Page 1

g

GE Power Management

745

TRANSFORMER MANAGEMENT RELAY™

INSTRUCTION MANUAL

Firmware Revision: 250.000

Manual P/N: 1601-0070-B2 (GE K-10 629 2)

Copyright © 2001 GE Power Management

g

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

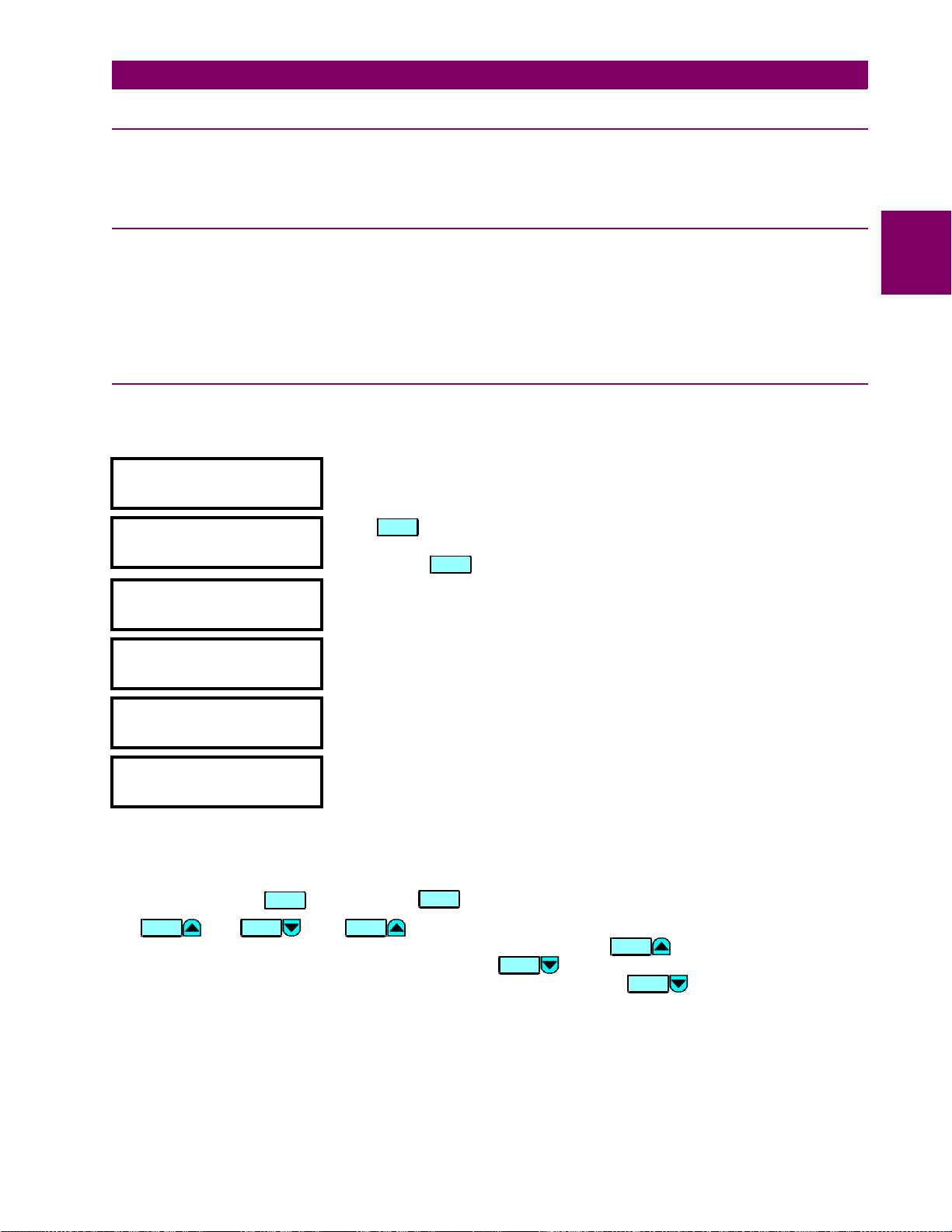

745 STATUS SYSTEM STATUS CONDITIONS

IN SERVICE

SELF-TEST

ERROR

TEST MODE

DIFFERENTIAL

BLOCKED

LOCAL

RESET

NEXT

PROGRAM PORT

745 Transformer Management Relay ™

TRANSFORMER

DE-ENERGIZED

TRANSFORMER

OVERLOAD

LOAD-LIMIT

REDUCED

SETPOINT GROUP 1

SETPOINT GROUP 2

SETPOINT GROUP 3

SETPOINT GROUP 4

SETPOINT

ACTUAL

ESCAPE

ENTER

7 89

MESSAGE

4

12 3

VALUE

.

TRIP

ALARM

PICKUP

PHASE A

PHASE B

PHASE C

GROUNDMESSAGE

5

0

6

HELP

814768AF.CDR

Manufactured under an

ISO9001 Registered system.

Page 2

These instruct ions do not purport to cover all details or variatio ns in equi pment no r provid

e

-

e

e

d

-

for every possible contingency to be met in connection with installation, operation, or main

tenance. Should furth er info rma tion be desi red or shoul d par ticu lar prob lems aris e whi ch ar

not covered sufficiently for the purchaser’s purpose, the matter should be referred to th

General Electric Company.

To the extent required the products described herein meet applicable ANSI, IEEE, an

NEMA standards; but no such assurance is given with respect to local codes and ordi

nances because they vary greatly.

Page 3

TABLE OF CONTENTS

1. PRODUCT OVERVIEW

2. GETTING STARTED

1.1 INTRODUCTION

1.1.1 DESCRIPTION.......................................................................................... 1-1

1.1.2 SUMMARY OF PROTECTION FEATURES.............................................. 1-2

1.1.3 ORDER CODES........................................................................................ 1-4

1.2 TECHNICAL SPECIFICATIONS

1.2.1 APPLICABILITY......................................................................................... 1-5

1.2.2 INPUTS...................................................................................................... 1-5

1.2.3 PROTECTION ELEMENTS..................................................................... ..1-6

1.2.4 OUTPUTS.................. ................................................ ................................ 1-9

2.1 USING THE FRONT PANEL DISPLAY

2.1.1 MANEUVERING........................................................................................2-1

2.2 CHANGING SETPOINTS

2.2.1 DESCRIPTION.......................................................................................... 2-3

2.2.2 INSTALLING THE SETPOINT ACCESS JUMPER ...................................2-3

2.2.3 NUMERICAL SETPOINTS........................................................................ 2-3

2.2.4 ENUMERATION SETPOINTS...................................................................2-4

2.2.5 TEXT SETPOINTS.................................................................................... 2-5

2.3 SECURITY

2.3.1 INSTALLATION......................................................................................... 2-6

2.3.2 PASSCODE SECURITY SETUP...............................................................2-6

a CHANGING THE PASSCODE .................................................................. 2-6

b DISABLING/ENABLING PASSCODE SECURITY....................................2-7

3. INSTALLATION

3.1 DRAWOUT CASE

3.1.1 CASE DESCRIPTION................................................................................ 3-1

3.1.2 PANEL CUTOUT.......................................................................................3-1

3.1.3 CASE MOUNTING..................................................................................... 3-2

3.1.4 UNIT WITHDRAWAL AND INSERTION.................................................... 3-2

a RELAY WITHDRAWAL..............................................................................3-2

b RELAY INSERTION................................................................................... 3-3

c DRAWOUT SEAL ................. ............. .. ............. .............. ............. ............. . 3-3

3.2 TYPICAL WIRING

3.2.1 DESCRIPTION.......................................................................................... 3-4

3.2.2 REAR TERMINAL LAYOUT...................................................................... 3-4

3.2.3 REAR TERMINAL ASSIGNMENTS........................................................... 3-5

3.2.4 TYPICAL WIRING DIAGRAMS.................................................................3-6

3.2.5 PHASE SEQUENCE AND TRANSFORMER POLARITY ......................... 3-8

3.2.6 AC CURRENT TRANSFORMER INPUTS ......................... .......................3-8

3.2.7 AC VOLTAGE INPUT................................................................................3-8

3.2.8 CONTROL POWER...................................................................................3-9

3.2.9 LOGIC INPUTS.......................................................................................... 3-9

3.2.10 ANALOG INPUT................ ......................................................................3-10

3.2.11 TAP POSITION IN PUT............................................................................3-10

3.2.12 RTD DRIVER/SENSOR.............................................................. ............. 3-10

3.2.13 OUTPUT RELAYS................................................................................... 3-11

3.2.14 SOLID STATE TRIP OUTPUT.................................................................3-11

3.2.15 ANALOG OUTPUTS................................................................................ 3-11

3.2.16 RS485 / RS422 COMMUNICATION PORTS ..........................................3-12

3.2.17 RS232 FRONT PANEL PROGRAM PORT ............................................. 3-13

3.2.18 IRIG-B...................................................................................................... 3-14

GE Power Management 745 Transformer Management Relay

i

Page 4

TABLE OF CONTENTS

g

3.2.19 DIELECTRIC STRENGTH TESTING ...................................................... 3-14

4. FRONT PANEL

OPERATION

4.1 FRONT PANEL

4.1.1 DESCRIPTION .......................................................................................... 4-1

4.2 DISPLAY, INDICATORS, AND FRONT PORT

4.2.1 DISPLAY.................................................................................................... 4-2

4.2.2 LEDS..........................................................................................................4-2

4.2.3 STATUS INDICATORS............ ......................... .........................................4-2

a IN SERVICE............................................................................................... 4-2

b SELF-TEST ERROR.................................................................................. 4-2

c TEST MODE.............................................................................................. 4-2

d DIFFERENTIAL BLOCKED....................................................................... 4-3

e LOCAL....................................................................................................... 4-3

f MESSAGE...................................................................................... ........... 4-3

4.2.4 SYSTEM STATUS INDICATORS.............................................................. 4-3

a TRANSFORMER DE-ENERGIZED........................................................... 4-3

b TRANSFORMER OVERLOAD..................................................................4-3

c LOAD-LIMIT REDUCED............................................................................4-3

d SETPOINT GROUP 1................................................................................ 4-3

e SETPOINT GROUP 2................................................................................ 4-3

f SETPOINT GROUP 3................................................................................ 4-3

SETPOINT GROUP 4................................................................................ 4-3

4.2.5 CONDITION INDICATORS............................................................... ......... 4-4

a TRIP.................... ........................................................................ ...............4-4

