Page 1

GE Oil & Gas

Masoneilan* Valves

SteamForm*

84000 Series

Steam Conditioning Solutions

Page 2

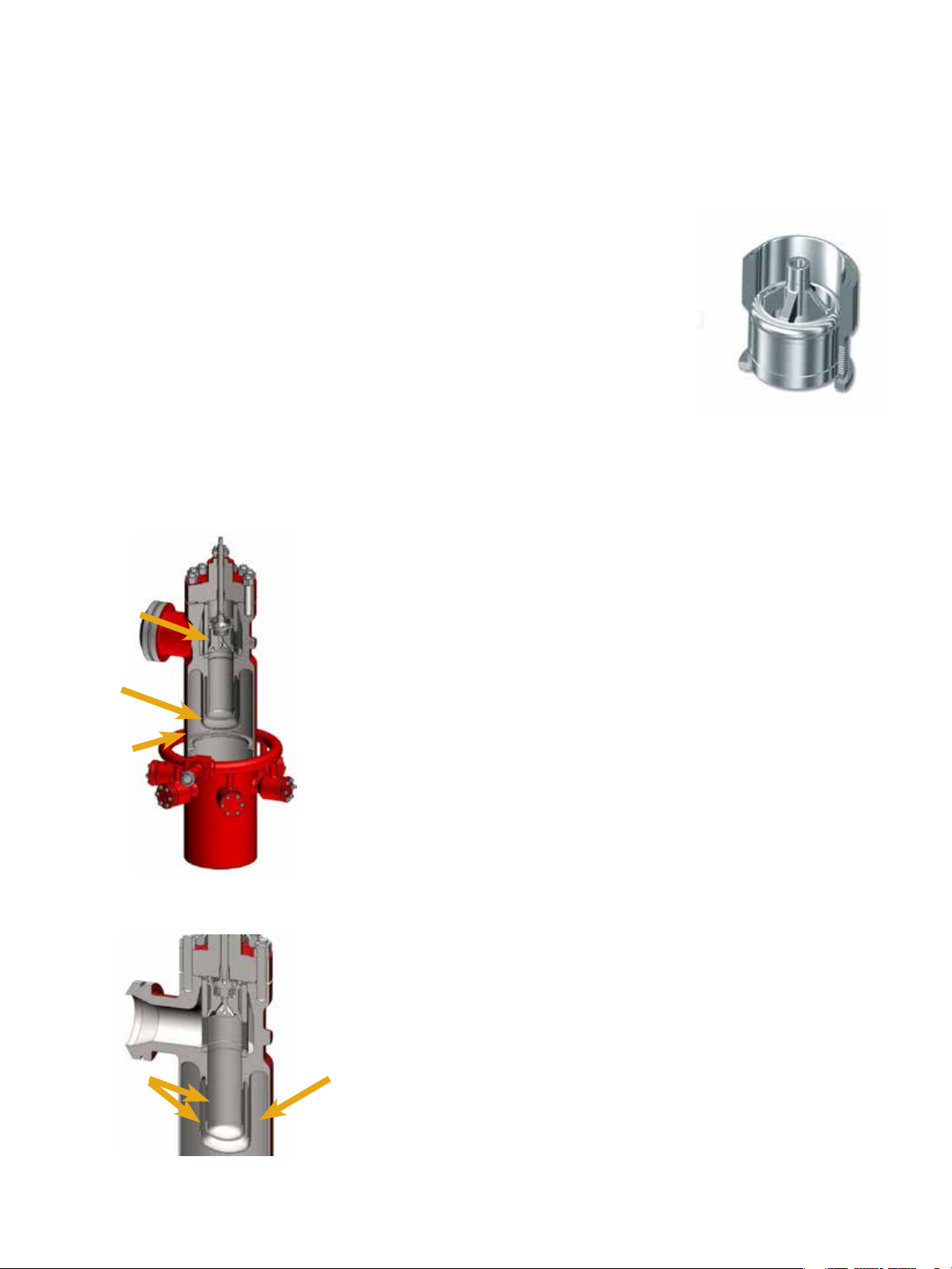

84000 Series SteamForm* Valve

GE’s Masoneilan* SteamForm* valve combines 15 years of proven pressure reduction

performance with an advanced, patented desuperheating technology design. Available

with a wide selection of performance enhancing configurations, Masoneilan* valves from

GE offer the optimized solution for virtually every steam conditioning application:

• Thermally Compensated Trim for High Temperature Cycling

• High Performance Spray Nozzles for Accurate Temperature Control

• Multi-Stage Lo-dB* Trim for High Pressure Reduction

• Fast Stroking Speeds for Turbine Bypass Quick Response

• Patented Flow Profiler for Enhanced Desuperheating Performance

21000 Series

Spray Water

Control Valves

Full Range of Options for Spray Water Control

Masoneilan products from GE complement SteamForm* valve

technology with a full line of spray water control valves ranging from the

single-stage pressure control of the 21000 Series valve, through the

high-end, multi-stage LincolnLog* valve solution for anti-cavitation.

