Page 1

I Use&~~~6’&ndlns

tallatiohGuide

Zoneline@

Conten@

Air Filter

Appliance Registration

Aufiliary

Care

Central Desk Control 4

Condenser Coils

Consumer Services

Ener~-Saving Tips

Fan Cycle Stitch 4

Freeze Sentinel 4

Installation Instructions

Master Controls

Model and Serial Numbers

Problem Solver

Controls

and Cleaning

15

11

6-10

11

Air Conditioner

5

2

4

5

5

3

2

Room cabinet and Case

Safety Instructions

Thermostat Control

Ventilation Control 4

a

Pup

Back Cover

Model

Warranty

GE Answer Center

800.626.2000

Zoneline@

Heat

3100 Series

GE Appliances

5

2

3

Page 2

Help us

bpotint

Stiety

help you...

Before using your

air conditioner, read

this book carefully.

It is

intended

and maintain your new

conditioner properly.

Keep it handy for answers to your

questions.

If you don’t understand something

or need more help, write (include

your phone number):

Consumer Affairs

GE Appliances

Appliance Park

Louisville, KY 40225

Write down the model and

serial numbers.

You’ll find them on a label behind

the room cabinet.

These numbers are also on the

Consumer Product Ownership

Registration Card that came with

your

air

sending in this card, please write

these numbers here:

to help you operate

air

conditioner. Before

Instmctions

Read all instructions

before using this appliance.

When using this air conditioner,

always exercise basic safety

precautions, including the following:

● Use this air conditioner only for

its intended purpose as described

in this Use and Care Book.

● This air conditioner must be

properly installed in accordance

with the Installation Instructions

before it is used.

● Never use an extension cord

with this air conditioner.

● Unplug or disconnect the unit

at the fuse box or circuit breaker

before making any repairs. Note:

We strongly recommend that any

servicing be performed by a

qualified individual.

● For your safety ... Do not store

or use combustible materials,

gasoline or other flammable vapors

or liquids in the vicinity of this or

any other appliance.

HYOU

To obtain service, see the

Consumer Services page in the

back of this book.

We’re proud of our service and

want you to be pleased. If for some

reason you are not happy with the

service you receive, here are three

steps to follow for further help.

FIRST, contact the people who

serviced your appliance. Explain

why you are not pleased. In most

cases, this will solve the problem.

NEXT, if you are still not pleased,

write all the details—including

your phone number—to:

Manager, Consumer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

FINALLY, if your problem is still

not resolved, write:

Major Appliance

20 North

Chicago, IL 60606

Need

Consumer Action Panel

Wacker

Sefice

Drive

Model Number

Serial Number

Use these numbers in

correspondence or service

concerning your

If you received a damaged air

conditioner, immediately contact

the

dealer

(or

builder) that sold you

the air conditioner.

Save time and money. Before

you request service, check the

Problem Solver in the back of

this book.

operating problems that you can

correct yourself.

It

lists causes of minor

any

calls

air conditioner.

2

SAVE THESE

~STRUCTIONS

Page 3

Operating the Controls

THERMOSTAT

56

+

4+/*—@\

&

:3@/

(

28

/+

1

$

1 %0

‘/. as

I

●

79

10

Thermostat Control

The thermostat knob is used to

control the room temperature. The

unit automatically cycles on and

off to maintain room temperature.

A comfortable temperature will be

maintained in

control is set at about “5” or “6.”

For cooler temperatures, turn the

control to a higher number.

For warmer temperatures, turn the

control to a lower number.

mos{

rooms when the

STOP FAN

LO HEAT ●

HI HEAT

●

●

@

8

●

LO COOL

●

HI COOL

Operation Switch

HI HEAT provides heating with

high fan speed operation.

LO HEAT provides heating with

low fan speed operation.

STOP

setting stops heating or

cooling.

connected to the unit

Freeze Sentinel still functions.

FAN provides fan operation

without cooling or heating.

HI COOL provides cooling with

high fan speed operation.

LO COOL provides cooling with

low fan speed operation.

However, power remains

and the

About Your Heat Pump...

Heat pumps can save money by

removing heat from the outside

air—even when the outside

temperature is below

and releasing that heat indoors.

To get the best from your heat

pump, don’t change the room

thermostat very often. Raising

the heat setting 2-3 degrees may

cause the

to use its electrical heating

elements in order to reach the

new temperature setting quickly.

The electric heating elements use

much more electricity than heat

pumps and cost more to operate.

Zoneline

freezing—

heat pump

Discharge Air Louvers

The angling of the discharge air may be adjusted from

the factory setting of 37° off vertical, to a setting 20°

off vertical.

37°0FF VERTICAL

NOTE: For high mounted

Room Cabinet.

20°0FF VERTICAL

Zonelines

where greater room cabinet louver adjustments are required, order the

To reposition the louvers, remove the room cabinet and

remove the 2 screws that hold the louver section in

place,

rotate the louver section 180° (end for end),

replace the screws and put the room cabinet back

air conditioner. Textured face of louver section must be

toward the room side.

