Page 1

INSTALLATION INSTRUCTIONS FOR YOUR NEW

30" ELECTRIC SLIDE-IN RANGE

Before you begin - Read these instructions completely and carefully.

IMPORTANT - Save these instructions for local inspector’s use.

IMPORTANT - OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Note to Installer - Be sure to leave these instructions with the Consumer.

Note to Consumer - Keep these instructions with your Use and Care Book for

future reference.

NOTE: This appliance must be properly grounded.

FOR YOUR SAFETY

CAUTION: For Personal

Safety remove house fuse or

open circuit breaker before

beginning installation. Failure

to do so could result in

serious injury or even death.

All rough-in and spacing dimensions must be

met for safe use of your range. Electricity to the

range can be disconnected at the outlet without

moving the range if the outlet is in the preferred

location (remove lower drawer).

To reduce the risk of burns or fire when reaching

over hot surface elements, cabinet storage

space above the cooktop should be avoided. If

cabinet storage space is to be provided above

the cooktop, the risk can be reduced by installing

a range hood that sticks out at least 5" beyond

the front of the cabinets. Cabinets installed

above a cooktop may be no deeper than 13".

Be sure your appliance is properly installed and

grounded by a qualified technician.

WARNING: To reduce the risk

of tipping the appliance, the

appliance must be secured by

properly installed anti-tip device

packed with the appliance.

STABILITY DEVICE

WARNING

• All Ranges Can Tip

• Injury To Persons Could

Result

• Install Anti-tip Device Packed

With Range

• See Installation Instructions

Remove all parts from the plastic bag found

inside the prepack of the oven and save

packaging tape.