b ALARM............................................................ ...........................................4-4

c PICKUP..................... ........................................................................ ......... 4-4

d PHASE A (B/C)................................................................................. ......... 4-4

e GROUND................................................................. .................................. 4-4

4.2.6 PROGRAM PORT .....................................................................................4-4

4.3 KEYPAD

4.3.1 SETPOINT KEY......................................................................................... 4-5

4.3.2 ACTUAL KEY............. ................................................................................ 4-5

4.3.3 ESCAPE KEY............................................................................................ 4-5

4.3.4 ENTER KEY...............................................................................................4-5

4.3.5 MESSAGE UP/DOWN KEY.......................................................................4-5

4.3.6 VALUE UP/DOWN KEY.............................................................................4-5

4.3.7 NUMBER KEYS.............................................. ...........................................4-6

4.3.8 HELP KEY ..................................... ............................................................4-6

4.3.9 RESET KEY............................................................................................... 4-6

4.3.10 NEXT KEY................................................................................................. 4-6

5. SETPOINTS

5.1 OVERVIEW

5.1.1 SETPOINT GROUPS................................................................................ 5-1

5.1.2 SETPOINT ENTRY....................................................................................5-2

5.1.3 SETPOINT WRITE ACCESS..................................................................... 5-2

5.2 AUTO-CONFIGURATION

5.2.1 DESCRIPTION .......................................................................................... 5-3

5.2.2 A TYPICAL POWER TRANSFORMER .....................................................5-3

5.2.3 DYNAMIC CT RATIO MISMATCH CORRECTION ...................................5-3

a PROBLEM 1:USE OF STANDARD CT RATIOS....................................... 5-3

b PROBLEM 2: ONLOAD TAP CHANGER.................................................. 5-4

5.2.4 PHASE SHIFTS ON THREE-PHASE TRANSFORMERS......................... 5-6

5.2.5 PHASE ANGLE CORRECTION ................................................................ 5-8

5.2.6 ZERO-SEQUENCE COMPONENT REMOVAL......................................... 5-9

ii

745 Transformer Management Relay

GE Power Management

Page 5

TABLE OF CONTENTS

5.2.7 TRANSFORMER TYPES TABLE............................................................5-10

5.2.8 TABLE OF PHASE SH IFTS..................................................................... 5-23

5.3 S1 745 SETUP

5.3.1 DESCRIPTION........................................................................................ 5-24

5.3.2 PASSCODE .............................................................................................5-24

5.3.3 PREFERENCES...................................................................................... 5-25

5.3.4 COMMUNICATIONS ............................................................................... 5-26

5.3.5 DNP COMMUNICATIONS.................................................................. ..... 5-27

5.3.6 RESETTING............ ................................................................................ 5-28

5.3.7 CLOCK.................................................................................. ...................5-28

5.3.8 DEFAULT MESSAGES........................................................................... 5-29

a ADDING DEFAULT MESSAGES ............................................................5-29

b REMOVING DEFAULT MESSAGES.......................................................5-29

5.3.9 SCRATCHPAD........................................................................................5-30

5.3.10 INSTALLATION.......................................................................................5-30

5.3.11 745 OPTIONS ..........................................................................................5-31

5.3.12 UPGRADE OPTIONS.............................................................................. 5-32

5.4 S2 SYSTEM SETUP

5.4.1 DESCRIPTION........................................................................................ 5-33

5.4.2 TRANSFORMER..................................................................................... 5-33

5.4.3 WINDING 1 (2/3)...................................................................................... 5-35

5.4.4 ONLOAD TAP CHANGER....................................................................... 5-36

5.4.5 HARMONICS........................................................................................... 5-37

5.4.6 FLEXCURVES......................................................................................... 5-37

5.4.7 VOLTAGE INPUT.................................................................................... 5-38

5.4.8 AMBIENT TEMPERATURE..................................................................... 5-39

5.4.9 ANALOG INPUT............................................ ..........................................5-40

5.4.10 DEMAND METERING ..................................... ........................................ 5-41

5.4.11 ANALOG OUTPUTS................................................................................ 5-42

5.5 SETPOINTS S3 LOGIC INPUTS

5.5.1 DESCRIPTION........................................................................................ 5-43

5.5.2 LOGIC INPUTS........................................................................................ 5-43

5.5.3 VIRTUAL INPUTS.................................................................................... 5-44

5.6 S4 ELEMENTS

5.6.1 DESCRIPTION........................................................................................ 5-45

5.6.2 INTRODUCTION TO ELEMENTS........................................ ...................5-45

5.6.3 SETPOINT GROUP.................................................................................5-46

5.6.4 DIFFERENTIAL....................................................................................... 5-46

a PERCENT DIFFERENTIAL..................................................................... 5-46

b HARMONIC INHIBIT...... ................................................ ..........................5-49

c ENERGIZATION INHIBIT..................................................................... ...5-49

d ENERGIZATION SENSING.......................................................... ........... 5-50

e 5TH HARMONIC INHIBIT........................................................................ 5-51

5.6.5 INSTANTANEOUS DIFFERENTIA L........................................................ 5-52

5.6.6 PHASE OVERCURRENT................. .................................................. ..... 5-52

a WINDING 1 (2/3) PHASE TIME OVERCURREN T..................................5-52

b WINDING 1 (2/3) PHASE INSTANTANEOUS OVERCURRENT 1......... 5-54

c WINDING 1 (2/3) PHASE INSTANTANEOUS OVERCURRENT 2 ........ 5-54

5.6.7 NEUTRAL OVERCURRENT ...................................................................5-55

a WINDING 1 (2/3) NEUTRAL TIME OVERCURRENT ............................. 5-55

b WINDING 1 (2/3) NEUTRAL INSTANTANEOUS OVERCURRENT 1 .... 5-56

c WINDING 1 (2/3) NEUTRAL INSTANTANEOUS OVERCURRENT 2 .... 5-56

5.6.8 GROUND OVERCURRENT ............... .....................................................5-57

a WINDING 1 (2/3) GROUND TIME OVERCURRENT.............................. 5-57

b WINDING 1 (2/3) GROUND INSTANTANEOUS OVERCURRENT 1 ..... 5-58

c WINDING 1 (2/3) GROUND INSTANTANEOUS OVERCURRENT 2..... 5-58

5.6.9 RESTRICTED GROUND (DIFFERENTIAL GROUND).................... ....... 5-59

a WINDING 1 (2/3) RESTRICTED GROUND FAULT............. ................... 5-59

GE Power Management 745 Transformer Management Relay

iii

Page 6

TABLE OF CONTENTS

b RESTRICTED GROUND FAULT SETTINGS EXAMPLE............... ......... 5-61

c SETPOINTS............................................................................................. 5-62

5.6.10 NEGATIVE SEQUENCE OVERCURRENT............... ............................. .5-63

a WINDING 1 (2/3) NEGATIVE SEQUENCE TIME OVERCURRENT....... 5-63

b WINDING 1 (2/3) NEG. SEQ. INSTANTANEOUS OVER CURREN T......5-64

5.6.11 FREQUENCY .......................................................................................... 5-65

a UNDERFREQUENCY 1 (2).....................................................................5-65

b FREQUENCY DECAY.............................................................................5-66

c OVERFREQUENCY ................................................................................5-67

5.6.12 OVEREXCITATION.................................................................................5-68

a 5TH HARMONIC LEVEL.........................................................................5-68

b VOLTS-PER-HERTZ 1 (2)....................................................................... 5-69

5.6.13 HARMONICS........................................................................................... 5-70

a WINDING 1 (2/3) THD LEVEL................................................................. 5-70

b WINDING 1 (2/3) HARMONIC DERATING ............................................. 5-71

5.6.14 INSULATION AGING / LOSS OF LIFE FEATURE.................................. 5-72

a DESCRIPTION ........................................................................................ 5-72

b HOTTEST-SPOT LIMIT ...........................................................................5-72

c INSULATION AGING SETPOINTS.........................................................5-73

5.6.15 AGING FACTOR LIMIT...........................................................................5-74

5.6.16 LOSS OF LIFE LIMIT........... ....................................................................5-75

5.6.17 ANALOG INPUT.................... ..................................................................5-76

a ANALOG LEVEL 1 (2) .............................................................................5-76

5.6.18 CURRENT DEMAND............................................... ................................ 5-77

5.6.19 TRANSFORMER OVERLOAD................................................................5-78

5.6.20 T AP C H ANGER FAILURE..................... .............. ............. .. .. ............. ...... 5-79

5.7 S5 OUTPUTS

5.7.1 DESCRIPTION ........................................................................................ 5-80

5.7.2 INTRODUCTION TO FLEXLOGIC™.............................................. ......... 5-80

5.7.3 FLEXLOGIC™ RULES............................................................................ 5-82

5.7.4 OUTPUT RELAYS...................................................................................5-84

5.7.5 TRACE MEMORY....................................................................................5-85

5.7.6 VIRTUAL OUTPUTS................................................................................5-85

5.7.7 TIMERS ...................................................................................................5-86

5.8 S6 TESTING

5.8.1 DESCRIPTION ........................................................................................ 5-87

5.8.2 OUTPUT RELAYS...................................................................................5-87

5.8.3 ANALOG OUTPUTS................................................................................ 5-87

5.8.4 SIMULATION...................................... ..................................................... 5-88

5.8.5 PREFAULT VALUES...............................................................................5-89

5.8.6 FAULT VALUES ...................................................................................... 5-90

5.8.7 FACTORY SERVICE...............................................................................5-90

5.9 TIME OVERCURRENT CURVES

5.9.1 NOTE.......................................................................................................5-91

5.9.2 ANSI CURVES.........................................................................................5-91

5.9.3 DEFINITE TIME CURVE ......................................................................... 5-93

5.9.4 IEC CURVES................. ....................................................................... ... 5-93

5.9.5 IAC CURVES................. ....................................................................... ... 5-95

5.10 INVERSE VOLTS-PER-HERTZ CURVES

5.10.1 INVERSE CURVE 1.................................................................................5-97

5.10.2 INVERSE CURVE 2.................................................................................5-98

5.10.3 INVERSE CURVE 3.................................................................................5-99

6. ACTUAL VALUES

iv

6.1 OVERVIEW

6.1.1 DESCRIPTION .......................................................................................... 6-1

745 Transformer Management Relay

GE Power Management

Page 7

TABLE OF CONTENTS

g

6.1.2 ACTUAL VALUES ORGANIZA TION .........................................................6-1

6.2 A1 STATUS

6.2.1 DESCRIPTION.......................................................................................... 6-2

6.2.2 DATE AND TIME ....................................................................................... 6-2

6.2.3 LOGIC INPUTS.......................................................................................... 6-2

6.2.4 VIRTUAL INPUTS...................................................................................... 6-2

