Page 1

6060 Spine Road

Boulder, CO 80301 USA

T 303 444 2009

F 303 444 9543

Sievers 800 TOC Analyzer Flow Switch Upgrade

(Flow Switch Kit and Firmware 2.12 CBI)

1. Purpose: To describe the mechanical installation for the flow switch, firmware 2.12 CBI

upgrade installation and operation of the flow switch.

2. Scope: This procedure describes the activities required to install the flow switch and

firmware 2.12 CBI in all Model 800 series TOC analyzers. For TURBO analyzers,

this procedure describes the installation and configuration of the flow switch.

Turbo Analyzers will omit the firmware installation section.

3. Materials and Tools:

7/16" open end or adjustable wrench

1/2" open end wrench

Flat head screwdriver

Phillips head screwdriver

Scriber

Teflon® tape

WARNINGS:

• A 60-micron filter must be used to ensure proper operation of the flow switch.

• Do not over tighten any fitting.

• Switch orientation should be no more than 15° from vertical alignment.

• Do not install units near ferrous metals, magnets or electromagnetic fields.

• Please review the enclosed Operation and Maintenance Manual. There have

been features added to the analyzers. These additions are dependent upon

the firmware version and software version currently in use.

GE Analytical Instruments, Inc. ©2005H Page 1 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 2

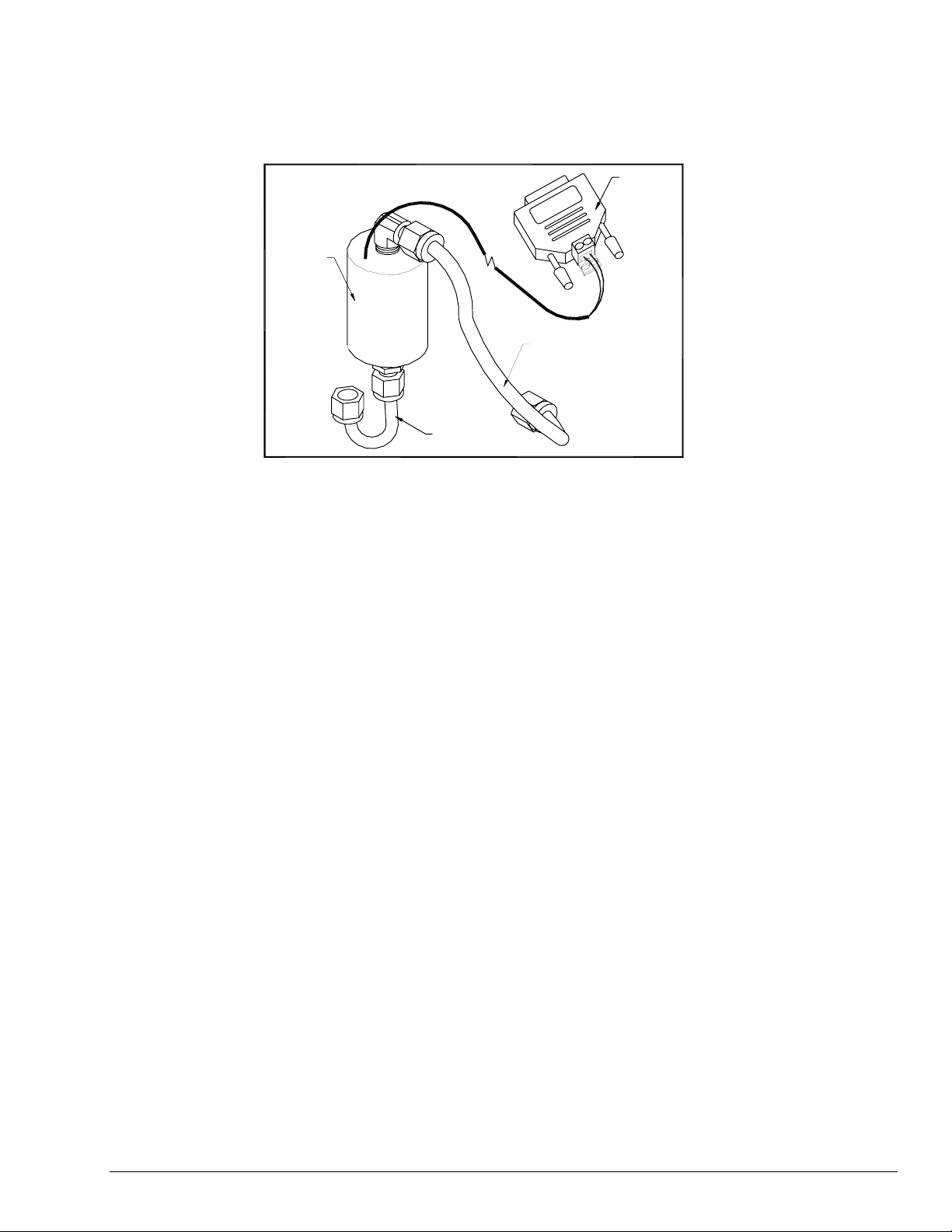

FLOW

SWITCH

4. Mechanical installation

Refer to Figures One or Two for this procedure. Reference will depend on orientation

of tubing from regulator.)

