Page 1

GE Oil & Gas

Technical Specifications

Masoneilan*

31000 Series Rotary

Control Valves

Eccentric Rotary Control Valves with PFA Liner

06/2013

Page 2

2 | GE Oil & Gas

Page 3

Table of Contents

Features .....................................................................................................................3

Numbering System .............................................................................................. 4

General Data

Connections

Pressure/Temperature Rating

............................................................................................................ 5

.............................................................................................................6

.......................................................................... 6

Features

Seat Leakage ........................................................................................................... 6

and FL ..................................................................................................................... 7

C

v

Materials of Construction ................................................................................... 8

Dimensions and Weight

................................................................................... 10

The 31000 Series control valve is a PFA lined, eccentric plug

control valve for corrosive applications which incorporates the

following features:

Excellent Performance

The eccentric rotary plug design provides excellent throttling

control accuracy, low dynamic forces and tight shut off. The

straight through flow pattern results in high fl ow capacities.

Corrosion Resistance

PFA lining with guaranteed minimum wall thickness provides

resistance to most corrosive fl uids.

Reduced Fugitive Emissions

The rotary design inherently reduces wear on the packing as

compared to a typical linear valve. Additionally, the standard

design includes PTFE/Graphite packing, chevron rings, backedup by a double O-ring follower to provide further reliability in

corrosive applications.

Ease of Maintenance

The compact dimensions and low weight design allows for easy

installation and removal without compromising piping forces.

Reliability

The dovetail grooves provide mechanical anchoring between

metal body and PFA lining to ensure high performance under

vacuum and at high temperature. The powerful, field proven

rolling diaphragm actuator provides positive fail-safe action. The

actuator linkage is totally enclosed that comes with a combination

handwheel and adjustable limit stop with locking mechanism.

All actuators are available with a complete line of options and

accessories.