6.2.5 OUTPUT RELAYS..................................................................................... 6-3

6.2.6 VIRTUAL OUTPUTS..................................................................................6-3

6.2.7 SELF-TEST ERRORS............................................................................... 6-3

6.3 A2 METERING

6.3.1 DESCRIPTION.......................................................................................... 6-4

6.3.2 CURRENT .................................................................................................6-4

a WINDING 1/2/3 CURRENTS............ ......................... ......................... ....... 6-4

b POSITIVE SEQUENCE CUR RENTS ........................................................ 6-5

c NEGATIVE SEQUENCE CURRENTS..................... .................................. 6-5

d ZERO SEQUENCE CURRENTS....................... ......................... ............... 6-5

e DIFFERENTIAL CURRENT....................................... ................................ 6-6

f RESTRAINT CURRENT............................................................................ 6-6

GROUND DIFFERENTIAL CURRENT......................................................6-6

6.3.3 HARMONIC CONTENT..................................... ........................................ 6-7

a HARMONIC SUB-COMPONENTS...................... ...................................... 6-7

b TOTAL HARMONIC DISTORTION (THD)................................................. 6-7

c HARMONIC DERATING FACTOR............................................................6-8

6.3.4 FREQUENCY ............................................................................................ 6-8

6.3.5 TAP CHANGER......................................................................................... 6-8

6.3.6 VOLTAGE..................................................................................................6-9

6.3.7 DEMAND ................................................................................................... 6-9

a DEMAND DATA CLEAR............... ............................................................. 6-9

b CURRENT DEMAND...............................................................................6-10

6.3.8 AMBIENT TEMPERATURE..................................................................... 6-10

6.3.9 LOSS OF LIFE.........................................................................................6-10

6.3.10 ANALOG INPUT................ ......................................................................6-11

6.3.11 POWER...................................................................................................6-11

6.3.12 ENERGY................ .................................................................................. 6-12

a ENERGY DATA CLEAR.......................................................................... 6-12

b W1/W2/W3 ENERGY............................................................................... 6-12

6.4 A3 EVENT RECORDER

6.4.1 DESCRIPTION........................................................................................ 6-13

6.4.2 EVENT DATA RESET.............................................................................6-13

6.4.3 EVENT RECORDS..................................................................................6-13

6.5 A4 PRODUCT INFO

6.5.1 DESCRIPTION........................................................................................ 6-17

6.5.2 TECHNICAL SUPPORT..........................................................................6-17

6.5.3 REVISION CODES .................................................................................. 6-17

6.5.4 CALIBRATION .........................................................................................6-18

6.6 TARGET MESSAGES

6.6.1 DESCRIPTION........................................................................................ 6-19

6.7 SELF-TEST ERRORS

6.7.1 DESCRIPTION........................................................................................ 6-21

6.7.2 MAJOR SELF-TEST ERRORS................................................................ 6-21

6.7.3 MINOR SELF-TEST ERRORS ................................................................ 6-21

6.8 FLASH MESSAGES

6.8.1 DESCRIPTION........................................................................................ 6-23

GE Power Management 745 Transformer Management Relay

v

Page 8

TABLE OF CONTENTS

7. SCHEME LOGIC

8. COMMUNICATIONS

7.1 INTRODUCTION

7.1.1 DESCRIPTION .......................................................................................... 7-1

7.1.2 SETPOINTS...............................................................................................7-1

7.1.3 MEASUREMENT UNITS........................................................................... 7-1

7.1.4 TIME DELAYS...........................................................................................7-1

7.1.5 LED INDICATORS.....................................................................................7-1

7.1.6 LOGIC........................................................................................................7-1

7.2 BLOCK DIAGRAMS

7.2.1 DIFFERENTIAL SCHEME LOGIC............................................................. 7-2

7.2.2 OVERCURRENT SCHEME LOGIC...........................................................7-8

7.2.3 FREQUENCY LOGIC.............................................................................. 7-20

8.1 OVERVIEW

8.1.1 PROTOCOLS ............................................................................................ 8-1

8.1.2 PHYSICAL LAYER.................................................................................... 8-1

8.2 MODBUS PROTOCOL

8.2.1 DESCRIPTION .......................................................................................... 8-2

8.2.2 GE POWER MANAGEMENT MODB U S PROTOCOL ....... ............. .. .. ...... 8-2

8.2.3 ELECTRICAL INTERFACE .............................................................. ......... 8-2

8.2.4 DATA FRAME FORMAT AND RATE ........................................................ 8-2

8.2.5 DATA PACKET FORMAT............................................................... ........... 8-3

8.2.6 CRC-16 ALGORITHM................................................................................ 8-4

8.2.7 MESSAGE TIMING.................................................................................... 8-4

8.2.8 SUPPORTED FUNCTION CODES...........................................................8-5

8.2.9 FUNCTION CODE 03H/04H: READ ACTUAL VALUES/SETPOINTS...... 8-6

8.2.10 FUNCTION CODE 05H: EXECUTE OPERATION.................................... 8-7

8.2.11 FUNCTION CODE 06H: STORE SINGLE SETPOINT........................ ...... 8-8

8.2.12 FUNCTION CODE 10H: STORE MULTIPLE SETPOINTS....................... 8-9

8.2.13 EXCEPTION RESPONSES..................................................................... 8-10

8.2.14 READING THE EVENT R ECORDER...................................................... 8-11

8.2.15 READING TRACE MEMORY.................................................................. 8-11

8.2.16 ACCESSING DATA VIA THE USER MAP .............................................. 8-12

8.2.17 FUNCTION CODE SUBSTITUTIONS..................................................... 8-15

a FUNCTION CODE 03H AND 04 SUBSTITUTIONS................................ 8-15

b FUNCTION CODE 05H SUBSTITUTION ................................................8-15

c FUNCTION CODE 06H SUBSTITUTION................................................ 8-16

8.2.18 MEMORY MAP ORGANIZATION.................................. .......................... 8-16

8.3 MODBUS MEMORY MAP

8.3.1 745 MEMORY MAP .................................................................................8-17

8.3.2 MEMORY MAP DATA FORMATS.................. ....................... ..................8-74

8.4 DNP COMMUNICATIONS

8.4.1 DEVICE PROFILE DOCUMENT ............................................................. 8-92

8.4.2 IMPLEMENATION TABLE.............. .................................... ..................... 8- 9 4

8.5 POINT LISTS

8.5.1 POINT LIST TABLES............................................................................... 8-96

9. 745 PC SOFTWARE

vi

9.1 OVERVIEW

9.1.1 DESCRIPTION .......................................................................................... 9-1

9.1.2 HARDWARE & SOFTWARE REQUIREMENTS .......................................9-2

9.1.3 MENU SUMMARY.....................................................................................9-2

745 Transformer Management Relay

GE Power Management

Page 9

TABLE OF CONTENTS

g

9.1.4 TOOLBAR.................................................................................................. 9-3

9.1.5 HARDWARE CONFIGURATION...............................................................9-3

9.2 INSTALLATION & CONFIGURATION

9.2.1 745PC INSTALLATION ............................................................................. 9-5

9.2.2 STARTUP & COMMUNICATIONS CONFIGURATION.............................9-6

9.3 USING 745PC

9.3.1 SAVING SETPOINTS TO A FILE......................................... .....................9-7

9.3.2 745 FIRMWARE UPGRADES ................................................................... 9-8

9.3.3 LOADING SETPOINTS FROM A FILE...................................................... 9-9

9.3.4 ENTERING SETPOINTS........................................................................... 9-9

9.3.5 VIEWING ACTUAL VALUES................................................................... 9-11

10. COMMISSIONING

10.1 GENERAL

10.1.1 INTRODUCTION .....................................................................................10-1

10.1.2 TESTING PHILOSOPHY.................... ..................................................... 10-1

10.1.3 SAFETY PRECAUTIONS........................................................................ 10-2

10.1.4 CONVENTIONS....................................................................................... 10-2

10.2 TEST EQUIPMENT

10.2.1 TEST SETUP........................................................................................... 10-3

10.3 GENERAL PRELIMINARY WORK

10.3.1 DESCRIPTION........................................................................................ 10-4

10.3.2 DIELECTRIC STRENGTH TESTING ...................................................... 10-5

10.4 LOGIC INPUTS & OUTPUT RELAYS

10.4.1 LOGIC INPUTS........................................................................................ 10-6

a PROCEDURE..........................................................................................10-6

10.4.2 OUTPUT RELAYS................................................................................... 10-7

a PROCUDURE:............................................ .............................................10-7

10.5 DISPLAY, METERING, COMMUNICATIONS, ANALOG

OUTPUTS

10.5.1 DESCRIPTION........................................................................................ 10-8

10.5.2 CURRENT INPUTS......... ........................................................................10-8

10.5.3 VOLTAGE INPUT.................................................................................... 10-9

10.5.4 TRANSFORMER-TYPE SELECTION ..................................................... 10-9

a AUTOMATIC TRANSFORM ATION PERFORMED IN THE 745............. 10-9

b EFFECTS OF ZERO-SEQUENCE COMPONENT REMOVAL ............. 10-10

10.5.5 AMBIENT TEMPERATURE INPUT.......................................................10-11

a BASIC CALIBRATION OF RTD INPUT................................................. 10-11

b DETAILED CALIBRATION OF RTD INPUT .......................................... 10-11

c AMBIENT TEMPERATURE BY MONTHLY AVERAGES...................... 10-12

10.5.6 ANALOG OUTPUTS.............................................................................. 10-13

10.5.7 TAP POSITION...................................................................................... 10-13

10.6 PROTECTION SCHEMES

10.6.1 WARNING.............................................................................................. 10-14

10.6.2 HARMONIC RESTRAINED PERCENT DIFFERENTIAL ......................10-14

a MINIMUM PICKUP.......... ......................................................................10-14

b VERIFICATION OF LOCAL RESET MODE .......................................... 10-15

c VER IFICATION OF R E MOTE RESET M O D E........ .. ............. .............. .. 10-15

d VERIFICATION OF SOLID STATE OUTPUT........................................ 10-15

e BASIC OPERATING TIME....................................................................10-16

f SLOPE MEASU REMENTS ....................................................................10-16

SLOPE KNEEPO I N T .. .. .. ............. .. .............. . ........................... .. ............ 10-17

h 2nd HARMONIC RESTRAINT............................................................... 10-18

i 5th HARMONIC RESTRAINT................................................................10-18

j ENERGIZATION DETECTION SCHEME.............................................. 10-19

GE Power Management 745 Transformer Management Relay

vii

Page 10

TABLE OF CONTENTS

k TARGET, OUTPUT CONTACT, & DISPLAY OPERATION .................. 10-20

l BLOCKING FROM LOGIC INPUTS ...................................................... 10-20

10.6.3 INSTANTANEOUS DIFFERENTIAL PROTECTION ............................. 10-20

a MINIMUM PICKUP .............. ..................................................................10-20

b OPERATING TIME................................................................................10-20

c TARGET, OUTPUT CONTACT, & DISPLAY OPERATION .................. 10-21

d BLOCKING FROM LOGIC INPUTS ...................................................... 10-21

10.6.4 PHASE TIME OVERCURRENT ............................................................ 10-21

