Page 1

IISO9001:2000

G

E

M

U

L

T

I

L

I

N

R

E

G

I

S

T

E

R

E

D

GE

Grid Solutions

745

Transformer Protection System

Instruction Manual

745 revision: 5.20

Manual Part Number: 1601-0161-AG

GE publication code: GEK-106635Q

GE Grid Solutions

650 Markland Street

Markham, Ontario

Canada L6C 0M1

Tel: +1 905 927 7070 Fax: +1 905 927 5098

Internet: http://www.gegridsolutions.com

*1601-0161-AG*

Page 2

© 2016 GE Multilin Inc. All rights reserved.

GE Multilin Inc. 745 Transformer Protection System instruction manual for revision 5.20.

745 Transformer Protection System, EnerVista, EnerVista Launchpad, EnerVista 745 Setup, and FlexLogic are registered

trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is furnished on license and may not be

reproduced in whole or in part without the permission of GE Multilin Inc. The content of this manual is for informational use

only and is subject to change without notice.

Part numbers contained in this manual are subject to change without notice, and should therefore be verified by GE

Multilin Inc. before ordering.

Part number: 1601-0161-AG (June 2016)

Page 3

Table of Contents

1: GETTING STARTED IMPORTANT PROCEDURES .......................................................................................................... 1-1

C

AUTIONS AND WARNINGS ............................................................................................... 1-1

I

NSPECTION CHECKLIST ...................................................................................................... 1-1

M

ANUAL ORGANIZATION ................................................................................................... 1-2

USING THE RELAY ............................................................................................................................ 1-3

M

ENU NAVIGATION ............................................................................................................. 1-3

P

ANEL KEYING EXAMPLE .................................................................................................... 1-5

CHANGING SETPOINTS ................................................................................................................. 1-6

I

NTRODUCTION .....................................................................................................................1-6

U

SING THE HELP KEY ........................................................................................................ 1-6

N

UMERICAL SETPOINTS ...................................................................................................... 1-6

E

NUMERATION SETPOINTS .................................................................................................1-7

T

EXT SETPOINTS .................................................................................................................. 1-7

SECURITY ............................................................................................................................................. 1-9

I

NSTALLATION ....................................................................................................................... 1-9

C

HANGING THE PASSCODE ................................................................................................1-9

D

ISABLING AND ENABLING PASSCODE SECURITY .......................................................... 1-10

2: OVERVIEW INTRODUCTION ................................................................................................................................2-1

ESCRIPTION ........................................................................................................................ 2-1

D

P

ROTECTION FEATURES ...................................................................................................... 2-2

O

RDER CODES ..................................................................................................................... 2-3

SPECIFICATIONS ............................................................................................................................... 2-5

A

PPLICABILITY ...................................................................................................................... 2-5

I

NPUTS .................................................................................................................................. 2-5

P

ROTECTION ELEMENTS ...................................................................................................... 2-6

O

UTPUTS ...............................................................................................................................2-9

M

ISCELLANEOUS .................................................................................................................. 2-10

3: INSTALLATION DRAWOUT CASE ............................................................................................................................... 3-1

ASE DESCRIPTION ............................................................................................................. 3-1

C

P

ANEL CUTOUT .................................................................................................................... 3-2

C

ASE MOUNTING ................................................................................................................. 3-2

U

NIT WITHDRAWAL AND INSERTION ................................................................................3-3

E

THERNET CONNECTION ..................................................................................................... 3-6

TYPICAL WIRING ............................................................................................................................... 3-7

D

ESCRIPTION ........................................................................................................................ 3-7

R

EAR TERMINAL LAYOUT ....................................................................................................3-7

W

IRING DIAGRAMS ............................................................................................................. 3-10

P

HASE SEQUENCE AND TRANSFORMER POLARITY ......................................................... 3-12

C

URRENT TRANSFORMER INPUTS .....................................................................................3-12

AC V

OLTAGE INPUT ............................................................................................................3-14

L

OGIC INPUTS ...................................................................................................................... 3-14

C

ONTROL POWER ................................................................................................................ 3-15

A

NALOG INPUT ....................................................................................................................3-16

T

AP POSITION INPUT ........................................................................................................... 3-16

RTD D

RIVER/SENSOR ........................................................................................................ 3-16

O

UTPUT RELAYS .................................................................................................................. 3-16

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL TOC–I

Page 4

SOLID STATE TRIP OUTPUT ................................................................................................ 3-17

A

NALOG OUTPUTS ..............................................................................................................3-17

RS485/RS422 C

RS232 F

RONT PANEL PROGRAM PORT ..........................................................................3-19

OMMUNICATIONS ................................................................................ 3-17

IRIG-B .................................................................................................................................. 3-20

D

IELECTRIC STRENGTH .......................................................................................................3-20

4: INTERFACES HARDWARE INTERFACE ................................................................................................................ 4-1

RONT PANEL ......................................................................................................................4-1

F

D

ISPLAY ................................................................................................................................. 4-2

LED

S ..................................................................................................................................... 4-2

LED I

NDICATORS .................................................................................................................4-2

P

ROGRAM PORT ................................................................................................................... 4-4

K

EYPAD ................................................................................................................................. 4-4

S

ETPOINT ENTRY .................................................................................................................. 4-5

D

IAGNOSTIC MESSAGES ..................................................................................................... 4-7

F

LASH MESSAGES ................................................................................................................4-7

ENERVISTA SOFTWARE INTERFACE .........................................................................................4-8

O

VERVIEW ............................................................................................................................ 4-8

H

ARDWARE ...........................................................................................................................4-8

I

NSTALLING THE ENERVISTA 745 SETUP SOFTWARE .................................................... 4-10

CONNECTING ENERVISTA 745 SETUP TO THE RELAY ...................................................... 4-13

C

ONFIGURING SERIAL COMMUNICATIONS ........................................................................4-13

U

SING THE QUICK CONNECT FEATURE ............................................................................ 4-15

C

ONFIGURING ETHERNET COMMUNICATIONS ................................................................. 4-15

C

ONNECTING TO THE RELAY .............................................................................................. 4-17

WORKING WITH SETPOINTS AND SETPOINT FILES ........................................................... 4-19

E

NGAGING A DEVICE ........................................................................................................... 4-19

E

NTERING SETPOINTS ......................................................................................................... 4-19

F

ILE SUPPORT ...................................................................................................................... 4-21

U

SING SETPOINTS FILES ..................................................................................................... 4-21

UPGRADING RELAY FIRMWARE ................................................................................................. 4-27

D

ESCRIPTION ........................................................................................................................ 4-27

S

AVING SETPOINTS TO A FILE ............................................................................................ 4-27

L

OADING NEW FIRMWARE ................................................................................................. 4-27

ADVANCED ENERVISTA 745 SETUP FEATURES ................................................................... 4-30

T

RIGGERED EVENTS .............................................................................................................4-30

W

AVEFORM CAPTURE (TRACE MEMORY) .......................................................................... 4-30

T

RENDING (DATA LOGGER) .................................................................................................4-32

E

VENT RECORDER ................................................................................................................4-35

M

ODBUS USER MAP ........................................................................................................... 4-36

V

IEWING ACTUAL VALUES .................................................................................................. 4-37

USING ENERVISTA VIEWPOINT WITH THE 745 ................................................................... 4-40

P

LUG AND PLAY EXAMPLE .................................................................................................4-40

5: SETPOINTS OVERVIEW ........................................................................................................................................... 5-1

ETPOINT MESSAGE MAP ................................................................................................... 5-1

S

S

ETPOINT ENTRY .................................................................................................................. 5-4

S

ETPOINT WRITE ACCESS ................................................................................................... 5-4

AUTO-CONFIGURATION ................................................................................................................ 5-6

I

NTRODUCTION .....................................................................................................................5-6