Anti-cavitation Control Valves

LincolnLog*

Instrumentation Technology for Improved

Process Yields

GE’s Masoneilan* products provide leading micro-processor based field instrumentation technology that maximizes plant operating

margins by improving process yields, while reducing plant operating and maintenance costs. Award winning HART* communicating

Smart Valve Interface (SVI*) and Fieldbus Valve Positioner (FVP*) digital positioners from GE help users realize improved asset

effectiveness resulting in higher returns on investment. These digital positioners deliver improved process yields through patented tuning

algorithms that optimize valve control performance.

A High Degree of Application Flexibility

Steam conditioning requirements and plant operating practices

vary across every industry. Process plants require steady operation

and precise steam temperature control to improve the performance

of downstream equipment such as paper machines or other

auxiliary equipment. Power plants rely on fast response and low

GE’s Masoneilan* FVP* - Foundation

Fieldbus

TM

Positioner Controller

noise performance to cycle their plants and manage turbine trips.

Each of these environments calls for a specific range of operating

criteria, including inlet and outlet pressures, temperature limits,

thermal cycling of equipment, and operating rangeability.

GE’s Masoneilan* SVI* II AP

Advanced Performance Digital Positioner

2 | GE Oil & Gas

Because the SteamForm* valve has a wide range of options, it’s

compatible with all facets of process steam operation, from noise

control to temperature control, fast opening operation to tight

shutoff, and daily start-stop to smooth continuous control. Each

SteamForm* valve solution is designed to meet specific customer

requirements for steam conditioning, ensuring a proper fit and long-

term success in operating performance.

84000 Series

SteamForm* Valve

Page 3

SteamForm* Valves

Pressure Reducing Technology

Pressure reduction through a control valve is associated with a release of energy from the steam

in the form of noise and vibration. Eliminating these undesirable effects of pressure reduction is

the primary design objective of the SteamForm* valve. The design of the SteamForm* valve allows

GE to offer a wide range of cost effective solutions, from single stage Lo-dB* trim to multi-stage

management trim. Each individual valve solution is engineered for optimization , addressing specific

applications needs according to severity and customer specifications.

Lo-dB* Technology

Smooth control and process stability are key requirements of many process control applications.

Critical steam applications are found in pulp & paper mills, specialty chemical plants, oil refineries,

and other industries that use a steady steam supply to drive a downstream process. The challenges

of these applications, typically requiring low to moderate pressure drop control, are easily satisfied by

using drilled hole single stage or double stage low noise (Lo-dB*) trim.

Lo-dB* Cage

For more severe pressure drop applications, the SteamForm* valve can be

equipped with a series of diffusers to provide additional stages of pressure

Diffuser

Expanded

Outlet Area

reduction. These higher pressure drop applications typically include an

expanded valve outlet to accommodate the volumetric expansion of the steam.

In addition to reducing noise, the diffuser design also provides a secondary

benefit as it disrupts the flow path of the high energy jet exiting the valve trim.

This flow transition generates lower noise levels in the downstream pipe, and

produces benifical turbulence to assist with desuperheating.

Low Noise, Energy Management Technology

Single Stage Lo-dB* Trim

84000 Series SteamForm* Valve

Single Stage Lo-dB* with Diffuser

Multiple

Diffusers

3-Stage Lo-dB* Trim

Expanding

Outlet

Higher pressure-drop applications, such as the “bypass-to-condenser”

operations found in power plants, may require a more sophisticated degree of

technology to manage high energy levels through the valve. The SteamForm*

valve’s engineered design results in a valve that is optimized for the application.

So, when it has to handle high amounts of energy, the valve body and outlet

are custom-configured to ensure that flow velocities are acceptable through

the entire desuperheating system.

The management of pressure reduction and volumetric expansion required

in high-energy steam flows is often accomplished with the use of multiple

diffusers. This approach creates a series of gradual expansion areas as the

steam transitions to outlet conditions. The additional diffusers create back

pressure, reducing the amount of pressure drop that is taken across the

controlling surfaces of the trim. This minimizes the amount of wear on the

controlling surfaces, which protects the shutoff integrity and further ensures

long- term, accurate control performance.

