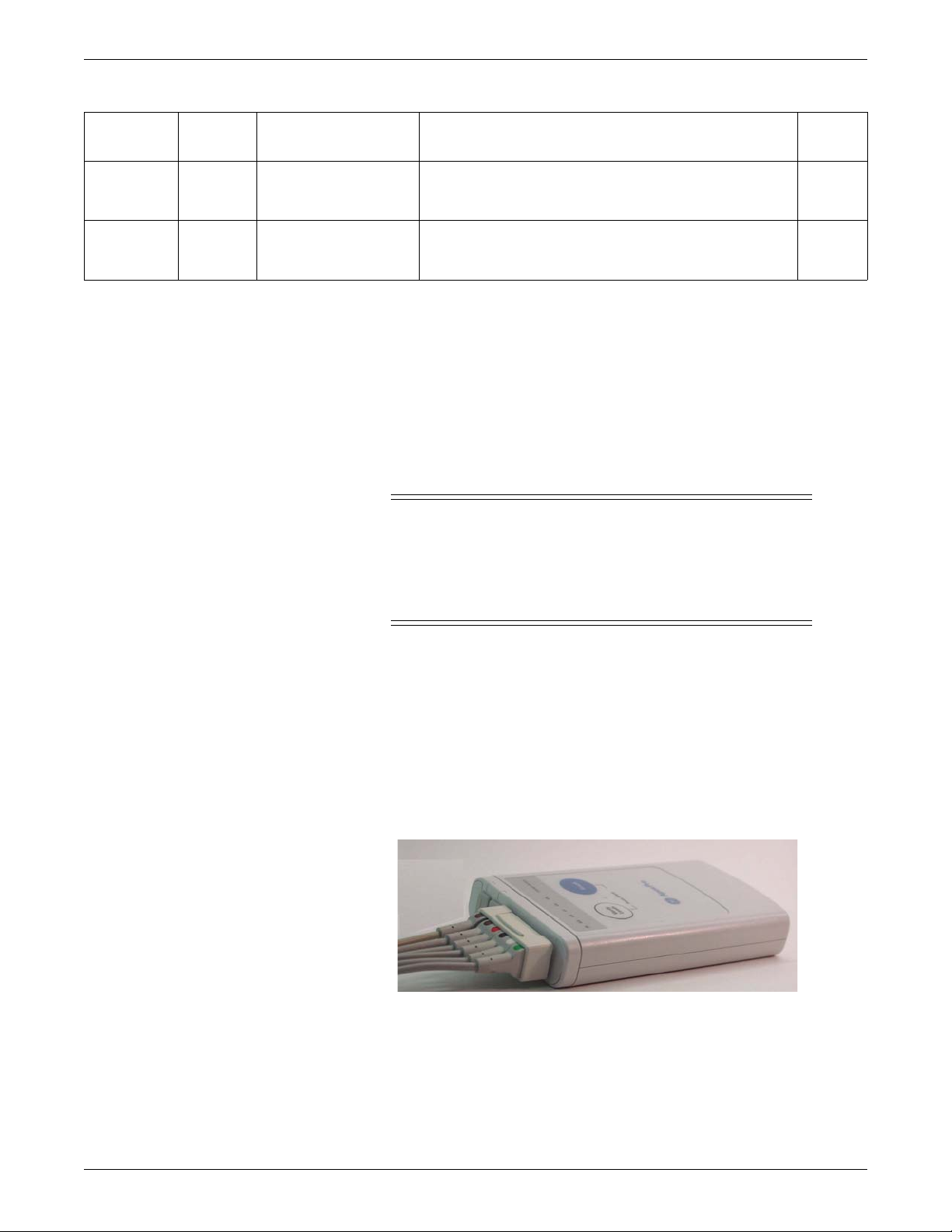

309C

ApexPro Transmitter

2-6 ApexPro™ 2001989-351A

Page 27

ApexPro CH Transmitter

Equipment Overview

205A

NOTE

Transmitter battery installation

NOTE

Install 2 new AA alkaline batteries in the transmitter.

1. Locate the battery cover at the bottom of the transmitter.

2. Slide the cover over to open the battery compartment.

3. Insert batteries, being careful to follow the polarity signs embossed on the lower

207B

CARESCAPE Telemetry T14 Transmitter

In this manual, wherever the transmitter is shown, the ApexPro, ApexPro CH and

T14 transmitter are valid, except where otherwise noted.

Refer to the ApexPro Telemetry System or the CARESCAPE Telemetry T14

Transmitter Operator’s Manual for further details on battery installation.

back side of the transmitter’s molded case.

2001989-351A ApexPro™ 2-7

Page 28

Equipment Overview

P

o

s

i

t

i

v

e

N

e

g

a

t

i

v

e

220A

4. Close the battery cover.

NOTE

When the Change Battery LED starts flashing, the transmitter has

approximately 1 hour of reserve power before the unit shuts down.