D

YNAMIC CT RATIO MISMATCH CORRECTION ................................................................ 5-6

TOC–II 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 5

PHASE SHIFTS ON THREE-PHASE TRANSFORMERS ......................................................... 5-8

P

HASE ANGLE CORRECTION .............................................................................................. 5-10

Z

ERO-SEQUENCE COMPONENT REMOVAL ....................................................................... 5-11

T

RANSFORMER TYPES ......................................................................................................... 5-13

P

HASE SHIFTS ...................................................................................................................... 5-24

S1 745 SETUP .................................................................................................................................... 5-25

P

ASSCODE ............................................................................................................................ 5-25

P

REFERENCES ....................................................................................................................... 5-25

C

OMMUNICATIONS .............................................................................................................. 5-26

R

ESETTING ............................................................................................................................ 5-29

C

LOCK ................................................................................................................................... 5-29

D

EFAULT MESSAGES ...........................................................................................................5-30

S

CRATCHPAD ........................................................................................................................ 5-31

I

NSTALLATION ....................................................................................................................... 5-31

U

PGRADE OPTIONS .............................................................................................................5-31

S

ETUP EVENT RECORDER ...................................................................................................5-33

S2 SYSTEM SETUP ............................................................................................................................ 5-34

D

ESCRIPTION ........................................................................................................................ 5-34

T

RANSFORMER ..................................................................................................................... 5-34

W

INDINGS 1 TO 3 ............................................................................................................... 5-36

O

NLOAD TAP CHANGER ..................................................................................................... 5-37

H

ARMONICS ......................................................................................................................... 5-38

F

LEXCURVES™ .................................................................................................................... 5-38

V

OLTAGE INPUT ................................................................................................................... 5-39

A

MBIENT TEMPERATURE ..................................................................................................... 5-39

A

NALOG INPUT ....................................................................................................................5-41

D

EMAND METERING ............................................................................................................5-41

A

NALOG OUTPUTS 1 TO 7 ................................................................................................. 5-43

S3 LOGIC INPUTS ............................................................................................................................. 5-44

D

ESCRIPTION ........................................................................................................................ 5-44

L

OGIC INPUTS 1 TO 16 ...................................................................................................... 5-44

V

IRTUAL INPUTS 1 TO 16 .................................................................................................. 5-45

S4 ELEMENTS ..................................................................................................................................... 5-46

I

NTRODUCTION TO ELEMENTS ........................................................................................... 5-46

S

ETPOINT GROUP ................................................................................................................ 5-47

D

IFFERENTIAL ELEMENT ..................................................................................................... 5-48

I

NSTANTANEOUS DIFFERENTIAL ........................................................................................ 5-57

P

HASE OVERCURRENT ........................................................................................................ 5-58

N

EUTRAL OVERCURRENT .................................................................................................... 5-66

G

ROUND OVERCURRENT .................................................................................................... 5-69

R

ESTRICTED GROUND FAULT .............................................................................................5-72

N

EGATIVE SEQUENCE OVERCURRENT .............................................................................. 5-76

F

REQUENCY .......................................................................................................................... 5-78

O

VEREXCITATION ................................................................................................................. 5-83

H

ARMONICS ......................................................................................................................... 5-88

I

NSULATION AGING .............................................................................................................5-90

A

NALOG INPUT LEVEL .........................................................................................................5-94

C

URRENT DEMAND ............................................................................................................. 5-95

T

RANSFORMER OVERLOAD ................................................................................................. 5-96

T

AP CHANGER FAILURE ...................................................................................................... 5-97

S5 OUTPUTS ....................................................................................................................................... 5-99

D

ESCRIPTION ........................................................................................................................ 5-99

R

ELAY ASSIGNMENTS .......................................................................................................... 5-99

I

NTRODUCTION TO FLEXLOGIC™ ...................................................................................... 5-99

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL TOC–III

Page 6

FLEXLOGIC™ RULES ........................................................................................................... 5-100

O

UTPUT RELAYS ..................................................................................................................5-102

T

RACE MEMORY ................................................................................................................... 5-105

V

IRTUAL OUTPUTS ...............................................................................................................5-106

T

IMERS .................................................................................................................................. 5-106

S6 TESTING .........................................................................................................................................5-107

D

ESCRIPTION ........................................................................................................................ 5-107

O

UTPUT RELAYS ..................................................................................................................5-107

A

NALOG OUTPUTS ..............................................................................................................5-108

S

IMULATION ......................................................................................................................... 5-108

F

ACTORY SERVICE ................................................................................................................ 5-112

6: ACTUAL VALUES OVERVIEW ........................................................................................................................................... 6-1

ESSAGE MAP .....................................................................................................................6-1

M

D

ESCRIPTION ........................................................................................................................ 6-3

A1 STATUS ........................................................................................................................................... 6-4

N

ETWORK STATUS ............................................................................................................... 6-4

D

ATE AND TIME ................................................................................................................... 6-4

L

OGIC INPUTS ...................................................................................................................... 6-4

V

IRTUAL INPUTS ................................................................................................................... 6-5

O

UTPUT RELAYS ..................................................................................................................6-5

V

IRTUAL OUTPUTS ...............................................................................................................6-5

S

ELF-TEST ERRORS ..............................................................................................................6-6

A2 METERING ..................................................................................................................................... 6-7

C

URRENT ...............................................................................................................................6-7

H

ARMONIC CONTENT ......................................................................................................... 6-10

F

REQUENCY ..........................................................................................................................6-12

T

AP CHANGER ...................................................................................................................... 6-12

V

OLTAGE ...............................................................................................................................6-12

D

EMAND ...............................................................................................................................6-13

A

MBIENT TEMPERATURE .....................................................................................................6-14

L

OSS OF LIFE ........................................................................................................................ 6-14

A

NALOG INPUT ....................................................................................................................6-15

P

OWER .................................................................................................................................. 6-15

E

NERGY ................................................................................................................................. 6-15

A3 EVENT RECORDER ..................................................................................................................... 6-17

E

VENT DATA CLEAR ............................................................................................................6-17

E

VENT RECORDS ..................................................................................................................6-17

A4 PRODUCT INFORMATION ....................................................................................................... 6-21

T

ECHNICAL SUPPORT .......................................................................................................... 6-21

R

EVISION CODES ................................................................................................................. 6-21

C

ALIBRATION ........................................................................................................................ 6-22

TARGET AND FLASH MESSAGES ................................................................................................ 6-23

T

ARGET MESSAGES ............................................................................................................. 6-23

S

ELF-TEST ERRORS ..............................................................................................................6-25

F

LASH MESSAGES ................................................................................................................6-27

7: COMMISSIONING GENERAL .............................................................................................................................................. 7-1

NTRODUCTION .....................................................................................................................7-1

I

T

ESTING PHILOSOPHY ......................................................................................................... 7-2

S

AFETY PRECAUTIONS ......................................................................................................... 7-2

C

ONVENTIONS ...................................................................................................................... 7-2

TOC–IV 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 7

TEST EQUIPMENT ................................................................................................................. 7-3

PRELIMINARY WORK ...................................................................................................................... 7-5

D

ESCRIPTION ........................................................................................................................ 7-5

D

IELECTRIC STRENGTH TESTING ....................................................................................... 7-6

LOGIC INPUTS AND OUTPUT RELAYS ...................................................................................... 7-7

L

OGIC INPUTS ...................................................................................................................... 7-7

O

UTPUT RELAYS .................................................................................................................. 7-8

METERING ........................................................................................................................................... 7-9

D

ESCRIPTION ........................................................................................................................ 7-9

C

URRENT INPUTS ................................................................................................................. 7-9

V

OLTAGE INPUT ................................................................................................................... 7-10

