Page 1

TINSEA517JBRZ 49-7594-1 10-08 JR

Air Conditioners

Safety Instructions . . . . . . . . . . .2

Operating Instructions

Controls—Dip Switches . . . . . . . . .3–5

Controls—Terminal

Connections . . . . . . . . . . . . . . . . . . .6, 7

On/Off Switch . . . . . . . . . . . . . . . . . . . .8

Ventilation Control . . . . . . . . . . . . . . . .8

Care and Cleaning

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . .9

Base Pan . . . . . . . . . . . . . . . . . . . . . . . . .9

Exhaust Coils . . . . . . . . . . . . . . . . . . . . .9

Installation Instructions

Electrical Supply . . . . . . . . . . . . .11–13

Installing the Zoneline . . . . . . .14–21

Preparation . . . . . . . . . . . . . . . . . . . . .10

Servicing . . . . . . . . . . . . . . . . . . . . . . . .22

Troubleshooting Tips . . . . . . .23

Normal Operating Sounds . . . . . . .24

Consumer Support

Consumer Support . . . . . .Back Cover

Warranty . . . . . . . . . . . . . . . . . . . . . . .27

Cool Only, Heat/Cool and

Heat Pump Models

7500 Series

Owner’s Manual and

Installation Instructions

ge.com

Write the model and serial

numbers here:

Model # __________________

Serial # __________________

Find these numbers on a label

on the front case panel.

Zoneline

®

Vertical

Printed in China

Page 2

Consumer Support Troubleshooting Tips Care and Cleaning Operating Instructions Safety Instructions

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire, electric

shock, or to prevent property damage, personal injury, or loss of life.

■ This Zoneline must be properly installed

in accordance with the Installation

Instructions before it is used.

See the Installation Instructions

in the back of this manual.

■ Replace immediately all electric service

cords that have become frayed or

otherwise damaged. A damaged power

supply cord must be replaced with

a new power supply cord obtained

from the manufacturer and not repaired.

Do not use a cord that shows cracks

or abrasion damage along its length

or at either the plug or connector end.

■ Product must be operated with

the electrical plug supplied with the

product. Do not replace the electrical

plug supplied with the product.

■ If the receptacle does not match the plug,

the receptacle must be changed out by

a qualified electrician.

■ Unplug or disconnect the Zoneline

at the fuse box or circuit breaker before

making any repairs.

NOTE: We strongly recommend that

any servicing be performed by a qualified

individual.

■ All air conditioners contain refrigerants,

which under federal law must be

removed prior to product disposal.

If you are getting rid of an old product

with refrigerants, check with the

company handling disposal about

what to do.

SAFETY PRECAUTIONS

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

2

Page 3

Safety Instructions Operating Instructions Care and Cleaning Troubleshooting Tips Consumer Support

3

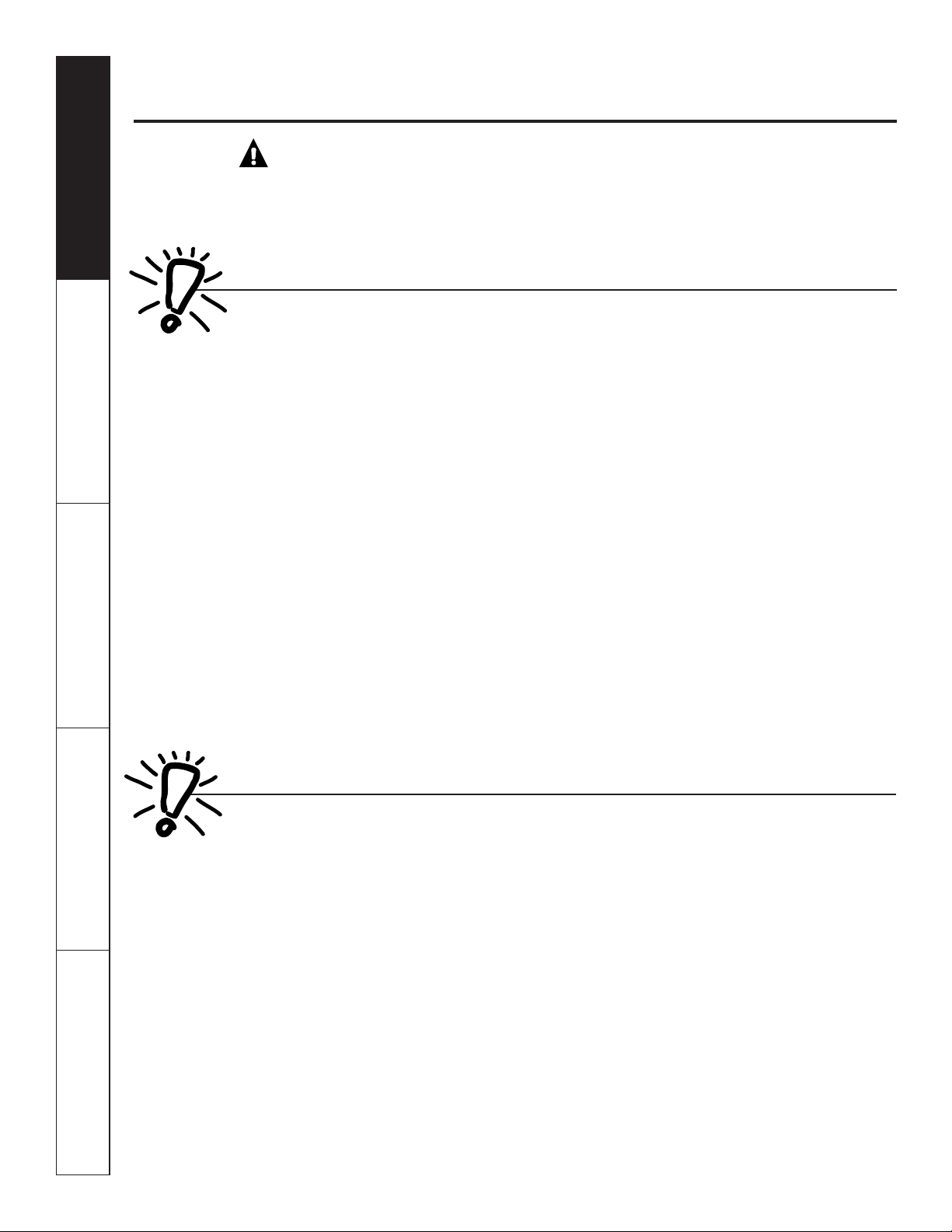

Controls–dip switches. ge.com

The dip switch controls are located behind

the front case panel, through an opening

on the front of the unit.

To access the dip switches, remove the front

case panel by removing the filter, taking out

the four front screws, the upper two screws from

the top of the panel and the shipping screws on

each side, if present. (Discard the two side shipping

screws, if present).

NOTE: The owner is responsible for setting

the appropriate dip switches and connecting

terminals.

Controls–Dip Switches

Dip

Switches

All Electric Heat (Heat pump models only)

When this switch is enabled (UP), heat pump

operation is locked out, causing the unit to provide

only electric resistance heat.

ALL I2R (All Electric Heat)

ALL I2R (All Electric Heat) (Heat-pump models only)

FREEZ S (Freeze Sentinel)

CONST FAN (Constant ON Fan)

TL1 (H) (Temp. Limit 1–Heat)

TL2 (H) (Temp. Limit 2–Heat)

TL3 (H) (Temp. Limit 3–Heat)

TL1 (C) (Temp. Limit 1–Cool)

TL2 (C) (Temp. Limit 2–Cool)

TL3 (C) (Temp. Limit 3–Cool)

No Function (Reserved for future use)

DUCT (Blower Fan)

OCCUPIED (Occupancy Sensor)

Side

shipping

screw

Side

shipping

screw

Page 4

Consumer Support Troubleshooting Tips Care and Cleaning Operating Instructions Safety Instructions

4

Controls–dip switches.

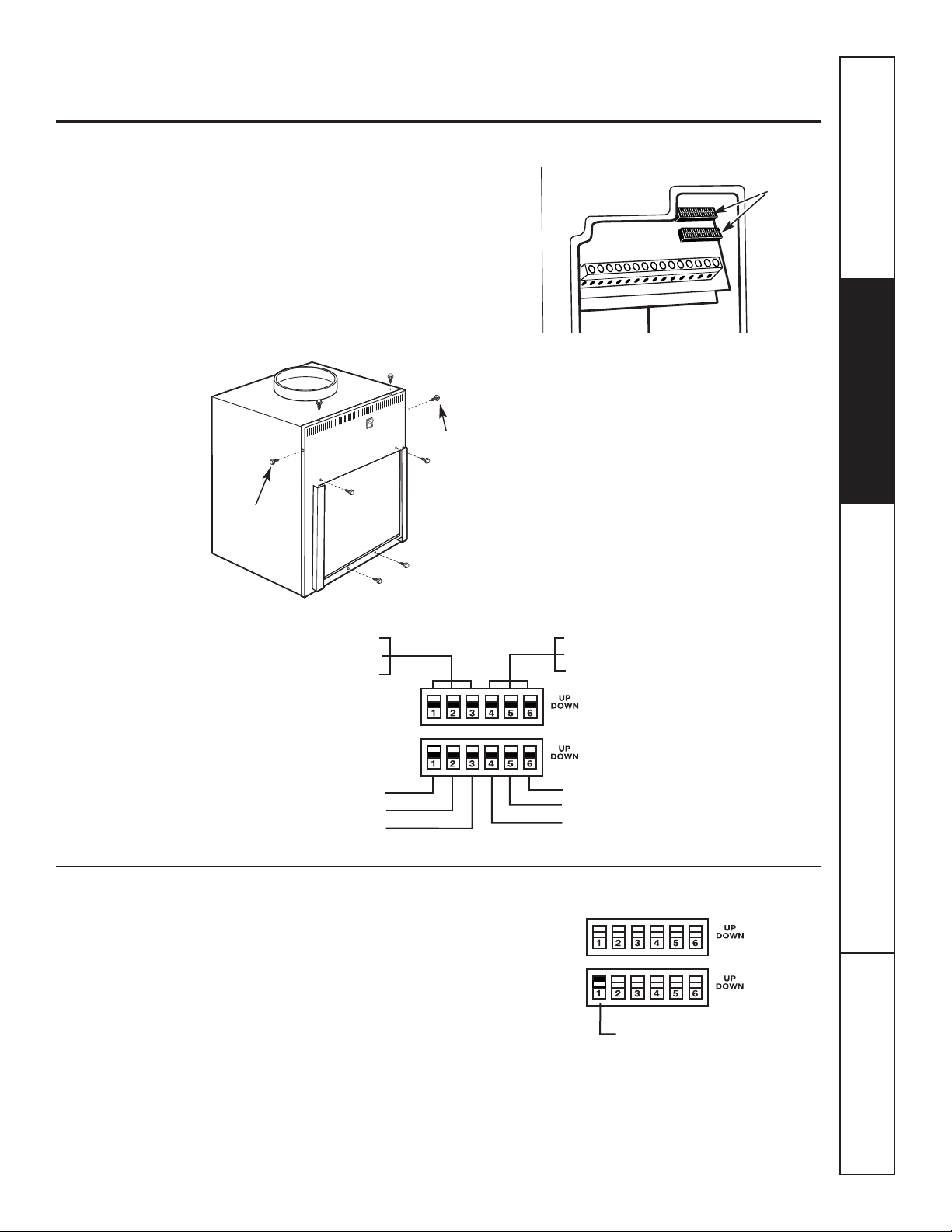

Freeze Sentinel (Requires room air sensor kit–RAVRMS)

When this switch is enabled (UP), it turns OFF

the freeze sentinel protection feature. With the

switch disabled (DOWN), the freeze sentinel is

activated which automatically provides heat

without user interface. This helps to prevent

plumbing damage by turning the heater

and fans ON at 41° F and OFF at 46° F.

Constant ON Fan

When this switch is enabled (UP), it allows the fan

to run continuously.

Occupancy Sensor

When this switch is enabled (UP), it allows the unit

to utilize an infrared motion sensor and a door

switch for occupancy detection. This feature

allows an energy management system

to be installed and operated in conjunction

with the unit.

FREEZE S (Freeze Sentinel)

CONST FAN (Constant

ON Fan)

OCCUPIED

(Occupancy Sensor)

Duct

The duct select function allows the indoor

fan to be operated at two variable fan speeds.

When this switch is enabled (UP), the unit

automatically selects either high or middle fan

speed (for longer ductwork applications). When set

in the down position, the unit is automatically

operated in either the middle or low fan speed

(for shorter ductwork applications).

DUCT

(Blower Fan)

Page 5

5

Safety Instructions Operating Instructions Care and Cleaning Troubleshooting Tips Consumer Support