31000 Series Rotary Control Valves | 3

Page 4

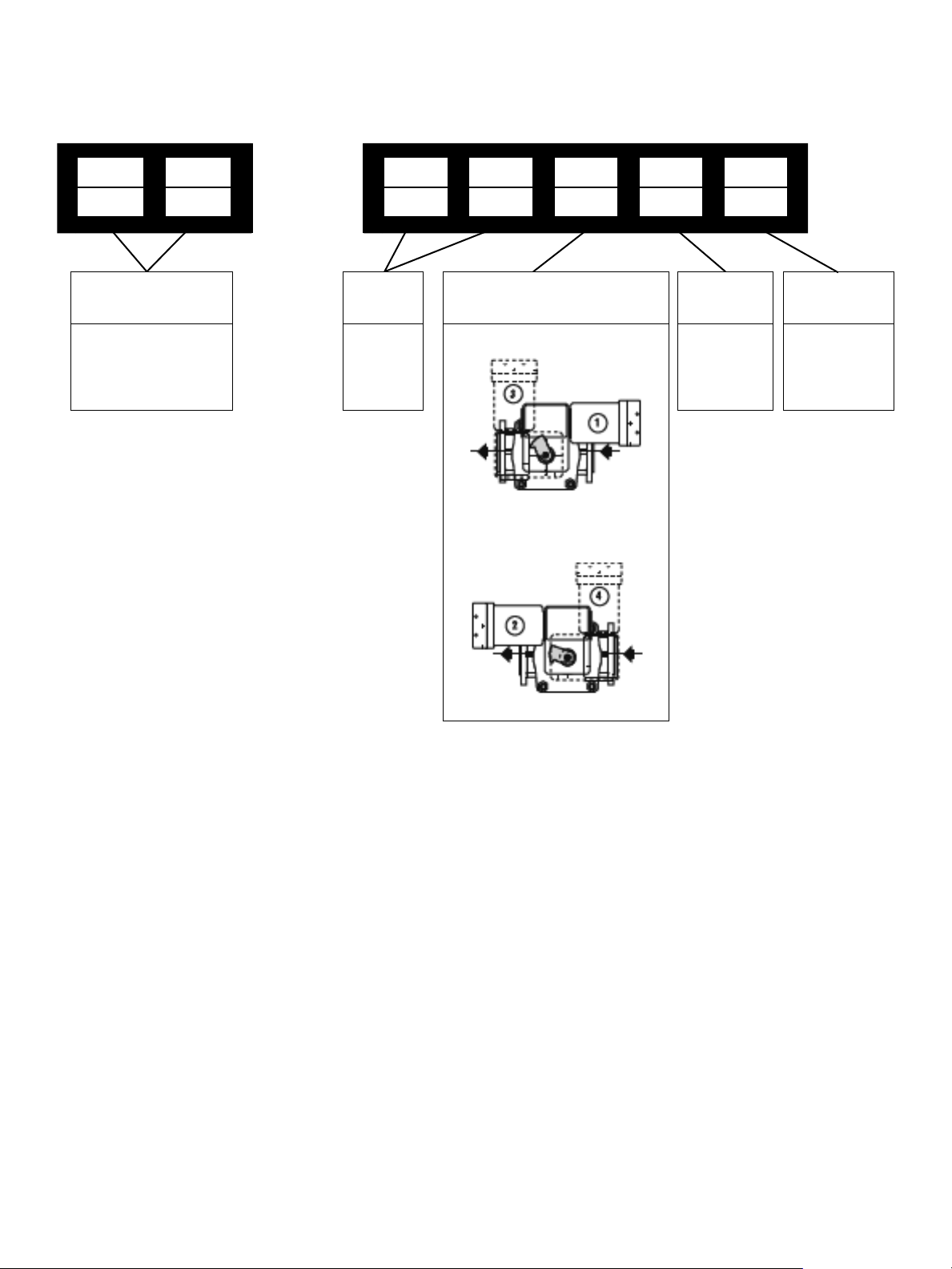

Numbering System

1st 2nd 1st 2nd 3rd 4th 5th

Actuator Type

35 Spring-opposed

rolling-diaphragm

—

—

Body

Series

31

3 1 0

Actuator Mounting

(Type 25 Only)

1 Parallel to pipeline, air to close

2

Parallel to pipeline, air to open

Seat

Material

1 PTFE

2

Special

Not Assigned

0

Note: Actuator positions 1 and 2 are standard configurations. View seen from actuator end. Other positions are available:

consult GE.

4 | GE Oil & Gas

Page 5

General Data

Body and Bonnet

Type: Cast, one piece, top entry,

Optional:

Material:

Lining:

Optional:

Connections:

Bonnet connection: Thr

Outside pr

otection: Epoxy coating

self fl ushing

with steam/hotw

jacket (SJ)

Nodular ductile ir

A, translucent, melt processed

PF

antistatic material

Flanged

ough-bolted

ater

on, heat treated

Trim

Plug type: Eccentrically rotating

Plug materials: PF

Seat ring type: Conical, sealed with O-ring

Seat ring material: Vir

Optional:

Optional:

* R

efer to specifi c actuator and accessory specifi cation literature

for complete information.

A coated stainless steel

gin PTFE

other materials

(consult GE)

PFE O-ring

Capacity:

Flow characteristic: Modifi ed linear

P

Optional:

C

v

acking:

ratio: 80:1

Full capacity and r

in all sizes

PTFE/Graphite, chevr

rings back

O-ring follower

leak detector or

flushing connection

ed up by a double

educed factor

on type

Flow Direction: Flow to close

Actuator:

Type: Spring-opposed rolling-diaphragm

Y

Optional:

*

oke:

(Model 35)

on

Cast ir

y handwheel/limit-stop

auxiliar

manual actuator (Model 20)

31000 Series Rotary Control Valves | 5

Page 6

Connections

Valve Size PN Connections ANSI Connections

Inches mm Flanges Face to Face

Dimensions

1, 2, 3 25, 50, 80 PN 10

1) Connections according to all standard PN (ISO, EN and equivalent national standards, AFNOR, BS, DIN, etc.)

2) Equivalent to DIN 3202/F1

3) Connections according to ANSI B16.5

(1)

PN 16

(125 AARH)

IEC 534-3

(2)

Table II

Flages Face to Face

(3)

150 RF

(125 AARH)

Pressure/Temperature Rating

Dimensions

ANSI B16.10

Globe Control

Valve

Vacuum operation within the same temperature range.

Seat Leakage

Leakage Class VI, according to IEC 534-4 and ANSI/FCI 70.2

6 | GE Oil & Gas

Page 7

CV and F

L

Valve Size Orifice Diameter Actuator Travel

Inches mm inl (mm) in. (mm)

- 3.5 (89) 0.64 1.2

- 3.5 (89) 0.64 2

- 3.5 (89) 0.64 3

1 25

2 50

3 80

- 3.5 (89) 0.64 4

.394 (10) 3.5 (89) 0.64 5

.472 (12) 3.5 (89) 0.64 8

.669 (17) 3.5 (89) 0.64 14

.827 (21) 3.5 (89) 0.64 20

- 3.5 (89) 0.64 10

.945 (24) 3.5 (89) 0.64 33

1.299 (33) 3.5 (89) 0.64 59

1.575 (40) 3.5 (89) 0.64 82

1.732 (44) 3.5 (89) 0.64 104

2.283 (58) 3.5 (89) 0.64 182

3.071 (71) 3.5 (89) 0.64 260

F

L

C

V

31000 Series Rotary Control Valves | 7

Page 8

Materials of Construction

Note: leak detector or fl ushing connection is optional

8 | GE Oil & Gas

Page 9

Materials of Construction

Ref. No. Description Standard Materials (Optional Materials)

