GE 77000 Brochure

GE Oil & Gas

Masoneilan

*

77000 Series

High Pressure Labyrinth Trim Control Valves

Integrated Smart Engineered

Best Fit Solutions

• Engineering Expertise

• Leading Technology

• Longer Service Life

77000 Series: High-Pressure

Labyrinth Trim Control Valve

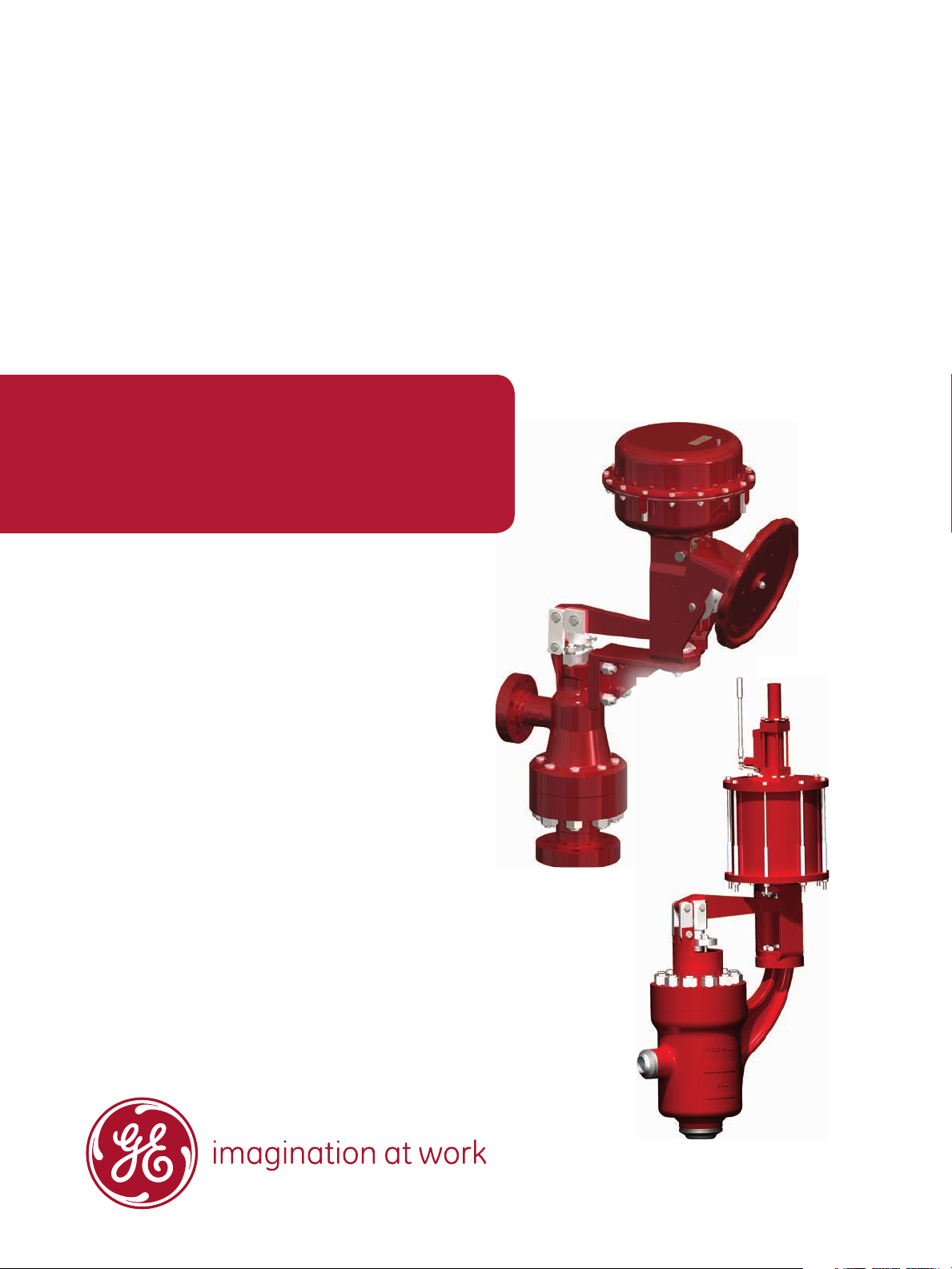

GE’s Masoneilan 77000 Series axial flow, labyrinth trim control

valve combines decades of engineering expertise with leading

technology and in-depth customer application knowledge.

