Page 1

GE Oil & Gas

Technical Specifications

Masoneilan* 77000 Series

High-Pressure Labyrinth

Trim Control Valve

These valves provide high pressure,

compressible fluid control

without the erosion,

04/2013

vibration and high noise associated

with conventional control valves.

Page 2

Table of Contents

Features and Benefits ............................................................................ 2-3

General Data ................................................................................................... 3

Numbering System ....................................................................................... 4

Temperature Range/Seat Leakage ....................................................... 5

Expanding Area Trim Design ....................................................................6

Sizes and Ratings (ANSI Class) .................................................................7

Features and Benefits

GE’s Masoneilan* 77000 series high-pressure labyrinth trim control

valve from GE delivers exceptionally stable control and durable

service life while saving replacement and maintenance costs. It

provides high-pressure, compressible fluid control without the

erosion, vibration, and high noise associated with conventional

control valves.

Ideal for service in multi-phase flow applications, the Masoneilan*

77000 series valve’s advanced energy management trim design

stands up to the damaging and abrasive conditions caused by

entrained liquids/solids or liquids with entrained solids. It features

an expanding area flow passage, and its multiple step plug and

seat ring design creates a beneficial shearing action across each

stage to manage the gradual pressure reduction.

Energy Management Trim

This valve applies the principle of energy management

technology to gradually reduce pressure through the creation of

flow path friction. This simulates the gradual pressure loss that

occurs over long pipelines. By passing the fluid through a number

of restrictions, referred to as pressure reduction stages, the

Masoneilan* 77000 series valve’s tortuous flow pattern dissipates

energy through high head loss rather than through shock waves.

Additionally, the flow area of the trim is gradually increased at

the latter stages of the design to compensate for the volumetric

expansion of the gas caused by the reduction in pressure. This

ensures nearly constant fluid velocity throughout the complete

throttling process and eliminates the damaging effects of high

energy spikes within the trim.

The reduced velocity minimizes the impact of erosion caused

by entrained solids or liquids resulting from a process fluid

phase change. Plus, the acoustical performance of the valve

is optimized through alignment of the pressure drop ratio with

the trim expansion factor. In some cases, downstream Lo-dB

cartridges or custom design trim areas are integrated into the

control valve design for extremely high-pressure drop ratios.

The unique axial flow construction of the Masoneilan* 77000

series valve is optimal for flashing or de-gassing applications.

The axial flow path within the angle body design directs the twophase fluid away from critical surfaces and the downstream pipe

wall.

2 | GE Oil & Gas

Flow Coefficient (Cv) and Expansion Ratio.........................................7

Bottom Entry 77000 Series Material Options ................................. 9

Top Entry 77000 Series Material Options ..................................... 11

Pressure Drop Tables (U.S.) ......................................................... 12-15

Pressure Drop Tables (Metric) .................................................... 16-19

Smooth, Stable Control

The high range (50:1) of this multi-stage valve allows wide

variations in controlled flow. Intermediate pressure flows through

internal plug porting for exceptional control stability. This creates a

balance force within the plug to minimize unbalanced force acting

on the trim.

What’s more, this uniquely balanced trim design has no secondary

balancing seal and only a single point for seat contact.

A toggle design for the actuation system provides high force

amplification through mechanical leverage resulting in stable

control during the throttling phase.

Adding GE’s Masoneilan* SVI* II Advanced Performance positioner

provides further process control, delivering high-precision valve

control and immediate response to the smallest step change in

signal.

Cavitation Elimination

The valve’s multi-stage trim design reduces the pressure drop in

smaller increments without allowing the local pressure at each

stage to drop below the fluid vapor pressure, thus preventing

cavitation. The actively controlled stages of this axial flow

design valve throttle in unison to avoid the adverse effects of an

exaggerated reduction at any single stage.

Dirt Tolerance

Wide flow paths in the trim allow for passage of large particles

entrained within the flow stream that would otherwise cause

damage or loss of capacity. This ensures continuous and efficient

operation by eliminating concerns of potential clogging due to

debris in the flow stream. GE’s Masoneilan* 77000 series valve

offers a proven design for many high-pressure, dirty service

applications, including wellhead choke valves.

Reliable Tight Shutoff

The standard seat design’s leakage rating meets IEC534-4 and

ANSI/FCI 70.2 Class V shutoff requirements. The valve can also be

supplied with block valve tight shutoff to comply with MSS-SP-61

specifications.

Page 3

Features and Benefits

Ease of Maintenance

GE’s Masoneilan* 77000 series valve comes in two design styles

for easy trim access in the field; a bottom-loaded flanged end

connection design and a top-loaded butt-weld end design provide

field maintenance flexibility.

In addition, short valve travel reduces packing wear and

significantly extends packing life, particularly in high-pressure/

high-temperature service.

Enhanced service life is achieved through the trim’s heavy guiding

coupled with the use of hardened materials on the seat and

guiding surfaces.

NACE and PED Compliance

GE’s Masoneilan 77000 series valve is available for sour service

applications using the design and construction methods defined

in NACE standard MR0103. Product configurations for applications

requiring MR0175 – 2003 or ISO 15156 compliance are also

available. In addition, the valve is designed for compliance with

Pressure Equipment Directives (PED) requirements.

Noise Prediction

Valve noise calculations can be performed using GE’s Masoneilan*

sizing and selection program based on the latest IEC equations.

Since noise intensity of a free gas jet varies to the eighth power of

the velocity, a 4:1 reduction in fluid through the expanding area can

reduce the expected noise level approximately 255 times (equivalent

to 24 dB). When predicting the overall noise level produced by the

control valve system, calculations of the noise levels at all stages of

the trim and at the outlet area are all considered.