Battery functional life

CAUTION

GE recommends that you always replace both batteries at the same

time. Re-using old batteries or using a combination of old and new

batteries in the transmitter will compromise functionality of the

transmitter and increase the risk of fire hazard.

Do not store the batteries in the transmitter when not in use. Storing

the batteries in the transmitter can cause corrosion of the batteries

and of the transmitter.

Be sure to insert batteries into the transmitter in the correct

direction as indicated on the back of the case. Do not insert batteries

in the reverse direction.

The transmitters runs on 2 AA batteries. For the ApexPro transmitter, the battery life

is approximately 40 hours. For the ApexPro CH transmitter, the battery life is

approximately 120 hours. For the T14 transmitter, the battery life is approximately 65

hours.

For optimum performance, follow these guidelines:

Install 2 new alkaline batteries each time you begin monitoring a new patient or

whenever the Change Battery LED on the transmitter is flashing.

Do not use rechargeable batteries.

Always change both batteries at the same time.

Always use new batteries.

2-8 ApexPro™ 2001989-351A

Page 29

Transmitter controls, indicators and labels

Views

The transmitters have the following buttons and LEDs:

Equipment Overview

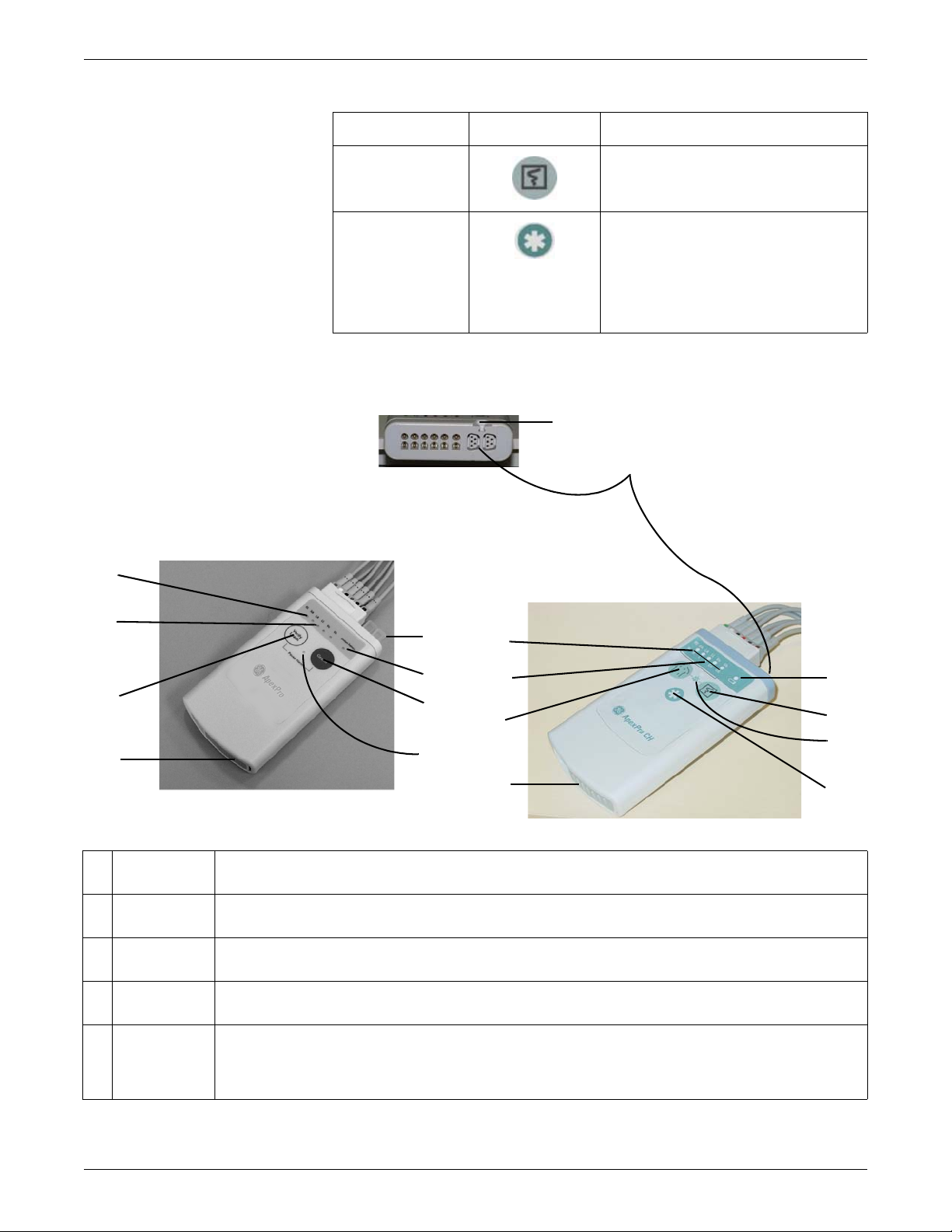

605A, 207A, 206B

ApexPro, ApexPro CH, and T14 Transmitters

ApexPro ApexPro CH & T14 Function

RL RA LA LL Va Vb RL RA LA LL Va Vb

N R L F Ca Cb

Change Battery When the battery power is running low, the

Verify Leads

Pause Alarm

When first powered up, the lead LEDs flash

rapidly, followed by two slow flashes. The

transmitter begins functioning after the two

slow flashes.

