Page 1

GE

Security

Phoenix Fiber Optic Communication System

A8950CC

installation instructions

11-A8950C

C

Page 2

Installation Instructions

EFORE YOU BEGIN

B

GETTING STARTED 2

Overview 2

etermine Mounting Configuration 2

D

Installing Power Supply 2

INSTALLING THE OPTICAL TRANSCEIVER MODULE 3

Point-to-Point, Repeater, Self-Healing Ring Diagrams 4

LED Operating Status 5

INSTALLING THE DATA MODULE 6

Configuring the Data Module 6

Install Data Module 7

Connect Data Module 7

Channel Mapping 7

Connection Instructions 8

RS-232, TTL, RS-422, RS-485, Manchester/Biphase Interface 9

RS-485, Sensornet, Test Mode 9

Data Module - Channel Sequence 10

INSTALLING THE ETHERNET MODULE 11

Install Ethernet Module 11

Connect Ethernet Module 12

INSTALLING THE VIDEO MODULE 13

Install Video Input Module 13

Install Video Output Module 13

Connection Instructions 14

Video Module - Channel Sequence 15

INSTALLING THE AUDIO MODULE 16

Configuring the Audio Module 16

Audio Input Termination Diagrams 17

Audio Input/ Output Charts 18

Audio Module - Channel Sequence 19

INSTALLING THE CONTACT CLOSURE MODULE 20

Install Contact Closure Module 20

Connection Instructions 21

RJ45, Contact Input/ Contact Output Charts 22

Contact Input/ Contact Output - Channel Sequence 22

CONFIGURING THE PHOENIX FIBER OPTIC COMMUNICATION SYSTEM 23

T

urn on power and check status 23

Select the system topology

Set the node ID

FRONT PANEL MENU TREE AND DESCRIPTIONS 27

Main Menu Options 28-31

Menu Options: Video 31-33

Menu Options: Data 34-36

Menu Options: Ethernet 37

Menu Options: Audio 38-39

Menu Options: Contact Closure 39-41

MAIN LOCAL POWER/ MAIN LOCAL TEST/ MAIN LOCAL ABOUT 41-42

MAIN REMO

ANK P

BL

OPTICAL TRANSCEIVER MODULE SPECIFICATIONS 45

DATA MODULE SPECIFICATIONS 46

THERNET MODULE SPECIFICATIONS

E

VIDEO MODULE SPECIFICATIONS 48

AUDIO MODULE SPECIFICATIONS 49

CONT

CUSTOMER SUPPORT 50

TE/ MAIN ABOUT

ANEL SPECIFICA

OSURE MODULE SPECIFICA

CT CL

A

TIONS AND LIMITED W

TIONS

ARRANT

Phoenix Fiber Optic Communication System

1

24-26

26

42-43

Y

44

47

50

Page 3

Before You Begin

Read these instructions before installing or operating this product.

Note: This installation should be made by a qualified service person and should conform to local codes.

his manual provides installation and operation information.

T

To use this document, you must have the following minimum qualifications:

• A basic knowledge of CCTV systems and components

• A basic knowledge of electrical wiring and low-voltage electrical hookups

Intended Use

Use this product only for the purpose for which it was designed; refer to the product

specification and user documentation.

Customer Support

For assistance in installing, operating, maintaining, and troubleshooting this product,

refer to this document and any other documentation provided. If you still have questions,

please contact technical support during normal business hours (Monday through Friday,

excluding holidays, between 6 a.m. and 5 p.m. Pacific Time).

GE Security

Call: 888 437-3287 (US, including Alaska and Hawaii; Puerto Rico; Canada)

Outside the toll-free area: 503 885-5700

Fax: 561 998-6224

Note: You should be at the equipment and ready with details before calling Technical Support.

Conventions Used in this Manual

Boldface or button icons highlight command entries. The following WARNING,

CAUTION, and Note statements identify potential hazards that can occur if the

equipment is handled improperly:

* WARNING:

Improper use of this equipment can cause severe bodily injury or equipment damage.

** CAUTION:

Improper use of this equipment can cause equipment damage.

Note:Notes contain impor

* This symbol indicates electrical warnings and cautions.

** This symbol indicates general warnings and cautions.

tant information about a pr

oduct or procedure.

1

Page 4

Getting Started

** CAUTION:

This product contains ESD-sensitive components. Although all precautions have been made to

reduce ESD susceptibility, use good grounding techniques when handling uninstalled modules

Overview

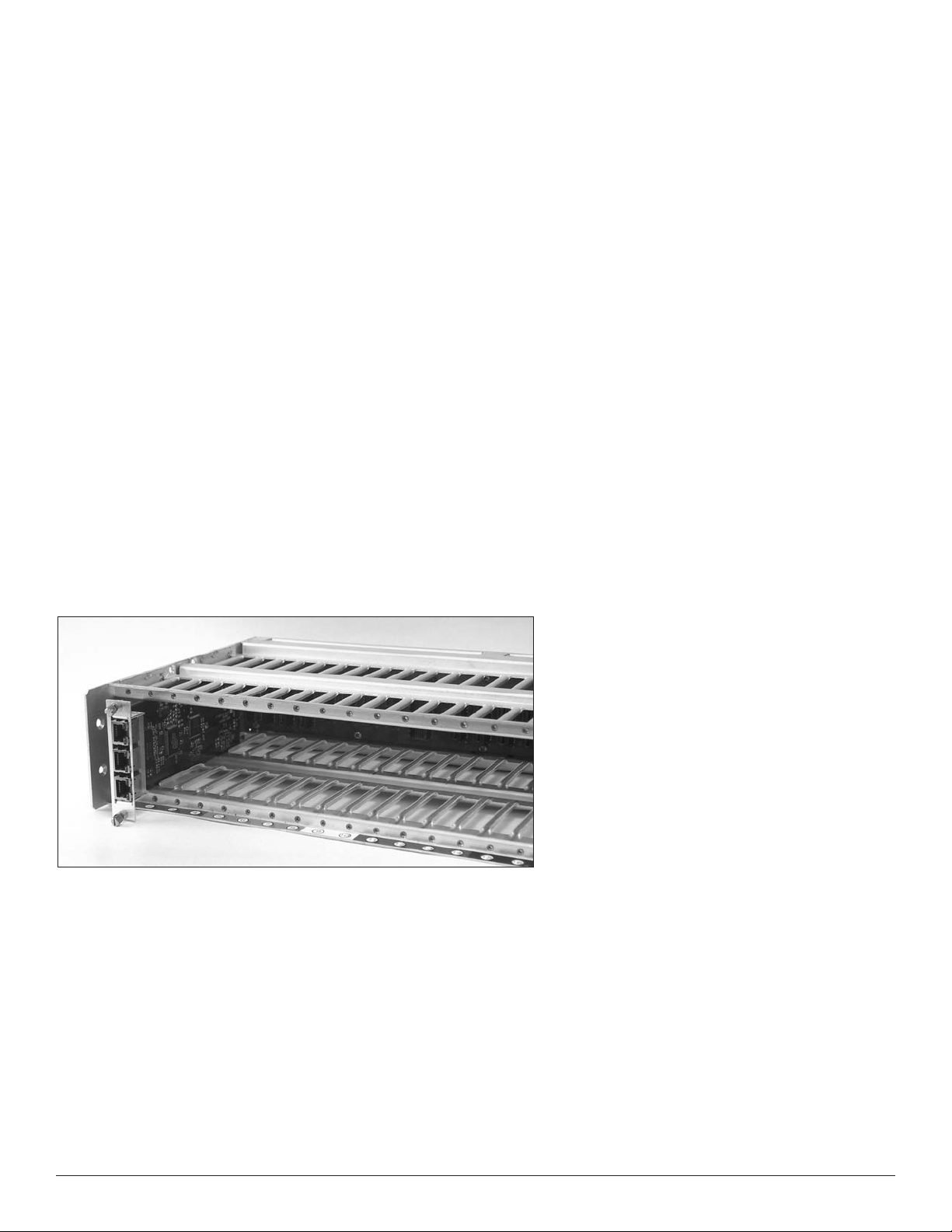

Installing the Phoenix chassis is a three-step process:

1. Install mounting hardware and power supplies.

2. Install modules and connect cabling.

3. Configure the system.

Determine Mounting Hardware

Mounting brackets are adjustable. Choose the best location to fit your application and

position brackets using the supplied hardware. Remove screws holding front mounting

bracket, move to top, bottom, back or front and refasten.

Installing Power Supplies

.

All installation should be from rear of rack unit.

To install power supply, slide power supply in slot "A" and secure with hardware. Remove

center support panel and use to cover open slot if redundant power supply is not used.

Optional Redundant Power Supply: When using the redundant power supply, remove panel

and insert second power supply in slot "B" and secure.

t Number

ar

Specifications

Model A8960AC

Size

Weight

1.65 in. W x 3.30 in. H x 8.00 in. D (42 x 84 x 203 mm)

1.25 lb

. (5.67 g)

Model

Model

Slot B

Model Part Number

Optional Redundant Power Supply

Slot A

A8960AC

.

Electrical

• Input power: 100 V to 240 V, 60 to 50 Hz

• Current requirement: 2 A

• Power consumption: 40 W

• Protection: 250 V, 2 A fuse

Model P

Model Part Number

Spare fuse

use

e f

Activ

Module Installation

The Optical Transceiver is the first module to be installed.

