Page 1

g

GE Power Management

ALPS

Advanced Line Protection™ System

Instruction Manual

Firmware Revision: V0004.04AA34 (Rev. A models)

Firmware Revision: V0005.02AA05 (Rev. B models)

Manual P/N: GEK-105555F

Copyright © 2002 GE Power Management

Note: All relays must be powered up at least once per year to avoid

deterioration of electrolytic capacitors and subsequent relay failure.

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/p m

Manufactured under an

ISO9002 Registered system.

Page 2

Page 3

These instructions do not purport to cover all details or variations in equipment nor provide for every possible contingency

to be met in connection with installation, operation, or maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purpose, the matter should be referred to the

General Electric Company.

To the extent required the products described herein meet applicable ANSI, IEEE, and NEMA standards; but no such

assurance is given with respect to local codes and ordinances because they vary greatly.

Page 4

Page 5

TABLE OF CONTENTS

1. PRODUCT DESCRIPTION

1.1 GETTING STARTED

1.1.1 INSPECTION ..................................................................................................... 1-1

1.1.2 PASSWORDS, FACTORY SET......................................................................... 1-1

1.1.3 REMOTE COMMUNICATIONS VIA LOCAL PC................................................1-2

1.1.4 ALPS-LINK QUICK REFERENCE ..................................................................... 1-2

1.1.5 ORDERING........................................................................................................ 1-3

1.2 INTRODUCTION

1.2.1 DESCRIPTION................................................................................................... 1-4

1.2.2 APPLICATION ................................................................................................... 1-4

1.2.3 PROTECTION FUNCTIONS..............................................................................1-4

1.2.4 GROUND DISTANCE QUADRILATERAL CHARACTERISTICS ...................... 1-5

1.2.5 LINE PROTECTION SCHEMES........................................................................ 1-8

1.3 CUSTOM PROGRAMMABILITY

1.3.1 INTRODUCTION................................................................................................1-9

1.3.2 PROGRAMMABLE LOGIC ................................................................................ 1-9

1.3.3 CONFIGURABL E INPUTS. ... ................... .................... ................... ... ................ 1-9

1.3.4 CONFIGURABL E OUTPUTS.. .................... ................... .................... .............. 1-10

1.4 AUXILIARY PROTECTION FUNCTIONS

1.4.1 POTENTIAL TRANSFORMER FUSE FAILURE (PTFF).................................1- 11

1.4.2 LINE PICKUP................................................................................................... 1-12

1.4.3 REMOTE-OPEN DETECTOR.......................................................................... 1-13

1.4.4 OUT-OF-STEP BLOCKING ............................................................................. 1-14

1.5 OTHER FEATURES

1.5.1 FLASH MEMORY ............................................................................................1-16

1.5.2 LINE OVERLOAD ............................................................................................ 1-16

1.5.3 CURRENT UNBALANCE DETECTION...........................................................1-16

1.5.4 FAULT LOCATION .......................................................................................... 1-16

1.5.5 FAULT REPORT.............................................................................................. 1-16

1.5.6 OSCILLOGRAPHY ..........................................................................................1-16

1.5.7 PLAYBACK ...................................................................................................... 1-17

1.5.8 SEQUENCE OF EVENTS..... .. .................... ................... .................... .............. 1-17

1.5.9 EQUIPMENT DUTY......................................................................................... 1-17

1.5.10 SELECTABLE GROUPS OF SETTINGS .................................... .................... 1-17

1.5.11 TIME SYNCHRONIZATION............................................................................ .1-18

1.5.12 TRIP BUS CHECK........................................................................................... 1-18

1.5.13 TRIP CIRCUIT MONITOR ........ .. ............................... ............................... .. .....1-18

1.5.14 ALARMS .......................................................................................................... 1-19

1.5.15 METERING ...................................................................................................... 1-19

1.5.16 BREAKER CONTROL ................................... ................... .................... ... ........ 1-19

1.6 COMMUNICATIONS

1.6.1 KEYPAD AND DISPL A Y. ... ................... .................... ................... ... ................. 1-20

1.6.2 SERIAL COMMUNICATIONS.......................................................................... 1-20

1.6.3 SCADA DIGITAL TO ANALOG (DTA) INTERFACE........................................ 1-20

1.7 SELF-TEST FEATURES

1.7.1 START-UP SELF-TESTS ................................................................................ 1-21

1.7.2 RUN-TIME SELF-TESTS..................................... ............................. .. .............1-21

1.7.3 CONTINUOUS MONITOR ............................................................................... 1-22

1.8 PROTECTION SCHEMES

1.8.1 INTRODUCTION..............................................................................................1-23

1.8.2 STEP DISTANCE............................................................................................. 1-23

1.8.3 PERMISSIVE UNDERREACH TRANSFER TRIP (PUTT)..............................1-25

1.8.4 PERMISSIVE OVERREACH TRANSFER TRIP (POTT1)............................... 1-27

1.8.5 POTT WITH BLOCKING FUNCTIONS (POTT2).............................................1-27

1.8.6 BLOCKING SCHEME ...................................................................................... 1-30

1.8.7 HYBRID SCHEME ........................................................................................... 1-33

1.8.8 SINGLE PHASE TRIPPING............................................................................. 1-35

1.9 PHASE IDENITIFIED CHANNEL SCHEMES

1.9.1 DESCRIPTION................................................................................................. 1-38

1.9.2 INTER-CIRCUIT FAULTS................................................................................1-38

1.9.3 TWO CHANNEL PHASE IDENTIFIED CHANNEL LOGIC ..............................1-38

1.9.4 FOUR CHANNEL PHASE IDENTIFIED CHANNEL LOGIC ............................ 1-40

GE Power Management

ALPS Advanced Line Protection System i

Page 6

TABLE OF CONTENTS

1.10 OUT-OF-STEP TRIPPING (OPTIONAL)

1.10.1 DESCRIPTION .................................................................................................1-41

1.10.2 OST CHARACTERISTIC SHAPE.....................................................................1-41

1.10.3 OUT-OF-STEP DETECTION............................................................................1-42

1.10.4 TWO-CHARACT E R IS TIC OP E R ATION........... ... ... ................... .................... ...1-43

1.10.5 OUT-OF-STEP OSCILLOGRAPHY CAPTURE................................................1-43

1.11 COMPENSATED POSITIVE SEQUENCE OVERVOLTAGE (OPTIONAL)

1.11.1 DESCRIPTION .................................................................................................1-44

1.11.2 APPLICATION ..................................................................................................1-44

1.12 RECLOSER (OPTIONAL)

1.12.1 DESCRIPTION .................................................................................................1-45

1.12.2 RECLOSING MODE.........................................................................................1-45

1.12.3 RECLOSING PROGRAMS...............................................................................1-45

1.12.4 RECLOSER INPU TS............................. ... .. .................... .................... ..............1 - 46

1.12.5 RECLOSER OUTP UT S............................................... .................... ................. 1 - 47

1.12.6 \SYNCHRONISM CHECK (OPTIONAL)...........................................................1-48

1.12.7 ALPS RECLOSING PROGRAM SUMMARY....................................................1-48

1.13 ELEMENTARY DIAGRAMS

1.13.1 ELEMENTARY DIAGRAMS .............................................................................1-49

2. CALCULATION OF

SETTINGS

2.1 INTRODUCTION

2.1.1 DESCRIPTION ...................................................................................................2-1

2.2 GENERAL SETTINGS

2.2.1 CONFIGURATION..............................................................................................2-2

2.2.2 COMMUNICATIONS ..........................................................................................2-4

2.2.3 OSCILLOGRAPHY.............................................................................................2-6

2.2.4 EQUIPMENT DUTY............................................................................................2-6

2.2.5 PROGRAMMABLE INPUTS...............................................................................2-8

2.3 PROTECTION SETTINGS

2.3.1 Z1DISTANCE .....................................................................................................2-9

2.3.2 ZONE 2, ZONE 3, AND ZONE 4 DISTANCE FUNCTIONS.............................2-13

2.3.3 Z2DISTANCE ...................................................................................................2-14

2.3.4 Z3DISTANCE ...................................................................................................2-16

2.3.5 Z4DISTANCE ...................................................................................................2-18

2.3.6 CURSUPVISN.......................................................................................... ........2-22

2.3.7 OVERCURRNT ........... .. ............................ .. .......................... .. .........................2-2 5

2.3.8 VOLTAGE.........................................................................................................2-27

2.3.9 POSITIVE-SEQUENCE VOLTAGE FUNCTIONS............................................2-28

2.3.10 BLK RECLOS ...................................................................................................2-29

2.3.11 LINEPICKUP ....................................................................................................2-30

2.3.12 REMOTEOPEN ................................................................................................2-31

2.3.13 LINEOVRLD .....................................................................................................2-32

2.3.14 SCHEME ..........................................................................................................2-32

2.3.15 SCHMTIMERS..................................................................................................2-33

2.3.16 LINE INFO ........................................................................................................2-36

2.3.17 SCADA DTA .....................................................................................................2-37

2.3.18 OS BLOCKING .................................................................................................2-38

2.3.19 OS TRIPPING...................................................................................................2-39

2.3.20 RECLOSER ......................................................................................................2-41

2.3.21 NONCRIT_AL ...................................................................................................2-46

2.3.22 OUTPUTS.........................................................................................................2-46

2.4 INVERSE CURVES

2.5 REFERENCE TABLES

2.5.1 INDEX NUMBERS............................................................................................2-51

2.5.2 PROTECTION SETTINGS GUIDE...................................................................2-57

2.5.3 GENERAL SETTINGS GUIDE .........................................................................2-64

2.5.4 PROTECTION SETTINGS DATA SHEETS .....................................................2-66

2.5.5 GENERAL SETTINGS DATA SHEETS............................................................2-73

ii ALPS Advanced Line Protection System

GE Power Management

Page 7

TABLE OF CONTENTS

3. HARDWARE DESCRIPTION

4. ACCEPTANCE/PERIODIC

TESTS

3.1 CASE ASSEMBLY

3.1.1 CONSTRUCTION .............................................................................................. 3-1

3.1.2 ELECTRICAL CONNECTIONS AND WIRING .................................................. 3-3

3.1.3 IDENTIFICATION...............................................................................................3-3

3.1.4 SYSTEM BLOCK DIAGRAM ............................................................................. 3-4

3.2 INSTALLATION

3.2.1 RECEIVING, HANDLING, AND STORAGE....................................................... 3-5

3.2.2 ENVIRONMENT................................................................................................. 3-5

3.2.3 MOUNTING........................................................................................................3-5

3.2.4 EXTERNAL CON N ECT I ONS......................... ................... .................... ............. 3-5

3.2.5 SURGE GROUND CONNECTIONS.................................................................. 3-5

3.3 PRINTED CIRCUIT BOARD MODULES

3.3.1 WARNING.......................................................................................................... 3-6

3.3.2 BASIC CONSTRUCTION..................................................................................3-6

3.3.3 MODULE IDENTIFICATION .............................................................................. 3-6

3.3.4 LOCAL USER INTERFACE (LUI)...................................................................... 3-6

3.3.5 INPUT BOARD............. ... ................... .................... .................... ................... ... .. 3-6