When any of the transmitter's buttons are

pushed, the lead LEDs flash twice.

change battery LED flashes.

When pressed, the lead LEDs flash twice. If a

lead is valid, its LED stays lit for one minute.

When the Pause Alarm condition occurs, the

pause alarm LED flashes until the condition

ends.

2001989-351A ApexPro™ 2-9

Page 30

Equipment Overview

F

C

G

H

I

J

H

I

J

K

A

B

C

D

E

A

B

D

ApexPro ApexPro CH & T14 Function

Controls and indicators

Graph

(not available) When pressed, a blue border displays

When pressed, a 20-second graph strip is

printed on the writer or printer.

around the event bed and an alarm tone

sounds at the CIC Pro center. The message

Remote Event displays under the ECG

parameter window for approximately ten

seconds.It also generates a 20-second graph

and saves the event.

317A, 420B, 432A

A RA LED Used in troubleshooting (Frequent lead fail on page 5-21) and when manually viewing or programming the TTX

number (Manually view/program TTX on page 3-19.)

B Good Lead

LEDs

C Verify Leads

button

D Battery

compartment

E Interface

connector

ports

These light when testing the verify leads function.

Checks the lead/skin preparation quality. Pressing the Verify Leads button enables the good lead LEDs. After

pressing this button, the LEDs for good leads illuminate for 1 minute.

Holds 2 AA alkaline batteries. The sliding cover of the compartment also functions as the on/off switch.

The interface connector ports (on the end of the transmitter) are used to connect the transmitter to the APEX

Programming Device. The TTX number and desired reference lead are programmed using the APEX Programming

Device. These interface connector ports may also be used to connect additional parameter devices to the

transmitter.

2-10 ApexPro™ 2001989-351A

Page 31

Equipment Overview

FWell for dust

covers

G Dust covers Transmitters have a set of 2 dust covers, used when the interface connectors are not being used. Markings on the

H Change

Battery LED

I Graph button Initiates the printing of a graph strip. Pressing the Graph button initiates printing a 20-second graph strip to the writer

J Pause Alarm

LED

K Event Marker

button

(Available on

the ApexPro

CH and T14

transmitter

only.)

Location for attaching the set of dust covers.

covers indicate the number of the interface connector port.

The Change Battery LED flashes when battery power is running low and the batteries need changing.

or printer.

To pause the alarms for the programmed amount of time (typically 5 minutes), press the Graph button and the

Verify Leads button simultaneously. The Pause Alarm LED flashes. “ALARM PAUSE” also displays in the patient’ s

waveform window on the CIC Pro center screen. At the end of the pause time, the LED on the transmitter no longer

flashes and alarms are reactivated. T o reactivate the alarms before the pause time has elapsed, press both buttons

simultaneously again.

When pressed, displays a message on the CIC Pro center that a graph is being generated to mark an event. This

function can be turned off at the CIC Pro center.

Labels

The main back label contains the ECG orientation chart, the serial number and any

certification markings required for each country (FCC, UL, etc.) This label also

provides the color coordination for the multi-link cables.

320A

The TTX number label corresponds to the TTX number that is programmed into the

transmitter.

2001989-351A ApexPro™ 2-11

Page 32

Equipment Overview

Transmitter appearance

T14 side labels

The T14 transmitter also has side labels to distinguish it from an ApexPro CH

transmitter. Additional side label kits may be ordered (See T14 on page 6-23.)

321

ApexPro transmitters have 2 user buttons: Verify Leads and Graph. They have a

white endcap on the end opposite the battery compartment cover.

The ApexPro CH and T14 transmitters have 3 user buttons: Verify Leads, Graph,

and Event Marker. There is a blue endcap on the end opposite the battery

compartment cover.

Start-up

At power-up, the transmitter LEDs flash during start-up. The following table defines

the sequence.

Refer to the ApexPro Telemetry System or CARESCAPE Telemetry T14 Operator’s

Manual for further details on transmitter operation and leadwire installation.

Transmitter interfaces

ECG Multi-Link leadwire set

Sequence of LED Flashes Function

All LEDs flash quickly Transmitter memory tests are being

performed.

All LEDs flash slowly twice. Indicates that all LEDs are functional.

The ECG connector is designed to accept 3-, 5- or 6-multi-link leadwire sets. The

ECG data is acquired from the patient through a set of leadwires. The signals are then

amplified, processed, and transmitted.