LOUVER SCREWS

/\

on

RAF45

the

3

Page 4

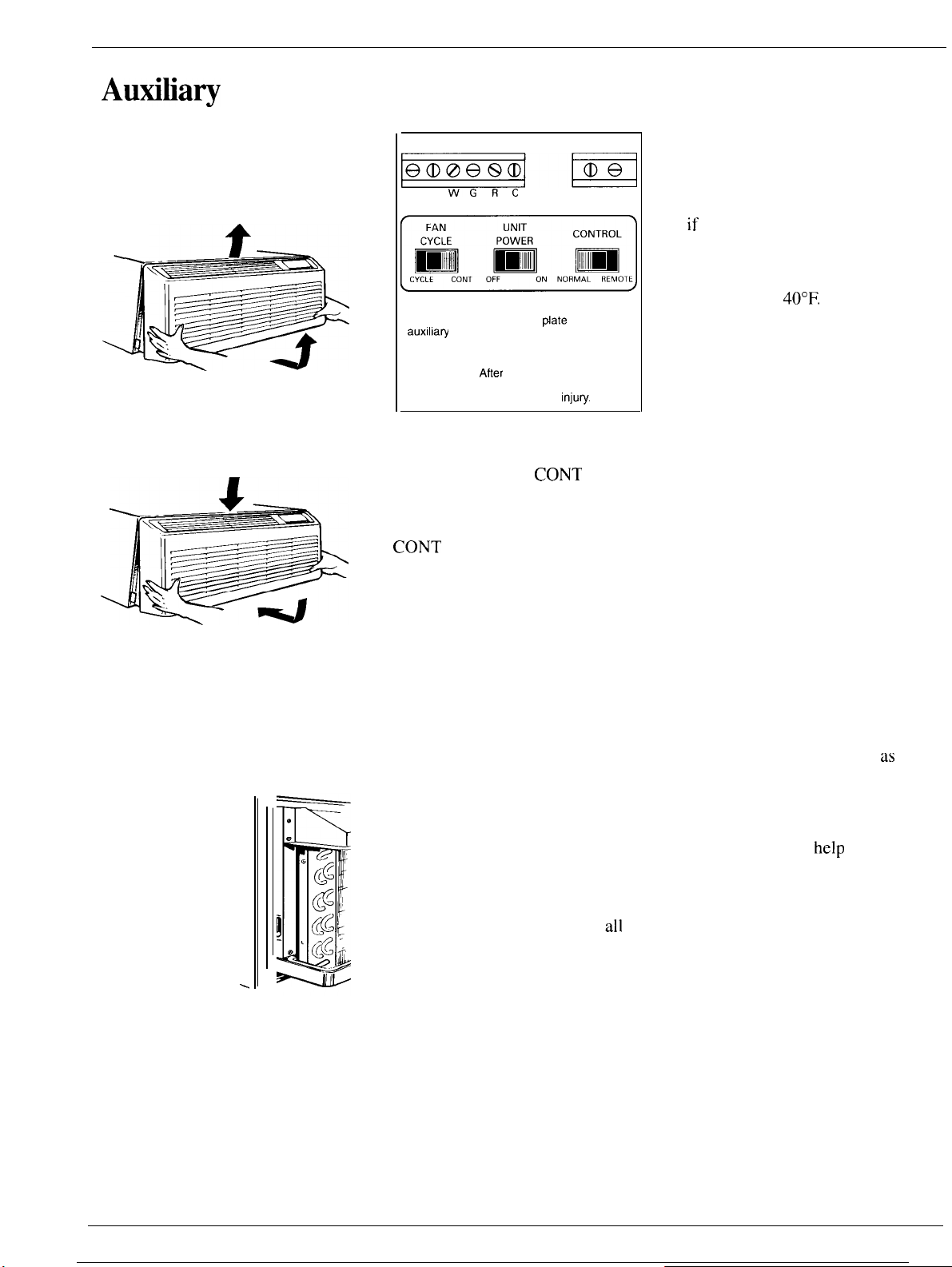

Autitia~

Controls

Additional controls are located

behind the room cabinet.

Access to the controls is obtained

by removing the room cabinet.

To remove the room cabinet,

grasp it at both sides, pull it out to

release it from the tabs. Then lift it

up and pull forward.

To replace the room cabinet,

position tabs at top of room cabinet

over the rail at top of chassis. Push

the room cabinet inward until it

snaps into place.

Ventilation Control

The ventilation

control lever is

located at the lower

left side of the unit,

behind the room

cabinet.

This knob is set

at CLOSE at the

factory. When in

this position, the

vent door is closed

and only indoor air is circulated

by the air conditioner.

Switching the knob to OPEN

opens the vent door to allow

outdoor air to enter the room.

However, leaving the vent door

OPEN reduces heating or cooling

effectiveness and increase

operating costs.