With a multi-stage, expanding area flow passage, the 77000

Series valve is designed to effectively handle difficult pressure

reduction applications while managing noise and vibration

levels that can otherwise severely damage equipment. The

result is smoother process flow and longer service life, which

not only saves time and money, but also mitigates risks in

demanding and crucial applications.

Used across a wide range of process applications, the 77000

Series controls high-pressure compressible fluids without

the erosion, vibration and high noise levels associated with

conventionally designed control valves. The 77000 Series is

also particularly well-suited for service applications involving

two-phase flow for either gas with entrained liquids/solids

or liquids with entrained solids. From upstream oil and gas

production to downstream refining and petrochemical

processing to some of the most severe steam applications in

power generation, the 77000 Series valve stands up to intense

temperatures and high pressures.

Customer Benefits

• Cost savings

• Improved process control

• Increased uptime

• Longer service life

• Maintenance simplicity

• Risk mitigation

Industries and Applications

UPSTREAM OIL AND GAS

High pressure, erosive-choke applications

Steam injection for tar sand oil extraction

DOWNSTREAM OIL AND GAS:

Refining and Petrochemical

High-pressure process control applications

Hot, high pressure separation

Delayed coker letdown

PTA crystallizer blow down

POWER GENERATION

Superheater bypass

Boiler blowdown

2 | GE Oil & Gas

Proven Control

Through Advanced Design

Multi-Stage, Expanding Area

Pressure Reduction

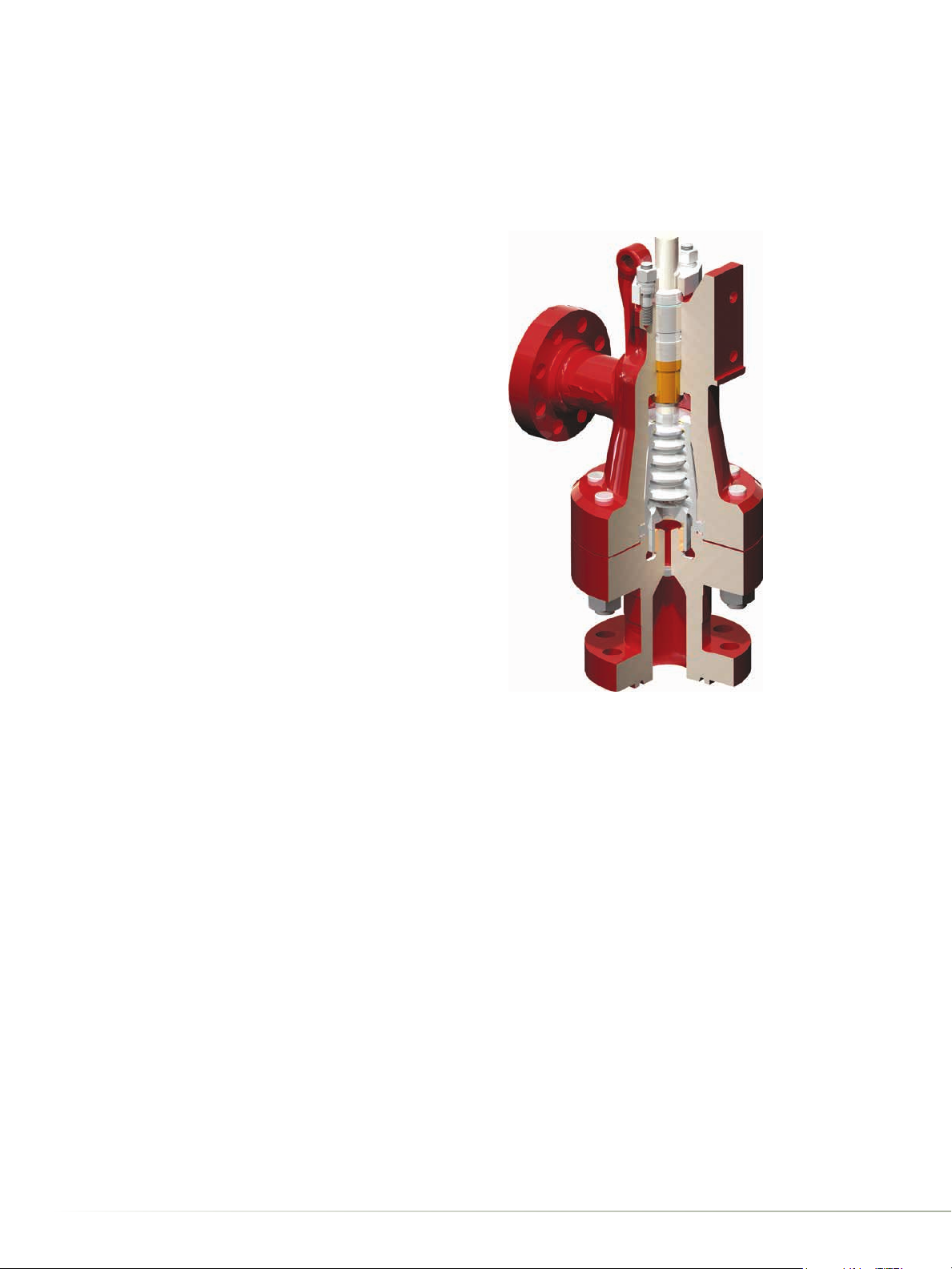

Using proven principles of energy management technology,

the 77000 Series gradually reduces fluid pressure, yielding