For ApexPro, ApexPro CH and T14 transmitter, the top set of pins is the ECG signal

lead. The bottom set of pins function as the signal lead shield connections. Also, the

2-12 ApexPro™ 2001989-351A

Page 33

Interface connector ports

Top row LEDs

Switches/LEDs

Equipment Overview

RA shield functions as the RF antenna for the ApexPro and ApexPro CH transmitter;

the T14 transmitter has an internal antenna.

317A

When enabled, interface connector ports provide an asynchronous communication

connection to other devices (NBP, SpO2, etc.) for extra monitoring or for service

connection to a programming box.

When power is applied to the transmitter, all of the LEDs should flash rapidly

indicating code is being loaded. The code is done loading and executed when just the

top row LEDs flash twice.

605A, 205B

While in normal application mode, pressing and releasing the Verify Leads button

causes the LEDs to light up for 1 minute if their corresponding lead is good. Pressing

and releasing the Graph button causes either a save or a manual graph at the CIC Pro

center.

Pressing both the Verify Leads and the Graph buttons together causes an alarm

pause condition for the programmed amount of time (typically 5 minutes) or until the

alarm pause action is initiated again. When the transmitter is in alarm pause, the

corresponding LED flashes once every second at a 1/8th duty cycle.

Upon any activation (Verify Leads, Graph, or Alarm Pause) the top row of LEDs

flash twice. All these functions are disabled in service mode.

2001989-351A ApexPro™ 2-13

Page 34

Equipment Overview

When the battery voltage drops below 1.9 volts for ApexPro,1.6 volts for ApexPro

CH or 1.73 volts for the T14, the Change Battery LED flashes once every second at

a 1/8 duty cycle.

RF

The RF output is transmitted through one of the shield wires on the multi-link cables.

The carrier frequency can be programmed to any frequency within the allowable

band.

DINAMAP PRO series monitors

The DINAMAP PRO 100, 200, 300, and 400 series monitors can be connected to the

transmitter using the DinaLink™ serial cable to monitor SpO2, NBP , and temperature.

Parameter data from the PRO 100–400 series monitors is displayed, trended, and

stored at the CIC Pro center.

The DinaLink interface cable assembly consists of a monitor adapter cable, the

DinaLink adapter, and an interconnection cable. It connects the transmitter to the

PRO 100–400 series monitors and provides electrical isolation. The interconnect

cable connects to either of the optional interface ports on the transmitter

201A

SpO2 oximeter modules

The oximeter is an optional module that, when connected to the transmitter, allows

telemetry monitoring of a patient’s pulse oximetry data. The oximeter must be

connected to an transmitter in order to convey SpO2 data to the CIC Pro center. Only

digital data is available; no waveforms are generated or transmitted .

2-14 ApexPro™ 2001989-351A

Page 35

Apex oximeter

Power

Display

On/Off

Pulse Rate

SpO %

2

Perfusion

oximeter

In red

In infrared

SpO = f

2

(

(

min

max

min

max

(

(

Equipment Overview

310C

NOTE

The telemetry system supports 2 SpO2 oximeter modules:

Apex Oximeter

Nonin Xpod Oximeter

Theory of operation - pulse oximetry

Pulse oximeters shine light (red and infrared) through perfused tissue and detect the

fluctuating signals caused by arterial blood pressure pulses. Well-oxygenated blood is

bright red, while poorly oxygenated blood is dark red. The pulse oximeter determines

functional oxygen saturation of arterial hemoglobin from this color difference by

measuring the ratio of absorbed red and infrared light as the blood volume fluctuates

with each heart beat. Since steady conditions (steady venous blood flow, skin

thickness, bone, finger nails, etc.) do not cause fluctuations, they do not affect the

saturation reading.

Mathematically:

Anything that affects the intensity of the light such as thick or colored skin affects the

maximum and minimum proportionally and thus the ratio minimum/m ax im um does

not change. However, if too little light gets through, the pulse oximeter does not

function.

Pulse oximeters use 2 different wavelengths of light (colors) and thus have the ability

to determine 1 component of blood. Pulse oximeters are calibrated to closely

approximate functional oxygen saturation values. Pulse oximeter oxygen saturation

values will closely approximate laboratory instrument fractional saturation values if

the dysfunctional hemoglobin saturation levels are negligible. If the dysfunctional

hemoglobin is carboxyhemoglobin or methemoglobin, then the difference between

the oxygen saturation value displayed by the Pulse oximeter and the oxygen

saturation values determined by the laboratory instrument are greater as the

dysfunctional hemoglobin levels rise approximately in accordance with the following

formulas:

801

2001989-351A ApexPro™ 2-15

Page 36

Equipment Overview

SpO2 = O2Hb + COHb + MetHb

SaO2 = 100 x O2Hb /(100 - COHb - MetHb)

Where:

SpO2 = Pulse oximeter determined and displayed oxygen saturation in percent

O2Hb = Fractional oxyhemoglobin saturation in percent

COHb = Carboxyhemoglobin saturation in percent

MetHb = Methemoglobin saturation in percent

SaO2 = Functional oxygen saturation in percent

The following table gives examples of the oximeter readings:

Example 1 Example 2

O2Hb = 96 O2Hb = 88

COHb = 0.5 COHb = 8

MetHb = 0.6 MetHb = 2

SpO2 = 97 SpO2 = 98

SaO2 = 97.07 SaO2 = 97.78

The mathematics are fixed in the pulse oximeter hardware and software. Thus, no

field calibrations are needed or are possible. There are no adjustable parts within the

pulse oximeter that affect the calibration.