1 Body Ductile Iron ASTM A395/PFA Lined

2 Bonnet Ductile Iron ASTM A395/PFA Lined

3 Plug PFA encapsulated Stainless Steel

4 Seat Ring

5 O-Ring

6 Packing PTFE/Graphite - Chevron Ring System

7 Packing Box Ring Stainless Steel

8 Disc Springs (Set) Spring Steel

9 Packing Follower Stainless Steel

10-11 O-Rings Viton

12 Actuator Connecting Flange Stainless Steel

13 Wiper Ring Neoprene

14-19 Bolting Stainless Steel

Virgin Solid PTFE

Other Materials (Consult GE)

FEP coated Viton

Perfl uoroelastomer (PFE)

®

®

31000 Series Rotary Control Valves | 9

Page 10

Dimensions and Weights

Dimensions (inches)

PN 10

PN 16

H

ANSI

Class

50

J K L

Valve Size A

Inch DN

1 25 6.30 7.25 6.93 11.81 8.31 6.42 5.52 4.61 3.15 3.62 10.04 2.05 7.28 40

2 50 9.06 10.00 6.93 11.81 8.31 6.42 5.52 4.61 4.53 5.00 10.63 3.07 7.87 60

3 80 12.21 11.75 6.93 11.81 8.31 6.42 5.52 4.61 6.10 5.87 11.42 3.94 8.66 97

* Including Handwheel

PN 10

PN 16

ANSI

Class

150

B C D E F G

Weight

(lbs)

*

10 | GE Oil & Gas

Page 11

Dimensions and Weights

Dimensions (millimeters)

PN 10

PN 16

H

ANSI

Class

50

J K L

Valve Size A

Inch DN

1 25 160 184 176 300 211 163 140 117 80 92 255 52 185 18

2 50 230 254 176 300 211 163 140 117 115 127 270 78 200 27

3 80 310 298 176 300 211 163 140 117 155 149 290 100 220 44

* Including Handwheel

PN 10

PN 16

ANSI

Class

150

B C D E F G

Weight

(kg)

*

31000 Series Rotary Control Valves | 11

Page 12

DIRECT SALES OFFICE LOCATIONS

BELGIUM

Phone: +32-2-344-0970

Fax:

+32-2-344-1123

BRAZIL

Phone:

+55-11-2146-3600

Fax:

+55-11-2146-3610

CHINA

Phone:

+86-10-8486-4515

Fax:

+86-10-8486-5305

FRANCE

Courbevoie

Phone:

+33-1-4904-9000

Fax:

+33-1-4904-9010

GERMANY

Ratingen

Phone:

+49-2102-108-0

Fax:

+49-2102-108-111

INDIA

Mumbai

Phone:

+91-22-8354790

Fax:

+91-22-8354791

New Delhi

Phone:

+91-11-2-6164175

Fax:

+91-11-5-1659635

ITALY

Phone:

+39-081-7892-111

Fax:

+39-081-7892-208

JAPAN Chiba

Phone:

+81-43-297-9222

Fax:

+81-43-299-1115

KOREA

Phone:

+82-2-2274-0748

Fax:

+82-2-2274-0794

MALAYSIA

Phone:

+60-3-2161-0322

Fax:

+60-3-2163-6312

MEXICO

Phone:

+52-5-310-9863

Fax:

+52-5-310-5584

THE NETHERLANDS

Phone:

+0031-15-3808666

Fax:

+0031-18-1641438

RUSSIA

Veliky Novgorod

Phone:

+7-8162-55-7898

Fax:

+7-8162-55-7921

Moscow

Phone:

F

ax:

S

AUDI ARABIA

Phone:

Fax:

+7 495-585-1276

+7 495-585-1279

+966-3-341-0278

+966-3-341-7624

SINGAPORE

Phone:

+65-6861-6100

Fax:

+65-6861-7172

SOUTH AFRICA

Phone:

+27-11-452-1550

Fax:

+27-11-452-6542

SOUTH and CENTRAL

AMERICA and the CARIBBEAN

Phone:

+55-12-2134-1201

Fax:

+55-12-2134-1238

SPAIN

Phone:

+34-93-652-6430

Fax:

+34-93-652-6444

UNITED ARAB EMIRATES

Phone:

+971-4-8991-777

Fax:

+971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone:

+44-1628-536300

Fax:

+44-1628-536319

UNITED STATES

Massachusetts

Phone:

+1-508-586-4600

Fax:

+1-508-427-8971

Corpus Christi, Texas

Phone:

+1-361-881-8182

Fax:

+1-361-881-8246

Deer Park, Texas

Phone:

+1-281-884-1000

Fax:

+1-281-884-1010

Houston, Texas

Phone:

+1-281-671-1640

Fax:

+1-281-671-1735

* Trademark of G eneral Elect ric Company

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2013 General El ectric Comp any. All rights r eserved.

GEA20234 06/2013

Loading...

Loading...