dramatically reduced noise and vibration. The product features

a multi-stage trim design that creates flow path friction to

simulate the gradual pressure loss that occurs over long

pipelines. This effect is produced by passing the fluid through a

tortuous flow pattern with multiple restrictions, referred to as

pressure reduction stages. Consequently, energy is dissipated

through high head loss without undesirable shock waves.

By reducing fluid velocity throughout the throttling process, the

77000 Series’ advanced design eliminates the damaging erosive

effects caused by high kinetic energy spikes and vibration.

The unique flow area of the 77000 Series trim gradually

increases at successive trim stages and offers an enlarged

outlet connection. The expanded flow areas are designed

to compensate for the change in gas density resulting from

pressure reduction, thus making the 77000 Series well-suited

for high-pressure-drop off-gassing applications. With more

than 30 years of installed experience, the Masoneilan 77000

Series has performed successfully in some of the most extreme

high-pressure-drop environments. The 77000 Series’ advanced

design results in minimized fluid velocity, which reduces erosion

damage to the trim and downstream process equipment,

particularly in applications—such as wellhead chokes in the oil

and gas industry—that include particulate in the flow stream.

Additionally, the 77000 Series’ low velocity outlet area minimizes

phase transformation process effects. That is an advantage for

many applications that experience flashing or hydrate service

conditions, such as startup valves in supercritical power plants,

hot high-pressure separator letdown valves in refineries, and

gas injection valves in gas extraction plants.