a WINDING #1 ELEMENTS.......... ............................................................ 10-21

b PICKUP LEVEL ..................................................................................... 10-22

c OPERATING TIME................................................................................10-22

d RESET TIME......................................................................................... 10-22

e PHASE B AND C ELEMENTS...............................................................10-22

f WINDING #2 AND #3 ELEMENTS........................................................10-23

10.6.5 PHASE INSTANTANEOUS OVERCURRENT 1 ................................... 10-23

a WINDING #1 ELEMENTS.......... ............................................................ 10-23

b PICKUP LEVEL ..................................................................................... 10-23

c OPERATING TIME................................................................................10-23

d PHASE B AND C ELEMENTS...............................................................10-23

e WINDING #2 AND #3 ELEMENTS ........................................................10-24

10.6.6 PHASE INSTANTANEOUS OVERCURRENT 2 ................................... 10-24

10.6.7 NEUTRAL TIME OVERCURRENT........................................................10-24

a WINDING #1 ELEMENT........................................................................ 10-24

b PICKUP LEVEL ..................................................................................... 10-24

c OPERATING TIME................................................................................10-25

d RESET TIME......................................................................................... 10-25

e WINDING #2 OR WINDING #3 ELEMENTS .........................................10-25

10.6.8 NEUTRAL INSTANTANEOUS OVERCURRENT 1............. ..................10-26

a WINDING #1 ELEMENT........................................................................ 10-26

b PICKUP LEVEL ..................................................................................... 10-26

c OPERATING TIME................................................................................10-26

d WINDING 2 AND 3 ELEMENTS ............................................................10-26

10.6.9 NEUTRAL INSTANTANEOUS OVERCURRENT 2............. ..................10-27

10.6.10 GROUND TIME OVERCURRENT................ ........................... .............. 10-27

a WINDING 1 ELEMENT............................................................... ........... 10-27

b PICKUP LEVEL ..................................................................................... 10-27

c OPERATING TIME................................................................................10-28

d RESET TIME......................................................................................... 10-28

e WINDING 2 OR 3 ELEM ENTS ..............................................................10-28

10.6.11 GROUND INSTANTANEOUS OVERCURRENT 1....................... ......... 10-28

a WINDING 1 ELEMENT............................................................... ........... 10-28

b PICKUP LEVEL ..................................................................................... 10-29

c OPERATING TIME................................................................................10-29

d WINDING 2 OR ELEMENT....................................................................10-29

10.6.12 GROUND INSTANTANEOUS OVERCURRENT 2....................... ......... 10-29

10.6.13 RESTRICTED GROUND FAULT....................................... ....................10-30

a WINDING #1 ELEMENT........................................................................ 10-30

b PICKUP LEVEL ..................................................................................... 10-30

c OPERATING TIME................................................................................10-31

d SLOPE...................................................................................................10-31

e WINDING 2 OR 3 ELEM ENTS ..............................................................10-31

10.6.14 NEGATIVE SEQUENCE TIME OVERCURRENT ................................. 10-31

a WINDING #1 ELEMENT........................................................................ 10-31

b PICKUP LEVEL ..................................................................................... 10-32

c OPERATING TIME................................................................................10-32

d RESET TIME......................................................................................... 10-33

e WINDINGS 2 AND 3 ELEMENTS..........................................................10-33

10.6.15 NEGATIVE SEQUENCE INSTANTANEOUS OVERCURRENT ...........10-33

a WINDING 1 ELEMENT............................................................... ........... 10-33

b PICKUP LEVEL ..................................................................................... 10-33

c OPERATING TIME................................................................................10-34

d WINDING 2 AND 3 ELEMENTS ............................................................10-34

10.6.16 FREQUENCY ELEMENTS.................................................................... 10-34

viii

745 Transformer Management Relay

GE Power Management

Page 11

TABLE OF CONTENTS

10.6.17 UNDERFREQUENCY 1......................................................................... 10-35

a PRELIMINARIES ................................................................................... 10-35

b VOLTAGE INPUT FUNCTION (VOLTAGE INPUT ENABLED).............10-35

c CURRENT INPUT FUNCTION (VOLTAGE INPUT DISABLED)...........10-36

10.6.18 UNDERFREQUENCY 2......................................................................... 10-37

10.6.19 OVERFREQUENCY .............................................................................. 10-37

a PRELIMINARIES ................................................................................... 10-37

b VOLTAGE INPUT FUNCTION (VOLTAGE INPUT ENABLED).............10-37

c CURRENT INPUT FUNCTION (VOLTAGE INPUT DISABLED)...........10-38

10.6.20 FREQUENCY DECAY RA T E 1 ....... .. .. ............. .............. .. ............. ........ 10-39

a PRELIMIN A R I ES .............. ......................... ............. ......................... ...... 10 - 3 9

b VOLTAGE INPUT FUNCTION (VOLTAGE INPUT ENABLED).............10-39

c CURRENT INPUT FUNCTION (VOLTAGE INPUT DISABLED)...........10-40

d FREQUENCY DECAY RATE 2, 3, & 4.................................................. 10-40

10.6.21 VOLTS-PER-HZ 1(2) ............................................................................. 10-41

10.6.22 5TH HARMONIC SCHEME...................................................................10-41

10.6.23 INSULATION AGING............................................................................. 10-42

a PRELIMINARIES ................................................................................... 10-42

b HOTTEST SPOT LIMIT......................................................................... 10-42

c AGING FACTOR LIMIT ......................................................................... 10-42

d LOSS-OF-LIFE LIMIT ............................................................................ 10-42

10.6.24 TAP MONITOR FAILURE...................................................................... 10-42

10.7 AUXILIARY PROTECTION/MONITORING FUNCTIONS

10.7.1 THD LEVEL SCHEME............................................................ ............... 10-43

a MINIMUM PICKUP.......... ......................................................................10-43

b OPERATING TIME................................................................................10-43

c MINIMUM OPERATING CURRENT...................... ................................ 10-43

d OTHER THD ELEMENTS......................................................................10-43

10.7.2 HARMONIC DERATING FUNCTION.................................................... 10-44

a OPERATING LEVEL.............................................................................. 10-44

b OPERATING TIME................................................................................10-44

10.7.3 T R AN SFORMER OVERLOAD .................. ............. .. ............. .............. .. 10-45

a OPERATING LEVEL.............................................................................. 10-45

b OPERATING TIME................................................................................10-45

10.8 PLACING RELAY INTO SERVICE

10.8.1 DESCRIPTION...................................................................................... 10-46

11. SETPOINT TABLES

A. FIGURES AND TABLES

B. EU DECLARATION OF

11.1 COMMISSIONING SUMMARY

11.1.1 S1 745 SETUP.........................................................................................11-1

11.1.2 S2 SYSTEM SETUP................................................................................ 11-2

11.1.3 FLEXCURVES .........................................................................................11-4

11.1.4 S3 LOGIC INPUTS..................................................................................11-5

11.1.5 S4 ELEMENTS........................................................................................ 11-6

11.1.6 S5 OUTPUTS........................................................................................ 11-18

A.1 FIGURES AND TABLES

A.1.1 LIST OF FIGURES....................................................................................A-1

A.1.2 LIST OF TABLES.......................................................................................A-2

B.1 EU DECLARATION OF CONFORMITY

CONFORMITY

GE Power Management 745 Transformer Management Relay

ix

Page 12

TABLE OF CONTENTS

C. WARRANTY

C.1 WARRANTY INFORMATION

C.1.1 WARRANTY..............................................................................................C-1

x

745 Transformer Management Relay

GE Power Management

Page 13

1 PRODUCT OVERVIEW 1.1 INTRODUCTION

1 PRODUCT OVERVIEW 1.1 INTRODUCTION 1.1.1 DESCRIPTION

The 745 is a high speed , multi-processor based, 3-phase, two or three wi nding, Tran sformer Management

Relay™ intended for the primary protection and management of small, medium and large power transformers.

The 745 combines Percent Differentia l, Overcur rent , Frequency and Overe xcitatio n protecti on eleme nts along

with monitoring of individual harmonics, and THD in one economical package.

The relay provides a variety of adaptive relaying features:

• Adaptive Harmonic Restraint which addresses the problem of false tripping during inrush

• Adaptive Time Overcurrent Elements which will adjus t their pick up setti ngs based on the calcula ted tran sformer capability when supplying load currents with high harmonic content

• Multiple Setpoint Groups which allow the user to enter and d ynamically select from up to four groups of

relay settings to address the protection requirements of different power system configurations

• Dynamic CT Ratio Mismatch Correction which monitors the on-load tap position and automatically corrects

for CT ratio mismatch

• FlexLogic™ which allows PLC style equations based on logic inputs & protection elements to be assigned

to any of the 745 outputs.

The 745 also include s a powe r ful t es tin g and si mu lat ion feat ur e. T his a ll ows the protec ti on e ngi nee r th e ab il ity

to test the relay operation based on captured or computer generated waveform data which can be converted to

a digitized format and downloaded into the 745’s simulation buffer for “playback”.

The 745 also provides its own Waveform Capture func tion which will rec ord waveform data for fault, inrush or

alarm conditions.

1

The Auto-Configuration fu nction eliminates the need for any spec ial CT connections by having all CTs connected in wye.

GE Power Management 745 Transformer Management Rel ay 1-1

Page 14

1.1 INTRODUCTION 1 PRODUCT OVERVIEW

1.1.2 SUMMARY OF PROTECTION FEATURES

1

SYMBOL COMMON PROTECTION ELEMENT SYMBOL WINDING 2 PROTECTION ELEMENT

59/81-1 Volts-Per-Hertz 1 250/46 Negative Sequence Instantaneous O/C

59/81-2 Volts-Per-Hertz 2 251/46 Negative Sequence Time O/C

81U-1 Underfrequency 1 250P1 Phase Instantaneous O/C 1

81U-2 Underfrequency 2 250P2 Phase Instantaneous O/C 2

81U-R1 Frequency Decay Rate 1 250N1 Neutral (3I

81U-R2 Frequency Decay Rate 2 250N2 Neutral (3I

) Instantaneous O/C 1

0

) Instantaneous O/C 2

0

81U-R3 Frequency Decay Rate 3 250G1 Ground Instantaneous O/C 1

81U-R4 Frequency Decay Rate 4 250G2 Ground Instantaneous O/C 2

81-H5 5th Harmonic Level 251P Phase Time O/C

81O Overfrequency 251N Neutral (3I

) Time O/C

0

87 Differential (Percent) 251G Ground Time O/C

50/87 Instantaneous Differential 287TG Ground Differential (

Restricted Ground Fault

AN-1 Analog Input Level 1 2THD Total Harmonic Distortion Level

AN-2 Analog Input Level 2 2AD Current Demand

Insulation Aging

– Aging Factor

– Hottest Spot Limit

– Total Accumulated Life

)

Tap Changer Monitor

SYMBOL WINDING 1 PROTECTION ELEMENT SYMBOL WINDING 3 PROTECTION ELEMENT

150/46 Negative Sequence Instantaneous O/C 350/46 Negative Sequence Instantaneous O/C

151/46 Negative Sequence Time O/c 351/46 Negative Sequence Time O/c

150P1 Phase Instantaneous O/C 1 350P1 Phase Instantaneous O/C 1

150P2 Phase Instantaneous O/C 2 350P2 Phase Instantaneous O/C 2

150N1 Neutral (3I

150N2 Neutral (3I

) Instantaneous O/C 1 350N1 Neutral (3I0) Instantaneous O/C 1

0

) Instantaneous O/C 2 350N2 Neutral (3I0) Instantaneous O/C 2

0

150G1 Ground Instantaneous O/C 1 351P Phase Time O/C

150G2 Ground Instantaneous O/C 2 351N Neutral (3I

) Time O/C

0

151P Phase Time O/C 351G Ground Time O/C

151N Neutral (3I

) Time O/C 387TG Ground Differential (

0

Restricted Ground Fault

151G Ground Time O/C 3THD Total Harmonic Distortion Level

187TG Ground Differential (

Restricted Ground Fault

) 3AD Current Demand

1THD Total Harmonic Distortion Level

1AD Current Demand

)