T

RANSFORMER TYPE SELECTION ....................................................................................... 7-11

A

MBIENT TEMPERATURE INPUT ......................................................................................... 7-13

A

NALOG OUTPUTS ............................................................................................................... 7-14

T

AP POSITION ...................................................................................................................... 7-15

PROTECTION SCHEMES ................................................................................................................. 7-16

P

RECAUTION ......................................................................................................................... 7-16

H

ARMONIC RESTRAINED PERCENT DIFFERENTIAL .......................................................... 7-16

I

NSTANTANEOUS DIFFERENTIAL PROTECTION ................................................................. 7-23

P

HASE TIME OVERCURRENT ............................................................................................... 7-25

P

HASE INSTANTANEOUS OVERCURRENT 1 ...................................................................... 7-27

P

HASE INSTANTANEOUS OVERCURRENT 2 ...................................................................... 7-28

N

EUTRAL TIME OVERCURRENT .......................................................................................... 7-29

N

EUTRAL INSTANTANEOUS OVERCURRENT 1 ................................................................. 7-31

N

EUTRAL INSTANTANEOUS OVERCURRENT 2 ................................................................. 7-32

G

ROUND TIME OVERCURRENT .......................................................................................... 7-32

G

ROUND INSTANTANEOUS OVERCURRENT 1 .................................................................. 7-35

G

ROUND INSTANTANEOUS OVERCURRENT 2 .................................................................. 7-36

R

ESTRICTED GROUND FAULT POLARITY TEST .................................................................7-36

R

ESTRICTED GROUND FAULT ELEMENT TEST ..................................................................7-37

N

EGATIVE-SEQUENCE TIME OVERCURRENT ..................................................................... 7-39

N

EGATIVE-SEQUENCE INSTANTANEOUS OVERCURRENT ................................................7-42

F

REQUENCY .......................................................................................................................... 7-43

O

VEREXCITATION ................................................................................................................. 7-52

I

NSULATION AGING .............................................................................................................7-54

T

AP MONITOR FAILURE ...................................................................................................... 7-55

AUXILIARY PROTECTION AND MONITORING FUNCTIONS ............................................. 7-56

THD L

EVEL SCHEME .......................................................................................................... 7-56

H

ARMONIC DERATING FUNCTION ..................................................................................... 7-57

T

RANSFORMER OVERLOAD ................................................................................................. 7-58

PLACING THE RELAY INTO SERVICE ......................................................................................... 7-60

P

RECAUTIONS ....................................................................................................................... 7-60

P

ROCEDURE .......................................................................................................................... 7-60

A: APPENDIX CHANGE NOTES ................................................................................................................................ A-1

EVISION HISTORY .............................................................................................................. A-1

R

C

HANGES TO THE 745 MANUAL ...................................................................................... A-2

EU DECLARATION OF CONFORMITY ........................................................................................ A-5

EU D

ECLARATION ...............................................................................................................A-5

GE DIGITAL ENERGY WARRANTY .............................................................................................. A-6

W

ARRANTY STATEMENT ..................................................................................................... A-6

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL TOC–V

Page 8

B: INDEX

TOC–VI 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 9

GE

NOTE

WARNING

CAUTION

Grid Solutions

745 Transformer Protection

Chapter 1: Getting Started

Getting Started

1.1 Important Procedures

System

1.1.1 Cautions and Warnings

Please read this chapter to guide you through the initial setup of your new relay.

Before attempting to install or use the relay, it is imperative that all

WARNINGS and CAUTIONS in this manual are reviewed to help

prevent personal injury, equipment damage, and/or downtime.

1.1.2 Inspection Checklist

• Open the relay packaging and inspect the unit for physical damage.

• View the rear nameplate and verify that the correct model has been ordered.

• Ensure that the following items are included:

– Instruction manual

– GE EnerVista CD (includes software and relay documentation)

– Mounting screws

• For product information, instruction manual updates, and the latest software updates,

please visit the GE Multilin website at http://www.GEmultilin.com

Note

If there is any noticeable physical damage, or any of the contents listed are missing,

please contact GE Multilin immediately.

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 1–1

Page 10

IMPORTANT PROCEDURES CHAPTER 1: GETTING STARTED

1.1.3 Manual Organization

Reading a lengthy instruction manual on a new product is not a task most people enjoy. To

speed things up, this introductory chapter provides guidelines for basic relay usability.

Important wiring considerations and precautions discussed in Typical Wiring on page 3–7

should be observed for reliable operation. Detailed information regarding accuracy, output

relay contact ratings, and so forth are detailed in Specifications on page 2–5. The

remainder of this manual should be read and kept for reference to ensure maximum

benefit from the 745 Transformer Protection System. For further information, please

consult your local sales representative or the factory. Comments about new features or

modifications for your specific requirements are welcome and encouraged.

Setpoints and actual values are indicated as follows in the manual:

A2 METERING LOSS OF LIFE HOTTEST-SPOT WINDING TEMPERATURE

This ‘path representation’ illustrates the location of a specific actual value or setpoint with

regards to its previous menus and sub-menus. In the example above, the HOTTEST-SPOT

WINDING TEMPERATURE actual value is shown to be an item in the LOSS OF LIFE sub-

menu, which itself is an item in the A2 METERING menu, which is an item of ACTUAL

VALUE S.

Sub-menu levels are entered by pressing the MESSAGE RIGHT or ENTER keys. When inside

a submenu, the MESSAGE LEFT or ESCAPE key returns to the previous sub-menu. The

MESSAGE UP and DOWN keys are used to scroll through the settings in a sub-menu. The

display indicates which keys can be used at any given point.

1–2 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 11

CHAPTER 1: GETTING STARTED USING THE RELAY

1.2 Using the Relay

1.2.1 Menu Navigation

Press the MENU key to access the header of each menu, which will be displayed in the

following sequence:

SETPOINTS []

ACTUAL VALUES []

TARGET MESSAGES []

To access setpoints, press the MENU key until the display shows the header of the

setpoints menu, and then press the MESSAGE RIGHT or ENTER key to display the header for

the first setpoints page. The setpoint pages are numbered, have an ‘S’ prefix for easy

identification and have a name which provides a general idea of the settings available in

that page. Pressing the MESSAGE UP and DOWN keys will scroll through all the available

setpoint page headers. Setpoint page headers look as follows:

SETPOINTS []

S1 745 SETUP

To enter a given setpoints page, press the MESSAGE RIGHT or ENTER key. Press the

MESSAGE UP or DOWN keys to scroll through sub-page headers until the required message

is reached. The end of a page is indicated by the message

page is indicated by the message

TOP OF PAGE.

END OF PAGE. The beginning of a

To access actual values, press the MENU key until the display shows the header of the

actual values menu, then press the MESSAGE RIGHT or ENTER key to display the header for

the first actual values page. The actual values pages are numbered, have an ‘A’ prefix for

easy identification and have a name, which gives a general idea of the information

available in that page. Pressing the MESSAGE UP or DOWN keys will scroll through all the

available actual values page headers. Actual values page headers look as follows:

ACTUAL VALUES []

A1 STATUS

To enter a given actual values page, press the MESSAGE RIGHT or ENTER key. Press the

MESSAGE UP or DOWN keys to scroll through sub-page headers until the required message

is reached. The end of a page is indicated by the message

page is indicated by the message

TOP OF PAGE.

END OF PAGE. The beginning of a

Similarly, to access additional sub-pages, press the MESSAGE RIGHT or ENTER key to enter

the first sub-page, and then the MESSAGE UP or DOWN keys to scroll through the available

sub-pages, until the desired message is reached. The process is identical for both setpoints

and actual values.

The following procedure illustrates the key sequence to access the Current Demand actual

values.