ge.com

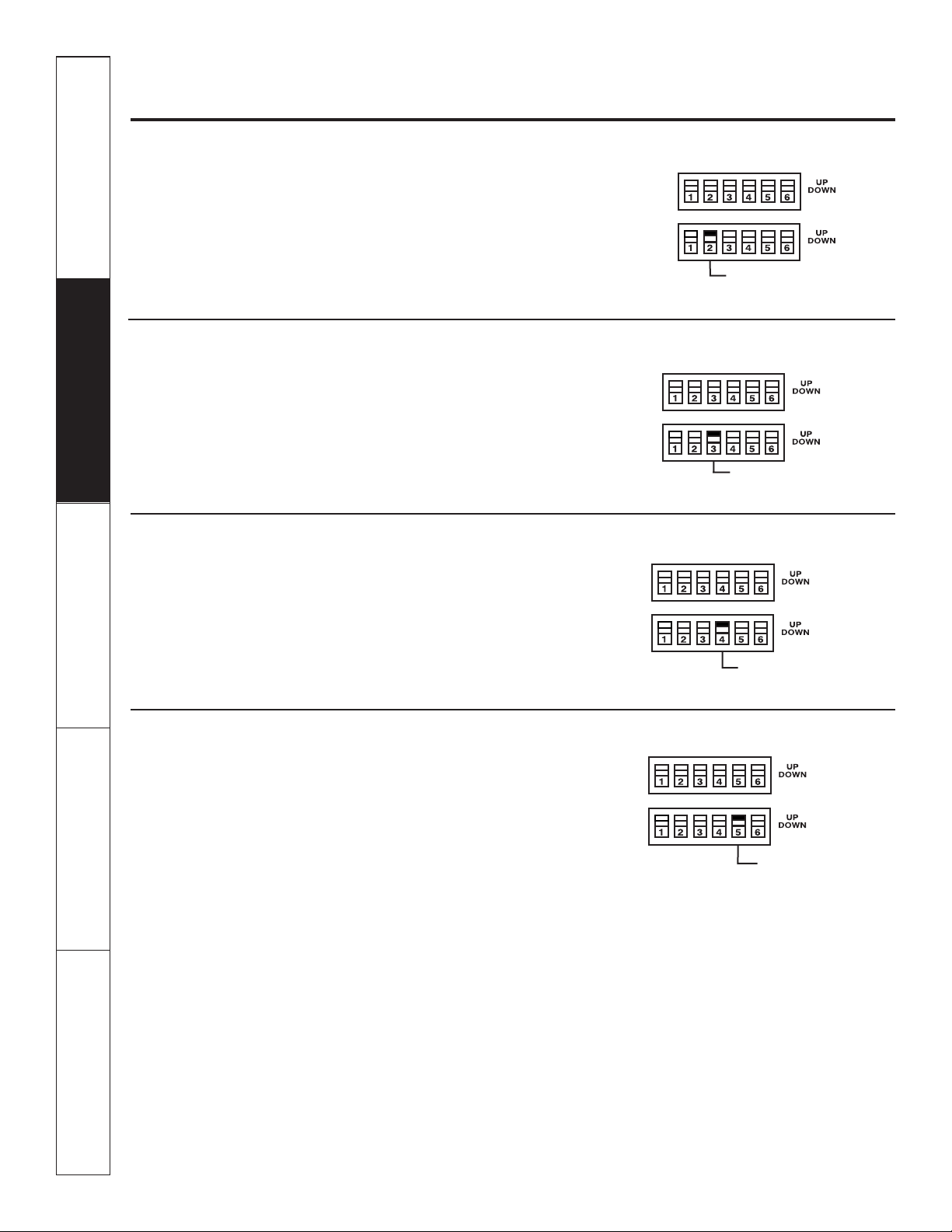

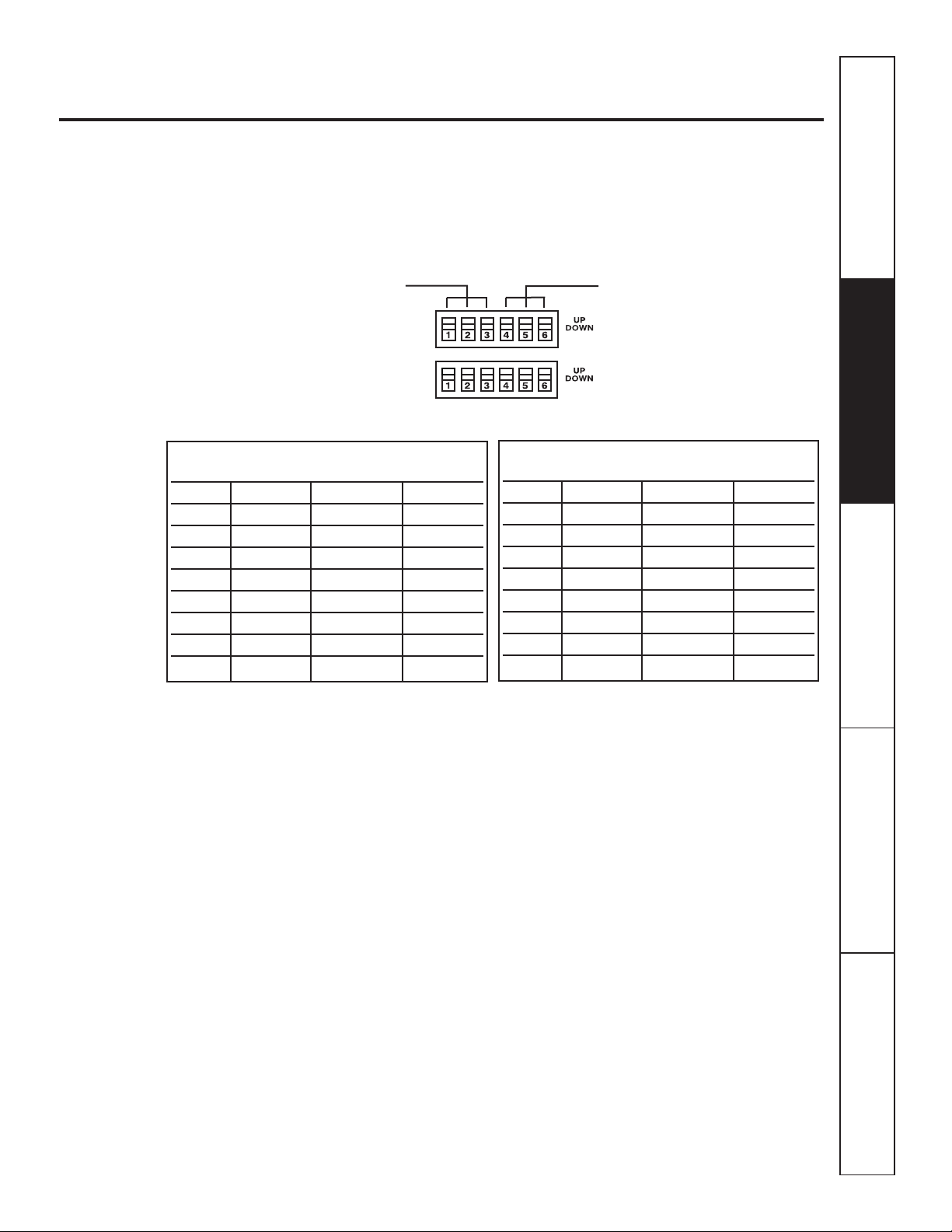

Temperature Limiting (Requires room air sensor kit–RAVRMS)

Temperature limiting can reduce energy costs

by limiting the lowest temperature that can be

set for cooling and the highest temperature that

can be set for heating. Temperature limiting is

controlled by switches 1–6 on the top block

of auxiliary controls. The first three switches are

used to select the cooling limits. The next three

switches are used to control the heating limits.

Temperature limiting during COOL mode

(all temperatures shown in °F)

UP DOWN Minimum Maximum

NONE 1, 2, 3 60° 85°

1 2, 3 64° 85°

1, 2 3 66° 85°

2 1, 3 68° 85°

2,3 1 70° 85°

1, 2, 3 NONE 72° 85°

1, 3 2 74° 85°

3 1, 2 76° 85°

Temperature limiting during HEAT mode

(all temperatures shown in °F)*

UP DOWN Minimum Maximum

NONE 4, 5, 6 60° 85°

4 5, 6 60° 80°

4, 5 6 60° 78°

5 4, 6 60° 76°

5,6 4 60° 74°

4, 5, 6 NONE 60° 72°

4, 6 5 60° 70°

6 4, 5 60° 65°

TL1 (C) (Temp. Limit 1–Cool)

TL2 (C) (Temp. Limit 2–Cool)

TL3 (C) (Temp. Limit 3–Cool)

TL1 (H) (Temp. Limit 1–Heat)*

TL2 (H) (Temp. Limit 2–Heat)*

TL3 (H) (Temp. Limit 3–Heat)*

* Not applicable to Cool-Only models

Page 6

6

Consumer Support Troubleshooting Tips Care and Cleaning Operating Instructions Safety Instructions

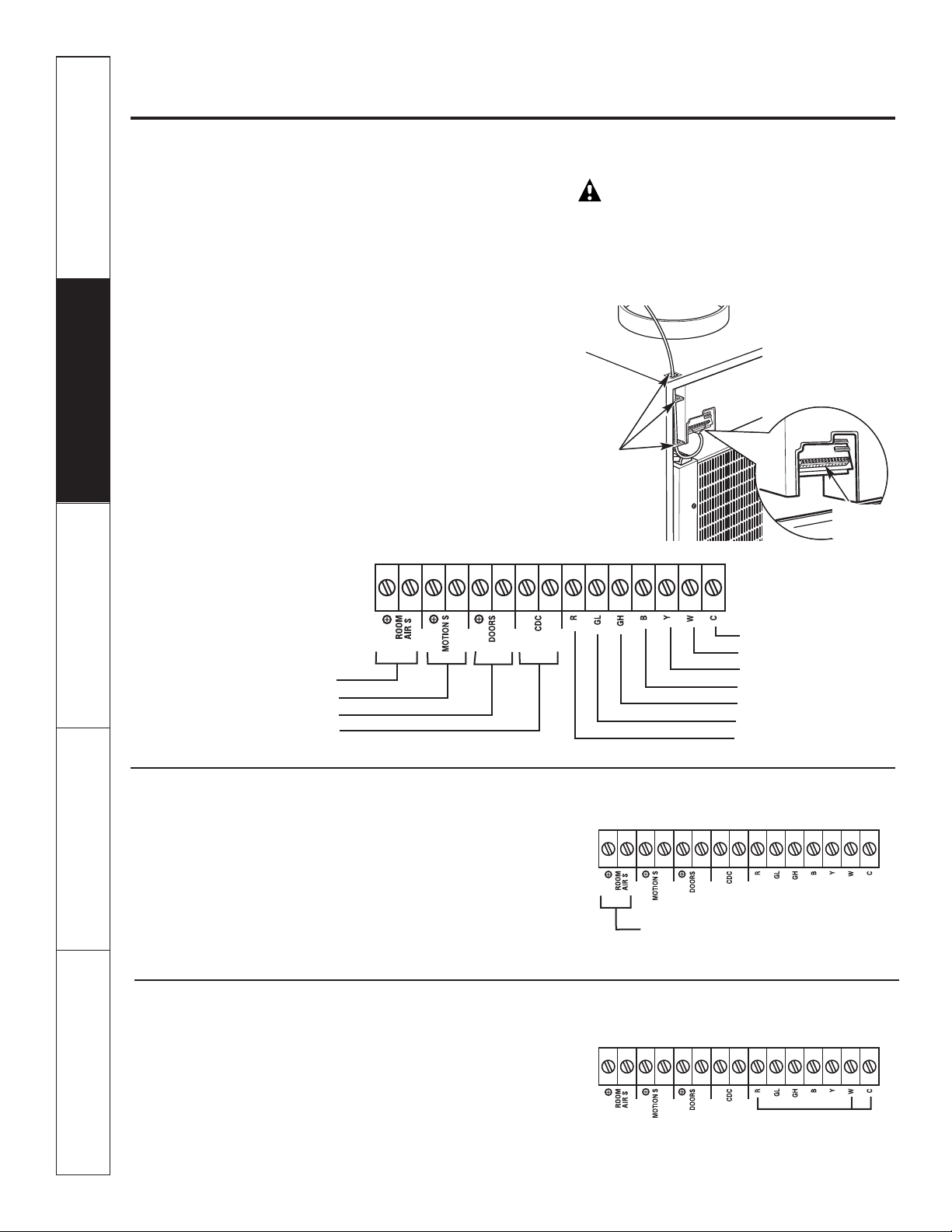

Controls—terminal connections.

Controls–Terminal Connections

The terminal connections are located behind

the front case panel through an opening

on the front of the unit.

To access the terminal connections, remove

the front panel by removing the filter, taking out

the four front screws, the upper two screws from

the top of the panel and the shipping screws on

each side, if present. (Discard the two side shipping

screws, if present.)

Insert the building hook-up wires into the bottom

of the terminals and tighten screws securely

to make the desired connections.

Route the wires from the terminal connections

through the unit wire guides and out through

the case wire guide.

NOTE: The owner is responsible for setting

the appropriate dip switches and connecting

terminals.

CAUTION:

Improper CDC wiring may damage the Zoneline

electronics or cause erratic Zoneline operation.

No common busing is permitted. A separate wire

pair must be run from each separate controlling

switch to each individual Zoneline.

Room Air Sensor (Requires room air sensor kit – RAVRMS)

When connected, the room air sensor will allow

utilization of the temperature limiting and freeze

sentinel features.

NOTE: If GE thermostat RAK148D1, RAK148P1

or RAK164D1, RAK164P1 is used with the unit,

the room sensor kit is not needed for temperature

limiting since this feature is incorporated in the

thermostats.

Route wires

through wire

guides

Room Air Sensor

Motion Sensor

Door Sensor

Central Desk Control

Common–Ground

White–Heater

Yellow–Compressor

Black–Reversing Valve

Green–High Speed Fan

Green–Low Speed Fan

Red–24V AC only

Room Air Sensor

Terminal

connections

Hydronic Heating (Requires Hydronic Heating Kit – RAVHW1, RAVHW2 or RAVHW3)

Required connections for hydronic heating kit.

NOTE: R, W, C terminal connections will

also be connected to the remote thermostat

if applicable.

Hydronic Heating

Page 7

Remote Thermostat

The unit will be controlled by a remote thermostat.

IMPORTANT:

The Zoneline thermostat connections

provide 24V AC only.

If using a digital/electronic wall thermostat,

you must set it to the 24V AC setting. See the

Installation Instructions for the wall thermostat.

CAUTION:

Damage to a wall thermostat or to the

Zoneline electronics can result from improper

connections. Exercise extra attention when

connecting blue and black wires. No line

voltage connections should be made to any circuit

in the thermostat. Isolate all wires in building from

line voltage.

7

Safety Instructions Operating Instructions Care and Cleaning Troubleshooting Tips Consumer Support

ge.com

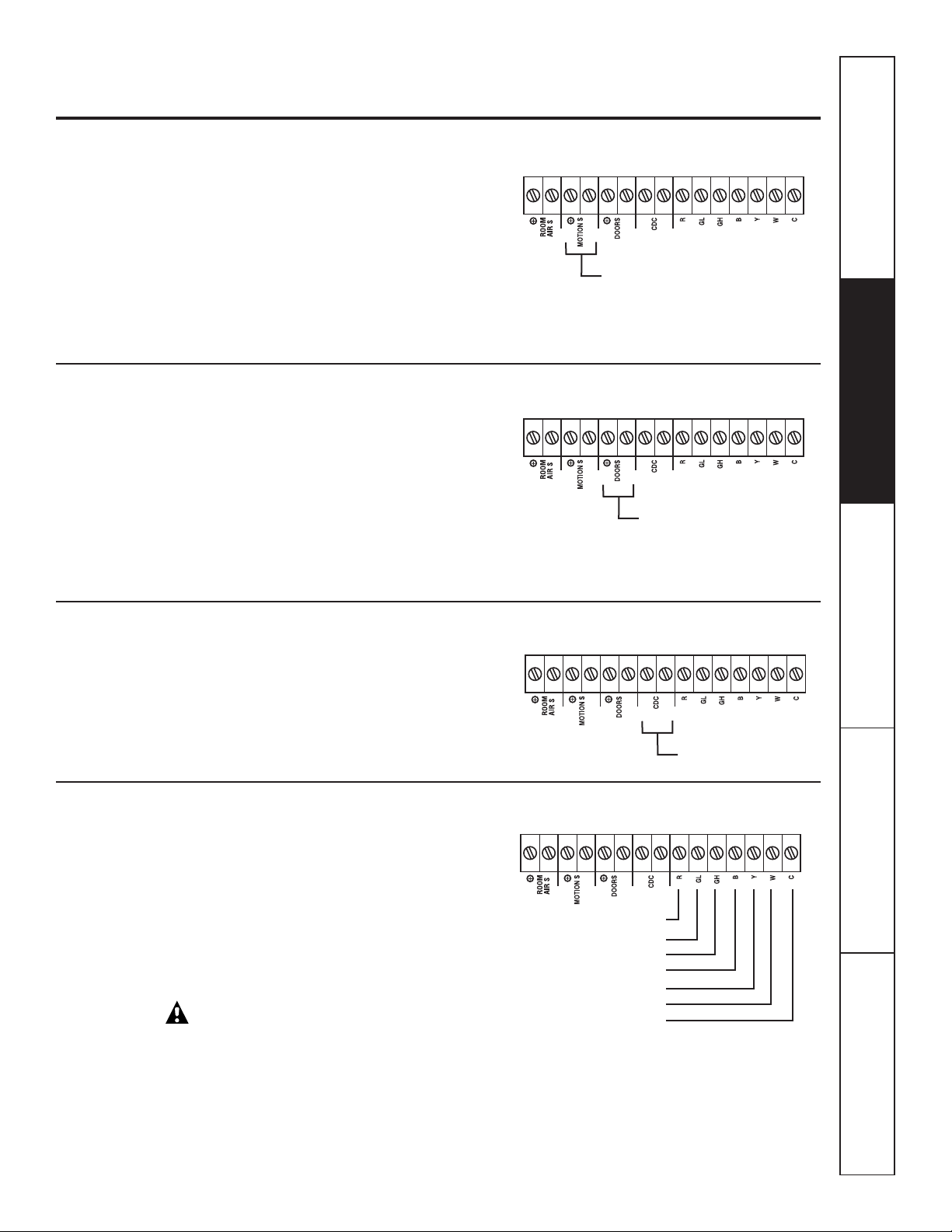

Door Sensor (Obtained locally)

The Occupancy Sensor dip switch must be

in the up position to use this feature.