General Data

Flow Direction

Standard: Flow-to-open

• Body

Type: Cast or forged angle style

Sizes: 1-inch to 8-inch (expanding outlets available) (DN 25

to 200)

Ratings: ANSI Class 600 to 2500 (ISO PN 100 to 420)

API Class 2000 to 10000

End Connections: RF Flange, RTJ flange

Print flanges (forgings only)

BWE and SWE (available for 2-inch and under)

• Bonnet

Type: Bottom entry; bolted outlet spool

Top entry; bolted bonnet

• Body and Bonnet

Materials: Carbon steel

Stainless steel

Chrome-moly

• Trim

Plug type: Multi-stage axial flow

(Trim A, B, C options)

Seat type: Metal seat

Guide: Top and bottom guiding

Cv Ratio: See table (page 7)

Flow Characteristic: Linear

• Actuator

Mounting: Toggle arm mount

Direct mount

Type: Spring-diaphragm

Spring-return cylinder

Double-acting cylinder

Handwheel: Optional

Optional designs are also available, such as larger sizes,

higher pressure ratings, special materials, modified staging,

and other configurations as required. Contact GE for design

details and specifications.

77000 Series High Pressure Labyrinth Trim Control Valves | 3

Page 4

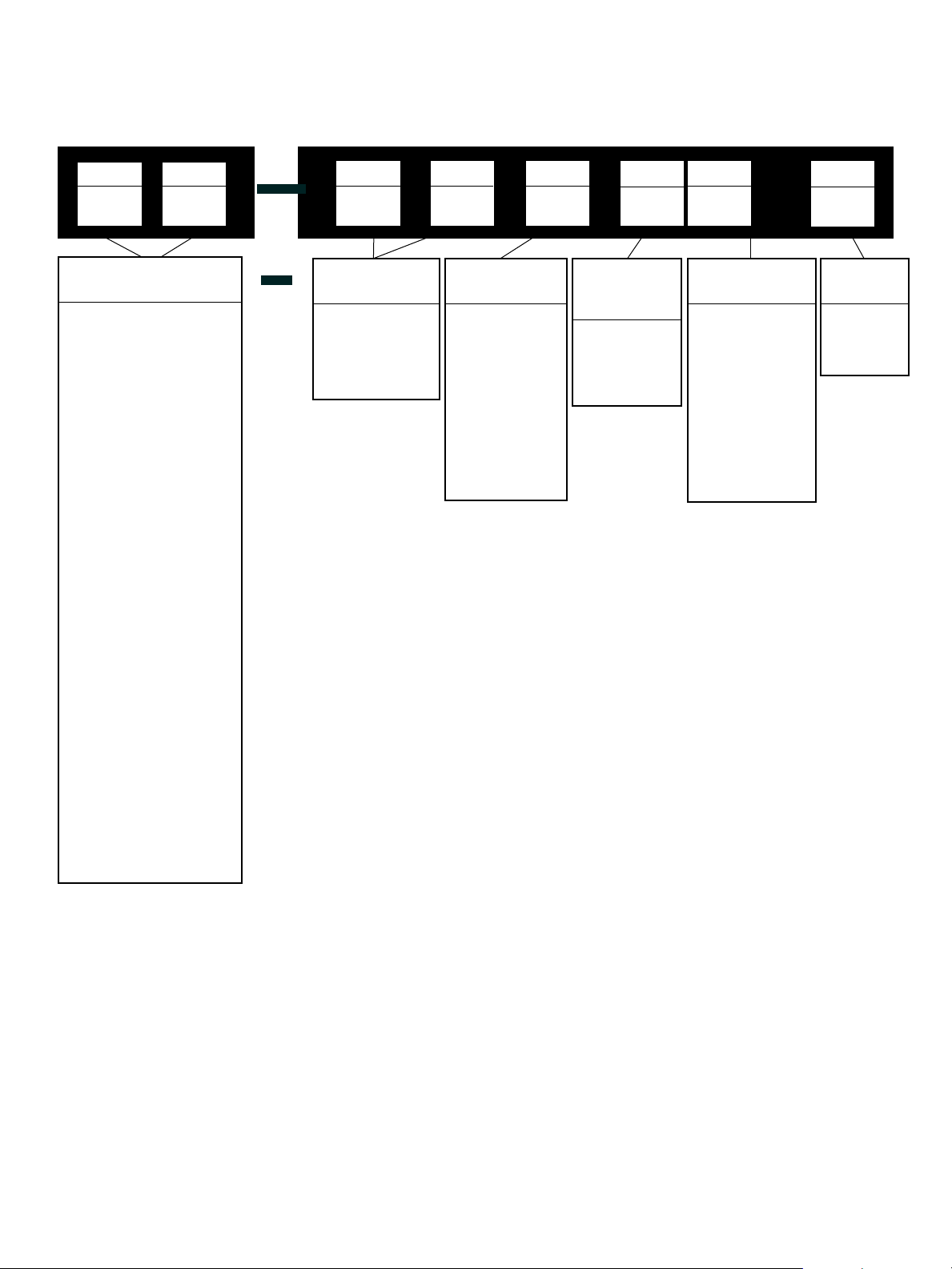

Numbering System

1st 2nd 5th4th3rd2nd

1st

7

Actuator Type

Spring Diaphragm

37 Spring-diaphragm

direct, air to open

(fail close action)

38 Spring-diaphragm

reverse, air to close

(fail open action)

87 Spring-diaphragm

direct, air to open

(fail close action)

88 Spring-diaphragm

reverse, air to close

(fail open action)