The function f, depends on the wavelengths of the sensor LEDs. These wavelengths

are fixed by specified manufacturing processes and materials. The sensors are

checked for correct operation before shipping, so no adjustment or calibration is

needed or possible.

Because the pulse oximeter does all critical computations in software and there are no

critical parts to drift; no re-calibration is needed.

Interconnection cables

NOTE

Refer to the ApexPro Telemetry System or CARESCAPE Telemetry T14

transmitter Operator’s Manual for further details on interconnection cables.

Apex oximeter and Accutracker DX

The interconnection cable used to connect the transmitter with the Apex Oximeter

and/or the Accutracker DX blood pressure monitor, and/or the DinaLink serial cable.

2-16 ApexPro™ 2001989-351A

Page 37

Nonin Xpod oximeter

Plugs into the

transmitter

Plugs into the

Nonin SpO2 probe

Plugs into the

transmitter

Equipment Overview

423B

The interconnection cables used to connect the transmitter and the SpO2 probe are a

part of the oximeter module.

502A

ApexPro receiver system

Overview

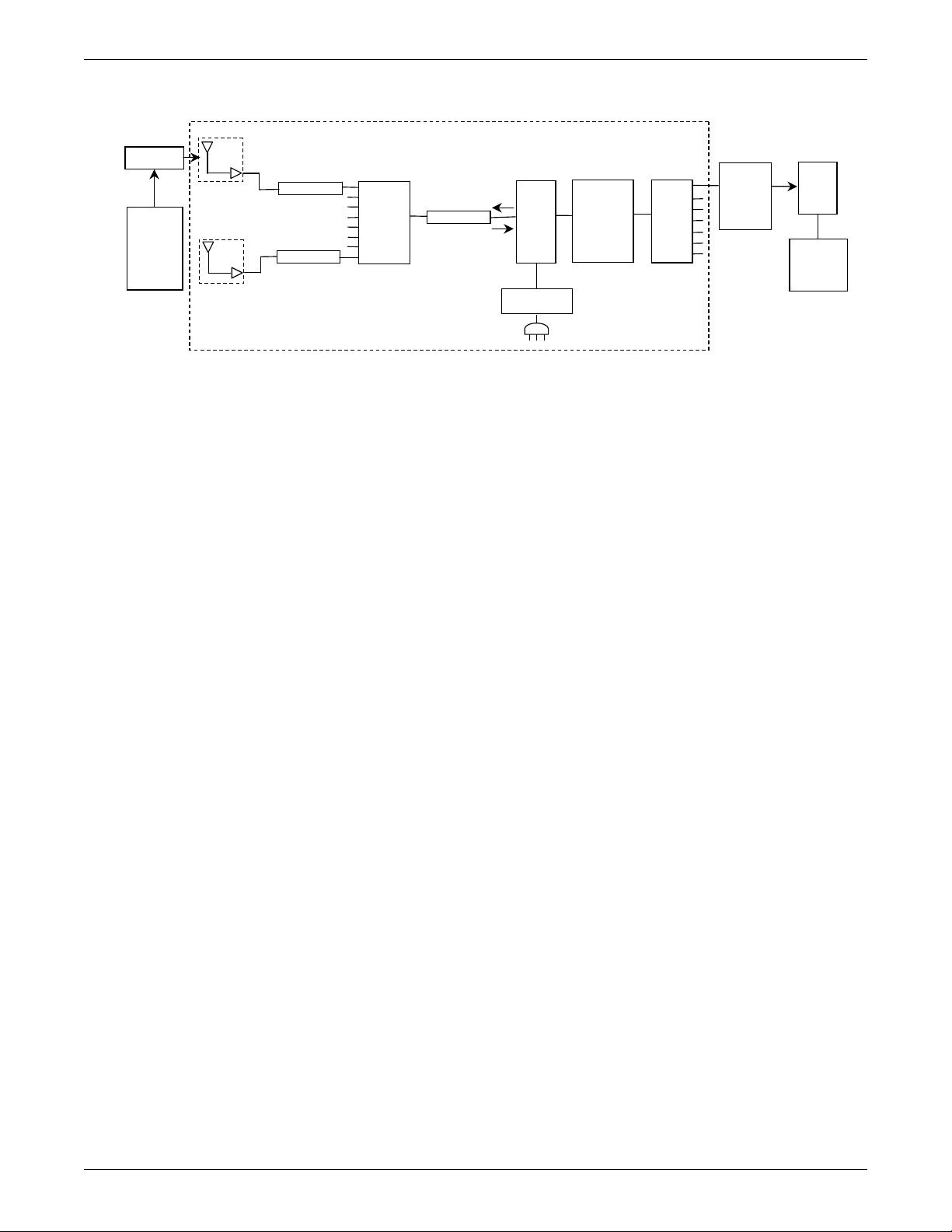

The Receiver System receives RF signals from the four antenna inputs. These inputs