When connected, the door sensor will detect

when the door in the room is opened or closed.

This feature must be used in conjunction with

the motion sensor.

The door and motion sensors work together

to automatically cycle the unit between normal

and energy management operations.

Central Desk Control

When connected, the unit lock-out is released

and it can be turned ON or OFF with a switch

located at the Central Desk Control. A separate

wire pair must be run from each separate

controlling switch to each individual Zoneline.

Motion Sensor (Obtained locally)

The Occupancy Sensor dip switch must be in

the up position to use this feature.

When connected, the wall mounted motion sensor

will detect motion in the room and automatically

cycle the unit between normal operation and

energy management operation.

The door and motion sensors work together

to automatically cycle the unit between normal

operation and energy management operation.

Motion Sensor

Door Sensor

Central Desk Control

Red–24V AC only

Green–Low Speed Fan

Green–High Speed Fan

Black–Reversing Valve

Yellow–Compressor

White–Heater

Common–Ground

Page 8

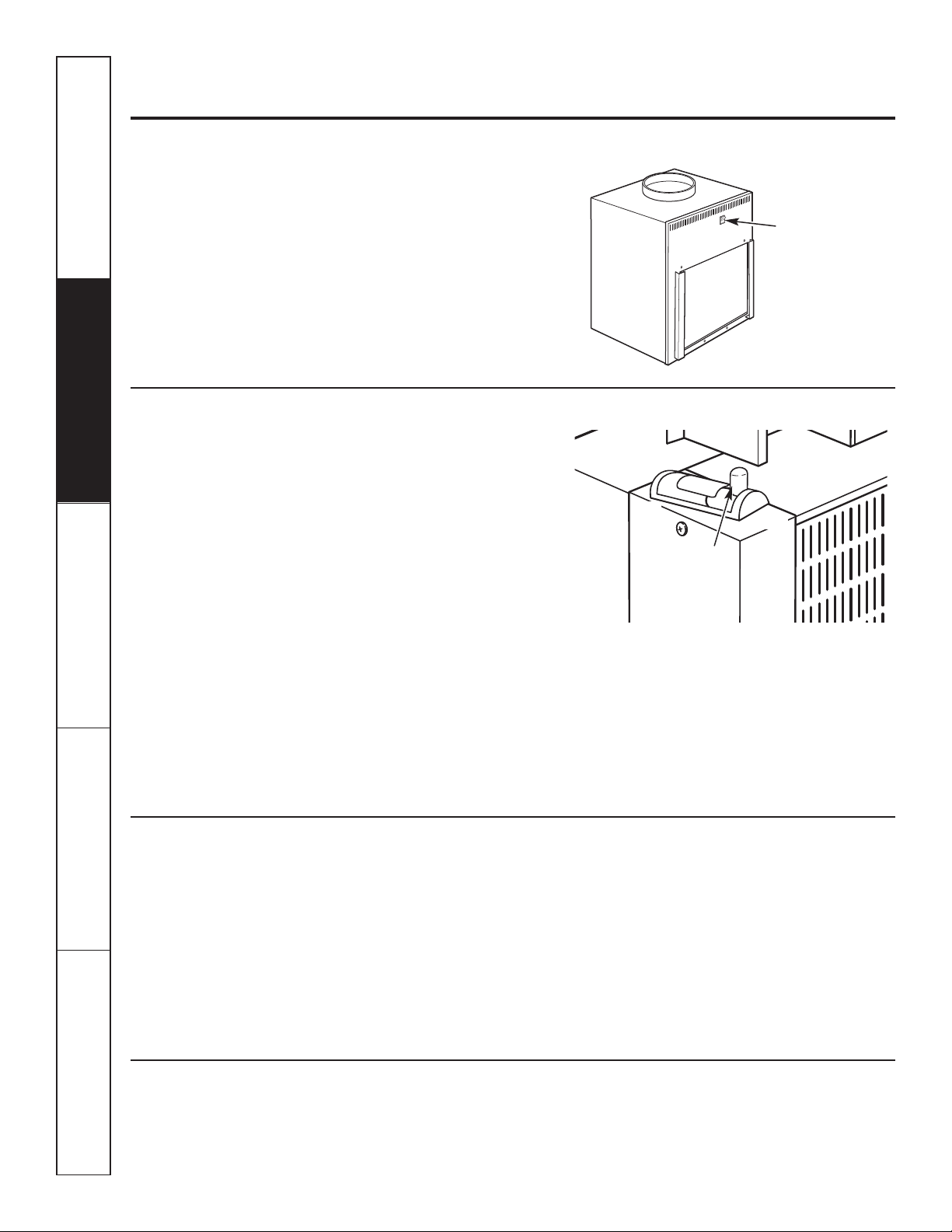

The ventilation control lever is located on the left

side of the Zoneline unit, behind the front case

panel.

To access the ventilation control lever, remove

the front panel by removing the filter, taking out

the four front screws, the upper two screws from

the top of the panel and the shipping screws on

each side, if present. (Discard the two side shipping

screws, if present).

When the lever is in the CLOSE position, only the air

inside the room is circulated and filtered.

When the lever is in the OPEN position, some

outdoor air will be drawn into the room. This

will reduce the heating or cooling efficiency.

To close the vent, push the vent lever handle

down, pull it forward and lock it up in place.

To open the vent, push the vent lever handle

down, push it back and lock it up in place.

Energy Tip: Keep the vent control in the CLOSE

position. The room air will be filtered and circulated.

8

Consumer Support Troubleshooting Tips Care and Cleaning

Operating Instructions Safety Instructions

Other features of your Zoneline.

About Heat Pumps (on some models)

Heat pumps can reduce operating costs by

exchanging heat from the outside air—even

when the outside temperature is below freezing—

and releasing that heat indoors.

To get the best economic benefit from your heat

pump, don’t change the room thermostat setting

very often. Raising the heat setting 2–3 degrees

will cause the Zoneline to use its electric heating

elements in order to reach the new temperature

setting quickly.

There is a three minute minimum compressor run

time at any setting to prevent short cycling.

The indoor fan motor starts before the compressor

and stops after the compressor cycles off.

The electric heating elements use much

more electricity than heat pumps and cost

more to operate.

Ventilation Control

Vent control

(push lever down

and pull forward

or back to

operate)

Open

Close

On/Off Switch

The unit on/off switch is located on the front

of the Zoneline.

To turn on the unit, press the top of the switch in.

To turn off the unit, press the bottom

of the switch in.

ON/OFF

switch

Do Not Operate Cool-Only Models in Freezing Outdoor Conditions

Cool-only air conditioners are not designed

for use when freezing outdoor conditions exist.

They must not be used in freezing outdoor

conditions.

Page 9

Indoor/Outdoor Coils

The exhaust coils on the Zoneline should be

checked regularly. If they are clogged with dirt

or soot, they may be professionally steam cleaned

by your GE service center. You will need to remove

the unit from the case to inspect the coils because

the dirt build-up occurs on the exhaust side.

9

Safety Instructions

Operating Instructions Care and Cleaning Troubleshooting Tips Consumer Support

Care and cleaning. ge.com

Base Pan

In some installations, dirt or other debris may

be blown into the unit from the outside and settle

in the base pan (the bottom of the unit).

In some areas of the United States, a “gel-like”

substance may be present in the base pan.

Check it periodically and clean, if necessary.

Turn off the Zoneline and disconnect the power supply before cleaning.

Outdoor coils

To maintain optimum performance, change the filter at least every 30 days.

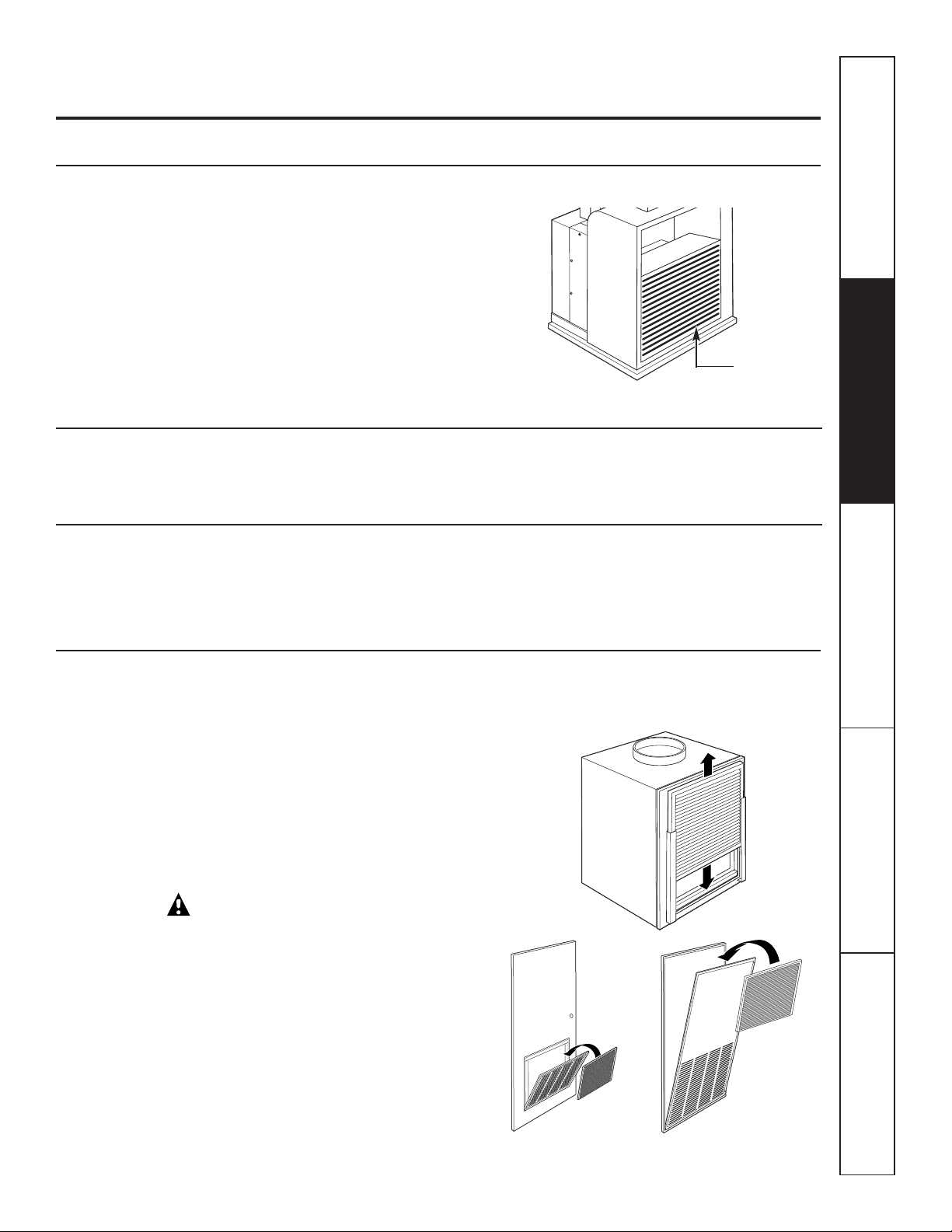

Air Filters

The most important thing you can do to maintain

the Zoneline is to change the filter at least every

30 days. Dirty filters reduce cooling, heating

and air flow.

Changing the filter will: Decrease cost of

operation, save energy, prevent clogged heat

exchanger coils and reduce the risk of premature

component failure.

CAUTION: Do not operate

the Zoneline without the filter in place. If a filter

becomes torn or damaged, it should be replaced

immediately.

Operating without the filter in place or with

a damaged filter will allow dirt and dust to reach

the indoor coil and reduce the cooling, heating,

airflow and efficiency of the unit.

Replacement filters should be purchased

from your local retailer where air conditioner

and furnace accessories are sold.

Filter size required is 20″ x 20″ x 1″.

Have the coils cleaned regularly.

Unit-mounted filter

Remove filter

Access-panel with

return air grille

Return air grille

Filter

Filter

To remove

and replace

the filter:

Drain

Clean the drain system regularly to prevent

clogging.

Page 10

BEFORE YOU BEGIN

Installation Zoneline Air

Instructions Conditioners

Read these instructions completely and carefully.

•

IMPORTANT

–

Save these instructions

for local inspector’s use.

•

IMPORTANT

–

Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the owner.

• Note to Owner – Keep these instructions

for future reference.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

• You MUST use all supplied parts and use proper

installation procedures as described in these

instructions when installing this air conditioner.

Questions? Visit our Website at: ge.com or call 800.GE.CARES (800.432.2737).

IMPORTANT ELECTRICAL

SAFETY–READ CAREFULLY

CAUTION:

• All electrical connections and wiring MUST

be installed by a qualified electrician.

• Follow the National Electrical Code (NEC)

and/or local codes and ordinances.

• For personal safety, this Zoneline unit and case

must be properly grounded.

• Protective devices (fuses or circuit breakers)

acceptable for Zoneline installations are specified

on the nameplate of each unit.

• Do not use an extension cord with this unit.

• Aluminum building wiring may present special

problems—consult a qualified electrician.

• When the unit is not running there is still voltage

to the electrical controls.

• Disconnect the power to the unit before

servicing by:

1. Removing the power cord (if it has one) from

the wall receptacle.

OR

2. Removing the branch circuit fuses or turning

the circuit breakers off at the panel.