Piston Cylinder

77 Multi-stage,

axial flow

labyrinth trim

control valve

Body Series

7

Trim Type

0 Undefined

1 Trim A

unbalanced

2 Trim B

unbalanced

3 Trim C

unbalanced

Trim

Charateristic

0 Undefined

1 Linear

Design

0 Undefined

1 Bottom entry;

outlet spool

design

2 Top entry;

bolted

bonnet

design

6th

Options

F Forged

Body

84 Cylinder: spring return,

direct, air to open,

single or double acting

(fail close action)

85 Cylinder: spring return,

reverse air to close,

single or double acting

(fail open action)

86 Cylinder:

double acting, without

spring, air to open or

air to close action

4 | GE Oil & Gas

Page 5

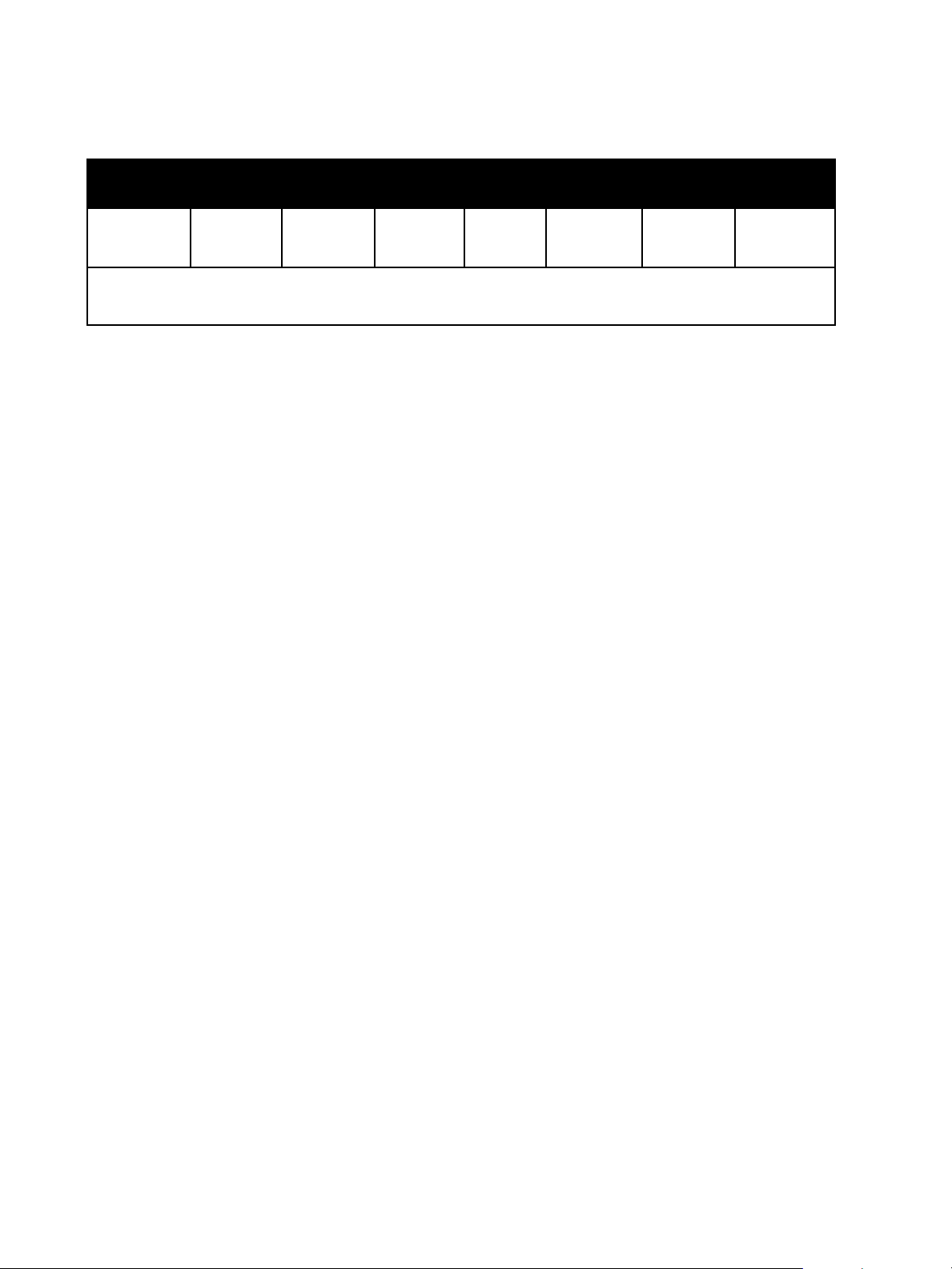

Temperature Range/Seat Leakage

Valve

(3)

Size

1-inch x

2-inch

through

1. Designs for higher or lower temperatures are available. Please consult GE.

2. Seat leakage class ratings per IEC 534-4 and ANSI/FCI 70.2. Class IV is the standard and Class V is optional.

3. Inlet and outlet connections also available with API size ranges.

ANSI

Class

600

through

2500

API

Rating

2000

through

10000

Trim

Typ e

Unbalanced Metal

Seat

Typ e

Temperature Range

Min. Max.

-20° F

(-29° C)

1050° F

(565° C)

(1)

Seat

Leakage

IV

or

V

(2)

77000 Series High Pressure Labyrinth Trim Control Valves | 5

Page 6

Expanding Area Trim Design

The circumference of each pressure reduction stage within

the Masoneilan* 77000 series trim is designed to gradually

increase as flow moves towards the downstream section. This

expansion compensates for the change in gas density with the

pressure and ensures a nearly constant fluid velocity throughout

the complete throttling process, providing the valve with two

advantages:

1. Reduction in noise produced by the fluid velocity

2. Considerable decrease in erosion of the plug and seat liner

caused by particulate in the flow stream or fluid flashing

77000 Series High-Pressure Labyrinth Trim Control Valve

For many applications that experience flashing service

conditions, such as supercritical power plant start-up valves

or hot high-pressure separator letdown in refineries, the

Masoneilan* 77000 series valve provides a low-velocity outlet

area to minimize any effect of the phase transformation process.