84000 Series SteamForm* Valve | 3

Page 4

SteamForm* Valves

Patented Technology

Desuperheating

The desuperheater section of the Masoneilan* SteamForm* valve is designed to reduce the steam temperature

by precisely injecting a finely atomized mist of water into a highly turbulent flow region of the valve. While the

quantity of water required to meet downstream conditions is routinely determined by thermodynamic principals,

the method of water injection is anything but routine.

Variable-Orifice Spray Nozzles

The SteamForm* valve’s design utilizes variable-orifice, spring-loaded spray nozzles to achieve a wide range of

temperature control. During low-flow operation, the spring-loaded nozzles introduce a fine aerosol spray of water

into the steam line by slowly easing the nozzles off of their seat. This ensures proper atomization of the spray

water, even at minimal process flow. As the flow rate increases, the water pressure lifts the nozzle plug further

off the seat and opens the orifice to provide a full conical spray pattern. GE’s spring-loaded nozzles can provide

maximum to minimum CV ratios in excess of 50:1.

The SteamForm* valve’s spray nozzle assembly uses an easy-to-access,

downstream water injection system that keeps costs low and makes

maintenance easy over the life of the valve. Locating the water injection

system downstream of the valve trim eliminates unnecessary thermal

stress on the trim, which simplifies the operation of critical components in

technically demanding applications.

Flow

Profiler

84000 Series SteamForm* Valve

Flow Profiler Technology

Flow Profiler

GE’s patented Flow Profiler feature has been designed to maximize temperature control

performance and protect the surrounding piping system from thermal stress caused by

injecting cold water into hot flowing steam.

Using field-tested technology, the Flow Profiler is sized and positioned to maximize the

effectiveness of the SteamForm* spray nozzles. These nozzles are configured in a radial

injection array, out of the core steam flow path, protecting the desuperheating elements

from the thermal shock of dramatic temperature swings between main steam and spray

water conditions. The Flow Profiler is strategically located to enhance steam turbulence

while permitting effective interaction of the water spray with the entire cross section of

steam flow.

Spring Loaded Conical

Spray Nozzle

Spray Nozzle

84000 Series SteamForm* Valve

Nozzle Assembly

Stand-alone Desuperheaters

GE’s Masoneilan products’ desuperheater uses the SteamForm* valve’s proven Flow Profiler

technology, which reduces the length of downstream piping required for the temperature control sensor installation. The Flow Profiler further reduces the thermal stress on the surrounding

piping system by shifting the process flow heat transfer region to the center of the pipe and

away from the vulnerable pipe wall.

4 | GE Oil & Gas

Masoneilan* Desuperheater with

Optional Lo-dB Plate

Page 5

SteamForm* Valves

High Efficiency Performance

High Rangeability

Many applications use steam conditioning valves to

throttle across a wide range of operating conditions. For

instance, many installations require the SteamForm* valve

to throttle at startup conditions as the plant comes on line

and continue to control as pressure builds up to the plant’s

maximum capacity. Startup duration may be prolonged

and can require the SteamForm* valve to control at

upwards of 50:1 rangeability over this time span. For these

applications, the valve uses multiple stages of pressure

reduction to properly manage the energy letdown, while

preventing excessive noise and vibration across the wide

range of conditions.

Heavy Guiding

Single Stage

Diffuser

Hung Cage

Plug Seating Surface

Lo-dB* Plug

Thermal Cycling

Thermal stress in a process system can lead to severe

damage, including sticking of the control trim, premature

valve wear, and even cracking of surrounding piping under

extreme temperature swings. The SteamForm* valve

utilizes a spring loaded trim design to allow for expansion of the trim within the valve. This design permits the trim to respond to short

term thermal transient conditions and recovers to normal state when the body and trim reach equilibrium. This feature ensures smooth

and accurate trim modulation during all cycles of valve deployment.

Seat Ring Seating Surface

Long-Term Shutoff

To address unwanted energy loss, The SteamForm* valve provides tight shutoff options for ANSI/FCI Class IV and Class V leakage, as well

as MSS-SP-61. To ensure long-term shutoff integrity, the SteamForm* valve has a metal-to-metal interface between the plug and seat

ring. These surfaces are also hardfaced for durability in high temperature service. GE considers this specification to be one of the most

critical for many applications including turbine bypass, as steam leakage directly impacts the efficiency of a plant.

Fast Response and Precision Control

SteamForm* valves can be actuated and accessorized for fast

opening (less than 1 second) in response to a turbine trip to protect the

turbine from undesirable conditions during either startup or an upset

condition. The SteamForm* valve will allow the steam in the system

to bypass the turbine and cycle through the plant as if it were online

during normal operation. This is much better than the undesirable

alternative of tripping the safety valve and venting the steam to

atmosphere.