77000 Series - Axial Flow Labyrinth Trim Control Valves | 3

Engineered Features

Axial Flow, Unison Throttling

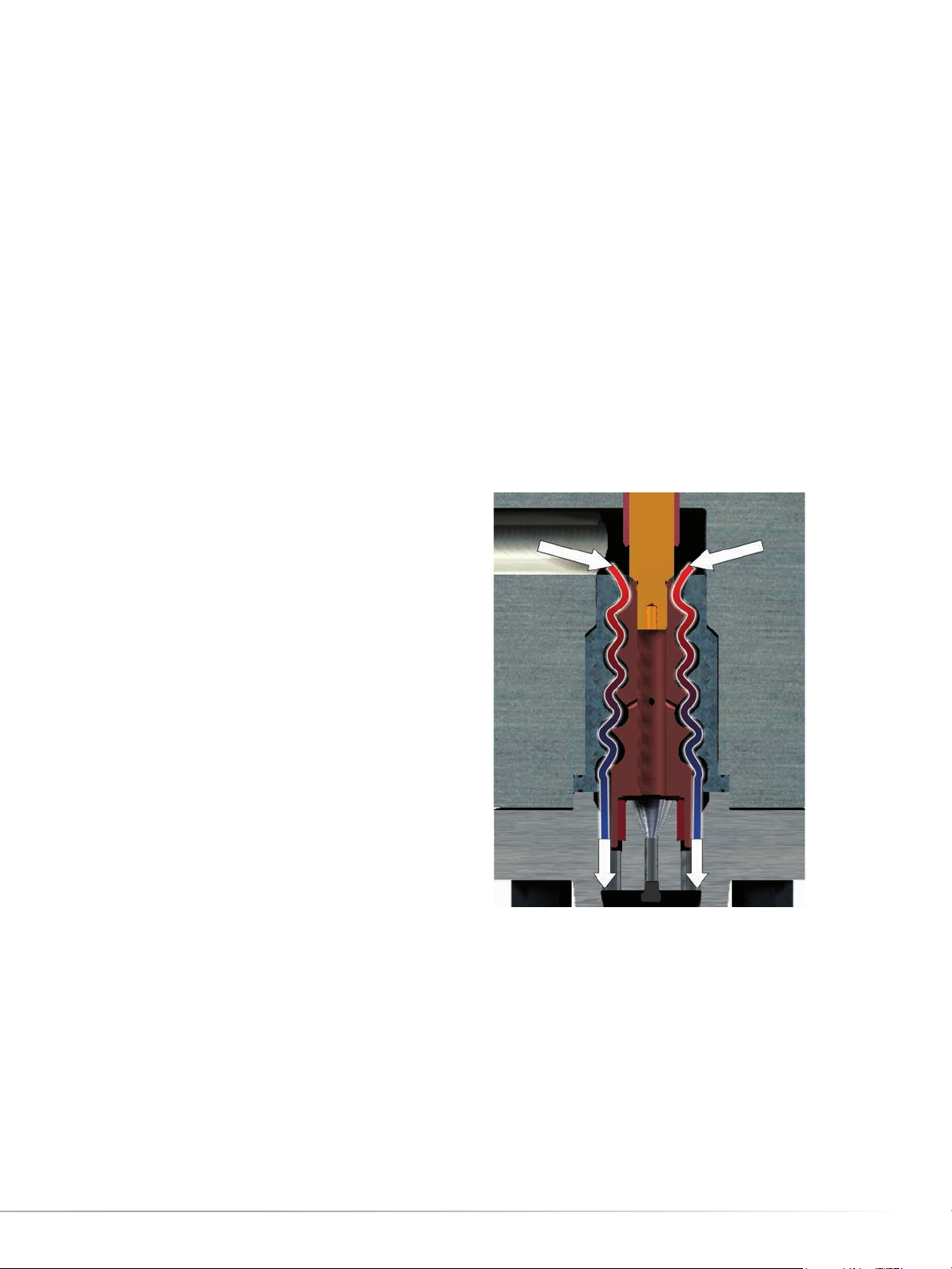

The 77000 Series design separates itself from more conventional

pressure-reducing valves by nature of its multi-stage axial flow

path design. Unlike radial flow path designs, the 77000 Series

throttles the fluid across successively larger stages along the axis

of the valve plug. With up to nine separate stages, the control

valve positions each stage so that they all operate in unison as

the plug strokes, ensuring that the fluid energy is managed in a

controlled manner to avoid cavitation. This design concept avoids

the stair-step performance that can characterize many radial

flow path designs. No single stage or radial flow path trim can

match the performance of the 77000 Series.