4.1. Remove the outlet PFA tube connector from the pressure regulator of the analyzer.

4.2. Detach the regulator from the analyzer by removing the two screws on the bottom of

the mounting bracket making sure not to lose the fiber spacers.

4.3. Remove the elbow from the outlet side of the regulator and clean the port and

connector threads of any Teflon® tape remains. Reapply 4 wraps of Teflon tape to

the elbow and screw the fitting back into the regulator ending with the tube fitting

pointing down as shown.

4.4. Reinstall the regulator to the analyzer with the two screws making sure to use the

fiber spacers.

4.5. Remove the PFA tube from the inlet of the sampling block.

4.6. Position the flow switch and secure the end of the stainless steel U-tube to the

regulator outlet. Wires must point up to have a calibrated normally open switch.

4.7. Secure the PFA tube from the outlet of the switch to the inlet of the sampling block.

4.8. Connect the wires from the flow switch to the Binary Input Module, polarity not

important to the binary module.

4.9. Route the electrical cable as desired and plug the end into the AUX PORT on the

opposite side of the instrument.

4.10. If installing the switch on a TURBO analyzer, proceed to 6, if not proceed to 5.

PFA

TUBING

STAINLESS

STEEL

TUBING

FIGURE ONE: Flow Switch Kit

BINARY

INPUT

MODULE

GE Analytical Instruments, Inc. ©2005H Page 2 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 3

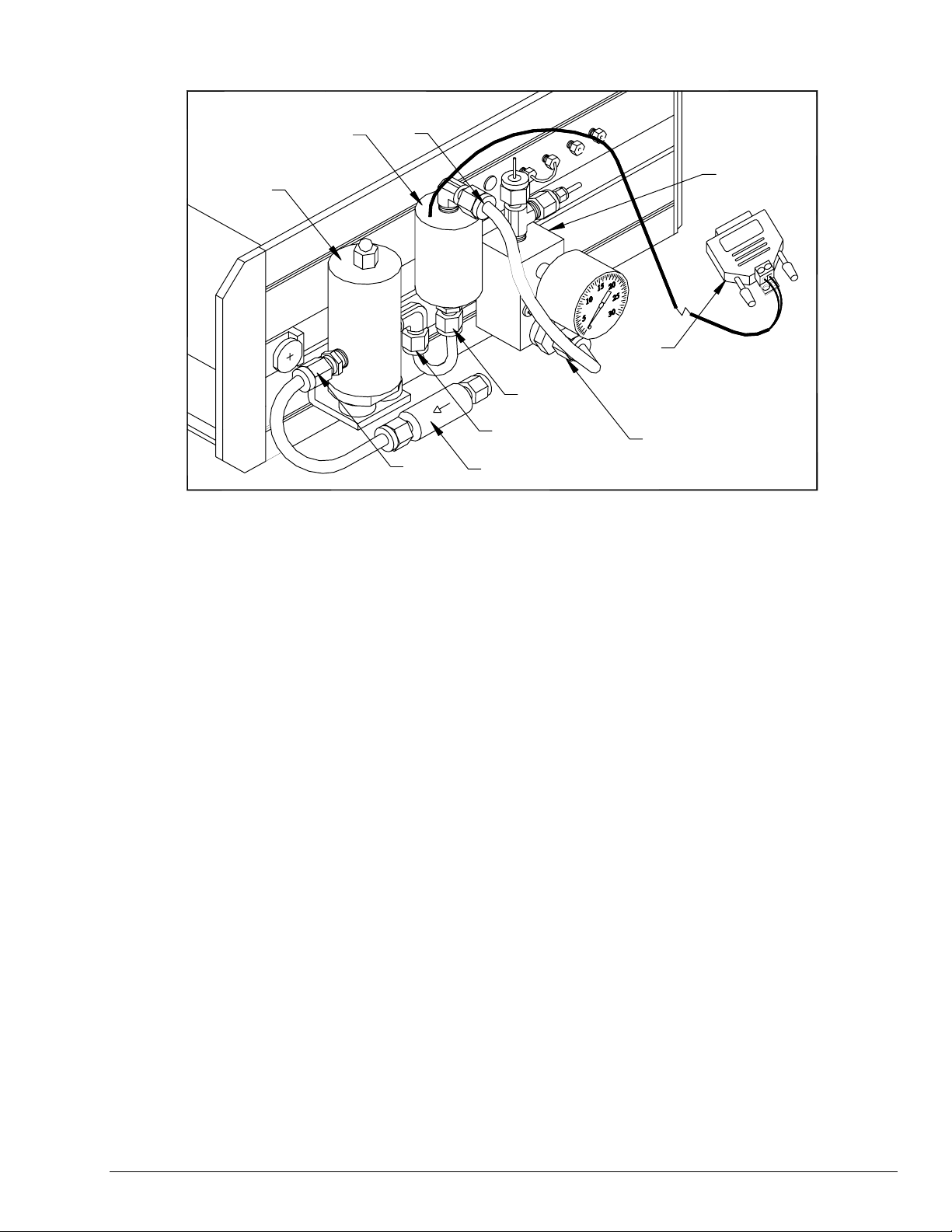

FLOW SWITCH

REGULATOR

FIGURE TWO: Installed Flow Switch on the Model 800 TOC Analyzer

5. Firmware installation

5.1. Print the current constants.

Any IBM compatible dot matrix printer with a parallel printer cable equipped with

a 25pin connection may be used. It is very advantageous to have a printout of the

constant values.