2

Page 5

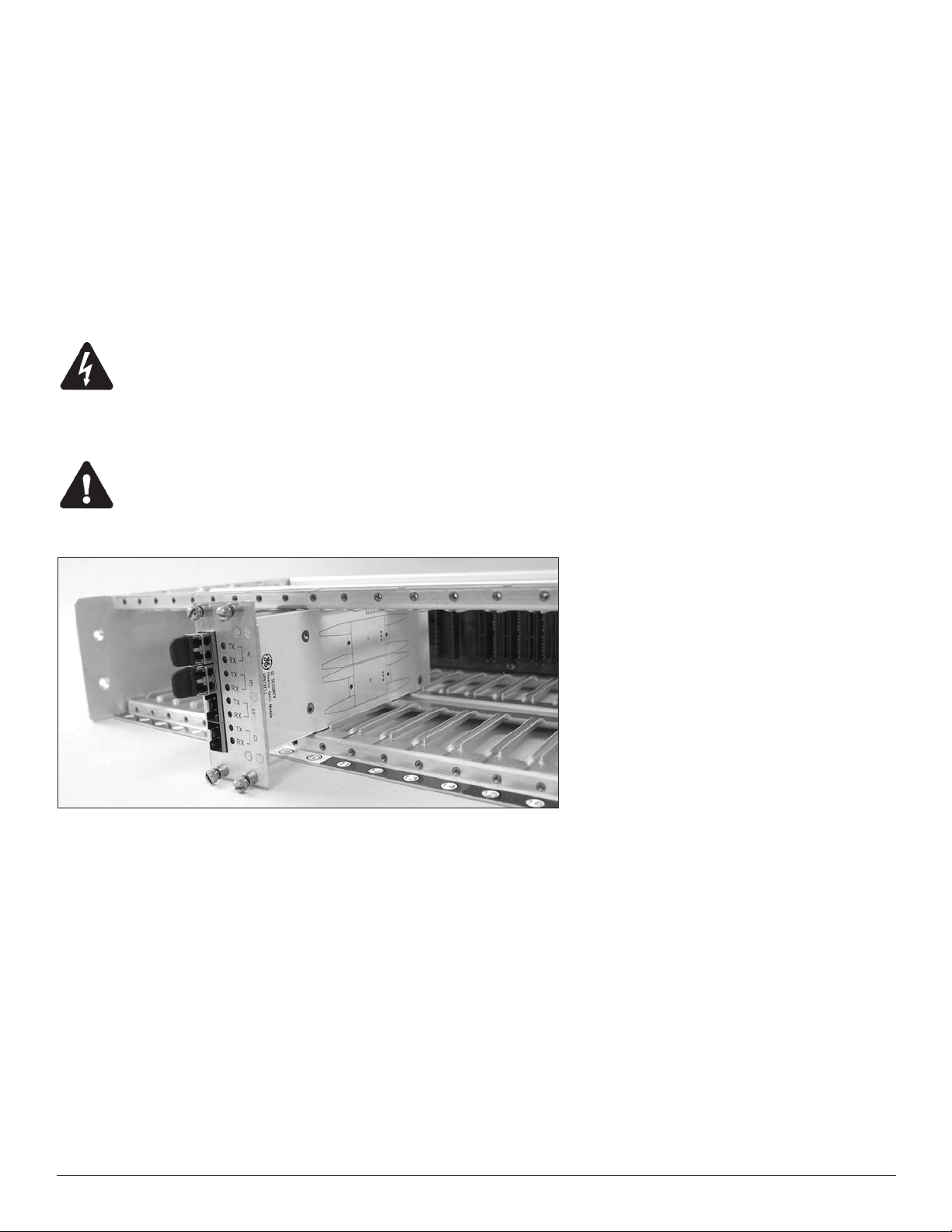

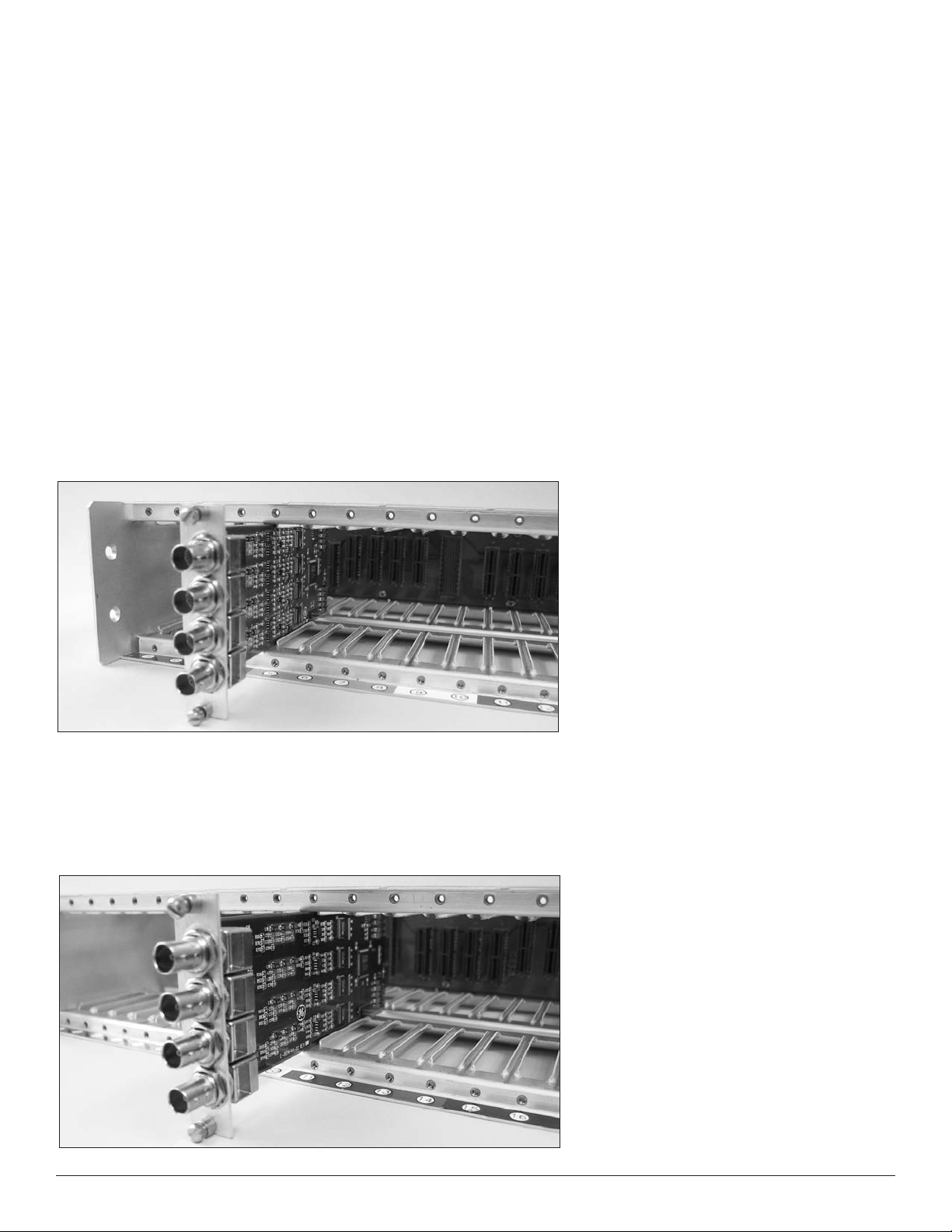

Installing the Optical Transceiver Module

Overview

The Phoenix optical transceiver module is used to provide connectivity to the fiber

connections between nodes. The A8972FLC optical transceiver module contains a single

optical transceiver with dual LC connectors and is used as an ‘end node’ in either a point

to point, or linear system. The A8974FLC optical transceiver module features two optical

transceivers with two dual LC connectors and is used in repeating nodes within a linear

system as well as all nodes in a self-healing ring system.

Tools and materials required

The optical module is held in place with simple thumbscrews with screwdriver slots.

The only tool recommended is a small flat blade screwdriver.

* WARNING:

Insure main power is off when installing or removing.

Installation instructions:

1. Install optical transceiver module in slots 9 and 10 (color-keyed white) and secure.

** CAUTION:

Use caution when inserting it into a slot adjacent to an existing module. It is best to install this

module in your node first, to avoid potential damage to components on the back of this module.

INSERT OPTICAL TRANSCEIVER MODULES IN SLOTS 9-10 (White)

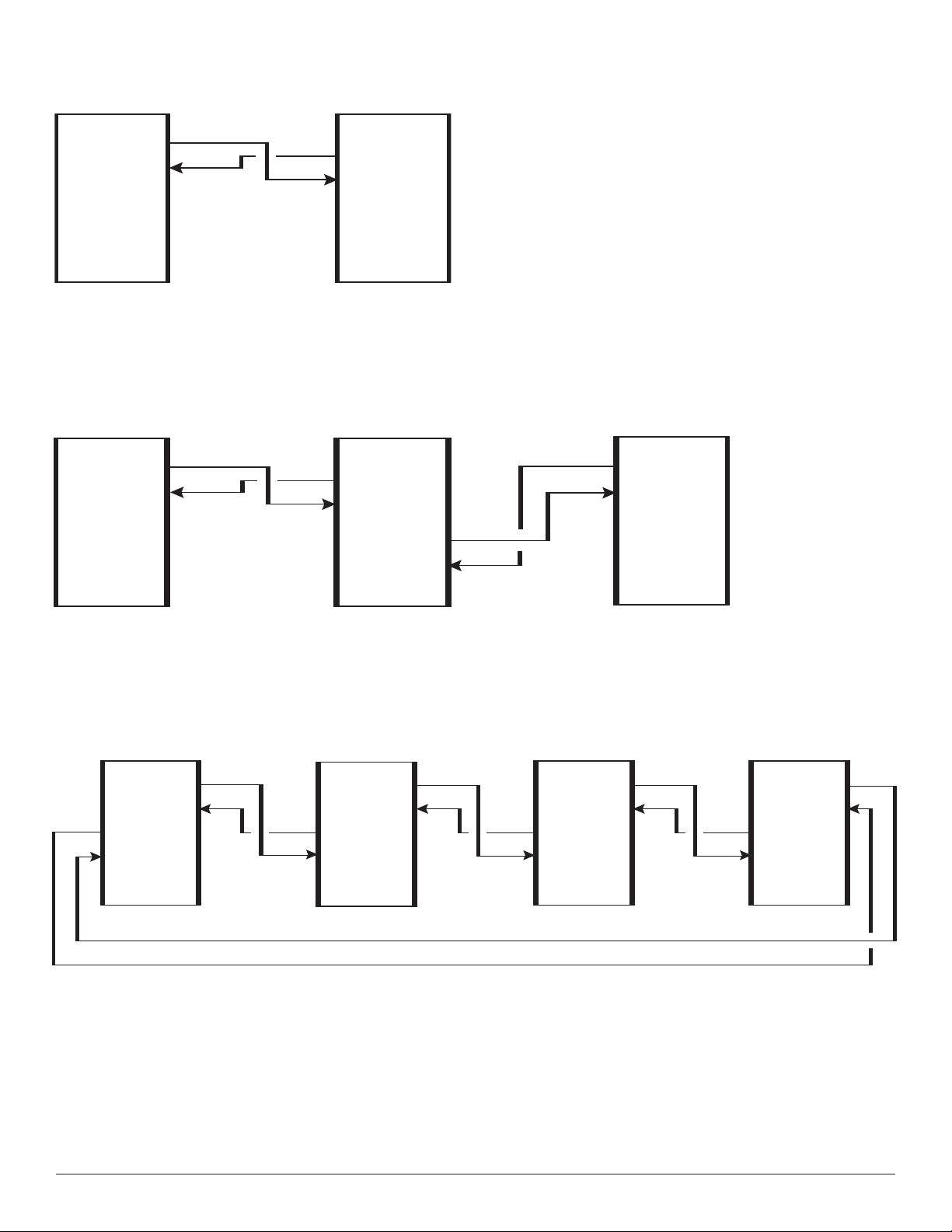

2. Connect fiber:

Connect single-mode fiber optic cables by using LC connectors. Each port connects to a

pair of fibers. The top fiber in a port is the laser output (Tx) and the bottom fiber is the

photo diode input (Rx). In a point-to-point system, connect the optic in port A from the

first node to the optic in port A in the second node. Remember that the two fibers need

to be crossed, so that the laser output on one node is connected to the photodiode

input in the other node. This can be verified by observing the corresponding LEDs as

shown in the table below.

In a linear system, connect the fiber to Optic A in the end node (node with only one

fiber transceiver) to Optic B in the subsequent node. Repeat until the ‘headend’ node

is reached, where the fiber must go into Optic A .

In self-healing ring systems, simply connect Optic A from one node to Optic B on the

next node, throughout the ring.

3

Page 6

Point-to-Point Connect

Tx A

Rx A

A8972FLC

x A

T

Rx A

A8972FLC

Repeater Connect

Tx A

Rx A

A8972FLC A8972FLC

Tx A

Rx A

Tx B

Rx B

A8974FLC

Tx A

Rx A

HEAD END MIDDLE NODES

Self-Healing Connect

Tx A

Rx A

Tx B

Rx B

A8974FLC A8974FLC A8974FLC A8974FLC

Tx A

Rx A

Tx B

Rx B

Tx B

Rx B

FIELD END NODE

Tx A

Rx A

x B

T

Rx B

Tx A

Rx A

4

Page 7

3. Verify fiber connectivity:

Using the LEDs on the back of the unit adjacent to the optic module, verify proper

operation as shown in the table below. Both optical launch power and optical receive

power, as well as transceiver status, can be verified from the LCD front panel.

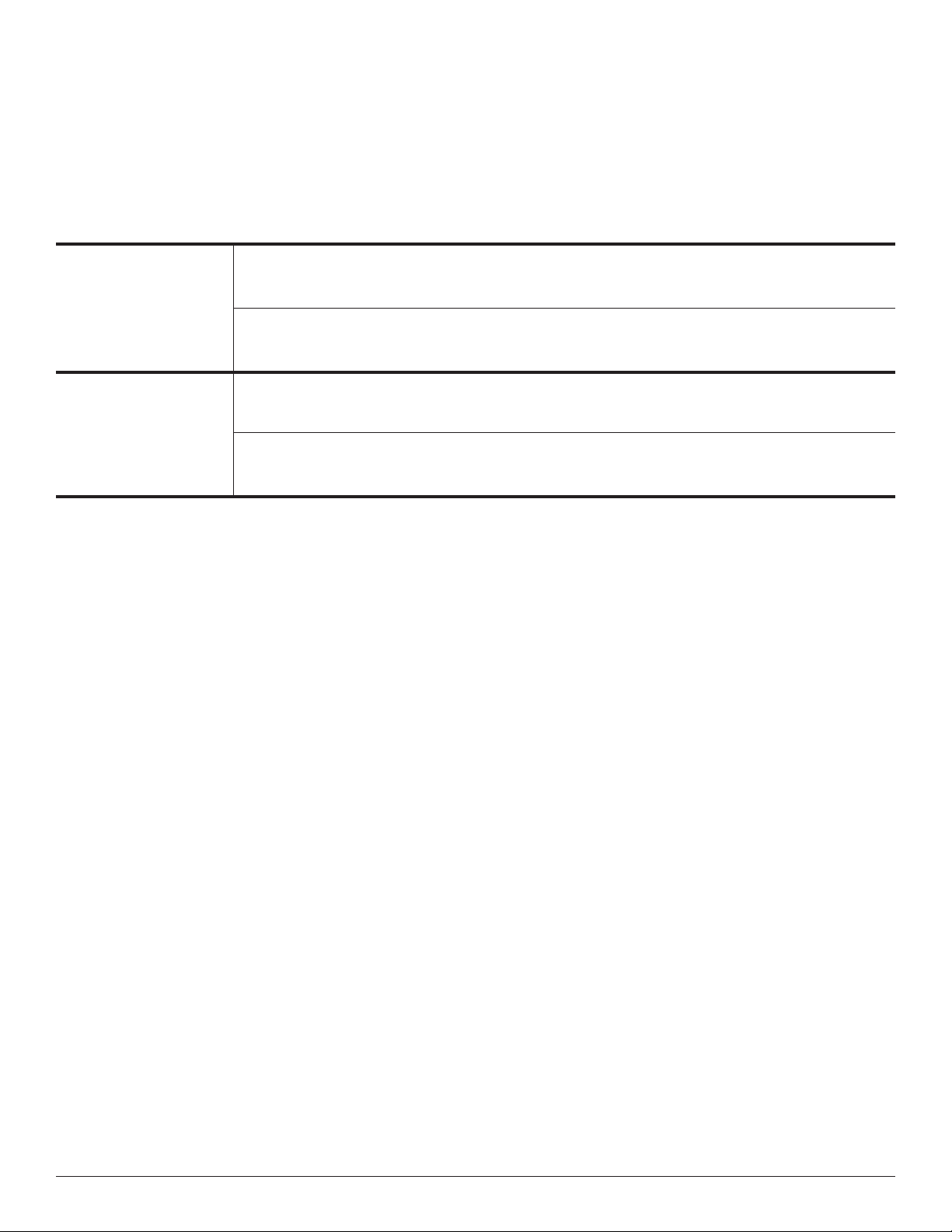

LED operating status

Optic LED

RED Indicates faulty LASER or no module installed

Tx

OFF LASER operating within specifications

GREEN Indicates sufficient power received and frame synchronization

Rx

OFF Indicates insufficient optical power

5

Page 8

Installing the Data Module

Overview

The Phoenix A8910MPD data module is capable of inserting/extracting

4 channels of multiprotocol serial data (MPD) per module. With a maximum of four

cards per node, the system capacity is 16 channels. Each channel is capable of

transmitting and receiving serial data throughout the Phoenix system. The card is not

limited to any single data type so that various formats can be mixed on a single card.