Similarly for applications with entrained solids, such as gas

wellhead choke applications, the valve reduces the velocity of

the moving particulate to minimize wear and erosive damage to

the trim and outlet flow area.

Many designs include a larger outlet compared to the inlet size

to retain the low velocity as the fluid exits the valve into the

downstream piping. This arrangement eliminates the need for

additional piping modifications, such as downstream reducers.

6 | GE Oil & Gas

77000 Series Top Entry 77000 Series Bottom Entry

Page 7

Sizes and Ratings (ANSI Class)

¨RF Flange £Socket Weld ¡Threaded uRTJ Flange nButt Weld

Valve

Size (inch)

1

2

3

4

6

8

1) Machined from an ANSI 1500/API 5000 rated body 2) API and special valve connections available upon request

Outlet

Options

1

2

3

2

3

4

3

4

6

4

6

8

6

8

10

8

10

12

ANSI 600(1)

API 2000

¨£¡un ¨£¡un ¨£¡un ¨£¡un

¨£¡un ¨£¡un ¨£¡un ¨£¡un

¨£¡un ¨£¡un ¨£¡un ¨£¡un

¨£¡un ¨£¡un ¨£¡un ¨£¡un

¨£¡un ¨£¡un ¨£¡un ¨£¡un

¨£¡un ¨£¡un ¨£¡un ¨£¡un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

¨un ¨un ¨un ¨un

ANSI 900(1)

API 3000

ANSI 1500(1)

API 5000

ANSI 2500

API 10000

Flow Coefficient (Cv) and Expansion Ratio

Trim Size

Valve Size

(inch)

1

2

3

4

6

8

* Note: Special designs with oversized and reduced Cv trim are available. Please consult GE.

Outlet Options

(Inch)

1

2

3

2

3

4

3

4

6

4

6

8

6

8

10

8

10

12

A B C

Expansion

Ratio

4:1 2 2:1 4 1.5:1 6

4:1 2 2:1 4 1.5:1 6

4:1 2 2:1 4 1.5:1 6

4:1 12 2:1 22 1.5:1 35

4:1 12 2:1 22 1.5:1 35

4:1 12 2:1 22 1.5:1 35

4:1 31 2:1 45 1.5:1 72

4:1 31 2:1 45 1.5:1 72

4:1 31 2:1 45 1.5:1 72

4:1 54 2:1 72 1.5:1 110

4:1 54 2:1 72 1.5:1 110

4:1 54 2:1 72 1.5:1 110

4:1 72 2:1 120 1.5:1 170

4:1 72 2:1 120 1.5:1 170

4:1 72 2:1 120 1.5:1 170

4:1 120 2:1 180 1.5:1 260

4:1 120 2:1 180 1.5:1 260

4:1 120 2:1 180 1.5:1 260

C

v

Expansion

Ratio

C

v

Expansion

Ratio

C

v

77000 Series High Pressure Labyrinth Trim Control Valves | 7

Page 8

8 | GE Oil & Gas

Page 9

Bottom Entry 77000 Series Material Options

Temperature Range

Ref

No.

1 Body

2 Outlet Spool

3 Seat Ring 316 St. St. or 347 St. St. Boronized with Hardfaced Seat

4 Spider 316 St. St. or 347 St. St.

5 Plug Stem 316 St. St. or 347 St. St. Boronized with Hardfaced Seat

6 Stem Guide Bushing Stellite® 6 UNS 30006

7 Lower Spider Gasket 316 St. St. with Flexible Graphite Filler (Spiral Wound) Inconel® with Graphite (Spiral Wound)

8 Upper Spider Gasket 316 St. St. with Flexible Graphite Filler (Spiral Wound) Inconel® with Graphite (Spiral Wound)

9 Body Stud

10 Bonnet /Spool Nut

11 Packing Set Teflon® V-Ring Flexible Graphite

12 Lantern Ring 300 Series Stainless Steel

13 Packing Follower 300 Series Stainless Steel

14 Packing Flange 300 Series Stainless Steel or Chrome Moly

15 Packing Flange Stud

16 Packing Flange Nut

17 Actuator Toggle Bracket ASTM A36 Carbon Steel

18 Bracket Stud

19 Bracket Nut

20 Body Clevis ASTM A36 Carbon Steel

21 Body Clevis Pin 440 C Stainless Steel

22 Body Clevis Retaining Ring ASTM A564 Gr 632

23 Lever ASTM A36 Carbon Steel

24 Stem Pivot Adapter 300 Series Stainless Steel

25 Anti-Rotation Screw 300 Series Stainless Steel

26 Locknut ASTM A194 Gr 8

27 Actuator Link Connector 300 Series Stainless Steel

28 Actuator Link Pin 440 C Stainless Steel

29 Actuator Link Retaining Ring ASTM A564 Gr 632

30 Travel Stop Stud 300 Series Stainless Steel

31 Travel Stop Nut 300 Series Stainless Steel

32 Drive Nut Carbon Steel ASTM A668 CL B or ASTM A2165 Gr WCC

36 Spud Adapter 300 Series Stainless Steel

37

Description Standard Materials and Optional Materials

ASTM A216 WCC Carbon Steel/ASTM A105 Carbon Steel

ASTM A217 WC6 Chrome-Moly/ASTM A182 F11 Chrome-Moly

ASTM A217 WC9 Chrome-Moly/ASTM A182 F22 Chrome-Moly

ASTM A351 CF8M Stainless Steel/ASTM A182 F316 Stainless Steel

ASTM A351 CF8C Stainless Steel/ASTM A182 F347 Stainless Steel

ASTM A216 WCC Carbon Steel/ASTM A105 Carbon Steel

ASTM A217 WC6 Chrome-Moly/ASTM A182 F11 Chrome-Moly

ASTM A217 WC9 Chrome-Moly/ASTM A182 F22 Chrome-Moly

ASTM A351 CF8M Stainless Steel/ASTM A182 F316 Stainless Steel

ASTM A351 CF8C Stainless Steel/ASTM A182 F347 Stainless Steel

(1)

