Page 1

GE Digital Energy

Multilin

Motor Protection System

339

Motor protection and control

339 revision: 1.40

Manual P/N: 1601-9103-A3

GE publication code: GEK-113562B

Copyright © 2010 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEmultilin.com

*1601-9103-A3*

Instruction manual

GE Multilin's Quality

Management System is

registered to ISO9001:2000

QMI # 005094

Page 2

© 2010 GE Multilin Incorporated. All rights reserved.

GE Multilin 339 Motor Protection System instruction manual for revision 1.40.

339 Motor Protection System, EnerVista, EnerVista Launchpad, and EnerVista SR3 Setup

are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-9103-A3 (September 2010)

Page 3

Table of Contents

1.INTRODUCTION Overview ................................................................................................................................1 - 1

Cautions and warnings ...................................................................................................1 - 2

Description of the 339 Motor Protection System................................................1 - 3

339 order codes..................................................................................................................1 - 6

Specifications.......................................................................................................................1 - 7

Password security....................................................................................................................1 - 7

Protection.....................................................................................................................................1 - 7

Metering........................................................................................................................................1 - 10

Data capture ..............................................................................................................................1 - 11

Control...........................................................................................................................................1 - 12

Inputs .............................................................................................................................................1 - 13

Outputs..........................................................................................................................................1 - 14

Power supply..............................................................................................................................1 - 14

Communications ......................................................................................................................1 - 15

Testing and certification .......................................................................................................1 - 15

Physical .........................................................................................................................................1 - 16

Environmental............................................................................................................................1 - 16

2.INSTALLATION Mechanical installation ...................................................................................................2 - 1

Dimensions..................................................................................................................................2 - 2

Product identification .............................................................................................................2 - 2

Mounting ......................................................................................................................................2 - 3

Unit withdrawal and insertion............................................................................................2 - 7

Electrical installation ........................................................................................................2 - 8

339 terminal identification...................................................................................................2 - 9

RMIO module installation......................................................................................................2 - 11

Phase sequence and transformer polarity...................................................................2 - 13

Phase current inputs...............................................................................................................2 - 13

Ground and CBCT inputs.......................................................................................................2 - 13

Zero sequence CBCT installation ......................................................................................2 - 14

Voltage inputs............................................................................................................................2 - 15

Control power ............................................................................................................................2 - 15

Contact inputs ...........................................................................................................................2 - 16

Trip and Close output relays ...............................................................................................2 - 16

Serial communications ..........................................................................................................2 - 19

IRIG-B .............................................................................................................................................2 - 20

3.INTERFACES Front control panel interface........................................................................................3 - 2

Software setup....................................................................................................................3 - 10

339C MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL TOC–1

Description ..................................................................................................................................3 - 2

Display ...........................................................................................................................................3 - 3

Working with the Keypad....................................................................................................3 - 3

LED status indicators..............................................................................................................3 - 4

Relay messages ........................................................................................................................3 - 6

Default message.....................................................................................................................3 - 6

Target messages.....................................................................................................................3 - 6

Self-test errors..........................................................................................................................3 - 7

Flash messages.......................................................................................................................3 - 9

Quick setup - Software interface ......................................................................................3 - 10

EnerVista SR3 Setup Software............................................................................................3 - 10

Page 4

Hardware and software requirements.........................................................................3 - 11

Installing the EnerVista SR3 Setup software..............................................................3 - 11

Connecting EnerVista SR3 Setup to the relay ............................................................ 3 - 14

Configuring serial communications...............................................................................3 - 14

Using the Quick Connect feature....................................................................................3 - 15

Configuring Ethernet communications........................................................................3 - 16

Connecting to the relay........................................................................................................3 - 17

Working with setpoints and setpoint files .................................................................... 3 - 18

Engaging a device..................................................................................................................3 - 18

Entering setpoints...................................................................................................................3 - 18

File support ................................................................................................................................3 - 20

Using setpoints files...............................................................................................................3 - 20

Downloading and saving setpoints files......................................................................3 - 20

Adding setpoints files to the environment..................................................................3 - 20

Creating a new setpoint file...............................................................................................3 - 21

Upgrading setpoint files to a new revision .................................................................3 - 22

Printing setpoints and actual values.............................................................................3 - 23

Printing actual values from a connected device.....................................................3 - 24

Loading setpoints from a file.............................................................................................3 - 25

Upgrading relay firmware ................................................................................................... 3 - 25

Loading new relay firmware..............................................................................................3 - 25

Advanced EnerVista SR3 Setup features ......................................................................3 - 27

Data logger................................................................................................................................3 - 27

Motor start data logger........................................................................................................3 - 28

Transient recorder (Waveform capture).......................................................................3 - 30

Protection summary..............................................................................................................3 - 33

Password security ..................................................................................................................3 - 34

4.ACTUAL VALUES Actual values overview ...................................................................................................4 - 1

A1 Status................................................................................................................................4 - 3

Motor status ...............................................................................................................................4 - 4

Clock............................................................................................................................................... 4 - 6

Contact inputs ...........................................................................................................................4 - 6

Output relays ............................................................................................................................. 4 - 6

Output relays - Breaker........................................................................................................4 - 6

Output relays - Contactor...................................................................................................4 - 7

Logic elements ..........................................................................................................................4 - 7

Virtual inputs ..............................................................................................................................4 - 7

Remote inputs ...........................................................................................................................4 - 7

Remote outputs ........................................................................................................................ 4 - 8

Contact inputs summary...................................................................................................... 4 - 8

Output relays summary........................................................................................................4 - 8

Logic elements summary..................................................................................................... 4 - 8

GOOSE status............................................................................................................................. 4 - 9

GOOSE HDR status .................................................................................................................. 4 - 9

RTD temp summary................................................................................................................4 - 9

A2 Metering ..........................................................................................................................4 - 10

Current..........................................................................................................................................4 - 10

Voltage.......................................................................................................................................... 4 - 11

Power............................................................................................................................................. 4 - 11

Energy ........................................................................................................................................... 4 - 12

RTD temperature......................................................................................................................4 - 12

Clear energy ...............................................................................................................................4 - 12

A3 Records............................................................................................................................4 - 13

Datalogger ..................................................................................................................................4 - 13

Motor start data logger.........................................................................................................4 - 13

TOC–2 339C MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 5

Event records .............................................................................................................................4 - 13

Transient records .....................................................................................................................4 - 30

Learned data..............................................................................................................................4 - 30

Learned data recorder...........................................................................................................4 - 32

Clear learned data ...................................................................................................................4 - 32

Clear transient record ............................................................................................................4 - 32

Clear event record ...................................................................................................................4 - 32

A4 Target messages.........................................................................................................4 - 33

5.QUICK SETUP -

Quick Setup settings.........................................................................................................5 - 3

FRONT CONTROL

PANEL

6.SETPOINTS Setpoints ................................................................................................................................6 - 1

Setpoint entry methods.........................................................................................................6 - 2

Common setpoints ..................................................................................................................6 - 3

Logic diagrams..........................................................................................................................6 - 3

Settings text abbreviations..................................................................................................6 - 4

S1 Relay setup .....................................................................................................................6 - 6

Clock...............................................................................................................................................6 - 7

Password security....................................................................................................................6 - 9

Access passwords..................................................................................................................6 - 10

Communications ......................................................................................................................6 - 12

RS485 interface .......................................................................................................................6 - 13

Ethernet.......................................................................................................................................6 - 13

Modbus........................................................................................................................................6 - 14

IEC60870-5-103 serial communication settings .....................................................6 - 15

IEC60870-5-104 protocol....................................................................................................6 - 29

DNP communication.............................................................................................................6 - 30

IEC 61850 GOOSE configuration......................................................................................6 - 43

Event recorder ...........................................................................................................................6 - 44

Transient recorder ...................................................................................................................6 - 45

Datalogger...................................................................................................................................6 - 47

Front panel ..................................................................................................................................6 - 47

Installation...................................................................................................................................6 - 48

Preset statistics .........................................................................................................................6 - 49

S2 System Setup.................................................................................................................6 - 50

Current sensing.........................................................................................................................6 - 50

Voltage sensing.........................................................................................................................6 - 52

Power system.............................................................................................................................6 - 53

Motor..............................................................................................................................................6 - 53

Switching device.......................................................................................................................6 - 54

S3 Protection........................................................................................................................6 - 55

Thermal Model...........................................................................................................................6 - 58

Total Capacity Used register (TCU) .................................................................................6 - 58

Start protection........................................................................................................................6 - 59

Thermal overload curves ....................................................................................................6 - 59

Thermal protection setpoints............................................................................................6 - 67

Short circuit.................................................................................................................................6 - 72

Mechanical Jam........................................................................................................................6 - 75

Undercurrent..............................................................................................................................6 - 78

Current unbalance...................................................................................................................6 - 81

Load increase alarm ...............................................................................................................6 - 84

Ground fault................................................................................................................................6 - 85

339C MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL TOC–3

Page 6

Neutral instantaneous overcurrent.................................................................................6 - 88

Phase undervoltage................................................................................................................6 - 90

Phase overvoltage...................................................................................................................6 - 93

Underfrequency........................................................................................................................6 - 96

Overfrequency...........................................................................................................................6 - 99

Underpower................................................................................................................................6 - 102

Negative sequence overvoltage.......................................................................................6 - 105

Phase reversal........................................................................................................................... 6 - 107

VT fuse fail ...................................................................................................................................6 - 107

Acceleration protection ........................................................................................................ 6 - 108

RTD protection...........................................................................................................................6 - 110

Two-speed motor ....................................................................................................................6 - 116

Two-speed motor setup ......................................................................................................6 - 117

High speed thermal protection........................................................................................6 - 118

High speed short circuit settings.....................................................................................6 - 118

High speed acceleration......................................................................................................6 - 121

High speed undercurrent....................................................................................................6 - 121

S4 Control..............................................................................................................................6 - 124

Virtual inputs ..............................................................................................................................6 - 125

Logic elements ..........................................................................................................................6 - 126

Breaker failure / Welded contactor.................................................................................6 - 142

Start inhibit..................................................................................................................................6 - 145

Emergency restart...................................................................................................................6 - 148

Lockout reset .............................................................................................................................6 - 148

Reset .............................................................................................................................................. 6 - 148

Breaker control ......................................................................................................................... 6 - 148

S5 Inputs/Outputs .............................................................................................................6 - 150

Contact inputs ...........................................................................................................................6 - 151

Output relays .............................................................................................................................6 - 152

Output Relays - Breaker.......................................................................................................6 - 153

Output Relays - Contactor..................................................................................................6 - 161

Virtual inputs ..............................................................................................................................6 - 164