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 1–3

Page 12

USING THE RELAY CHAPTER 1: GETTING STARTED

1. Press the MENU key until you reach the actual values main menu.

ACTUAL VALUES []

2. Press MESSAGE RIGHT or ENTER key to enter the first actual values page, and then the

MESSAGE UP or DOWN key to scroll through pages, until the A2 METERING DATA page

appears.

ACTUAL VALUES []

A2 METERING DATA

3. Press the MESSAGE RIGHT or ENTER key to display the first sub-page heading for the

Metering Data actual values page:

CURRENT []

METERING

Pressing the MESSAGE UP or DOWN keys will scroll the display up and down through the

sub-page headers. Pressing the MESSAGE LEFT or ESCAPE key at any sub-page heading will

return the display to the heading of the corresponding setpoint or actual value page, and

pressing it again, will return the display to the main menu header.

4. Press the MESSAGE DOWN key until the ZERO-SEQUENCE CURRENT METERING subpage heading appears.

ZERO SEQUENCE []

CURRENT METERING

5. At this point, pressing MESSAGE RIGHT or ENTER key will display the messages under

this sub-page. If instead you press the MESSAGE UP key, it will return to the previous

sub-page heading. In this case,

POS. SEQUENCE []

CURRENT METERING

6. When the symbols

and appear on the top line, it indicates that additional sub-

pages are available and can be accessed by pressing the MESSAGE RIGHT or ENTER

key. Pressing MESSAGE RIGHT or ENTER while at the zero-sequence current metering

sub-page heading displays the following:

W1 NEG SEQ CURRENT:

0 A at 0° Lag

Pressing the MESSAGE LEFT key returns to the zero-sequence current metering sub-page

heading.

7. Press the MESSAGE DOWN key to display the next actual value of this sub-page. Actual

values and setpoints messages always have a colon separating the name of the value

and the actual value or setpoint. This particular message displays the current demand

as measured by the relay.

The menu path to the value shown above is indicated as A2 METERING DATA

SEQUENCE CURRENT METERING

W1 NEG SEQ CURRENT. Setpoints and actual values

ZERO

messages are referred to in this manner throughout the manual.

1–4 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 13

CHAPTER 1: GETTING STARTED USING THE RELAY

1.2.2 Panel Keying Example

For example, the S4 ELEMENTS INSULATION AGING AGING FACTOR LIMIT AGING

FACTOR LIMIT PICKUP

1. Press the MENU key until the setpoints header appears on the display.

SETPOINTS []

path representation describes the following key-press sequence:

2. Press the MESSAGE RIGHT or ENTER key, and then the MESSAGE DOWN key until the

ELEMENTS

SETPOINTS []

S4 ELEMENTS

3. Press the MESSAGE RIGHT or ENTER key to display

INSULATION []

AGING

4. Press the MESSAGE RIGHT or ENTER key to display

AGING FACTOR []

LIMIT

5. Press the MESSAGE RIGHT or ENTER key to reach the

message is displayed.

INSULATION AGING message.

AGING FACTOR LIMIT message.

AGING FACTOR LIMIT PICKUP

S4

message and the corresponding setpoint value.

AGING FACTOR LIMIT

PICKUP: 2.0

6. Press the MESSAGE DOWN key to display the next actual value message as shown

below:

AGING FACTOR LIMIT

DE LAY: 1 0 min .

7. Pressing the MESSAGE UP or DOWN keys scrolls the display up and down through all

the setpoint displays in this corresponding sub-page.

8. Pressing the MESSAGE LEFT key reverses the process described above and returns the

display to the previous level.

AGING FACTOR []

LIMIT

9. Press the MESSAGE LEFT key twice to return to the

SETPOINTS []

S4 ELEMENTS

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 1–5

S4 ELEMENTS page header.

Page 14

CHANGING SETPOINTS CHAPTER 1: GETTING STARTED

1.3 Changing Setpoints

1.3.1 Introduction

There are several different classes of setpoints, distinguished by the way their values are

displayed and edited. This section describes how to edit the values used by all setpoint

classes.

Hardware and passcode security features are designed to provide protection against

unauthorized setpoint changes. Since we will be programming new setpoints using the

front panel keys, a hardware jumper must be installed across the setpoint access terminals

(D9 and D10) on the back of the relay case. A keyswitch may also be used across these

terminals to enable setpoint access. Attempts to enter a new setpoint via the front panel

without this connection will be unsuccessful.

1.3.2 Using the HELP Key

Each numerical setpoint has its own minimum, maximum, and increment value associated

with it. These parameters define what values are acceptable for a setpoint.

1. Select the

VOLTAGE

NOMINAL VT SECONDARY

VOLTAGE: 120.0 V

2. Press HELP. The following context sensitive flash message will appear for several

seconds. For the case of a numerical setpoint message, the HELP key displays the

minimum, maximum, and step value.

Range: 60.0

to 120.0 by 0.1

1.3.3 Numerical Setpoints

The following two methods of editing and storing a numerical setpoint value are available.

1. 0 to 9 and the decimal key: The relay numeric keypad works the same as that of any

electronic calculator. A number is entered one digit at a time. The left-most digit is

entered first and the right-most digit is entered last. Pressing the ESCAPE key, before

the ENTER key, returns the original value to the display.

2. VALUE keys: The VALUE UP key increments the displayed value, by the step value, up to

the maximum value allowed. While at the maximum, pressing the VALUE UP key again

will allow setpoint selection to continue from the minimum value. The VALUE DOWN

key decrements the displayed value, by the step value, down to the minimum value.

Again, continuing to press the VALUE DOWN key while at the minimum value will

continue setpoint selection from the maximum value.

S2 SYSTEM SETUP VOLTAGE INPUT NOMINAL VT SECONDARY

setpoint.

1–6 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 15

CHAPTER 1: GETTING STARTED CHANGING SETPOINTS

As an example, let’s set the nominal VT secondary voltage setpoint to 69.3 V. Press the

appropriate numeric keys in the sequence ‘6 9 . 3‘. The display message will change as

the digits are being entered.

NOMINAL VT SECONDARY

VOLTAGE: 69.3 V

Editing changes are not registered until the ENTER key is pressed. Press the ENTER key to

store the new value in memory. This flash message momentarily appears to confirmation

the storing process. If 69.28 were entered, the value is automatically rounded to 69.3, since

the step value for this setpoint is 0.1.

NEW SETPOINT HAS

BEEN STORED

1.3.4 Enumeration Setpoints

Enumeration setpoints have data values which are part of a set, whose members are

explicitly defined by a name. A set is comprised of two or more members.

Enumeration type values are changed using the VALUE keys. The VALUE UP key displays

the next selection while the VALUE DOWN key displays the previous selection. As an

example we may need to set the phase sequence to ACB. Press the VALUE keys until the

proper selection is displayed.

Editing changes are not registered until ENTER is pressed, storing the new value in

memory. This flash message momentarily appears to confirm the storing process.

1.3.5 Text Setpoints

Text setpoints have data values which are fixed in length, but user defined in character.

They may be comprised of upper case letters, lower case letters, numerals, and a selection

of special characters.

The editing and storing of a text value is accomplished with the use of the decimal, ENTER,

VALUE, and ESCAPE keys. For example:

1. The name for output relay 3 should be more descriptive than the default value. For this

2. Press VALUE keys until the character “I” is displayed in the first position, then press the

PHASE SEQUENCE:

ACB

NEW SETPOINT HAS

BEEN STORED

example let us rename output relay as

INST DIFF TRIP. Press the decimal key and an

underscore (_) will appear at the first character position.

OUTPUT 3 NAME:

T

rip 3

decimal key to store the character and advance the cursor. Change the second

character to a “N” using the VALUE keys and save this change by pressing the decimal

key again. Continue editing all the characters in the text until the string

INST DIFF TRIP

is entered. Note that a space is selected like a character. If a character is entered

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 1–7

Page 16

CHANGING SETPOINTS CHAPTER 1: GETTING STARTED

incorrectly, press the decimal key repeatedly until the cursor returns to the position of

the error and re-enter the character as required. Once complete, press ENTER to

remove the solid cursor and save the result.