As with other GE Security MPD products, data translation capabilities are included.

Tools and materials required

The data modules are held in place with simple thumbscrews with screwdriver slots.

The only tool recommended is a small flat blade screwdriver.

Installation instructions:

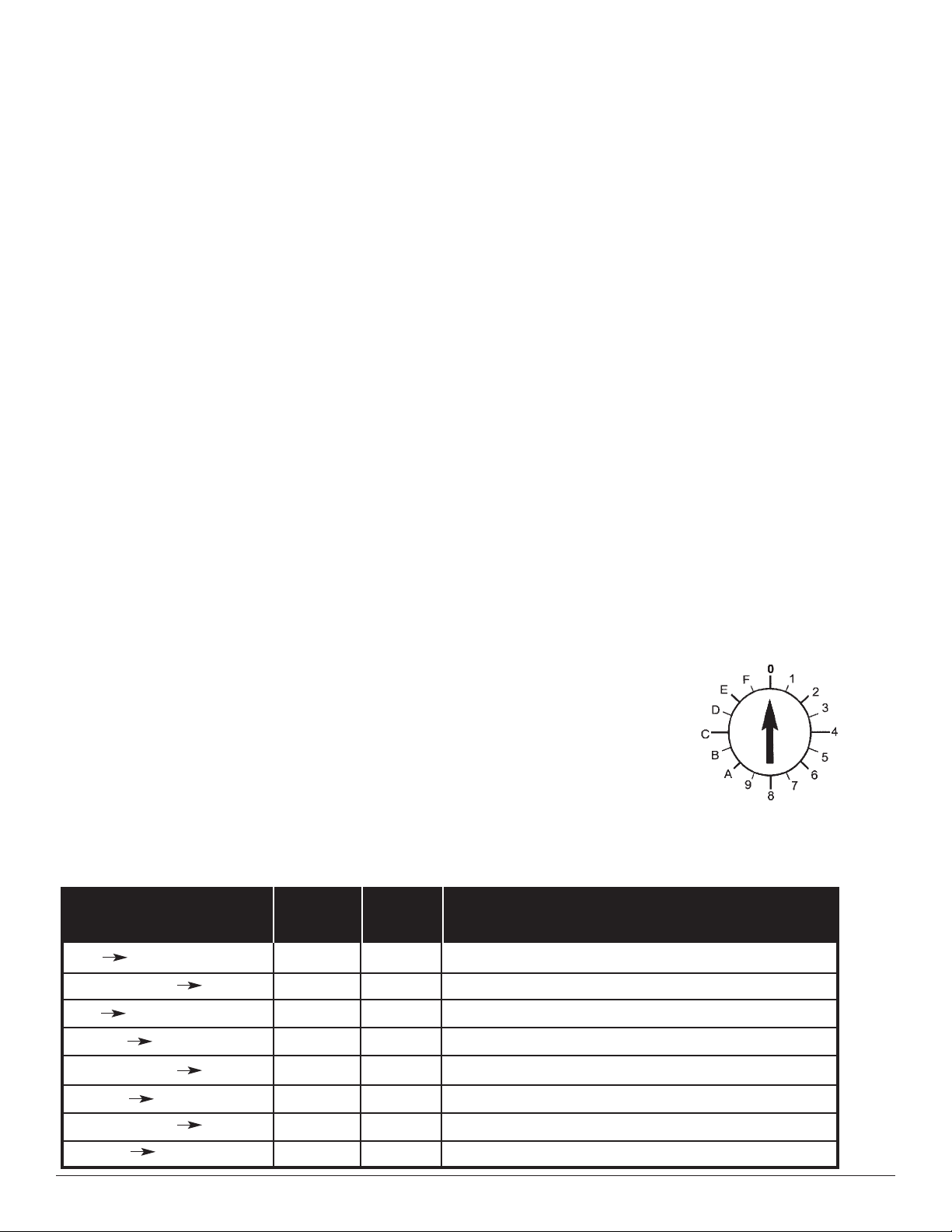

1. Configure data module:

Prior to installation, you must specify the appropriate data format using the rotary

switches on the module. For each channel on the data module, rotate the dial switch to

the desired format. If you want to select the data format from the front panel, leave the

switch in position 0.

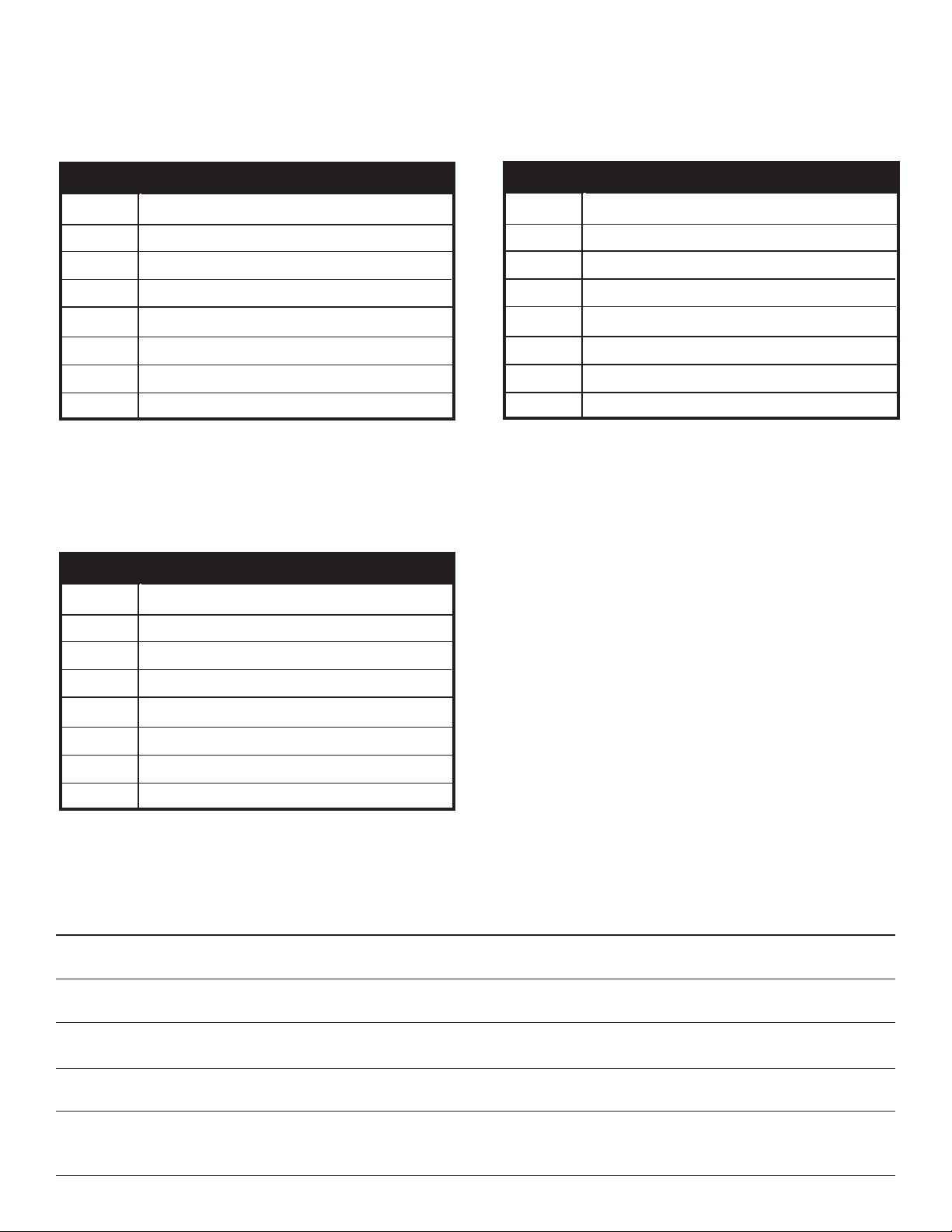

Setting Mode

0 Softw

are-selectable (factory preset)

1 RS-232 (3-wire)

2 RS-232 + handshake

3 TTL

4 RS-422 2-wire

5 Manchester/biphase

6 RS-485 2-wire standard/Sensornet

7 RS-485 2-wire 1V

Setting Mode

8 RS-485 2-wire 2 V

9 RS-485 4-wire standard

A RS-485 4-wire 1 V

B RS-485 4-wire 2 V

C Reserved

D Reserved

E Reserved

F Test Mode

NOTE: The DATA SELECT switches are shipped in the Software-Selectable setting.

As with all GE Security MPD products, data translation can easily

be accomplished using the table information below.

Translation

TTL RS-232, 3-wire

RS-232, 3-wire TTL

TTL RS-422

RS-422 TTL-wire

RS-232, 3-wir

e RS-422

Input

3

1

3

4

1

Output

1

3

4

3

4

Comment

Signal level conversion.

Signal level conversion.

Single ended to differential conversion.

Differential to single ended conversion.

Single ended to differ

ential conv

ersion.

RS-422 RS-232, 3-wire

RS-232, 5-wire RS-485

RS-485 RS-232, 5-wire

4

2

7 - A

1

7 - A

2

sion.

ential to single ended conv

Differ

RS232 Handshaking bit is used to indicate Tri-state.

Tri-state detection circuitry activates handshaking bit.

er

6

Page 9

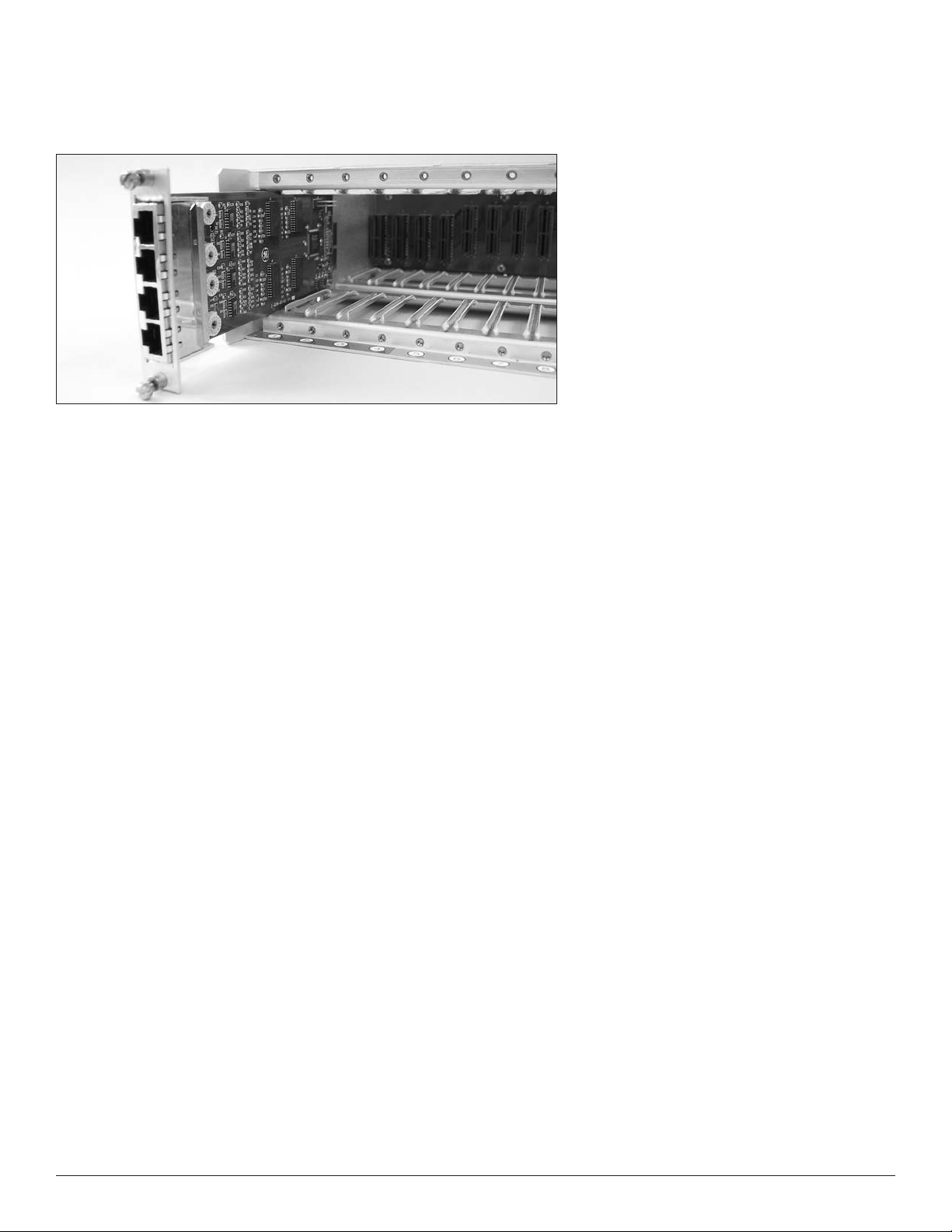

2. Install data module:

Up to four data modules can be installed in the Phoenix node.