7.MAINTENANCE M1 Relay information.......................................................................................................7 - 4

M2 Motor maintenance ..................................................................................................7 - 6

M3 Breaker maintenance ..............................................................................................7 - 7

Trip coil.......................................................................................................................................... 7 - 7

Close coil ......................................................................................................................................7 - 10

Breaker trip counter................................................................................................................7 - 13

Reset counters ..........................................................................................................................7 - 15

M4 Breaker monitor..........................................................................................................7 - 16

M5 Relay maintenance ...................................................................................................7 - 17

Ambient temperature ............................................................................................................ 7 - 17

M6 Factory service............................................................................................................7 - 20

APPENDIX Change notes ...................................................................................................................Appendix - 1

Manual Revision history.................................................................................................... Appendix - 1

TOC–4 339C MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 7

Digital Energy

Multilin

339 Motor Protection System

Chapter 1: Introduction

Introduction

Overview

The 339 Motor Protection System is a microprocessor based relay providing suitable

protection of medium voltage motors. The small footprint and the withdrawable option

make the relay ideal for panel mounting on either new or retrofit installations. The

combination of proven hardware, a variety of protection and control features, and

communications, makes the relay ideal for total motor protection and control. Equipped

with serial (RS485), USB, and Ethernet ports, and a wide selection of protocols such as

Modbus, DNP3.0, IEC 60870-5-103, 60870-5-104, GOOSE, the relay is the best-in-class for

MCCs, SCADA and inter-relay communications. The relay provides excellent transparency

with respect to power system conditions and events, through its four-line 20-character

display, as well as the EnerVista SR3 Setup program. Conveniently located LEDs provide

indication of overall relay operation, as well as alarm, pickup, and motor status.

The relay provides the following key benefits:

• Withdrawable small footprint – saves on rewiring and space.

• Fast setup (Quick Setup) menu provided, to guide users through a wide range of motor

• Large four-line LCD display, LEDs, and an easy-to-navigate keypad.

• Multiple communication protocols for simultaneous access when integrated into

management applications.

monitoring and control systems.

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–1

Page 8

CAUTIONS AND WARNINGS CHAPTER 1: INTRODUCTION

NOTE

CAUTION

DANGER

Cautions and warnings

Before attempting to install or use this device, it is imperative that all caution and danger

indicators in this manual are reviewed to help prevent personal injury, equipment damage,

or downtime. The following icons are used to indicate notes, cautions, and dangers.

Figure 1: Note icons used in the documentation

The standard note icon emphasizes a specific point or indicates minor problems that may

occur if instructions are not properly followed.

The caution icon indicates that possible damage to equipment or data may occur if

instructions are not properly followed.

The danger icon provides users with a warning about the possibility of serious or fatal

injury to themselves or others.

1–2 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 9

CHAPTER 1: INTRODUCTION DESCRIPTION OF THE 339 MOTOR PROTECTION SYSTEM

Description of the 339 Motor Protection System

CPU

Relay functions are controlled by two processors: a Freescale MPC5554 32-bit

microprocessor measures all analog signals and digital inputs and controls all output

relays; a Freescale MPC520B 32-bit microprocessor controls all the Ethernet

communication protocols.

Analog Input Waveform Capture

Magnetic transformers are used to scale-down the incoming analog signals from the

source instrument transformers. The analog signals are then passed through a 960 Hz low

pass anti-aliasing filter. All signals are then simultaneously captured by sample and hold

buffers to ensure there are no phase shifts. The signals are converted to digital values by a

12-bit A/D converter before finally being passed on to the CPU for analysis.

Both current and voltage are sampled thirty-two times per power frequency cycle. These

‘raw’ samples are scaled in software, then placed into the waveform capture buffer, thus

emulating a fault recorder. The waveforms can be retrieved from the relay via the EnerVista

SR3 Setup software for display and diagnostics.

Frequency

Frequency measurement is accomplished by measuring the time between zero crossings

of the Bus VT phase A voltage . The signals are passed through a low pass filter to prevent

false zero crossings. Sampling is synchronized to the Va-x voltage zero crossing which

results in better co-ordination for multiple relays on the same bus.

Phasors, Transients, and Harmonics

Current waveforms are processed twice every cycle with a DC Offset Filter and a Discrete

Fourier Transform (DFT). The resulting phasors have fault current transients and all

harmonics removed. This results in a motor that is extremely secure and reliable; one that

will not overreach.

Processing of AC Current Inputs

The DC Offset Filter is an infinite impulse response (IIR) digital filter, which removes the DC

component from the asymmetrical current present at the moment a fault occurs. This is

done for all current signals used for overcurrent protection; voltage signals bypass the DC

Offset Filter. This filter ensures no overreach of the overcurrent protection.

The Discrete Fourier Transform (DFT) uses exactly one sample cycle to calculate a phasor

quantity which represents the signal at the fundamental frequency; all harmonic

components are removed. All subsequent calculations (e.g. RMS, power, etc.) are based

upon the current and voltage phasors, such that the resulting values have no harmonic

components.

Protection Elements

All protection elements are processed twice every cycle to determine if a pickup has

occurred or a timer has expired. The protection elements use RMS current/voltage, based

on the magnitude of the phasor. Hence, protection is impervious to both harmonics and DC

transients.

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–3

Page 10

DESCRIPTION OF THE 339 MOTOR PROTECTION SYSTEM CHAPTER 1: INTRODUCTION

896814.CDR

52

37

46

49

50P

50BF

50G

49

MOTOR

LOAD

Stator RTDs

Bearing RTDs

Phase CT 3

Ground CT 1

BUS

339

MOTOR PROTECTION SYSTEM

Ambient air

RTD

38

Optional Remote RTD

51

86

START

50N

TRIP

CLOSE

START INHIBIT

27P 59P

47

59_2

81O 81U

59_2

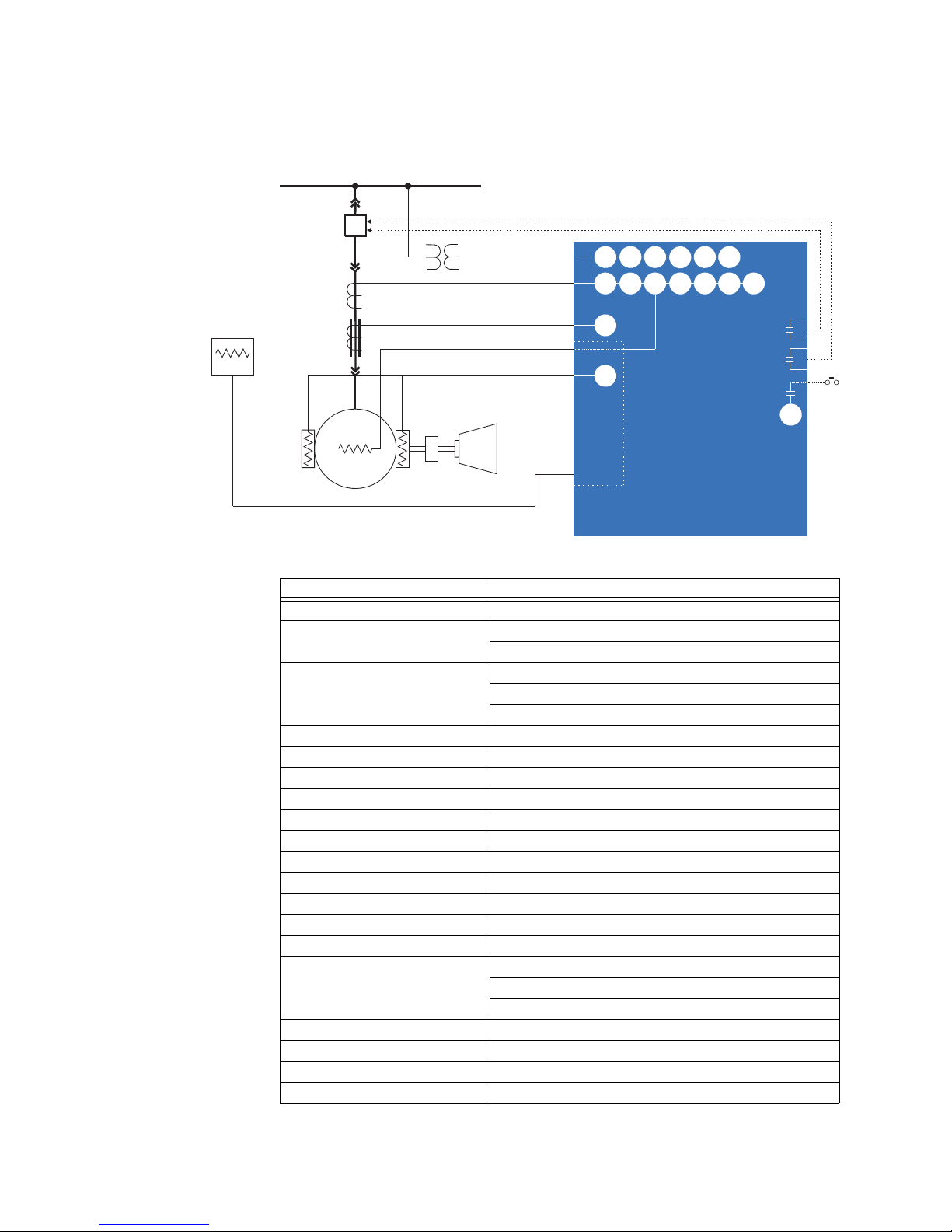

Figure 2: Line Diagram

Table 1: Protection functions

ANSI device Description

27P Phase UV

37 Undercurrent

Underpower

38 Bearing RTD

Stator/Ambient/Other

RTD Trouble Alarm

46 Current Unbalance

47 Voltage Phase Reversal

48 Acceleration Time

49 Thermal Protection/Stall Protection

50BF Breaker Failure / Welded Contactor

50G Ground Fault

50P Short Circuit

51P Mechanical Jam

50N Neutral Instantaneous Overcurrent

59_2 Negative Sequence OV

59P Phase OV

66 Starts per Hour & Time Between Starts

81O Overfrequency

81U Underfrequency

86 Lockout

VTFF VT Fuse Failure

Restart Block

Thermal Inhibit

1–4 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 11

CHAPTER 1: INTRODUCTION DESCRIPTION OF THE 339 MOTOR PROTECTION SYSTEM

ACTUAL VALUES

QUICK SETUP

SETPOINTS

MAINTENANCE

ACTUAL VALUES

A1 STATUS

A2 METERING

A3 RECORDS

A4 TARGET MESSAGES

▼

QUICK SETUP

RELAY STATUS

NOMINAL FREQUENCY

GROUND CT TYPE

VT CONNECTION

VT SECONDARY

VT RATIO

MOTOR FLA

THERMAL O/L FUNC

S/C FUNC

MECH JAM FUNC

U/CURR TRIP FUNC

GND TRIP FUNC

PH UV FUNC

PHASE CT PRIMARY

SWITCHING DEVICE

52a CONTACT

52b CONTACT

▼

SETPOINTS

S1 RELAY SETUP

S2 SYSTEM SETUP

S3 PROTECTION

S4 CONTROLS

S5 INPUTS/OUTPUTS

▼

MAINTENANCE

M1 RELAY INFO

M2 MOTOR MAINTEN

M3 BKR MAINTENANCE

M4 BKR MONITOR

M6 FACTORY SERVICE

▼

896756.cdr

THERMAL PROTECTION

START PROTECTION

SAFE STALL T COLD

THERMAL O/L PKP

UNBALANCE K FACTOR

COOL TIME RUNNING

COOL TIME STOPPED

HOT/COLD RATIO

LOCKED ROTOR CURR

▼

SHORT CIRCUIT

S/C PKP

S/C DELAY

▼

MECHANICAL JAM

MECH JAM PKP

MECH JAM DELAY

▼

UNDERCURRENT

U/CURR TRIP PKP

UCURR TRIP DELAY

▼

GROUND FAULT

GND TRIP PKP

GND TRIP ON RUN

GND TRIP ON START

▼

PHASE UV

PH UV PKP

PH UV DELAY

▼

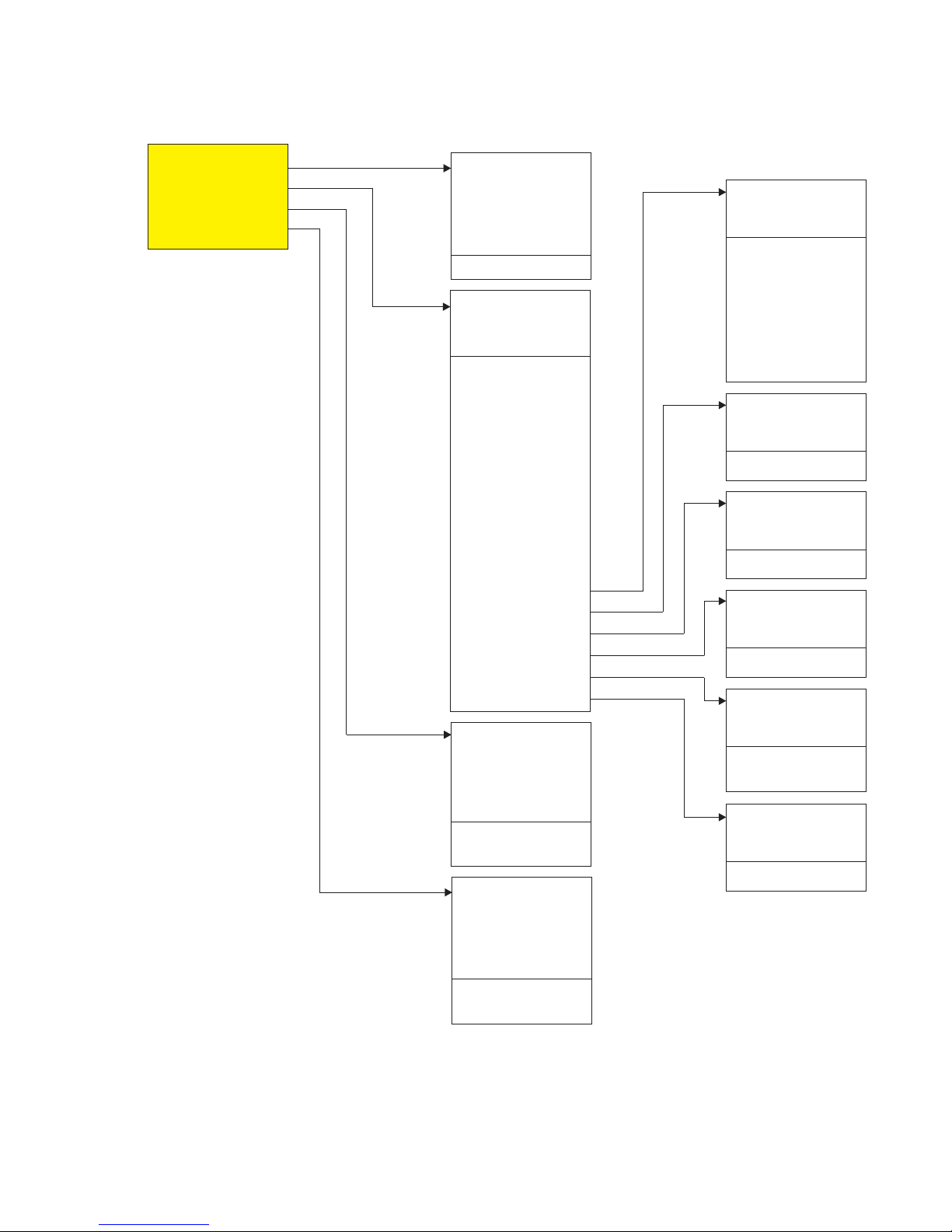

Figure 3: Main Menu structure

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–5

Page 12

339 ORDER CODES CHAPTER 1: INTRODUCTION

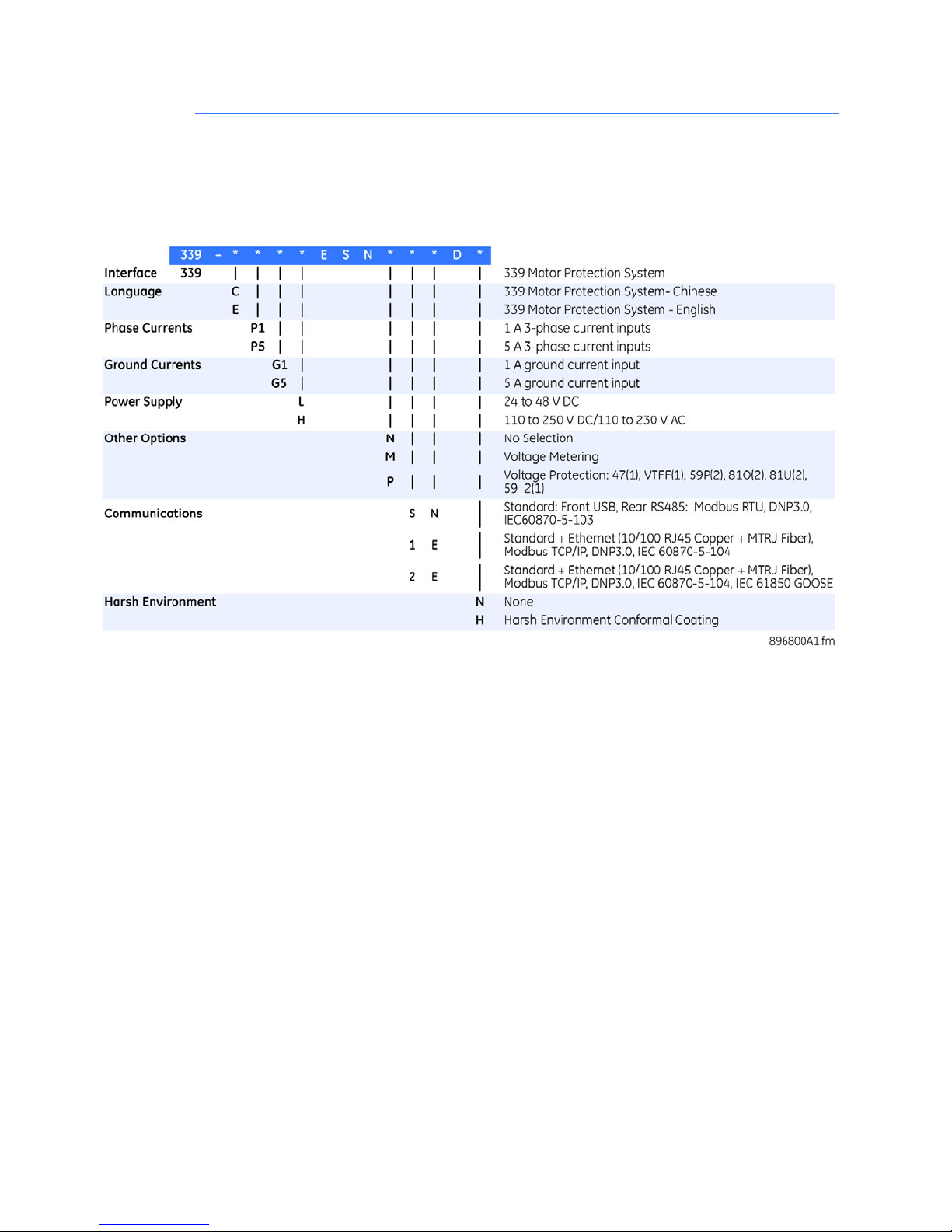

339 order codes

The information to specify a 339 relay is provided in the following order code table.

Figure 4: Order Codes

1–6 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 13

CHAPTER 1: INTRODUCTION SPECIFICATIONS

NOTE

Specifications

NOTE:

Specifications are subject to change without notice.

Password security

PASSWORD SECURITY

Master Reset Password: ..................................8 to 10 alpha-numeric characters

Settings Password:.............................................3 to 10 alpha-numeric characters for local and remote

access

Control Password:...............................................3 to 10 alpha-numeric characters for local and remote

access

Protection

NEUTRAL INSTANTANEOUS OVERCURRENT

Pickup Level:..........................................................0.05 to 20 x CT in steps of 0.01 x CT

Dropout Level: ......................................................96 to 99% of Pickup @ I > 1 x CT

Pickup - 0.02 x CT @ I <1 x CT

Time Delay: ............................................................0.00 to 300.00 sec in steps of 0.01

Operate Time:.......................................................<30 ms @ 60Hz (I > 2.0 x PKP), 0 ms time delay

<35 ms @ 50Hz (I > 2.0 x PKP), 0 ms time delay

Timer Accuracy:...................................................0 to 1 cycle

Level Accuracy:....................................................per CT input

Elements: ................................................................Trip or Alarm

NEUTRAL DIRECTIONAL OVERCURRENT

Directionality:........................................................Co-existing forward and reverse

Polarizing: ...............................................................Voltage, Current, Dual

Voltage can be:

- Calculated from VT phases (VTs must be connected in

"Wye")

- Measured by Vaux input (3V

delta connection)

Polarizing Voltage:..............................................-V

Polarizing Current:..............................................I

MTA:...........................................................................From 0o to 359o in steps of 1

Angle Accuracy:...................................................±2

Operation Delay: .................................................20 to 30 ms

0

G

o

UNDERCURRENT

Pickup Level:..........................................................0.1 to 0.95 x FLA in steps of 0.01 x FLA

Dropout Level: ......................................................101 to 104% of Pickup

Time Delay: ............................................................1.00 to 60.00 s in steps of 0.01 s

Block from Start:..................................................0 to 600 s in steps of 1 s

Pickup Accuracy:.................................................as per phase current inputs

Timing Accuracy:................................................± 0.5 s or ± 0.5% of total time

Elements: ................................................................Trip and Alarm

provided by an external open

0

o

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–7

Page 14

SPECIFICATIONS CHAPTER 1: INTRODUCTION

CURRENT UNBALANCE

Unbalance: ............................................................See table below

Unbalance Pickup Level: .................................4 to 40% in steps of 1%

Unbalance Time Delay:....................................1.00 to 60.00 s in steps of 0.01 s

Single Phasing Pickup Level: .........................unbalance level > 40% or when I

any phase is less than the cutoff current

Single Phasing Time Delay:............................2 sec

Dropout Level:......................................................96 to 99% of pickup

Pickup Accuracy:................................................. ±2%

Timing Accuracy:................................................ ±0.5 s or ± 0.5% of total time

Unbalance Elements:........................................Trip and Alarm

Single Phasing Elements:................................Trip

≥25%FLA and current in

avg

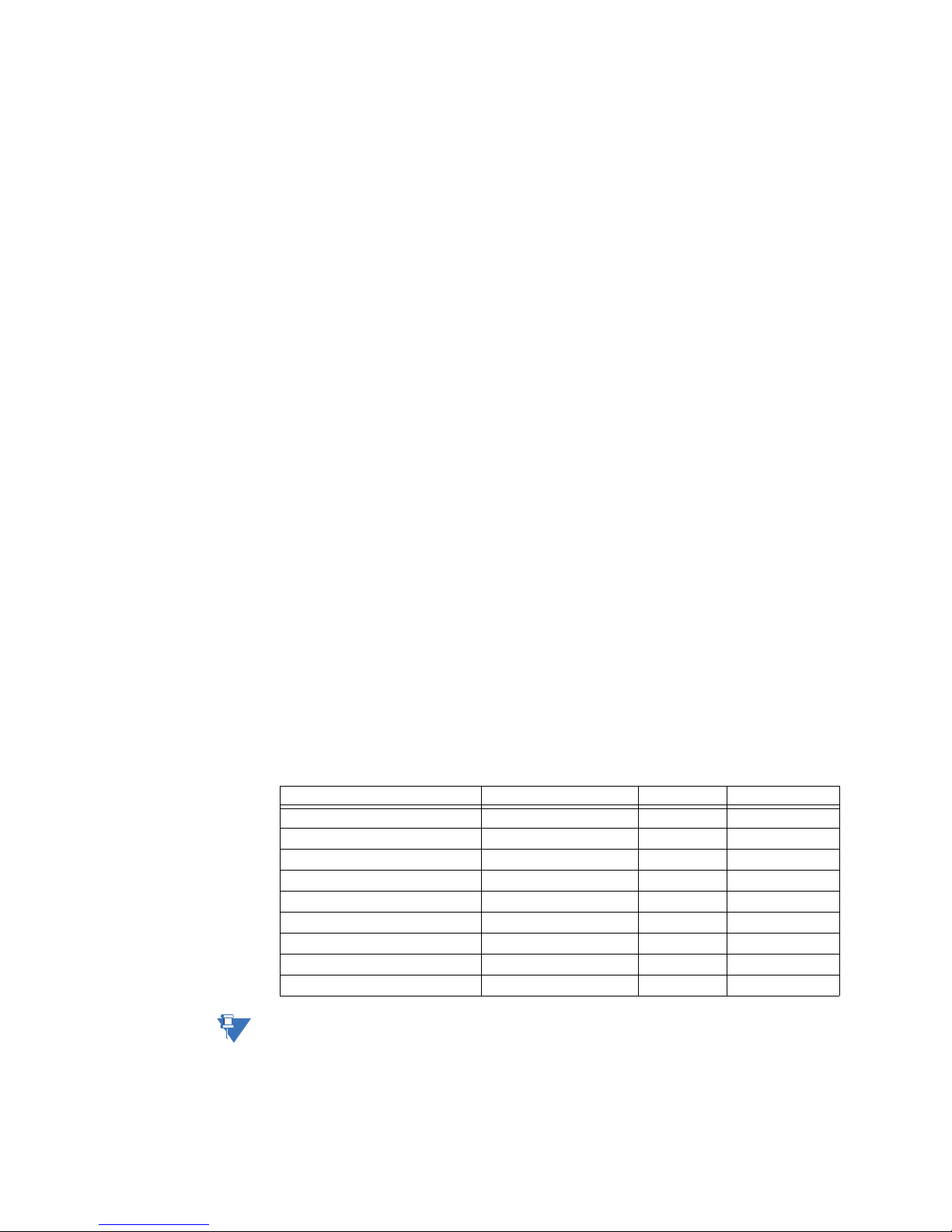

Table 2: Current Unbalance equations

RTD

Pickup:...................................................................... 1 to 250oC in steps of 1oC

Pickup Hysteresis:............................................... 2

Time Delay:............................................................ 3 sec

Elements:................................................................Trip and Alarm

o

C

RTD TROUBLE ALARM

RTD Trouble Alarm: ............................................ <-50oC or >250oC

LOAD INCREASE ALARM

Pickup Level: .........................................................50 to 150%FLA in steps of 1%FLA

Dropout Level:......................................................96 to 99% of Pickup

Alarm Time Delay:.............................................. 1.00 to 60.00 s in steps of 0.01 s

Pickup Accuracy:................................................. as per phase current inputs

Timing Accuracy:................................................ ±0.5 s or ±0.5% of total time

SHORT CIRCUIT

Pickup Level: .........................................................1.00 to 20.00 x CT in steps of 0.01 x CT

Dropout Level:......................................................96 to 99% of Pickup @ I > 1 x CT

Pickup - 0.02 x CT @ I < 1 x CT

Alarm Time Delay:.............................................. 0.00 to 60.00 s in steps of 0.01 s

Pickup Accuracy:................................................. as per phase current inputs

Operate Time: ...................................................... <30 ms @ 60Hz (I > 2.0 x PKP), 0 ms time delay

<35 ms @ 50Hz (I > 2.0 x PKP), 0 ms time delay

Timer Accuracy:..................................................0 to 1 cycle

Elements:................................................................Trip or Alarm

MECHANICAL JAM TRIP

Pickup Level: .........................................................1.01 to 4.50 x FLA in steps of 0.01 x FLA, blocked from start

Dropout Level:......................................................96 to 99% of Pickup

Trip Time Delay:...................................................0.10 to 30.00 s in steps of 0.01 s

Pickup Accuracy:................................................. as per phase current inputs

Timing Accuracy:................................................ ±0.5 s or ±0.5% of total time

1–8 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 15

CHAPTER 1: INTRODUCTION SPECIFICATIONS

GROUND FAULT

Pickup Level:..........................................................0.03 to 1.00 x CT in steps of 0.01 x CT

0.50 to 15.00 A in steps of 0.01 A (CBCT)

Dropout Level: ......................................................Pickup - 0.02 x CT

96 to 99% of Pickup (CBCT)

Alarm Time Delay on Run:..............................0.00 to 60.00 s in steps of 0.01 s

Alarm Time Delay on Start:............................0.00 to 60.00 s in steps of 0.01 s

Trip Time Delay on Run:...................................0.00 to 5.00 s in steps of 0.01 s

Trip Time Delay on Start:.................................0.00 to 10.00 s in steps of 0.01 s

Pickup Accuracy:.................................................as per ground current inputs

Operate Time:.......................................................<30 ms @ 60Hz (I > 2.0 x PKP), 0 ms time delay

<35 ms @ 50Hz (I > 2.0 x PKP), 0 ms time delay

Timing Accuracy:................................................0 to 1 cycle

Elements: ................................................................Trip and Alarm

THERMAL PROTECTION

Locked Rotor Current:.......................................2.0 to 11.0 x FLA in steps of 0.1 x FLA

Safe Stall Time:.....................................................1.0 to 600.0 s in steps of 0.1 s

Curve Multiplier:...................................................1 to 15 in steps of 1

Pickup Level:..........................................................1.01 to 1.25 x FLA in steps of 0.01 x FLA

Curve Biasing:.......................................................Phase unbalance

Hot/cold biasing

Stator RTD biasing

Exponential Running and Stopped Cooling Rates

TCU Update Rate: ...............................................3 cycles

Pickup Accuracy:.................................................per phase current inputs

Timing Accuracy:................................................±200 ms or ±2% of total time

Elements: ................................................................Trip and Alarm

PHASE/AUXILIARY UNDERVOLTAGE

Minimum Voltage:...............................................Programmable from 0.00 to 1.25 x VT in steps of 0.01

Pickup Level:..........................................................0.00 to 1.25 x VT in steps of 0.01

Dropout Level: ......................................................101 to 104% of pickup

Curve: .......................................................................Definite Time, Inverse Time

Time Delay: ............................................................0.1 to 600.0 s in steps of 0.1

Operate Time:.......................................................T ime delay ±30 ms @ 60 Hz (V < 0.85 x PKP)

Time delay ±40 ms @ 50 Hz (V < 0.85 x PKP)

Time Delay Accuracy:.......................................±3% of expected time, or 1 cycle, whichever is greater

Level Accuracy:....................................................Per voltage input

UNDERPOWER

Pickup Level:..........................................................1 to 100% Hz MNR 1%

Dropout Level: ......................................................101% to 104% of Pickup

Time Delay: ............................................................1.0 to 60.0 s in steps of 0.1

Pickup Accuracy:.................................................as per power monitoring specification

Timing Accuracy:................................................±0.5 s or ±0.5% of total time

Elements: ................................................................Trip and Alarm

NEGATIVE SEQUENCE/PHASE OVERVOLTAGE

Pickup Level:..........................................................0.00 to 1.25 x VT in steps of 0.01

Dropout Level: ......................................................96 to 99% of pickup

Time Delay: ............................................................0.1 to 600.0 s in steps of 0.1

Operate Time:.......................................................T ime delay ±30 ms @ 60 Hz (V < 0.85 x PKP)

Time delay ±40 ms @ 50 Hz (V < 0.85 x PKP)

Timing Accuracy:................................................±0.5 s or ±0.3% of total time

Level Accuracy:....................................................Per voltage input

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–9

Page 16

SPECIFICATIONS CHAPTER 1: INTRODUCTION

NOTE

PHASE REVERSAL

Configuration: ......................................................ABC or ACB phase rotation

Time Delay:............................................................ 100 ms

Timing Accuracy:................................................ ±0.5 s

Elements:................................................................Trip or Alarm

UNDERFREQUENCY

Minimum Voltage: .............................................. 0.00 to 1.25 x VT in steps of 0.01

Pickup Level: .........................................................40.00 to 70.00 Hz in steps of 0.01

Dropout Level:......................................................Pickup +0.03 Hz

Time Delay:............................................................ 0.1 to 600.0 s in steps of 0.1

Timing Accuracy:................................................ ±0.5 s or ±0.5% of total time

Level Accuracy:.................................................... ±0.01 Hz

Elements:................................................................Trip and Alarm

OVERFREQUENCY

Minimum Voltage: .............................................. 0.3 x VT

Pickup Level: .........................................................40.00 to 70.00 Hz in steps of 0.01

Dropout Level:......................................................Pickup - 0.03 Hz

Time Delay:............................................................ 0.1 to 600.0 s in steps of 0.1

Timing Accuracy:................................................ ±0.5 s or ±0.5% of total time

Level Accuracy:.................................................... ±0.01 Hz

Elements:................................................................Trip and Alarm

FUSE FAIL

Time Delay:............................................................ 1 s

Timing Accuracy:................................................ ±0.5 s

Elements:................................................................Trip or Alarm

ACCELERATION TIME TRIP

Pickup Level: .........................................................Motor start condition

Dropout Level:......................................................Motor run, trip, or stop condition

Timers for single-speed:..................................Stopped to running

Timers for two-speed:...................................... Stopped to high speed, stopped to low speed, low to high

speed

Time Delay:............................................................ 1.0 to 250.0 s in steps of 0.1

Timing Accuracy:................................................ ±200 ms or ±1% of total time

Metering

PARA METER ACCURACY RESOLUTION RANGE

3-Phase Real Power (kW) ±1% of full scale 0.1 kW ±100000.0 kW

3-Phase Reactive Power (kvar) ±1% of full scale 0.1 kvar ±100000.0 kvar

3-Phase Apparent Power (kVA) ±1% of full scale 0.1 kVA 100000.0 kVA

3-Phase Positive Watthour (MWh) ±1% of full scale ±0.001 MWh 50000.0 MWh

3-Phase Negative Watthour (MWh) ±1% of full scale ±0.001 MWh 50000.0 MWh

3-Phase Positive Varhour (Mvarh) ±1% of full scale ±0.001 Mvarh 50000.0 Mvarh

3-Phase Negative Varhour (Mvarh) ±1% of full scale ±0.001 Mvarh 50000.0 Mvarh

Power Factor ±0.05 0.01 -0.99 to 1.00

Frequency ±0.05 Hz 0.01 Hz 40.00 to 70.00 Hz

NOTE:

1–10 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Full scale for CT Input is 3 x CT

Page 17

CHAPTER 1: INTRODUCTION SPECIFICATIONS

Data capture

DATA LOGGER

Number of Channels: ........................................10

Parameters: ...........................................................Any available analog actual value

Sampling Rate:.....................................................1 cycle, 1 second, 1 minute, 1 hour

Trigger Source:.....................................................All logic elements, Logic operand: Any Trip PKP/OP/DPO, Any

Alarm PKP/OP/DPO

Mode:........................................................................Continuous or triggered

MOTOR START DATA LOGGER

Length:.....................................................................6 buffers, containing a total of 30 seconds of motor starting

data

Trigger:.....................................................................Motor start status

Trigger Position:...................................................1-second pre-trigger duration

Logging Rate:........................................................1 sample/200 ms

TRANSIENT RECORDER

Buffer size:..............................................................3 s

No. of buffers:......................................................1x192 cycles, 3x64 cycles, 6x32 cycles

Sampling rate: ......................................................32 samples per cycle

Triggers:...................................................................Manual Command

Contact Input

Virtual Input

Logic Element

Element Pickup/Trip/Dropout/Alarm

Data:..........................................................................AC input channels

Contact input state

Contact output state

Virtual input state

Logic element state

Data storage:........................................................RAM - battery backed-up

EVENT RECORDER

Number of events:..............................................256

Content:...................................................................event number, date of event, cause of event, per-phase

current, ground current, sensitive ground current, neutral

current, per-phase voltage (VTs connected in “Wye”), or

phase-phase voltages (VTs connected in “Delta”), system

frequency, power, power factor, thermal capacity, motor

load, current unbalance

Data Storage:........................................................Non-volatile memory

LEARNED DATA RECORDER

Number of events:..............................................250

Header: ....................................................................Date, number of records

Content:...................................................................learned acceleration time , learned starting current, learned

starting capacity, last starting current, last starting capacity,

last acceleration time , average motor load learned, average

run time after start (days), average run time after start

(minutes)

Data Storage:........................................................Non-volatile memory

CLOCK

Setup:........................................................................Date and time

Daylight Saving Time

RTC Accuracy: ± 1 min / month at 25°C

IRIG-B:.......................................................................Auto-detect (DC shift or Amplitude Modulated)

Amplitude modulated: 1 to 10 V pk-pk

DC shift: 1 to 10 V DC

Input impedance: 40 kOhm ± 10% at 25°C

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–11

Page 18

SPECIFICATIONS CHAPTER 1: INTRODUCTION

Control

LOGIC ELEMENTS

Number of logic elements:.............................16

Trigger source inputs per element:............3

Block inputs per element: ............................... 3

Supported operations: .....................................OR, AND, NOT, Pickup / Dropout timers

Pickup timer: ......................................................... 0 to 60000 ms in steps of 1 ms

Dropout timer:...................................................... 0 to 60000 ms in steps of 1 ms

BREAKER CONTROL

Operation: ..............................................................Asserted Contact Input, Logic Element, Virtual Input, Manual

Command, Remote Input

Function:.................................................................Opens/closes the motor breaker

START INHIBIT

Thermal Start Inhibit: ........................................Thermal Inhibit Margin: 0 to 25 % in steps of 1%

Starts per Hour Inhibit:.....................................Maximum: 1 to 5 starts in steps of 1

Time Between Starts Inhibit: .........................T ime Between Starts: 1 to 3600 s in steps of 1 s

Restart Inhibit:......................................................Restart Inhibit Delay: 1 to 50000 s in steps of 1 s

BREAKER FAILURE/WELDED CONTACTOR

Current Supervision:.......................................... Phase Current

Current Supervision Pickup:........................... 0.05 to 20.00 x CT in steps of 0.01 x CT

Time Delay 1: ........................................................ 0.03 to 1.00 s in steps of 0.01 s

Time Delay 2: ........................................................ 0.00 to 1.00 s in steps of 0.01 s

Current Supervision Dropout: ....................... 97 to 98% of pickup

Current Supervision Accuracy:..................... per CT input

Timing Accuracy:................................................ 0 to 1 cycle (Timer 1, Timer 2)

BREAKER TRIP COUNTER

Trip Counter Limit (Pickup):............................. 1 to 10000 in steps of 1

EMERGENCY RESTART

Function:.................................................................Defeats all motor start inhibit features, resets all trips and

alarms, and discharges the thermal capacity to zero so that

a hot motor can be restarted in the event of an emergency

Operation: ..............................................................Contact Input 1 to 10, Virtual Input 1 to 32, Logic Element 1

to 16, Remote Input 1 to 32

LOCKOUT RESET

Function:.................................................................Reset any lockout trips when this feature is configured.

Operation: ..............................................................Contact Input 1 to 10, Virtual Input 1 to 32, Logic Element 1

to 16, Remote Input 1 to 32

RESET

Function:.................................................................Resets any alarms and non-lockout trips when LOCKOUT

RESET is configured, or resets any alarms and trips (lockout

and non-lockout trips) when LOCKOUT RESET is not

configured.

Operation: ..............................................................Contact Input 1 to 10, Virtual Input 1 to 32, Logic Element 1

to 16, Remote Input 1 to 32

AMBIENT TEMPERATURE

High Temperature Pickup:.............................. 20°C to 80°C in steps of 1°C

Low Temperature Pickup:...............................-40°C to 20°C in steps of 1°C

Time Delay:............................................................ 1 to 60 min in steps of 1 mins

Temperature Dropout:......................................Configurable 90 to 98% of pickup

Temperature Accuracy:...................................±10°C

Timing Accuracy:................................................ ±1 second

1–12 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 19

CHAPTER 1: INTRODUCTION SPECIFICATIONS

Inputs

CONTACT INPUTS

Inputs:.......................................................................10

Selectable thresholds: ......................................17, 33, 84, 166 VDC

Recognition time:................................................1/2 cycle

Debounce time: ...................................................1 to 64 ms, selectable, in steps of 1 ms

Continuous current draw:...............................2 mA

Type:..........................................................................opto-isolated inputs

External switch: ...................................................wet contact

Maximum input voltage:..................................300 VDC

PHASE & GROUND CURRENT INPUTS

CT Primary:.............................................................30 to 1500 A

Range: ......................................................................0.05 to 20 × CT

Input type: ..............................................................1 A or 5 A (must be specified with order)

Nominal frequency: ...........................................50/60 Hz

Burden: ....................................................................<0.1 VA at rated load

Accuracy:................................................................±1% of reading at 1× CT

±3% of reading from 0.2 to 20 × CT

±20% of reading from 0.05 to 0.19 × CT

CT withstand: ........................................................1 second at 100 × rated current

2 seconds at 40 × rated current

continuous at 3 × rated current

CBCT INPUT (50:0.025)

Range: ......................................................................0.5 to 15.0 A

Nominal frequency: ...........................................50 or 60 Hz

Accuracy (CBCT):..................................................±0.1 A (0.5 to 3.99 A)

±0.2 A (4.0 A to 15 A)

FREQUENCY

Accuracy:................................................................±0.05 Hz

Resolution:..............................................................0.01 Hz

Range: ......................................................................40.00 to 70.00 Hz

PHASE VOLTAGE INPUTS

Source VT:...............................................................100 to 20000 V

VT secondary range: .........................................50 to 240 V

VT ratio:....................................................................1 to 300 in steps of 1

Nominal frequency: ...........................................50/60 Hz

Accuracy:................................................................±1.0% throughout range

Voltage withstand: .............................................260 VAC continuous

RMIO RTD INPUTS

RTD Type: ................................................................100 Ohm platinum (DIN.43760)