OUTPUT 3 NAME:

INST DIFF TRIP

1–8 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 17

CHAPTER 1: GETTING STARTED SECURITY

1.4 Security

1.4.1 Installation

Note that the relay is defaulted to the “Not Programmed” state before it leaves the factory.

This safeguards against the installation of a relay whose setpoints have not been entered.

In addition, a relay in the “Not Programmed” state blocks signaling of any output relay, and

turns off the In Service LED indicator.

Move to the

S1 745 SETUP INSTALLATION 745 SETPOINTS message. To put the relay

in the “Programmed” state, press the VALUE UP or DOWN key once and press ENTER. Enter

“Yes” for the

745 SETPOINTS:

Not Programmed

1.4.2 Changing the Passcode

To guarantee that the relay settings cannot be tampered with, the user may setup the

passcode security feature.

1. Move to the

cannot be edited directly. It simply indicates whether passcode security is enabled

(

SETPOINT ACCESS: “Read Only”), or passcode security is disabled (SETPOINT ACCESS:

“Read & Write”). Each relay is shipped from the factory with setpoint access allowed.

The passcode is also defaulted to '0', which disables the passcode security feature

entirely.

SETPOINT ACCESS:

Read & Write

2. Press the MESSAGE DOWN key once.

CHANGE PASSCODE?

No

ARE YOU SURE? message. The In Service LED indicator will now turn on.

S1 745 SETUP PASSCODE SETPOINT ACCESS message. This message

3. Press the VALUE UP or VALUE DOWN key once.

CHANGE PASSCODE?

Ye s

4. Press the ENTER key to begin the procedure of changing the passcode. The displayed

message will change as shown. The current passcode is '0', so press the '0' numeric

key. The relay will acknowledge the key press by displaying ‘*’.

PLEASE ENTER CURRENT

PASSCODE:

5. Press the ENTER key.

ENTER NEW PASSCODE

FOR ACCESS:

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 1–9

Page 18

SECURITY CHAPTER 1: GETTING STARTED

6. For this example, change the passcode to “123” by pressing the appropriate numeric

keys in the ‘1 2 3’ sequence. The message will change as the digits are entered, with

the end result being as shown.

ENTER NEW PASSCODE

FOR ACCESS: ***

7. Press the ENTER key to store the new passcode and a confirmation message appears.

As a safety measure, the relay requires you to enter a new passcode twice. This

ensures the passcode has been entered correctly.

PLEASE RE-ENTER NEW

PASSCODE:

8. After pressing the appropriate numeric keys in the sequence ‘1 2 3’, press ENTER. This

flash message appears momentarily on the display and confirms the new passcode is

stored in memory.

NEW PASSCODE

HAS BEEN STORED

9. After a few seconds, the original display returns.

10. Press the MESSAGE UP key. As soon as a non-zero passcode is entered, setpoint

access will automatically become restricted.

ALLOW ACCESS TO

SETPOINTS? No

1.4.3 Disabling and Enabling Passcode Security

Suppose at some time in the future you want to alter a setpoint. In order to do this, you

must first disable passcode security, make the setpoint change, and then re-enable the

passcode security.

1. Move to message

from here that we will disable passcode security. Please note that this message is

hidden, when the passcode security feature is disabled by entering a passcode of “0”.

ALLOW ACCESS TO

SETPOINTS? No

2. Press the VALUE UP or DOWN key once to select “Yes” and press ENTER. The displayed

message will change as shown.

PLEASE ENTER CURRENT

PASSCODE:

3. Enter the current passcode and press the ENTER key. This flash message indicates

that the keyed in value was accepted and that passcode security is now disabled.

SETPOINT ACCESS

IS NOW ALLOWED

S1 745 SETUP PASSCODE ALLOW ACCESS TO SETPOINTS. It is

1–10 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 19

CHAPTER 1: GETTING STARTED SECURITY

4. This message will appear after a few seconds. Now that setpoint access is enabled,

the

ALLOW ACCESS TO SETPOINTS message has been replaced by the RESTRICT

ACCESS TO SETPOINTS

message. The relay’s setpoints can now be altered and stored.

If no front panel keys are pressed for longer than 30 minutes, setpoint access will

automatically become restricted again.

RESTRICT ACCESS TO

SETPOINTS? No

5. To disable setpoint access, immediately after setpoint editing, move back to message

S1 745 SETUP PASSCODE RESTRICT ACCESS TO SETPOINTS and enter “Yes”. Key

the current passcode into the shown message.

PLEASE ENTER CURRENT

PASSCODE:

6. Press the ENTER key and this message will flash on the display. It indicates that

passcode security is now enabled.

SETPOINT ACCESS

IS NOW RESTRICTED

7. After a few seconds, the original display returns.

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 1–11

Page 20

SECURITY CHAPTER 1: GETTING STARTED

1–12 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 21

GE

Grid Solutions

2.1 Introduction

745 Transformer Protection

System

Chapter 2: Overview

Overview

2.1.1 Description

These instructions do not purport to cover all details or variations in equipment nor provide

for every possible contingency to be met in connection with installation, operation, or

maintenance. Should further information be desired or should particular problems arise

which are not covered sufficiently for the purchaser’s purpose, the matter should be

referred to the General Electric company.

To the extent required the products described herein meet applicable ANSI, IEEE, and

NEMA standards; but no such assurance is given with respect to local codes and

ordinances because they vary greatly.

The 745 Transformer Protection System™ is a high speed, multi-processor based, threephase, two or three winding, transformer management relay intended for the primary

protection and management of small, medium and large power transformers. The 745

combines percent differential, overcurrent, frequency, and overexcitation protection

elements along with monitoring of individual harmonics, and total harmonic distortion

(THD) in one economical package.

The relay provides a variety of adaptive relaying features:

• Adaptive harmonic restraint which addresses the problem of false tripping during

inrush

• Adaptive time overcurrent elements which will adjust their pickup settings based on

the calculated transformer capability when supplying load currents with high

harmonic content

• Multiple setpoint groups which allow the user to enter and dynamically select from up

to four groups of relay settings to address the protection requirements of different

power system configurations

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 2–1

Page 22

INTRODUCTION CHAPTER 2: OVERVIEW

• Dynamic CT ratio mismatch correction which monitors the on-load tap position and

automatically corrects for CT ratio mismatch

• FlexLogic™ which allows PLC style equations based on logic inputs and protection

elements to be assigned to any of the 745 outputs.

The 745 also includes a powerful testing and simulation feature. This allows the protection

engineer the ability to test the relay operation based on captured or computer generated

waveform data which can be converted to a digitized format and downloaded into the

745’s simulation buffer for “playback”. A waveform capture function that records waveform

data for fault, inrush, or alarm conditions is also provided.

The auto-configuration function eliminates the need for any special CT connections by

having all CTs connected in wye.