3.3.6 MAGNETICS MODULE .....................................................................................3-8

3.3.7 COMMUNICATIONS INTERFACE .................................................................... 3-9

3.3.8 DIGITAL OUTPUT / POWER SUPPLY BOARD.............................................. 3-10

3.3.9 DSP / ANI / COMM / LUI.................................................................................. 3-11

3.3.10 960 CPU BOARD............................................................................................. 3-12

4.1 OVERVIEW

4.1.1 INTRODUCTION................................................................................................4-1

4.1.2 TEST EQUIPMEN T......... ................... .................... .................... ................... ... .. 4-1

4.1.3 DRAWINGS AND R EF ER E NC E S ........... ... ................... .................... ................ 4-1

4.1.4 EQUIPMENT GROUNDING ............. .. ...............................................................4-2

4.1.5 REQUIRED SETTI N GS .......... ... ... ................... .................... .................... .......... 4-2

4.1.6 GENERAL INSTRUCTIONS .............................................................................. 4-2

4.1.7 SETTING CHANGE S............................... ... ................... .................... ................ 4-3

4.1.8 ENTERING TEST M OD E........ ... ... ................... .................... .................... .......... 4-4

4.1.9 USING COMMUNICATIONS (OPTIONAL)........................................................ 4-4

4.2 GENERAL RELAY TESTS

4.2.1 T1 – RELAY STATUS AND DISPLAY TESTING...............................................4-7

4.2.2 DISPLAY AND KEYPAD TESTS ....................................................................... 4-7

4.2.3 T2 – DIGITAL OUTPUT TEST ........................................................................... 4-8

4.2.4 T3 – CONFIGURABLE INPUT AND OUTPUT TEST ........................................ 4-9

4.2.5 T4 – AC SYSTEM INPUT TEST ...................................................................... 4-10

5. FUNCTIONAL TESTS

(FACTORY SETTINGS)

GE Power Management

5.1 TEST SUMMARY

5.1.1 DESCRIPTION................................................................................................... 5-1

5.2 MEASURING UNIT TESTS

5.2.1 T1 – FAULT DETECTOR TEST......................................................................... 5-2

5.2.2 T2 – IT TRIP SUPERVISION TEST................................................................... 5-2

5.2.3 T3 – IB BLOCKING SUPERVISION TEST ........................................................ 5-3

5.2.4 T4 – GROUND DIRECTIONAL TRIP TEST, IPT + NT...................................... 5-3

5.2.5 T5 – GROUND DIRECTIONAL BLOCK TEST, IPB + NB.................................. 5-3

5.2.6 T6 – PHASE INSTANTANEOUS OVERCURRENT 50 ........... ..........................5-4

5.2.7 T7 – GROUND INSTANTANEOUS OVERCURRENT 50G...............................5-4

5.2.8 T8 – GROUND TIME OVERCURRENT 51G.....................................................5-4

5.2.9 UNDERVOLTAGE TEST....................................................... ............................5-5

5.2.10 T9 – T10 – OVERVOLTAGE TEST ................................................................... 5-5

5.3 ZONE REACH AND TIMER TESTS

5.3.1 GENERAL ZONE REACH TESTING CONSIDERATIONS ............................... 5-8

5.3.2 T11 – ZONE 1 GROUND REACH, M1G GROUND FAULTS . ...........................5-8

5.3.3 T12 – ZONE 2 GROUND REACH, MTG GROUND FAULTS............................5-9

5.3.4 T13 – ZONE 3 GROUND REACH, M3G GROUND FAULTS . ...........................5-9

5.3.5 T14 - ZONE 4 GROUND REACH, M4G GROUND FAULTS...........................5-10

ALPS Advanced Line Protection System iii

Page 8

TABLE OF CONTENTS

5.3.6 T15 – GROUND (ZONE BACKUP) TIMER TESTS..........................................5-11

5.4 PHASE-TO-PHASE ZONE REACH TESTING

5.4.1 T16 – ZONE 1 PHASE REACH, M1 FAULTS ..................................................5-13

5.4.2 T17 – ZONE 2 PHASE REACH, M2 FAULTS ..................................................5-13

5.4.3 T18 – ZONE 3 PHASE REACH, M3 FAULTS ..................................................5-14

5.4.4 T19 – ZONE 4 PHASE REACH, M4 FAULTS ..................................................5-15

5.4.5 T20 – PHASE (ZONE BACK-UP) TIMER TESTS ............................................5-16

5.5 MOB TESTING

5.5.1 T21 – OUT-OF-STEP REACH, MOB................................................................5-19

5.5.2 ENDING FUNCTIONAL TESTS................................................. ......................5-19

6. FUNCTIONAL TESTS (USER

SETTINGS)

6.1 ALPS FUNCTIONAL TESTS

6.1.1 DESCRIPTION ...................................................................................................6-1

6.1.2 DRAWINGS AND R EF ER E NC E S .......................... .. .................... .................... ..6-2

6.1.3 GENERAL INSTRUCTIONS...............................................................................6-3

6.1.4 ENTERING TEST M OD E ........................... .................... .................... ................ 6- 3

6.1.5 USING ALPS-LINK (OPTIONAL) .......................................................................6-3

6.2 GENERAL RELAY TESTS

6.2.1 T1 – LUI RELAY STATUS ..................................................................................6-4

6.2.2 T2 – LUI DISPLAY TEST....................................................................................6-4

6.2.3 T3 – DIGITAL OUTPUT TEST............................................................................6-4

6.2.4 T4 – AC SYSTEM INPUT TEST .........................................................................6-5

6.3 MEASURING UNIT TESTS

6.3.1 WARNING ..........................................................................................................6-6

6.3.2 T5 – IT TRIP SUPERVISION TEST ...................................................................6-6

6.3.3 T6 – IB BLOCKING SUPERVISION TEST (BLOCKING SCHEMES) ................6-6

6.3.4 T7 – GROUND DIRECTIONAL TRIP TEST, IPT + NT.......................................6-6

6.3.5 T8 – GROUND DIRECTIONAL BLOCK TEST, IPB + NB ..................................6-7

6.4 BACKUP PROTECTION TESTS

6.4.1 T9 – PHASE INSTANTANEOUS OVERCURRENT 50......................................6-8

6.4.2 T10 – GROUND INSTANTANEOUS OVERCURRENT 50G..............................6-8

6.4.3 T11 – GROUND TIME OVERCURRENT 51G....................................................6-9

6.5 ZONE REACH TESTS

6.5.1 GENERAL CONSID E RATIONS .................................. .................... .................6 - 10

6.5.2 ZONE 1–4 PHASE-TO-GROUND CALCULATIONS........................................6-10

6.5.3 T12 – ZONE 1 GROUND REACH TEST, M1G GROUND FAULTS................6-12

6.5.4 T13 – ZONE 2 GROUND REACH, MTG GROUND FAULTS ..........................6-13

6.5.5 T14 – ZONE 3 GROUND REACH, M3G GROUND FAULTS...........................6-13

6.5.6 T15 – ZONE 4 GROUND REACH, M4G GROUND FAULTS...........................6-14

6.5.7 ZONE 1 TO 4 PHASE-PHASE REACH CALCULATIONS ...............................6-14

6.5.8 T16 – ZONE 1 PHASE REACH, M1 FAULTS ..................................................6-16

6.5.9 T17 – ZONE 2 PHASE REACH, MT FAULTS..................................................6-16

6.5.10 T18 – ZONE 3 PHASE REACH, M3 FAULTS..................................................6-17

6.5.11 T19 – ZONE 4 PHASE REACH, M4 FAULTS..................................................6-17

6.5.12 ENDING FUNCTIONAL TESTS (USER SETTINGS).......................................6-17

7. SPECIFICATIONS

8. LOCAL USER INTERFACE

7.1 ALPS SPECIFICATIONS

7.1.1 DESCRIPTION ...................................................................................................7-1

8.1 INTRODUCTION

8.1.1 DESCRIPTION ...................................................................................................8-1

8.1.2 DISPLAY AND KEYPAD ....................................................................................8-1

8.1.3 CONTROL KEYS................................................................................................8-2

8.1.4 MESSAGES........................................................................................................8-3

8.1.5 SETTINGS..........................................................................................................8-4

8.1.6 EDIT PROTECTION SETTINGS ........................................................................8-4

8.1.7 [END] KEY ............................ .................... ................... .................... ...................8-6

iv ALPS Advanced Line Protection System

GE Power Management

Page 9

TABLE OF CONTENTS

8.1.8 EDIT GENERAL SETTINGS.............................................................................. 8-7

8.1.9 SELECT ACTIVE SETT GRP ............................................................................ 8-7

8.1.10 MODIFY DATE/TIME......................................................................................... 8-7

8.1.11 ACTIONS ........................................................................................................... 8-8

8.1.12 DISABLE OUTPUTS.......................................................................................... 8-8

8.1.13 ENABLE OUTPUT S................... .................... ................... .................... ............. 8-9

8.1.14 TRIP BREAKER................................................................................................. 8-9

8.1.15 CLOSE BREAKER............................................................................................. 8-9

8.1.16 RELAY TEST ................................................................................................... 8-10

8.1.17 CHANNEL TEST.. ... .. .................... ... ................... .................... ................... ...... 8-11

8.1.18 KEYPAD/DISPL AY INTERFACE TEST................................................ ........... 8-12

8.1.19 DIGITAL OUTPUT TEST ................................................................................. 8-12

8.1.20 PLAYBACK ...................................................................................................... 8-13

8.1.21 CHANGE PASSWORD....................................................................................8-14

8.1.22 ENABLE/DISABLE PASSWORDS .. .. ... .................... ................... .................... 8-15

8.1.23 RESET DATA................................................................................................... 8-15

8.1.24 RESET RECLOSER ........................................................................................8-15

8.1.25 ADJUST CONTRAST ...................................................................................... 8-15

8.2 INFORMATION

8.2.1 DESCRIPTION................................................................................................. 8-16

8.2.2 REQUEST STATUS INFORMATION .............................................................. 8-16

8.2.3 REQUEST FAULT INFORMATION .................................................................8-17

8.2.4 REQUEST PRESENT VALUES....................................................................... 8-18

8.2.5 CONTACT CONVERTER STATUS................................................................. 8-18

8.2.6 DIGITAL OUTPUT STATUS ............................................................................ 8-18

8.2.7 EVENT INFORMATION................................................................................... 8-19

8.2.8 COMMUNICATION PASSWORDS.................................................................. 8-21

8.2.9 REQUEST STATION/LINE ID.......................................................................... 8-21

8.2.10 REQUEST ALPS MODEL/VERSION............................................................... 8-21

8.2.11 OSCILLOGRA PHY SNAPSHOT.............. ... ................... .................... .............. 8-22

8.3 ASCII INTERFACE

8.3.1 DESCRIPTION................................................................................................. 8-23

8.3.2 RECOMMENDED REMOTE COMMUNICATIONS PACKAGE....................... 8-23

8.4 REMOTE COMMUNICATION INTERFACE

8.4.1 HARDWARE SWITCHES ................................................................................ 8-24

8.4.2 MODEM CONNECTIONS AND SETTINGS .................................................... 8-24

8.4.3 PC MODEM ..................................................................................................... 8-25

8.4.4 ALPS MODEM ................ ... ... ................... .................... ................... ................. 8-25