Phillips screwdriver

TOOLS YOU WILL NEED

10

WARNING:

Before beginning the

installation, switch power off at the service panel

and lock the area to prevent power from being

switched on accidentally. When the area cannot

be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

Adjustable wrench

Saw

Hammer

Tape measure

Page 11

11

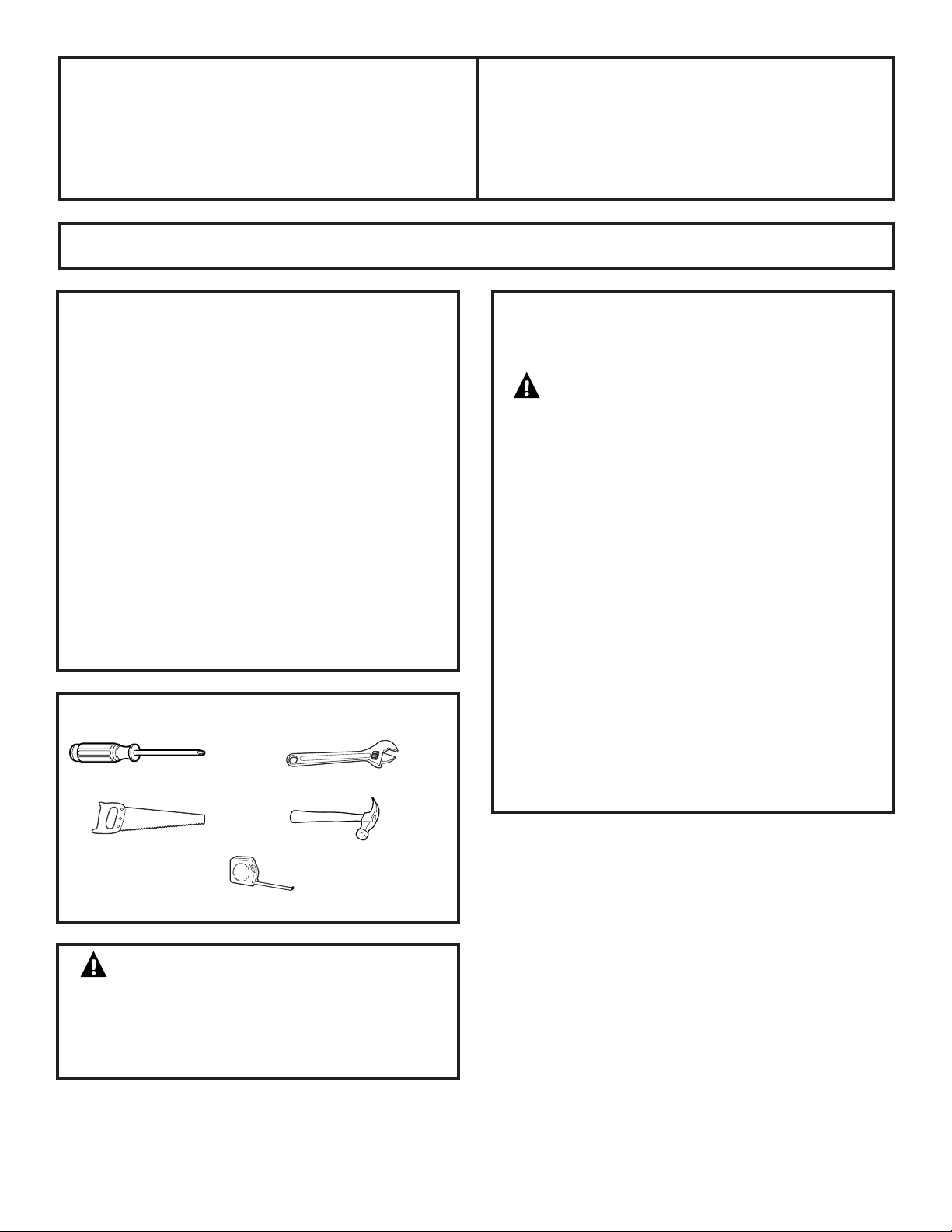

Installation Instructions

ELECTRICAL REQUIREMENTS

230/208 VOLT

ELECTRICAL SUPPLY

Tandem

15 Amp

230/208 volt receptacle configuration

Perpendicular

20 Amp

Large Tandem

30 Amp

• Use ONLY the wiring size recommended for single

outlet branch circuit.

• Proper current protection is the responsibility

of the owner.

A power supply kit must be used to supply power

to the Zoneline unit. The appropriate kit is determined

by the voltage, the means of electrical connection

and the amperage of the branch circuit. See the POWER

CONNECTION CHARTon page 13 to select the appropriate kit.

All wiring, including installation of the receptacle,

must be in accordance with the NEC and local codes,

ordinances and regulations.

Power supply kit

Recommended branch circuit wire sizes*

Nameplate

maximum circuit AWG Wire

breaker size size**

15A 14

20A 12

30A 10

AWG – American Wire Gauge

* Single circuit breaker from main box

** Based on copper wire, single insulated conductor at 60° C

NOTE: Use copper conductors only.

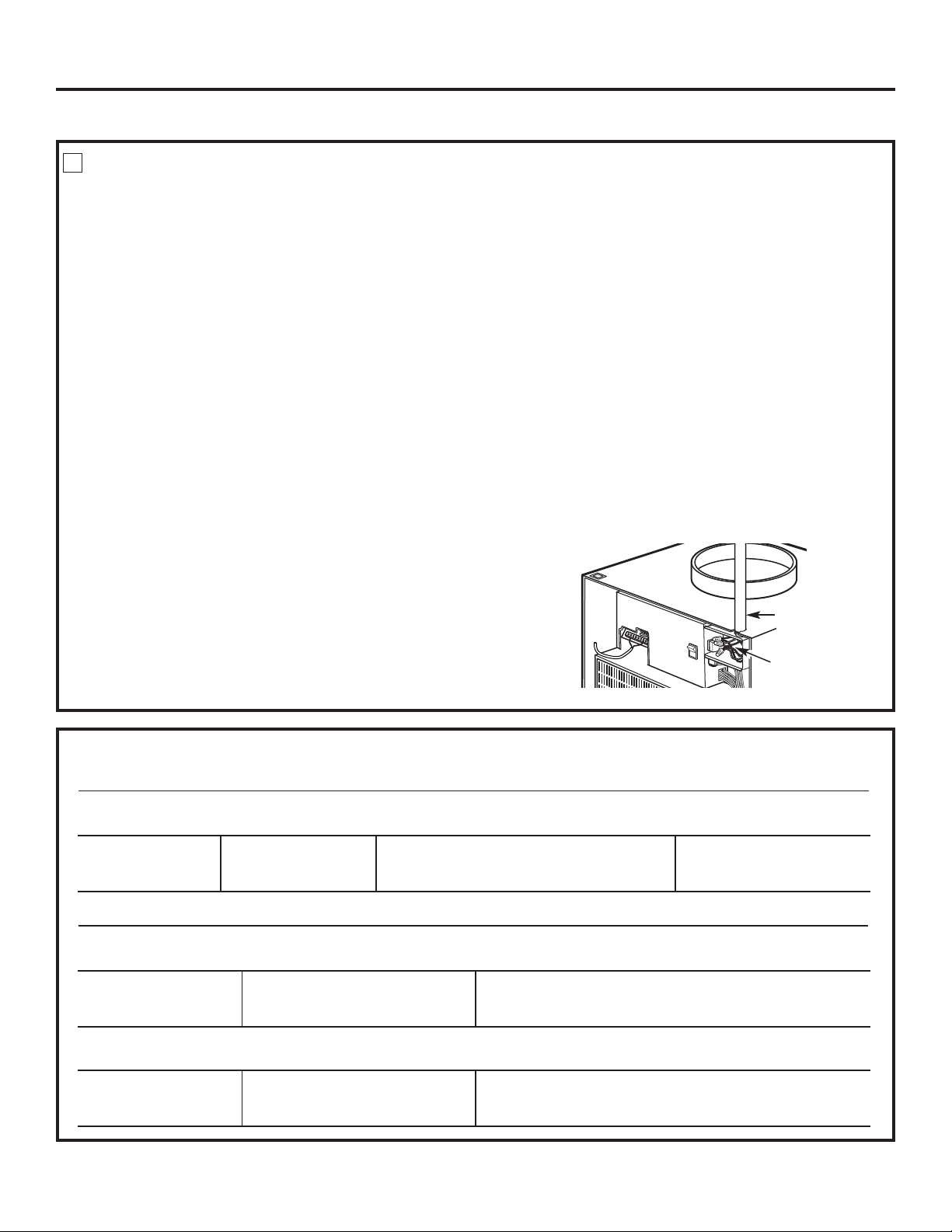

FOR 230/208 VOLT POWER CORD

CONNECTIONS ONLY

1. Remove the front panel by taking out the four

front screws, the upper two screws from the top

of the panel and the shipping screws on each side,

if present. (Discard the two side shipping screws,

if present.)

2. Remove the junction box cover and the junction box

and discard.

3. Connect the power cord, with a loop, through

the strain relief.

Strain relief

IMPORTANT:

Power cord must

have a loop.

Remove

junction box

and cover

Side

shipping

screw

Side

shipping

screw

Page 12

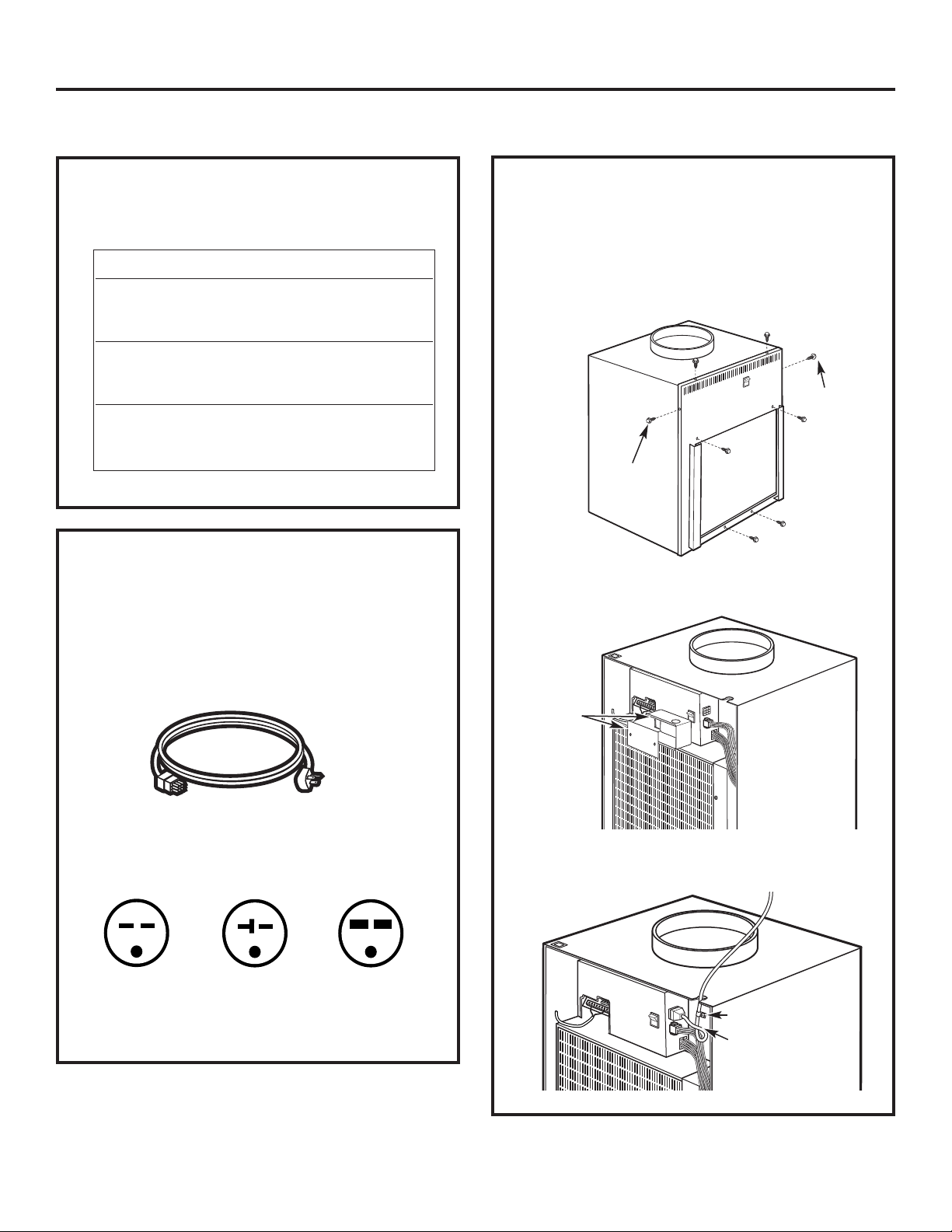

REMOVE JUNCTION BOX COVER

• Remove the junction box cover by taking out the front

two screws.

1

Junction box

Installation Instructions

12

DIRECT CONNECT APPLICATIONS

FOR 265 VOLT DIRECT CONNECT

APPLICATIONS ONLY

IMPORTANT: Connection of a 265V AC product

to a branch circuit MUST be done by direct connection

in accordance with the National Electrical Code. Plugging

this unit into a building mounted exposed receptacle

is not permitted by code.

These models must be installed using the appropriate

GE power supply kit for the branch circuit amperage

and the electrical resistance heater wattage desired.

See the POWER CONNECTION CHART on page 13

to select the appropriate kit.

It is the responsibility of the installer to ensure

the connection of components is done in accordance

with electrical codes.

Direct connection to branch circuit wiring inside

the provided junction box must be made by connecting

as follows in steps 1–3 below.

ATTACH CONDUIT

• Use the round knockout hole at the top

of the junction box to install conduit coming

from the branch circuit. Install and clamp the conduit

through the conduit clamp and bring wire leads into

the junction box. Leave 8″ of wire free from the end

of the conduit.

2

Conduit

FOR 230/208 VOLT DIRECT CONNECT

APPLICATIONS ONLY

Direct connection to branch circuit wiring inside

the provided junction box must be made by connecting

as follows in steps 1–3 below.

Connector

Conduit

clamp

Junction box cover

Page 13

13

Installation Instructions

DIRECT CONNECT APPLICATIONS

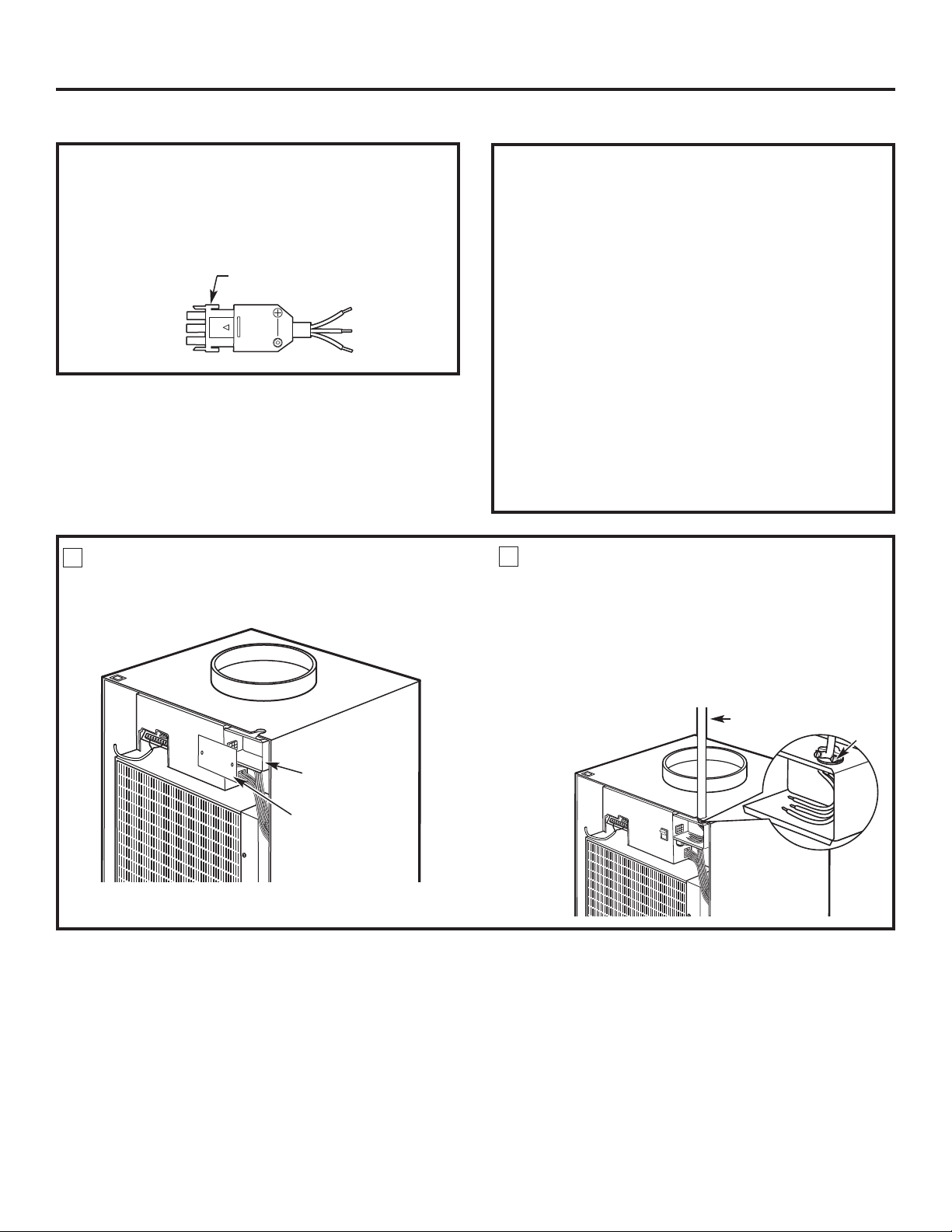

MAKE WIRE LEAD CONNECTIONS INSIDE THE JUNCTION BOX

1. Make all wire connections by using appropriate UL-listed electrical connectors and techniques.

2. Select the applicable wiring situation and follow the instructions accordingly:

3. Be sure that all wire leads are inside the junction box and not

pinched between the box and the unit. The green insulated

ground wire from the Zoneline MUST be connected to the branch

circuit ground wire.