If a printer is not available, go to Step 5.2.

5.1.1. From the RUN-TIME Menu, press STOP TOC.

5.1.2. The MAIN Menu will be displayed select SETUP, press Enter.

5.1.3. Select PRINTER, press Enter.

5.1.4. Select PRINT CONSTANTS, press Enter.

5.2. If a printer is not available, access the FACTORY ACCESS Menu to scroll through and

record constant values on the Constants Record Form within this procedure.

Constant values for C1THERM A, C2THERM A, C1THERM B, AND C2THERM B will be

rounded values. The displayed constant value will differ from the printed constant

value. This should not impact the analyzer’s performance. Contact GE Analytical

Instruments for the last printed Constant Value list, if desired.

5.2.1. From the MAIN menu select CALIBRATE, press Enter.

5.2.2. Select TC ZERO OFFSET, press Enter.

FLOW

SWITCH

OUTLET

REGULATOR

INLET

FLOW

SWITCH

INLET

REGULATOR

OUTLET

60 MICRON FILTER

BINARY

INPUT

MODULE

SAMPLE

BLOCK

INLET

SAMPLING BLOCK

P2

GE Analytical Instruments, Inc. ©2005H Page 3 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 4

A

R

S

P

S

P

R

A

H

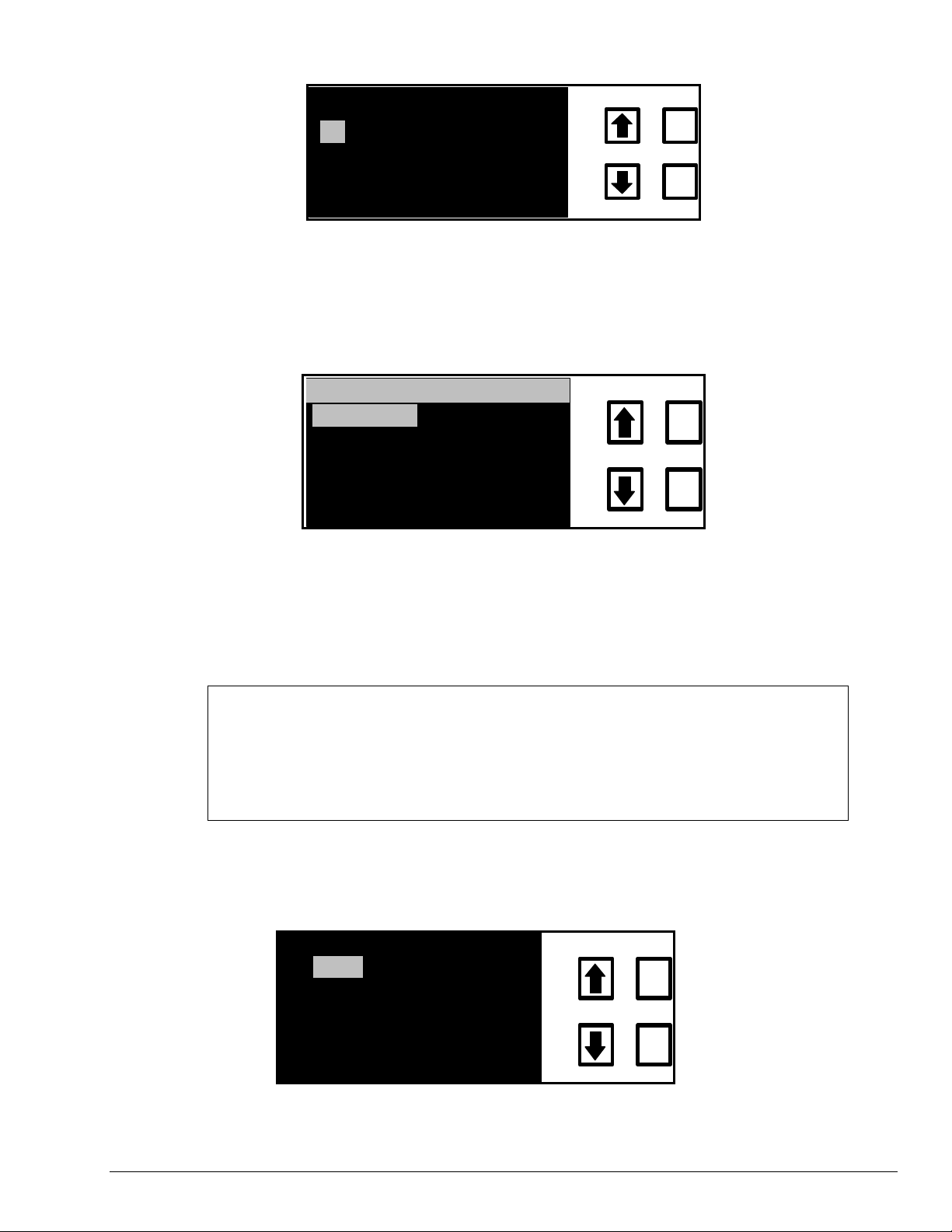

TC ZERO CORRECTION

ENTER

-1.3250000

ENT = SAVE CHAR/NUM

CLR = RESTART/EXIT

RROWS = CHANGE CHA

CLEAR

FIGURE THREE: TOC ZERO OFFSET Screen

5.2.3. Enter 911 by using the arrows, and then press Enter.

ENTERING 911 WILL IN, NO WAY AFFECT THE VALUE OF THE

TC ZERO CORRECTION.