1-2 745 Transformer Management Relay GE Power Management

Page 15

1 PRODUCT OVERVIEW 1.1 INTRODUCTION

745

1

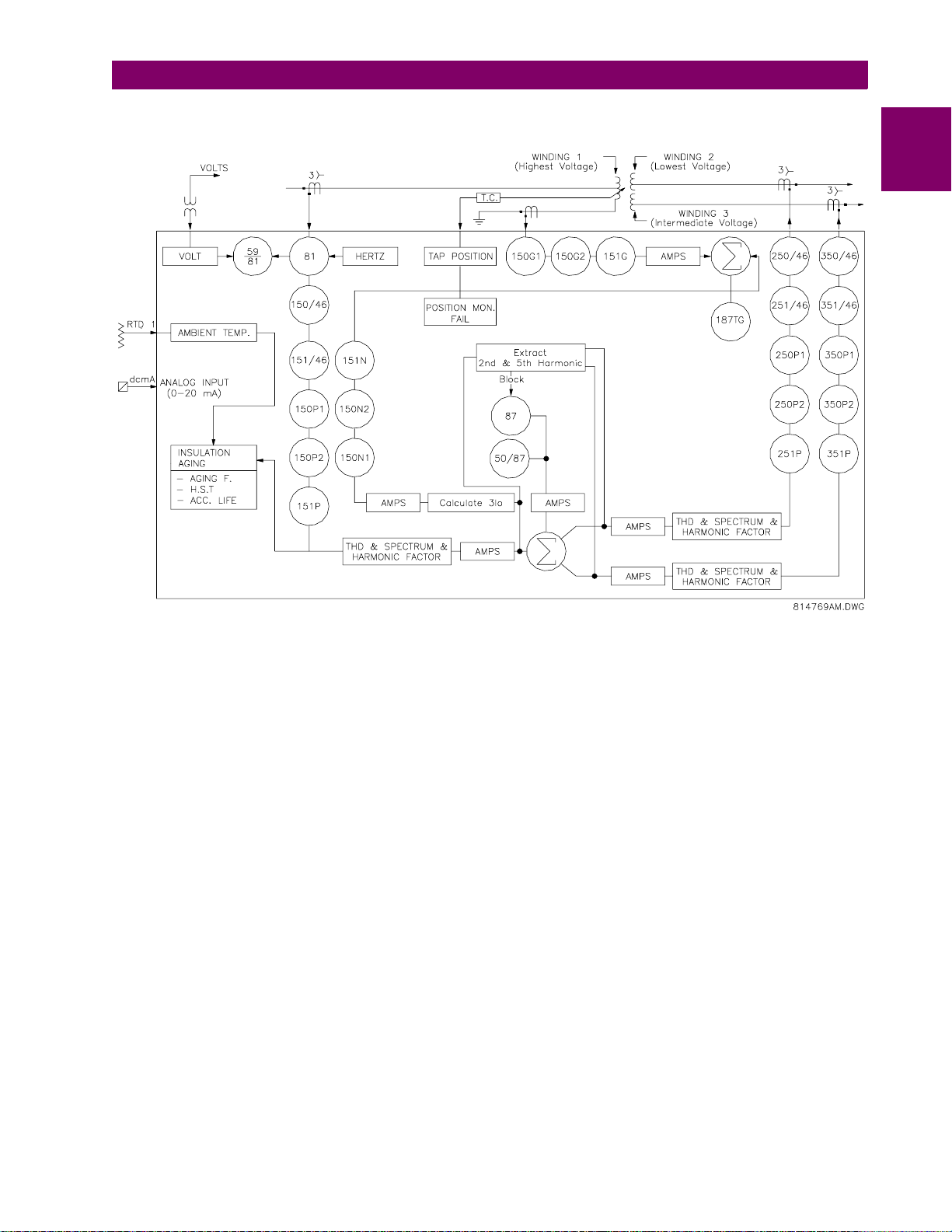

Figure 1–1: SINGLE LINE DIAGRAM

GE Power Management 745 Transformer Management Rel ay 1-3

Page 16

1

1.1 INTRODUCTION 1 PRODUCT OVERVIEW

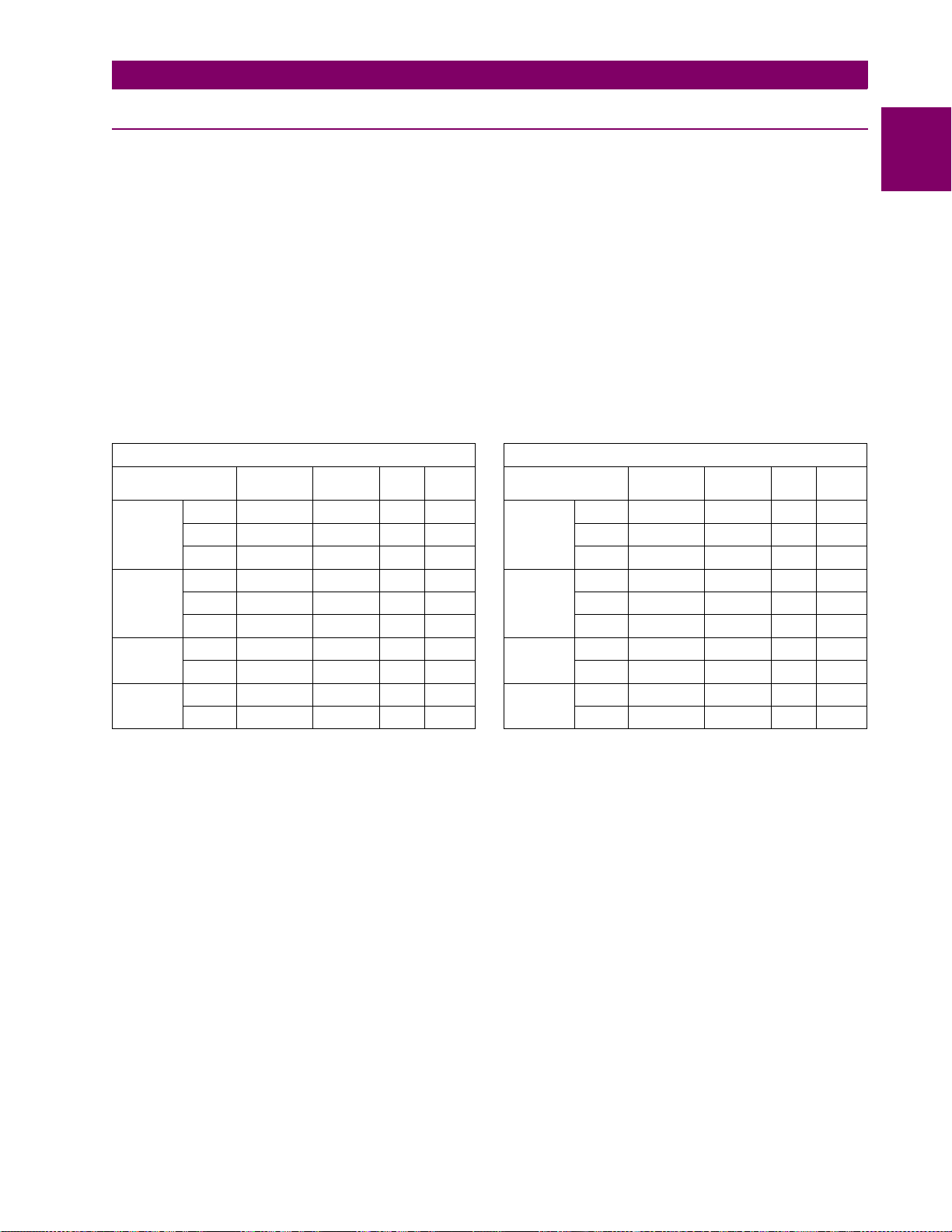

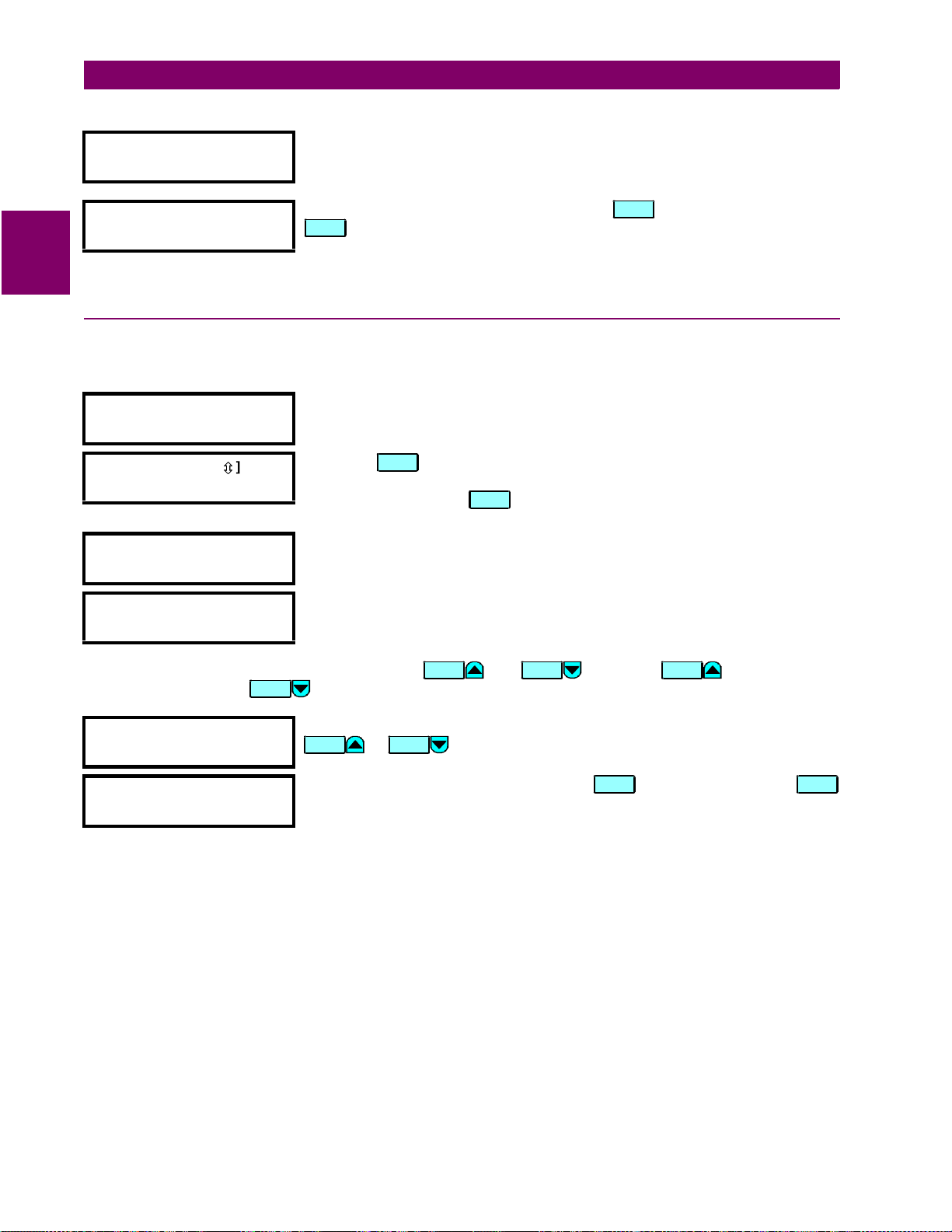

1.1.3 ORDER CODES

745

W2 P5

745

TRANSFORMER

MANAGEMENT

®

RELAY

WINDINGS PER PHASE

W2=2WINDING

W3=3WINDING

PHASE CURRENT INPUT RATINGS

WINDING

P1

P5

P15

P51

P115

P151

P155

P511

P515

P551

1

=

1A

=

5A

=

1A

=

5A

=

1A

=

1A

=

1A

=

5A

=

5A

=

5A

1A

5A

5A

1A

1A

5A

5A

1A

1A

5A

3

(1 A)

(5 A)