are for four separate, overlapping fields. The system performs the following

functions:

filters RF (backplane)

distributes RF to quad receiver modules (backplane)

demodulates and decodes transmitter data (quad receiver modules)

retrieves decoded data (backplane)

packetizes and sends data out over RX network (backplane)

The asynchronous serial communication port is for diagnostics, service and

installation information.

2001989-351A ApexPro™ 2-17

Page 38

Equipment Overview

The RX network is directly connected by a network crossover cable to an ApexPro

Telemetry System. The RX network should not be tied to any other network.

Receiver subsystem (backplane)

The subsystem provides an interface between the quad receiver modules and the

telemetry software running on the ApexPro Telemetry System connected via 10BaseT

Ethernet. The subsystem accommodates up to four quad receiver modules. The

subsystem performs the initial amplification and filtering necessary on the RF input

signals from the transmitter.

Quad receiver modules

The quad receiver module receives the GMSK modulated RF signals from the

transmitter through the receiver subsystem (backplane). The RF signals are mixed to

an intermediate frequency, filtered, and mixed again to baseband and re-filtered. The

baseband signal is separated into its in-phase and quadrature components then

sampled. The DSP takes the samples, demodulates, corrects, and decodes packets of

TLINK data. The information is passed on to the receiver subsystem for furthe r

processing and transport over Ethernet. Each module has four functionally identical

receivers.