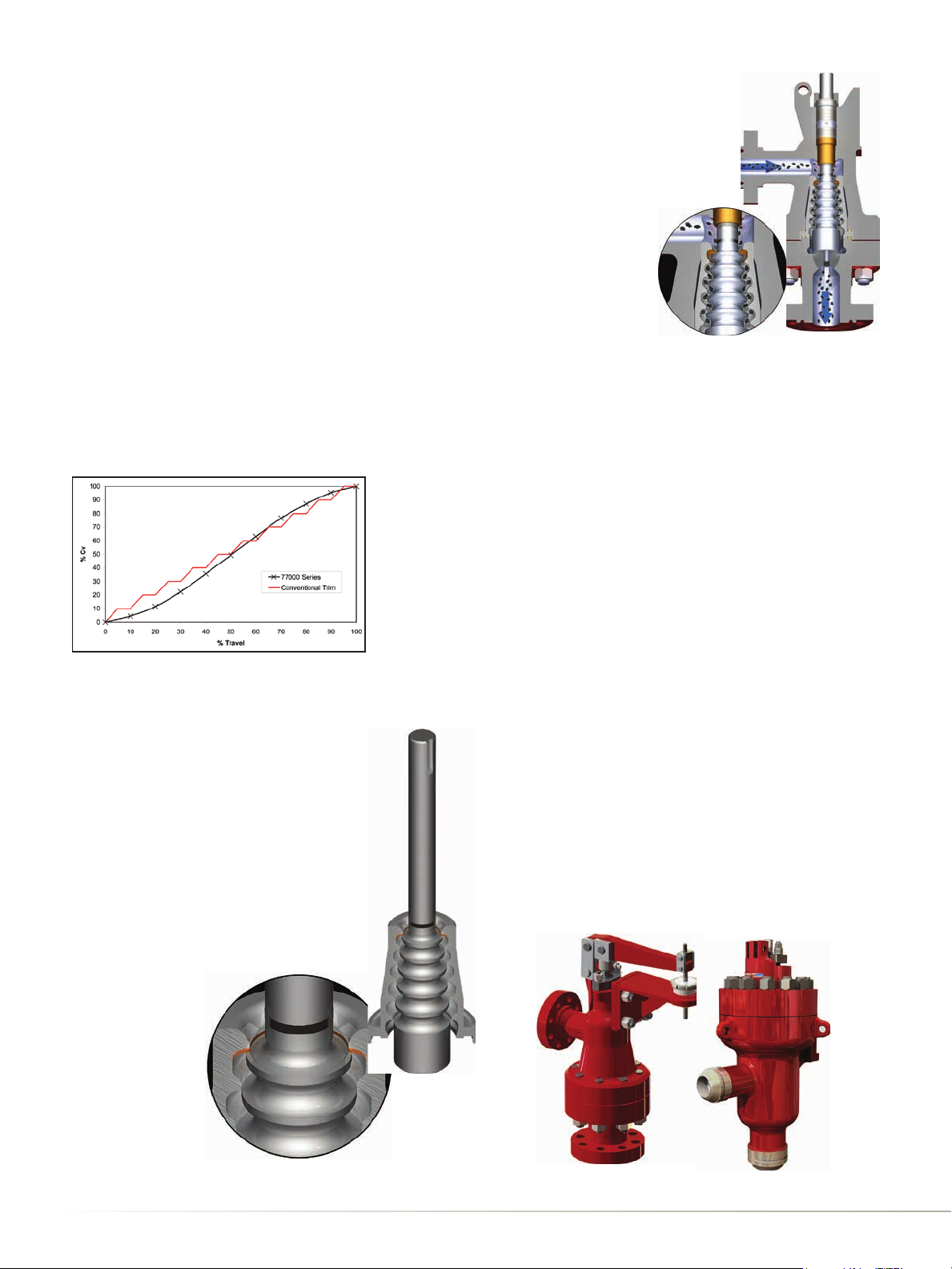

Travel vs C

v

Tight Shutoff, Upstream Seat,

Durable Trim Design

Unbalanced,

Flow-to-Open

Design

The 77000 Series employs

a simple unbalanced plug

design that eliminates any

secondary leak paths that

could compromise shutoff integrity. The resulting high-actuator

loads are managed by using an offset actuator where loading

forces are multiplied by the actuator lever arm. The flow-toopen trim orientation can be useful for applications where

service conditions warrant a reliable failure mode.

Trash-Tolerant, Robust Design

The 77000 Series provides large flow paths that allow for

the passage of flow-entrained particulate, which can clog

conventional drilled-hole or stacked-disk trim. The smooth axial

flow path allows particulate to move through the valve without

navigating complex trim geometry. This prevents plugging

and galling of the trim, which can lead to loss of capacity or

premature valve failure. The 77000 Series has a proven track

record in many high-pressure, dirty-service applications where

a robust valve design delivers essential reliability.

Seat protection in a high-pressure valve

design is critical to prevent premature seat

wear leading to unwanted and undetected

leakage. A damaged valve seat can lead to wire

drawing and eventually to rapid trim damage

from cavitation or flashing when the valve is in

the closed position. Seat damage effects are

minimized in the 77000 Series by locating the

seat on the upstream section of the trim. This

design feature ensures that the seat is isolated

from the most severe and potentially damaging

pressure-reduction

stages, which

are located in the

downstream section

of the trim.

Flexible Platform, Ease-of-Maintenance

The 77000 Series design comes in two styles for easy trim access

in the field. A bottom-loaded, flanged-end connection is ideal

for process plants, while a top-loaded, butt-weld end design

works well in high- pressure power applications. Both styles offer

flex- ibility and simple field maintenance for reduced service

complexity and cost.

4 | GE Oil & Gas

Loading...

Loading...