(1)

(1)

(1)

(1)

(1)

Actuator Link Clevis

(Sizes from 1 to 3 inches) ASTM A36 Carbon Steel

ASTM A193 Gr B7

ASTM A194 Gr 2H

304 Stainless Steel ASTM A193 Gr B8 Class 2

304 Stainless Steel ASTM A194 Gr 8

ASTM A193 Gr B7

ASTM A194 Gr 2H

(2)

or ASTM A193 Gr B7M

(2)

or ASTM A19F Gr2HM

(3)

(3)

(2)

or ASTM A193 Gr B7M Nickel Plated

(2)

or ASTM A194 Gr 2HM Nickel Plated

(340°C)

3)

(3)

650°F

800ºF

(427°C)

ASTM A193

Gr B16

ASTM A194

Gr 4

950°F

(510°C)

1050°F

(565°C)

ASTM A453

Gr 660

ASTM A194

Gr 8

Notes:

(1) Studs and Nuts are Nickel or Zinc Plated for use with Stainless Steel Bodies.

(2) Non-Nace and Nace Non-Exposed (Class III)

(3) Nace Exposed (Class I & II)

77000 Series High Pressure Labyrinth Trim Control Valves | 9

Page 10

10 | GE Oil & Gas

Page 11

Top Entry 77000 Series Material Options

Ref

No.

10 Bonnet / Spool Nut

11 Packing Set Teflon® V-Ring Flexible Graphite

12 Lantern Ring 300 Series Stainless Steel

13 Packing Follower 300 Series Stainless Steel

14 Packing Flange 300 Series Stainless Steel or Chrome Moly

15 Packing Flange Stud

16 Packing Flange Nut

17 Actuator Toggle Bracket ASTM A36 Carbon Steel

18 Bracket Stud

19 Bracket Nut

20 Body Clevis ASTM A36 Carbon Steel

21 Body Clevis Pin 440 C Stainless Steel

22 Body Clevis Retaining Ring ASTM A564 Gr 632

23 Lever ASTM A36 Carbon Steel

24 Stem Pivot Adapter 300 Series Stainless Steel

25 Anti-Rotation Screw 300 Series Stainless Steel

26 Locknut ASTM A194 Gr 8

27 Actuator Link Connector 300 Series Stainless Steel

28 Actuator Link Pin 440 C Stainless Steel

29 Actuator Link Retaining Ring ASTM A564 Gr 632

30 Travel Stop Stud 300 Series Stainless Steel

31 Travel Stop Nut 300 Series Stainless Steel

32 Drive Nut Carbon Steel ASTM A668 CL B or ASTM A2165 Gr WCC

33 Seat Ring Retainer 316 St. St. or 347 St. St.

34 Bonnet Gasket 316 St. St. with Flexible Graphite Filler (Spiral Wound) Inconel® with Graphite (Spiral Wound)

35 Lower Guide Bushing RTFE Stellite® 6 UNS 30006

37

38 Conical Spring Inconel 718

Temperature Range

Description Standard Materials and Optional Materials

ASTM A216 WCC Carbon Steel/ASTM A105 Carbon Steel

ASTM A217 WC6 Chrome-Moly/ASTM A182 F11 Chrome-Moly

1 Body

2 Bonnet

3 Seat Ring 316 St. St. or 347 St. St. Boronized with Hardfaced Seat

4 Spider 316 St. St. or 347 St. St.

5 Plug Stem 316 St. St. or 347 St. St. Boronized with Hardfaced Seat

6 Stem Guide Bushing Stellite

7 Lower Spider Gasket 316 St. St. with Flexible Graphite Filler (Spiral Wound) Inconel

8 Upper Spider Gasket 316 St. St. with Flexible Graphite Filler (Spiral Wound) Inconel

9 Body Stud

Actuator Link Clevis

(Sizes from 1 to 3 inches) ASTM A36 Carbon Steel

(1)

(1)

(1)

(1)

(1)

(1)

ASTM A217 WC9 Chrome-Moly/ASTM A182 F22 Chrome-Moly

ASTM A351 CF8M Stainless Steel/ASTM A182 F316 Stainless Steel

ASTM A351 CF8C Stainless Steel/ASTM A182 F347 Stainless Steel

ASTM A216 WCC Carbon Steel/ASTM A105 Carbon Steel

ASTM A217 WC6 Chrome-Moly/ STM A182 F11 Chrome-Moly

ASTM A217 WC9 Chrome-Moly/ASTM A182 F22 Chrome-Moly

ASTM A351 CF8M Stainless Steel/ASTM A182 F316 Stainless Steel

ASTM A351 CF8C Stainless Steel/ASTM A182 F347 Stainless Steel

®

6 UNS 30006

ASTM A193 Gr B7

ASTM A194 Gr 2H

304 Stainless Steel ASTM A193 Gr B8 Class 2

304 Stainless Steel ASTM A194 Gr 8

ASTM A193 Gr B7

ASTM A194 Gr 2H

(2)

or ASTM A193 Gr B7M

(2)

or ASTM A193 Gr 2HM

(3)

(3)

(2)

or ASTM A193 Gr B7M Nickel Plated

(2)

or ASTM A194 Gr 2HM Nickel Plated

650°F

(340°C)

®

w/ Graphite (Spiral Wound)

®

w/ Graphite (Spiral Wound)

(3)

(3)

(427°C)

Notes:

(1) Studs and Nuts are Nickel or Zinc Plated for use with Stainless Steel Bodies.