8.4.5 NULL-MODEM CONNECTIONS ..................................................................... 8-27

9. SERVICING

10. ALPS TEST PROGRAM

GE Power Management

9.1 SPARES

9.1.1 DESCRIPTION................................................................................................... 9-1

9.1.2 SERVICING WITH THE RELAY SELF-TEST.................................................... 9-1

9.2 TROUBLESHOOTING

9.2.1 DESCRIPTION................................................................................................... 9-3

9.2.2 THE INFORMATION STATUS COMMAND....................................................... 9-3

9.2.3 SERVICING A CRITICAL FAILURE .................................................................. 9-3

9.2.4 LOCATING THE DEFECTIVE BOARD.............................................................. 9-4

9.2.5 SERVICING A NON-CRITICAL FAILURE ......................................................... 9-4

9.2.6 LOCATING THE DEFECTIVE BOARD.............................................................. 9-4

9.2.7 SERVICE SYSTEM STATUS FAILURES.......................................................... 9-5

10.1 INTRODUCTION

10.1.1 DESCRIPTION................................................................................................. 10-1

10.1.2 STARTING PROGRAM AFTER THE FIRST TIME ......................................... 10-1

10.2 TEST CALCULATIONS

10.2.1 DESCRIPTION................................................................................................. 10-2

10.2.2 ENTERING INPUT QUANTITIES.................................................................... 10-2

10.2.3 ENTERING A VALU E ...................... ................... .................... ................... ... ... 10-3

10.2.4 SELECTING A VALUE..................................................................................... 10-3

ALPS Advanced Line Protection System v

Page 10

TABLE OF CONTENTS

10.2.5 M1 PHASE UNITS – ZONE 1...........................................................................10-3

10.2.6 MT PHASE UNITS – ZONE 2...........................................................................10-4

10.2.7 M3 PHASE UNITS – ZONE 3...........................................................................10-4

10.2.8 M4 PHASE UNITS – ZONE 4...........................................................................10-5

10.2.9 MOB PHASE UNIT...........................................................................................10-5

10.2.10 MIG GROUND UNITS – ZONE 1 .....................................................................10-6

10.2.11 MTG GROUND UNITS – ZONE 2...................................... ..............................10-6

10.2.12 M3G GROUND UNITS – ZONE 3 ................................................. ...................10-7

10.2.13 M4G GROUND UNITS – ZONE 4 ................................................. ...................10-7

10.3 FILE MENU

10.3.1 NEW TEST FILE...............................................................................................10-8

10.3.2 OPEN TEST FILE.............................................................................................10-8

10.3.3 OPEN SETTING FILE ......................................................................................10-8

10.3.4 CLOSE TEST FILE...........................................................................................10-9

10.3.5 SAVE INPUT QUANTITIES..............................................................................10-9

10.3.6 SAVE INPUT QUANTITIES AS ......................................................................10-10

10.3.7 SAVE OUTPUT AS.......... .. ... .................... ................... .................... ...............1 0 - 10

10.3.8 PRINT................................ .................... ................... .................... ... ...............1 0 - 10

10.3.9 PRINT SETUP ........ ... .................... ................... .................... ................... .......10-10

10.3.10 LAST 4 OPENED SETTINGS FILES..............................................................10-10

10.3.11 EXIT................................................................................................................10-10

10.4 EDIT MENU

10.4.1 COPY..............................................................................................................10-11

10.4.2 COPY TEXT ONLY.........................................................................................10-11

10.4.3 COPY MHO CIRCLE ONLY ...........................................................................10-11

10.5 VIEW MENU

10.5.1 DESCRIPTION ...............................................................................................10-12

10.5.2 TOOLBAR.......................................................................................................10-12

10.5.3 STATUS BAR ............ ... ................... .................... ................... .................... ....10-12

10.6 TOOLS MENU

10.6.1 DESCRIPTION .......... .................... .................................... .............................10-13

10.7 WINDOW MENU

10.7.1 DESCRIPTION ...............................................................................................10-15

10.7.2 CASCADE ......................................................................................................10-15

10.7.3 TILE ................................................................................................................10-15

10.7.4 ARRANGE ICONS..........................................................................................10-15

10.7.5 VIEWING MULTIPLE TESTS .........................................................................10-15

10.8 HELP MENU

10.8.1 CONTENTS ....................................................................................................10-16

10.8.2 ABOUT ALPS_TST ........................................................................................10-16

11. ALPS-LINK USER GUIDE

11.1 INSTALLATION

11.1.1 OVERVIEW ......................................................................................................11-1

11.1.2 USING ON-LINE HELP ....................................................................................11-1

11.1.3 SUPPORTED ARCHITECTURE .............. ................... .................... ... ..............1 1- 1

11.1.4 HARDWARE INSTALLATION ..........................................................................11-1

11.1.5 SOFTWARE INSTALLATION...........................................................................11-3

11.2 USING ALPS-LINK

11.2.1 STARTUP .........................................................................................................11-5

11.2.2 MENU BAR.......................................................................................................11-5

11.2.3 TOOLBAR.........................................................................................................11-5

11.2.4 STATUS BAR ............ ... ................... .................... ................... .................... ... ...11-5

11.3 SETTING UP YOUR HOST MACHINE

11.3.1 DESCRIPTION .................................................................................................11-6

11.3.2 COM PORT SETUP .........................................................................................11-6

11.3.3 MODEM SETUP ........ .................... .. .................... ................... .................... ......11-6

11.3.4 PRINTER SETUP.............................................................................................11-7

11.3.5 DEVICE SETUP .. ... ... .................... ................... .................... ................... .........11-7

11.3.6 ADDING A DEVICE..........................................................................................11-7

vi ALPS Advanced Line Protection System

GE Power Management

Page 11

TABLE OF CONTENTS

11.4 CONNECTING TO AND LOGGING OUT OF A DEVICE

11.4.1 DESCRIPTION................................................................................................. 11-9

11.4.2 CONNECT TO A DEVICE................................................................................ 11-9

11.4.3 LOGOUT FROM A DEVICE............................................................................. 11-9

11.5 SETTINGS AND ACTIONS

11.5.1 SETTINGS ..................................................................................................... 11-10

11.5.2 ACTIONS ....................................................................................................... 11-12

11.6 INFORMATION

11.6.1 DESCRIPTION............................................................................................... 11-14

11.6.2 OPEN REPORT ............................................................................................. 11-14

11.6.3 NEW REPORT............................................................................................... 11-14

11.6.4 FAULT REPORT............................................................................................ 11-15

11.6.5 OSCILLOGRA PHY REPORT .......... .. .................... .................... ................... . 11-15

11.6.6 BREAKER HEALTH REPORT....................................................................... 11-15

11.6.7 DEMAND REPORT...... ... ... ................... ... .................... ................... ............... 11- 15

11.6.8 DIAGNOSTICS REPORT .............................................................................. 11-15

11.6.9 EVENT REPORT ........................................................................................... 11-15

11.6.10 PRESENT VALUES REPORT.......................................................................11-15

11.6.11 STAT U S R EP ORT.... ... ... ... ................... .................... ................... .................. 1 1 - 15

11.6.12 CONTACT STATUS REPORT.......................................................................11-16

11.6.13 LUI PASSWORD REPORT............................................................................11-16

11.6.14 OPEN REPORT ............................................................................................. 11-16

11.6.15 SAV E RE PORT....... .. .................... ................... .................... .................... ...... 11-16

11.6.16 PRIN T R EP ORT .. ... ................... .................... ................... .................... ......... 11-16

11.7 LOGGING

11.7.1 SESSION LOG............. ... ... ................... ... .................... ................... ............... 11 - 17

11.7.2 TURN OFF.....................................................................................................11-17

11.7.3 CURRENT SESSION LOG..................... .. ............................ .........................11-17

11.7.4 OPEN SESSION LOG ................................................................................... 11-17

11.7.5 ARCHIVAL ..................................................................................................... 11-17

11.7.6 ARCHIVE ....................................................................................................... 11-17

11.7.7 RETREIVE ..................................................................................................... 11-18

12. ASCII COMMUNICATIONS

13. XPRESSION BUILDER

14. ALPS-SET PC SOFTWARE

12.1 INTRODUCTION

12.1.1 DESCRIPTION................................................................................................. 12-1

12.1.2 ASCII INTERFACE .......................................................................................... 12-1

13.1 INTRODUCTION

13.1.1 OVERVIEW...................................................................................................... 13-1

13.1.2 INSTALLATION................................................................................................ 13-1

13.1.3 DESIGN CONSIDE R A TIO N S ....... ................... .................... .................... ........ 13-1

13.1.4 BOOLEAN OPERATORS, LATCHES, TIMERS, & COUNTERS .................... 13-2

13.2 XPRESSION BUILDER FLAGS

13.2.1 CONTACT CONVERTER INPUTS.................................................................. 13-4

13.2.2 INPUT/OUTPUT FLA G S. ... ................... .................... ... ................... ................. 1 3- 4

13.3 CREATING XPRESSION BUILDER LOGIC

13.3.1 DESCRIPTION................................................................................................. 13-9

13.3.2 COMPILING AND DOWNLOADING XPRESSION BUILDER LOGIC...........13-11

13.3.3 BREAKER FAILU R E EX A M PL E.................................................. .................. 1 3 - 11

14.1 INTRODUCTION

14.1.1 INSTALLATION................................................................................................ 14-1

14.1.2 STARTING THE PROGRAM ........................................................................... 14-1

14.1.3 PRINT SETTINGS REPORT ........................................................................... 14-3

14.1.4 EDIT MENU – COPY SETTINGS REPORT .................................................... 14-3

14.1.5 TOOLS MENU .................................................................................................14-3

14.1.6 HELP MENU .................................................................................................... 14-4

GE Power Management

ALPS Advanced Line Protection System vii

Page 12

TABLE OF CONTENTS

A. FREQUENTLY ASKED

QUESTIONS

B. MODBUS

C. DNP

A.1 FREQUENTLY ASKED QUESTIONS

B.1 MODBUS INTRODUCTION

B.1.1 DESCRIPTION..................................................................................................B-1

B.1.2 COMMUNICATIONS SETTINGS......................................................................B-1

B.1.3 SUPPORTED MODBUS FUNCTIONS..............................................................B-1

B.1.4 EXCEPTION OR ERROR REPLIES.................................................................B-2

B.1.5 DATA FORMATS...............................................................................................B-2

B.2 REGISTER MAPS

B.2.1 SUMMARY........................................................................................................B-3

B.2.2 MODBUS MEMORY MAP.................................................................................B-5

B.2.3 MEMORY MAP DATA FORMATS...................................................................B-15

C.1 OVERVIEW

C.1.1 DESCRIPTION..................................................................................................C-1

C.1.2 MODIFYING SETTINGS USING DNP...............................................................C-1

C.2 DEVICE PROFILE

C.2.1 DNP V3.00 DEVICE PROFILE DOCUMENT....................................................C-2

C.2.2 IMPLEMENTATION TABLE..............................................................................C-4

C.2.3 IMPLEMENTATION TABLE NOTES.................................................................C-5

C.2.4 DEFAULT VARIATIONS....................................................................................C-5

C.3 POINT LISTS

C.3.1 DESCRIPTION..................................................................................................C-6

C.3.2 BINARY INPUT, BINARY INPUT CHANGE......................................................C-6

C.3.3 BINARY OUTPUT, CONTROL RELAY OUTPUT BLOCK..............................C-11

C.3.4 BINARY COUNTER, FROZEN COUNTER.....................................................C-12

C.3.5 ANALOG INPUT, ANALOG INPUT CHANGE.................................................C-13

C.3.6 ANALOG OUTPUT, ANALOG OUTPUT BLOCK............................................C-19

C.3.7 DATA FORMATS – ANALOG INPUT AND OUTPUT POINTS.......................C-26

D. KEYPAD MENUS

E. FIGURES AND TABLES

F. WARRANTY

INDEX

D.1 KEYPAD MENUS

D.1.1 SET KEYPAD MENU.........................................................................................D-1

D.1.2 ACT KEYPAD MENU........................................................................................D-2

D.1.3 INF KEYPAD MENU..........................................................................................D-3

E.1 FIGURES AND TABLES

E.1.1 LIST OF FIGURES............................................................................................E-1

E.1.2 LIST OF TABLES..............................................................................................E-3

F.1 WARRANTY INFORMATION

F.1.1 GE POWER MANAGEMENT WARRANTY.......................................................F-1

INDEX

viii ALPS Advanced Line Protection System

GE Power Management

Page 13

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED 1.1.1 INSPECTION

Before attempting to install or use this relay, it is imperative that all WARNINGS and CAUTIONS in this ma nual are reviewed to help prevent personal injury, equipment damage, and/or downtime.