From left, locate and insert data modules into slot 1, 2, 3, or 4

(color-keyed red) and secure.

INSERT DATA CARDS IN SLOTS 1-4 (Red)

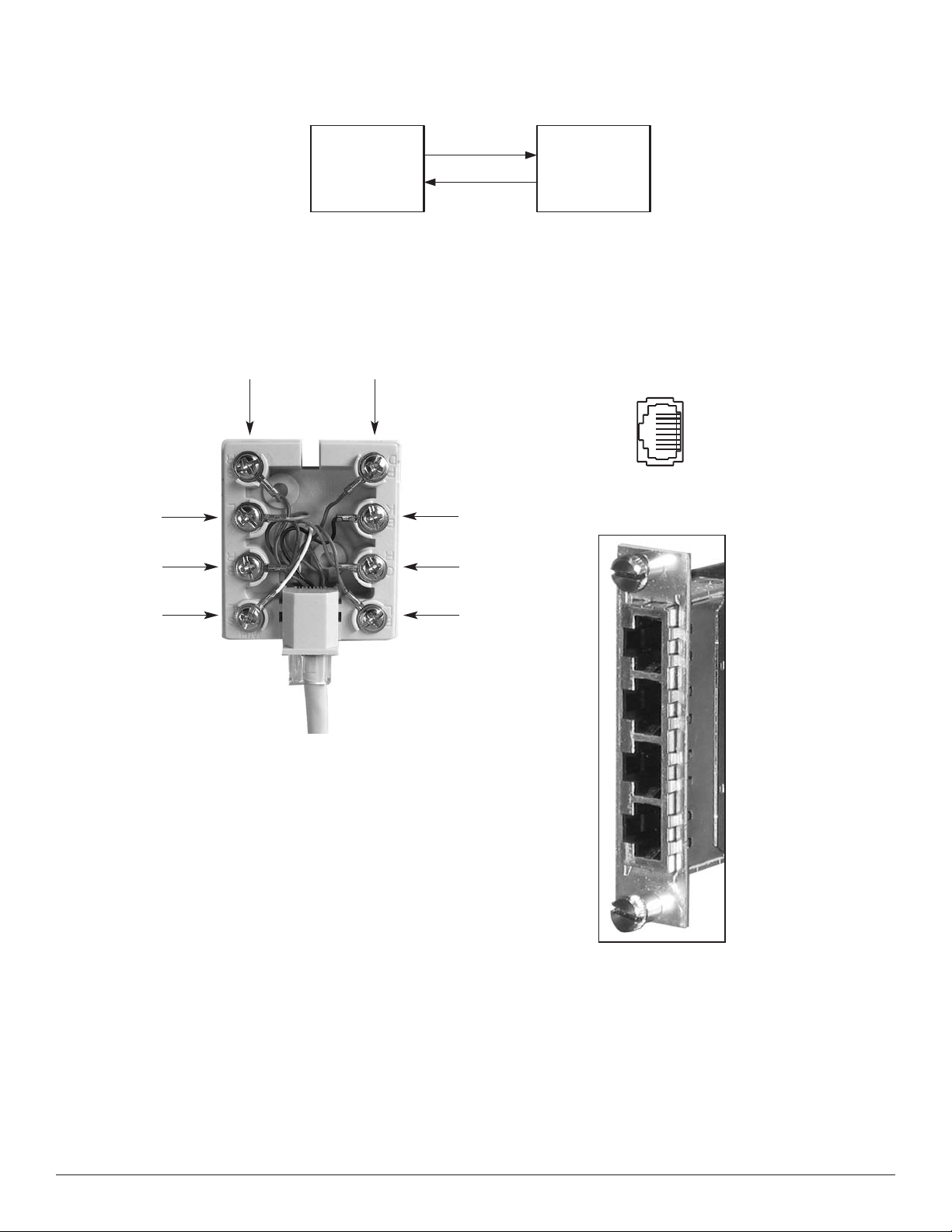

3. Connect:

Each data module is shipped with (four) RJ45 cables and (four) breakout boxes to aid in

connecting to the Phoenix. Use the tables below to determine pinout information for

your application. GE Security recommends using shielded cable for all single ended

applications and twisted shielded cable for all differential formats. Wire gauge is

dependent on copper run length. Refer to manufacturer of data equipment for

specific recommendations. Once the data equipment has been connected, confirmation

of data activity can be verified on the front panel LCD.

The channel order is sequential, beginning with the top RJ45 in slot 1 as Channel 1,

working vertically such that the bottom RJ45 in slot 1 is Channel 4, and the top RJ45 in

slot 2 is Channel 5. This continues to the bottom RJ45 in slot 4, which is mapped to

Channel 16.

7

Page 10

D

ATA EQUIPMENT

F

IBER LINK

Pin

1 8

DATA OUT

DATA IN

DATA IN

DATA OUT

igure 1. Fiber Link Data Connections

Pin

1 8

F

Figure 1. Terminal Block Pin Assignments

5

6

7

8

4

3

2

1

Using the breakout box

A breakout box with a 3’ CAT 5 patch cord

(supplied) can be used to interface to the

Phoenix system. Pinouts are shown in the

tables and figures above.

Figure 2. RJ45 Socket

(Viewed from the rear of the unit)

RJ45-A

RJ45-B

RJ45-C

RJ45-D

8

Page 11

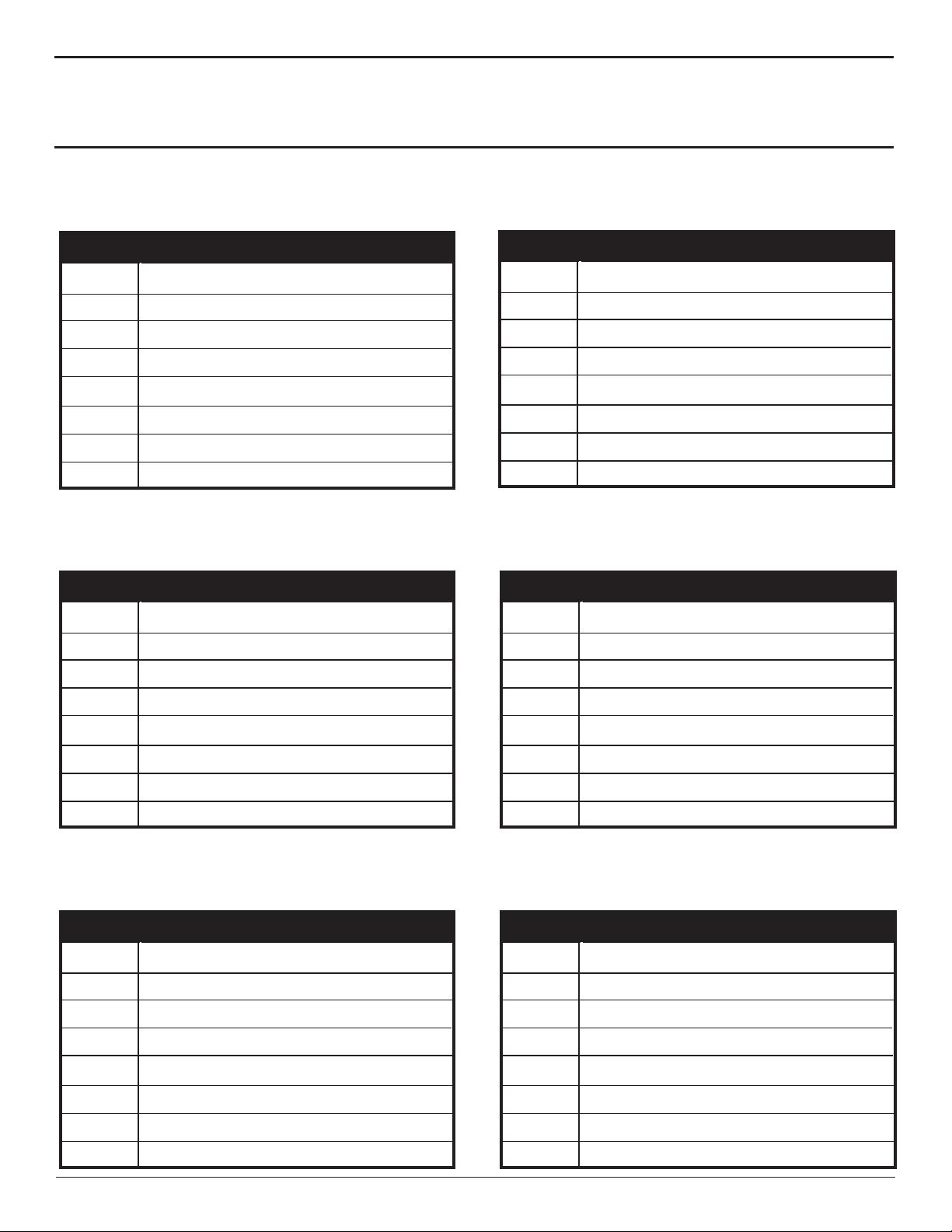

NOTE: When making data connections listed in Tables 3 through 11, always connect the pins labeled IN

on the fiber unit to the pins labeled OUT on the external equipment, and the pins labeled IN on the

external equipment to the pins labeled OUT on the fiber unit.

ABLE 4: RS-232 WITH HANDSHAKING INTERFACE

TABLE 3: RS-232 INTERFACE

ATA SELECT Switch: Position 1

D

T

DATA SELECT Switch: Position 2

Pin

1

2

3

4

5

6

7

8

TABLE 5: TTL INTERFACE

DATA SELECT Switch: Position 3

Pin

1

2

3

4

Signal

RS-232 Out

N/C

GND/SHIELD

N/C

N/C

GND

N/C

RS-232 In

Signal

N/C

TTL Out

GND/SHIELD

N/C

Pin

1

2

3

4

5

6

7

8

TABLE 6: RS-422 INTERFACE

DATA SELECT Switch: Position 4

Pin

1

2

3

4

Signal

RS-232 Out

RTS/CTS Out

GND/SHIELD

N/C

N/C

GND

RTS/CTS In

RS-232 In

Signal

RS-422 Out (+)

RS-422 Out (-)

GND/SHIELD

N/C

5

6

7

8

TABLE 7: MANCHESTER/BIPHASE INTERFACE

DATA SELECT Switch: Position 5

Pin

1

2

3

4

5

6

7

8

N/C

GND/SHIELD

TTL In

Tie to pin 6

Signal

Manchester/Biphase Out (+)

N/C

Manchester/Biphase Out (-)

N/C

ermination, tie to 8 if req’d.

T

GND/SHIELD

Manchester/Biphase In (-)

Manchester/Biphase In (+)

5

6

7

8

T

ABLE 8: RS-485 2-WIRE INTERFACE

DATA SELECT Switch: Position 6 (<200mV),

osition 7 (<1V), P

P

Pin

1

2

3

4

5

6

7

8

Termination, tie to 8 if req’d.

GND/SHIELD

RS-422 In (-)

RS-422 In (+)

osition 8 (<2V)

Signal

N/C

N/C

GND

+5 VDC Bias Out

Termination, tie to 8 if req’d.