-

‘

CLASS 2 REMOTE

-m

BY

WGRC

=

The CLASS 2 REMOTE and CDC terminals

are located behind a cover

auxilia~

controls. To remove the plate,

remove and save the screws that hold the

plate to the unit.

IMPORTANT:

completed, replace the plate to prevent

damage to the unit or personal

Afier

@ate

the wire connections are

CDC

above the

inju~.

Fan Cycle Switch

This switch is set at

the factory to provide continuous

fan operation in cool or heat

modes. Leaving the switch in the

CONT setting allows continuous

circulation of room air and

will result in a more balanced

temperature throughout the room.

If you want the fan to cycle on

and off with the compressor or

resistance heater, set the switch

at CYCLE.

CONT

at

Unit Power Switch

This switch controls power to the

cool, heat or fan modes. When set

at ON it allows the unit to operate

in the cool, heat or fan modes.

If this switch is set at OFF, the

unit will not operate in any modes

but the Freeze Sentinel will

still function.

Caution: The Unit Power Switch

is not a power disconnect. If

power must be disconnected from

the unit, remove the line cord plug

from the wall outlet, or remove the

fuses, or turn off the circuit

breakers at the power panel.

all

Freeze Sentinel

The Freeze Sentinel sensor helps

prevent plumbing damage due to

sub-freezing temperatures—even

if you have turned the operation

switch to STOP. The sensor

automatically turns on the heater

and fan if the room temperature

falls to about

40°F.

You do not have to do anything to

activate the Freeze Sentinel. It will

work as long as power to the unit

has not been interrupted.

Remote Control

The unit may be controlled either

by the controls on the unit or by

changing the CONTROL switch to

REMOTE and connecting the unit

to a remote thermostat.

See Installation Instructions.

Central Desk

Control (CDC)

The unit may be connected to a

Central Desk Control system by

connecting the wires from the

central control system to the CDC

terminals located on the panel

behind the room cabinet. These

terminals may also be used

interface for other systems used to

control the unit such as infrared

detectors, key-activated systems,

etc. The Freeze Sentinel remains in

an active mode to

help

against low temperature damage

even though the unit may be OFF

at the central control location.

See Installation Instructions.

as

protect

an

4

Page 5

Care and Cleating

Temperature Limiter

The normal range of the thermostat

control is approximately

to

85°F.

The control range may be

narrowed by the use

temperature limiting screws

located behind the control panel.

Stop

Scre~s

● ● Knob Shaft

4

the

u’

“

left

of the knob shaft

●

w

To set the limiting screws:

1.

Remove the room cabinet.

2. Pull both THERMOSTAT knob

and the OPERATION knob

shafts and remove the control panel.

3. Remove and relocate either or

both stop screws on the exposed

control box cover.

[War;est)

To limit the maximum heating

temperature, move the stop

screw

at

clockwise. To limit the minimum

cooling temperature, move the stop

screw on the right counterclockwise.

Make sure the stop arm is between

the stop screws as shown.

Because actual room temperature

can be affected by location and

installation as well as outdoor

weather conditions, you may want

to experiment to determine the

stop screw locations that best meet

your temperature requirements.

After adjusting the limiting

screws, reinstall the control panel,

knobs and room cabinet.

of the

60°F.

stop

Arm

●

off

the

(Cotiest)

For peak operating efficiency and

durability of your air conditioner

follow these necessary Care and

Cleaning instructions regularly.

~rn

the

Zoneline

before cleaning.

off

Room Cabinet & Case

Wash the room cabinet and case

finish with mild soap or detergent

and lukewarm water.

Outdoor Coil

The

coil

on the outdoor side

of the unit should be checked

periodically and cleaned if

clogged with dirt or soot from

the atmosphere. If extremely dirty,

it may need to be professionally

steam cleaned, a service available

through many GE service outlets.

Base Pan

In some installations dirt or other

foreign matter may be blown into

the unit from the outside and settle

in the base pan (the bottom of the

unit).

Check the base pan periodically

and clean it out, if necessary.