FACTORY ACCESS V. 0.00

ENTER

CLEAR

ERASE ERR

PRNT SETU

SET EEPROM

SYRNGE M OV

SET SYRNGE

SET SERVO

DUMP RAM

SET 4-20MA

SYRNG PUL

FIGURE FOUR: FACTORY ACCESS Menu

5.2.4. Using the arrows, select SETEEPROM, and press Enter.

5.2.5. Constants will be displayed in the sequence listed on the Constants Record

Form. Record each constant value on the form contained within this

document.

IMPORTANT:

It is critical that this Printout or Constants Record Form is retained for

comparison to the Constant Printout or Record Form at end of upgrade

procedure. These Constants will have to be checked and any variations

must be corrected after the upgrade is completed.

5.2.7. Record Dates and Percents for consumables on the Constants Record

Form. These will need to be reentered after upgrade.

5.2.8. From the MAIN MENU select CONSUMABLES, press Enter.

LAM

CID

O XIDIZE

PUMP TUBING

ENTER

CLEAR

REAGENT FLUS

FIGURE FIVE: Consumables Menu

GE Analytical Instruments, Inc. ©2005H Page 4 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 5

N

5.2.9. Select each consumable, press Enter. Write the information on

the Printout or the Constants Record Form. Record date and

percent left for the OXIDIZER. Record the percent left for the

LAMP, PUMP TUBING and ACID.

5.2.10. REAGENT FLUSH is not a consumable to record.

5.2.11. Print or record Errors and Warnings if desired.

5.2.12. Data on the Ram Card will not be erased or affected in any way

upon performing this procedure.

5.3. Replace the EPROM chip (IC chip).

CAUTION:

Prior to performing the following instructions it is essential, to be grounded

according to established procedures. Failure to be properly grounded will

result in damage to the EPROM Chip and void the warranty.