Adding GE’s Masoneilan* SVI* II AP digital positioner to the

SteamForm* valve provides extreme control accuracy with advanced

response to the slightest change in the input signal. The result is

reduced plant downtime and improved bottom-line return.

84000 Series SteamForm* Valve | 5

Page 6

SteamForm* Valves

Flexible Valve Body Design

Industry Designs

The variations across industries and application-specific operating conditions make customization a

necessity for steam conditioning. The SteamForm* valve’s design can be engineered in angle– and

globe-style configurations, as well as in cast- and forged-body construction. This design flexibility

allows each valve to be custom-fit to our customers’ needs.

Power Industry Designs

Many power industry applications pose greater steam

conditioning challenges due to extreme conditions.

Today’s plants are operating at higher pressures and

higher temperatures, and are cycling on and off daily.

Extreme duty cycling can be very demanding on any steam

conditioning valve, but the SteamForm* valve offers body

configurations to fit high-end trim solutions for these

applications.

For high-end solutions, the SteamForm* valve is available

in upper tier ASME class ratings and advanced 9Cr-Mo-V materials to satisfy cyclical service and

meet the rigors of today’s peaking plants. Thermally compensated trim and multiple pressure

drop staging allows the SteamForm* valve to perform to the demanding specification of modern

power plant operations.

The SteamForm* valve is ideally suited for large pressure-drop applications,

such as turbine bypass, that result in a large change in the steam density.

Each SteamForm* valve body is engineered for expanded outlet options,

so that the change in steam density does not result in excessive velocity

p at any point within the valve. Additionally, each valve is engineered with

an optimized number of spray water nozzles and complimentary spray

water valve to accurately control downstream steam temperature across

conditions ranging from start-up, to normal operation to

turbine trip.

84000 SteamForm*

Globe Style Valve

84000 SteamForm*

Forged Body Valve

Process Industry Designs

Not all plants operate alike, and many process

steam applications, such as those found in pulp and

paper mills or oil refineries, may operate under less

demanding conditions. For these applications, a

compact cast body design is available in both angle

and globe style configurations. For many process

letdown applications, steam is conditioned with only a minor pressure drop to meet the needs of a lower pressure header. An easy-toinstall globe-style SteamForm* valve design can handle these small pressure differential applications.

6 | GE Oil & Gas

Page 7

SteamForm* Valves

Features & Benefits

8

5

9

1

2

3

3

FEATURE

Metal-to-Metal Hardfaced Seating Long-Term, Reliable Tight Shutoff

Multiple Stages of Pressure

Reduction

SVI* II AP Positioner

High Rangeability (Turndown)

Fast Response Bypass System,

Precision Control

ADVANTAGE

4

12

END USER

BENEFIT

Increased Plant Performance &

Efficiency

Smooth Transition Starts &

Ramp-up

Prevents Over-Pressure

1

2

REVENUE ENHANCEMENT

4

5

6

7

8

9

10

11

12

High Performance Actuation Stability and Control Reliability Higher Product Yield

Forged/Cast Angle & Globe

Configurations

Flow Profiler Desuperheater

Technology

Multiple Spray Water Control Valve

Options

Quick Change Trim Option Easy Installation and Maintenance Reduced Downtime

Thermally Compensated Trim

Outlet Area Desuperheating

Spring Loaded Spray Nozzles High Performance Desuperheating

Multi-Stage Designs for High

Pressure Applications

Made to Fit Existing Piping Designs Flexible, Engineered Installation

Reduced Downstream Piping

Requirements and Enhances

Temperature Control

High Performance Control, Cavitation

Elimination

Prevent Thermal Expansion & Trim

Sticking

Protects Critical Trim from Thermal

Shock

Prevents System Vibration Reduced Equipment Damage

Reduced Piping Cost

Longer Trim Life

Protects Trim

Reduces Valve Damage &

Trim Erosion

Protects Downstream Piping &

Equipment from High Temperatures

COST REDUCTION

RISK MITIGATION

84000 Series SteamForm* Valve | 7

Page 8

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth

Phone: +61-8-6595-7018

Fax: +61-8-6595-7299

Melbourne

Phone: +61-3-8807-6002

Fax: +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-5689-3600

Fax: +86-10-5689-3800

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-55-3640-5060

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Masoneilan, SVI, FVP, ValVue, LodB, MARC, ValSpeQ, ValvKeep and ValScope are registered trademarks of the General Electric Company.

Other company names and product names used in this document are the registered trademarks or trademarks of their respective owners.

© 2014 General Electric Company. All rights reserved.

GEA19358A 07/2014

[Formerly Masoneilan BT8400 08/06]

Loading...

Loading...