(2) Non-Nace and Nace Non-Exposed (Class III)

(3) Nace Exposed (Class I & II)

77000 Series High Pressure Labyrinth Trim Control Valves | 11

800°F

950°F

(510°C)

ASTM A193

Gr B16

ASTM A194

Gr 4

ASTM A453

Gr 660

ASTM A194

Gr 8

1050°F

(565°C)

Page 12

77000 Pressure Drop Tables (U.S.)

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class IV

Packing: Graphite

Air to Open Air to Close

Valve

Size

(Inches)

1 0.25 6 0.8 21-45 4855 3435 4609 5797

1 0.25 10 0.8 21-45 7200 5797 7200 7200

1 0.25 16 0.8 21-45 7200 7200 7200 7200

2 0.25 10 1.5 21-45 3058 2159 2899 3652

2 0.25 16 1.5 11-23 2551 3493 4681 5870

2 0.25 23 1.5 11-23 3696 5058 6768 7200

2 0.25 15 1.5 12-30 3101 3884 5203 6522

2 0.25 15 1.5 14-31 3565 3884 5203 6522

3 0.38 10 2.5 21-45 1725 1435 1638 2058

3 0.38 16 2.5 21-45 2783 1971 2652 3319

3 0.38 23 2.5 11-23 2087 2855 3826 4797

3 0.38 18 2.5 12-30 2522 3159 4232 5304

3 0.38 18 2.5 15-33 3159 3159 4232 5304

4 0.50 24 3.5 9-30 2290 3841 5145 6435

4 0.50 24 3.5 18-45 4623 3841 5145 6435

4 0.50 154 3.5 35-50 3246 1435 1884 2348

4 0.50 314 3.5 35-50 6652 2290 3232 4174

6 0.50 24 3.5 19-46 3594 2638 3536 4420

6 0.50 24 3.5 21-49 4275 2638 3536 4420

6 0.50 154 3.5 35-50 2232 1435 1435 1609

6 0.50 314 3.5 35-50 4580 1565 2217 2870

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 154 3.5 (1) (1) (1) (1) (1)

8 1.00 314 3.5 (1) (1) (1) (1) (1)

Plug

Travel

(Inches)

Actuator

Size

Actuator

Travel

(Inches)

Bench

Range

Allowable

Pressure

Drop

(PSI)

Allowable Pressure Drop (PSI)

Bench Range **

Supply Pressure (PSI)

30 35 40

** Spring Diaphragm 3-15 Note (1) Consult GE

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

12 | GE Oil & Gas

Page 13

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class V

Packing: Graphite

Air to Open Air to Close

Valve

Size

(Inches)

1 0.25 6 0.8 21-45 4507 3101 4275 5449

1 0.25 10 0.8 21-45 7200 5449 7200 7200

1 0.25 16 0.8 21-45 7200 7200 7200 7200

2 0.25 10 1.5 21-45 28 41 1957 2696 3435

2 0.25 16 1.5 11-23 2333 3290 4478 5667

2 0.25 23 1.5 11-23 3478 4841 6551 7200

2 0.25 15 1.5 12-30 2884 3681 5000 6304

2 0.25 15 1.5 14-31 3348 3681 5000 6304

3 0.38 10 2.5 21-45 1551 1435 1464 1899

3 0.38 16 2.5 21-45 2623 1812 2478 3159

3 0.38 23 2.5 11-23 1913 2696 3667 4638

3 0.38 18 2.5 12-30 2348 3000 4072 5145

3 0.38 18 2.5 15-33 3000 3000 4072 5145

4 0.50 24 3.5 9-30 2159 3710 5000 6304

4 0.50 24 3.5 18-45 4478 3710 5000 6304

4 0.50 154 3.5 35-50 3101 1435 1754 2217

4 0.50 314 3.5 35-50 6522 2145 3087 4043

6 0.50 24 3.5 19-46 3478 2522 3420 4304

6 0.50 24 3.5 21-49 4159 2522 3420 4304

6 0.50 154 3.5 35-50 2116 1435 1435 1493

6 0.50 314 3.5 35-50 4464 1449 2101 2754

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 154 3.5 (1) (1) (1) (1) (1)

8 1.00 314 3.5 (1) (1) (1) (1) (1)

Plug

Travel

(Inches)

Actuator

Size

Actuator

Travel

(Inches)

Bench

Range

Allowable

Pressure

Drop

(PSI)

Allowable Pressure Drop (PSI)

Bench Range **

Supply Pressure (PSI)

30 35 40

** Spring Diaphragm 3-15 Note (1) Consult GE

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

77000 Series High Pressure Labyrinth Trim Control Valves | 13

Page 14

77000 Pressure Drop Tables (U.S.)

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class IV

Packing: PTFE

Air to Open Air to Close

Valve

Size

(Inches)