4. Plug the 9-pin connector into the 9-pin receptacle in the junction box.

5. Replace the junction box cover by replacing the two screws

removed earlier.

3

230/208 Volt Wall Plug Heater Wattage

Power Supply Kits Configuration Circuit Protective Device @ 230/208 Volts

RAK3152 Tandem 15-Amp Time-Delay Fuse or Breaker 2.55/2.09 KW

RAK3202 Perpendicular 20-Amp Time-Delay Fuse or Breaker 3.45/2.82 KW

RAK3302 Large Tandem 30-Amp Time-Delay Fuse or Breaker 5.00/4.10 KW

230/208 Volt Heater Wattage

Power Supply Kits @ 230/208 Volts Circuit Protective Device

RAK4157 2.55 KW/2.09 KW 15-Amp Time-Delay Fuse or Breaker

RAK4207 3.45 KW/2.82 KW 20-Amp Time-Delay Fuse or Breaker

RAK4307 5.00 KW/4.10 KW 30-Amp Time-Delay Fuse or Breaker

265 Volt Heater Wattage

Power Supply Kits @ 265 Volts Circuit Protective Device

RAK5157 2.55 KW 15-Amp Time-Delay Fuse or Breaker

RAK5207 3.45 KW 20-Amp Time-Delay Fuse or Breaker

RAK5307 5.00 KW 30-Amp Time-Delay Fuse or Breaker

Conduit

Make wire lead

connections

• 1-Phase 220-240 VAC

When connecting the Zoneline to a single-phase circuit

for 230V applications:

Connect the white and black leads of the Zoneline

power supply kit to the branch circuit L1 and L2 leads.

(The white lead of the power supply kit should be

identified by the installer using electrical tape with some

color other than green or white.) Connect the green lead

of the power supply kit to the power supply and branch

circuit ground.

• 3-Phase 208 VAC

When connecting the Zoneline to a three-phase circuit

for 208V applications:

Connect the white and black leads of the Zoneline

power supply kit to the branch circuit L1 and L2 leads.

(The white lead of the power supply kit should be

identified by the installer using electrical tape with some

color other than green or white.) Connect the green lead

of the power supply kit to the power supply and branch

circuit ground.

• 3-Phase 208 VAC with “Crazy Leg”

When connecting the Zoneline to a three-phase circuit

with “Crazy Leg” for 208V applications:

Connect the white and black leads of the Zoneline

power supply kit to the branch circuit Neutral and L1

leads. (The white lead of the power supply kit should

be connected to neutral.) Connect the green lead of

the power supply kit to the power supply and branch

circuit ground.

• 3-Phase 253-277 VAC

When connecting the Zoneline to a three-phase circuit

for 265V applications:

Connect the white and black leads of the Zoneline

power supply kit to the branch circuit Neutral and L1

leads. (The white lead of the power supply kit should

be connected to neutral.) Connect the green lead of

the power supply kit to the power supply and branch

circuit ground.

Power Cord Connections

POWER CONNECTION CHART

Direct Connections

Page 14

Installation Instructions

14

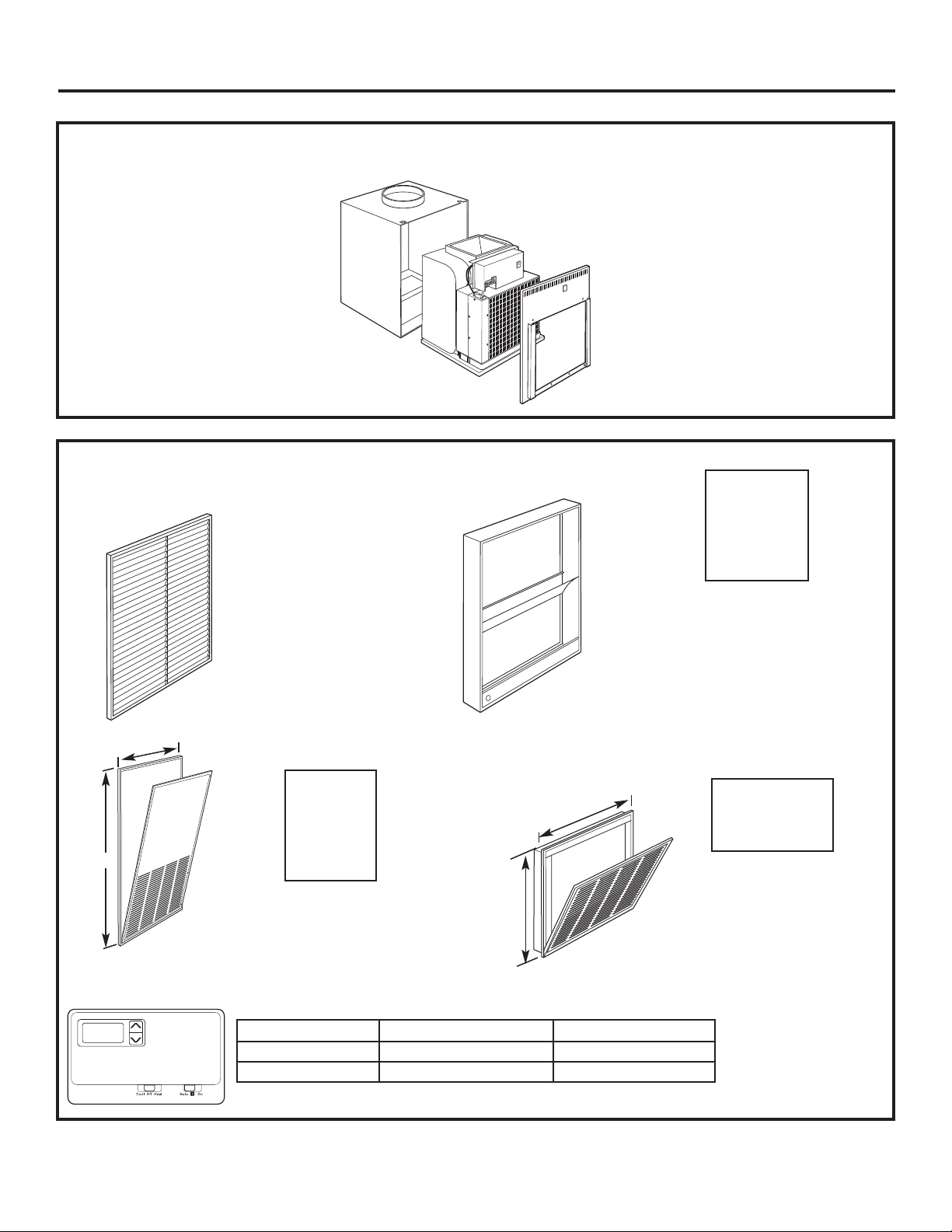

ZONELINE COMPONENTS

Case

Zoneline unit

Front Case Panel

REQUIRED ACCESSORIES

(Check the “Essential Elements” label on the unit.)

Architectural Louver

RAVAL1

Wall Plenum

RAVWP6 - 6″D x 19

3

⁄4″W x 32″H

RAVWP8 - 8″D x 19

3

⁄4″W x 32″H

RAVWP12 - 12″D x 19

3

⁄4″W x 32″H

RAVWP15 - 15″D x 19

3

⁄4″W x 32″H

Cutout

Dimensions:

20″ W x 32

1

⁄4″ H

Access Panel with

Return Air Grille

RAVRG1

Return Air Grille

RAVRG2

Cutout

Dimensions:

28″W x 48″H

Cutout

Dimensions:

20

3

⁄8″W x 203⁄8″H

OR

Wall Thermostat

Model Type Mechanical Thermostat Electronic Thermostat

Heat/Cool Models 4-wire 5-wire

Heat Pump Models 6-wire 6-wire

Check the thermostat instructions for correct wiring and installation requirements.

30″

50″

22 1⁄2″

22 1⁄2″

Page 15

Installation Instructions

15

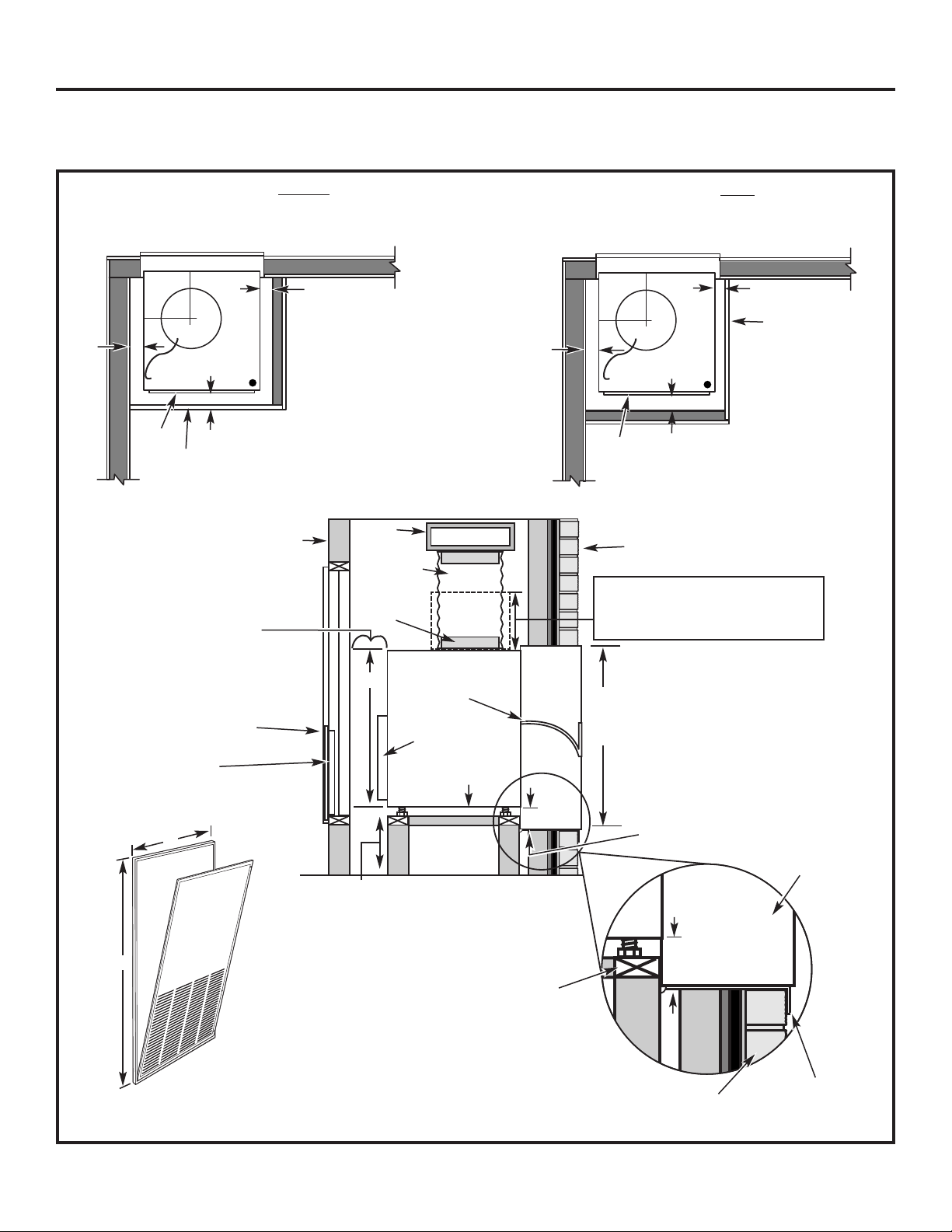

TYPICAL UTILITY CLOSET AND DIMENSIONS

(FOR REFERENCE ONLY)

Side View

Top View

Architectural Louver

10″

duct

Door/access panel

3″ min.

5″ min.

Unit front

3″

min.

14″ min. – Required only if optional Hydronic

Heating Kit (RAVHW1, RAVHW2, RAVHW3) is to

be installed. Clearance for installation should be

taken into consideration if this kit is to be used.

Exterior/Outside

Outside wall

Wall

plenum

Inside wall

Air discharge

outlet

Rigid

ductwork

Flexible or

rigid duct

Wall plenum

divider

31″

Option 1

Access panel with

return air grille

Option 2

Return air grille

Filter bracket

Secure platform

to the floor

Platform: 23

1

⁄4″ x231⁄4″ square

Min. load capacity: 175 lbs.

• 4″ min. from front of case – Unit

installed through FRONT of case.

• 5″ min. from front of case – Unit

installed through SIDE of case.

• 3″ min. from two sides of case.

Plenum

cutout

321⁄4″ H

x 20″ W

Drain fittings 3⁄4″

Outside wall

Platform

Wall plenum

Field supplied

outer flashing

10″

111⁄2″

A

B

A Minimum recommended access door width: 30″

B Minimum recommended access door height: 50″

UNIT INSTALLED THROUGH SIDE OF CASE

Top View

Architectural Louver

10″

duct

Door/access panel

3″ min.

4″ min.

Unit

front

3″

min.

10″

11

1

⁄2″

UNIT INSTALLED THROUGH FRONT OF CASE

Bottom of case approx. 2″

above bottom of plenum

8″ min.

for drain

access

Bottom of case approx. 2″

above bottom of plenum

Unit

Page 16

Installation Instructions

16

UTILITY CLOSET CONNECTION LOCATIONS

IMPORTANT: Plan and locate plenum, wall plug, drains and

thermostat carefully to avoid interference. Hard-to-reach locations

will make installation and service difficult!

Reference Dimensions

A Thermostat cable: 91⁄2′ long

B Power cord: 60″ long

C Case width and depth: 231⁄8″

D Case height: 31″

E Condensate drains: 3/4″ connector

• Primary Drain – Centerline of cutout is

approximately 51⁄4″ from left case wall

and 81⁄2″ from back case wall.

• Secondary Drain – Centerline of cutout is

approximately 61⁄2″ from left case wall

and 51⁄4″ from back case wall.