5.3.1. Turn off the analyzer power and disconnect the power cord.

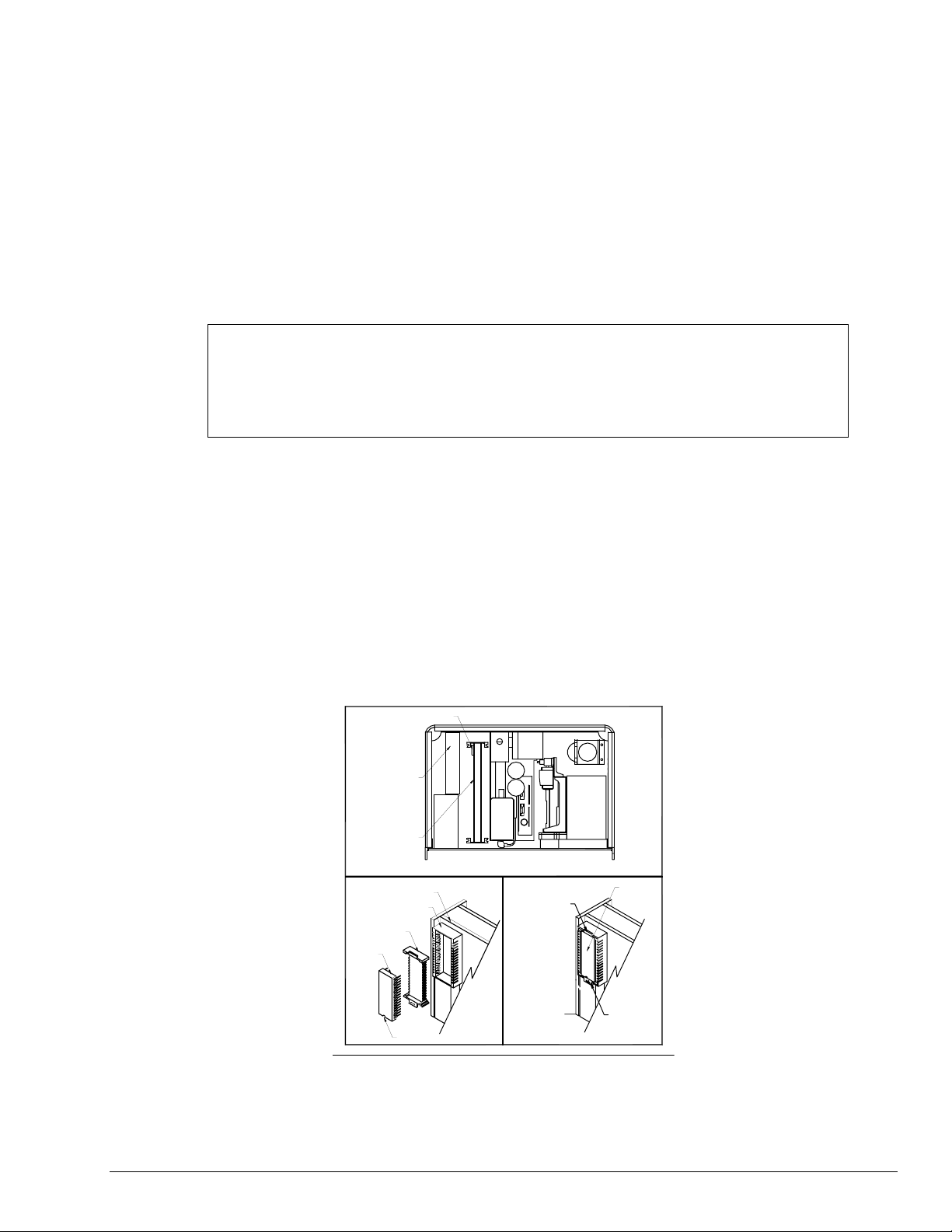

5.3.2. Lift the analyzer cover and locate the PC electronics board, refer to

Figure Six.

5.3.3. Depending on the type of chip holder in the analyzer, different

techniques are required to replace the existing EPROM with the EPROM

labeled 2.12CBI. Facing the analyzer’s front panel, locate the EPROM

socket on the left side of the PC electronics board near the rear of the

analyzer. If the chip socket has a metal lever at the top, it is a Zero

Insertion Force Socket (Step 5.3.4). If the chip socket does not have a

lever, it is a Low Profile Socket (step 5.3.5). Figure Six illustrates the low

profile socket. Use the appropriate instruction to replace the chip.

IC SOCKET

(POWER SUPPLY)

PC BOARD

FRONT OF TOC

RIGHT INDEX

FINGER HERE

LOWER TAB

EPROM

CARRIER

PC BOARD

SOCKET

OTCH

SCREW DRIVER HERE

UPPER TAB

FIGURE SIX: Low Profile Socket Replacement

GE Analytical Instruments, Inc. ©2005H Page 5 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 6

5.3.4. Replace the EPROM from a Zero Insertion Force Socket.

5.3.4.1. There is a small brass lever on the socket to secure the EPROM

chip. It should be in the locked position (end of the lever close to

the PC board).

5.3.4.2. Prior to removing the existing EPROM chip, open the protected

packaging and place the upgrade EPROM chip on the

packaging.

5.3.4.3. To remove the existing chip, hold the EPROM chip with one hand

and unlock the socket with the other by pushing the end of the

lever away from the PC board. Pull the existing EPROM chip

straight out of the socket, note NOTCH position, and place it on

the protected packaging that surrounded the upgrade EPROM

chip.

5.3.4.4. To install the upgrade 2.12CBI EPROM chip in the socket, locate

the NOTCH on the chip and ensure that the notch is facing

down. Align the pins to the socket openings and insert the

EPROM chip in the socket. While pressing on the EPROM chip

push the locking lever to the locked position (toward the PC

board) to secure the EPROM chip in place.

CAUTION:

Be sure the NOTCH of the EPROM chip is toward the bottom of the analyzer

and all the pins are engaged into the socket. Improper or forced installation

will cause irreversible damage to the chip.

5.3.5. Replace the EPROM Chip from a Low Profile type Socket.

5.3.5.1. The EPROM socket consists of two parts, the main socket that is

soldered to the PC board and the keyed carrier for holding the

EPROM chip refer to lower left corner of Figure Six. Note: The

keyed carrier will only go in the socket in one direction.

5.3.5.2. Prior to removing the existing EPROM chip, open the protected

packaging and place the new EPROM chip on the packaging.

5.3.5.3. To remove the existing chip, place the screwdriver at a right

angle on the upper tab of the socket. Once carrier is pried away

from the socket, slide screwdriver under the carrier and rock the

chip and carrier by applying force to the top with your finger

and then with the screwdriver along the length of the carrier.

Pull the chip and carrier from the socket, see lower right corner

of Figure Six. Be sure to pull the chip out straight so as not to

damage the EPROM chip pins.

5.3.5.4. Place the chip and the carrier on the protected packaging that

contained the upgrade chip.

5.3.5.5. To install the upgrade EPROM chip into the carrier, note the

location of the NOTCH of the existing chip and remove it from

the carrier. Replace it with the upgrade chip, ensuring that the

orientation of the NOTCH is the same. If the chip falls from the

GE Analytical Instruments, Inc. ©2005H Page 6 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 7

carrier, gently press the pins of the chip to conform to the

carrier.

CAUTION:

Be sure the NOTCH of the EPROM chip is toward the bottom of the analyzer

and all the pins are engaged into the socket. Improper or forced

installation will cause irreversible damage to the chip.

5.3.5.6. Align the key of the assembly with the key position of the socket

and gently press the EPROM chip and carrier assembly evenly

into the PC board socket until fully inserted. A fully inserted

assembly will be flush with the socket housing on both sides. A

click will be heard when the chip and carrier are firmly in place.

CAUTION:

Do not force the carrier into the socket. If it does not go into the socket,

ensure that the key is in the proper location and the IC chip pins are not

bent.

If the chip and carrier are not properly installed, a blank blue screen will

appear on the front panel display.

5.4. Once the EPROM chip is installed, close the analyzer.

5.4.1. Place the replaced chip in the protected packaging for proper disposal

according to local regulations.