RTD Sensing Current:.........................................5 mA

Isolation:..................................................................2 kV from base unit

Distance: .................................................................250 m maximum

Range: ......................................................................-50 to +250

Accuracy:................................................................±2

Lead Resistance: .................................................25 Ohm max per lead

o

o

C

C

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–13

Page 20

SPECIFICATIONS CHAPTER 1: INTRODUCTION

Outputs

FORM-A RELAYS

Configuration: ......................................................2 (two) electromechanical

Contact material:................................................silver-alloy

Operate time:........................................................ <8 ms

Continuous current:........................................... 10 A

Make and carry for 0.2s:.................................. 30 A per ANSI C37.90

Break (DC inductive, L/R=40 ms):.................24 V / 1 A

48 V / 0.5 A

125 V / 0.3 A

250 V / 0.2 A

Break (DC resistive): ........................................... 24 V / 10 A

48 V / 6 A

125 V / 0.5 A

250 V / 0.3 A

Break (AC inductive):.......................................... 720 VA @ 250 VAC Pilot duty A300

Break (AC resistive):............................................ 277 VAC / 10 A

FORM-A VOLTAGE MONITOR

Applicable voltage: ............................................20 to 250 VDC

Trickle current: .....................................................1 to 2.5 mA

FORM-C RELAYS

Configuration: ......................................................5 (five) electromechanical

Contact material:................................................silver-alloy

Operate time:........................................................ <8 ms

Continuous current:........................................... 10 A

Make and carry for 0.2s:.................................. 30 A per ANSI C37.90

Break (DC inductive, L/R=40 ms):.................24 V / 1 A

48 V / 0.5 A

125 V / 0.3 A

250 V / 0.2 A

Break (DC resistive): ........................................... 24 V / 10 A

48 V / 6 A

125 V / 0.5 A

250 V / 0.3 A

Break (AC inductive):.......................................... 720 VA @ 250 VAC Pilot duty A300

Break (AC resistive):............................................ 277 VAC / 10 A

TRIP / CLOSE SEAL-IN

Relay 1 trip seal-in: ............................................0.00 to 9.99 s in steps of 0.01

Relay 2 close seal-in:......................................... 0.00 to 9.99 s in steps of 0.01

Power supply

HIGH RANGE POWER SUPPLY

Nominal:.................................................................. 120 to 240 VAC125 to 250 VDC

Range:......................................................................60 to 300 VAC (50 and 60 Hz)

Ride-through time:.............................................35 ms

LOW RANGE POWER SUPPLY

Nominal:.................................................................. 24 to 48 VDC

Range:......................................................................20 to 60 VDC

ALL RANGES

Voltage withstand:.............................................2 × highest nominal voltage for 10 ms

Power consumption: ......................................... 15 W nominal, 20 W maximum

1–14 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

84 to 250 VDC

20 VA nominal, 28 VA maximum

Page 21

CHAPTER 1: INTRODUCTION SPECIFICATIONS

Communications

SERIAL

RS485 port: ............................................................Opto-coupled

Baud rates:.............................................................up to 115 kbps

Response time:.....................................................1 ms typical

Parity:........................................................................None, Odd, Even

Protocol: ..................................................................Modbus RTU, DNP 3.0, IEC 60870-5-103

Maximum distance: ...........................................1200 m (4000 feet)

Isolation:..................................................................2 kV

ETHERNET (COPPER)

Modes:......................................................................10/100 MB (auto-detect)

Connector:..............................................................RJ-45

Protocol: ..................................................................Modbus TCP, DNP3.0, IEC 60870-5-104, IEC 61850 GOOSE

ETHERNET (FIBER)

Fiber type:...............................................................100 MB Multi-mode

Wavelength: ..........................................................1300 nm

Connector:..............................................................MTRJ

Protocol: ..................................................................Modbus TCP, DNP3.0, IEC 60870-5-104, IEC 61850 GOOSE

Transmit power:...................................................-20 dBm

Receiver sensitivity:............................................-31 dBm

Power budget: ......................................................9 dB

Maximum input power:....................................-11.8 dBm

Typical distance:..................................................2 km (1.25 miles)

Duplex:.....................................................................half/full

USB

Standard specification: ....................................Compliant with USB 2.0

Data transfer rate:..............................................115 kbps

Testing and certification

CERTIFICATION

CE compliance EMC Directive EN61000-6-2, EN61000-

ISO Manufactured under a registered

TYPE TESTS

TEST REFERENCE STANDARD TEST LEVEL

Dielectric voltage withstand IEC60255-5 2.3KV

Impulse voltage withstand IEC60255-5 5KV

Insulation resistance 500VDC >100mohm

Damped Oscillatory IEC61000-4-18/IEC60255-22-1 2.5KV CM, 1KV DM

Electrostatic Discharge EN61000-4-2/IEC60255-22-2 Level 4

Radiated RF immunity EN61000-4-3/IEC60255-22-3 Level 3

Fast Transient Disturbance EN61000-4-4/IEC60255-22-4 Level 4

Surge Immunity EN61000-4-5/IEC60255-22-5 Level 3 & 4

Conducted RF Immunity EN61000-4-6/IEC60255-22-6 Level 3

Applicable Council Directive According to:

Low voltage directive EN60255-5, EN60947-1,

EN60947-6-1

6-4

ISO9001

quality program

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 1–15

Page 22

SPECIFICATIONS CHAPTER 1: INTRODUCTION

TEST REFERENCE STANDARD TEST LEVEL

Power Frequency Magnetic

Field Immunity

Voltage Dip & Interruption IEC61000-4-11 0,40,70% dips, 250/300cycle

Radiated & Conducted

Emissions

Sinusoidal Vibration IEC60255-21-1 Class 1

Shock & Bump IEC60255-21-2 Class 1

Ingress Protection IEC60529 IP40 (front) , IP10 (back)

Environmental (Cold) IEC60068-2-1 -20

Environmental (Dry heat) IEC60068-2-2 85

Relative Humidity Cyclic IEC60068-2-30 6 day variant 2

Fast Transient Disturbance IEEE C37.90.1 4KV CM & DM

SWC Damped Oscillatory IEEE C37.90.1 2.5KV CM & DM

Electrostatic Discharge IEEE C37.90.3 8KV CD, 15KV AD

IEC61000-4-8 Level 4

interrupts

CISPR11 /CISPR22/ IEC60255-25 Class A

o

C 16 hrs

o

C 16hrs

Physical

DIMENSIONS

Size: ........................................................................... Refer to Chapter 2

Weight: ....................................................................4.1 kg [9.0 lb]

Environmental

OPERATING ENVIRONMENT

Ambient temperatures:

Storage/Shipping: - 40

Operating: -40

Humidity: Operating up to 95% (non condensing) @ 55

Altitude: 2000 m (max)

Pollution Degree: II

Overvoltage Category: III

Ingress Protection: IP40 Front , IP10 Back

o

C to 85oC

o

C to 60oC

per IEC60068-2-30 Variant 2, 6 days)

o

C (As

1–16 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 23

Digital Energy

Multilin

339 Motor Protection System

Chapter 2: Installation

Installation

Mechanical installation

This section describes the mechanical installation of the system, including dimensions for

mounting and information on module withdrawal and insertion.

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 2–1

Page 24

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

Dimensions

The dimensions of the 339 are shown below. Additional dimensions for mounting and

panel cutouts are shown in the following sections.

Figure 1: 339 dimensions

Product identification

The product identification label is located on the side panel of the 339. This label indicates

the product model, serial number, and date of manufacture.

Figure 2: Product Identification label

2–2 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 25

CHAPTER 2: INSTALLATION MECHANICAL INSTALLATION

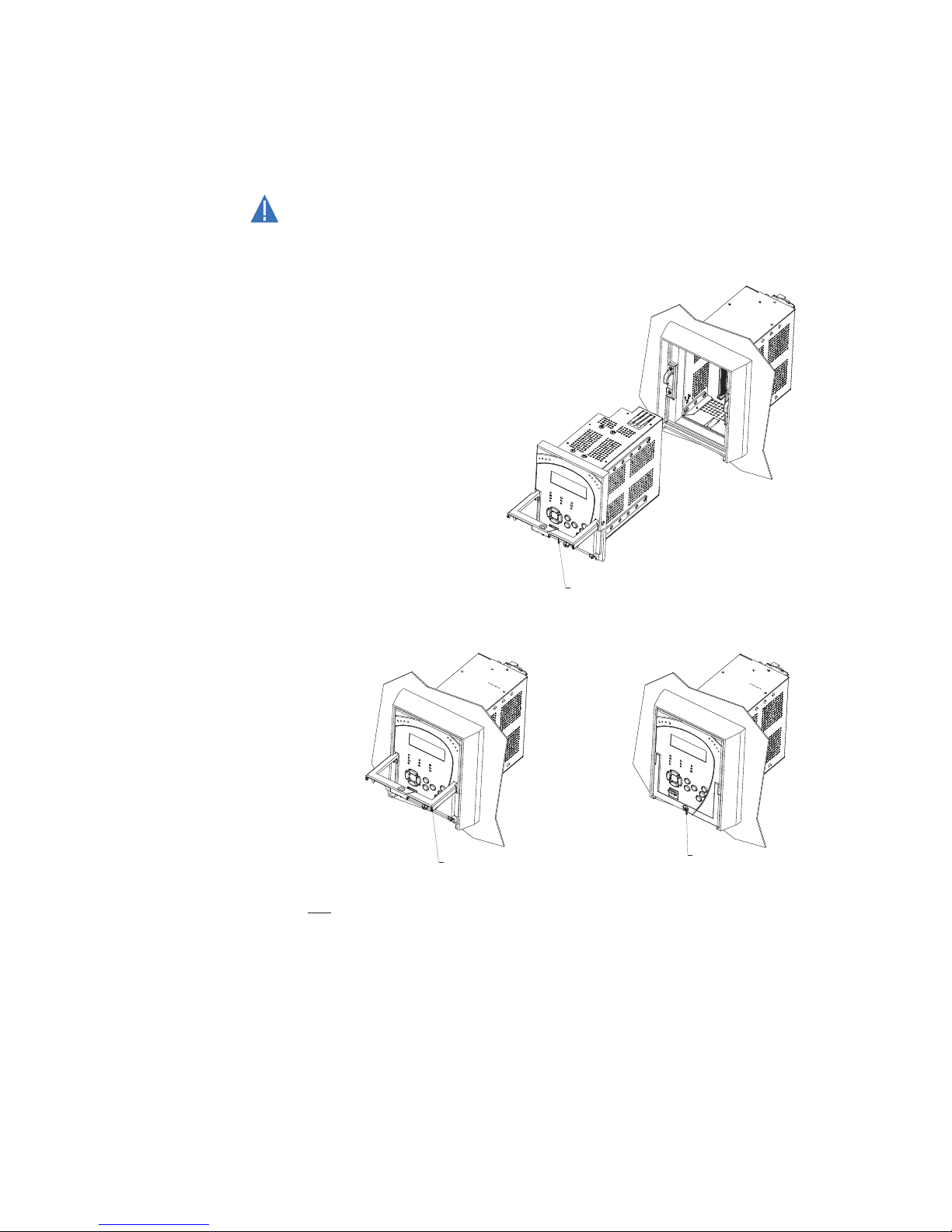

CAUTION

KEEP THE HANDLE IN ITS ROTATED

POSITION UNTIL THE DRAW-OUT UNIT

IS INSERTED COMPLETELY

PUSH THE HANDLE DOWN AND TIGHTEN

THE SCREW UNTIL THE HANDLE IS PARALLEL

WITH THE FRONT PANEL SURFACE

THE HANDLE MUST BE ROTATED 90

WHILE SLIDING THE 339 DRAW-OUT

UNIT INTO THE CAPTIVE UNIT

⁰

NOTE: IT IS THE RESPONSIBILITY OF THE USER TO ENSURE THAT THE EQUIPMENT IS INSTALLED, OPERATED, AND USED FOR ITS

INTENDED FUNCTION, IN THE MANNER SPECIFIED BY THE MANUFACTURER. IF THIS IS NOT THE CASE, THEN THE SAFETY PROTECTION

PROVIDED BY THE EQUIPMENT MAY BE IMPAIRED.

STEP 1

STEP 2

STEP 3

Mounting

STANDARD PANEL MOUNT

The standard panel mount and cutout dimensions are illustrated below.

CAUTION:

To avoid the potential for personal injury due to f ire hazards, ensure the unit is

mounted in a safe location and/or within an appropriate enclosure.

Figure 3: Panel mounting

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 2–3

Page 26

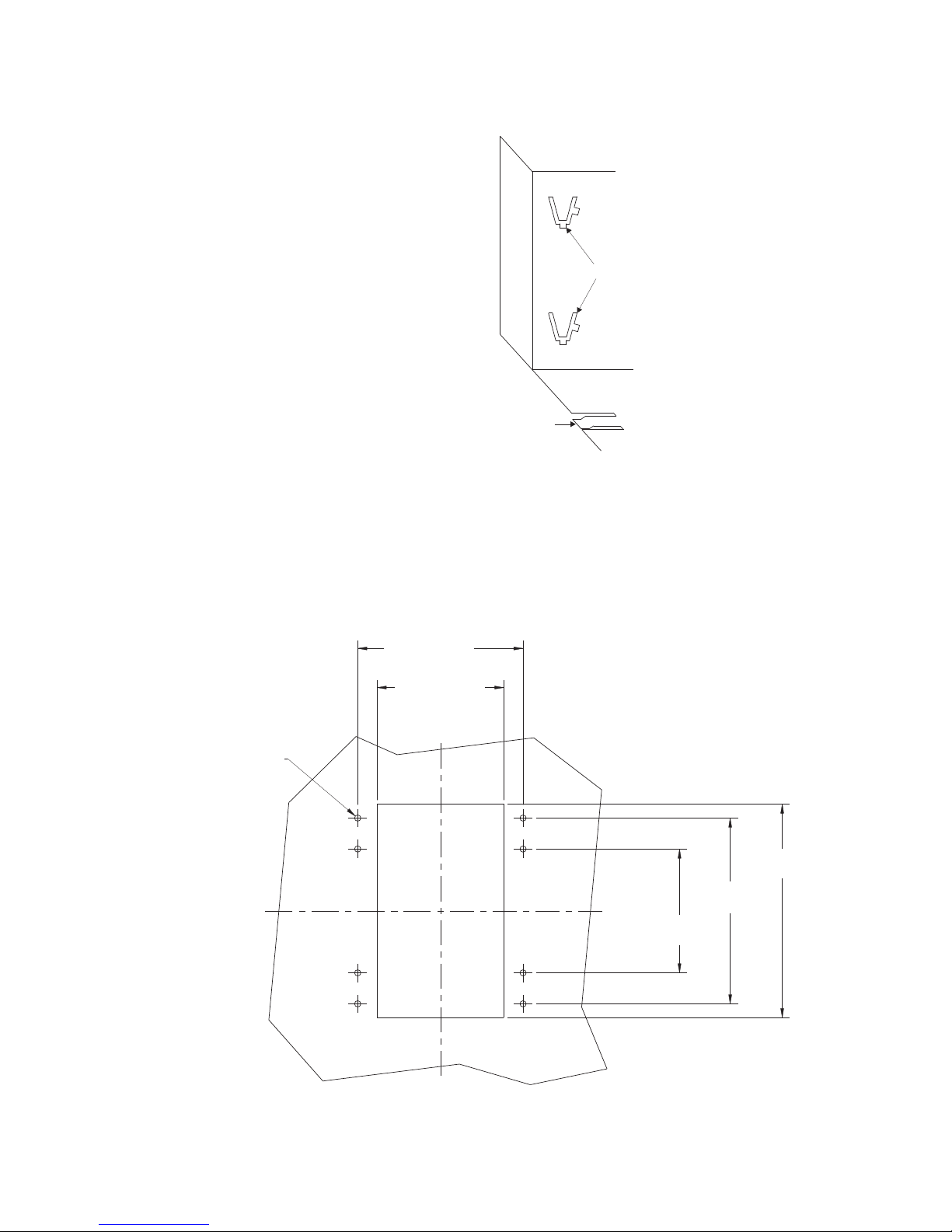

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

BOTTOM TAB

“V” TABS

5.350” 0.010”

(135.9 mm 0.25mm)

±

±

4.100” 0.010”

(104.1 mm 0.25 mm)

±

±

0.200”

(5.1 mm)

Φ

6.900” 0.010”

(175.3 mm 0.25 mm)

±

±

6.000” 0.010”

(152.4 mm 0.25 mm)

±

±

4.000” 0.010”

(101.6 mm 0.25 mm)

±

±

C

L

C

L

Figure 4: Mounting tabs (optional)

1. From the front of the panel, slide the empty case into the cutout until the bottom tab

clicks into place (see above).

2. From the rear of the panel screw the case into the panel at the 8 screw positions

shown above.

3. If added security is required, bend the retaining "V"tabs outward, to about 90°. These

tabs are located on the sides of the case and appear as shown above.

The relay can now be inserted and can be panel wired.

Figure 5: Panel cutout dimensions

2–4 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 27

CHAPTER 2: INSTALLATION MECHANICAL INSTALLATION

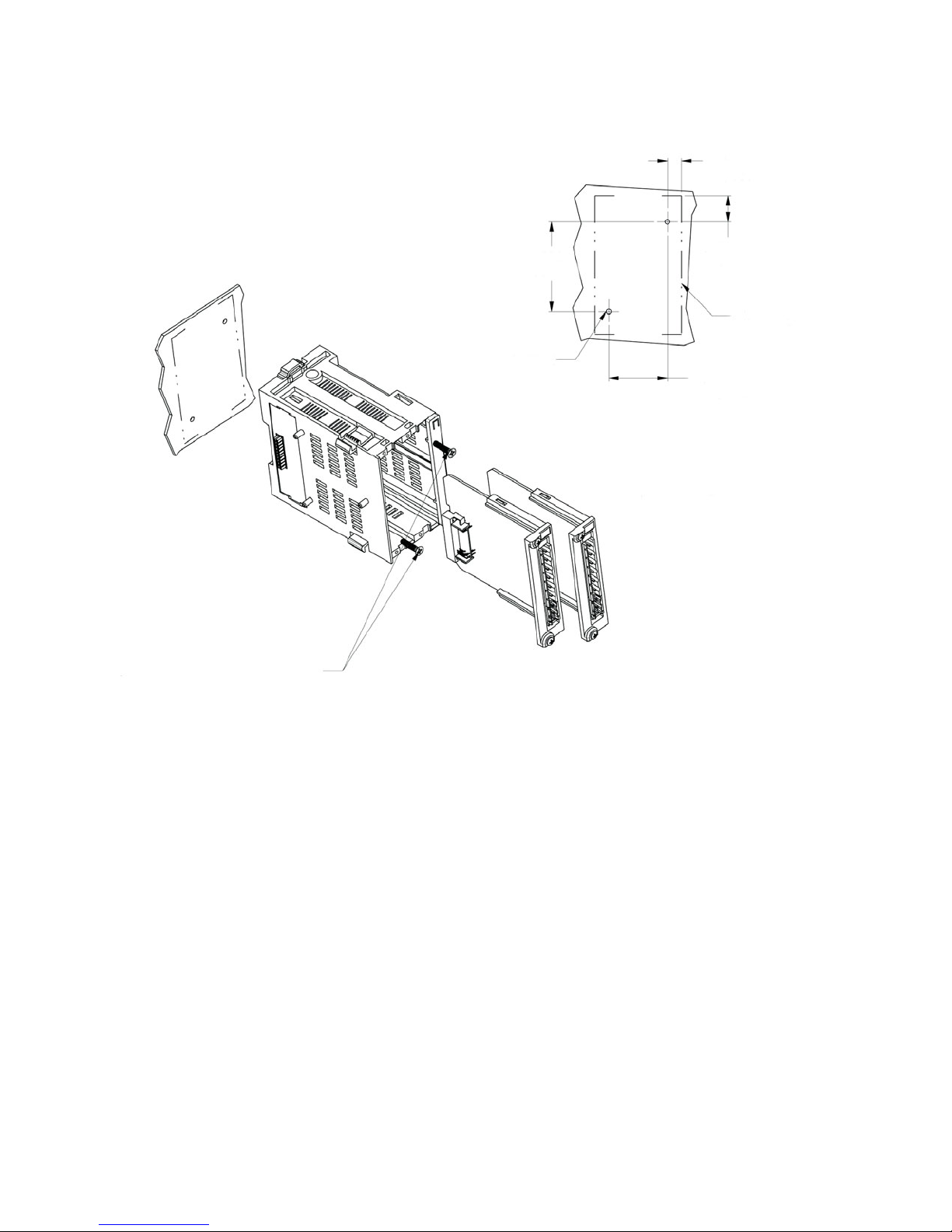

SNAP-IN THE DIN CLIPS (QTY: 4)

FOR DIN RAIL MOUNTING

0.30”

(7,6 mm)

1.38”

(35,1 mm)

DIN 3 RAIL

853726A1.CDR

MEETS VIBRATION REQUIREMENT OF

IEC 60255 SEC 21.1, 21.2, & 21.3

2.250”

(57,15 mm)

#6 -32 THREADED HOLE

QTY: 2

4.100”

(104,14 mm)

853727A1.CDR

Figure 6: RMIO - DIN rail mounting - Base & Expansion units

Figure 7: RMIO - Base Unit screw mounting

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 2–5

Page 28

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

#6-32X1/2 FT FLAT HEAD PHIL ZINC

QTY: 2; (SUPPLIED); GE PART # 1406-0117

TIGHTENING TORQUE: 10 lb. in.