2.1.2 Protection Features

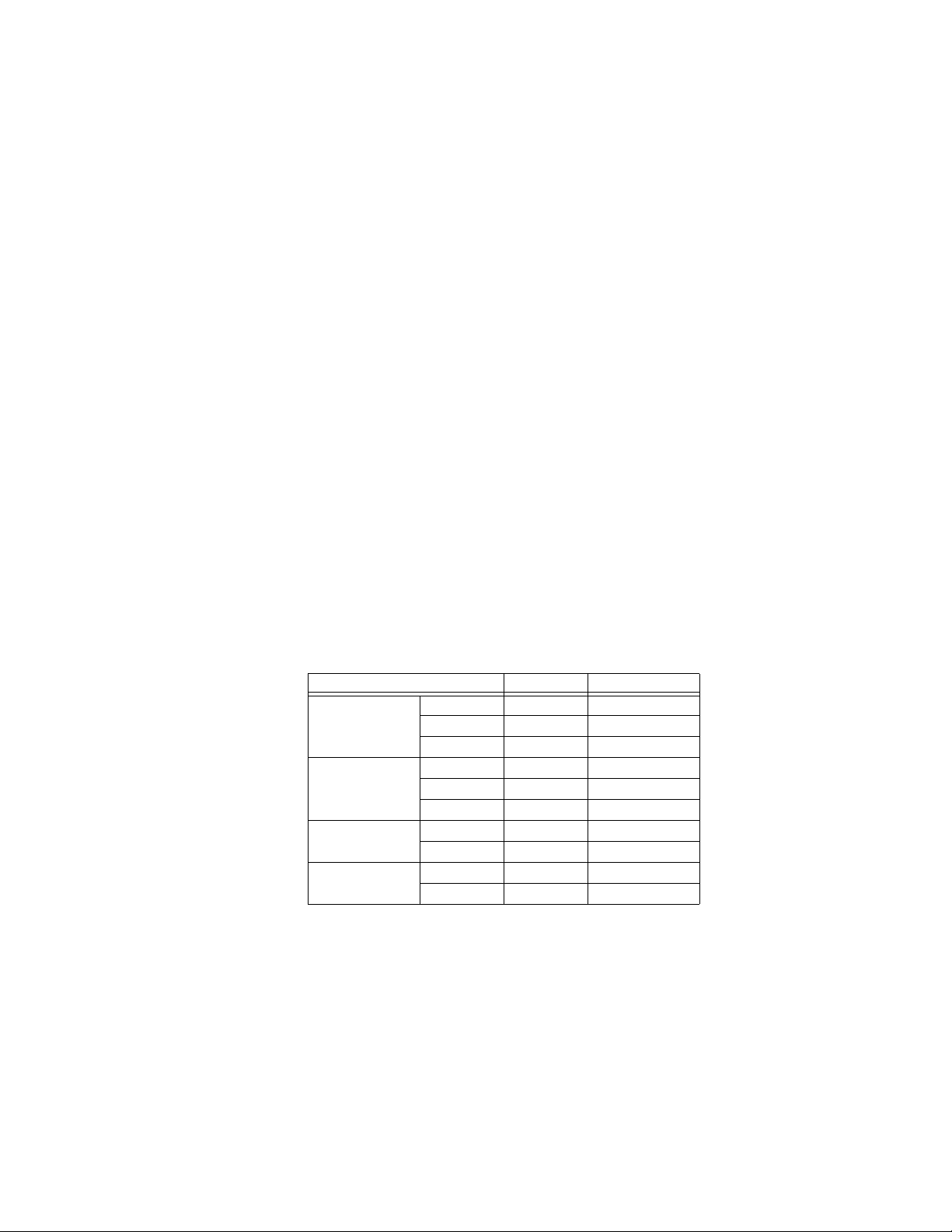

The following table outlines the protection features available for windings 1, 2, and 3, as

well as the common protection elements.

Symbol Common protection element Symbol Winding 1 protection elements

59/81-1 Volts-per-hertz 1 150/46 Negative sequence instantaneous overcurrent

59/81-2 Volts-per-hertz 2 151/46 Negative sequence time overcurrent

81U-1 Underfrequency 1 150P1 Phase instantaneous overcurrent 1

81U-2 Underfrequency 2 150P2 Phase instantaneous overcurrent 2

81U-R1 Frequency decay rate 1 150N1 Neutral (3I

81U-R2 Frequency decay rate 2 150N2 Neutral (3I

81U-R3 Frequency decay rate 3 150G1 Ground instantaneous overcurrent 1

81U-R4 Frequency decay rate 4 150G2 Ground instantaneous overcurrent 2

81-H5 5th harmonic Level 151P Phase time overcurrent

81O Overfrequency 151N Neutral (3I

87 Differential (percent) 151G Ground time overcurrent

50/87 Instantaneous differential 187TG Ground differential (restricted ground fault)

AN-1 Analog input level 1 1THD Total harmonic distortion level

AN-2 Analog input level 2 1AD Current demand

--- Insulation aging: aging factor, hottest spot limit,

and total accumulated life

--- Tap changer monitor

) instantaneous overcurrent 1

0

) instantaneous overcurrent 2

0

) time overcurrent

0

2–2 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 23

CHAPTER 2: OVERVIEW INTRODUCTION

Symbol Winding 2 protection elements Symbol Winding 3 protection elements

250/46 Negative sequence instantaneous overcurrent 350/46 Negative sequence instantaneous overcurrent

251/46 Negative sequence time overcurrent 351/46 Negative sequence time overcurrent

250P1 Phase instantaneous overcurrent 1 350P1 Phase instantaneous overcurrent 1

250P2 Phase instantaneous overcurrent 2 350P2 Phase instantaneous overcurrent 2

250N1 Neutral (3I

250N2 Neutral (3I

) instantaneous overcurrent 1 350N1 Neutral (3I0) instantaneous overcurrent 1

0

) instantaneous overcurrent 2 350N2 Neutral (3I0) instantaneous overcurrent 2

0

250G1 Ground instantaneous overcurrent 1 351P Phase time overcurrent

250G2 Ground instantaneous overcurrent 2 351N Neutral (3I

) time overcurrent

0

251P Phase time overcurrent 351G Ground time overcurrent

251N Neutral (3I

) time overcurrent 387TG Ground differential (restricted ground fault)