5.4.2. Reconnect the power to the analyzer.

5.5. Turn the analyzer on while depressing the UP arrow.

5.5.1. The analyzer will display message screens. The analyzer will set default

constants, dates, and times.

5.5.2. A screen stating SYSTEM INITIALIZATION IS COMPLETE will appear, press any

key to return to the MAIN Menu.

5.5.3. After all procedures are complete, pressing any key will return the analyzer to

the MAIN Menu.

NOTE:

Following the installation of the new EPROM, the instrument may be ready to

recalibrate the syringes, this process will take 3-4 minutes. Allow the process

to occur. Additionally, a non-fatal error #38 can be expected.

5.6. Print or record the new memory constants by following Step 5.1.

5.6.1. Verify new constant values. There are new constant values to enter and some

variations must be reentered to return the constants to the prior values. Use

the Constants Record Form within this procedure as a guide. To enter constant

values there is limited access to the FACTORY ACCESS menu.

GE Analytical Instruments, Inc. ©2005H Page 7 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 8

R

R

A

R

R

A

S

A

A

R

R

A

CAUTION:

IF THERE ARE ANY VARIATIONS, CONSTANTS MUST BE ENTERED THROUGH

THE FACTORY ACCESS MENU. ACCESS TO THIS MENU IS LIMITED AND WILL

REQUIRE A PASSWORD. ENSURE THAT ACCESS TO THIS MENU IS

RESTRICTED. ANY WRONGFUL DATA ENTRY WILL RESULT IN THE ANALYZER

PERFORMING OUT OF SPECIFICATION!!!

5.6.1.1. From the MAIN menu select SETUP, press Enter.

5.6.1.2. From the SETUP menu, select CALIBRATE, press Enter.

5.6.1.3. Select TC ZERO OFFSET, press Enter.

TC ZERO CORRECTION

ENTE

-1.3250000

ENT = SAVE CHAR/NUM

CLEA

CLR = RESTART/EXIT

RROW S = CHANGE CHA

FIGURE SEVEN: TOC ZERO OFFSET Screen

5.6.1.4. Enter 911 by using the arrows, and then press Enter.

NOTE:

ENTERING 911 WILL IN NO WAY AFFECT THE VALUE OF THE TC ZERO

CORRECTION.

FACTORY ACCESS V. 0.00

ERASE CARD

ERASEERRS

PRNT SETUP

SETEEPROM

COND ZERO

FIGURE EIGHT: FACTORY ACCESS Menu

5.6.1.5. Using the arrows, select SETEEPROM, and press Enter.

5.6.1.6. Constants will be displayed in the same order as the printed or

recorded constants list.

5.6.1.7. Once scrolling through the list has begun, the entire list must be

seen. DO NOT PRESS THE CLEAR KEY. Pressing the Clear key will

result in the erasing of the Constant Value entered. To move up

or down the list use the arrow keys.

NALOG #

FACTMODE

RAW DAT

SET 4-20M

ENTER

CLEA

C1 CONST:

0.800600

ENTE

ENT = CHANGE VALUE

CLR = SET TO DEFAULT

RROW S = NEXT VALUE

GE Analytical Instruments, Inc. ©2005H Page 8 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

CLEA

Page 9

R

R

FIGURE NINE: First Constant Screen

5.6.1.8. Use the Constants Record Form as a guide. If a number is on

the Constants Record Form, the new constant value must be

that value. If the Constants Record Form states “same as prior

value”, change the value to match. If the constants Record

Form states “do not change”, do not change the value.

5.6.1.9. If the value displayed does not have to be changed, press the

UP arrow key to progress to the next constant value on the list.

5.6.1.10. If the value displayed must be changed, press Enter. Use the

arrows to scroll to the first digit/decimal/minus sign, press Enter

to save that character and go to the next.

5.6.1.11. When upgrading Model 810 and Model 820 from very early

Firmware revisions, it is critical to check that the constant

setting for AC FREQUENCY is set to 50. Model 800 must be set to

60. There are some 100 volt analyzers that are 60Hz, in this

case use the C1 XFER. C2 Xfer and TC/IC OFFSET of the

appropriate frequency. The 50 Hz calibration constants are

toward the bottom of the list.

5.6.1.12. Press Enter to save the constant value. Press the Up arrow key

to progress to the next constant value. Press the Down Arrow to

return to previous constant value. Press Clear to return the

constant to its default value.

5.6.1.13. There may be new constants when upgrading, make all

changes as instructed on the Constants Record Form to keep

the analyzer in specification.

5.6.1.14. When the last constant value (LINERARITY VAR.E) has been

verified, the following screen will appear:

END OF EEPRO M LIST

ENTE

EXIT? ENT = Y CLR = N

CLEA

FIGURE TEN: Set EEPROM Exit screen

5.6.1.15. Pressing Enter will return to the MAIN Menu.

5.6.1.16. Pressing Clear will return to the last value of the constant list.

Scroll using the DOWN arrow to change any constant value.

Scroll back to the end of the list to exit. Press Enter to return to

the MAIN Menu.

5.7. From the MAIN Menu, a final configuration must be performed. Before the analyzer

may be used, the flowrates and the sampling mode must be reset. Refer to the user

manual for more a detailed procedure.