—

—

5A

1A

5A

1A

5A

1A

G5

LO

L

AR

GROUND CURRENT INPUT RATINGS

WINDING

1/222/3

G1

=

1A

G5

G15

G51

=

=

=

5A

1A

5A

1A

5A

5A

1A

CONTROL POWER

LO = 24-60 Vdc

20-48 Vac @ 48-62 Hz

HI = 90-300 Vdc

70-265 Vac @ 48-62 Hz

OPTIONS

A = ANALOG INPUT/OUTPUTS

L = LOSS OF LIFE

R = RESTRICTED GROUND FAULT

Figure 1–2: 745 ORDER CODES

745ORDER.CDR

1-4 745 Transformer Management Relay GE Power Management

Page 17

1 PRODUCT OVERVIEW 1.2 TECHNICAL SPECIFICATIONS

1.2 TECHNICAL SPECIFICATIONS 1.2.1 APPLICABILITY

Transformers: 2 Winding or 3 Winding

Frequency: 50 or 60 Hz nominal

(frequency tracking allows operation from 2 to 65 Hz)

CONTROL POWER (POWER SUPPLY)

Options: LO/HI (specified when ordering)

LO Range: DC = 20 to 60 V; AC = 20 to 48 V @ 48 to 62 Hz

HI Range: DC = 90 to 300 V; AC = 70 to 265 V @ 48 to 62 Hz

Power: 30 VA nominal, 40 VA maximum

Fuse (not accessible): Hi-Volt: Current rating: 3.15 A

Type: 5 × 20 mm Slow-Blow Littelfuse, High Breaking Capacity

Model #: 2153.15

Low-V olt: C urrent rating: 3.15 A

Type: 5 × 20 mm Slow-Blow Littelfuse, High Breaking Capacity

Model #: 2153.15

PHASE CURRENT INPUT

Source CT: 1 to 50000 A primary / 1 or 5 A secondary

Relay Input: 1 A or 5 A (specified when ordering)

Burden: Less than 0.2 VA at rated load per phase

Conversion Range: 0.02 to 46 × CT

Accuracy: at < 4 x CT: ± 0.25% of 4 × CT (± 0.01 × CT)

at ≥ 4 x CT: ± 0.5% of 46 × CT (± 0.2 × CT)

Overload Withstand: 1 second at 80 times rated current

2 seconds at 40 times rated current

continuous at 3 times rated current

1

1.2.2 INPUTS

GROUND CURRENT INPUT

Source CT: 1 to 50000 A primary / 1 or 5 A secondary

Relay Input: 1 A or 5 A (specified when ordering)

Burden: Less than 0.2 VA at rated load

Conversion Range: 0.02 to 46 × CT

Accuracy: at < 4 × CT: ± 0.25% of 4 x CT (± 0.01 × CT)

at ≥ 4 × CT: ± 0.5% of 46 x CT (± 0.2 × CT)

Overload Withstand: 1 second at 80 times rated current

2 seconds at 40 times rated current

continuous at 3 times rated current

VOLTAGE INPUTS

Source VT: 2 to 600 kV / 60 to 120 V

Source VT Ratio: 1 to 5000 in steps of 1

Relay Input: 60 V to 120 V phase-neutral

Burden: Less than 0.025 VA at 120 V

Max. Continuous: 273 V

Accuracy: ± 1% of 2 × VT (± 0.02 × VT)

LOGIC INPUTS (16)

Dry Contacts: 1000 Ω maximum ON resistance (32 V DC at 2 mA provided by 745)

Wet Contacts: Inputs 1 to 16: 30 to 300 V DC at 1.5 mA

GE Power Management 745 Transformer Management Rel ay 1-5

Page 18

1.2 TECHNICAL SPECIFICATIONS 1 PRODUCT OVERVIEW

ANALOG INPUT

Type: DC mA

1

Ranges: 0-1 mA, 0-5 mA, 0-10 mA, 0-20 mA, or 4-20 mA (programmable)

Input Impedance: 375 Ω ± 10%

Conversion Range: 0 to 21 mA

Accuracy: ± 1% of full scale (based on input range)

TAP POSITION

Type: resistance (ohms)

Range: 0 to 500 Ω or 0.5 to 5.0 kΩ

Bias Current: 1 mA or 10 mA (based on input range)

Accuracy: ± 1% of full scale (based on input range)

RTD

Type: 3 wire

RTD Type 100 Ω Platinum (DIN.43760)

100 Ω Nickel

120 Ω Nickel

IRIG-B INPUT

Amplitude-Modulated: 1.0 to 10 V pk-pk

DC Shift: TTL

Input Impedance 70 to 100 kΩ

PERCENT DIFFERENTIAL PROTECTION

Operating Current Pickup: 0.05 to 1.00 in steps of 0.01 x CT

Dropout Level: 97 to 98% of Pickup

SLOPE-1 Range: 15% to 100% in steps of 1

SLOPE-2 Range: 50% to 200% in steps of 1

KP (SLOPE-1 Kneepoint): 1.0 to 20.0 in steps of 0.1 x CT

Harmonic Restraint: 0.1% to 65.0% in steps of 0.1

Operate Time: Solid State Output: Pickup < 1 x CT: 42 to 52 ms

1 x CT < Pickup < 1.1 × kneepoint: 34 to 44 ms

Pickup > 1.1 × kneepoint: 26 to 36 ms

Relay Outputs 2-5: Pickup < 1 x CT: 46 to 56 ms

1 x CT < Pickup < 1.1 × kneepoint: 38 to 48 ms

Pickup > 1.1 × kneepoint: 30 to 40 ms

INSTANTANEOUS DIFFERENTIAL OVERCURRENT

Pickup Level: 3.00 to 20.00 in steps of 0.01 x CT

Dropout Level: 97 to 98% of Pickup

Level Accuracy: Per current input

Operate Time: Solid State Output: at 1.2 x pickup: 22 to 30 ms

at 2.0 x pickup: 18 to 26 ms

at 4.0 x pickup:11 to 19 ms

Relay Outputs 2-5: at 1.2 x pickup: 28 to 36 ms

at 2.0 x pickup: 24 to 32 ms

at 4.0 x pickup: 17 to 25 ms

1.2.3 PROTECTION ELEMENTS

1-6 745 Transformer Management Relay GE Power Management

Page 19

1 PRODUCT OVERVIEW 1.2 TECHNICAL SPECIFICATIONS

PHASE / NEUTRAL / GROUND / NEGATIVE SEQUENCE TIME OVERCURRENT

Pickup Level: 0.05 to 20.00 in steps of 0.01 x CT

Dropout Level: 97 to 98% of Pickup

Curve Shape: ANSI Extreme ly/Very/Moderately/Normally Inverse;

Definite Time (0.1 s base curve);

IEC Curve A/B/C and Short;

FlexCurve™ A/B/C (programmable curves);

IAC Extreme/Very /In ve rse /Short

Curve Multiplier Time Dial: 0.5 to 30 for ANSI, IAC & Flex Curves™ in steps of 0.1 s;

0.05 to 100.00 for IEC curves in steps of 0.01

Reset Type: Instantaneous or Linear

Level Accuracy: Per current input

Timing Accuracy: at ≥ 1.03 × pickup: ± 3% of trip time or ± 20 ms (whichever is greater)

PHASE / NEUTRAL / GROUND / NEGATIVE SEQUENCE INSTANTANEOUS OVERCURRENT

Pickup Level: 0.05 to 20.00 in steps of 0.01 × CT

Dropout Level: 97 to 98% of Pickup

Time Delay: 0 to 60000 in steps of 1 ms

Level Accuracy: Per current input

Operate Ti me: Solid State Output: at 1.2 × pickup: 22 to 30 ms

at 2.0 × pickup: 18 to 26 ms

at 4.0 × pickup: 11 to 19 ms

Relay Outputs 2-5: at 1.2 × pickup: 28 to 36 ms

at 2.0 × pickup: 24 to 32 ms

at 4.0 × pickup: 17 to 25 ms

1

UNDERFREQUENCY (2 ELEMENTS)

Operating Current Pickup: 0.05 to 1.00 in steps of 0.01 × CT

Operating Voltage Pickup 0.10 to 0.99 in steps of 0.01 × VT

Pickup Level: 45.00 to 59.99 in steps of 0.01 Hz

Dropout Level: Pickup + 0.03 Hz

Time Delay: 0.00 to 600.00 s in steps of 0.01 s

Signal Source: Winding 1 phase A current / voltage

Level Accuracy: ±0.02 Hz

Operate Time: Solid State Output: at 3% beyond pickup: 120 to 150 ms

Relay Outputs 2 to 5: at 3% beyond pickup: 125 to 155 ms (delay set at 0.0 sec.)

FREQUENCY RATE OF CHANGE (4 ELEMENTS)

Operating Current Pickup: 0.05 to 1.00 in steps of 0.01 × CT

Operating Voltage Pickup 0.10 to 0.99 in steps of 0.01 × VT

Pickup Level: 45.00 to 59.99 in steps of 0.01 Hz

Dropout Level: Pickup + 0.03 Hz

Rate 1/2/3/4: 0.1 to 5.0 in steps of 0.1 Hz/sec.

Dropout Level: Pickup + 0.07 Hz/sec.

Signal Source: Winding 1 phase A current / voltage

Level Accuracy: ±0.02 Hz

Operate Time: The operate time of the fr equ ency trend elemen t is va riable a nd is de penden t on t he deca y

rate setting and the supervision frequency level.

GE Power Management 745 Transformer Management Rel ay 1-7

Page 20

1.2 TECHNICAL SPECIFICATIONS 1 PRODUCT OVERVIEW

OVERFREQUENCY (1 ELEMENT)

Operating Current Pickup: 0.05 to 1.00 in steps of 0.01 × CT

1

Operating Voltage Pickup 0.10 to 0.99 in steps of 0.01 × VT

Pickup Level: 50.01 to 65.00 in steps of 0.01 Hz

Dropout Level: Pickup – 0.03 Hz

Time Delay: 0.00 to 600.00 s in steps of 0.01 s

Signal Source: Winding 1 phase A current / voltage

Level Accuracy: ±0.02 Hz

Operate Time: Solid State Output: at 3% beyond pickup: 120 to 150 ms

Relay Outputs 2-5: at 3% beyond pickup: 125 to 155 ms (delay set to 0.0 s)

OVEREXCITATION ON VOLTS/HERTZ (2 ELEMENTS)

Operating Voltage Pickup: 0.10 to 0.99 in steps of 0.01 × VT

Pickup Level: 1.00 to 4.00 in steps of 0.01 V/Hz

Curve Shape: Definite Time (0.1 sec. base curve);

IEC Curve A/B/C

Time Delay: 0.00 to 600.00 s in steps of 0.01 s

Reset Delay: 0.0 to 6000.0 s in steps of 0.1 s

Signal Source: Voltage

Range: 10 to 65 Hz

Level Accuracy: ±0.02 V/Hz

Operate Ti me: Solid State Output: at 1.10 × pickup: 165 to 195 ms

Relay Outputs 2-5: at 1.10 × pickup: 170 to 200 ms (delay set to 0.0 s)

OVEREXCITATION ON 5TH HARMONIC LEVEL

Operating Current Pickup: 0.03 to 1.00 in steps of 0.01 × CT

Pickup Level: 0.1 to 99.9 in steps of 0.1%

Dropout: 95% of pickup

Time Delay: 0 to 60000 s in steps of 1 s

Signal Source: All phase currents

Operate Ti me: Solid State Output: at 1.10 × pickup: 20 to 120 ms

Relay Outputs 2-5: at 1.10 × pickup: 25 to 125 ms (delay set at 0.0 s)

INSULATION AGING: HOTTEST-SPOT LIMIT

Pickup Level: 50 to 300 in steps of 1°C

Delay: 0 to 60000 in steps of 1 min.