0.356”

[9.03 mm]

0.672”

[17.06 mm]

1.500”

[38.10 mm]

EXPANSION UNIT

OUTLINE

2.285”

[58.04 mm]

#6-32 THREADED HOLE

QTY: 2

853755A1.cdr

Figure 8: RMIO - Expansion Unit screw mounting

2–6 339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL

Page 29

CHAPTER 2: INSTALLATION MECHANICAL INSTALLATION

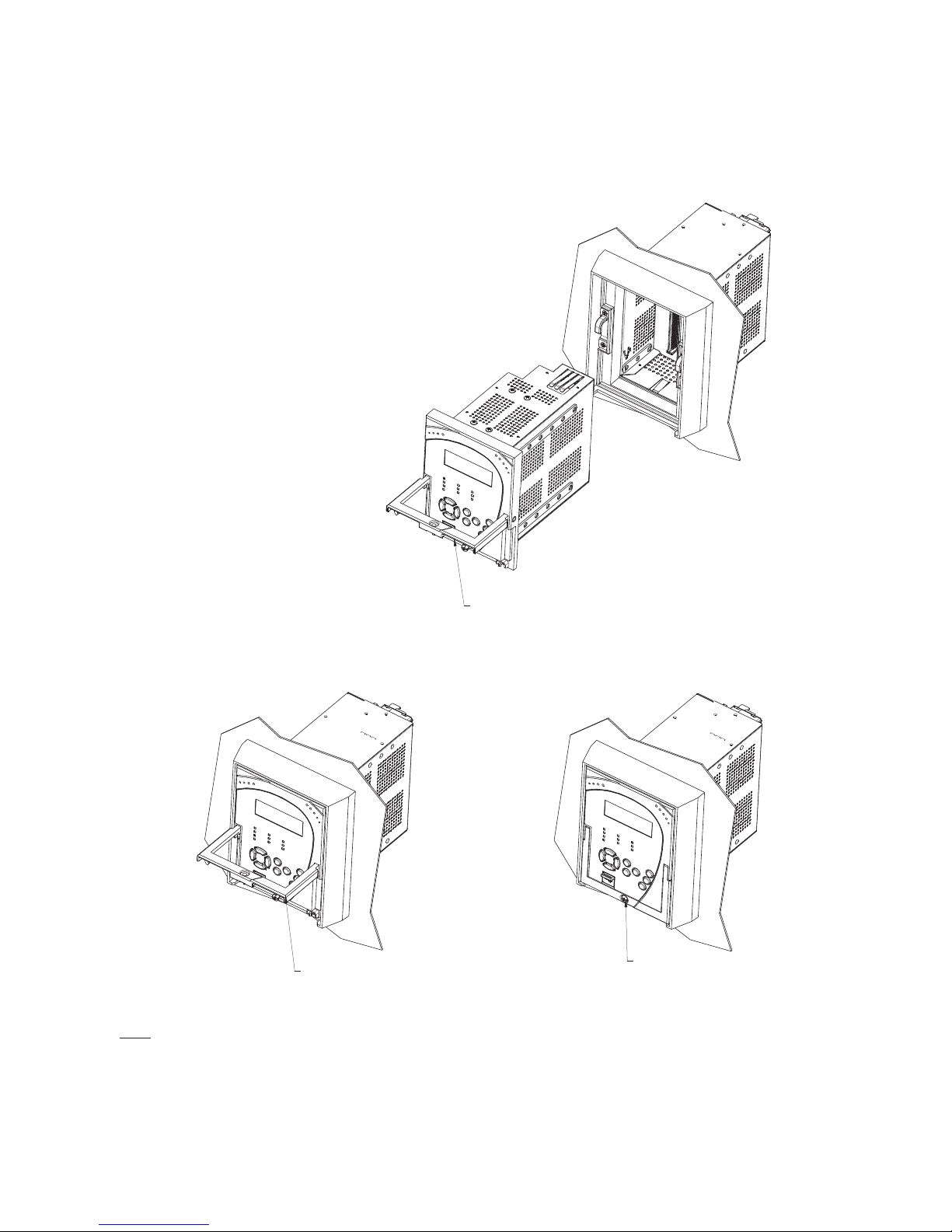

KEEP THE HANDLE IN ITS ROTATED

POSITION UNTIL THE DRAW-OUT UNIT

IS INSERTED COMPLETELY

PUSH THE HANDLE DOWN AND TIGHTEN

THE SCREW UNTIL THE HANDLE IS PARALLEL

WITH THE FRONT PANEL SURFACE

THE HANDLE MUST BE ROTATED 90

WHILE SLIDING THE 339 DRAW-OUT

UNIT INTO THE CAPTIVE UNIT

⁰

NOTE: IT IS THE RESPONSIBILITY OF THE USER TO ENSURE THAT THE EQUIPMENT IS INSTALLED, OPERATED, AND USED FOR ITS

INTENDED FUNCTION, IN THE MANNER SPECIFIED BY THE MANUFACTURER. IF THIS IS NOT THE CASE, THEN THE SAFETY PROTECTION

PROVIDED BY THE EQUIPMENT MAY BE IMPAIRED.

STEP 1

STEP 2

STEP 3

Unit withdrawal and insertion

Figure 9: Unit withdrawal and insertion diagram

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 2–7

Page 30

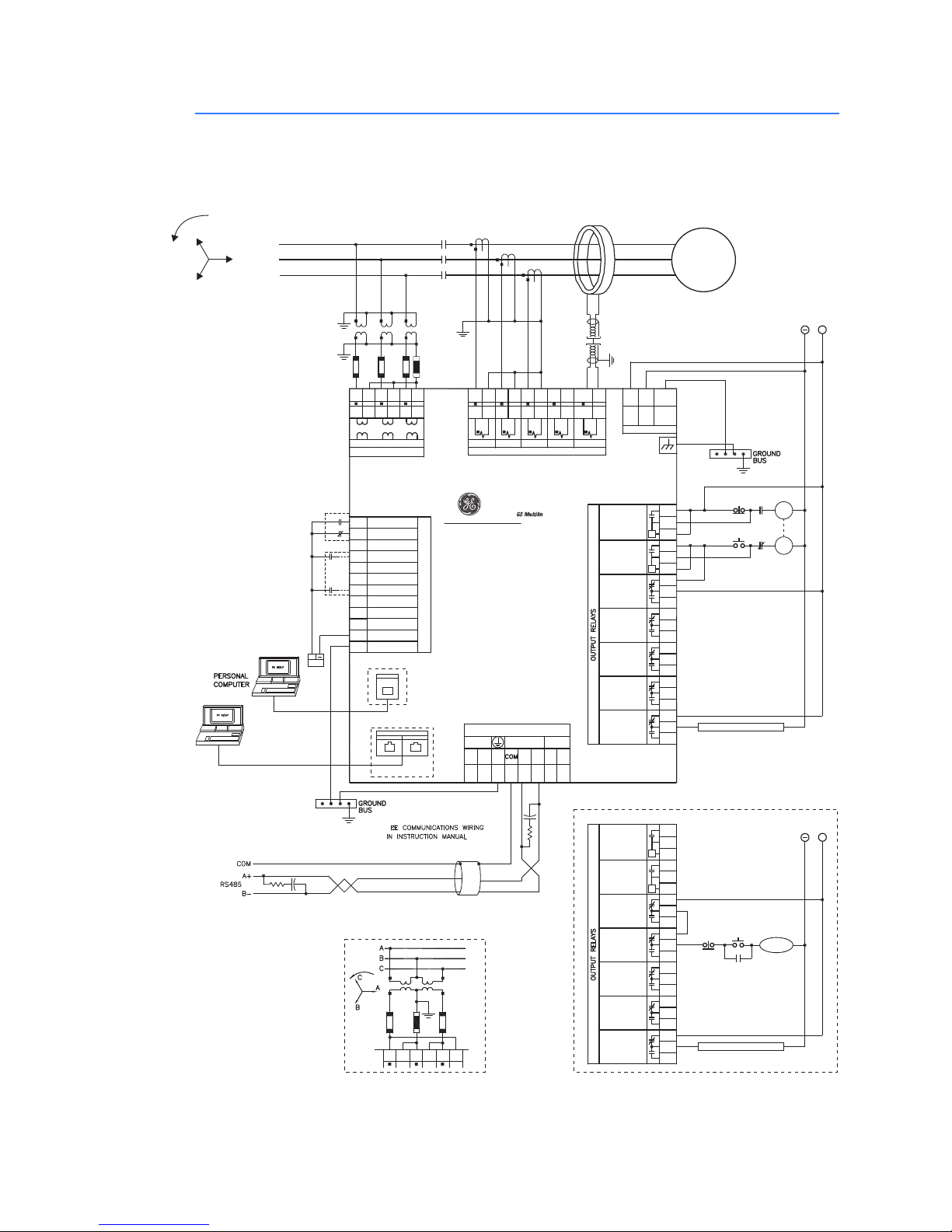

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

896729.CDR

POWER SUPPLY

B1

A1

B2

+

-

chassis

gnd

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

DIGITAL INPUTS

52a

52b

INPUT 3

INPUT 4

INPUT 5

INPUT 6

INPUT 7

INPUT 8

ETHERNET

RJ45

MTRJ

10/100BASE-T

100 BASE-FX

USB

TYPE B

A5

A6

A7

A2

A3

A4

A8

A9

A10

A11

A12

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

V

V

4 WIRE USB

4 WIRE ETHERNET

USB

+

F5 F4 F3

--

++

RS485

IRIG-B

F6F8

COMMUNICATIONS

CONTROL

POWER

A

B

C

E5

D5

E6

D6

E7

D7

E8

D8

1A/5A

VOLTAGE INPUTS

WYE VT

CONNECTION

E9

D9

E10

D10

E11

D11

V

AVA

V

B

V

B

V

C

V

C

7 CRITICAL

FAILURE

3START

INHIBIT

4 AUXILIARY

5 AUXILIARY

6 AUXILIARY

2 CLOSE