0

251G Ground time overcurrent 3THD Total harmonic distortion level

287TG Ground differential (restricted ground fault) 3AD Current demand

2THD Total harmonic distortion level

2AD Current demand

FIGURE 2–1: Single line diagram

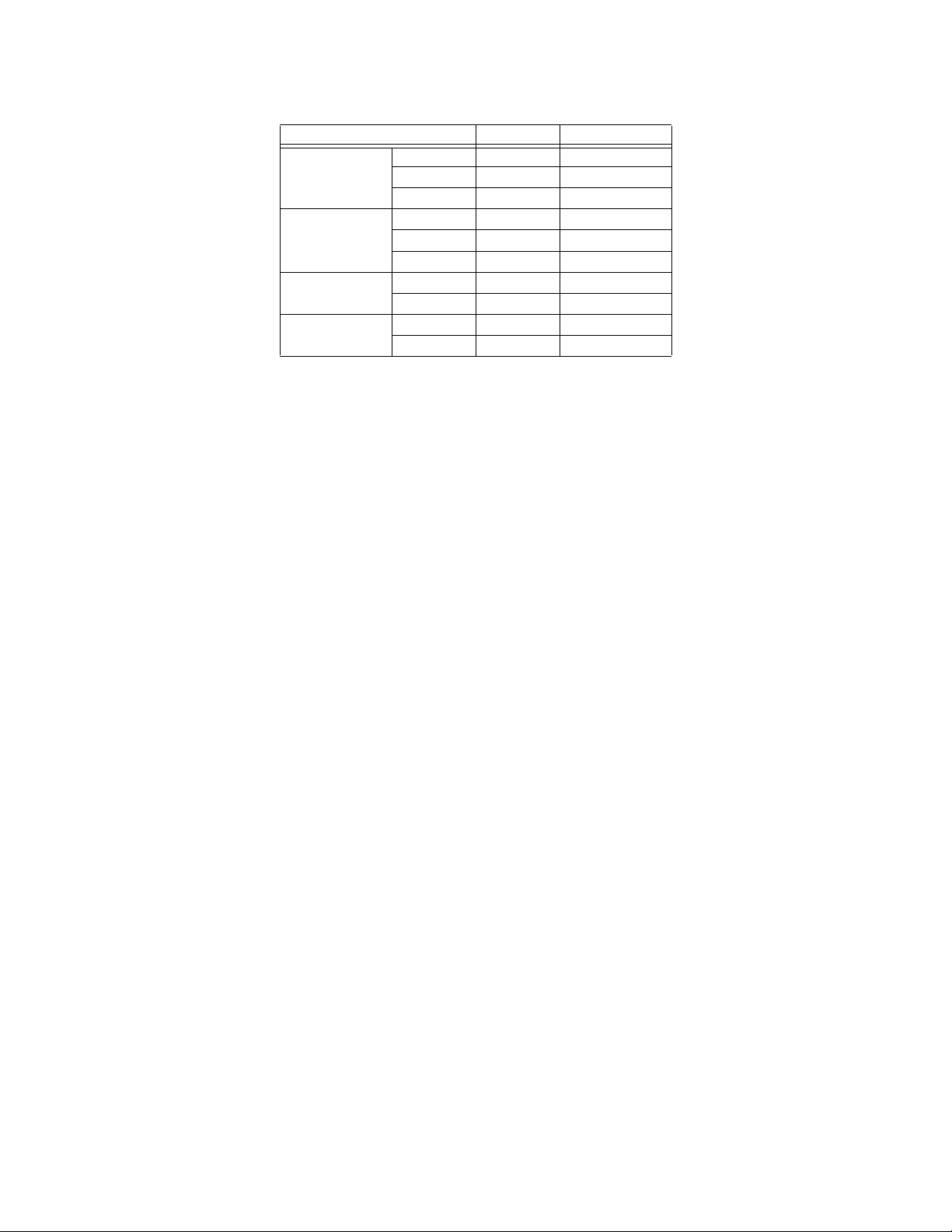

2.1.3 Order Codes

The order codes for the 745 Transformer Protection System are shown below.

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 2–3

Page 24

INTRODUCTION CHAPTER 2: OVERVIEW

Table 2–1: 745 order codes

745 – * – * – * – * – * – * – *

Base unit 745 | | | | | | | 745 Transformer Protection System

Windings per

phase

Phase current

input ratings

Ground current

input ratings

Control power LO | | | 20 to 60 V DC; 20 to 48 V AC at 48 to 62 Hz

Options A | | Analog inputs/outputs

Display/Ethernet B | Discontinued: Basic display

Harsh environment H Harsh (chemical) environment conformal coating

W2 | | | | | | Two windings per phase

W3 | | | | | | Three windings per phase

P1|||||Winding 1 = 1 A, Winding 2 = 1 A, Winding 3 = 1 A

P5|||||Winding 1 = 5 A, Winding 2 = 5 A, Winding 3 = 5 A

P15 | | | | | Winding 1 = 1 A, Winding 2 = 5 A

P51 | | | | | Winding 1 = 5 A, Winding 2 = 1 A

P115 | | | | | Winding 1 = 1 A, Winding 2 = 1 A, Winding 3 = 5 A

P151 | | | | | Winding 1 = 1 A, Winding 2 = 5 A, Winding 3 = 1 A

P155 | | | | | Winding 1 = 1 A, Winding 2 = 5 A, Winding 3 = 5 A

P511 | | | | | Winding 1 = 5 A, Winding 2 = 1 A, Winding 3 = 1 A

P515 | | | | | Winding 1 = 5 A, Winding 2 = 1 A, Winding 3 = 5 A

P551 | | | | | Winding 1 = 5 A, Winding 2 = 5 A, Winding 3 = 1 A

G1 | | | | Winding 1/2 = 1 A, Winding 2/3 = 1 A

G5 | | | | Winding 1/2 = 5 A, Winding 2/3 = 5 A

G15 | | | | Winding 1/2 = 1 A, Winding 2/3 = 5 A

G51 | | | | Winding 1/2 = 5 A, Winding 2/3 = 1 A

HI | | | 88 to 300 V DC; 70 to 265 V AC at 48 to 62 Hz

L | | Loss of life

R | | Restricted ground fault

E | Enhanced display, larger LCD, two RS485 ports

T | Enhanced display, larger LCD, one RS485, Ethernet

2–4 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 25

CHAPTER 2: OVERVIEW SPECIFICATIONS

2.2 Specifications

2.2.1 Applicability

TRANSFORMERS AND FREQUENCY

Transformers:...................................................two-winding or three-winding

Frequency:.........................................................50 or 60 Hz nominal

Frequency tracking:......................................40 to 65 Hz for 0.05 × CT < current ≤ 1 × CT

5 to 65 Hz for current > 1 × CT

2 to 65 Hz for voltage > 50% of VT (only if voltage sensing

is enabled)

2.2.2 Inputs

CONTROL POWER

Options:...............................................................LO/HI (specified when ordering)

LO range:............................................................20 to 60 V DC; 20 to 48 V AC at 48 to 62 Hz

HI range:.............................................................90 to 300 V DC; 70 to 265 V AC at 48 to 62 Hz

Power:..................................................................30 VA nominal, 40 VA maximum

Total loss of voltage ride-through time (0% control power): 16.7 ms

Fuse current rating:.......................................3.15 A (fuse not accessible)

Fuse type: ..........................................................5 × 20 mm slow-blow Littelfuse, high breaking capacity;

model 2153.15

PHASE CURRENT INPUT

Source CT:..........................................................1 to 50000 A primary; 1 or 5 A secondary

Relay input:.......................................................1 A or 5 A (specified at order)

Burden:................................................................less than 0.2 VA at rated load per phase

Conversion range:..........................................0.02 to 46 × CT at 50/60 Hz nominal frequency

Accuracy at < 4 × CT: ...................................±0.25% of 4 × CT (±0.01 × CT) at 50/60 Hz nominal

frequency

Accuracy at ≥ 4 × CT: ...................................±0.5% of 46 × CT (±0.2 × CT) at 50/60 Hz nominal

frequency

Overload withstand:......................................1 second at 80 times rated current; 2 seconds at 40 times

rated current; continuous at 3 times rated current

GROUND CURRENT INPUT

Source CT:..........................................................1 to 50000 A primary, 1 or 5 A secondary

Relay input:.......................................................1 A or 5 A (specified at order)

Burden:................................................................less than 0.2 VA at rated load

Conversion range:..........................................0.02 to 46 × CT

Accuracy at < 4 × CT: ...................................±0.25% of 4 × CT (±0.01 × CT)

Accuracy at ≥ 4 × CT: ...................................±0.5% of 46 × CT (±0.2 × CT)

Overload withstand:......................................1 second at 80 times rated current; 2 seconds at 40 times

rated current; continuous at 3 times rated current

VOLTAGE INPUTS

Source VT:..........................................................2 to 600 kV / 60 to 120 V

Source VT ratio:...............................................1 to 5000 in steps of 1

Relay input:.......................................................60 to 120 V phase-neutral

Burden:................................................................less than 0.025 VA at 120 V

Maximum continuous input: 273 V

Maximum accuracy input: 260 V (full-scale)

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 2–5

Page 26

SPECIFICATIONS CHAPTER 2: OVERVIEW

Accuracy:...........................................................±2.0% of full-scale

LOGIC INPUTS

Number of inputs: ..........................................16

Dry contacts:....................................................1000 Ω maximum ON resistance (32 V DC at 2 mA

provided by the 745)

Wet contacts:...................................................30 to 300 V DC at 1.5 mA

ANALOG INPUT

Type:.....................................................................DC mA

Ranges:................................................................0 to 1 mA, 0 to 5 mA, 0 to 20 mA, 4 to 20 mA

(programmable)

Input impedance:...........................................375 Ω ±10%

Conversion range:..........................................0 to 21 mA

Accuracy:...........................................................±1% of full scale (based on input range)