GND/SHIELD

RS-485 (-)

RS-485 (+)

9

Page 12

TABLE 9: RS-485 4-WIRE INTERFACE

DATA SELECT Switch SW1:

osition 9 = standard offset

P

osition A = 1V offset

P

Position B = 2V offset

TABLE 10: SENSORNET INTERFACE

DATA SELECT Switch: Position 6

Pin

1

2

3

4

5

6

7

8

TABLE 11: TEST MODE LOOPBACK INTERFACE

DATA SELECT Switch: Position F

Pin

1

2

Signal

RS-485 Out (+)

RS-485 Out (-)

GND/SHIELD

+5 VDC Bias Out

Termination, tie to 8 if req’d.

GND/SHIELD

RS-485 In (-)

RS-485 In (+)

Signal

Tie to pin 8

Tie to pin 7

Pin

1

2

3

4

5

6

7

8

Signal

N/C

N/C

GND

N/C

Termination, tie to 8 if req’d.

GND/SHIELD

Sensornet (-)

Sensornet (+)

3

4

5

6

7

8

N/C

N/C

N/C

N/C

Tie to pin 2

Tie to pin 1

Data module - channel sequence

Slot 1

RJ45-A Ch 1 IN/OUT

RJ45-B

Ch 2 IN/OUT

RJ45-C Ch 3 IN/OUT

RJ45-D Ch 4 IN/OUT

Slot 2

Ch 5 IN/OUT

Ch 6 IN/OUT

Ch 7 IN/OUT

Ch 8 IN/OUT

Slot 3

Ch 9 IN/OUT

Ch 10 IN/OUT

Ch 11 IN/OUT

Ch 12 IN/OUT

Slot 4

Ch 13 IN/OUT

Ch 14 IN/OUT

Ch 15 IN/OUT

Ch 16 IN/OUT

10

Page 13

Installing the Ethernet Module

Overview

The Phoenix A8911ETH Ethernet module provides Ethernet connectivity to the Phoenix

system. Each module has three RJ-45 ports supporting full-duplex 10/100Base-T interfaces.

Each port also supports Auto-Negotiation and automatic MDI/MDI-X selection.

Unlike other modules used in the Phoenix system, the ethernet module does not use “channels”. Each slot position provides access to one of four independent Ethernet

networks. Every port on a module can communicate with every other port on other

modules connected to the same network (i.e. modules plugged into the same slot number

at different nodes). There is no restriction to the number of modules connected to a

network, however they must share bandwidth between nodes. Each network can sustain

25Mbps throughput between nodes.

Note: Ethernet is inherently a bi-directional communication protocol. Therefore all nodes in

a Phoenix system with Ethernet modules must be connected with duplex fiber connections.

Simplex connections between nodes will cause the network to fail.

Tools and materials required

The Ethernet modules are held in place with simple thumbscrews with screwdriver slots.

The only tool r

ecommended is a small flat blade screwdriver.

Installation instructions:

1. Install the Ethernet module:

Up to four Ethernet modules can be installed in the Phoenix node. From left, locate and

insert Ethernet modules into slot 1, 2, 3, or 4 (color-keyed red) and secure.

INSERT ETHERNET MODULES IN SLOTS 1-4 (Red)

11

Page 14

2. Connect:

Connect Ethernet-capable equipment directly to the Ethernet module using CAT5 twistedpair cables with male RJ-45 connectors at both ends. Do not use breakout boxes.

Standard CAT5 cabling used for Ethernet is available with either straight-through or

crossover connections. Either variety may be used with the Ethernet module. The

auto-MDI/MDI-X feature of each port automatically detects the type of cable

connection to establish link.

3. Configure:

At power-up, every port has Auto-Negotiation enabled. This should work seamlessly

with most Ethernet equipment. However, if necessary, Auto-Negotiation, Link Speed

and Duplex can be configured manually via the Phoenix chassis’s front panel.

Refer to the section Front Panel Menu Tree and Descriptions for more information.

12

Page 15

Installing the Video Module

Overview

The Phoenix A8900VI input module is capable of inserting up to four baseband,

composite video signals per card. A maximum of four cards can be installed in any node,

allowing up to 16 inputs per node.

The Phoenix A8905VO output module is capable of outputting up to 4 base band, composite

video signals per card. A maximum of four cards can be installed in any node, allowing up

to 16 outputs per node.

Tools and materials required

The video modules are held in place with simple thumbscrews with screwdriver slots.

The only tool recommended is a small flat blade screwdriver.

Installation instructions:

1. Install video input module:

As shown below, install video Input modules in slots 5, 6, 7, or 8 (color-keyed green)

and secure. Up to four modules may be installed per Phoenix node. Up to four incoming

video signals can be installed per module by connecting to BNC mounts (four) on each card.

INSERT VIDEO INPUT MODULES IN SLOTS 5-8 (Green)

2. Install video output module:

As shown below, install video output modules in slots 11, 12, 13, or 14 (color-keyed blue)

and secure. Up to four modules may be installed per Phoenix node. Up to four outgoing

video signals for monitoring or recording can be installed per module by connecting to

BNC mounts (four) on each card.

INSERT VIDEO OUTPUT MODULES IN SLOTS 11-14 (Blue)

13

Page 16

Connection instructions

Video Inputs:

Connect video source equipment such as cameras or matrix switcher outputs to the

video input modules using the BNCs on the back of the panel. Confirmation of video

presence can be confirmed on the front panel LCD. The channel order is sequential,

beginning with the top BNC in slot 5 as Channel 1, working vertically such that the

bottom BNC in slot 5 is assigned Channel 4, and the top BNC in slot 6 is

assigned Channel 5. This continues to the bottom BNC in slot 8, which is mapped

to Channel 16.

Video Outputs:

Connect video monitoring equipment including monitors and recording devices, to

the video output cards using the BNCs on the back of the panel. Confirmation of video

output can be confirmed on the front panel LCD. As with the inputs cards, the channel

order is sequential, beginning with the top BNC in slot 11 as Channel 1, working vertically

such that the bottom BNC in slot 11 is assigned Channel 4, and the top BNC in slot 12 is

assigned Channel 5. This continues to the bottom BNC in slot 14, which is Channel 16.

14

Page 17

Video Input module - channel sequence

lot 5

S

BNC A Ch 1 IN

Slot 6

Ch 5 IN

Slot 7

Ch 9 IN

Slot 8

Ch 13 IN

BNC B Ch 2 IN

BNC C Ch 3 IN

BNC D Ch 4 IN

Ch 6 IN

Ch 7 IN

Ch 8 IN

Video Output module - channel sequence

Slot 11

BNC A Ch 1 OUT

BNC B Ch 2 OUT

BNC C Ch 3 OUT

BNC D Ch 4 OUT

Slot 12

Ch 5 OUT

Ch 6 OUT

Ch 7 OUT

Ch 8 OUT

Ch 10 IN

Ch 11 IN

Ch 12 IN

Slot 13

Ch 9 OUT

Ch 10 OUT

Ch 11 OUT

Ch 12 OUT

Ch 14 IN

Ch 15 IN

Ch 16 IN

Slot 14

Ch 13 OUT

Ch 14 OUT

Ch 15 OUT

Ch 16 OUT

BNC A

BNC B

BNC C

BNC D

15

Page 18

Installing the Audio Module

Overview

The Phoenix A8920A audio module is capable of inputting and outputting up to 4 audio

channels. The audio module occupies one audio slot (color coded black) and with up to

four slots available, each node has a capacity of 16 channels. The audio interface

connector is four, ganged RJ45 connectors located on each card. The audio module

supports an audio test pattern, similar to GE Security standards.

Tools and materials required

The audio modules are held in place with simple thumbscrews with screwdriver slots.

The only tool recommended is a small flat blade screwdriver.

Installation instructions:

1. Configure audio module:

Prior to installation, the audio modules need to be configured for proper

use in the system. Refer to the Fig. 1 and Fig. 2 for switch locations and settings.

a. Input termination: Input termination should be set depending on your system

requirements. You can choose either high-impedance (default) or 600 ohm

termination on an individual channel basis.

b. Input range: Based on the level of input signal you will be applying the

specific channel, you may choose to modify the input range selection switches.

By default, the switches are set to high range (+18dBu) and will transmit any

audio signal within the specifications of the unit. If lower level input signals are

expected, you may change the input range to low (+8dBu) to increase the overall

signal to noise ratio. Clipping (distortion) however, will occur if input levels exceed

+8dBu. Note that for each channel, two switches must be thrown to change

the input range.

c. Output range: To normalize the system, you must switch the output range

switch to the same setting as the CORRESPONDING input range switch. Note, this

does not mean that the switches on the same board need to be the same, just

that the switches at the input node, must match the switches at the output node.

If multiple outputs are mapped (broadcast mode) than all outputs must be set to

the same gain range.

UDIO INPUT

A

TERMINATION

AUDIO OUTPUT

RANGE

AUDIO INPUT

RANGE

Figure 1. Audio Level Switch Locations

16

Page 19

AUDIO INPUT TERMINATION

Note: One switch per channel

AUDIO INPUT RANGE

Note: Two switches per channel

AUDIO OUTPUT RANGE

Note: One switch per channel

N

O

S1

Ch A

Ch B

High Z

ON

S2

High Z

600Ω

Ch C

Ch D

600Ω

The A8920A units are shipped

with the input impedance set

at (high-Z). To select a 600Ω

input impedance in place of the

high-Z input, set switches SW1

and SW2 on the audio to 600Ω.

Figure 2. Audio Level Switch Positions

S3

S4

S5

S6

Low

Low

Low

O

ON

ON

ON

N

High

High

High

Ch A

Ch B

Ch C

N

O

S7

Ch A

Ch B

Low

S8

Low

High

ON

Ch C

Ch D

High

If a low audio level causes the output

audio signal to degrade, the input

sensitivity of the A8920A can be

increased by switching to the 8 dBu

maximum scale.

You can set the transmitter input to

8 dBu and the receiver output to 18

dBu to add 10 dB of gain to the

system, however, this also increases

system signal-to-noise ratio (S/N).

Ch C

Low

High

2. Installing audio modules:

Audio modules must be installed in slots 15, 16, 17, or 18 (color coded black).

Up to four Audio modules can be installed per Phoenix node.

The channel sequence is as follows:

Slot 15, top RJ45 connector is assigned to Channel Inputs 1 and 2.

The second RJ45 connector gets assigned to Channel Inputs 3 and 4.

The third RJ45 connector gets assigned to Channel Outputs 1 and 2.

The bottom RJ45 connector gets assigned to Channel Outputs 3 and 4.

Subsequent modules, placed in slots 16, 17, and 18 are assigned

to Channels 5-8, 9-12, and 13-16 respectively.

17

Page 20

INSERT AUDIO CARDS IN SLOTS 15-18 (Black)

3. Connecting to audio modules:

GE Security recommends connecting to the terminal block using high-quality shielded,

twisted-pair wire for best audio performance.

The I/O for the audio inputs and outputs are as follows:

RJ45 - A (Top) AUDIO INPUTS - CHANNELS A-B

Pin

1

2

3

4

5

6

7

8

RJ45 - C AUDIO OUTPUTS - CHANNELS A-B

Pin

1

2

3

Audio Signal

IN A (+)

IN A (-)

GND/SHIELD

GND

GND

GND/SHIELD

IN B (+)

IN B (-)

Audio Signal

OUT A (+)

OUT A (-)

GND/SHIELD

RJ45 - B AUDIO INPUTS - CHANNELS C-D

Pin

1

2

3

4

5

6

7

8

RJ45 - D (Bottom) AUDIO OUTPUTS - CHANNELS C-D

Pin

1

2

3

Audio Signal

IN C (+)

IN C (-)

GND/SHIELD

GND

GND

GND/SHIELD

IN D (+)

IN D (-)

Audio Signal

OUT C (+)

OUT C (-)

GND/SHIELD

4

5

6

7

8

GND

GND

GND/SHIELD

OUT B (+)

OUT B (-)

4

5

6

7

8

GND

GND

GND/SHIELD

OUT D (+)

OUT D (-)

18

Page 21

P

in

1 8

Figure 1. Terminal Block Pin Assignments

5

4

Figure 2. RJ45 Socket

Viewed from the rear of the unit)

(

6

7

8

3

2

1

Using the breakout box

A breakout box with a 3’ CAT 5 patch cord

(supplied) can be used to interface to the

Phoenix system. Pinouts are shown in the

tables and figures above.

RJ45-A

RJ45-B

RJ45-C

RJ45-D

Audio module - channel sequence

Slot 15

RJ45-A Ch 1-2 IN

RJ45-B Ch 3-4 IN

RJ45-C Ch 1-2 OUT

RJ45-D Ch 3-4 OUT

Slot 16

Ch 5-6 IN

Ch 7-8 IN

Ch 5-6 OUT

Ch 7-8 OUT

Slot 17

Ch 9-10 IN

Ch 11-12 IN

Ch 9-10 OUT

Ch 11-12 OUT

Slot 18

Ch 13-14 IN

Ch 15-16 IN

Ch 13-14 OUT

Ch 15-16 OUT

19

Page 22

Installing the Contact Closure Module

Overview

The Phoenix A8930C contact closure module is capable of supporting up to

8 contact closure inputs, and 8 contact closure outputs per module. With up to 4

modules available per system, up to 32 contact inputs and outputs can be transmitted.