NOTE

Unpack the relay, the mounting brackets, and the hardware for attaching the mounting brackets to the sides of the relay.

Examine the rela y for an y dam age sustained in t rans it , and if damage is ev id ent, no tify the shipping c om pa ny an d the nearest GE Power Management sales office immediately.

Prior to applying power, ensure that the model number of the relay listed on the front panel corresponds to the model

ordered. Make sure that the DC supply power matches the rated voltage listed on the front panel. Refer to the elementary

diagrams on pages 1–49 to 1–52 for the locations of the DC power inputs

Instructi ons o n using the keypad to c hange s etti ngs an d put t he rel ay in to te st mode can b e fo und in Secti on 4.1 .7: SE TTING CHANGES on page 4–3. Complete instructions on operating the keypad are found in Chapter 8: LOCAL USER

INTERFACE.

GE Power Management contact information:

GE Power Management

215 Anderson Avenue

Markham, Ontario

Canada L6E 1B3

Telephone: Toll Free North America: (800) 547-8629

Europe +34 94 485 88 54

Other Areas (905) 294-6222

Emergency (416) 414-4941

Fax: (905) 201-2098

Email: info.pm@indsys.ge.com

Home Page: www.GEindustrial.com/pm

1

1.1.2 PASSWORDS, FACTORY SET

The ALPS requires passwords to change settings or perform actions. No password is required to obtain information from

the relay, including viewing the existing settings. The relay is shipped from the factory with the following MMI passwords:

SETTINGS: 123.

ACTIONS: 456.

MASTER: 789.

The decimal point following the digits is part of the password. Factory passwords MUST be changed

before the user can modify settings or initiate Actions.

NOTE

In order to change the default password, follow these steps:

1. Press the ACTIONS key [ACT].

2. Press the ENTER key [ENT].

3. Scroll to the CHANGE PASSWORD option.

4. Select the Password Privilege level to be changed.

5. Press [ENT].

6. Enter the factory password (for example: 789. for Master Password).

7. Enter your password.

8. Re-enter your password.

9. Press [END], press [ENT], and then press [CLR].

The keypad passwords stored in the relay may be viewed, in encoded format, via remote communications.

GE Power Management

ALPS Advanced Line Protection System 1-1

Page 14

1.1 GETTING STARTED 1 PRODUCT DESCRIPTION

1.1.3 REMOTE COMMUNICATIONS VIA LOCAL PC

1

To communicate with the relay through a PC, connect the relay to a serial port of an IBM-compatible computer with a

null-modem cable. Connection can be made either to the 25 pin D-connector on the back of the relay (PL2A), or the 9 pin

D-connector on the front (PL1). Cable diagrams are shown in the following:

• Figure 8–2: MODEM CABLE on page 8–23

• Figure 8–3: 25-PIN NULL MODEM CABLE on page 8–23

• Figure 8–4: 25-PIN NULL MODEM CABLE on page 8–27

• Figure 8–5: NULL MODEM CABLE FOR PORT PL1 on page 8–27

The communications software required to access the relay, ALPS-Link, is included on the enclosed Products CD. Follow

instructions in Section 11.1.5 SOFTWARE INSTALLATION on page 11–3 to load ALPS-Link onto the PC.

1.1.4 ALPS-LINK QUICK REFERENCE

The ALPS relay requires the use of passwords to obtain information from the relay, to change Settings, or to perform

Actions. The relay is shipped from the factory with the following communications passwords:

VIEW: VIEW!

SETTINGS: SETTING!

ACTIONS: CONTROL!

MASTER: MASTER!

The exclamation point following the letters is part of the factory password. The factory passwords MUST

be changed before the user can modify Settings or initiate Actions. The user can log into the relay at any

NOTE

password level. After logging into the relay, the password can be changed under the ACTION menu by

selecting CHANGE PASSWORD.

The user must logout from the ALPS before changing another password. The remaining passwords can then be changed

by logging into the ALPS using another default password. The communications passwords may be viewed, in an encoded

format, via the [INF] (information) key.

To log into the relay, follow the instructions in Section 4.1.9: USING COMMUNICATIONS (OPTIONAL) on page 4–4. Any

one of the factory passwords can be used to log on to the relay. The relay UNITID (General Setting 101) is factory set to

"0".

1-2 ALPS Advanced Line Protection System

GE Power Management

Page 15

1 PRODUCT DESCRIPTION 1.1 GETTING STARTED

1.1.5 ORDERING

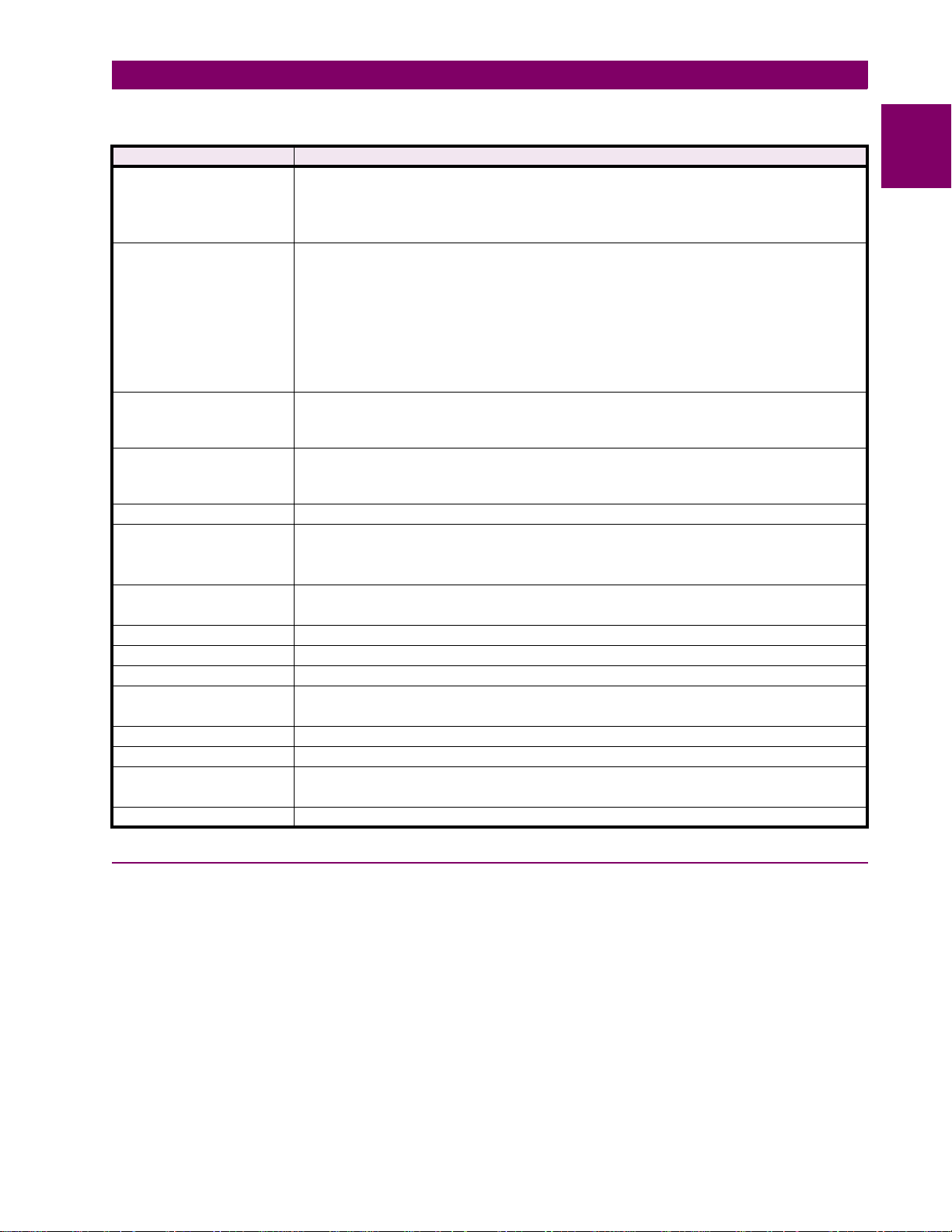

Table 1–1: ORDER CODES

ALPS * * * * * * * * * * * * – *

Base Unit

Distance Relay

Revision

Tripping Logic

Current Rating

Series

Capacitors

Battery

Voltage

Trip Outputs

Comm Ports

Mounting

Oscillography

ALPS

|||||||||||| |

D

| | | | | | | | | | | |

A

|||||||||| |

B

|||||||||| |

1

| | | | | | | | | |

3

| | | | | | | | | |

1

|||||||| |

5

|||||||| |

U

| | | | | | | |

C

| | | | | | | |

0

|||||| |

1

|||||| |

2

|||||| |

1

| | | | | |

2

| | | | | |

3

| | | | | |

4

| | | | | |

2

|||| |

3

|||| |

H

| | | |

V

| | | |

S

E

OST / Positive

Sequence

Overvoltage

Recloser

Protocol

† These options are applicable to Revision A models only.

|| |

|| |

0

| |

1

| |

2

| |

3

| |

N

R

S

Base Unit

Distance Relay

ALPS Revision A

ALPS Revision B

Single Phase Tripping Logic

Three Phase Tripping Logic

1 Ampere rated current

5 Ampere rated current

For applications without series capacitors

For Applications with series capacitors

48V DC battery voltage

110/125 V DC battery voltage

220/250 V DC battery voltage

SCR trip outputs & contact channel interface

Contact trip outputs & contact channel interface

SCR trip outputs & 5V / 20mA channel interface

Contact trip outputs & 5V / 20 mA channel interface

Front RS232 port & 1 settable RS232/RS485 rear port (GEmodem/ASCII)

Front RS232 port & 2 settable RS232/RS485 rear ports (GEmodem/ASCII)

Horizontal mounting

Vertical mounting

Standard oscillography memory

Extended oscillography memory

No out-of-step tripping or positive sequence overvoltage

With out-of-step tripping

With positive sequence overvoltage units

With positive sequence overvoltage units & out-of-step tripping

No recloser

|

Recloser

|

Recloser with sync check

|

AC

Modbus RTU communication

†

†

†

†

†

EXAMPLE: ALPSDA35U122VE1N = ALPS Digital Line Protection Distance Relay; revision A; three phase tripping logic;

rated at 5 amperes; without series capacitor protection; 110/125 VDC supply; contact tripping outputs; 2 communications

ports; vertical mounting; with extended memory; without OST functions; and no recloser.