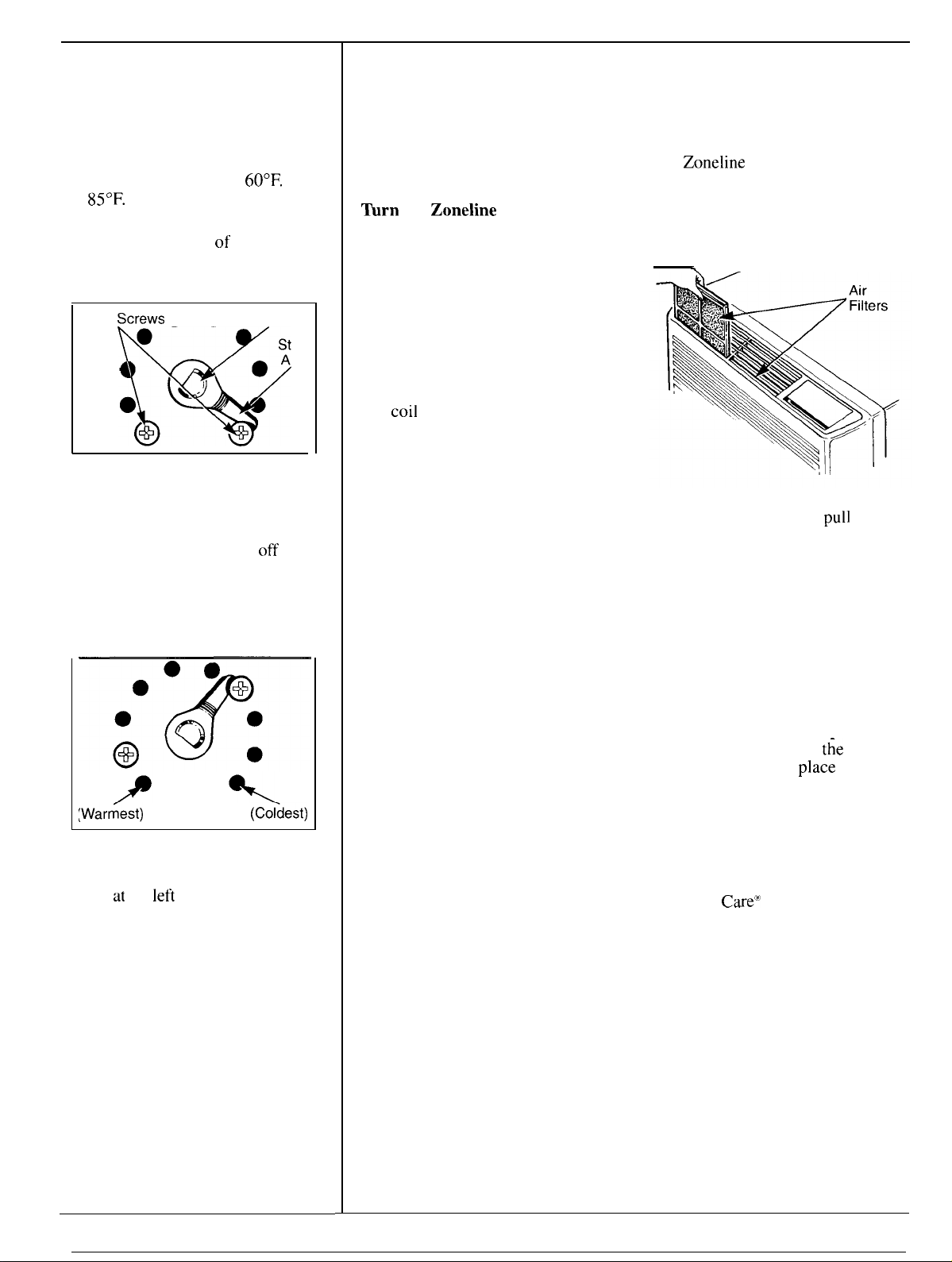

Air Filters

The

Zoneline

should be cleaned at least every

30 days.

The two air filters are located in

front of the air louvers.

\

To remove the air filters, grasp

the top of the filters and

straight up and out of their slots.

Vacuum the filters on the dirty

side or wash them with running

water.

cleaner side of the filter to drive out

dust and lint. Allow the filters to dry

thoroughly before replacing them.

Note: Do not operate the air

conditioner without the filters in

place. If a filter becomes torn or

damaged it should be replaced

immediately Operating

without the filters in

damaged filters will allow dirt and

dust to reach the indoor coil and

reduce the efficiency of the unit.

Replacement filters are available

from your GE Dealer, Factory

Service Center or authorized

Customer

To reinstall the air filter after

cleaning, make sure the word

FRONT is facing out. Insert the

bottom of each filter in their slots

and push down into place.

air filters inside

pull

Run water through from the

t;e

unit

place

or with

Care”’

servicers.

5

Page 6

BEFORE YOU BEGIN

Read these instructions completely and carefully.

lMPORTANT–Observe

ordinances.

lNSTALLER—Be

sure to leave these instructions

with the Consumer.

CONSUMER—Keep these instructions for future

reference.

all governing codes and

CAUTION

Before starting the installation, the power to

the direct connect wiring should be OFF.

THE GE

Exterior Grille/Louver**

ZONELIN~

Room Cabinet*

ELECTRICAL REQUIREMENTS

FOR PERSONAL SAFETY:

●

FOIIOW

National Electrical Code (NEC) and

local codes, ordinances and regulations. All

wiring — including installation of receptacle,

must be in accordance with these codes.

●

This unit must be properly grounded.

●

Do

not use an extension cord with this unit.

●

NEC

requires permanent connection for

installations over 250 volts.

●

NEC requires units controlled by NEC Class 2

low voltage remote controls to be permanently

connected.

●

protective devices

installations are specified on the nameplate of

each.