1 0.25 6 0.8 21-45 7200 5435 7200 7200

1 0.25 10 0.8 21-45 7200 7200 7200 7200

2 0.25 10 1.5 21-45 4797 3406 4565 5725

2 0.25 16 1.5 11-23 4014 5493 7200 7200

2 0.25 23 1.5 11-23 5797 7200 7200 7200

2 0.25 15 1.5 12-30 4870 6116 7200 7200

2 0.25 15 1.5 14-31 5594 6116 7200 7200

3 0.38 10 2.5 21-45 2493 1768 2377 2986

3 0.38 16 2.5 21-45 4029 2855 3826 4812

3 0.38 23 2.5 11-23 3014 4145 5536 6942

3 0.38 18 2.5 12-30 3652 4580 6130 7200

3 0.38 18 2.5 15-33 4580 4580 6130 7200

4 0.50 24 3.5 9-30 3449 5797 7200 7200

4 0.50 24 3.5 18-45 6957 5797 7200 7200

4 0.50 154 3.5 35-50 4884 2159 2855 3551

4 0.50 314 3.5 35-50 7200 3449 4870 6290

6 0.50 24 3.5 19-46 4754 3493 4667 5841

6 0.50 24 3.5 21-49 5638 3493 4667 5841

6 0.50 154 3.5 35-50 2942 1435 1710 2130

6 0.50 314 3.5 35-50 6043 2072 2928 3783

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 154 3.5 (1) (1) (1) (1) (1)

8 1.00 314 3.5 (1) (1) (1) (1) (1)

Plug

Travel

(Inches)

Actuator

Size

Actuator

Travel

(Inches)

Bench

Range

Allowable

Pressure

Drop

(PSI)

Allowable Pressure Drop (PSI)

Bench Range **

Supply Pressure (PSI)

30 35 40

** Spring Diaphragm 3-15 Note (1) Consult Factory

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

14 | GE Oil & Gas

Page 15

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class V

Packing: PTFE

Air to Open Air to Close

Valve

Size

(Inches)

Plug

Travel

(Inches)

Actuator

Size

Actuator

Travel

(Inches)

Bench

Range

Allowable

Pressure

Drop

(PSI)

Allowable Pressure Drop (PSI)

Bench Range **

Supply Pressure (PSI)

30 35 40

1 0.25 6 0.8 21-45 7130 4899 6768 7200

1 0.25 10 0.8 21-45 7200 7200 7200 7200

2 0.25 10 1.5 21-45 4464 3072 4232 5406

2 0.25 16 1.5 11-23 3681 5174 7029 7200

2 0.25 23 1.5 11-23 5478 7200 7200 7200

2 0.25 15 1.5 12-30 4536 5783 7200 7200

2 0.25 15 1.5 14-31 5261 5783 7200 7200

3 0.38 10 2.5 21-45 2246 1522 2130 2739

3 0.38 16 2.5 21-45 3783 2623 3594 4565

3 0.38 23 2.5 11-23 2783 3899 5304 6696

3 0.38 18 2.5 12-30 3406 4333 5884 7200

3 0.38 18 2.5 15-33 4333 4333 5884 7200

4 0.50 24 3.5 9-30 3246 5594 7200 7200

4 0.50 24 3.5 18-45 6754 5594 7200 7200

4 0.50 154 3.5 35-50 4681 1942 2652 3348

4 0.50 314 3.5 35-50 7200 3232 4667 6087

6 0.50 24 3.5 19-46 4594 3333 4507 5696

6 0.50 24 3.5 21-49 5478 3333 4507 5696

6 0.50 154 3.5 35-50 2783 1435 1565 1986

6 0.50 314 3.5 35-50 5899 1913 2783 3638

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 24 3.5 (1) (1) (1) (1) (1)

8 1.00 154 3.5 (1) (1) (1) (1) (1)

8 1.00 314 3.5 (1) (1) (1) (1) (1)

** Spring Diaphragm 3-15 Note (1) Consult Factory

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

77000 Series High Pressure Labyrinth Trim Control Valves | 15

Page 16

77000 Pressure Drop Tables (Metric)

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class IV

Packing: Graphite

Air to Open Air to Close

Valve

Size

(Inches)

1 6 6 20 21-45 335 237 318 400

1 6 10 20 21-45 497 400 497 497

1 6 16 20 21-45 497 497 497 497

2 6 10 38 21-45 211 149 200 252

2 6 16 38 11-23 176 241 323 405

2 6 23 38 11-23 255 349 467 497

2 6 15 38 12-30 214 268 359 450

2 6 15 38 14-31 246 268 359 450

3 9 10 63 21-45 119 99 113 142

3 9 16 63 21-45 192 136 183 229

3 9 23 63 11-23 144 197 264 331

3 9 18 63 12-30 174 218 292 366

3 9 18 63 15-33 218 218 292 366

4 13 24 88 9-30 158 265 355 444

4 13 24 88 18-45 319 265 355 444

4 13 154 88 35-50 224 99 130 162

4 13 314 88 35-50 459 158 223 288

6 13 24 88 19-46 248 182 244 305

6 13 24 88 21-49 295 182 244 305

6 13 154 88 35-50 154 99 99 111

6 13 314 88 35-50 316 108 153 198

8 25 24 88 (1) (1) (1) (1) (1)

8 25 24 88 (1) (1) (1) (1) (1)

8 25 154 88 (1) (1) (1) (1) (1)

8 25 314 88 (1) (1) (1) (1) (1)

Plug

Travel

(mm)

Actuator

Size

Actuator

Travel

(mm)

Bench

Range

Allowable

Pressure

Drop

(Bar)

Allowable Pressure Drop (Bar)

Bench Range **

Supply Pressure (Bar)

2.1 2.4 2.8

** Spring Diaphragm 3-15 Note (1) Consult Factory

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

16 | GE Oil & Gas

Page 17

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class V

Packing: Graphite

Air to Open Air to Close

Valve

Size

(Inches)

Plug

Travel

(mm)

Actuator

Size

Actuator

Travel

(mm)