1

†

GE Power Management

ALPS Advanced Line Protection System 1-3

Page 16

1.2 INTRODUCTION 1 PRODUCT DESCRIPTION

1.2 INTRODUCTION 1.2.1 DESCRIPTION

1

The Advanced Line Protection System (ALPS) is a microprocessor-based digital relay system that uses waveform sampling with appropriate algorithms to provide three phase or single phase tripping schemes for transmission line protection,

fault location, and related features. The models covered by this instruction book are intended for either three phase or single phase tripping applications. The relay samples the current and voltage inputs from the power system 64 times per

cycle. Protection algorithms process this sampled data in sets of four, sixteen times per cycle. The ALPS uses advanced

Fourier calculation techniques and adaptive measuring functions to achieve high-speed tripping for severe faults.

The ALPS is packaged in a compact 3 Rack Unit high (one RU = 1.75 Inches) 19-in ch rack moun t cas e and is ava il abl e for

either horizontal or vertical mounting. The case outline and mounting dimensions are shown in Figure 3–2: FRONT AND

REAR VIEW on page 3–2.

All models include a f ull ke yp ad a nd a liquid crystal displa y (LCD ) for local access to re lay da ta an d s etti ngs . In add iti on, up

to three communicatio n po rts are pro vided for both l ocal and rem ote ac cess with a PC. Each port may be indepe ndentl y set

for ASCII or GEmodem protocols.

1.2.2 APPLICATION

The models covered by this instruction book are designed to be used on transmission lines of any voltage level, with or

without series capacitor compensation, where either single or three-phase tripping is required. Detailed application considerations are described in this chapter and in Chapter 2: CALCULATION OF SETTINGS.

The ALPS can provide high speed detection and clearing of power system faults, and includes logic for step distance and

five standard pilot tripping schemes. The scheme logic is described in Section 1.8: PROTECTION SCHEMES on page 1–

23. The external connections for the ALPS are shown in the elementary diagrams on pages 1–49 to 1–52.

The ALPS is available with either a contact interface to the pilot channel equipment or an electronic (5 V, 20 mA) interface

so that the relay may b e appl ied with a wi de vari ety of chann el equ ipmen t. Typical cha nnels incl ude: AM and FSK via po wer

line carrier (PLC), FSK via microwave, and multiplexed fiber optic cable.

1.2.3 PROTECTION FUNCTIONS

The measurement functions are listed in Table 1–2: ALPS MEASUREMENT FUNCTIONS on page 1–5.

The Zone 1 distance functions provide secure high-speed tripping for all fault types over most of the protected line. The

Zone 1 ground distance functions can be selected to be either ground variable-Mho distance functions, or ground-reactance distance functions. The ALPS also offers ground quadrilateral distance functions as Zone 1 ground distance functions. A unique adaptive reach for the supervising Mho characteristic is used when ground-reactance functions are

selected.

Overreaching Zone 2 p has e and ground distance func tio ns are us ed fo r pi lot tripping schemes. G ro und -directional overcurrent functions can be selected to replace or supplement the overreaching zone (Zone 2) ground-distance functions in any

of the pilot schemes. The ALPS also offers Zone 2 ground quadrilateral characteristics. The Zone 2 phase and ground distance functions are provided with independent timers for time delayed backup protection.

Overreaching Zone 3 phase and ground distance functions are provided with independent timers for time delayed backup

protection. The ALPS also has the option for quadrilateral ground-distance functions.

The Zone 4 variable-Mho distance functions can be reversed in direction when a reversed or blocking function is required.

When the POTT 2, Blocking or H ybrid scheme i s selected, Zon e 4 is automatic ally set to the rev erse directi on, because

these schemes require a reverse-looking blocking function. The Zone 4 phase and ground distance functions are provided

with independent timers for time delayed backup protection. The ALPS with three phase tripping also has the option to use

Zone 4 ground quadrilateral distance functions for time-delayed backup protection.

When both phase and ground distance functions are used for a zone of protection, six individual measuring functions are

available: three fo r pha se dis tan ce and thre e for ground distance. The alg orit hm that im ple me nts the variable-Mho measuring functions is derived from designs that have evolved through several different families of static analog and digital relay

systems which have accumulated decades of dependable and secure in-service experience.

An instantaneous overcurrent tripping function (50G) provides direct tripping for severe phase-to-ground faults. Time-overcurrent tripping (51G) provides time-delayed backup tripping for phase-to-ground faults. Either or both of these groundovercurrent functions can be controlled by the NT negative-sequence directional trip unit, at the customer’s discretion.

1-4 ALPS Advanced Line Protection System

GE Power Management

Page 17

1 PRODUCT DESCRIPTION 1.2 INTRODUCTION

Table 1–2: ALPS MEASUREMENT FUNCTIONS

ZONE OR TYPE FUNCTIONS

Zone 1 • 3 Variable-Mho phase-distance functions

• 3 Variable-Mho ground-distance functions

• 3 Reactance ground-distance functions with “adaptive reach” Mho supervision

3 Quadrilateral ground-distance functions (Revision B relays only).

Zone 2 (Pilot Zone) • 3 Variable-Mho phase distance functions

3 Variable Mho ground-distance functions

Ground directional-overcurrent functions consisting of:

IPT: Ground Trip overcurrent

NT: Negative Sequence Directional Trip

IPB: Ground Block overcurrent

NB: Negative Sequence directional block

or

3 Quadrilateral ground-distance functions (Revision B relays only)

Zone 3 • 3 Variable-Mho phase-distance functions

• 3 Variable-Mho ground-distance functions,

3 Quadrilateral ground-distance functions (Revision B relays only)

Zone 4 • 3 Reversible variable-Mho phase-distance functions

• 3 Reversible variable-Mho ground-distance functions,

3 Quadrilateral ground-distance functions (Revision B relays only)

Out of Step Blocking (OSB) • 3 Variable-Mho phase-distance functions

Overcurrent Backup • 50: Phase-overcurrent direct trip (directional or nondirectional

• 50G: Ground-overcurrent direct trip (directional or nondirectional)

• 51G: Ground time-overcurrent direct trip (directional or nondirectional)

Overcurrent Supervision • IT: Trip-supervision overcurrent

• IB: Block-supervision overcurrent

Fault Detector • FD

Line-Pickup Overcurrent • I1

Remote-Open Detectors • ROD

Line-Overload Detectors • Level 1 Overcurrent

• Level 2 Overcurrent

Phase Undervoltage • Three fixed pickup phase undervoltage detectors

Phase Over / Undervoltage • T hree adjustable over or under voltage detectors with time delay

Positive-Sequence Voltage

Detectors

Out of Step Tripping (OST) • 3 Variable-Mho positive sequence-distance functions

•V1,

• V1 compensated

and/or

or

or

or

1

1.2.4 GROUND DISTANCE QUADRILATERAL CHA RACTERISTICS

The ALPS relay has been modified to include the option to use either quadrilateral characteristics or variable Mho characteristics for all zones of ground distance protection. The model numbers affected by this modification are: ALPSDB

XXXXXXXXX

(where X may be any valid character) with firmware version V0005.00AA00 or higher. A new version of

ALPS-Link may be required to access the new settings via remote communications (ALPS-Link must be version 3.5 or

higher). If required, the updated version of ALPS-Link may be downloaded from the GE power Management website at

www.GEindustrial.com/pm

.