F Typical wall plug: 6″–12″ above case

G Room air sensor kit: 10′ long

Outside wall

Flex duct may be used

for transitions only

Use rigid duct for 90°

bends and tees

F

C

C

D

E

Platform

B

A

230/208 VAC

wall receptacle

or

conduit for direct

connection

G

Page 17

Installation Instructions

17

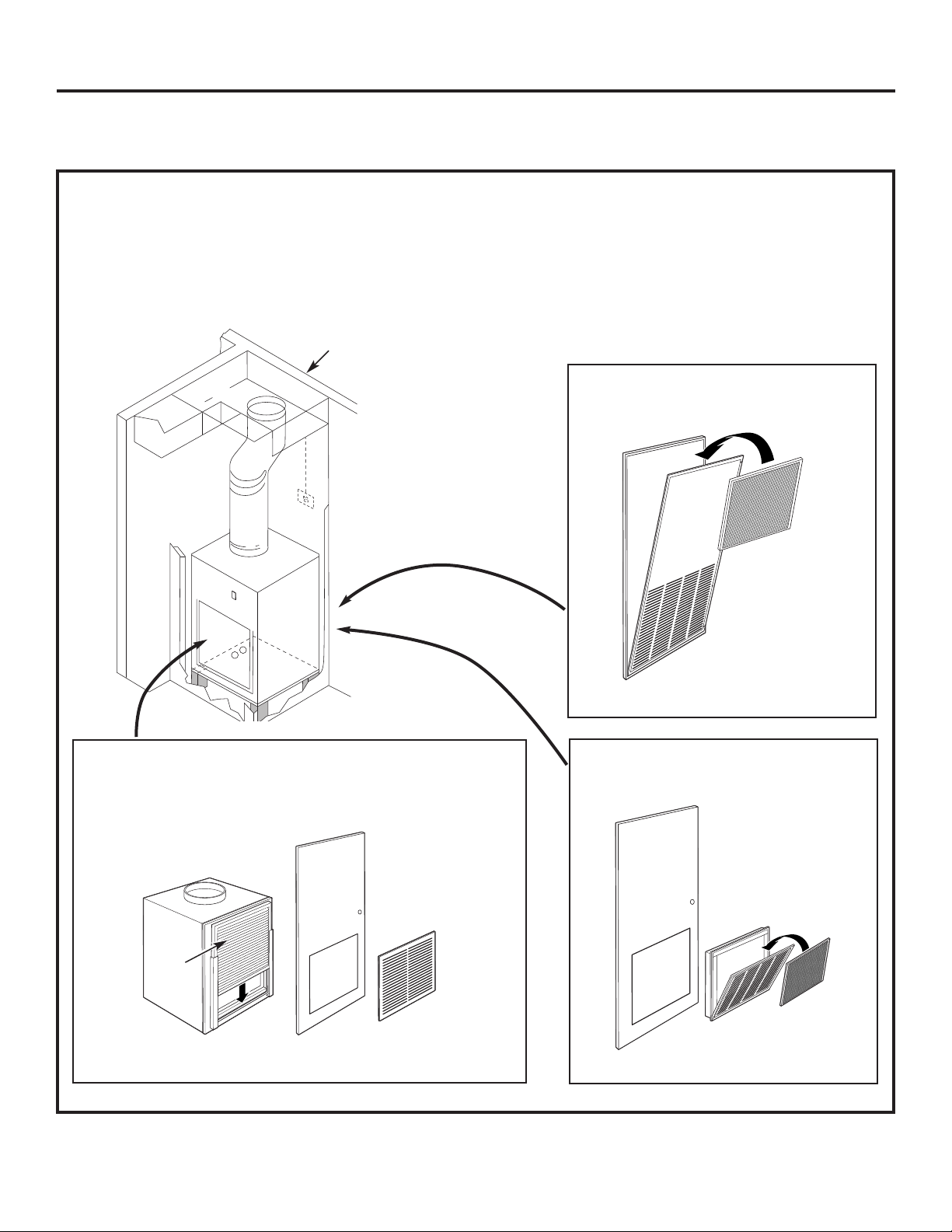

RETURN AIR GRILLE INSTALLATION OPTIONS

The room return air grille may be installed toward the front or either side of the unit. Improper return air arrangements

will cause performance problems.

There are three indoor return air grille installation options. Choose the option that best suits your installation

requirements. Follow the Installation Instructions provided with the return air grille accessory for installation details.

NOTE: Use only one filter in the installation. The filter may be installed on the unit or in the access panel/door.

Unit-mounted filter with a field-supplied return

air grille and access door/panel

RAVRG2 – Return air grille

RAVRG1 – Access panel with

return air grille

Filter

Filter

Filter

Outside wall

Option 1

Option 2

Option 3

Page 18

BUILD AND INSTALL THE ZONELINE

BASE PLATFORM

1. Construct a 231⁄4″ min. x 231⁄4″ min. square platform

with legs to raise the platform a minimum of 8″.

NOTE: The platform must have a load-bearing

capacity of 175 lbs. minimum.

1

Installation Instructions

18

WALL PLENUM AND ARCHITECTURAL LOUVER INSTALLATION

• Install the appropriate wall plenum through the exterior wall in accordance with the Installation Instructions

provided with the plenum.

IMPORTANT: The wall plenum is not designed to carry structural loads.

Proper wall header construction is required. The plenum requires proper flashing,

shim and caulk for a weather resistant installation.

Properly square

and level plenum.

Proper header for structural

support.

Apply proper caulking

and flashing.

Architectural Louver—

RAVAL1

Exterior/Outside Wall

Case

Wall Plenum

RAVWP6 – 6″D x 193⁄4″W x 32″H

RAVWP8 – 8″D x 19

3

⁄4″W x 32″H

RAVWP12 – 12″D x 19

3

⁄4″W x 32″H

RAVWP15 – 15″D x 19

3

⁄4″W x 32″H

2. Make drain hole cutout(s):

• Primary Drain – Centerline of drain is

approximately 51⁄4″ from left platform edge

and 81⁄2″ from back platform edge.

• Secondary Drain – Centerline of drain

is approximately 6

1

⁄2″ from left platform edge

and 51⁄4″ from back platform edge.

3. Place the platform in the utility closet

with the following clearance between it

and the interior surface of the walls/door/panel:

• 4″ min. from front of the case –

Unit to be installed through FRONT of case

• 5″ min. from front of the case –

Unit to be installed through SIDE of case

• 3″ min. from two sides of the case

4. Align the platform with the opening of

the wall plenum and secure to the floor

using appropriate brackets and bolts.

231⁄4″ min.

8″ min.

for drain

access

Cutout for drain

connection(s)

(see NOTE below)

Back of platform

Left side of platform

NOTE: Specific cutout size

for drain connections needs

to be determined by the installer

for the given installation situation.

51⁄4″

23

1

⁄4″ min.

5

1

⁄4″

61⁄2″

8

1

⁄2″

Page 19

INSTALL THE DRAIN(S)

An external or an internal drain must be attached

to the primary drain connector. A secondary drain

is supplied if required by state and local codes. Refer

to the local codes for proper installation of the drains.

If the secondary drain is not used, seal its drain port

with a 3/4″ MNPT plug.

External Drain

Attach a 90° PVC elbow to the unit’s female 3/4″ NPT

drain connector. Use the other end of the elbow to run

a 3/4″ Sch. 40 PVC pipe through the knockout holes of

both the wall plenum and the architectural louver to the

outside. Seal the gap between the plenum hole and PVC

tube. See the Installation Instructions in the RAVAL1.

Internal Drain

Attach PVC to the unit’s female 3/4″ NPT drain

connector. See the Installation Instructions

in the RAVAL1. Local codes may apply.

2

DUCTWORK

Prepare the closet ductwork for later connection

to the case.

The total flow rate (CFM) and external static pressure

(ESP) available can be estimated from the chart below.

Use these charts to select your fan speed setting. The

collar on top of the case accepts standard 10″ duct.

Pull all duct tight. Extra duct slack can greatly increase

static pressure.

CAUTION: Flex duct can collapse and

cause airflow restrictions. Do not use flex duct for 90°

bends or unsupported runs of 5 ft. or more.

3

Installation Instructions

Your airflow should be balanced based on many factors,

such as available ESP, room CFM, and ductwork. Consult

an HVAC engineer for proper applications. External static

pressure (ESP) can be measured with a manometer or

pitot tube. Once this ESP is established, you can

calculate the CFM using the above chart.

CFM Recommendations

9,000 BTU 12,000 BTU 18,000 BTU

275 300 325 350 375 400 450 500 550

•••

• = Recommended Mid Range

Higher CFMs tend to increase Sensible capacity,

enhance room circulation and increase duct noise,

while lower CFMs tend to increase Latent capacity

and reduce noise.

Side View

Inside wall

Female drain

fitting 3⁄4″

PVC

90° Elbow

PVC

(External drain)

PVC

(Internal drain)

Side View

Inside wall

Female drain

fitting 3⁄4″

Airflow – CFM@230 Volts and @ 265 Volts

Indoor Fan CFM

DUCT SELECT SWITCH

UP DOWN

ESP

(in. water)

High

CFM

Medium

CFM

Medium

CFM

Low

CFM

0.0

0.1

0.2

0.3

0.4

390

370

350

330

310

340

320

300

280

260

340

320

300

280

260

305

290

270

250

230

0.0

0.1

0.2

0.3

0.4

475

450

425

400

375

390

370

350

330

315

390

370

350

330

315

350

325

300

275

250

0.0

0.1

0.2

0.3

0.4

630

610

590

570

550

545

530

515

495

475

545

530

515

495

475

490

480

470

455

440

AZ75(H/E)09AZ75(H/E)12AZ75(H/E)18

To correct for 208 volts: 0.91

19

Page 20

INSTALL AND CONNECT THE CASE

1. Remove the front case panel and pull

the unit out of the case. Place the empty case onto

the platform in the closet with the outdoor side facing

the wall plenum opening. Align the case with plenum

opening and attach with six field-supplied sheet metal

screws (corrosion-resistant screws recommended).

2. Adjust all four leveling legs until the case is level.

3. Using field-supplied screws, bolt the case

to the platform.

4. Connect the internal or external drain(s) as necessary.

4

Installation Instructions

INSTALL AND GROUND

THE UNIT TO THE CASE

UNIT INSTALLED THROUGH FRONT OF CASE

1. Slide the back of the unit into the case. Push the unit

all of the way into the case until it stops.

NOTE: Either of the case sides may be removed

to enable the unit to be slid into the case.

2. Ground the unit to the case by installing the front

case-to-unit hex-bolt and/or case-to-unit side screw.

5a

Hex bolt

Air

discharge

outlet

Rigid

ductwork

Inside

wall

20

Primary female

drain fitting 3⁄4″

Leveling legs

INSTALL AND GROUND

THE UNIT TO THE CASE

UNIT INSTALLED THROUGH SIDE OF CASE

1. Slide the side of the unit into the case. Push the unit

all of the way into the case until it stops.

NOTE: Either of the case sides may be removed

to enable the unit to be slid into the case.

2. Attach the case side panel to the main case.

3. Ground the unit to the case by installing the front

unit-to-case hex-bolt and/or case-to-unit side screw.

5b

Side screw

Hex bolt

Side screw

(may be

installed on

either side)

External

drain

OR

Internal

drain(s)

Bolt case to

platform

Secondary 3⁄4″ drain

option. If not used,

seal with a MNPT plug

NOTE: Piping is not

supplied with the unit.

Obtain locally.

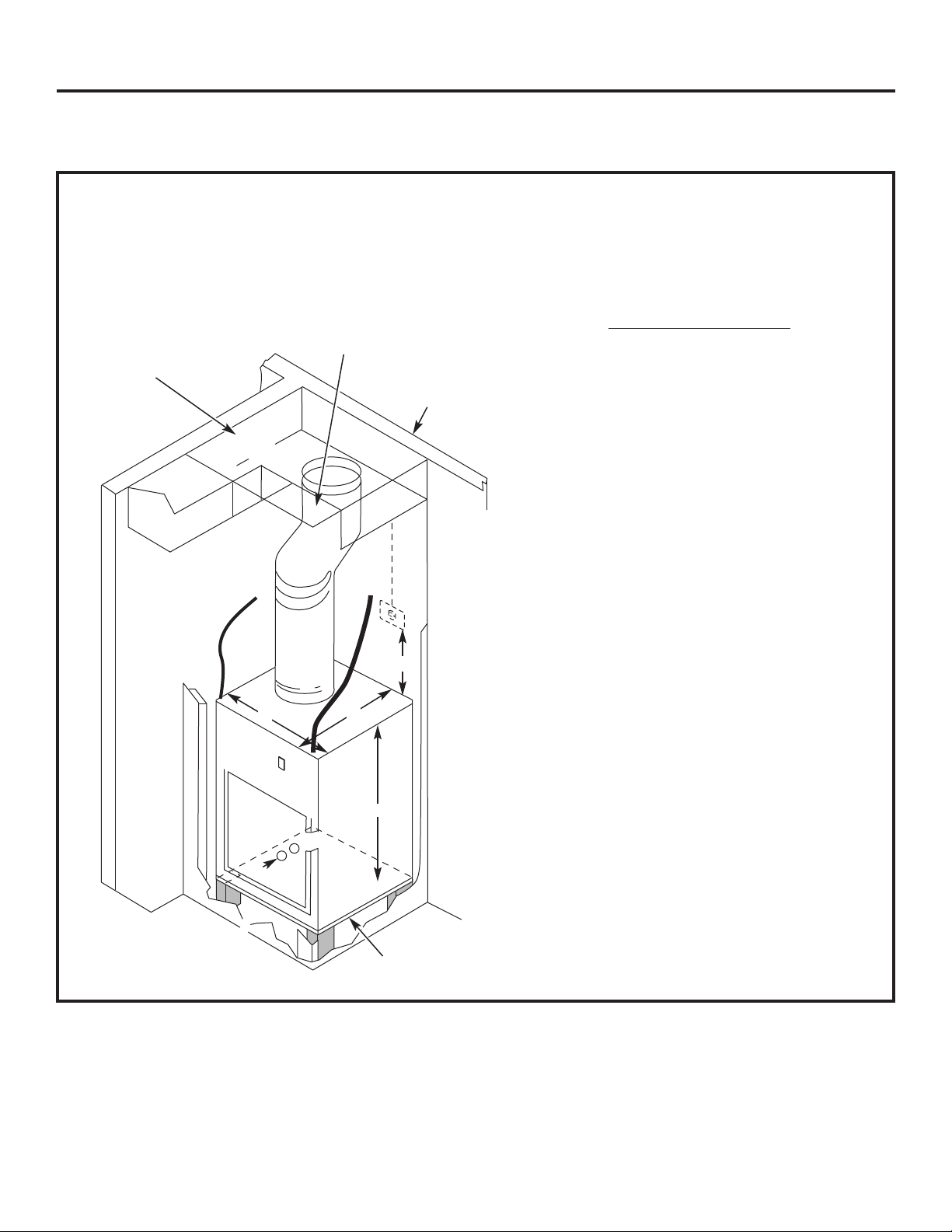

Page 21

Top duct

Clamp

Case top

duct adjusting

screws

MAKE UNIT ELECTRICAL

CONNECTIONS

1. Connect the thermostat wires to the unit and set

the dip switches to the appropriate settings.

NOTE: See the Controls–Terminal Connections

and Controls–Dip Switches sections

of this manual and the manual with

the separate thermostat for proper

connections and settings.

2. Make power connections to the unit.

NOTE: See the ELECTRICAL REQUIREMENTS and

DIRECT CONNECT APPLICATIONS sections,

as appropriate, of this manual for proper

connections.

3. Replace the case front panel by replacing the four

front screws and the two top screws.

6

Installation Instructions

Thermostat

Unit Connections

21

Maximum Wiring

Length for Thermostat

Connection to the Unit

66 ft. for AWG 18

60 ft. for AWG 20

40 ft. for AWG 24

AWG – American Wire Gauge

CONNECT THE TOP DUCT

1. Install the duct onto the air discharge outlet.

2. Secure the top duct to the unit by turning the four

case top duct adjusting screws until they are tight.

Use a field supplied clamp to lock the top duct

to the case.

7

Air

discharge

outlet

Rigid

ductwork

Inside

wall

Flexible or rigid

ductwork

Page 22

Installation Instructions

SERVICING

WARNING:

Before servicing, switch

power off at the service panel and lock the area to

prevent power from being switched on accidentally.

When the area cannot be locked, securely fasten

a prominent warning device, such as a tag,

to the service panel.

NOTE: We strongly recommend that any servicing

be performed by a qualified individual.