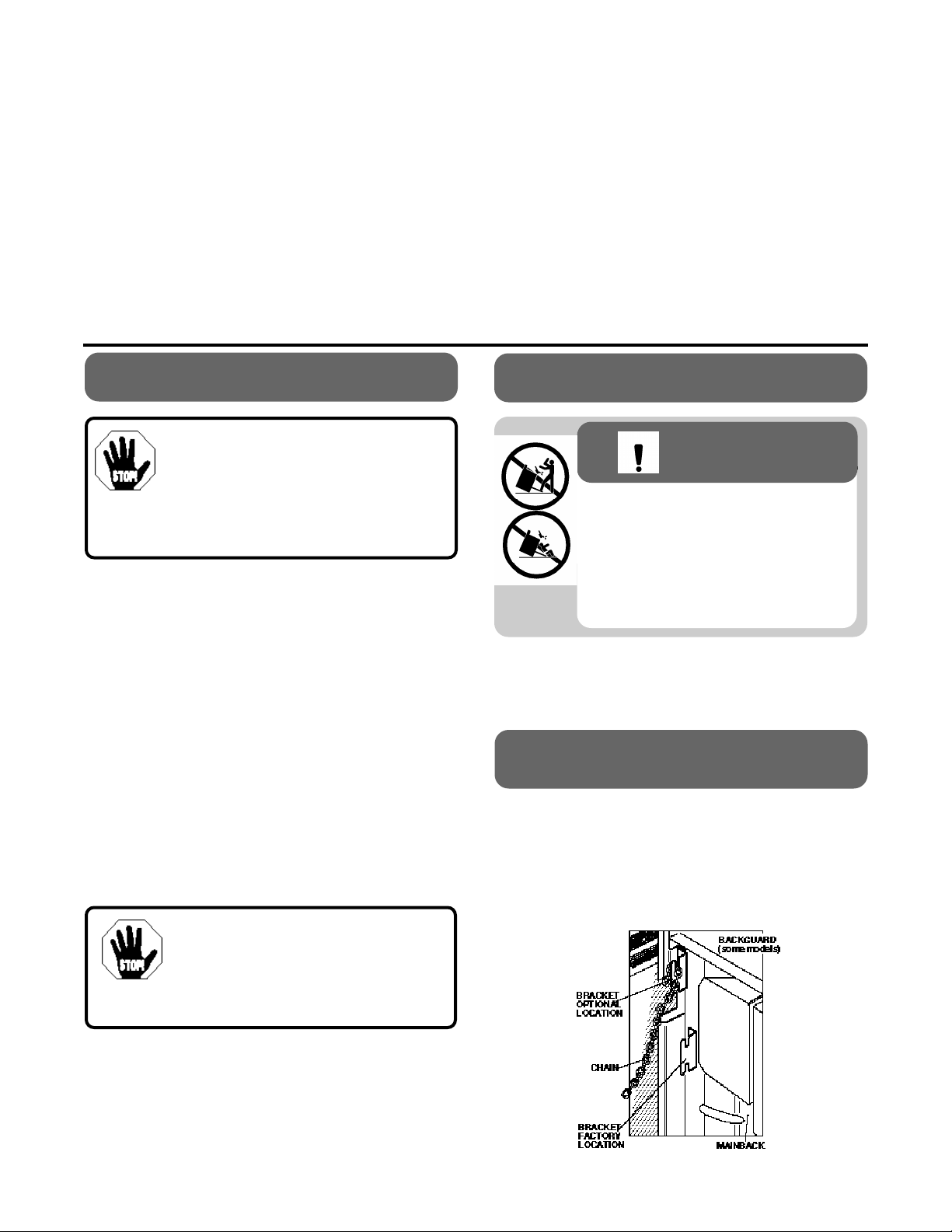

INSTALLATION OF THE

ANTI–TIP DEVICE

Before placing range in the counter, check the

factory location of the stability device on the

back of the range. For convenience you can

hook the stability chain in the upper set of

holes. Make sure there is no structural

interference when using the upper set of holes.

Fig. 1

INT303-6

Pub No. 31-10070

1

Page 2

1. Decide on a location

that has no electrical

wiring or plumbing.

2. With the long screw

provided anchor the

chain to the floor or

wall.

3. Make sure the screw

is going into the wall

plate or stud at the

base of the wall at

least 3/4".

4. Attach the stability

chain so that it lines

up with the bracket on the back of the range.

5. Tug the chain to make sure it is securely

fastened.

6. Take the packaging tape

and temporarily attach

the loose end of the chain

to the rear of the

countertop.

7. Slide the range into the

counter leaving enough

space behind to attach

the chain to the bracket.

8. Slip the nearest

link of the chain

onto the bracket.

Pull to make sure it

is as snug as

possible.

9. Slide the range all

the way back. It is

normal to have

some slack in the

chain, but it should

not be excessive.