Contact closure modules are color coded black, and can be installed in slots 15, 16, 17,

or 18. The input/output interface is four, ganged RJ45 connectors located on each card,

See contact closure pin-out connection in Fig. 2.

Tools and materials required

The contact closure modules are held in place with simple thumbscrews with screwdriver

slots. The only tool recommended is a small flat blade screwdriver.

Installation instructions:

1. Install contact closure module:

Install contact closure modules in slots 15, 16, 17, or 18 (color-coded black) and secure.

Up to four contact closure modules can be installed in each node. Connect contact

closure wires to terminal blocks on each card by using the RJ45 connectors.

The channel sequence is as follows:

Slot 15, top RJ45 connector is assigned to Channel Inputs 1, 2, 3, and 4.

The second RJ45 connector gets assigned to Channel Inputs 5, 6, 7, and 8.

The third RJ45 connector gets assigned to Channel Outputs 1, 2, 3, and 4.

The bottom RJ45 connector gets assigned to Channel Output 5, 6, 7, and 8.

Subsequent modules, placed in slots 16, 17, and 18 are mapped

to Channels 9-16, 17-24, and 25-32 respectively.

INSERT CONTACT CLOSURE CARDS IN SLOTS 15-18 (Black)

20

Page 23

Pin

1 8

2. Connect to the module:

Each contact closure module is shipped with (four) RJ45 cables and (four) breakout

boxes to aid in connecting to the Phoenix. Use the tables below to determine pin out

information for your application. GE Security recommends using shielded cable for all

single ended applications and shielded twisted-pair for all differential formats.

Wire gauge is dependent on copper run length. Refer to manufacturer of data

equipment for specific recommendations.

Figure 1. Terminal Block Pin Assignments

5

6

7

8

4

3

2

1

Using the breakout box

A breakout box with a 3’ CAT 5 patch cord

(supplied) can be used to interface to the

Phoenix system. Pinouts are shown in the

tables and figures below.

Figure 2. RJ45 Socket

(Viewed from the rear of the unit)

RJ45-A

RJ45-B

RJ45-C

RJ45-D

21

Page 24

RJ45 - A (Top) CONTACT INPUTS - CHANNELS A-D

RJ45 - B CONTACT INPUTS - CHANNELS E-H

Pin

1

2

3

4

5

6

7

8

RJ45 - C CONTACT OUTPUTS - CHANNELS A-D

Pin

1

2

3

4

Contact Signal

N A

I

(GND)

IN B

(GND)

IN C

(GND)

IN D

(GND)

Contact Signal

C A

N/O A

C B

N/O B

Pin

1

2

3

4

5

6

7

8

RJ45 - D (Bottom) CONTACT OUTPUTS - CHANNELS E-H

Pin

1

2

3

4

Contact Signal

IN E

(GND)

IN F

(GND)

IN G

(GND)

IN H

(GND)

Contact Signal

C E

N/O E

C F

N/O F

5

6

7

8

To activate a relay, provide a connection from an IN (+) to GROUND.

C C

N/O C

C D

N/O D

Contact Input module - channel sequence

Slot 15

RJ45-A Ch 1-4 IN

RJ45-B Ch 5-8 IN

RJ45-C Ch 1-4 OUT

RJ45-D Ch 5-8 OUT

Slot 16

Ch 9-12 IN

Ch 13-16 IN

Ch 9-12 OUT

Ch 13-16 OUT

5

6

7

8

• IN

• GND

Slot 17

Ch 17-20 IN

Ch 21-24 IN

Ch 17-20 OUT

Ch 21-24 OUT

C G

N/O G

C H

N/O H

Slot 18

Ch 25-28 IN

Ch 29-32 IN

Ch 25-28 OUT

Ch 29-32 OUT

22

Page 25

Configuring the Phoenix Fiber Optic Communications System

This section explains how to configure a Phoenix chassis using the front panel. The front

panel has seven status LEDs, an LCD display, seven push buttons and two RJ-45 ports.

These RJ-45 ports (labeled LAN and DATA) are currently unused. Do NOT connect any

cables or equipment to these ports; it may damage the Phoenix chassis.

Basic configuration of a Phoenix chassis is a three-step process:

1. Turn on power and check status.

2. Select the system topology.

3. Set the node ID.

If your system requires non-default settings (e.g. channel mapping, PAL video, etc.),

please refer to the section titled FRONT PANEL MENU TREE AND DESCRIPTIONS after

you have completed the basic configuration.

If you have not already done so, install the Power Supply Module(s), Optic Module, and

any other plug-in modules (i.e. Data, Video Input, Video Output, etc.) and connect cabling

as instructed in the previous sections of this manual

23

Page 26

1. Turn on power and check status

Turn on the power to the Phoenix chassis using the switches on the Power Supply

modules. If two power supplies are installed, turn on both switches. The LEDs perform a

brief test when the chassis powers up: all seven LEDs turn green and then turn red. After

the test has completed the LEDs indicate the status of the power supplies and optics.

Power A and Power B: If a module is installed, and the power switch is on, and the

supply is working properly the corresponding LED will be green. If the supply is installed,

but the power switch is off or a problem has been detected the LED will turn red.

If either power supply slot is empty then the corresponding LED will be off.

Optic A and Optic B: If an optic transceiver is installed in one of the top two Optic

Module transceiver slots, the corresponding LEDs indicate the status of the following

conditions:

1. The transmit laser is working properly.

2. The receive photodiode detects sufficient light over the fiber.

3. The receiver detects another Phoenix node at the other end of the fiber.

If all three of these conditions are true, then the LED will be green. If any of these

conditions is not true, then the LED will be red. If an optic transceiver module slot is

empty, then the LED will be off.

Optic C and Optic D: These LEDs are unused. After the power-on test,

they will always be off.

Status: This LED indicates the status of the ring when the Phoenix system is configured

as a Self-Healing Ring (SHR). If the ring is complete (no fiber breaks) the LED will be green.

If a single fiber break is detected the LED turns amber/orange. If a double fiber break is

detected the LED turns red. Note that a single fiber break will not result in a loss of video,

audio, or data. A double fiber break

may result in lost video, audio, or data. The LED is off

if the system is a Linear topology.

2. Select the system topology

In order for a Phoenix chassis to r

oute information over its fiber links correctly, it must

know the topology of the entire system. A chassis can be part of either a Linear or

Self-Healing Ring topology. If you are configuring a Self-Healing Ring topology, then

each node must also know the total length of optical fiber used in the ring. Once set,

the topology (and ring length) will be remembered if the chassis loses power.

24

Page 27

The topology and node ID are set using the front panel LCD display. The LCD displays a

GE SECURITY

Phoenix

Main Menu

1. Local

2. Remote

3. About

Local Menu

1. Node: 0 - Linear

2. Optics AB

3. Video 1/0 - 4/0

menu from which sub-menus or features can be selected. The push buttons allow you to

navigate through the menus. A small black arrow is used as a cursor. The "up" and

"down" buttons move the cursor up or down one line in the menu, respectively. The

"enter" button selects the sub-menu or feature at which the cursor is pointing. The "left"

button takes you back up one level in the menu hierarchy. The remaining three buttons,

"right", "+", and "-" are menu-specific and are described later.

A brief initialization routine is displayed on the LCD when the chassis powers up.

A splash screen showing the GE logo and Phoenix product name is displayed after

the routine completes. After approximately one minute of inactivity the LCD display

will turn off. The display can be re-enabled by pressing any of the seven buttons on

the front panel.

If the splash screen is displayed or if the display is blank press the "enter" button one

time. This will bring up the Main Menu. If any other menu is displayed, then press the

"left" button until the Main Menu is shown:

Use the "up" and "down" buttons to move the cursor to "1. Local".

Press the "enter" key to select the Local Menu:

25

Page 28

Press "enter" again to select the Node Menu:

Node Menu

1

. ID - 0

2. Type - Linear

3. Load Defaults

Topology Menu

1. Linear

2. Self Healing Ring

Node ID: 0

If you are configuring a system with a linear topology, and item 2 in the menu reads, "2.

Type – Linear", then you do not have to make any changes and can continue to Step 3,

below. Otherwise, select item 2 from the menu. This displays the Topology Menu:

Move the cursor to the topology of the system from the menu’s choices: Linear or SelfHealing Ring (SHR). Press "enter". A new screen will appear asking you to confirm your

choice for topology. Move the cursor to "Accept" and press "enter". The next screen will

ask you whether or not you would like to load defaults. Move the cursor to "Accept" and

press "enter". If you chose Linear then you can continue to Step 3 after you have been

returned to the Node Menu.

If you chose Self-Healing Ring, then you must also specify the length of fiber used in the

entire ring. The "+" key increments the length by 10km. The "-" key decrements the

length by 10km. Round up when selecting the ring length. Press "enter" when you are

done. You must confirm your selection on the following screen by moving the cursor to

"Accept" and pressing, "enter". The topology is now set and you are returned to the Node

Menu. Note that the topology (and ring length) is indicated on item 2 in the menu.

3. Set the Node ID.

Every Phoenix node (i.e. chassis) in a system should have a unique node ID number. The

node ID is set to 0 the first time a Phoenix chassis is switched on. This is an invalid ID; it

must be a number between 1 and 255. Once set, the node ID will be remembered if the

chassis loses pow

er.

Navigate to the Node Menu if it is

not currently displayed on the LCD.

Move the cursor to "1. ID" and press "enter":

The ID will increment by one if you press “+”. Similarly, the ID will decrement by one if

you press “-”. If you press and hold either of these buttons, the node ID will slowly

increment or decrement. The rate will increase if you continue pressing the button.

Once you have the node ID set, pres the “enter” button. Another menu will ask you

to confirm your selection. Move the cursor to “Accept” and press “enter”. The node ID is

now set and you are returned to the Node Menu. Note that the node ID is now shown

after “1. ID” in the menu.

Congratulations! You have completed the basic configuration. If your system requires

non-default settings (e.g. channel mapping or PAL video), or if you would like to learn

more about the available menus and features refer to the following section.

26

Page 29

FRONT PANEL MENU TREE AND DESCRIPTIONS

The menus accessible from the front panel are shown in the menu tree below:

Navigating through the menu tree is accomplished using the push buttons and LCD

display. The LCD shows menus from which sub-menus or features can be selected.

A small black arrow is used as a cursor. The "up" and "down" buttons move the cursor up

or down one line in the menu, respectively. The "enter" button selects the sub-menu or

feature at which the cursor is pointing. The "left" button takes you back up one level in

the menu hierarchy. The remaining three buttons, "right", "+", and "-" are menu-specific

and are described later.

27

Page 30

Main Menu:

Main Menu

1. Local

2. Remote

3. About

Local Menu

1. Node: 1 - Linear

2. Optics AB

3. Video 1/0 - 4/0

Node Menu

1. ID - 3

2. Type - Linear

3. Load Defaults

The menus accessible from the front panel are shown in the menu tree below:

Pressing any key from the opening screen will take you to the Main Menu.

Main -> Local:

There are nine selections available to configure and monitor the local node.

Some of the choices show information regarding the node or the modules installed:

1. Node: Shows node ID, topology (and ring length if SHR).

2. Optics: Shows optic ports that have transceivers installed.

3. Video I/O: Shows the number of input and output video channels installed.

4. Data: Shows the number of installed data channels.

5. Audio: Shows the number of installed audio channels.

6. Contacts: Shows the number of installed contact channels.

7. Power: Shows which power supplies are installed.

8. Test

9. About

Only three of the menu choices are visible on the LCD at one time. Pressing the "down"

button when the cursor is at the bottom of the screen will display the next three menu

choices. Similarly, pressing the "up" button when the cur

sor is at the top of the screen

will display the previous three menu choices.

Main -> Local -> Node:

28

Page 31

The Node Menu shows the node ID and topology.

Node Menu

1. ID - 3

2. Type - Linear

3. Load Defaults

Topology Menu

1. Linear

2. Self Healing Ring

Main -> Local -> Node -> ID

Every Phoenix node (i.e. chassis) in a system must have a unique node ID number.

The node ID is set to zero the first time a Phoenix chassis is switched on, or if you Load

Defaults. Zero is an invalid node ID; it must be a number between 1 and 255.

Once set, the node ID will be remembered if the chassis loses power.

The ID will increment by one if you press "+". Similarly, the ID will decrement by one

if you press "-". If you press and hold either of these buttons, the node ID will slowly

increment or decrement. The rate will increase if you continue pressing the button.

Once you have the node ID set, press the "enter" button. You will be asked to

confirm your selection.