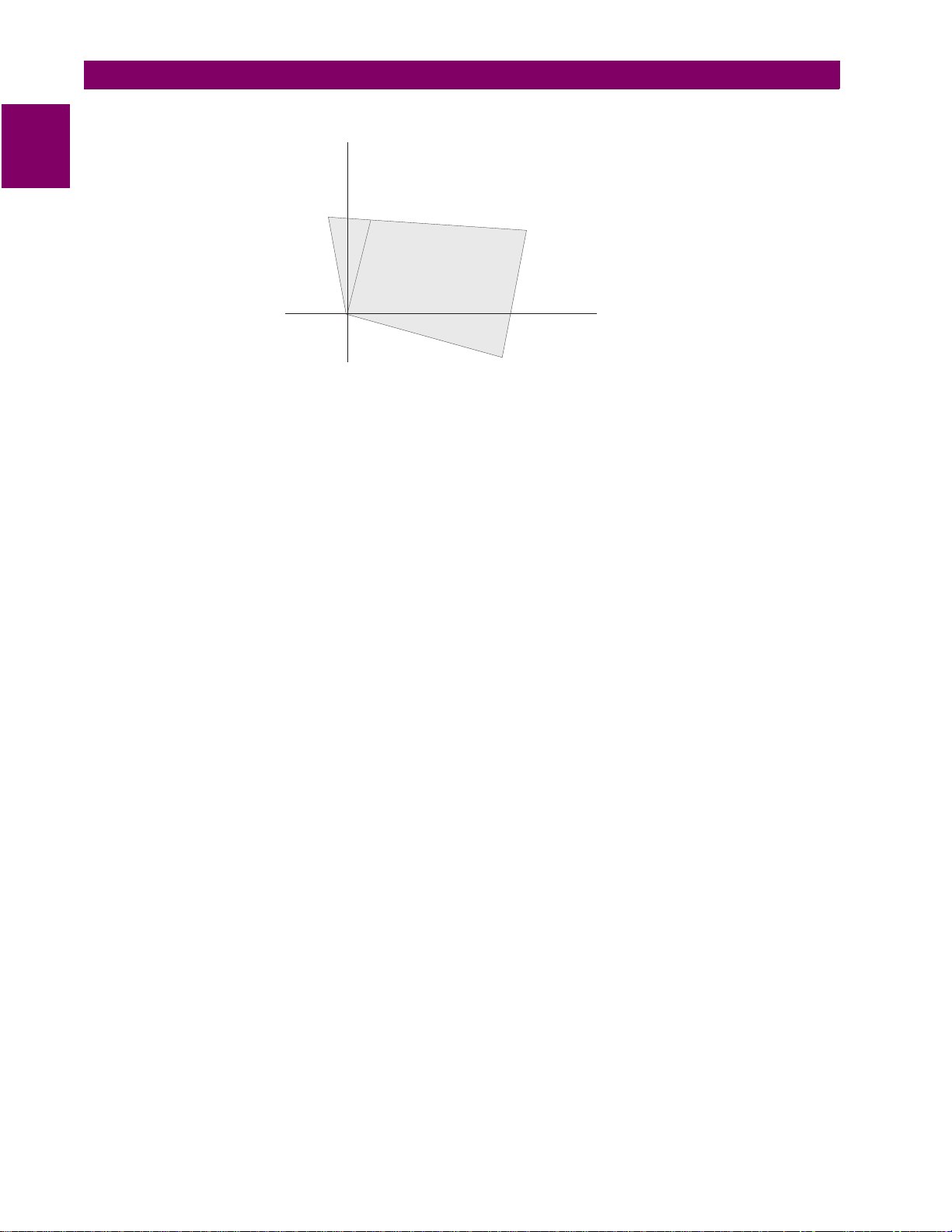

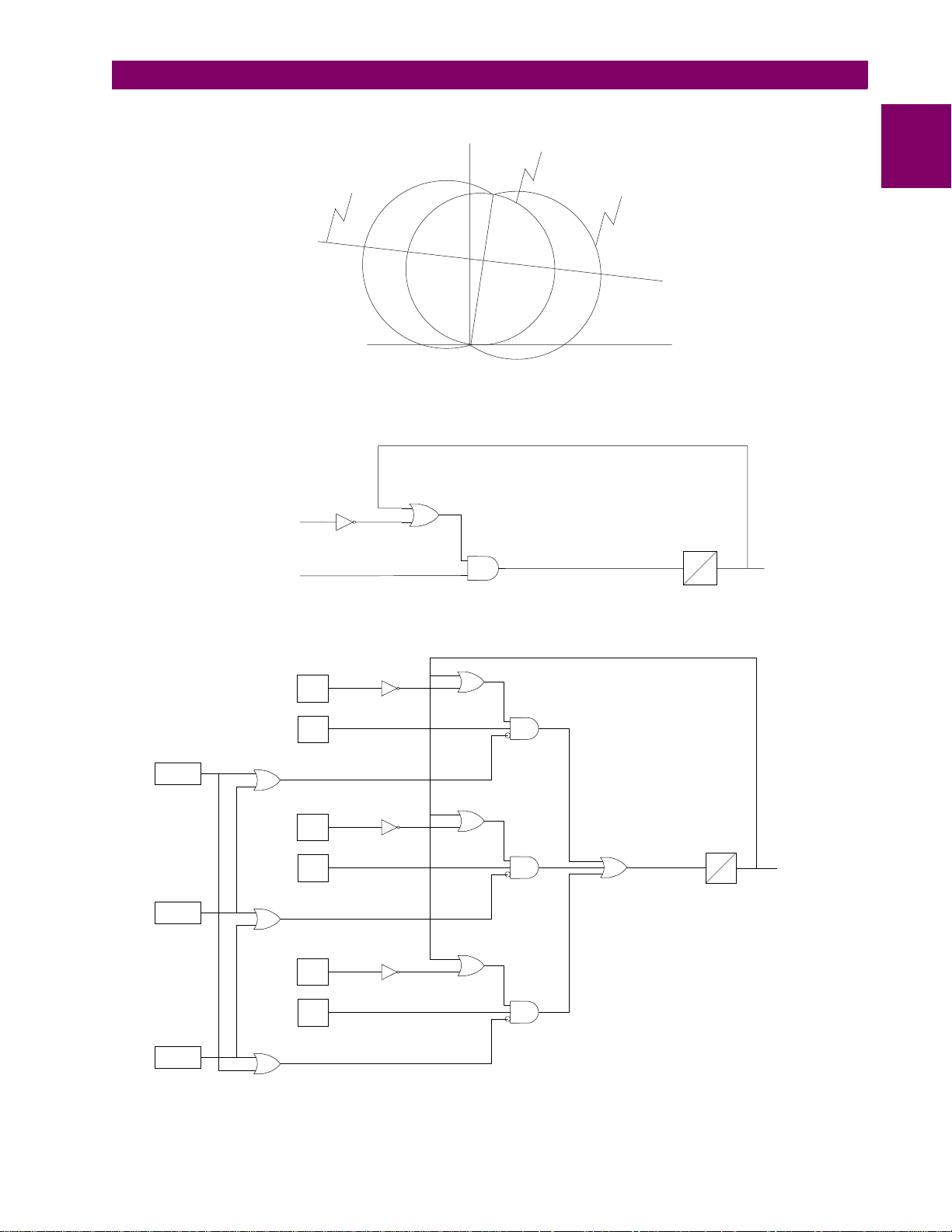

Many protective re la y engineers prefer to us e a qua dri late r al (p oly gon al ) c hara ct eris tic f or grou nd di stance functions to p rovide more fault resistance coverage than the circular mho characteristic. A typical quadrilateral characteristic is shown in

Figure 1–1: GROUND DISTANCE QUADRILATERAL CHARACTERISTIC. The characteristic is comprised of four straight

lines; the trip zone is the inside area bounded by all four characteristics. The upper boundary, the reactance characteristic,

may also be used with a variable mho function. The variable mho provides both directional supervision for reverse faults.

and resistive limits to prevent operation on load.

GE Power Management

ALPS Advanced Line Protection System 1-5

Page 18

1.2 INTRODUCTION 1 PRODUCT DESCRIPTION

1

X

1

4

3

R

2

Figure 1–1: GROUND DISTANCE QUADRILATERAL CHARACTERISTIC

In the ALPS r el ay t he fo ur strai ght line s of th e qu adri lat eral cha rac teri sti c are deve lop ed b y a combin ati on of th e fo llo wing

three characteristics:

1. Reactance characteristic (section 1). The tilt of the reactance characteristic is determined by the characteristic timer

setting. The range of the setting is 80° to 155° in 1° steps.

2. Restricted directional characteristic (sections 2 and 4)

3. Ri ght (pos iti ve ) resist ive bli nder (section 3)

The following definitions pertain to all of the distance functions:

I

= phase A current at relay

A

I

= phase B current at relay

B

I

= phase C current at relay

C

I

= zero-sequence current at relay

0

V

= phase A to ground voltage at relay

A

V

= phase B to ground voltage at relay

B

V

= phase C to ground voltage at relay

C

X

= positive-sequence component of

1

X

= negative-sequence component of

2

= memory (pre-fault) value of

X

M

Z

x

= Zone x positive-sequence reach setting:

1

Z

x

= Zone x zero-sequence reach setting:

0

Note: The magnitudes of

K

1 = Zone 1 zero-sequence compensation factor: Z1K0

0

K

= zero-sequence compensation factor

0

Zx

X

1

and

X

X

ZxR

∠ POSSEQANG

ZxR

∠ ZERSEQANG

Zx

are identical - these quantities differ in phase angle only.

0

a) REACTANCE CHARACTERSTIC

The reactance characte ris tic us ed f or the ground quadrilateral is the si mi lar a s th e ex is tin g ne gat ive / zero sequence phase

angle comparator reactance characteristic. The function has been modified by the addition of a fourth comparator input

(Pol. #3). The operate and polarizing signals used in this function are:

Operate:

Pol.# 1:

Pol.# 2:

Pol.# 3:

where:

Iφ′Z

–

Vφ

I0Z

1

I2Z

1

I

Z

1

F

1

Iφ′Z

is the compen sated IZ product

Z

is the positive sequence replica impedance

1

Vφ

is the phase to ground voltage

I

is the zero sequence current component

0

I

is the negative sequence current component, referenced to the proper phase.

2

I

is the fault component of the positive sequence current component, referenced to the proper phase.

1

F

The pre-fault load current is removed from this quantity.

1-6 ALPS Advanced Line Protection System

GE Power Management

Page 19

1 PRODUCT DESCRIPTION 1.2 INTRODUCTION

All zones of ground reac tan ce ch arac teri st ics w il l ha ve a c hara cte ris tic tim er wi th a pic ku p ran ge of 90 to 1 55° i n s teps of 1.

The characteristic timer setting will be used to “tilt” the reactance characteristic (Tent) to prevent over-reach on non-homogeneous systems, as shown below. Note that the “tent” is not the same as tilting the reactance because it also tilts down to

the left of the maximu m re ach bal anc e point. By adjusting the an gle of the phase angle comparator rat her th an the angle of

“maximum torque”, the transient over reach is not increased.

X

“TENT” CHARACTERISTIC

1

4

R

3

2

TENTCHAR.CDR

Figure 1–2: TENT CHARACTERISTIC

For the Zone 1 ground function, the signals are:

I

-

I

)·Z11 +

K

1·

I

·Z10 –

·Z10 –

·Z10 –

V

V

A

B

V

C

Phase A: (

Phase B: (

Phase C: (

I

A

I

0

I

A1F

I

I

B

I

0

I

B1F

I

I

C

I

0

I

C1F

A

2

·Z1

-

B

2

·Z1

-

C

2

·Z1

·Z1

·Z1

I

·Z1

·Z1

·Z1

·Z1

0

1

0

1

I

0

1

1

1

)·Z11 +

1

1

)·Z11 +

1

1

0

0

K

1·

I

0

0

K

1·

I

0

0

1

b) RESTRICTED DIRECTIONAL CHARACTERISTIC

The restricted directional characteristic for the ground quadrilateral requires a separate directional unit for each phase. No

settings are required for this characteristic. The input signals to the comparator are:

Phase A:

Phase B:

Phase C:

I

·

ZD

A

V

A

I

·

ZD

B

V

B

I

·

ZD

C

V

C

where ZD is the angle of “maximum torque” and is equal to 65°.

The characteristic timer angle will be fixed at 115°. That is, the function will operate when the input signals are within ±65°

of each other.

If the faulted p has e vo lta ge magnitude is too low (as fo r a c los e-i n Zon e 1 fault), the phase d ire cti ona l fun cti on w il l n ot op er-

ate. This might also occur for a remote fault when the relay is located near a strong source. Therefore, if the phase voltage

is less than the minimum threshold voltage, the positive-sequence memory voltage from the ground Mho functions is used

in place of the phase voltage to polarize the directional function.

GE Power Management

ALPS Advanced Line Protection System 1-7

Page 20

1.2 INTRODUCTION 1 PRODUCT DESCRIPTION

c) RIGHT RESISTIVE BLINDER

The right resistive blinder is a two input phase angle comparator. The input signals for the comparator are:

1

Operate:

Polarize:

Iφ′·RB

Iφ′·RB

1 1

Vφ

where:

The magnitude of

RB

1 (Right Blinder for Zone 1) is the point at which the characteristic intersects the R

axis. The range of adjustment will be 0.1 to 500.0 ohms in 0.1 ohm steps.

The angle of RB1 is be fixed based on the positive sequence line angle, the zero sequence line angle,

K

and the

Iφ

′ is the compensated phase current, (

0 factor. The angle is:

2 POSSEQANG

⋅

------------------------------------------------------------------------------------------------------

K

0ZERSEQANG

⋅

+

2

K

0

+

I

-

A

I

) +

K

1•

0

I

0

0

The characteristic timer angle will be fixed at 90°. For the Zone 1 ground function, the operate and polarizing signals are:

Phase A:

Phase B:

Phase C:

I

′·RB1 –

A

I

′·RB1

A

I

′·RB1 –

B

I

′·RB1

B

I

′·RB1 –

C

I

′·RB1

C

V

A

V

B

V

C

where:

I

I

I

K

A

B

C

0

′ = (

′ = (

′ = (

1 = |

I

-

I

) +

K

1·

A

0

I

-

I

) +

B

0

I

-

I

) +

C

0

K

1| – (ZERSEQANG – POSSEQANG)

0

I

0

0

K

1·

I

0

0

K

1·

I

0

0

1.2.5 LINE PROTECTION SCHEMES

The ALPS provides four zones of distance protection with overcurrent backup functions. The ALPS is a highly flexible system: along with predefined protection schemes, it also has the ability to be programmed by the user. The custom programmability of the ALPS is discussed in the next section.

The ALPS pilot protection schemes are as follows:

• Permissive Underreach Transfer Trip (PUTT)

• Permissiv e Overreach Transfer Trip (POTT1)

• Permissiv e Overreach Transf er Trip with blocking functions (POTT2)

•Blocking

•Hybrid

• Phase Identified Channel

In addition, each of the above schemes includes up to four zones of step distance backup with individual timers for phase

and ground zones.

1-8 ALPS Advanced Line Protection System

GE Power Management

Page 21

1 PRODUCT DESCRIPTION 1.3 CUSTOM PROGRAMMABILITY

WARNING

1.3 CUSTOM PROGRAMMABILITY 1.3.1 INTRODUCTION

The ALPS offers a high degree of custom programmability. Custom programming of the ALPS is accomplished using

Xpression Builder. Xpression Builder is a Windows based program that allows the user to design programmable logic and

make I/O (Input/Output) assignments for the ALPS and other GE Power Management relays. Xpression Builder is included

with ALPS software suite on the GE Power Management CD. A complete description of Xpression Builder is included in

Chapter 13: XPRESSION BUILDER.