TAP POSITION

Type:.....................................................................resistance (ohms)

Range:..................................................................0 to 500 Ω or 0.5 to 5.0 kΩ

Bias current:......................................................1 mA or 10 mA (based on input range)

Accuracy:...........................................................±1% of full scale (based on input range)

RTD

Type:.....................................................................3 wire

RTD Type ............................................................100 Ω Platinum (DIN.43760), 100 Ω Nickel, 120 Ω Nickel

IRIG-B INPUT

Amplitude-modulated:.................................1.0 to 10 V pk-pk

DC shift:...............................................................TTL

Input impedance:...........................................70 to 100 kΩ

2.2.3 Protection Elements

PERCENT DIFFERENTIAL

Operating current pickup: 0.05 to 1.00 × CT in steps of 0.01

Dropout level:...................................................97 to 98% of pickup

Slope 1 range:..................................................15% to 100% in steps of 1

Slope 2 range:..................................................50% to 100% in steps of 1

KP (Slope-1 kneepoint):................................1.0 to 20.0 × CT in steps of 0.1

Harmonic restraint:.......................................0.1 to 65.0% in steps of 0.1

Solid state output operate time:

pickup < 1 × CT: ........................42 to 52 ms

1 × CT < pickup < 1.1 × kneepoint: 34 to 44 ms

pickup > 1.1 × kneepoint:......26 to 36 ms

Relay outputs 2 to 5 operate time:

pickup < 1 × CT:.........................46 to 56 ms

1 × CT < pickup < 1.1 × kneepoint: 38 to 48 ms

pickup > 1.1 × kneepoint:......30 to 40 ms

INSTANTANEOUS DIFFERENTIAL OVERCURRENT

Pickup level:.......................................................3.00 to 20.00 × CT in steps of 0.01

Dropout level:...................................................97 to 98% of pickup

Level accuracy:...............................................per current input

2–6 745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 27

CHAPTER 2: OVERVIEW SPECIFICATIONS

Solid state output operate time:

at 1.2 × pickup: ......................... 22 to 30 ms

at 2.0 × pickup: ......................... 18 to 26 ms

at 4.0 × pickup: ......................... 11 to 19 ms

Relay outputs 2 to 5 operate time:

at 1.2 × pickup: ......................... 28 to 36 ms

at 2.0 × pickup: ......................... 24 to 32 ms

at 4.0 × pickup: ......................... 17 to 25 ms

PHASE / NEUTRAL / GROUND / NEGATIVE SEQUENCE TIME OVERCURRENT

Pickup level: ......................................................0.05 to 20.00 × CT in steps of 0.01

Dropout level:...................................................97 to 98% of pickup

Curve shapes: ..................................................ANSI extremely/very/moderately/normally inverse;

definite time (0.1 s base curve); IEC curve A/B/C and short;

FlexCurve™ A/B/C (programmable curves); IAC extreme/

very/inverse/short

Curve multiplier: .............................................0.00 to 100.00 in steps of 0.01

Reset type:.........................................................instantaneous or linear

Level accuracy:...............................................per current input

Timing accuracy: ...........................................±3% of trip time or ±20 ms (whichever is greater) at ≥ 1.03

× pickup

PHASE / NEUTRAL / GROUND / NEGATIVE SEQUENCE INSTANTANEOUS OVERCURRENT

Pickup level: ......................................................0.05 to 20.00 × CT in steps of 0.01

Dropout level:...................................................97 to 98% of pickup

Time delay:........................................................0 to 60000 ms in steps of 1

Level accuracy:...............................................per current input

Solid state output operate time:

at 1.2 × pickup: ......................... 22 to 30 ms

at 2.0 × pickup: ......................... 18 to 26 ms

at 4.0 × pickup: ......................... 11 to 19 ms

Relay outputs 2 to 5 operate time:

at 1.2 × pickup: ......................... 28 to 36 ms

at 2.0 × pickup: ......................... 24 to 32 ms

at 4.0 × pickup: ......................... 17 to 25 ms

RESTRICTED GROUND FAULT

Number of elements:....................................2

Minimum pickup:............................................0.02 to 20.00 × CT in steps of 0.01

Dropout level:...................................................97 to 98% of pickup

Slope range:......................................................0 to 100% in steps of 1

Pickup delay:....................................................0.00 to 600.00 s in steps of 0.01

Solid-state output operating time:

at 1.1 × pickup: 30 to 50 ms

at 10 × pickup: 20 to 30 ms

(delay set at 0.0 s)

Relay outputs 2 to 5 operating time:

at 1.1 × pickup: 30 to 50 ms

at 10 × pickup: 20 to 30 ms

(delay set at 0.0 s)

UNDERFREQUENCY

Number of elements:....................................2

Operating current pickup: 0.05 to 1.00 × CT in steps of 0.01

Operating voltage pickup: 0.10 to 0.99 × VT in steps of 0.01

Pickup level: ......................................................45.00 to 59.99 Hz in steps of 0.01

Dropout level:...................................................pickup + 0.03 Hz

745 TRANSFORMER PROTECTION SYSTEM – INSTRUCTION MANUAL 2–7

Page 28

SPECIFICATIONS CHAPTER 2: OVERVIEW

Time delay:........................................................0.00 to 600.00 s in steps of 0.01

Signal source:...................................................winding 1 phase A current / voltage

Level accuracy:...............................................±0.02 Hz

Solid state output operate time: 39 to 60 ms at 3% beyond pickup (delay set at 0.0 s)

Relay outputs 2 to 5 operate time: 42 to 66 ms at 3% beyond pickup (delay set at 0.0 s)

FREQUENCY RATE OF CHANGE

Number of elements:....................................4

Operating current pickup: 0.05 to 1.00 × CT in steps of 0.01

Operating voltage pickup: 0.10 to 0.99 × VT in steps of 0.01

Pickup level:.......................................................45.00 to 59.99 Hz in steps of 0.01

Dropout level:...................................................pickup + 0.03 Hz

Rate 1/2/3/4: ....................................................0.1 to 5.0 Hz/sec. in steps of 0.1

Dropout level:...................................................pickup + 0.07 Hz/sec.

Signal source:...................................................winding 1 phase A current / voltage

Level accuracy:...............................................±0.02 Hz

Operate time: ...................................................The operate time of this element is variable and is

dependent on the decay rate setting and the supervision

frequency level.

OVERFREQUENCY

Operating current pickup: 0.05 to 1.00 × CT in steps of 0.01

Operating voltage pickup: 0.10 to 0.99 × VT in steps of 0.01

Pickup level:.......................................................50.01 to 65.00 Hz in steps of 0.01

Dropout level:...................................................pickup – 0.03 Hz

Time delay:........................................................0.00 to 600.00 s in steps of 0.01

Signal source:...................................................winding 1 phase A current / voltage

Level accuracy:...............................................±0.02 Hz

Solid state output operate time: 39 to 60 ms at 3% beyond pickup (delay set at 0.0 s)

Relay outputs 2 to 5 operate time: 42 to 66 ms at 3% beyond pickup (delay set at 0.0 s)

OVEREXCITATION ON VOLTS PER HERTZ

Number of elements:....................................2

Operating voltage pickup: 0.10 to 0.99 × VT in steps of 0.01

Pickup level:.......................................................1.00 to 4.00 V/Hz in steps of 0.01

Curve shapes: ..................................................definite time (0.1 second base curve); IEC curve A/B/C

Time delay:........................................................0.00 to 600.00 s in steps of 0.01

Reset delay:.......................................................0.0 to 6000.0 s in steps of 0.1

Signal source:...................................................voltage

Range:..................................................................10 to 65 Hz

Level accuracy: .....................................±0.02 V/Hz

Solid state output operate time: 165 to 195 ms at 1.10 × pickup: