Page 1

GE Healthcare

Instructions 71-5000-15 AD Pre-activated media

CNBr-activated

Sepharose 4 Fast Flow

Introduction

The preparation and use of affinity chromatography media by coupling biospecific

ligands to CNBr-activated matrices is a widely used, successful and well-documented

technique.

CNBr-activated Sepharose

combines the advantages of CNBr coupling with the high flow and stability

characteristics of Sepharose 4 Fast Flow. In our experience, the CNBr coupling

technique has a well-proven track record for the purification of therapeutic

proteins. This, plus the performance of the matrix at large scale, makes the use of

CNBr-activated Sepharose 4 Fast Flow particularly attractive for manufacturing

applications in the biopharmaceutical industry. Fur thermore, the medium is a

member of the BioProcess

for production scale chromatography. All BioProcess media are produced with

validated methods and are tested to meet manufacturing requirements. Secure

ordering and delivery routines give a reliable supply of media for production

scale. Regulatory Support Files (RSF) are available to assist process validation and

submissions to regulatory authorities.

To ensure best performance and trouble-free operation, please read these

instructions before using CNBr-activated Sepharose 4 Fast Flow.

TM

4 Fast Flow is a pre-activated affinity matrix that

TM

media. BioProcess media are developed and suppor ted

Page 2

Table of contents

1. Product description 2

2. Coupling 3

3. Column packing guidelines 5

4. Evaluation of packing 7

5. Cleaning, Sanitization and Storage 10

6. Ordering information 11

1. Product description

CNBr-activated Sepharose 4 Fast Flow is a bead-formed, highly crosslinked pre-activated matrix produced by reacting Sepharose 4 Fast Flow

with cyanogen bromide (CNBr). This coupling makes the medium more

rigid which in turn improves the pressure/flow characteristics. Proteins

and other molecules containing primary amino groups can be coupled

directly to the pre-activated medium. Multi-point at tachment of proteins

provides the immobilized product with good chemical stability. The resulting

affinity medium can isolate a specific substance from a complex mix ture,

often achieving very high yield and purity in a single step. Many references

demonstrate that binding affinity is frequently well maintained after CNBr

coupling.

A typical application of pre-activated affinity media like CNBr-activated

Sepharose 4 Fast Flow is based on antigen-antibody reactions with

immobilized monoclonal antibodies as ligands. In such cases, purification

factors of 2 000–20 000 can be obtained.

Table 1 summarizes the main characteristics of CNBr-activated Sepharose 4

Fast Flow.

p. 2

Page 3

Table 1 . Medium characteristics.

Mean particle size 90 μm

Particle size range 45–165 μm

Bead structure Highly cross-linked 4% agarose, spherical

Linear flowrate

Base matrix 150 –250 cm/h, 0.1 MPa (1 bar) , XK 50/60 column, bed height 25 cm

Swelling factor 4–5 ml drained medium/g

Coupling capacity 13–26 mg α-chymotrypsinogen/ml

pH stability*

long term 3–11

short term (CIP) 3–11

* Refers to s tability of co upling betwe en ligand abd b ase matrix. L igands can be l ess stable.

Sepharose 4 Fast Flow matrix

Sepharose 4 Fast Flow is a highly cross-linked agarose matrix. In its preactivated CNBr form, it offers much improved performance when compared

with the well established CNBr-activated Sepharose 4B. The Sepharose 4

Fast Flow matrix has higher rigidity and can thus be run at high flow rates

(see Table 1).

The higher mechanical strength of the cross-linked matrix makes it wellsuited for use in large columns. Scaling up a purification developed on CNBractivated Sepharose 4 Fast Flow is therefore simple and more predictable.

The coupled product is stable at low pH, which is often required for elution

from some immunoadsorbents.

For applications that require operation at high pH, note that the amide bond

formed when using the companion product NHS-activated Sepharose 4

Fast Flow is stable up to pH 13 for normal use.

2. Coupling

CNBr-activated Sepharose 4 Fast Flow is supplied freeze-dried in the

presence of additives. These additives need to be washed away at low

pH (pH-2–3) before coupling the desired ligand. The use of low pH ( pH2–3)

preser ves the activity of the reactive groups, which otherwise hydrolyse at

high pH.

p. 3

Page 4

In order to retain maximum binding capacity of CNBr-activated Sepharose 4

Fast Flow prior to coupling the ligand, use cold (0 –4 °C) solutions. The

time interval between washing and coupling must be minimised; therefore

preparations of all required solutions prior to coupling is recommended.

1. Prepare the coupling solution, i.e. dissolve the ligand to be coupled in

a suitable coupling buffer, e.g. 0.1 M NaHCO

NaCl. For good coupling efficiency avoid unnecessarily dilute solutions

pH 8.3 containing 0.5 M

3

(Recommended ratio of volumes, coupling solution/medium is 0.5:1). The

coupling pH depends on the ligand. Normally pH in the range 7–9 is used.

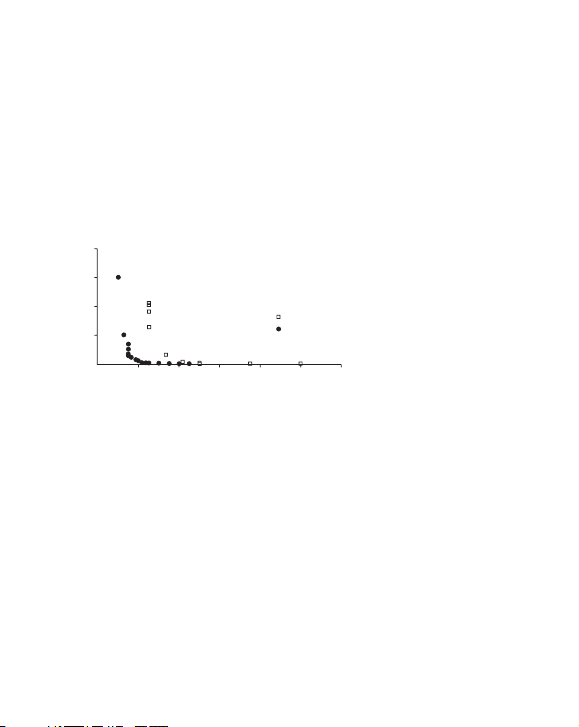

ppm sugar

400

300

200

100

0

0

10 20 30 40 50 60

A-method

B-method

A-method: Add portions of 4

column volumes cold 1 mM HCl,

stir and immediately remove the

liquid.

B-method: Add portions of 1

column volume cold 1 mM HCl,

stir for approx. 5 min and then

remove the liquid.

Gel vol.

Fig 1. The content of sugar in the filtrate after washing with different

medium volumes of cold 1 mM HCl.

2. CNBr-activated Sepharose 4 Fast Flow is supplied freeze-dried with

sugar additives and is washed initially with 10–15 medium volumes of

cold 1 mM HCl, see Fig 1. Use small wash por tions (e.g. 1 medium volume)

and let the mixture equilibrate a few minutes during each washing step.

After washing, determine the exact medium volume obtained using e.g.

centrifugation or PD-10 column (the medium volume may vary between

experiments).

3. Mix the washed medium and coupling solution. Adjust pH to the desired

value. To obtain good reproducibility it is wise to adjust total reaction

volume to a fixed value with coupling buffer.

4. Coupling is normally very fast. At room temperature the reaction is

usually completed after 2–4 hours. If coupling is per formed at 4 °C, it can

be performed overnight. It may be practical to follow the reaction using

UV-absorbance measurements.

p. 4

Page 5

5. Wash away exess ligand with at least 5 medium volumes of coupling buffer.

6. After coupling, non-reacted groups on the medium should be blocked.

Transfer the medium to 0.1 M Tris-HCl buf fer pH 8.0 or 1 M ethanolamine

pH 8.0. Let it stand for 2 hours.