1.3.2 PROGRAMMABLE LOGIC

In addition to the pre-programmed line protection schemes and configurable I/O, the ALPS relay includes the capability for

the user to design c ustom lo gic. This l ogic may be use d to suppl ement or to repl ace the built-i n sche me lo gic. Th e program mable logic includes the following: up to 40 logic gates (AND, OR, NOT), each with up to 4 inputs; 8 programmable timers

each with a settable pickup and dropout delay; 8 counters; and 8 latches.

1.3.3 CONFIGURABLE INPUTS

All of the contact converters (Digital Inputs) in the ALPS are user configurable. However, each ALPS relay is shipped with

Default Contact Converter Assignments as shown below and on the default elementary diagrams on pages 1–49 to 1–52.

Each configurable input can be assigned only one flag – assigning more than one flag to a configurable

input may cause maloperation!

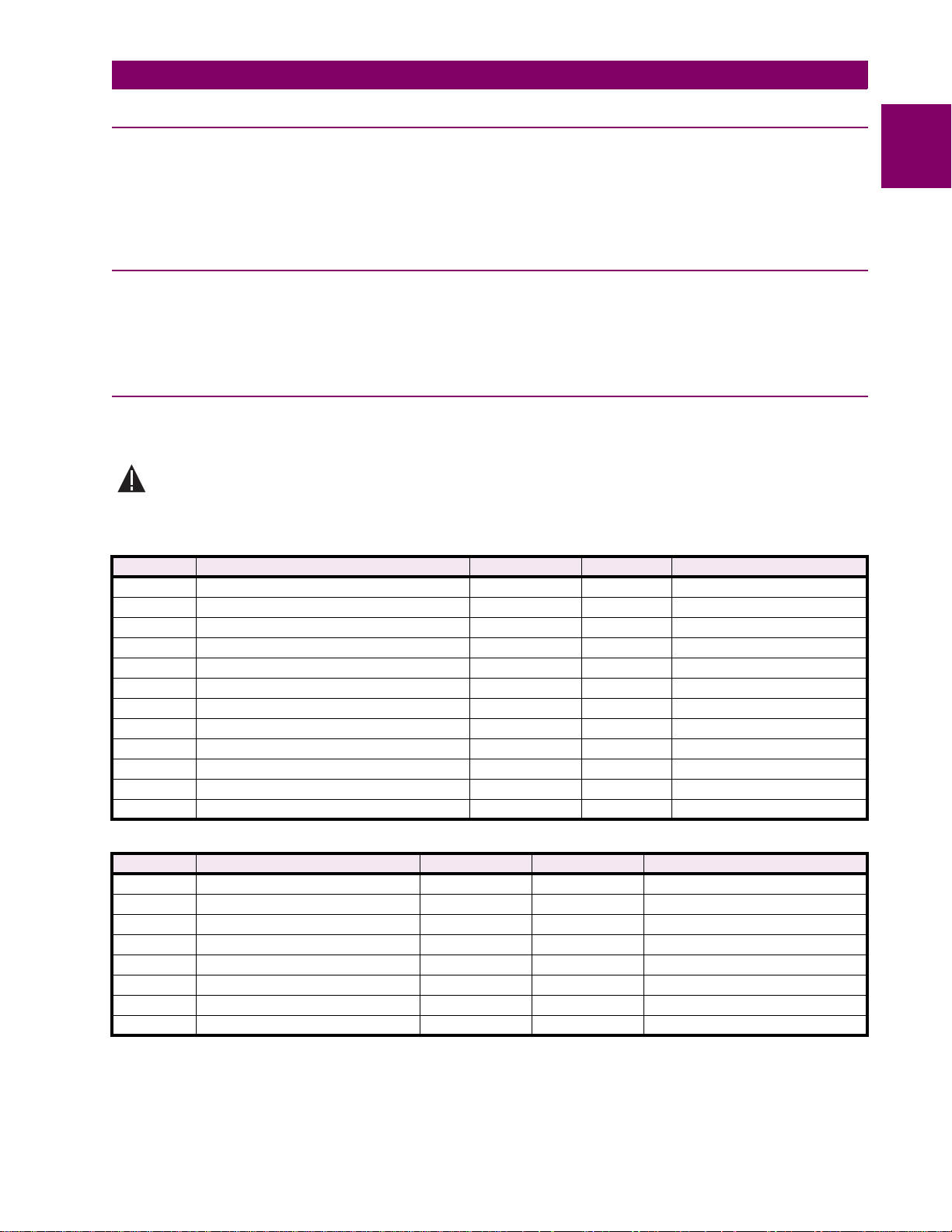

Table 1–3: ALPS DEFAULT CONTACT CONVERTER ASSIGNMENTS: SINGLE PHASE MODEL

INPUT DESCRIPTION MNEMONIC INDEX # NOTE

CC1 RECEIVER #1 RCVR1 12

CC2 RECEIVER #2 RCVR2 13 (if used)

CC3 EXTERNAL STOP CARRIER STCR 10 (Blocking Scheme Only)

CC4 BLOCK PILOT TRIPPING BLPTRP 11 (Blocking Scheme Only)

CC5 ENABLE THREE PHASE TRIPPING ETRP3P 7

CC6 REMOTE TARGET RESET RESET 20

CC7 BKR 1 52b PHASE A 52B_1A 1

CC8 BKR 1 52b PHASE B 52B_1B 2

CC9 BKR 1 52b PHASE C 52B_1C 3

CC10 BKR 2 52b PHASE A 52B_2A 4

CC11 BKR 2 52b PHASE B 52B_2B 5

CC12 BKR 2 52b PHASE C 52B_2C 6

1

Table 1–4: ALPS DEFAULT CONTACT CONVERTER ASSIGNMENTS: THREE PHASE MODEL

INPUT DESCRIPTION MNEMONIC INDEX # NOTE

CC1 RECEIVER #1 RCVR1 12

CC2 RECEIVER #2 RCVR2 13 (if used)

CC3 EXTERNAL STOP CARRIER STCR 10 (Blocking Scheme Only)

CC4 BLOCK PILOT TRIPPING BLPTRP 11 (Blocking Scheme Only)

CC5

CC6

CC7 BKR 1 52B 52B_1 1

CC8 BKR 2 52B 52B_2 4

GE Power Management

ALPS Advanced Line Protection System 1-9

Page 22

1.3 CUSTOM PROGRAMMABILITY 1 PRODUCT DESCRIPTION

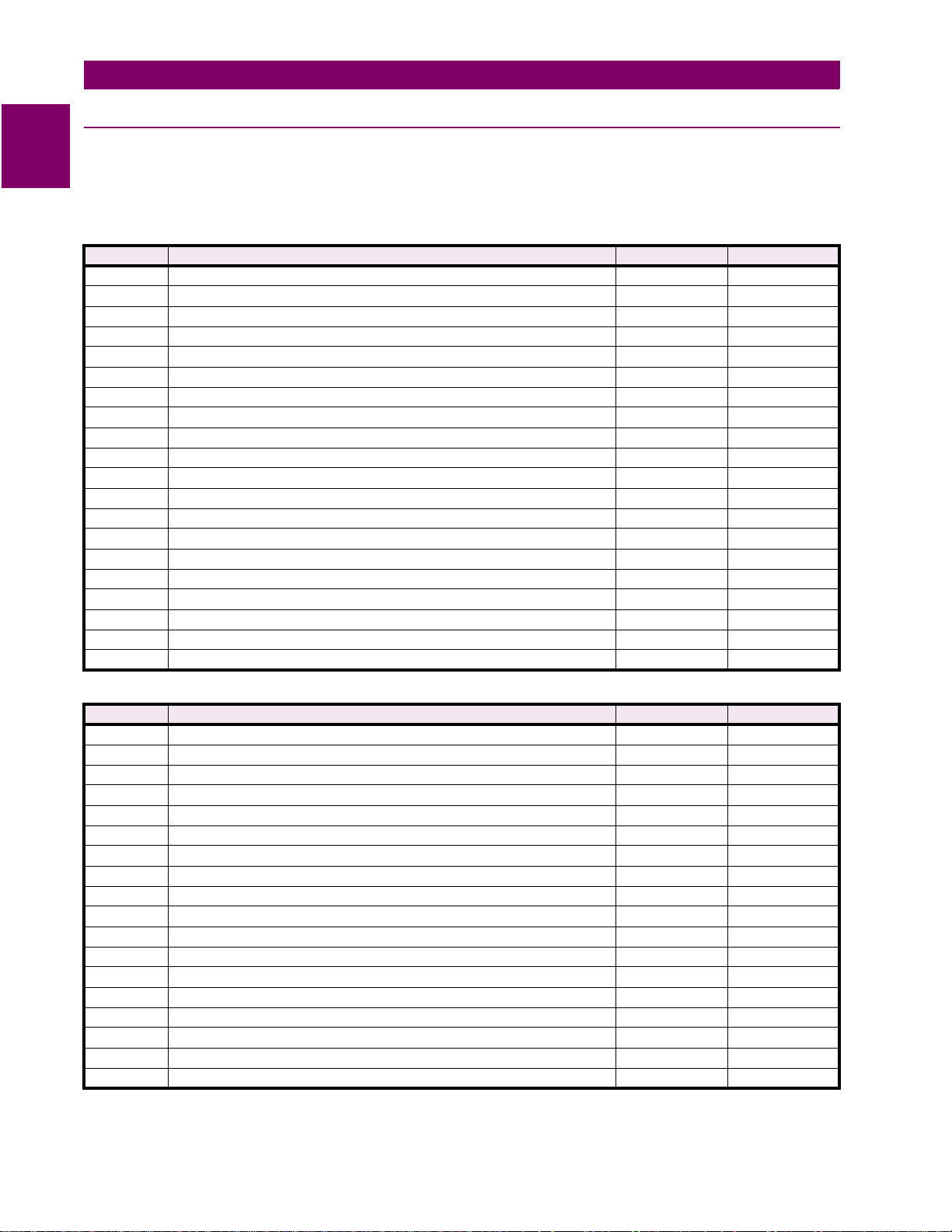

1.3.4 CONFIGURABLE OUTPUTS

1

All of the output relays in t he AL PS, ex ce pt for the alarm output relays , are us er-c onf igu r abl e. Ho w ever, each ALPS re la y i s

shipped with Default Output Relay Assignments. These are shown below and in Figure 1–28: ELEMENTARY DIAGRAM

WITH DEFAULT I/O (THREE PHASE TRIPPING) on page 1–50 for the three phase model and Figure 1–27: ELEMENTARY DIAGRAM WITH DEFAULT I/O (SINGLE PHASE TRIPPING) on page 1–49 for the single phase model.

Table 1–5: ALPS DEFAULT OUTPUT CONTACT ASSIGNMENTS: SINGLE PHASE MODEL

RELAY DESCRIPTION MNEMONIC INDEX NO.