INSULATION AGING: AGING FACTOR LIMIT

Pickup Level: 1.1 to 10.0 in steps of 0.1

Delay: 0 to 60000 in steps of 1 min.

INSULATION AGING: LOSS OF LIFE LIMIT

Pickup Level: 0 to 20000 in steps of 1 x 10 h

1-8 745 Transformer Management Relay GE Power Management

Page 21

1 PRODUCT OVERVIEW 1.2 TECHNICAL SPECIFICATIONS

1.2.4 OUTPUTS

Analog Outputs (7)

Output Range: 0-1 mA, 0-5 mA, 0-10 mA, 0-20 mA, or 4-20 mA

Maximum Load: 0-1 mA: 10 kΩ

4-20 mA: 600 Ω

Isolation: Fully isolated

Accuracy: ± 1% of full scale

Solid State Output

Maximum Ratings: Make & Carry 15 A at 250 V DC for 500 ms

Output Relays

Configuration: 2-5 TRIP: Form A (breaker trip rated)

6-8 AUXILIARY : Form C

9 SELF-TEST: Form C

Contact Material: silver alloy

Max Ratings: 300 V AC, 250 V DC, 15 A, 1500 VA

RELAYS: 2-5 TRIP RELAYS: 6-8 AUXILIARY, 9 SELF-TEST

VOLTAGE MAKE/CARRY

DC

Resistive

DC

Inductive

L/R = 40 ms

AC

Resistive

AC Inductive

PF = 0.4

30 V DC 20 A 40 A 10 A 300 W DC

125 V DC 20 A 40 A 0.8 A 300 W 125 V DC 10 A 30 A 0.5 A 62.5 W

250 V DC 20 A 40 A 0.4 A 300 W 250 V DC 10 A 30 A 0.3 A 75 W

30 V DC 20 A 40 A 5 A 150 W DC

125 V DC 20 A 40 A 0.3 A 150 W 125 V DC 10 A 30 A 0.25 A 31.3 W

250 V DC 20 A 40 A 0.2 A 150 W 250 V DC 10 A 30 A 0.15 A 37.5 W

120 V AC 20 A 80 A 20 A 5000 VA AC

240 V AC 20 A 80 A 20 A 5000 VA 240 V AC 10 A 30 A 10 A 2770 VA

120 V AC 20 A 80 A 8 A 5000 VA AC Inductive

240 V AC 20 A 80 A 7 A 5000 VA 240 V AC 10 A 30 A 3 A 750 VA

CONTINUOUS

MAKE/

CARRY 0.2s

BREAK MAX

LOAD

VOLTAGE MAKE/CARRY

30 V DC 10 A 30 A 10 A 300 W

Resistive

30 V DC 10 A 30 A 5 A 150 W

Inductive

L/R = 40 ms

120 V AC 10 A 30 A 10 A 2770 VA

Resistive

120 V AC 10 A 30 A 4 A 480 VA

PF = 0.4

CONTINUOUS

MAKE/

CARRY 0.2s

BREAK MAX

LOAD

1

COMMUNICATIONS

All Ports: 300 to 19200 baud, programmable parity, Modbus RTU protocol, DNP

CLOCK

Resolution: 1 ms

Accuracy with IRIG-B: ±1 ms

without IRIG-B: ±1 minute/month

Backup Battery Life: 10 years continuous use

HARMONICS

Individual Range: 0.00 to 99.9%

Accuracy: ±1% of Full Scale @ 0.5 x CT

THD Range: 0.00 to 99.9%

Accuracy: ±1% of Full Scale @ 0.5 x CT

OPERATING ENVIRONMENT

Operating Temperature Range:–40°C to +60°C

Ambient Storage Temperature: –40

°

C to +80°C

Humidity: up to 90% non-condensing

Altitude: 2000 m

Pollution degree: II

GE Power Management 745 Transformer Management Rel ay 1-9

Page 22

1.2 TECHNICAL SPECIFICATIONS 1 PRODUCT OVERVIEW

CASE

Fully drawout unit (automatic CT shorts); Seal provision; Dust tight door; Panel or 19" rack mount

1

Weight (case & relay): 18 lbs., 6 oz.

IP class: X0

PRODUCTION TESTS

Thermal: Operational test at ambient then increasing to 60 °C

Dielectric Strength: Per IEC 255-5 and ANSI/IEEE C37.90

On CT inputs, VT inputs, Control Power inputs, Switch inputs, and Relay outputs

(2 kV for 1 second)

TYPE WITHSTAND TESTS

Fast Transient: per ANSI/IEEE C37.90.1 (5 kV)

per IEC 255-22-4 (4 kV)

Insulation Resistance: per IEC 255-5 (500 V DC, 2000 MΩ)

Dielectric Strength: per IEC 255-5 and ANSI/IEEE C37.90 (2 kV at 60 Hz for 1 minute)

Surge Immunity: per EN 61000-4-5 (common mode 4 kV, differential modes 2 kV)

per ANSI/IEEE C37.90.1, IEC 255-22-1, and Ontario Hydro A-28M-82

Voltage Dips: per IEC 1000-4-1 (0%, 40%)

Electrostatic Discharge: per IEC 255-22-2 (8/15 kV)

Power Freq uency/

Magnetic Field Immunity: per EN 61000-4-8

Damp Heat (Cyclic Humidity) per IEC 68-2-30 (6 days)

Temperature Cycle: –40°C, +60°C

Mechanical Stress 2 g

Make and Carry Rating 30 A

Current Withstand: per ANSI/IEEE C37.90 (40 × rated A for 2 seconds, 80 × rated A for 1 second)

RFI Radiated Immunity: per IEC 255-22-3 (160 MHz, 460 MHz)

per EN 61000-4-3 (10 V/m)

RFI Conducted Immunity: per EN 61000-4-6 (10 V)

RFI Conducted/Radiated

Emission: per EN 55011 / CISPR 11 FCC Part 15

APPROVALS

CSA: CSA approved

CE: Conforms to IEC 1010-1 / EN 50082-2

UL: UL approved

ISO: Manufactured under ISO9001 registered program

It is recommended that all 745 re lays be powered up at least once per year to avoid deterioration of electrolytic capacitors in the power supply.

NOTE

Specifications subject to change without notice.

1-10 745 Transformer Management Relay GE Power Management

Page 23

2 GETTING STARTED 2.1 USING THE FRONT PANEL DISPLAY

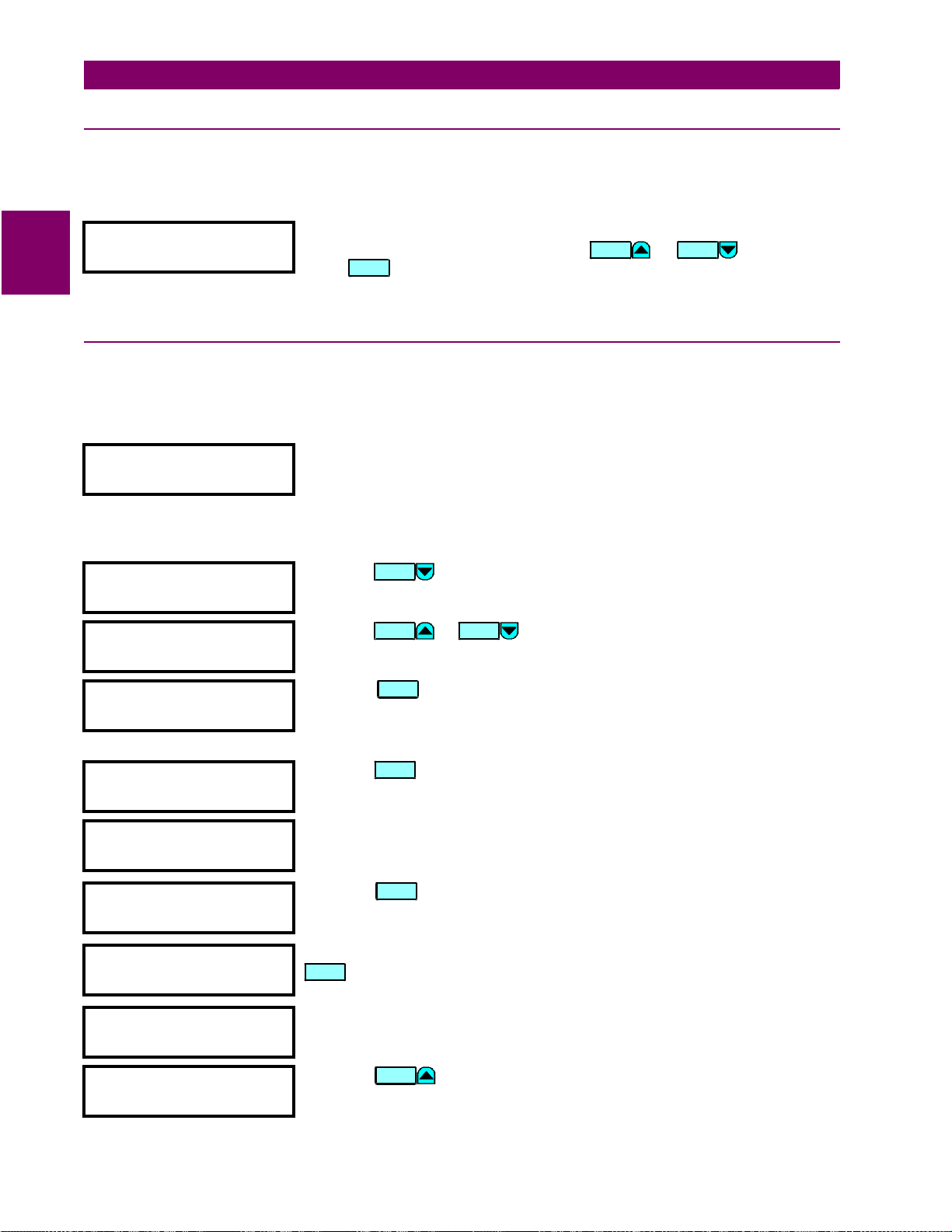

2 GETTING ST ARTED 2.1 USING THE FRONT PANEL DISPLAY 2.1.1 MANEUVERING

The following procedure describes how to maneuver through the 745 setpoints and actual values.

yy SETPOINTS HAVE NOT

yy BEEN PROGRAMMED!

yy ACTUAL VALUES

yy A1 STATUS

yy SETPOINTS

yy S1 745 SETUP

yy SETPOINTS

yy S2 SYSTEM SETUP

y PASSCODE

y[ENTER] for more

y END OF PAGE S1

y

When powered on successfully, the SELF-TEST ERROR and MESSAGE

indicators will be on with thi s mess age on th e display. It indicates that the 745

is in the

Not Programmed

state and safeguards against the installation of a relay

whose setpoints hav e not been entered. This message wil l remain until the

relay is explicitly put in the

Programmed

state.