rcrsysblk

Receiver System Block Diagram

2-18 ApexPro™ 2001989-351A

Page 39

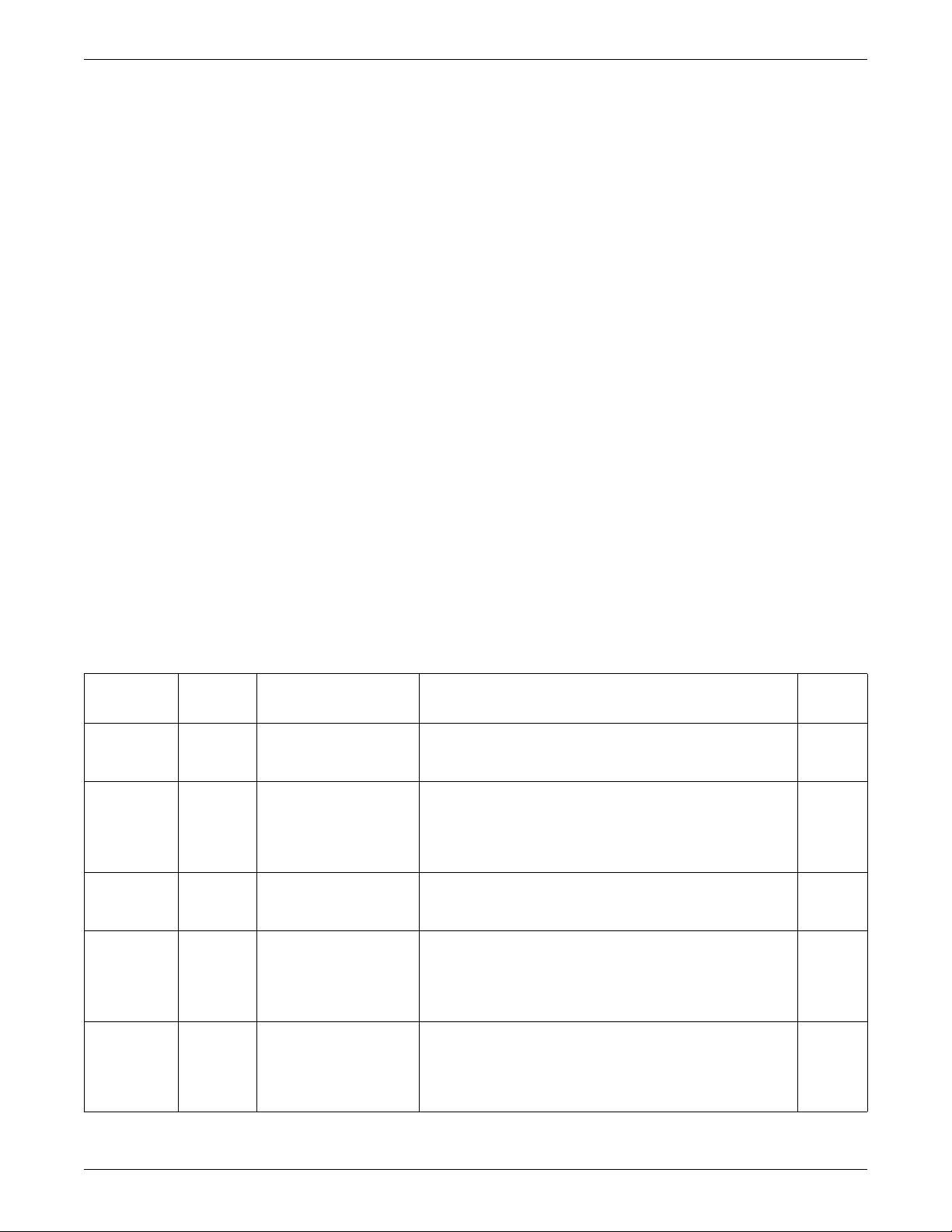

Input/output connectors and signals

F-Connectors, J1, J2, J3, and J4

RJ-45 Ethernet port, J6

Equipment Overview

Pin Description

J1 Antenna A field input

J2 Antenna B field input

J3 Antenna C field input

J4 Antenna D field input

Pin Description

1HOST_XMIT_POS

2HOST_XMIT_NEG

3 HOST_RCV_POS

4N/C

5N/C

6 HOST_RCV_NEG

7N/C

8N/C

RS-232 async comm port, J15

Pin Description

1N/C

2TX

3RX

4N/C

5DGND

6N/C

7N/C

8N/C

9N/C

2001989-351A ApexPro™ 2-19

Page 40

Equipment Overview

Input power plug, J16

Pin Description

1GND

2GND

3GND

4+5V

5+5V

6+5V

2-20 ApexPro™ 2001989-351A

Page 41

3

Installation and configuration

2001989-351A ApexPro™ 3-1

Page 42

Installation and configuration

1

2

3

4

5

Infrastructure installation

Overview

This chapter provides direction for how to install specific parts and gives guidelines

for specific tools to use for installation.

Install coaxial cable

Installation guidelines

Use the hospital scaled prints and the logical antenna schematic to install the cabling.

The logical antenna schematic is generated by ND&I.

Keep the following in mind when installing coax cable.

Always follow the National Electric Code regulations.

Always use PVC for the feed-throughs.

Do not kink the cable. If the cable is kinked, cut out the kinked part and reattach.

Do not pull cable over any metal edges or other abrasive surfaces.

Do not pull cable for one room at a time. The entire cable spool should be

accessible and multiple runs should be pulled at the same time into the ceiling.

Do not lay cable on top of light fixtures.

Lay out cable uniformly and with excess slack. The slack should consist of about

25 cm (1 foot) or so every 3 m (10 feet), both horizontally and vertically.

Do not coil up any extra cable, but instead increase the amount of excess slack

throughout the entire length of cable.

Coaxial cable preparation

These sections describe how to strip coaxial cable and crimp connectors to the cable.

Below are descriptions of the components of a coaxial cable.

1 Center conductor — The center-most feature of coaxial cable. It consists of solid copper

or copper-clad aluminum wire.

2 Dielectric — An electrical insulation utilized to maintain position of the center conductor.

It is composed of polyethylene in either solid or foam state. This insulator/positioner may

3-2 ApexPro™ 2001989-351A

also be evenly spaced solid polyethylene discs.

200A

Page 43

Strippers and crimpers

Installation and configuration

3 Outer conductor or foil — Either solid aluminum tube or an aluminum foil wrap. The cable

size is usually derived from its outside diameter.

4 Braid — Interwoven strands of aluminum or copper mesh. It extends the conductivity of

the outer conductor to the sleeve of the connector.

5 Jacket — The black polyethylene coating over the aluminum outer conductor protects it

from scratches or abrasions during handling and provides a weather-tight seal. The

jacket on plenum cable is made of teflon specified by fire codes.

Recommended tools

The following table indicates the recommended cable strippers and crimpers.

NOTE

The CT611QS will work for both RG-6 Riser and RG-11 Plenum cable.

The current RG-11 crimper will work with the new RG-11 cable and

connector.

The old RG-6 Riser crimp tool will work for the RG-6 Plenum.

Italics = preferred tool.

Following the descriptions is a section describing how to correctly strip coaxial cable.

RG-6 is the recommended coaxial cable, but RG-11 cabling is used for some

installations.