T1 TRIP BUS PHASE A TRIPA 33

T2 TRIP BUS PHASE A TRIPA 33

T3 TRIP BUS PHASE A TRIPA 33

T4 TRIP BUS PHASE A TRIPA 33

T5 TRIP BUS PHASE B TRIPB 34

T6 TRIP BUS PHASE C TRIPC 34

A1 M ANUAL CLOSE BREAKER 1 MNCLS1 58

A2 M ANUAL CLOSE BREAKER 2 MNCLS2 59

A3 TRIP BUS PHASE A TRIPA 33

A4 TRIP BUS PHASE A TRIPA 33

A5 THREE PHASE RECLOSE INITIATE RI-3P 37

A6 THREE PHASE RECLOSE INITIATE RI-3P 37

A7 RE CLOSE CANCEL OUTPUT FROM SCHEME LOGIC CANCL 38

A8 to A12 UNASSIGNED --- --KT1 KEY TRA N SMITTER 1 / CARRIER START #1 KEY1 39

KT2 KEY TRA NSMITTER 2 / CARRIER STOP #1 KEY2 4 0

KT3 KEY TRA N SMITTER 1 / CARRIER START #1 KEY1 39

KT4 KEY TRA N SMITTER 2 / CARRIER START #2 KEY2 40

C1 NON-CRITICAL ALARM NCALM 52

C2 PT FUSE FAILURE ALARM FF 115

Table 1–6: ALPS DEFAULT OUTPUT CONTACT ASSIGNMENTS: THREE PHASE MODEL

RELAY DESCRIPTION MNEMONIC INDEX NO.

T1 TRIP CIRCUIT #1 TRIPA 33

T2 TRIP CIRCUIT #2 TRIPA 33

T3 TRIP CIRCUIT #3 TRIPA 33

T4 TRIP CIRCUIT #4 TRIPA 33

A1 MANUAL CLOSE CIRCUIT BREAKER #1 MNCLS1 58

A2 MANUAL CLOSE CIRCUIT BREAKER #2 MNCLS2 59

A3 BREAKER FAILURE INITIATE #1 TRIP A 33

A4 BREAKER FAILURE INITIATE #2 TRIP A 33

A5 RECLOSE INITIATE #1 RI_3P 37

A6 RECL OSE INITIATE #2 R1_3P 37

A7 RECLOSE CANCEL CANCL 38

A8 RECLOSE CANCEL CANCL 38

KT1 KEY TRA N SMITTER 1 / CARRIER START #1 KEY1 39

KT2 KEY TRA NSMITTER 2 / CARRIER STOP #1 KEY2 4 0

KT3 KEY TRA N SMITTER 1 / CARRIER START #1 KEY1 39

KT4 KEY TRA N SMITTER 2 / CARRIER START #2 KEY2 40

C1 NON-CRITICAL ALARM NCALM 52

C2 PT FUSE FAILURE ALARM FF 115

1-10 ALPS Advanced Line Protection System

GE Power Management

Page 23

1 PRODUCT DESCRIPTION 1.4 AUXILIARY PROTECTION FUNCTIONS

1.4 AUXILIARY PROTECTION FUNCTIONS 1.4.1 POTENTIAL TRANSFORMER FUSE FAILURE (PTFF)

Because a distance o r di rectio nal fun ction ma y o perate fo r a full or parti al los s of AC po tentia l caus ed by one or m ore blo wn

fuses, PTFF is provided to block distance and directional function tripping when a fuse failure is detected. If the backup

overcurrent functions 50, 50G, and 51G are not directionally controlled, they are allowed to trip during a potential fuse failure condition. If any of the backup, overcurrent functions, 50, 50G or 51G, is directionally supervised, then that function is

not allowed to trip. Rather, a second overcurrent function, 50_FF, 50G_FF, or 51G_FF is placed in service during the fuse

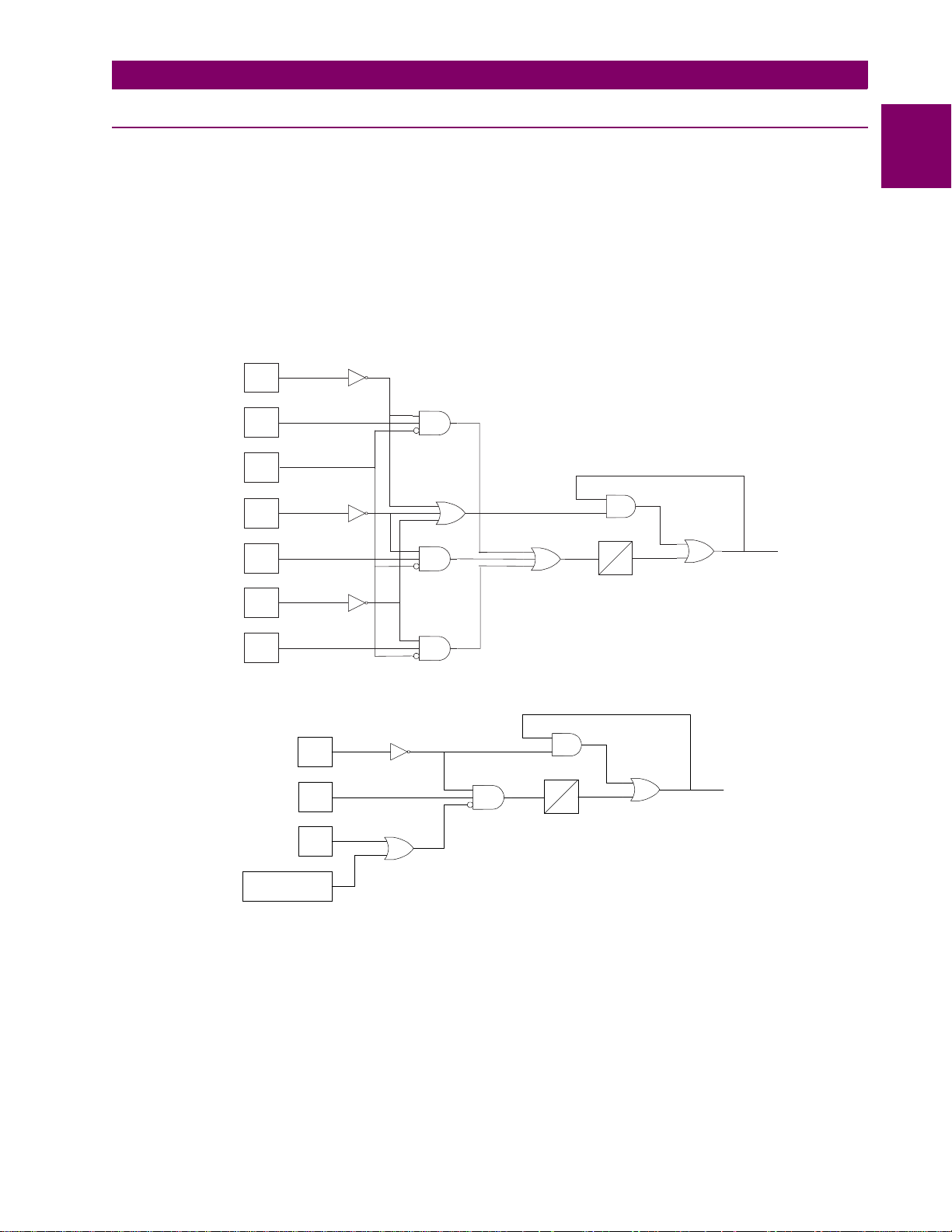

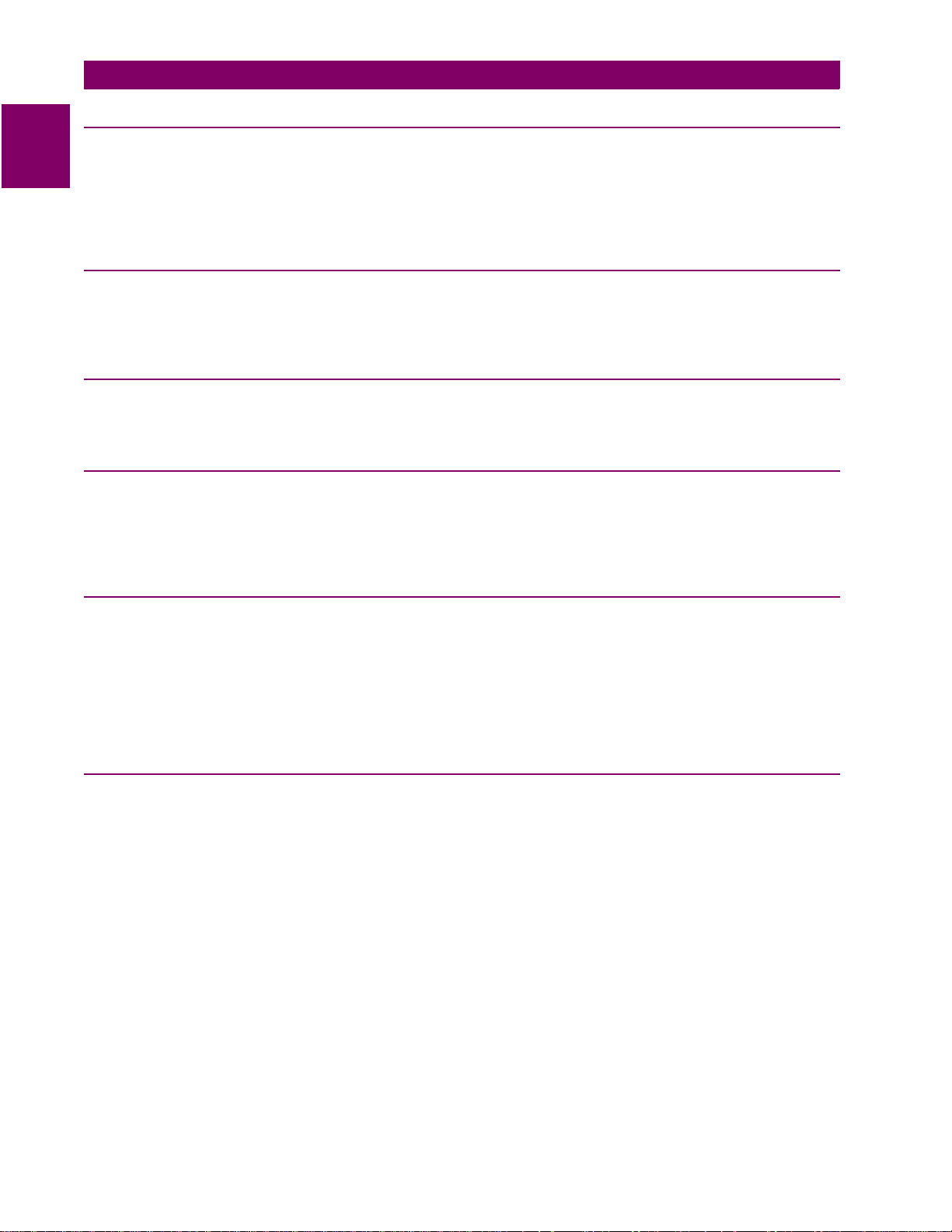

failure condition. The pickup level setting of these functions is independent from the normal pickup setting. The PTFF functional logic is shown below.

If AC potential is los t o n one or more phases, th e An y Phase Under Voltage signal pro duc es a lo gic 1 out put, and the upper

input is present at AND1. The phase undervoltage pickup setting is fixed at 75% of nominal and the pickup-to-dropout ratio

is virtually 100%. Th e lower in put to AND1 is d epende nt upon wheth er the fa ult dete ctor FD ha s opera ted or whethe r one or

more phases of the protected line are de-energized (open). When one or more phases of protected line are open, PTFF is

disabled.