Main -> Local -> Node -> Topology

In order for a Phoenix chassis to route information over its fiber links correctly, it must

know the topology of the entire system. A chassis can be part of either a Linear or

Self-Healing Ring topology. If you are configuring a Self-Healing Ring topology, then

each node must also know the total length of optical fiber used in the ring.

Once set, the topology will be remembered if power to the chassis is lost.

Select the topology of the system from the menu’s choices: Linear and Self-Healing Ring

(SHR). A new screen will appear asking you to confirm your choice for topology. Note

that SHR is an acronym for Self-Healing Ring used throughout the menus. The next

screen will ask you whether or not you would like to load defaults.

IMPORTANT: If you

choose to load defaults, the node ID will be set to zero and all channel mapping

information for this node will be lost. Select cancel if you do not wish to load defaults.

If you chose Linear then you are returned to the Node Menu after you confirm your

selection. If you chose Self-Healing Ring, then you must also specify the length of fiber

used in the entire ring. The "+" key increments the length by 10km. The "-" key

decrements the length by 10km. Round up when selecting the ring length. Press

"enter" when you are done. You must confirm your selection before continuing.

29

Page 32

Main -> Local -> Node -> Load Defaults

Optic Menu

1. Transmit

2. Receive

3. Info

Tx Optic B C D

4.23 mW

Status: Good

A

Rx Optic: ABCD

3.97 mW

Status: Good

This feature sets the node ID back to zero and clears all channel mapping information

for this node. The topology is retained.

Main -> Local -> Optics:

Information about the fiber optic transceivers can be accessed from the sub-menus.

Main -> Local -> Optics -> Transmit:

This screen shows the optical launch power of the selected optic transceiver. Use the "+"

button to select the next transceiver. Use the "-" button to select the previous transceiver.

The launch power is displayed in milliwatts (mW). Values around +4mW are normal.

Additionally, the transceiver transmit (TX) status is displayed. The status is reported as

either Good, Faulty, or Not Found if the selected transceiver is not installed.

Main -> Local -> Optics -> Receive:

This screen shows the optical receive power of the selected optic transceiver. Use the "+"

button to select the next transceiver. Use the "-" button to select the previous transceiver.

The power is displayed in milliwatts (mW). The receive power can be used to verify path

loss if the transmit launch power at the other end of a fiber is known. Sensitivity must be

greater than 0.04 mW to insure enough optical power is being received. Additionally, the

transceiver receive (RX) status is displayed. The status is reported as Good, Sync Loss,

Signal Loss or Not Found if the selected transceiver is not installed.

30

Page 33

Main -> Local -> Optics -> Info:

Video Menu

1. Input Mapping

2. Output Mapping

3. Test Select

Optic Info: ABCD

W

avelength: 1310 nM

Max Distance: 15 km

Vendor: Infineon

Video:

Exit

A

B

1

1

1

The Info Menu shows the wavelength (normally 1310nM), maximum distance

(normally 15km) and optic transceiver vendor name (Infineon) for the selected

optic transceiver. Use the "+" button to select the next transceiver. Use the "-" button

to select the previous transceiver.

Main -> Local -> Video:

Video Input and Video Output mapping, monitoring, and tests can be accessed from the

sub-menus.

Main -> Local -> Video -> Input Mapping:

This screen allows you to assign a video input channel to a video output channel over a

selected fiber port. The camera icon in the middle of the screen indicates the presence

of a video signal for the selected channel. If the camera has an X through it, video is not

present on this channel. If the camera does not have an X through it, then video is

present. The number under the camera icon indicates the currently selected input

channel. The numbers under the monitor icons to the left and/or right of the camera

represent the output channel numbers. The arrows to the left and/or right of the

camera (labeled A and B, respectively) indicate over which fibers this mapping is

enabled. If the selected input channel is mapped to the output channel then a black

square is shown in the middle of the monitor icon and the arrow is displayed. If a

mapping does not exist for this input and output channel pair, then the monitor icon

is blank and the arrow is not shown.

Use the "left" and "right" button to move the cursor at the bottom of the screen. Use "+"

and "-" to increment and decrement the channel numbers. Incrementing the input

channel automatically increments both output channels. Pr

at an output channel to enable a mapping. Move the cursor to "Exit" and press enter to

leave this screen. All channel mapping are saved when you leave this menu.

ess "enter" while the cursor is

31

Page 34

When a Phoenix node is initially configured (or if Load Defaults is selected from the Node

Video:

Exit

A

B

A

B

1

Video:

Exit

A

B

A

B

1

Video:

Exit

A

B

A

B

1

Menu), every input channel is mapped to the output channel of the same number (e.g.

input channel 1 is mapped to output channel 1, etc) on both fiber ports (for SHR) or just

fiber port A (for Linear).

IMPORTANT: In Linear mode, mappings on fiber ports A and B are independent. For

example, you could map input channel 1 to output channel 7 on fiber port A, but then

map input channel 1 to output channel 12 on fiber port B. This allows you to have a total

of 32 channels enabled in a system simultaneously; 16 in one direction and 16 in the

other. However, in Self-Healing Ring mode, mappings on fiber ports A and B are identical.

For example, if you map input channel 1 to output channel 7 on fiber port A, then the

same mapping is made to output channel 7 over fiber B. Therefore, the maximum

number of enabled channels in a Self-Healing Ring is 16. Channel mapping behaves

the same way for Data and Audio channels.

Main -> Local -> Video -> Output Mapping:

This screen allows you to select which optic port is being reviewed for each of the

16 video output channels. The number under the monitor icon indicates which output

channel is selected. The letters under the camera icons indicate at which optic port the

selected output channel will be looking. Arrows to the left and right of the monitor icon

indicate that the mapping is enabled. If the output channel is not mapped to a fiber

then the corresponding arrow is not shown. The status of the output video signal is

depicted on the screen of the monitor icon. All channel mapping are saved when

you leave this menu.

• Blank: If there is no output mapping (i.e. neither fiber is selected)

then a blank monitor icon is shown.

• Two-Bar: If the output is mapped but video is not detected on any of the

selected fibers then two bars are shown in the monitor.

32

Page 35

• One-Bar: If the input and output channels are both mapped but no input video signal

Video:

E

xit

A

B

A

B

1

Video:

Exit

A

B

A

B

1

Video Test

1. Channel: 1

2. Test: Off

3. Format: NTSC

is detected then one bar is shown in the monitor.

• Square: If the input and output channels are both mapped and active video is detected

then a black square is shown in the center of the monitor.

Press "+" and "-" to select an output channel while the cursor is under the middle icon.

Use "left" and "right" to move the cursor at the bottom of the screen. To enable fiber port

A move the cursor to the left and then press "enter." Similarly, to select fiber B, move the

cursor to the right and press "enter." To leave this screen move the pointer to "Exit" and

press "enter." All channel mapping are saved when you leave this menu.

When a Phoenix node is initially configured (or if Load Defaults is selected from the Node

Menu), the default output mappings depend on the system topology. In Linear mode

every output channel is initially mapped to fiber port A. In Self-Healing Ring mode every

output channel is initially mapped to both fiber ports.

IMPORTANT: In Linear mode either A, B or no optic port can be selected depending on

what optics are installed. In Self-Healing Ring mode, either both fiber ports are mapped

or neither port is mapped.

This menu allows the user to select the format of the video test patterns and to initiate a

test pattern for a specified channel. The first and second lines of this menu show the

currently selected video channel and the status of the test pattern (Off or Ramp),

respectively. An input video module does not have to be installed to view the pattern at

the output video module. The test pattern will only be visible if the corresponding input

channels, output channels and optic ports are mapped. The third line indicates the video

format (NTSC or PAL). The default is NTSC. The video format is a global selection and

affects all test patterns (e.

g. Ramp, One-Bar, Two-Bar, etc.) on all video channels.

Use "+" and "-" to change selections at each line in the menu. Press "left" to exit this

screen. When leaving this menu with test patterns enabled, a warning message comes

up alerting that test patterns have been disabled to allow real video to pass.

33

Page 36

Main -> Local -> Data:

Data Menu

1

. Input Mapping

2. Output Mapping

3. Format Select

Data:

1

010

Exit

1

010

1

010

A B

1

1

1

Data:

1010

Exit

1010

1010

Z

A B

1

1

1

Data:

1010

Exit

1010

1010

H

A B

1

1

1

Data:

1010

Exit

1010

1010

L

A B

1

1

1

Data Input and Data Output channel mapping, monitoring, format and tests can be

accessed from the sub-menus.

Main -> Local -> Data -> Input Mapping:

This screen allows you to assign a data input channel to a data output channel over

a selected fiber port. The number under the middle oscilloscope icon indicates the

currently selected input channel. The numbers under the oscilloscope icons to the left

and/or right of the middle oscilloscope icon represent the output channel numbers. The

arrows to the left and/or right of the middle icon (labeled A and B, respectively indicate

over which fibers this mapping is enabled. If the selected input channel is mapped to the

output channel then a square-wave is displayed on the oscilloscope icon and the arrow

is displayed. If a mapping does not exist for the selected input and output channel pair,

then the square-wave and the arrow are not displayed. The status of the input data

signal is depicted on the screen of the middle icon:

• Z: A high-impedance condition is detected at the data input

(i.e. no equipment is driving an active signal).

• H: A high level is detected at the data input (i.e. a logic-1).

• L: A low level is detected at the data input (i.e. a logic-0).

34

Page 37

• Square Wave: Active data is detected at the data input.

Data:

1

010

Exit

1

010

1

010

A B

1

1

1

Data:

1010

Exit

1010

1010

A B

B

1

A

Data:

1010

Exit

1010

1010

Z

A B

1

1

1

Data:

1010

Exit

1010

1010

H

A B

1

1

1

Data:

1010

Exit

1010

1010

L

A B

1

1

1

Please refer to the Video Input Mapping Menu described earlier in this manual for important notes regarding channel mapping and instructions on how to enable mappings.

Main -> Local -> Data -> Output Mapping:

This screen allows you to select which optic port is being reviewed for each of the 16

data output channels. The number under the middle oscilloscope icon indicates which

data channel is selected. The letters under the oscilloscope icons to the left and right

indicate at which optic port the selected output channel will be looking. Arrows to t

he left and right of the middle icon indicate that the mapping is enabled. If the output

channel is not mapped to a fiber then the corresponding arrow is not shown.

The status of the output data signal is depicted on the screen of the middle icon:

• Z: A high-impedance condition is detected at the data input

(i.e. no equipment is driving an active signal).

• H: A high level is detected at the data input (i.e. a logic-1).

• L: A low level is detected at the data input (i.e. a logic-0).

35

Page 38

• Square Wave: Active data is detected at the data input.

Data:

1

010

Exit

1

010

1010

A B

1

1

1

Data:

1. Channel: 1

2. Format: 232 - 3

3. Test: Off

Please refer to the Video Output Mapping Menu described earlier for important notes

regarding channel mapping and instructions on how to enable mappings.

Main -> Local -> Data -> Format Select:

This menu allows the user to view and change the format for a specified data channel.

The first line of this menu shows the currently selected channel. The second line shows

the current data format. If the switch on the Data Module for the corresponding data

channel is set to position 0, then the data format can be modified. If the switch is set to

any other position then the format cannot be changed. The third line indicates the status

of a test pattern ("OFF" or "ON 1-0-Z"). The test pattern is generated at the specified

output channel, so an Input Data Module is not required and channel mappings will

have no affect on the test pattern.

Setting Mode

0 Software-selectable (factory preset)

1 RS-232 (3-wire)

2 RS-232 + handshake

3 TTL

4 RS-422 2-wire

5 Manchester/biphase

6 RS-485 2-wire standard/Sensornet

7 RS-485 2-wire 1V

Setting Mode

8 RS-485 2-wire 2 V

9 RS-485 4-wire standard

A RS-485 4-wire 1 V

B RS-485 4-wire 2 V

C Reserved

D Reserved

E Reserved

F Test Mode

NOTE: The DATA SELECT switches are shipped in the Software-Selectable setting.

Use "+" and "-" to change selections at each line in the menu. Press "left" to exit this

screen. When leaving this menu with test patterns enabled, a warning message comes

up alerting that test patterns have been disabled to allow real data to pass.

36

Page 39

Main -> Local -> Ethernet:

Ethernet Menu

1. Port Status

2

. Port Control

3. Port Traffic

Port Status Menu

Slot: 1 Port: A

Link: Up

Spd: 100 Dpx: Full

Port Control Menu

Slot: 1 Port: A

Auto Neg: Enabled

Spd: Dpx:

Port Traffic Menu

Slot: 1 Port: A

Tx Pkts: 158

Rx Pkts: 12

Port configurations, status and traffic statistics can be accessed from these submenus.

Main -> Local -> Ethernet -> Port Status:

This screen allows you to monitor the link status of each port of an Ethernet module. Use

the arr

ow keys to move back and forth between the slot and port selections. The ‘+’ and

‘-’ buttons increment and decrement the slot and port selections. Port A is the top port,

Port B is the middle port and Port C is the bottom port. The link status is indicated as

either Up or Down. If the Link is up, the negotiated speed and duplex are indicated.