●

Aluminum

problems—consult a qualified electrician.

● Disconnect power to the air conditioner before

servicing by:

1.

Removing the power cord from the wall

receptacle, if it has one.

2. Removing the branch circuit fuses or turning

the circuit breakers off at the panel.

building wiring may pose special

acceptable for

Zoneline

Wall Case

Chassis

Power

Connection

* Shipped with the chassis

** Check essential elements list on chassis

*** Line cord connection shown only as example

WALL CASE & GRILLE

1.

The

RAB

70 or 77 Wall Case must be properly

installed per instructions packed with the case.

2. Remove the corrugated stiffener and the

outdoor protective panel. Use the slit in the

outdoor panel as a handhold and push out.

Protective

Panel

Slit

/

TOOLS NEEDED

Phillips screwdriver

Flat Blade screwdriver

6

/

Stiffener

H/

3. Install the Exterior Grille from the room side

per instruction packed with the grille.

Page 7

I

INSTALLATION INSTRUCTIONS

(cont,nue,)

I

NEWDUCTEDINSmLLAVON

If

this unit is to be installed in a new ducted

application using a duct adaptor kit, the kit must

be installed before the chassis is placed in the wall

case. The Installation Instructions are packed with

the kit.

MISVNGDUCTEDINSWILAVON

Replacement of an existing ducted unit may require

different components. Request this information

from your sales representative.

I

INSMLLATION

1. Remove the room cabinet by pulling out at the

bottom to release it, then lift it up to clear the rail

along the chassis top.

lNS~LLATION

3. Reinstall the room cabinet by hooking the top

over the rail along the chassis top, then pushing it

in at the bottom.

POWER

The power connection kit must be used to supply

power to the

is determined by the voltage, the means of

electrical connection and the amperage of the

branch circuit.

Connections of 208 or 230 volt circuits maybe

with a line cord kit or a permanent connection kit.

Connections of 265 volt circuits must be with a

permanent connection kit.

Electrical Wiring Wall

Outlets 230/208 volt

CONNECVON

Tandem 15 amp

(continued)

Zoneline chassis. The appropriate kit

2.

Slide the chassis into the wall case and secure

with four screws through the chassis flange holes.

Case

●

:

o

Perpendicular 20 amp

.:

o

Lsrge

tandem 30 amp

.:

PERMANENT

CONNECTION KIT

&

%

o

NEC requires permanent connection for

installations over 250 volts.

All wiring, including installation of the receptacle,

must be in accordance with the National Electrical

Code and local codes, ordinances and regulations.

(continued next page)

7

Page 8

I

INSTALLATION INSTRUCTIONS

(contln.e,)

POWER

230/208 Volt

Line Cord Kits

RAK315 Tandem

RAK320

RAK330*

230/208 Volt

Permanent

Connection Kits

RAK41 5/415L

RAK420/420L

RAK430/430L*

Kits ending in “L” have flexible conduit to reach from the kit to the knockout hole (above right side inspection

plate) in the RAK 203 Sub-Base.

265 Volt

Permanent

Connection Kits

RAK51 5/515LF

RAK517/517LF 15 Amp TD Fuse

RAK520/520LF

RAK530/530LF*

Kits ending in

plate) in the

*Not recommended for use on 6000

of 3.45

CONNEC70N(continue@

Wall Plug

Configuration

Perpendicular

Large Tandem

Circuit Protective Device

15 Amp

20 Amp TD Fuse or Breaker

30 Amp TD Fuse or Breaker

Circuit Protective Device

15 Amp

20 Amp TD Fuse

30 Amp TD Fuse 5.00

“LF”

have flexible conduit to reach from the kit to the knockout hole (above right side inspection

RAK203

KW

at 230 volts and 3.7 KW at 265 volts.)

Sub-Base and have an Integral Fuse.

TD Fuse or Breaker

TD Fuse

BTUH Units. (If this connection kit is used it will provide a maximum heat

Circuit Protective Device

15 Amp

20 Amp

30 Amp Fuse or Breaker

TD Fuse or Breaker

TD fuse or Breaker

Heater Wattage

@

230/208 Volts

2.55/2.09

3.45/2.82

5.00/4.10

Heater Wattage

@

265 Volts

1.70

KW

KW

3.00

3.70

KW

KW

KW

KW

KW

Heater Wattage

@

230/208 Volts

2.55/2.09

3.45/2.82

5.00/4.10

KW

KW

KW

ADJUSTMENTS AND AUXILIARY CONTROLS AVAILABLE WITH THE ROOM CABINET REMOVED

DISCHARGEAIRLOUVERS

The angling of the discharge air maybe adjusted from

the factory setting of 37° off vertical, to a setting 20°

off vertical.

37 ‘OFF VERTICAL

NOTE: For high mounted Zonelines where greater room cabinet louver adjustments are required, order the

I

RAF45

Room Cabinet.