7. Wash the coupled medium using alternate low and high pH.

Recommended buffers are 0.1M acetate buffer pH 3-4 containing 0.5 M

NaCl and 0.1 M Tris-HCl buf fer pH 8–9 containing 0.5 M NaCl. A suitable

procedure could be 3x1 medium volume Tris HCl buffer followed by

3×1 volumes acetate buffer. Repeat this cycle 3–6 times.

8. The coupled medium is now ready for use. To prevent microbial growth,

store in 20% ethanol for example.

3. Column packing guidelines

General column packing guidelines for Sepharose Fast Flow based media.

3.1 Recommended columns

Lab-scale columns

• Tricorn

• Tricorn 5/50 (5 mm i.d.) for bed volumes up to 1.1 ml at bed heights up to

• Tricorn 10/20 (10 mm i.d.) for bed volumes up to 2.2 ml at bed height s up

• Tricorn 10/50 (10 mm i.d.) for bed volumes up to 4.5 ml at bed heights up

• Tricorn 10/100 (10 mm i.d.) for bed volumes up to 8.5 ml at bed heights up

• XK 16/20 (16 mm i.d.) for bed volumes up to 30 ml at bed heights up to

• XK 26/20 (26 mm i.d.) for bed volumes up to 80 ml at bed height s up to

TM

5/20 (5 mm i.d.) for bed volumes up to 0.55 ml at bed height s up

to 2.8 cm

5.8 cm

to 2.8 cm

to 5.8 cm

to 10.8 cm

15 cm.

15 cm.

p. 5

Page 6

Large scale columns

TM

• BPG

variable bed, glass columns. Inner diameters from 100–450 mm,

bed volumes from 2.4–131 litres; bed height max 83 cm.

• CHROMAFLOW

TM

variable bed columns. Inner diameters from

400–600 mm.

3.2 Packing lab-scale columns

1. Assemble the column (and packing reservoir if necessary).

2. Remove air from the column dead spaces by flushing the end-piece

and adaptor with packing buffer. Make sure no air has been trapped

under the column bed support. Close the column outlet leaving the bed

suppor t covered with packing buffer.

3. Re-suspend medium stored in its container by shaking (avoid stirring the

sedimented medium). Mix the packing buf fer with the medium to form

50–70% slurry (sedimented bed volume/slurry volume = 0.5–0.7).

4. Pour the slurry into the column in a single continuous motion. Pouring

the slurry down a glass rod held against the column wall will minimize

the introduction of air bubbles.

5. If using a packing reservoir, immediately fill the remainder of the

column and reservoir with packing buffer. Mount the adaptor or lid of

the packing reservoir and connect the column to a pump. Avoid

trapping air bubbles under the adaptor or in the inlet tubing.

6. Open the bottom outlet of the column and set the pump to run at the

desired flow rate. Ideally, Sepharose 4 Fast Flow based media are

packed at a constant pressure of approximately 1 bar (0.1 MPa). If the

packing equipment does not include a pressure gauge, use a packing

flow velocity of approximately 400 cm/h (15 cm bed height, 25 °C, low

viscosity buffer).

If the recommended pressure or flow rate cannot be obtained, use

the maximum flow rate the pump can deliver. This should also give a

reasonably well-packed bed.

Note: Do not exceed 75% of the packing f low velocity in subsequent

chromatographic procedures using the same pump.

p. 6

Page 7

7. When the bed has stabilized, close the bottom outlet and stop the pump.

8. If using a packing reservoir, disconnect the reservoir and fit the adaptor

to the column.

9. With the adaptor inlet disconnected, push down the adaptor

approximately 2 mm into the bed, allowing the packing solution to flush

the adaptor inlet.