For ease of service, the unit can be removed

from the case:

1. Unplug the power cord and disconnect the wall

thermostat connections.

2. Raise the top duct by turning all four case top duct

adjusting screws counterclockwise.

3. Remove the front case panel.

4. Remove the front and/or side case-to-unit grounding

screw, if present.

5. Slide the unit out of the case.

22

FINAL CHECK

Review this Checklist before restoring power.

• Correct line voltage?

• Single circuit only?

• HVACR type breaker/fuse?

• Ductwork connected?

• Case and unit level?

• Wall plenum caulked? Level? Flashing?

• Drain connected?

• Wall thermostat wired correctly?

• Unit wired correctly?

• Hydronic plumbing connections (if applicable)

• Hydronic wiring connections (if applicable)

8

CONNECT POWER

1. If all the above items are correct, turn the power

on at the main service panel.

2. Turn the unit power switch, on the front of the unit,

to ON by pressing the top of the switch in.

9

Page 23

Safety Instructions Operating Instructions Care and Cleaning Troubleshooting Tips Consumer Support

Before You Call For Service… ge.com

Troubleshooting Tips

Problem Possible Causes What To Do

Zoneline does The unit is unplugged. • Make sure the Zoneline plug is pushed completely

not start into the outlet.

The fuse is blown/circuit • Check the house fuse/circuit breaker box and replace

breaker is tripped. the fuse or reset the breaker.

The unit is waiting for • This is normal. The Zoneline will start again after it resets.

the compressor overload

protector to reset.

Power failure. • There is a protective time delay (up to 3 minutes) to

prevent tripping of the compressor overload. For this

reason, the unit may not start normal heating or cooling

for 3 minutes after it is turned back on.

Zoneline does not cool Indoor airflow is restricted. • Make sure there are no curtains, blinds or furniture

or heat as it should blocking the air discharge grille or the return air grille.

Outdoor airflow is • Make sure the architectural louver is not restricted.

restricted or recirculated. This can cause the unit to cycle off due to the compressor

overload.

• Outdoor grille must have a minimum of 65% free area.

Non-GE grilles may be too restrictive for proper

performance. Consult your salesperson for assistance.

The air filter is dirty. • Change the filter at least every 30 days.

See the Care and Cleaning–Air Filters section.

The room may have • When the Zoneline is first turned on you need to

been hot or cold. allow time for the room to cool down or warm up.

Outdoor air is • Set the vent control to the CLOSE position.

entering the room.

Burning odor Dust is on the surface • This can cause a “burning” odor at the beginning of

at the start of the heating element. the heating operation. This odor should quickly fade.

of heating operation

The air is not always The heat pump is not • This is normal. The heat pump will produce warm air

cool or hot during producing hot air. but not as hot as air produced when the higher-cost

operation electric heat is used.

The fan switch may be • This causes the fan to blow room temperature air

set at continuous fan. even when the compressor or heater cycles off.

The continuous air movement provides better

overall temperature control.

The air does not feel The heat pump alone • Use the Electric Heat Option. This turns off the heat

warm enough during produces air that feels pump and warms with electric heat only.

heating operation cooler than desired. NOTE: Use of this option will result in increased energy

consumption.

23

Page 24

Consumer Support

Troubleshooting Tips

Care and Cleaning Operating Instructions Safety Instructions

24

Normal Operating Sounds

You may hear a pinging noise caused by water being

picked up and thrown against the condenser on rainy

days or when the humidity is high. This design feature

helps remove moisture and improve efficiency.

You may hear relays click when the controls cycle

on and off or are adjusted to change the room

temperature.

Water will collect in the base pan during high humidity

or on rainy days. The water may overflow and drip

from the outdoor side of the unit.

The indoor fan runs continuously when the unit is

operating in the cooling mode, unless the fan switch

behind the case front panel is set at fan cycle (up).

This will cause the fan to cycle on and off with

the compressor. You may also hear a fan noise

stop and start.

You may notice a few minutes delay in starting

if you try to restart the Zoneline too soon after

turning it off or if you adjust the thermostat right after

the compressor has shut off. This is due to a built-in

restart protector for the compressor that causes

a 3-minute delay.

During the defrost cycle, both indoor and outdoor

fans stop and the compressor will operate in the

cooling mode to remove frost from the outdoor coil.

After defrost, the unit will restart in electric heat to

quickly warm the room to the desired comfort level.

To protect the compressor and prevent short cycling,

the unit is designed to run for a minimum of 3 minutes

after the compressor starts at any thermostat setting.

Things that are normal.

3-Minute

Delay

“CLICK”

SILENCE

COMPRESSOR

PROTECTION

Page 25

Safety Instructions Operating Instructions Care and Cleaning Troubleshooting Tips Consumer Support

Notes. ge.com

25

Page 26

Notes.

Consumer Support Troubleshooting Tips Care and Cleaning Operating Instructions Safety Instructions

26

Page 27

For The Period Of: GE Will Replace:

One Year Any part of the Zoneline which fails due to a defect in materials or workmanship. During this

From the date of the limited one-year warranty, GE will also provide, free of charge, all labor and related service

original purchase to replace the defective part.

Five Years Any part of the sealed refrigerating system (the compressor, condenser, evaporator

From the date of the and all connecting tubing) which fails due to a defect in materials or workmanship.

original purchase During this four-year limited additional warranty, GE will also provide, free of charge,

all labor and related service to replace the defective part.

Five Years For the second through the fifth year from the date of original purchase, GE will replace

From the date of the certain parts that fail due to a defect in materials or workmanship. Parts covered are fan

original purchase motors, switches, thermostats, electric resistance heater, electric resistance heater protectors,

compressor overload, solenoids, circuit boards, auxiliary controls, thermistors, frost controls,

ICR pump, capacitors, varistors and indoor blower bearing. During this four-year limited

additional warranty, you will be responsible for any labor or on-site service costs.

Safety Instructions Operating Instructions Care and Cleaning Troubleshooting Tips Consumer Support

27

Vertical Zoneline Warranty.

■ Service trips to your site to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ If you have an installation problem, or if the air

conditioner is of improper cooling or heating capacity

for the intended use, contact your dealer or installer.

You are responsible for providing adequate electrical

connecting facilities.

■ In commercial locations, labor necessary to move

the unit to a location where it is accessible for service

by an individual technician.

■ Failure or damage resulting from corrosion due

to installation in an environment containing corrosive

chemicals.

■ Replacement of fuses or resetting of circuit breakers.

■ Filters.

■ Failure of the product resulting from modifications

to the product or due to unreasonable use including

failure to provide reasonable and necessary

maintenance.

■ Failure or damage resulting from corrosion due

to installation in a coastal environment, except

for models treated with special factory-applied

anti-corrosion protection as designated

in the model number.

■ Damage to product caused by improper power supply

voltage, accident, fire, floods or acts of God.

■ Incidental or consequential damage caused

by possible defects with this air conditioner.

■ Damage caused after delivery.

■ Product not accessible to provide required service.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for use within the USA and Canada. If the product is located in an area where service by a GE Authorized

Servicer is not available, you may be responsible for a trip charge or you may be required to bring

the product to an Authorized GE Service location for service. In Alaska, the warranty excludes

the cost of shipping or service calls to your site.

Some states or provinces do not allow the exclusion or limitation of incidental or consequential damages.

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state or province to province. To know what your legal rights are, consult your local, state or provincial

consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule

service, on-line, visit us at ge.com, or call 800.GE.CARES

(800.432.2737). For service in Canada, contact Gordon

Williams Corp. at 1.888.209.0999. Please have serial number

and model number available when calling for service.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited Warranty.

Any implied warranties, including the implied warranties of merchantability or fitness for a particular purpose, are limited

to one year or the shortest period allowed by law.

Page 28

Consumer Support.

GE Appliances Website

ge.com

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day,

any day of the year! For greater convenience and faster service, you can now download Owner’s Manuals,

order parts or even schedule service on-line.

Schedule Service ge.com

Expert GE repair service is only one step away from your door. Get on-line and schedule your service at

your convenience any day of the year! Or call 800.GE.CARES (800.432.2737) during normal business hours.

For service in Canada, contact Gordon Williams Corp. at 1.888.209.0999.

Real Life Design Studio ge.com

GE supports the Universal Design concept—products, services and environments that can be used by

people of all ages, sizes and capabilities. We recognize the need to design for a wide range of physical and

mental abilities and impairments. For details of GE’s Universal Design applications, including kitchen design ideas

for people with disabilities, check out our Website today. For the hearing impaired, please call 800.TDD.GEAC

(800.833.4322).

Parts and Accessories ge.com

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today, 24 hours every day or by phone

at 800.626.2002 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since improper

servicing may cause unsafe operation.

Contact Us ge.com

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details

including your phone number, or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

Register Your Appliance ge.com

Register your new appliance on-line—at your convenience! Timely product registration will allow for

enhanced communication and prompt service under the terms of your warranty, should the need arise.

You may also mail in the pre-printed registration card included in the packing material.

Page 29

TINSEA517JBRZ 49-7594-1 10-08 JR

Climatiseurs

Consignes de sécurité . . . . . . . . . . . . . . . . .2

Directives de fonctionnement

Commandes – Bornes de raccordement . .6, 7

Commandes – Commutateurs DIP . . . . . . . .3–5

Commande de ventilation . . . . . . . . . . . . . . . . . .8

Interrupteur de marche/arrêt . . . . . . . . . . . . . . .8

Entretien et nettoyage

Filtres à air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Plateau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Serpentins extérieurs . . . . . . . . . . . . . . . . . . . . . . .9

Directives d’installation

Alimentation électrique . . . . . . . . . . . . . . . .11–13

Installation du climatiseur Zoneline . . . .14–21

Préparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Réparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Bruits normaux de fonctionnement . . . . . . . .24

Service à la clientèle

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Service à la clientèle . . . . . . . . . . .Dernière page

Modèles à climatisation

seulement,

à chauffage/climatisation

et thermopompe

Série 7500

Manuel d'utilisation et

directives d'installation

Inscrivez ci-dessous les numéros

de modèle et de série :

N° de modèle __________________________

N° de série ____________________________

Ils se trouvent sur une étiquette sur le panneau

avant de l’appareil.

verticaux Zoneline

MD

Imprimé à la Chine

Page 30

CONSIGNES DE SÉCURITÉ IMPORTANTES.

VEUILLEZ LIRE TOUTES LES CONSIGNES AVANT D’UTILISER L’APPAREIL.

AVERTISSEMENT!

Pour votre sécurité, veuillez observer les consignes données dans le présent manuel afin de réduire

au minimum les risques d’incendie, de choc électrique, de dommages matériels ou de blessures

graves ou mortelles.

■ Avant d’être utilisé, cet appareil

Zoneline doit être correctement installé,

en conformité avec les Directives

d’installation. Reportez-vous aux

Directives d’installation à la fin du présent

manuel.

■ Remplacez immédiatement tout cordon

d’alimentation effiloché ou endommagé.

Si le cordon d’alimentation est

endommagé, il ne faut pas le réparer

mais plutôt le remplacer par un neuf

acheté auprès du fabricant. N’utilisez pas

un cordon d’alimentation présentant

des fissures ou des marques d’abrasion

ou dont l’une de ses extrémités est

endommagée.

■ Le produit doit être utilisé avec la fiche

électrique fournie avec l’appareil. Ne

remplacez pas la fiche électrique fournie

avec le produit.

■ Si la prise de courant ne convient pas à

la fiche électrique, il faut faire remplacer

cette prise par un électricien qualifié.

■ Avant d’effectuer une réparation,

débranchez l’appareil ou coupez

l'alimentation électrique en enlevant le

fusible ou en déclenchant le disjoncteur.

REMARQUE : Nous recommandons

fortement de confier toute réparation

à un technicien qualifié.

■ Tous les climatiseurs contiennent

des frigorigènes qui, en vertu de la loi

fédérale, doivent être retirés avant de

jeter les appareils. Si vous vous

débarrassez d’un ancien produit qui

contient des frigorigènes, informez-vous

auprès d’une entreprise spécialisée dans

l’élimination des frigorigènes pour savoir

quoi faire.

CONSIGNES DE SÉCURITÉ

VEUILLEZ LIRE ET SUIVRE À LA LETTRE CES CONSIGNES DE SÉCURITÉ.

CONSERVEZ CES DIRECTIVES

2

Service à la clientèle Dépannage Entretien et nettoyage Fonctionnement Consignes de sécurité

Page 31

Consignes de sécurité Fonctionnement Entretien et nettoyage Dépannage Service à la clientèle

3

Commandes – Commutateurs DIP.

Les commutateurs DIP se trouvent derrière

le panneau avant et sont accessibles pour

une ouverture à l’avant de l’appareil.

Pour y accéder, enlevez le panneau avant en

retirant le filtre, en enlevant les quatre vis à l’avant,

les deux vis sur le dessus du panneau et les vis

d’expédition de chaque côté (s’il y a lieu).

(Si l’appareil est pourvu de deux vis d’expédition

sur le côté, vous pouvez les jeter.)

REMARQUE : Le propriétaire a la responsabilité

de régler les commutateurs DIP et de raccorder

les bornes de la façon appropriée.

Commandes – Commutateurs DIP

Commutateurs

DIP

Chauffage électrique (thermopompe seulement)

Lorsque ce commutateur est réglé au niveau haut

(UP), le fonctionnement de la thermopompe est

bloqué, le chauffage étant assuré uniquement par

l'élément chauffant.

= ALL I2R (Chauffage électrique)

All I2R (Chauffage électrique) (Thermopompe seulement)

FREEZ S (Protection antigel Sentinel)

CONST FAN (Fonctionnement continu des ventilateurs)

TL1 (H) (Limite de temp. 1 – Chauffage)

TL2 (H) (Limite de temp. 2 – Chauffage)

TL3 (H) (Limite de temp. 3 – Chauffage)

TL1 (C) (Limite de temp. 1 – Climatisation)

TL2 (C) (Limite de temp. 2 – Climatisation)

TL3 (C) (Limite de temp. 3 – Climatisation)

Non utilisé (réservé à une utilisation future)

DUCT (Ventilateur)

OCCUPIED (Détecteur d'occupation)

Vis

d’expédition

latérale

Vis

d’expédition

latérale

Page 32

Service à la clientèle Dépannage Entretien et nettoyage Fonctionnement Consignes de sécurité

4

Commandes – Commutateurs DIP.

Protection antigel Sentinel (exige l’ensemble de capteur RAVRMS)

Lorsque ce commutateur est réglé au niveau haut

(UP), la protection antigel est DÉSACTIVÉE. Lorsque

ce commutateur est au niveau bas (DOWN),

la fonction antigel est activée, de sorte que

l’appareil diffuse automatiquement de la chaleur

sans aucune intervention de l’utilisateur. Cette

fonction empêche tout dommage à la plomberie

en mettant en marche l’élément chauffant et

les ventilateurs à 5,0 °C (41 °F) et en les éteignant

à 7,7 °C (46 °F).

Fonctionnement continu des ventilateurs

Lorsque ce commutateur est au niveau haut (UP),

le ventilateur fonction continuellement.

Détecteur d’occupation

Lorsque ce commutateur est au niveau haut (UP),

il permet à l’appareil d’utiliser un détecteur

de mouvement à infrarouge et un détecteur

d’ouverture de porte pour détecter la présence

d’occupants. Cette fonction permet d’installer

et de faire fonctionner un système de gestion

de l’énergie conjointement avec l’appareil.