20:OFFVERTICAL””

‘

To reposition the louvers, remove the room cabinet

and remove the 2 screws that hold the louver section

in place, rotate the louver section 180° (end for end),

re~lace the screws and ~ut the room cabinet back on

the air conditioner. Textured face of louver section

must be toward the room side.

LOUVER SCREWS

/\

Page 9

I

INSTALLATION INSTRUCTIONS

(cont,nue,)

TEMPERATURE LIMITING

The normal range of the thermostat control is

approximately

may be narrowed by the use of the temperature

limiting screws located behind the control panel.

Repositioning the screw on the left will limit the

maximum temperature about

in a clockwise rotation; the screw on the right will

limit the minimum temperature when moved

counterclockwise. Limiting the maximum and

minimum settings prevents users from turning

the controls to extreme positions. Restrictions to

full rotation of the thermostat knob may require

explanation to the room occupant that unit

will provide comfortable conditions at

settings allowed.

To access the limiting screws, remove the room

cabinet, remove the Thermostat knob and the

Operation knob by pulling each knob off its shaft

and removing the control panel. Set the limiters to

the desired setting, replace the control panel and

the control knobs. If the original settings do not

allow sufficient room temperature control the

limiter screws may have to be repositioned.

stop

Link

‘warm:)%

If the temperature limiters are used it is

recommended that the limiters be set no higher

than the second hole from the original bottom

position. This provides an operating range

between approximately

maximize the benefit of the temperature limiting it

may be necessary to adjust the limiter screws

seasonally to allow unoccupied rooms to be

maintained at moderate temperatures (i.e., heating

season temperatures limited between

75°F.;

between

●

k

cooling season temperatures limited

60°F.

to

85°F.

‘ /Tapped

7:o’~:Tos’at

Stop location as shipped

66°F.

85°F.

and

65°F.).

The control range

3°F. for each hole

Holes (10)

and

79°F.

In order to

60°F.

and

VENTILATION CONTROL

The VENTILATION control lever is located at the

lower left side of the unit, behind the room cabinet.

This lever controls the

vent door and is set in the

CLOSE position at the

factory so outdoor air will

not enter the room through

the unit and only indoor

air is circulated by the

air conditioner.

Moving the lever to OPEN

opens the vent door and

draws outdoor air through

the air conditioner and into

the room. Leaving the vent

door OPEN during extreme

temperature conditions reduces heating or cooling

effectiveness and increases operating

costs.

WATER DRIPPAGE

Water dripping from the wall case during heat

pump operation is to be expected. In heat pump

operation, water condenses on the outdoor coil

and frost melts, causing drippage.

It can be eliminated by attaching a drain kit to the

unit and routing the water through a drain system.

If the unit has an Internal Condensate Removal

(lCR) feature, the drippage should be minimal.

Installation of a drain system is recommended if no

drippage of condensate to the outdoors is allowable.

9

Page 10

3100 SERIES

Auxiliary Control Panel

CLASS 2 REMOTE

e@Oe

BY

FAN

CYCLE

-1

CYCLE CONT OFF ON NORMAL REMOTE

E

The CLASS 2 REMOTE and CDC terminals are

located behind a cover plate above the

controls. To remove the plate, remove and save

the screws that hold the plate to the unit.

IMPORTANT: After the wire connections are

completed, replace the plate to prevent damage

to

the unit or personal injuy.

WGRC

80

POWER

m]

uNIT

Coc

me

CONTROL

m

auxiliay

REMOTE CONTROL – 3100 SERIES

The unit may be controlled either by the unit

mounted controls or by changing the “CONTROL”

switch located behind the room cabinet to

“REMOTE” and connecting the unit to a 6 wire

Class 2 remote thermostat (GE Model

or RAK 152A or equivalent) the unit may be

converted to remote thermostat control.

2

STAGE HEAT

1 STAGE COOL

MANUAL THERMOSTAT

RAK147A

CENTRAL DESK CONTROL

The unit may be connected to a switch at the front

desk. When the switch is OPEN the unit is operable.

When the switch is CLOSED, the unit is made

inoperable. Connect the wires from the central

control system to the “CDC” terminals located on

the panel behind the room cabinet. Follow the

recommended wire sizing in the table below. Two

wires must be used from each CDC switch to each

individual unit. Do

CDC wiring. A 24 volt transformer is contained

within the unit and no external voltage should be

applied to the unit through the CDC terminals. These

terminals may also be used as an interface for other

systems used to control the unit, such as infrared

detectors, key-activated systems, etc. The Freeze

Sentinel remains in an active mode to help protect

against low temperature damage even though the

unit may be “OFF” at the central control location.

Recommended

Control Installation

Wire Size #

#24

#22

#20

#18

#16

not use a common buss in the

Wire Size for Central Desk

AWG

Maximum Allowable Length

400 ft.

600 ft.

900 ft.

1500 ft.

2000 ft.