10. Connect the pump, open the bottom outlet and continue packing.

The bed will be fur ther compressed at this point and a space will form

between the bed surface and the adaptor.

11. Close the bottom outlet. Disconnect the column inlet and lower the

adaptor approximately 2 mm into the bed. Connect the pump. The

column is now ready to use.

3.3 Packing large scale columns

General packing recommendations

Columns can be packed in different ways depending on the type of column

and equipment used. Always read and follow the relevant column

instruction manual carefully. For general process-scale column packing

instructions, please visit suppor t section at:

www.gehealthcare.com/protein-purification

4. Evaluation of packing

To check the quality of the packing and to monitor this during the working

life of the column, column efficiency should be tested directly after packing,

prior to re-use, and when separation performance is seen to deteriorate.

The best method of expressing the efficiency of a packed column is in terms

of the height equivalent to a theoretical plate, HETP, and the asymmetry

. These values are easily determined by applying a sample such as

factor, A

S

1% acetone solution to the column. Sodium chloride can also be used as a

test substance. Use a concentration of 2.0 M NaCl in water with 0.5 M NaCl in

water as eluent.

p. 7

Page 8

The calculated plate number will vary depending on the test conditions

and it should therefore be used as a reference value only. It is also

impor tant that conditions and equipment are kept constant so that results

are comparable. Changes in solute, solvent, eluent, sample volume, flow

rate, liquid pathway, temperature, etc., will influence the results.

For optimal results, the sample volume should be at max. 2.5% of the

column volume and the flow velocity between 15 and 30 cm/h.

If an acceptance limit is defined in relation to column per formance, the

column plate number can be used as par t of the acceptance criteria for

column use.

Method for measuring HETP and As

To avoid dilution of the sample, apply it as close to the column inlet as

possible.

Conditions

Sample volume: 2.5% of the bed volume

Sample conc.: 1.0% v/v acetone

Flow velocity: 15 cm/h

UV: 280 nm, 1 cm, 0.1 AU

Calculate HETP and AS from the UV curve (or conductivity curve if NaCl is

used as sample) as follows:

HETP = L/N

N = 5.54(V

where L = Bed height (cm)

N = number of theoretical plates

V

W

= Peak elution distance

e

= Peak width at half peak height

h

Ve and Wh are in the same units.

To facilitate comparison of column performance the concept of reduced

plate height is often used.

e/Wh

)2

p. 8

Page 9

The reduced plate height is calculated:

HETP/d

where d is the diameter of the bead. As a guideline, a value of <3 is normally

acceptable.

The peak should be symmetrical, and the asymmetry factor as close as

possible to 1 (values between 0.8–1.5 are usually acceptable). A change in

the shape of the peak is usually the first indication of bed deterioration due

to use.

Peak asymmetry factor calculation:

A

= b/a

S

where

a = 1st half peak width at 10% of peak height

b = 2nd half peak width at 10% of peak height.

Figure 2 shows a UV trace for acetone in a typical test chromatogram in

which the HETP and As values are calculated.

Column: BPG 300

Media: Sepharose 6 Fast Flow

Bed height: 57.5 cm

Bed volume: 40.6 litres

Eluent: Distilled water

Sample: 1.05 litres (1% acetone)

Flow velocity: 19 cm/h

=18.7

W

e

=0.9

W

h

HETP =0.024 cm

a: 0.90

b: 0.85

: 0.94

A

s

UV

absorption

W

h

b

a

V

e

Volume

Fig 2. UV trace for acetone in a typical test chromatogram showing the HETP

AND A

value calculations.

S

p. 9

Page 10

5. Cleaning, Sanitization and Storage

For best performance of coupled CNBr-activated Sepharose 4 Fast Flow over

a long working life, follow the general procedures described below. In all

cases, we recommend testing the procedures at small scale first.

Equilibration

After packing, and before a chromatographic run, equilibrate with working

buffer by washing with at least 5 bed volumes.