Connector Crimp tool Stripper tool

Part number and

description

2018510-001

RG-6 Plenum

(replaces 1886-008)

2018509-001

RG-6 Riser NP

(replaces 1886-004)

2018511-001

RG-11 Plenum

(replaces 1886-007)

2018512-001

RG-11 Riser NP

(replaces 1886-003)

Thomas

& Betts

(T&B)

PL56CS 0.260 HCT-659

AMF6 0.360 CT611QS

PL11CS 0.470 HCT-211

F11QS 0.470 HCT-211

Hex

0.470 CT611QS

0.470 CT611QS

Tool # and

Manufacturer

CablePrep

T&B

CablePrep

T&B

CablePrep

T&B

Tool # and

Manufacturer

3CSK-GN

Cooper/Xcelite

3CSK-GN

Cooper/Xcelite

RG11 Maxi-Corex, 360

Cooper

RG11 Maxi-Corex, 360

Cooper

Strippers

For RG-6 coax cable, use Xcelite coaxial cable stripper (3CSK-GN).

For RG-11 coax cable, use Cooper cable stripper, RG11 Maxi-Corex 360.

2001989-351A ApexPro™ 3-3

Page 44

Installation and configuration

Coaxial cable

Crimp here

205A

Crimpers

The typical hex crimping tool is shown below. The recommended crimping tool part

numbers are the following.

For RG-6 plenum, use a HCT-659 crimper from CablePrep.

For RG-6 riser, use a CT611QS crimper from T&B.

For RG-11 riser and plenum, use a CT611QS crimper from T&B (recommended)

or HCT-211 crimper from CablePrep.

Before you crimp, check the dimensions for the specific type of coaxial cable and

connector.

215A

RG-6 plenum cable preparation

Required stripping dimensions for RG-6 plenum cabling are shown below.

3-4 ApexPro™ 2001989-351A

Page 45

Installation and configuration

1/4

to

5/16

1/4 1/4

Crimp area

For this cable, use stripper 3CSK-GN from Cooper/Xcelite. The stripper requires 3

blades.

1. To start with a squarely-cut cable end, open the stripper and place the cable so

that 1/4 – 5/16 inch of cable extends past the first blade. Then close and latch the

stripper and rotate around the cable 3 – 4 times.

2. Open the stripper and adjust stripping blades until the correct dimensions are

achieved as shown in the figure above. Then strip the cabling.

a. Expose the center conductor 1/4 – 5/16 inch. Do not score the conductor.

b. Expose the dielectric another 1/4 inch without braid.

c. Expose the braid an additional 1/4 inch. Do not score the braid.

220A

d. Remove and discard excess dielectric, foil and braiding.

3. Place the connector over the prepared cable end.

NOTE

Make sure the braid does not fold back over the jacket.

The connector is properly positioned when the cable dielectric end is flush

with the connector post end.

221A

Position cable dielectric end flush with connector post .

4. Crimp the collar once in the area shown below using a 0.260 inch hex crimp tool.

217A

5. Wrench-tighten the connector.

RG-6 riser cable preparation

Required stripping dimensions for RG-6 riser cabling are shown below.

2001989-351A ApexPro™ 3-5

Page 46

Installation and configuration

1/4” 1/4”

Crimp area

222A

For this cable, use stripper 3CSK-GN from Cooper/Xcelite. The stripper requires 2

blades.

1. To start with a squarely-cut cable end, open the stripper and place the cable so

that 1/4 – 5/16 inch of cable extends past the first blade. Then close and latch the

stripper and rotate around the cable 3 – 4 times.

2. Open the stripper and adjust stripping blades until the correct dimensions are

achieved as shown in the figure above. Then strip the cabling.

a. Expose the center conductor 1/4 inch. Do not score the conductor.

b. Expose the braid another 1/4 inch. Do not score the braid.

c. Remove and discard excess dielectric, foil and braiding.

3. Fold the braid back over the jacket.

218A

4. Place the connector, reversed as shown below , over the cable end until it bottoms

against the braid.

219A

5. Remove the connector. Reverse it once more. Position the connector over the

cable end as shown below. Then push and rotate the connector until it bottoms.

The connector is properly positioned when the cable dielectric end is flush with

the connector post end.

223A

6. Crimp the collar once in the area shown below using a 0.360 inch hex crimp to ol

224A

7. Wrench-tighten the connector.

RG-11 plenum cable preparation

Required stripping dimensions for RG-11 plenum cabling are shown below.

3-6 ApexPro™ 2001989-351A

Page 47

Installation and configuration

1/8”

1/2”

1-1/16”

First crimp

Second crimp

For this cable, use stripper RG11 Maxi-Corex, 360. The stripper requires 3 blades.

1. To start with a squarely-cut cable end, open the stripper and place the cable so

that 1/4 – 5/16 inch of cable extends past the first blade. Then close and latch the

stripper and rotate around the cable 3 – 4 times.

2. Open the stripper and adjust stripping blades until the correct dimensions are

achieved as shown in the figure above.

a. Expose the center conductor 1/2 inch. Do not score the conductor.

b. Expose the dielectric another 1/8 inch without braid.

c. Expose the braid an additional 7/16 inch (a total of 1-1/16 inch from the end

of the center conductor.) Do not score the braid.

225A

d. Remove and discard excess dielectric, foil and braid.

3. Place the connector over the prepared cable end.

NOTE