I

BY

WGRC

CLASS 2 REMOTE

LOW VOLTAGE

TERMINAL ON ZONELINE

FREEZE SENTINEL

The unit is equipped with a sensor that

automatically turns on the resistance heater and

fan if the room temperature, as sensed at the unit,

drops to approximately 40° F. and will shut the

heater off when the temperature reaches about

520 F. The Freeze Sentinel system helps prevent

damage due to sub-freezing temperatures and will

operate regardless of the mode setting of the unit.

Freeze Sentinel is active as long as power to the

unit has not been interrupted.

FAN CYCLE SWITCH

This switch is set at CONT at the factory to provide

continuous fan operation in cool or heat modes.

Leaving the switch in the CONT setting allows

continuous circulation of room air and will result in a

more uniform temperature throughout the room.

Setting the switch at CYCLE will cause the fan to cycle

on and off with the compressor or resistance heater.

UNITPOWER SWITCH

This switch controls power to the cool, heat and fan

modes. It is set in the ON position at the factory to

allow the air conditioner to operate in these modes.

If this switch is set in the OFF position the air

conditioner will not operate in any modes but the

Freeze Sentinel will still function.

Caution: The UNIT POWER switch is not a

power disconnect.

disconnected from the unit remove the line cord

plug from the outlet, or remove the fuses, or turn

off the circuit breakers at the building power panel,

or unplug the power connector from the chassis.

If all power must be

10

Page 11

Energ-Saving

Tips

● Keep the air filter clean.

(See Care and Cleaning section.)

● For most efficient operation,

keep vent in closed position.

● Don’ t

too cold. Whenever possible, turn

the unit on before the room heats

up or cools off. If you don’t, the air

conditioner will take longer to

produce the desired comfort

condition.

● Keep windows and doors

closed. Conditioned air escapes

when they’re open.

● Keep furnace floor registers and

cold air returns closed when

cooling is desired. Conditioned air

can easily escape through them.

●

Don’t let drapes or furniture block

the front of the air conditioner. This

will restrict air

is operating.

● It’s best to operate your air

conditioner at high speed during

extremely hot or cold weather.

● Keep outdoor condenser coil

clean. (See Care and Cleaning

section.)

●

Turn air conditioner off during

vacations or extended absences.

let

the room get too hot or

flow

when the unit

~

~

Questions?

Use This Problem Solver

~

PROBLEM

AIR CONDITIONER

DOES NOT OPERATE

AIR CONDITIONER

“DOES NOT COOL

OR HEAT AS IT

SHOULD”

“BURNING” ODOR

AT START OF

HEATING

OPERATION

OPERATING SOUNDS

POSSIBLE CAUSE

● Power cord not plugged in, fuse

blown,

or

circuit breaker tripped.

● Unit is waiting for compressor overload

protector to reset.

● Curtains, blinds or furniture blocking the front

of the air conditioner will restrict air flow.

● Thermostat Control may not be set high

enough. Turn the control to a lower or higher

number. (Note: In some installations, the

Thermostat Control cannot be turned all the

way to “1“ or “10.” This is normal. Do not

attempt to force the control beyond its stopping

points.)

● Dirty air filter blocking air flow. Filter

should be cleaned at

least

every 30 days. See

instructions in cleaning section.

● Room may have been very hot or very cold

when the air conditioner was first turned on.

Allow time for it to cool down or warm up.

●

Ventilation control may be set at OPEN

position, allowing outside air to enter the room.

●

Dust on the surface of the heating

element can cause “a burning” odor

at the beginning of the heating operation.

This odor should quickly fade.

● Relay clicks may be heard when the

compressor or fan cycles on and off. This is

normal.

● Fan runs continuously when the unit

is operating unless the Fan Cycle Switch

behind the room cabinet is set at CYCLE.

Then the fan cycles on and off with the heater.

OUTDOOR WATER

DRIPPING DURING

HEATING OPERATION

● Water dripping from the outside of the

heat pump is normal during heating operation.

Drain kits are available. Water can be routed

through a drain system to eliminate the

problem.

If you need more help.. call, toll free:

GE Answer Center

(p

800.626.2000

consumer information service

11

Page 12

Page 13

Notes

13

Page 14

Notes

Page 15

Wdll

With the purchase

Be There

ofyour

new GE appliance, receive the

assurance that if you ever need information or assistance

from GE, we’ll be there. All you have to do is call–toll-free!

GEAnswer Center@

8006262000

In-Home Repair

Service

80ME$ARES

(80M32-2737)

AGEconsurner selwi[:eI>rofkssion:~l”

will provide

scheduled

for

you. Many

company-operated” locations

you service today or tomorrow, or at

your convenience

weekdays,

days).

know your appliance inside and outso most repairs

(me

visit.

expert

repair service,

at a time

9:()()

Our

f’actory-trained technicians

that.’s

convenient

(;E (lonsunler

(7:()()

a.m. to

a.m. to

2:()()

p.m. Satur-

can be handled in just

Semice

offer

7:()()

p.m.