FREEZE S (Protection antigel

Sentinel)

CONST FAN (Fonctionnement

continu des ventilateurs)

OCCUPIED

(Détecteur d’occupation)

Conduit

Cette fonction permet au ventilateur intérieur

de fonctionner à deux vitesses variables. Lorsque

ce commutateur est au niveau haut (UP), l’appareil

règle automatiquement la vitesse moyenne ou

élevée du ventilateur (dans le cas des applications

où le conduit est plus long). Lorsque le

commutateur est au niveau bas, l’appareil

fonctionne automatiquement à vitesse moyenne

ou faible (pour les applications où le conduit est

plus court).

DUCT

(Ventilateur)

Page 33

5

Consignes de sécurité Fonctionnement Entretien et nettoyage Dépannage Service à la clientèle

Limitation de la température (Exige l’ensemble de capteur RAVRMS)

La limitation de la température peut réduire

les coûts de l’énergie en limitant la température

minimum que vous pouvez régler pour

la climatisation, ainsi que la température maximum

que vous pouvez régler pour le chauffage.

La limitation de la température est réglée

par les commutateurs 1 à 6 du bloc supérieur

de commandes auxiliaires. Les trois premiers

commutateurs permettent de sélectionner

les limites de climatisation, tandis que les trois

suivants sont utilisés pour régler les limites

de chauffage.

Limitation de la température au mode

CLIMATISATION (températures en °C/°F)

HAUT (UP) BAS (DOWN) Minimum Maximum

AUCUN 1, 2, 3 15,5/60 29,4/85

1 2, 3 17,7 /64 29,4/85

1, 2 3 18,8/66 29,4/85

2 1, 3 20,0/68 29,4/85

2,3 1 21,1/70 29,4/85

1, 2, 3 AUCUN 22,2/72 29,4/85

1, 3 2 23,3/74 29,4/85

3 1, 2 24,4/76 29,4/85

Limitation de la température au mode CHAUFFAGE

(températures en °C/°F)

HAUT (UP) BAS (DOWN) Minimum Maximum

AUCUN 4, 5, 6 15,5/60 29,4/85

4 5, 6 15,5/60 26,6/80

4, 5 6 15,5/60 25,5/78

5 4, 6 15,5/60 24,4/76

5,6 4 15,5/60 23,3/74

4, 5, 6 AUCUN 15,5/60 22,2/72

4, 6 5 15,5/60 21,1/70

6 4, 5 15,5/60 18,3/65

TL1 (C) (Limite de temp. 1 – Climatisation)

TL2 (C) (Limite de temp. 2 – Climatisation)

TL3 (C) (Limite de temp. 3 – Climatisation)

TL1 (H) (Limite de temp. 1 – Chauffage)*

TL2 (H) (Limite de temp. 2 – Chauffage)*

TL3 (H) (Limite de temp. 3 – Chauffage)*

*Ne s’applique pas aux modèles à climatisation seulement.

Page 34

6

Service à la clientèle Dépannage Entretien et nettoyage Fonctionnement Consignes de sécurité

Commandes – Bornes de raccordement.

Commandes – Bornes de raccordement

Les bornes de raccordement se trouvent derrière

le panneau avant et sont accessibles pour

une ouverture à l’avant de l’appareil.

Pour y accéder, enlevez le panneau avant en

retirant le filtre, en enlevant les quatre vis à l’avant,

les deux vis sur le dessus du panneau et les vis

d’expédition de chaque côté (s’il y a lieu).

(Si l’appareil est pourvu de deux vis d’expédition

sur le côté, vous pouvez les jeter.)

Acheminez les fils de raccordement de l’immeuble

à la partie inférieure des bornes et serrez

fermement les vis pour effectuer les raccordements

désirés.

Faites passer les fils des bornes de raccordement

dans les guide-fils de l’appareil, puis dans

le guide-fils du boîtier.

REMARQUE : Le propriétaire a la responsabilité

de régler les commutateurs DIP et de raccorder

les bornes de la façon appropriée.

ATTENTION :

Un raccordement incorrect des fils aux bornes

CDC (poste de commande central) pourrait

endommager les composants électroniques

de l’appareil ou provoquer un mauvais

fonctionnement de ce dernier. Il est interdit d’utiliser

une barre omnibus. Il faut acheminer deux fils

distincts à partir de chaque interrupteur de

commande vers chacun des appareils Zoneline.

Capteur d’air ambiant (exige l’ensemble de capteur RAVRMS)

Lorsqu’il est raccordé, le capteur d’air ambiant

permet l’utilisation des fonctions de limitation

de la température et de protection antigel Sentinel.

REMARQUE : Si le thermostat GE RAK148D1,

RAK148P1 ou RAK164D1, RAK164P1 est installé

sur l’appareil, il n’est pas nécessaire d’utiliser

l’ensemble de capteur d’air ambiant pour

le fonction de limitation de la température

puisque ce fonction est intégré à ce thermostat.

Faites passer

les fils dans

les guide-fils

Capteur d’air ambiant

Détecteur de mouvement

Détecteur d’ouverture de porte

Poste de commande central

Borne commune – Mise à la terre

Blanc – Élément chauffant

Jaune – Compresseur

Noir – Robinet inverseur

Vert – Vitesse élevée du ventilateur

Vert – Basse vitesse du ventilateur

Rouge – C.a. de 24 V seulement

Capteur d’air ambiant

Bornes de

raccordement

Chauffage hydronique (exige l’ensemble de chauffage hydronique – RAVHW1, RAVHW2 ou RAVHW3)

Raccordements pour l’ensemble de chauffage

hydronique.

REMARQUE : Les bornes R, W et C doivent

également être raccordées au thermostat,

s’il y a lieu.

Chauffage hydronique

Page 35

Thermostat mural

L’appareil est commandé par un thermostat mural.

IMPORTANT :

L’appareil Zoneline permet de raccorder uniquement

un thermostat alimenté par un courant alternatif

de 24 V seulement.

Si vous utilisez un thermostat mural électronique/

numérique, vous devez le régler en vue

d’une alimentation en c.a. de 24 V. Reportez-vous

aux directives d’installation du thermostat mural.

ATTENTION :

Un raccordement inadéquat pourrait endommager

le thermostat mural ou les composants électroniques

de l’appareil. Faites surtout attention lorsque vous

branchez les fils bleu et noir. Il ne faut brancher aucun

fil de tension de secteur à un circuit quelconque

du thermostat. Isolez tous les fils de l’immeuble

de la tension de secteur.

7

Consignes de sécurité Fonctionnement Entretien et nettoyage Dépannage Service à la clientèle

Détecteur d’ouverture de porte (acheté localement)

Pour pouvoir utiliser cette fonction, le commutateur DIP

du détecteur d’occupation doit être au niveau haut (UP).

Lorsqu’il est raccordé, le détecteur d’ouverture de porte

détecte l’ouverture ou la fermeture de la porte de la

pièce. Cette fonction exige l’utilisation du détecteur

de mouvement.

Le détecteur de mouvement et le détecteur d’ouverture

de porte travaillent ensemble pour faire fonctionner

automatiquement de façon cyclique l’appareil entre

le mode de fonctionnement normal et le mode

de gestion de l’énergie.

Poste de commande central

Lorsque cette fonction est raccordée, l’appareil est

déverrouillé et peut être MIS EN MARCHE ou ARRÊTÉ

au moyen d’un interrupteur du poste de commande

central. Il faut acheminer deux fils distincts à partir

de chaque interrupteur de commande vers chacun

des appareils Zoneline.

Détecteur de mouvement (acheté localement)

Pour pouvoir utiliser cette fonction, le commutateur DIP

du détecteur d’occupation doit être au niveau haut (UP).

Lorsqu’il est raccordé, le détecteur de mouvement

mural détecte tout mouvement dans la pièce et fait

automatiquement fonctionner l’appareil d’une manière

cyclique entre le mode de fonctionnement normal

et le mode de gestion de l’énergie.

Le détecteur de mouvement et le détecteur d’ouverture

de porte travaillent ensemble pour faire fonctionner

automatiquement de façon cyclique l’appareil entre

le mode de fonctionnement normal et le mode

de gestion de l’énergie.

Détecteur de mouvement

Détecteur d’ouverture de porte

Poste de commande central

Rouge – C.a. de 24 V seulement

Vert – Basse vitesse du ventilateur

Vert – Vitesse élevée du ventilateur

Noir – Robinet inverseur

Jaune – Compresseur

Blanc – Élément chauffant

Commune – Mise à la terre

Page 36

Le levier de la commande de ventilation est situé du côté

gauche de l’appareil Zoneline, derrière le panneau avant.

Pour y accéder, enlevez le panneau avant en retirant

le filtre, en enlevant les quatre vis à l’avant, les deux vis

sur le dessus du panneau et les vis d’expédition de

chaque côté (s’il y a lieu). (Si l’appareil est pourvu de

deux vis d’expédition sur le côté, vous pouvez les jeter.)

Lorsque le levier est à la position FERMÉE, l’air à l’intérieur

de la pièce est recyclé et filtré.

Lorsque le levier est à la position OUVERTE, de l’air

provenant de l’extérieur est aspiré dans la pièce.

Ce réglage atténue l’efficacité du chauffage ou

de la climatisation.

Pour fermer l’évent, poussez sur la poignée du levier

vers le bas, tirez-la vers l’avant, puis relevez-la pour

la bloquer en place.

Pour ouvrir l’évent, poussez sur la poignée du levier

vers le bas, poussez-la vers l’arrière, puis relevez-la

pour la bloquer en place.

Conseil pour économiser l’énergie : Laissez

la commande de ventilation à la position FERMÉE.

L’air de la pièce est ainsi filtré et recyclé.

8

Service à la clientèle Dépannage Entretien et nettoyage

Fonctionnement Consignes de sécurité

Autres caractéristiques de votre appareil Zoneline.

À propos des thermopompes (sur certains modèles)

La thermopompe peut abaisser les frais de

fonctionnement en effectuant un échange de chaleur

entre l’air extérieur—même lorsque la température à

l’extérieur est inférieure au point de congélation—puis

en libérant cette chaleur à l’intérieur.

Pour tirer le maximum de votre thermopompe sur le plan

économique, ne modifiez pas très souvent le réglage du

thermostat mural. Lorsque vous augmentez le réglage de

2 ou 3 degrés pour le chauffage, l’appareil Zoneline utilise

ses éléments chauffants électriques pour atteindre

rapidement la nouvelle température réglée.

Peu importe le réglage effectué, le compresseur

fonctionne pendant une période minimum de 3 minutes

afin d’éviter les cycles courts.

Le moteur du ventilateur intérieur se met en marche

avant le compresseur et s’arrête après le fonctionnement

cyclique du compresseur.

Les éléments chauffants électriques consomment plus

d’électricité que la thermopompe et leur coût de

fonctionnement est donc plus élevé.

Commande de ventilation

Commande de

ventilation (poussez

le levier vers le bas

et tirez-le vers

l’avant ou l’arrière

pour l’actionner)

Ouvrir

Fermer

Interrupteur de marche/arrêt

L’interrupteur de marche/arrêt de l’appareil se trouve

à l’avant de l’appareil Zoneline.

Pour mettre l’appareil en marche, appuyez sur la partie

supérieure de l’interrupteur.

Pour arrêter l’appareil, appuyez sur la partie inférieure

de l’interrupteur.

Interrupteur de

MARCHE/ARRÊT

Ne faites pas fonctionner les modèles à climatisation seulement lorsque

la température à l’extérieur est sous le point de congélation

Les appareils à climatisation seulement ne sont pas

conçus pour fonctionner lorsque la température

à l’extérieur est sous le point de congélation. Ils

ne doivent pas être utilisés dans de telles conditions.

Page 37

Pour maintenir l’appareil Zoneline en bon état

de fonctionnement, le plus important est

de remplacer le filtre au moins tous les 30 jours.

Un filtre sale réduit la capacité de climatisation

et de chauffage et diminue la circulation de l’air.

En remplaçant le filtre, vous diminuerez les frais

de fonctionnement, économiserez de l’énergie,

empêcherez l’obstruction des serpentins

de l’échangeur de chaleur et réduirez les risques

de défaillance prématurée des composants.

ATTENTION : Ne faites

pas fonctionner l’appareil Zoneline sans le filtre.

Si le filtre est déchiré ou endommagé, il faut

le remplacer immédiatement.

Lorsque l’appareil fonctionne sans le filtre ou avec

un filtre endommagé, cela permet à la saleté et

à la poussière d’atteindre les serpentins intérieurs,

ce qui réduit la capacité de climatisation et

de chauffage, et diminue la circulation de l’air

et l’efficacité de l’appareil. Procurez-vous des filtres

de rechange auprès de votre détaillant local

d’accessoires pour climatiseurs et systèmes

de chauffage.

Le filtre mesure 50,8 cm x 50,8 cm x 2,5 cm

(20 po x 20 po x 1 po).

Serpentins intérieurs/extérieurs

Il faut vérifier régulièrement les serpentins de sortie

de l’appareil Zoneline. S’ils sont obstrués par de la

poussière ou de la suie, ils peuvent être nettoyés

à la vapeur de façon professionnelle par votre

Centre de service après-vente GE. Pour ce faire,

il vous faudra sortir l’appareil de son boîtier pour

inspecter les serpentins car l’accumulation

de saleté se produit du côté sortie.

9

Entretien et nettoyage.

Avant de le nettoyer, éteignez l’appareil Zoneline et débranchez-le.

Serpentins extérieurs

Faites nettoyer régulièrement les serpentins.

Filtre installé

sur l’appareil

Enlevez le filtre

Panneau d’accès doté

d’une grille de retour d’air

Grille de retour d’air

Filtre

Filtre

Pour enlever

et remplacer

le filtre :

Système d’écoulement

Nettoyez le système d’écoulement régulièrement

pour éviter toute obstruction.

Plateau

Dans certaines installations, de la saleté

ou d’autres débris peuvent s’infiltrer dans l’appareil

en provenance de l’extérieur et se déposer

dans le plateau (le fond de l’appareil).

Dans certaines régions des États-Unis,

une substance ressemblant à de la «gelée» peut

se former dans le plateau.

Nettoyez le plateau régulièrement et nettoyez-le

au besoin.

Pour maintenir un rendement optimum, remplacez le filtre au moins tous les 30 jours.

Filtres à air

Consignes de sécurité Fonctionnement Entretien et nettoyage Dépannage Service à la clientèle

Page 38

AVANT DE COMMENCER

Directives Climatiseurs

d’installation Zoneline

Veuillez lire attentivement toutes les directives

qui suivent.

•

IMPORTANT

–

Conservez les présentes

directives pour l’inspecteur local.

•

IMPORTANT

–

Observez tous les codes

et ordonnances en vigueur.

• Note à l’installateur – Veuillez laisser

les présentes directives au propriétaire.

• Note au propriétaire – Veuillez conserver

les présentes directives pour consultation ultérieure.

• L’installateur est responsable de la qualité de

l’installation.

• Toute défaillance du produit attribuable à une

installation inadéquate n’est pas couverte par

la garantie.

• Lors de l’installation de ce climatiseur, vous DEVEZ

utiliser toutes les pièces fournies et suivre les

procédures d’installation appropriées, comme

expliqué dans les présentes directives.

Des questions? Communiquez avec la firme Gordon Williams Corp. au 1.888.209.0999.

CONSIGNES DE SÉCURITÉ

IMPORTANTES

EN ÉLECTRICITÉ – VEUILLEZ

LIRE ATTENTIVEMENT

ATTENTION :

• Le câblage et tous les raccordements électriques

DOIVENT être effectués par un électricien qualifié.

• Veuillez observer le code national d’électricité

et(ou) les ordonnances et codes locaux.

• Pour votre sécurité, le boîtier et l’appareil Zoneline