Press any front panel k ey onc e an d the hea der for th e firs t ac tua l val ues pag e

appears. This page con tains syst em and relay status inf ormation. Repe atedly

press the key to display the 2

headers. Press the key once more to return to the 1

ACTUAL

ACTUAL

nd

, 3rd, and 4th actual values page

st

actual values

page header. There are 4 actual values pa ges in all, numbered from A1 (the

'A' prefix indicating that it is an actual va lues page) to A4. Actual va lues page

headers, as with setpoint page headers, h ave double scroll bars on the left

side of the message.

Press the key an d the header for the first page of s etpoints appears.

SETPOINT

This page contains setpoints to configure the 745 relay.

Press the ke y to move to the next setpoi nts page. This p age contains

setpoints for entering the characteristics of the power transformer being

protected. Repeated ly press the key to display the 3

SETPOINT

SETPOINT

rd

, 4th, 5th and 6

page headers and then back to the fir st setpoints page he ader. As you have

discovered, there are 6 setp oint pag es in all, nu mbe red from S1 ( the 'S' prefix

indicating that it is a setpoint page) to S6.

From the page one header of setpoints, press the key once to

MESSAGE

display the first sub-header. Setpoints under this sub-header are related to

passcode security. Note that the lower line of every sub-header message

[ENTER] for more

reads

Press the key repeatedly and display the remaining sub-header

MESSA GE

and that there is a single scroll bar on the left side.

messages in this page. The last message appears as shown.

2

th

y PREFERENCES

y[ENTER] for more

By pressing the key repeatedly, move to the second sub-header

message. Setpoints unde r this sub-header me ssage allow the user to sp ecify

MESSAGE

keypad and display operati on pre fer en ces.

BEEPER:

Enabled

Press to display the first setpoint under the preferences sub-header. All

setpoint and actual value messages have two parts. The first part (

ESCAPE

BEEPER:

), is

displayed in uppercase and followed by a colon. This is the name or

description of the data. The second part (

Enabled

), either starts with an

uppercase character followed by lowercase characters or is a number followed

by units. This second part is the present value of the data.

DEFAULT MESSAGE

INTENSITY:25%

To view the rem aining setpoints a ssociated with the pre ferences sub-heade r,

repeatedly press the key. The last message appears as shown.

MESSA GE

GE Power Management 745 Transformer Management Relay 2-1

Page 24

2.1 USING THE FRONT PANEL DISPLAY 2 GETTING STARTED

ESCAPE

Let us review how we got to this last message.

1. First, we started at the setpoints page header

S1 745 SETUP

2. We then moved to the second sub-header message under page S1, which is

pressed the key .

ENTER

.

PREFERENCES

3. We then moved to the last message in this group.

A path can be used as a means of spec ifying wher e a mess age is loca ted in the 745 re lay. For this last mes-

2

sage, the path would be

S1 745 SETUP / PREFERENCES / DEFAULT MESSAGE INTENSITY

. For the purposes of this

manual, we will refer to messages in this manner. Press the key to return to the preferences sub-header

message. Pressing the key from any of the messages under a sub-header will return the display to that

sub-header message. From a sub-header message, the repeated pressing of moves the display

ESCAPE

MESSAGE

through the list of sub-header messages to the page header. As an alternative, you could press the key

and move directly to the next page.

, and we

SETPOINT

2-2 745 Transformer Management Relay GE Power Management

Page 25

2 GETTING STARTED 2.2 CHANGING SETPOINTS

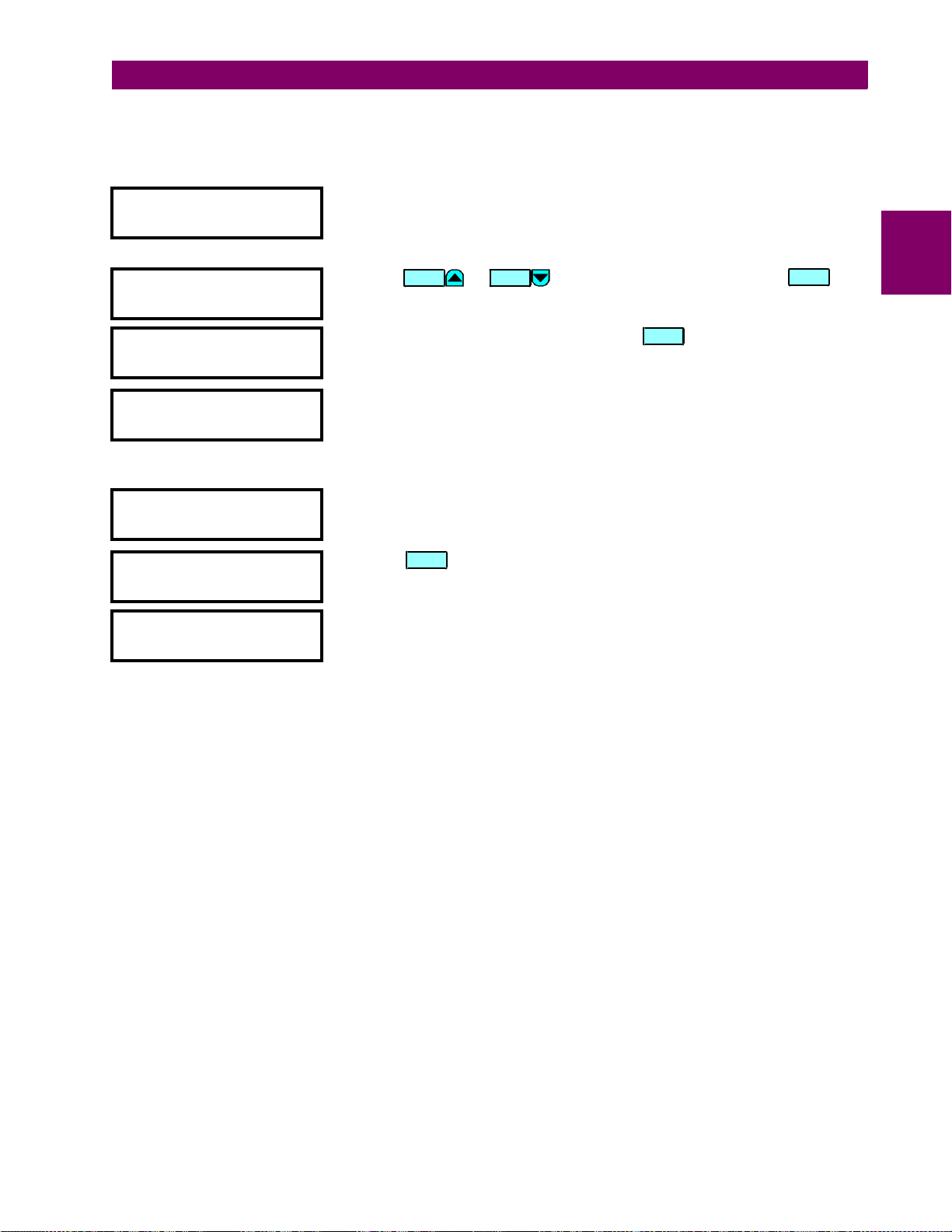

2.2 CHANGING SETPOINTS 2.2.1 DESCRIPTION

There are several different classes of setpoints, distinguished by the way their values are displayed and edited.

This section describes how to edit the values used by all setpoint classes.

2.2.2 INSTALLING THE SETPOINT ACCESS JUMPER

Hardware and passco de security features are design ed to provide protection against unauthorized setpoint

changes. Since we wi ll be pr og ra mmi ng new se tpoi nts u si ng t he f ro nt p ane l k eys , a h ar dwa re ju mpe r mus t b e

installed across the se tpoint access termin als (D9 and D10) on the back of the relay case. A keys witch may

also be used acr oss these termina ls to enabl e setpoi nt acce ss. Attemp ts to enter a new setpoin t via th e front

panel without this connection will be unsuccessful.

2.2.3 NUMERICAL SETPOINTS

Each numerical setpoint has its own minimum, maximum, and increment value associated with it. These

parameters define what values are acceptable for a setpoint.

NOMINAL VT SECONDARY

VOLTAGE: 120.0 V

y MINIMUM: 60.0

y MAXIMUM: 120.0

Select the

setpoint message

Press . The following context sensitiv e flash mes sages will sequent ially

appear for several seconds each. For the case of a numerical setpoint

message, the key displays the minimum, maximum, and step value.

S2 SYSTEM SETUP / VOLTAGE INPUT / NOMINAL VT SECONDARY VOLTAGE

HELP

HELP

y IN STEPS OF:

y 0.1

y PRESS (0)-(9) OR

y VALUE

2

yy PRESS [ENTER] TO

yy STORE NEW VALUE

y END OF PAGE S1

y

Two methods of editing and storing a numerical setpoint value are available.

0

1.

to 9 and the decimal key:

The relay numeric keypad works the same as that of any electronic calculator.

A number is entered one digit at a time. The leftmost digit is entered first and the rightmost digit is entered

last. Pressing the key, before the key, returns the original value to the display.

VALUE VALUE VALUE

2.

and :

ESCA PE

The k ey increments the displayed value, by the step value, up to the

maximum value all owe d. W hi le at the maximum val ue, pres si ng the key ag ain will allow setpoin t

selection to co ntinue from th e minimum v alue. The key decrement s the disp layed value, by the

step value, down to the minimum value. Again, continuing to press the key while at the minimum

ENTER

VALUE

VALUE

VALUE

value will continue setpoint selection from the maximum value.

GE Power Management 745 Transformer Management Relay 2-3

Page 26

2.2 CHANGING SETPOINTS 2 GETTING STARTED

VALUE

NOMINAL VT SECONDARY

VOLTAGE

yy NEW SETPOINT

yy HAS BEEN STORED

2

As an example, let’s set the nomin al VT seco ndary voltag e setpoint to 69.3 V.

Press the appropriate numeric keys in the sequence ‘

6 9 . 3

message will change as the digits are being entered.

Editing changes are no t registered until the key is pressed. Pr ess the

ENTER

key to store the new value in memory. This flash message momentarily

ENTER

appears to confirmation the storing process. If 69.28 were entered, the value is

automatically rounded to 69.3, since the step value for this setpoint is 0.1.

2.2.4 ENUMERATION SETPOINTS

Enumeration setpoi nts have data values which are part of a se t, whose members are explicitl y defined by a

name. A set is comprised of two or more members.

PHASE SEQUENCE

Move to message

S2 SYSTEM SETUP / TRANSFORMER / PHASE SEQUENCE

ABC

yy PRESS [VALUE

MAKE SELECTION

yy

Ú

Ú

] TO

Press the key and the follow ing context sensitive fl ash messages will

sequentially appear for several seconds each. For the case of an enumeration

setpoint message, the key displays the number of selections in the

HELP

HELP

enumeration.

PRESS [ENTER]

yy

STORE NEW VALUE

yy

TO

‘. The display

.

FOR FURTHER HELP

yy

REFER TO MANUAL

yy

Enumeration type values are c hanged using the and keys. The key displa ys the

next selection while the key displays the previous selection.

INPUT 1 FUNCTION:

ENABLED

NEW SETPOINT

yy

HAS BEEN STORED

yy

VALUE

As an example we may need to set the phase sequence to ACB. Press

VALUE VALUE