Press ‘enter’ to leave this menu.

Main -> Local ->Ethernet -> Port Control:

This screen allows you to control the link parameters for each port of an Ethernet module. Use the arrow keys to navigate around the screen. The ‘+’ and ‘-’ buttons increment

and decrement the slot and port selections, and toggle the Auto-Negotiation, Speed and

Duplex settings. Port A is the top port, Port B is the middle port and Port C is the bottom

port. Port A is the top port, Port B is the middle port and Port C is the bottom port. Press

‘enter’ to leave this menu.

Main -> Local ->Ethernet -> Port Traffic:

This screen allows you to monitor the number of error-free packets sent and received at

each port of an Ethernet module. The ‘+’ and ‘-’ buttons increment and decrement the

slot and port selections. Port A is the top port, Port B is the middle port and Port C is the

bottom port. The packet counters wrap around to 0 once they reach 65,535. Press

‘enter’ to leave this menu.

37

Page 40

Main -> Local -> Audio:

A

udio Menu

1. Input Mapping

2. Output Mapping

3

. Test Select

Audio

Exit 1 1 1

A

Audio

Exit A 1 B

Audio Input and Audio Output mapping and tests can be accessed from the sub-menus.

Main -> Local -> Audio -> Input Mapping:

This screen allows you to assign an audio input channel to an audio output channel over

a selected fiber port. The number under the microphone icon indicates the currently

selected input channel. The numbers under the speaker icons to the left and/or right of

the microphone represent the output channel numbers. The arrows to the left and/or

right of the microphone (labeled A and B, respectively) indicate over which fibers this

mapping is enabled. If the selected input channel is mapped to the output channel then

three lines are displayed radiating out of the speaker icon and the arrow is displayed. If

a mapping does not exist for this input and output channel pair, then the lines next to

speaker and the arrow are not displayed.

Please refer to the Video Input Mapping Menu described earlier for important notes

regarding channel mapping and instructions on how to enable mappings.

Main -> Local -> Audio -> Output Mapping:

This screen allows you to select which optic port is being reviewed for each of the 16

audio output channels. The number under the speaker icon indicates which audio

channel is selected. The letters under the microphone icons indicate at which optic port

the selected output channel will be looking. Arrows to the left and right of the speaker

icon indicate that the mapping is enabled. If the output channel is not mapped to a fiber

then the corresponding arrow is not shown.

Please refer to the Video Output Mapping Menu described earlier for important notes

regarding channel mapping and instr

uctions on how to enable mappings.

38

Page 41

Main -> Local -> Audio -> Test:

Audio:

1. Channel: 1

2. Test: Off

Contact Menu

1. Input Mapping

2. Output Mapping

3. Configure

Contact:

Exit

1, 2

1

A B

1

•

•

•

•

This menu allows the user to initiate a 1KHz test tone for a specified channel. The first

line of this menu shows the currently selected audio channel. The second line indicates

the status of the test tone (Off or 1.0 KHz), respectively. An input audio module does not

have to be installed to hear the test tone at the output audio module. The test pattern

will only be audible if the corresponding input channels, output channels and optic ports

are mapped. Use "+" and "-" to change selections at each line in the menu. Press "left" to

exit this screen. When leaving this menu with test patterns enabled, a warning message

comes up alerting that test patterns have been disabled to allow real audio to pass.

Main -> Local -> Contacts:

Contacts Input and Contacts Output channel mapping, monitoring, and configuration

can be accessed from the sub-menus.

Main -> Local -> Contacts -> Input Mapping:

This screen allows you to assign a pair of contact input channels to a pair of contact

output channels over a selected fiber port. The numbers under the switch icon indicates

the currently selected input channels. The number under the circuit icons to the left

and/or right of the switch icon represent the first of two output channel numbers. The

arrows to the left and/or right of the switch icon (labeled A and B, respectively) indicate

over which fibers this mapping is enabled. If the selected input channels are mapped to

the output channel then the circuit in the icon is closed and the arrow is displayed. If a

mapping does not exist for the selected input and output channels, then the circuit is

open and the arrow is not displayed. The status of the input contacts are depicted on

switches in the middle icon:

• Open: If the contact closure is open then the plunger of the switch is raised,

as shown above.

39

Page 42

• Closed: If the contact closure is closed then the plunger of the switch is lowered.

Contact:

Exit

1, 2

A

A

B

B

Contact:

Exit

1, 2

A

A B

B

Contact Config 1

1. Style Momentary

2. Type Transmitted

3. Force None

Contact:

Exit

1, 2

1

A

B

1

•

•

•

•

Please refer to the Video Input Mapping Menu described earlier for important notes

regarding channel mapping and instructions on how to enable mappings. However, note

that contact signals are mapped as pairs since there are 8 contact channels per

Contact Closure Module.

Main -> Local -> Contacts -> Output Mapping:

This screen allows you to select which optic port is being reviewed for each of the 32

contact output channels. The number under the circuit icon (in the middle of the screen)

indicates which contact channels are selected. The letters under the switch icons to the

left and right indicate at which optic port the selected output channels will be looking.

Arrows to the left and right of the circuit icon indicate that the mapping is enabled. If the

output channels are not mapped to a fiber then the corresponding arrow is not shown.

The status of the output contacts are depicted on the circuits in the middle icon:

• Open: If the contact closure is open then the circuit is open, as shown above.

• Closed: If the contact closure is closed then the circuit is closed.

Please refer to the Video Output Mapping Menu described earlier for important notes

regarding channel mapping and instructions on how to enable mappings. However, note

that contact signals are mapped as pairs since there are 8 contact channels per Contact

Closure Module.

Main -> Local -> Contacts -> Configure:

This menu allows the user to change the format or test a specified contact channel. Use

"+" and "-" to change selections at each line in the menu. Press "left" to exit this screen.

The top line of this menu shows the currently selected channel. The second line,

"1. Style" shows the current contact format:

• Momentary: Configures the selected input channel to behave like a momentary switch.

• Latched: Configures the selected input channel to toggle each time the contact closes.

40

Page 43

The third line, "2. Type" allows system events to be mapped to contact closure

Power Supply: A Pass

+5V -5V +12V -12V

5.2 -4.9 11.9 -12.3

B

Test Menu

1. LED/LCD/Alarm

2. Temp

3. Video

output channels:

• Transmitted. The contact behaves normally.

• Optic A: A problem on optic port A closes the selected contact.

• Optic B: A problem on optic port B closes the selected contact.

• Optic A or B: A problem on either optic port closes the selected contact.

• Video X: Loss of video on the specified video input channel

(where X is the video channel) closes the selected contact.

• Video W,X,Y,Z: Loss of video on any of the specified video input channels

(where W,X,Y,Z are the video channels) closes the selected contact.

The fourth line, "3. Force" allows a contact output to be forced into a known

state for test:

• None: The test is disabled and the contact behaves normally.

• Open: The contact is forced open.

• Closed: The contact is forced closed.

When leaving this menu with test patterns enabled, a warning message comes up

alerting that the test states have been disabled to allow real contact closure

information to pass.

Main -> Local -> Power:

This menu displays the measured voltages of the selected power supply. It also indicates

the status of the power supply (Pass/ Fail). Use "+" to select the next power supply. Use "" to select the previous power supply. Press "left" to exit this menu.

Main -> Local -> Test:

Various tests can be selected from the sub-menus.

41

Page 44

Main -> Local -> Test -> LED/LCD/Alarm:

About Menu:

1

Slot

3

Rev

Data

Card Type

This selection runs through a series of three tests:

1. LED Test: All LEDs turn off, then turn green, and then turn red.

2. LCD Test: The screen turns black. Then the GE logo is displayed.

3. Alarm Test: The front panel alarm sounds for a few seconds.

Main -> Local -> Test -> Temp:

This selection displays the temperature of inside optic transceiver A.

Main -> Local -> Test -> Video:

This menu is identical to the Main -> Local -> Video -> Test Menu, described earlier.

Main -> Local -> Test -> Data:

This menu is identical to the Main -> Local -> Data -> Format Menu, described earlier.

Main -> Local -> Test -> Audio:

This menu is identical to the Main -> Local -> Audio -> Test Menu, described earlier.

Main -> Local -> Test -> Contact:

This menu is identical to the Main -> Local -> Contact -> Configure Menu,

described earlier in this section.

Main -> Local -> About:

The Local About Menu displays the software version for each module installed in the

chassis. Press "+" to view the next slot. Press "-" to view the previous slot.

42

Page 45

Main -> Remote:

Under Construction

Phoenix Controller

Version 1.1

Date 02-16-05

This option is not available. An "Under Construction" message is displayed when

selecting this menu.

Main -> About:

The Main About Menu displays the software version of the chassis.

43

Page 46

Blank Panel Installation and Specifications

Overview

The Phoenix blank panel(s) are available in one-slot

(

A8957RP1) and four-slot (A8957RP4) models and are designed

and recommended for covering any open or unused card

access points on the back of the Phoenix card rack.

Tools and materials required

The blank panels are held in place with simple thumbscrews

with screwdriver slots. The only tool recommended is a small

flat blade screwdriver.

Installation instructions:

From back of Phoenix card rack, locate any unused module

slots. If they are one card slot wide, use part number

A8957RP1 for single slot openings and A8957RP4 if the

opening is four slots wide.

Line up the thumbscrews with the threaded hole on the open

panel and tighten top and bottom screws until panel fits

snugly in empty slot.

Limited warranty

E Security warrants that equipment will be free from defects in material

G

nd workmanship and will substantially conform to the relevant

a

pecifications published by GE Security for a period of five years from

s

delivery. During this period, GE Security will, at its option repair or replace

ny defective item of equipment or part or component of equipment,

a

hich GE Security determines was defective due to faulty material or

w

workmanship and coordinate the replacement of the failed equipment

provided that GE Security was responsible for the original installation

f the equipment.

o

GE Security will warrant that equipment shall be free from defects in

material and workmanship and will substantially conform to the relevant

specifications published by GE Security for a period of one year from

elivery. During this period, GE Security will at its option, repair or replace

d

ny defective item of equipment or part or component of equipment

a

which GE Security determines was defective due to faulty material or

orkmanship. Customer will pay transportation and insurance costs to

w

hip the equipment. GE Security will pay the return costs if the equipment

s

is determined to have been defective.

odel Part Number

M

rrow symbol in upper right

A

hand corners of blank panels

epresent direction panels are

r

o be attached to chassis.

t

V

Model Part Number

1 Slot Panel A8957RP1

Specifications

Model

Size

Weight

A8957RP1 A8957RP4

0.74 in. W x 3.30 in. H (19 x 84 mm)

.2 oz. (5.7 g)

2.99 in. W x 3.30 in. H (77 x 84 mm)

.8 oz. (22.85 g)

Model Part Number

4 Slot Panel A8957RP4

Product ordering

Model Part Number

1 Slot Panel A8957RP1

anel

4 Slot P

A8957RP4

44

Page 47

Optical Transceiver Module Specifications

Model

Mechanical

Size

Weight

Connections

Optical

• Mode: Single-mode

• Optical Budget: 20 dB

• Operating distance: 20 km

• Emitter: Laser

• Wavelength: 1310 nm

• Transmitter launch power: (-) 2 dBm typical

• Receiver sensitivity: (-) 22 dBm typical

• Gain control: OAGC

• Connector style: Duplex LC

A8972FLC module

1.50 in. W x 3.30 in. H x 8.20 in. L (38 x 84 x 208 mm)

8.0 oz. (227 g)

one or two duplex LC connectors

A8974FLC module

Product ordering

Model

Single optical input/output module

Dual optical input/output module

Part number

A8972FLC

A8974FLC

45

Page 48

Data Module Specifications

Model

Mechanical

Size:

Weight:

Connections:

Data

• Channels: 4 duplex

• Formats: RS-232 (3-wire/5-wire), TTL, RS-422 (2-wire/4-wire),

RS-485, Manchester, Biphase, Sensornet

• Baud rate: DC to 512 kbps (depending on data format)

• Bit error rate: > 10

• Test signal: Internally generated RS-485 signal

-9

A8910MPD duplex data module

0.75 in. W x 3.30 in. H x 8.88 in. L (19 x 84 x 226 mm)

4.0 oz. (113 g)

RJ45 or factory-supplied breakout box

Product Ordering

Model

Duplex data module

Part number

A8910MPD

46

Page 49

Ethernet Module Specifications

Model

Mechanical

Size

Weight

Ethernet

• Ports: 3 10/100BASE-T

• Auto-Negotiation

• Supports Full and Half-Duplex

• Throughput:

Module Port-to-Port: Line-Rate

Between Nodes: 25 Mbps

• Auto MDI/MDI-X

Product Ordering

A8911ETH Ethernet Module