Cleaning-In-Place

Cleaning-in-place, (CIP), is a cleaning procedure which removes

contaminants such as lipids, precipitates or denatured proteins that may

remain in the packed column after regeneration. Such contamination is

especially likely when working with crude materials. Regular CIP prevents

the build-up of these contaminants in the packed bed, and helps to maintain

the capacity, flow properties and general per formance of the medium.

A specific CIP protocol should be designed for each process according to the

type of contaminants present and stability of coupled ligand. The frequency

of CIP depends on the nature and the condition of the starting material and

other process requirements, but one CIP cycle is generally recommended

every 1–5 separation cycles. Following are generally recommended

procedures.

CIP protocol

Precipitated or Wash with 2 column volumes of

denatured 6 M guanidine hydrochloride. Wash

substances substances immediately with at least

5 column volumes of sterile filtered binding

buffer.

Hydrophobically Wash the column with 2 column volumes of

bound substances a non-ionic detergent (conc. 0.1–0.5%).

Wash immediately with at least 5 column

volumes of sterile filtered binding buffer.

p. 10

Page 11

or

Wash the column with 3– column volumes of 70%

ethanol. Wash immediately with at least 5 column

volumes of sterile filtered binding buffer.

Sanitization

Sanitization inactivates microbial contaminants in the packed column and

related equipment. A specific sanitization protocol should be designed for

each process according to the type of contaminant s present and stability of

coupled ligand. Following are generally recommended procedures.

Equilibrate with a buffer consisting of 2% hibitane digluconate and 20%

ethanol. Allow to stand for 6 hours, then wash with at least 5 column

volumes of sterile binding buffer.

or

Equilibrate with 70% ethanol. Allow to stand for 12 hours, then wash with at

least 5 column volumes of sterile binding buffer.

Note: Specific regulations may apply when using 70% ethanol since it can

require the use of explosion-proof areas and equipment.

Storage

CNBr-activated Sepharose 4 Fast Flow is supplied freeze dried. Additives are

included to preserve the bead form of the medium. When stored below 8 °C,

the shelf life is at least 18 months. Packed columns should preferebly be

equilibrated in binding buffer containing 20% ethanol (ligand dependent) to

prevent microbial growth.

6. Ordering information

Produc t Pack size Code No

CNBr-activated Sepharose 4 Fast Flow 10 g 17-0981-01

250 g 17-0981-03

2 kg 17-0981-05

All products are supplied freese dried in the precence of additives.

p. 11

Page 12

www.gehealthcare.com

GE Healthcare Bio-Sciences AB

Björkgatan 30

751 84 Uppsala

Sweden

BioProcess, BPG, CHROMAFLOW, Drop Design, Sepharose, and Tricorn are trademarks of GE Healthcare companies.

GE, imagination at work and GE monogram are trademarks of General Electric Company.

All goods and services are sold subject to the terms and conditions of sale of the company within GE Healthcare which

supplies them. GE Healthcare reserves the right, subject to any regulatory and contractual approval, if required, to make

changes in specifi cations and features shown herein, or discontinue the product described at any time without notice or

obligation. Contact your local GE Healthcare representative for the most current information.

© 2006 General Electric Company – All rights reserved.

GE Healthcare Bio-Sciences AB, a General Electric Company.

GE Healthcare Europe GmbH

Munzinger Strasse 5

D-79111 Freiburg

Germany

GE Healthcare UK Ltd

Amersham Place

Little Chalfont

Buckinghamshire, HP7 9NA

UK

GE Healthcare

Bio-Sciences Corp

800 Centennial Avenue

P.O. Box 1327

Piscataway, NJ 08855-1327

USA

GE Healthcare Bio-Sciences KK

Sanken Bldg.

3-25-1, Hyakunincho

Shinjuku-ku, Tokyo 169-0073

Japan

71-5000-15 AD 03/2006

Elanders Östervåla 2006

Loading...

Loading...