Bench

Range

Allowable

Pressure

Drop

(Bar)

Allowable Pressure Drop (Bar)

Bench Range **

Supply Pressure (Bar)

2.1 2.4 2.8

1 0.25 6 20 21- 45 311 214 295 376

1 0.25 10 20 21-45 497 376 497 497

1 0.25 16 20 21-45 497 497 497 497

2 6 10 38 21-45 196 135 186 237

2 6 16 38 11-23 161 227 309 391

2 6 23 38 11-23 240 334 452 497

2 6 15 38 12-30 199 254 345 435

2 6 15 38 14-31 231 254 345 435

3 9 10 63 21-45 107 99 101 131

3 9 16 63 21-45 181 125 171 218

3 9 23 63 11-23 132 186 253 320

3 9 18 63 12-30 162 207 281 355

3 9 18 63 15-33 207 207 281 355

4 13 24 88 9-30 149 256 345 435

4 13 24 88 18-45 309 256 345 435

4 13 154 88 35-50 214 99 121 153

4 13 314 88 35-50 450 148 213 279

6 13 24 88 19-46 240 174 236 297

6 13 24 88 21-49 287 174 236 297

6 13 154 88 35-50 146 99 99 103

6 13 314 88 35-50 308 100 145 190

8 25 24 88 (1) (1) (1) (1) (1)

8 25 24 88 (1) (1) (1) (1) (1)

8 25 154 88 (1) (1) (1) (1) (1)

8 25 314 88 (1) (1) (1) (1) (1)

** Spring Diaphragm 3-15 Note (1) Consult Factory

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

77000 Series High Pressure Labyrinth Trim Control Valves | 17

Page 18

77000 Pressure Drop Tables (Metric)

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class IV

Packing: PTFE

Air to Open Air to Close

Valve

Size

(Inches)

1 6 6 20 21-45 497 375 497 497

1 6 10 20 21-45 497 497 497 497

2 6 10 38 21-45 331 235 315 395

2 6 16 38 11-23 277 379 497 497

2 6 23 38 11-23 400 497 497 497

2 6 15 38 12-30 336 422 497 497

2 6 15 38 14-31 386 422 497 497

3 9 10 63 21-45 172 122 164 206

3 9 16 63 21-45 278 197 264 332

3 9 23 63 11-23 208 286 382 479

3 9 18 63 12-30 252 316 423 497

3 9 18 63 15-33 316 316 423 497

4 13 24 88 9-30 238 400 497 497

4 13 24 88 18-45 480 400 497 497

4 13 154 88 35-50 337 149 197 245

4 13 314 88 35-50 497 238 336 434

6 13 24 88 19-46 328 241 322 403

6 13 24 88 21-49 389 241 322 403

6 13 154 88 35-50 203 99 118 147

6 13 314 88 35-50 417 143 202 261

8 25 24 88 (1) (1) (1) (1) (1)

8 25 24 88 (1) (1) (1) (1) (1)

8 25 154 88 (1) (1) (1) (1) (1)

8 25 314 88 (1) (1) (1) (1) (1)

Plug

Travel

(mm)

Actuator

Size

Actuator

Travel

(mm)

Bench

Range

Allowable

Pressure

Drop

(Bar)

Allowable Pressure Drop (Bar)

Bench Range **

Supply Pressure (Bar)

2.1 2.4 2.8

** Spring Diaphragm 3-15 Note (1) Consult GE

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

18 | GE Oil & Gas

Page 19

Leakage: Per IEC 534-4 and ANSI/FCI 70.2 Class V

Packing: PTFE

Air to Open Air to Close

Valve

Size

(Inches)

Plug

Travel

(mm)

Actuator

Size

Actuator

Travel

(mm)

Bench

Range

Allowable

Pressure

Drop

(Bar)

Allowable Pressure Drop (Bar)

Bench Range **

Supply Pressure (Bar)

2.1 2.4 2.8

1 6 6 20 21-45 497 338 467 497

1 6 10 20 21-45 497 497 467 497

2 6 10 38 21-45 308 212 292 373

2 6 16 38 11-23 254 357 485 497

2 6 23 38 11-23 378 497 497 497

2 6 15 38 12-30 313 399 497 497

2 6 15 38 14-31 363 399 497 497

3 9 10 63 21-45 155 105 147 189

3 9 16 63 21-45 261 181 248 315

3 9 23 63 11-23 192 269 366 462

3 9 18 63 12-30 235 299 406 497

3 9 18 63 15-33 299 299 406 497

4 13 24 88 9-30 224 386 497 497

4 13 24 88 18-45 466 386 497 497

4 13 154 88 35-50 323 134 183 231

4 13 314 88 35-50 497 223 322 420

6 13 24 88 19-46 317 230 311 393

6 13 24 88 21-49 378 230 311 393

6 13 154 88 35-50 192 99 108 137

6 13 314 88 35-50 407 132 192 251

8 25 24 88 (1) (1) (1) (1) (1)

8 25 24 88 (1) (1) (1) (1) (1)

8 25 154 88 (1) (1) (1) (1) (1)

8 25 314 88 (1) (1) (1) (1) (1)

** Spring Diaphragm 3-15 Note (1) Consult GE

Piston Cylinder 154/10-14

Piston Cylinder 314/12-18

77000 Series High Pressure Labyrinth Trim Control Valves | 19

Page 20

DIRECT SALES OFFICE LOCATIONS

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-5689-3600

Fax: +86-10-5689-3800

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-55-3640-5060

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH and CENTRAL

AMERICA and the CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Trademark of G eneral Elect ric Company

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2014 General Ele ctric Compa ny. All rights res erved.

GEA20210A 07/2014

Loading...

Loading...