Service Contracts

80&626-2224

YOLI

can have the secure fkeling

(;E (lonsunler

there

after your warranty expires. l)ur-

chase a

ranty is still in

a substantial

year

conl.ract, you’re

service at today’s prices.

Service will still be

(;E

contrac[ while your war-

efi’ect and you’ll receive

discount. With a nlultiple-

2issLncd offuture

Lhat

Whatevcryoul

rnaj( )r

appliance,

inf;)rnlat.ion ser~i(e is available to

help.

Your call–and

will he answered promptly

coLlrteously.”

time.

(;E

open

24

Telecommunication

question

(;E1

And you can call any

Answer

hours a day, 7 days a week.

(lenter”

Detice

aboLll

Answer

yOLn- question-

ancl

service is

for

tie

(lentel

Deaf

any(;

Patis andAccessories

80&626-2002

Individu~ qufified

o-

appliances

parts or accessories sent directly to

their

home.

‘I-he (1E

vides access

all

(;E (Jenuine

fidly warranted. VISA, Master(;ard

and Discover cards are accepted.

User maintenance instructions

contained in this

dures intended to be performed by

any user. Other servicing

shodd

vice personnel. Caution must be

exercised, since improper servicing

may cause unsafe operation.

to over

be referred to

to service their

can

have needed

parts system pro-

47,()()()

parts.. and

Renewal Parts arc

boo~et cover proce-

generdy

qudfied

ser-

s,cmoNA.A

...,.. .,-..,..,,..,.,-.=..

... W. L.. LW.S”..,”C,..,.

kr

Customers With

.“.,.

..., =,.,

Special Needs...

Upt)n request,

controls”

and a

brochure

barriel--free kitchen for persons with

limited

fi-c>c

or speech who have access to a TDD

01- a conventional Teletypewriter

call 800-TDD-(;MC;”

to requesl

mobility. T()

of’rharge,

(lonsumers with impaired hearing

C;E

will provide Braille

for a variety

to

assisl

call

800.tj26.2000.

infk~rmation

of’(;E

appliances,

in planning a

obt>~in

these items,

(800-833-4:322)”

or service.

may

Page 16

YOUR GE ZONELINE AIR CONDITIONER

WARRANTY

Save

I

proof of original purchase date such as

your sales slip or

cancelled

check to establish warranty period.

WHAT IS COVERED

FULL ONE-YEAR WARRANTY

For one year from date of original

purchase, we will provide, free of

charge, parts and on-site service

labor to repair or replace

the

room air conditioner that

of

~a~~:~tecause

FULL-FIVE YEAR WARRANTY

For five years from the date of

original purchase, we will provide,

free of charge, parts and on-site

sewice labor to repair or replace

anypati

system

evaporator and all connecting

tubing) that fails because of a

manufacturing defect.

of a manufacturing

of the sealed refrigerating

(the compressor, condenser,

any part

This warranty is extended to

the original purchaser and any

succeeding owner for products

purchased for use in the 48

mainland states, Hawaii and

Washington,

warranty is the same except that it

is LIMITED because you must pay

to ship the product to the service

shop or for the

travel costs to your home.

All warranty

provided by our Factory Service

Centers or by our authorized

Customer

normal working hours.

Call I-800-GE CARES

(1-800-432-2737).

D.C. In Alaska the

sewice technician’s

sewice will be

Care” sewicers during

For each of the above warranties:

Transportation expense to and

from a service shop and shop

service labor if required will be free

of charge.

WHAT IS NOT COVERED

● Service trips to teach you

how to use the product.

Read your Use and Care material.

If you then have any questions

about operating the product please

contact your dealer or our

Consumer Affairs office at the

address below, or call, toll free:

GE Answer Center

800.626.2000

consumer information service

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which

To know what your legal rights are in your state, consult your local or state consumer affairs office or your state’s Attorney General.

(o

● Improper installation.

If you have an installation

problem,

or if the air conditioner is

of improper cooling capacity for the

intended use, contact your dealer

or installer. You are responsible for

providing adequate electrical

connecting facilities.

● Replacement of house fuses or

resetting of circuit breakers.

● In commercial locations labor

necessa~ to move the unit to a

location where it is accessible for

service by an individual technician.

● Failure of the product resulting

from modifications to the product or

due to unreasonable use including

failure to provide reasonable and

necessary maintenance.

● Failure due to corrosion on

models not corrosion-protected.

c

Damage to product caused

by improper power supply voltage,

accident, fire, floods or acts of God.

WARRANTOR IS

RESPONSIBLE FOR

CONSEQUENTIAL DAMAGES.

va~

from state to state.

NOT

I

Pub.

6/92

No.

CG

49-7251

Warrantor: General Electric Company

If further help is needed concerning this warranty, write:

Manager—Consumer Affairs, GE Appliances, Louisville, KY 40225

Zoneline(’)

Heat Pump

31OO

serie~

Loading...

Loading...