5.7.1. Set Clock – From the MAIN Menu, select SETUP. Press Enter. Select CLOCK.

Press Enter. Use the arrow buttons to scroll to each digit option. Press Enter

GE Analytical Instruments, Inc. ©2005H Page 9 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 10

to save digits. After resetting the clock, Warning 35 will occur until the power

has been cycled two times.

5.7.2. Set Flowrates – The Firmware allows selection of different flow rates for on-

line sampling and grab (container) sampling. The grab flow rates can be

viewed and changed from the MAIN – SETUP/REAGENTS menu and from the

GRAB SAMPLING – SETUP/REAGENTS menu. Make sure to view and change

the desired flow rates for the sample mode being used.

5.7.3. From the SETUP menu, choose REAGENTS. From the REAGENTS menu, choose

ONLINE FLOW RATES. Set both reagent flowrates to the desired level. Select

the sampling mode.

5.7.3. From the SETUP menu, choose SAMPLE MODE.

5.7.3.1. Select ON LINE SAMPLING or GRAB SAMPLING. If GRAB SAMPLING is

selected, START TOC will access the GRAB SAMPLING menu, where

additional setup options may be implemented.

5.7.4. Select Frequency, only if AC FREQ. SETTING” is set to 50 for the 810 and 820

analyzers.

5.7.5.1. From SETUP, select 50/60HZ.

5.7.5.2. Select the appropriate Frequency for the analyzer.

5.7.6. Reset Acid/Oxidizer/UV Lamp/Pump Tubing dates and percentages.

5.7.6.1. Select CONSUMABLES from the MAIN Menu, press Enter.

5.7.6.2. Select ACID, OXIDIZER, UV LAMP, or PUMP TUBING, press Enter.

5.7.6.3. For the oxidizer, select SET % LEFT and enter the percent recorded on

the printout or the Constants Record Form. Use the arrow keys to

scroll through digits and press the Enter key to set the digits. Select

SET INSTALL DATE, press Enter. Use the arrow keys to scroll through

digits and press the Enter key to set the digits.

5.7.6.4. For the ACID, LAMP and PUMP TUBING, select SET % LEFT and enter the

percent recorded on the printout or the Constants Record Form. Use

the arrow keys to scroll through digits and press the Enter key to set

the digits.

GE Analytical Instruments, Inc. ©2005H Page 10 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 11

Constants Record

CONSTANT VALUE

NAME

C1 CONST:

C2 CONST:

C1 THERM A:

C2 THERM.A:

C1 THERM B:

C2 THERM B:

C1 THERM C:

C2 THERM C:

C1 XFER (60Hz):

C2 XFER (60Hz):

C1 COND:

C2 COND:

C1 TEMP:

C2 TEMP:

STEPPER 1:

STEPPER 2:

SOAK 1: 300

SOAK 2: 300

FLUSH 1: 60

FLUSH 2: 60

SYRINGE 1: 0.01445

SYRINGE 2: 0.01445

BAUD: 9600

STEPFILL 1: 20000

STEPFILL 2: 20000

STEPZERO: 24

DELAY: 24

CELL1 ZERO: 10

CELL2 ZERO: 10

COND SKIP: 8

A/D NOISE LEVEL: 60

TOC MODE:

PRINTER COLUMS:

PRINTER BREAK: 0

PRINTER TIME: 0

SERVO FILL PULSE:

SERVO DRAIN PULSE:

SLOPE WINDOW: 60

ANALOG MIN:

CONSTANT VALUE AFTER

UPGRADE

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Same as prior value

Analyzer will automatically enter

this value – do not change.

Analyzer will automatically enter

this value – do not change.

Same as prior value

Same as prior value

Analyzer will automatically enter

this value – do not change

Analyzer will automatically enter

this value – do not change

Same as prior value

CONSTANT VALUE PRIOR

TO UPGRADE

GE Analytical Instruments, Inc. ©2005H Page 11 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 12

CONSTANT VALUE

NAME

CONSTANT VALUE AFTER

UPGRADE

CONSTANT VALUE PRIOR

TO UPGRADE

ANALOG MAX:

Same as prior value

TOTAL ACID VOL: 150

TOTAL OXID VOL: 150

ALARM #1 TYPE:

ALARM #2 TYPE:

ALARM #1 LEVEL:

ALARM #2 LEVEL:

Same as prior value

Same as prior value

Same as prior value

Same as prior value

LAMP MAX DAYS: 182

HOSE MAX DAYS: 365

OXID MAX DAYS: 90

HYSTERESIS CNT: 40

TC/IC OFFSET (60Hz):

Same as prior value

SLOPE PPM/HOUR: 5000

S1 TOC ACID FLOW: 0.2

S1 TOC OXID FLOW: 0

S2 TOC ACID FLOW: 0.4

S2 TOC OXID FLOW: 0.2

S3 TOC ACID FLOW: 0.75

S3 TOC OXID FLOW: 0.5

S4 TOC ACID FLOW: 0.75

S4 TOC OXID FLOW:

2.5 or 2.0

same as prior value

REFILL DELAY: 15

SERIAL NUMBER:

Same as prior value

TC TEMP CORR A: 2.03149

TC TEMP CORR B: -0.0593627

TC TEMP CORR C: 0.00101571

TC TEMP CORR D: -5.7161E-06

IC TEMP CORR A: 2.57516

IC TEMP CORR B: -0.0975902

IC TEMP CORR C: 0.00194737

IC TEMP CORR D: -1.34084E-05

DAC RANGE MIN:

DAC RANGE MAX:

Same as prior value

Same as prior value

PRINTOUT INTERVAL: 0

SAMPLE STEPZERO: 100

SAMPLE FLOWRATE:

55 or 71

same as prior value

SYRINGE MAX POINT: 31000

SYRINGE MAX RANGE: 3100

SYRINGE ZERO RANGE: 150

REAGENT FLUSH REPS: 2

NUMBER OF STREAMS: 4

AC FREQ. SETTING:

Same as prior value

GE Analytical Instruments, Inc. ©2005H Page 12 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 13

CONSTANT VALUE

NAME

CONSTANT VALUE AFTER

UPGRADE

CONSTANT VALUE PRIOR

TO UPGRADE

C1 XFER (50Hz):

C2 XFER (50Hz):

TC/IC OFFSET (50Hz):

Same as prior value

Same as prior value

Same as prior value

IC COND.OFFSET: 0

TC COND.OFFSET: 0

LINEARITY VAR.A: 1

LINEARITY VAR.B: 0

LINEARITY VAR.C: 0

LINEARITY VAR.D: 0

LINEARITY VAR.E: 0

Oxidizer Install Date

Oxidizer Percent Left

Acid Install Date

Acid Percent Left

Lamp Install Date

Lamp Percent Left

Pump Install Date

Pump Tubing Percent Left

GE Analytical Instruments, Inc. ©2005H Page 13 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 14

6. Firmware Configuration

It is necessary to configure the binary inputs following the firmware upgrade. Follow these

instructions to configure inputs and select proper polarity.

If more information is required read the Operation and Maintenance Manual concerning

setting up Binary/Digital Inputs. Thoroughly read the chapters on Installation and Operation.

The purpose of the Binary/Digital Input Module is to send a binary/digital signal to the

analyzer that will change operating mode to a PAUSED state.

6.1. Wire the analyzer for binary/digital inputs:

6.1.1. Connect the flow switch to the provided terminal block on the Binary Switch

Module located on the Auxiliary Port, which is on the left side of the analyzer.

6.1.2. Use a continuous closure contact system only. Applying voltage to the Binary

Switch Module may damage the analyzer.

6.1.3. Use either opening in the Binary Switch Module. There is no polarity on the

terminal block.

6.2. Setup the analyzer for binary/digital input:

6.2.1. From the MAIN Menu select SETUP using the up/down arrows.

SETUP

HISTORY

ERRORS

START TOC

CALIBRATE

CONSUMABLES

ENTER

CLEAR

FIGURE ELEVEN: Analyzer’s MAIN Menu

6.2.2. Press Enter.

CLOCK

REAGENTS

PRESETS

SAMPLE MODE

PRINTER

INPUTS

OUTPUTS

PW

UV LAMP

ENTER

CLEAR

FIGURE TWELVE: Analyzer’s SETUP Menu

6.2.3. Select INPUTS by using the up/down arrows. Press Enter.

GE Analytical Instruments, Inc. ©2005H Page 14 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 15

R

A

A

T

T

ENTER

ENABLE/DISABLE

SET POLARITY

CLEA

FIGURE THIRTEEN: Analyzer’s INPUT Menu

6.2.4. Select ENABLE/DISABLE. Press Enter.

DIGITAL INPUT CONTROL

CONTROL IS:

CHANGE TO:

ON

OFF

ENTER

CLEAR

RROWS TO CHANGE

ENT = SET

CLR = EXIT

FIGURE FOURTEEN: DIGITAL INPUT CONTROL screen

6.2.5. The digital input is either in a state of ON or OFF. To change this state, press

the up/down arrows to toggle between the two choices. When the state in the

change is correct, press Enter to set. To allow input, the state must be ON.

Press Clear to return to the INPUT Menu.

ENTER

ENABLE/DISABLE

SET POLARITY

CLEAR

FIGURE FIFTEEN: Analyzer’s INPUT Menu

6.2.6. Select SET POLARITY by using the up/down arrows, press Enter.

DIGITAL INP. POLARITY

RUN WHEN:

CHANGE TO:

OPEN

CLOSED

ENTER

CLEAR

RROWS TO CHANGE

ENT = SE

FIGURE SIXTEEN:

CLR = EXI

DIGITAL INP. POLARITY Screen

6.2.7. The DIGITAL INP. POLARITY is either in a OPEN or CLOSED condition. To change

this condition, press the up/down arrows to toggle between the two

conditions. When the condition is correct, press Enter to set. It is critical to

have the polarity set to the same condition as the switch, whether it is

GE Analytical Instruments, Inc. ©2005H Page 15 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Page 16

normally open or closed. Press Clear twice to return to the INPUT Menu.

6.2.8. Press Clear to return to the MAIN MENU.

The analyzer will function as described in the Operation and Service Manual. When the

switch is activated, and binary/digital signal is received, the analyzer will convert to a

PAUSED mode. This will be noted on the MEASUREMENT DISPLAY screen.

GE Analytical Instruments, Inc. ©2005H Page 16 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

Loading...

Loading...