TAPE

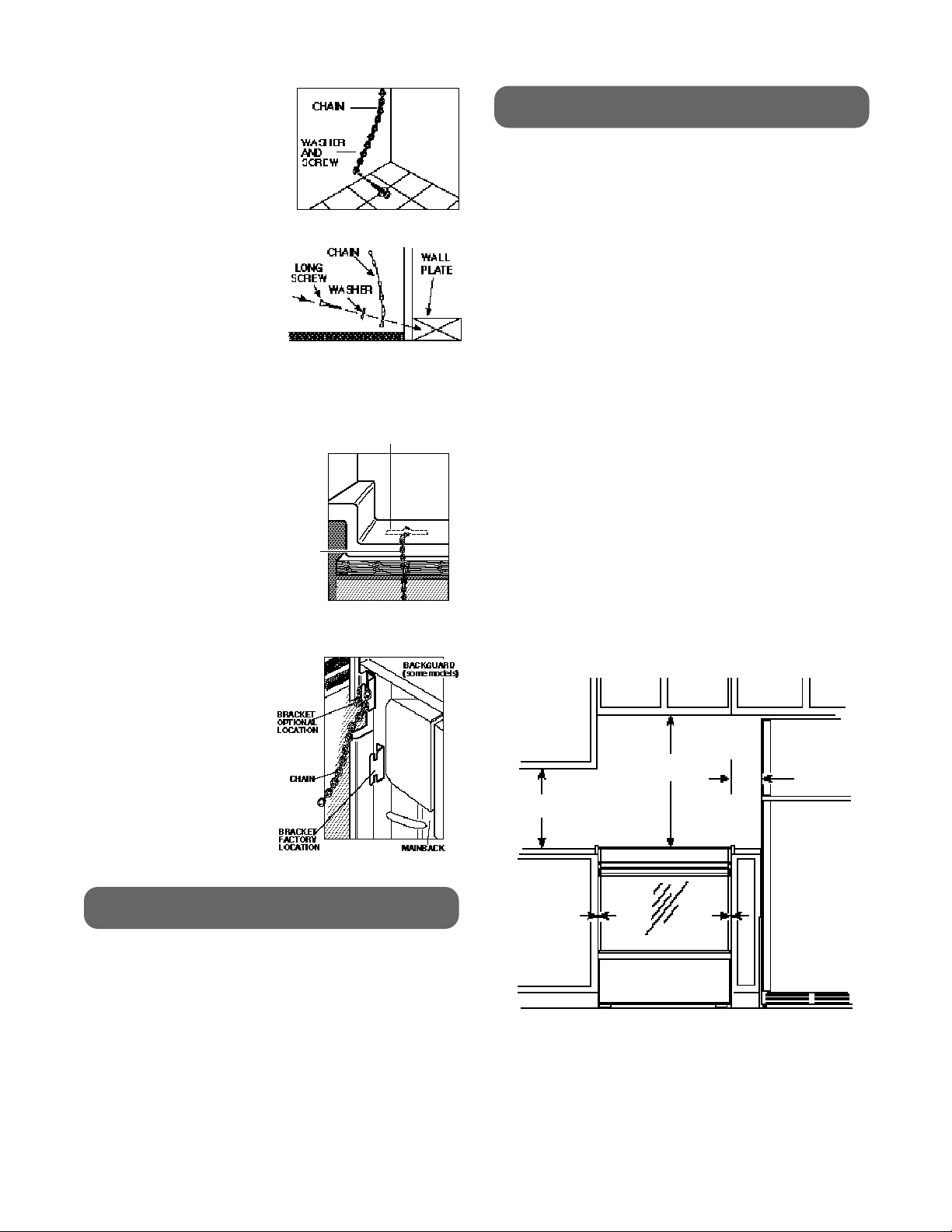

MINIMUM CLEARANCES

• The distance from the floor to the top of the

counter must be at least 35 7/8". The

maximum counter height is 38".

• 30" ranges conform to U.L. requirements for

0" spacing from vertical walls above

countertops. However, some kitchen cabinet

finishes can be damaged by heat from the

range surface elements. Where varnished

wood or plastic film finishes are used, a

minimum clearance of 6" must be maintained.

• For listed over-the-range microwave ovens,

the microwave ovens can be installed above

the cooktop as per manufacturer's installation

instructions.

• The range may be placed with 0" clearance

(flush) at the back wall and side walls if the

range side trims extend beyond the cabinet

fronts at least 1/4".

• See Figures 1 and 2 for all rough-in and

spacing dimensions. These dimensions must

be met for safe use of your range. The

location of the electrical outlet may be

changed as needed, but electricity to the

range can be disconnected at the outlet

without moving the range if the outlet is in the

suggested location (remove lower drawer).

Fig. 6

30" MIN

18" MIN

6"

MIN

TOOL LIST

• Hand or electric drill

• Hand or saber saw

• Pencil

• Tape measure

• Straightedge

• 1/8" drill bit

0"

MINIMUM DIMENSIONS BETWEEN COOKTOP

AND CABINETS OR WALLS

0"

2

Page 3

REMOVING PACKAGING

MATERIAL

Any packaging materials must

be removed during installation.

This will include adhesive tape, wire ties,

cardboard and protective plastic. Failure

to remove these materials could result in

damage to the appliance once the

appliance has been turned on and

surfaces have heated.

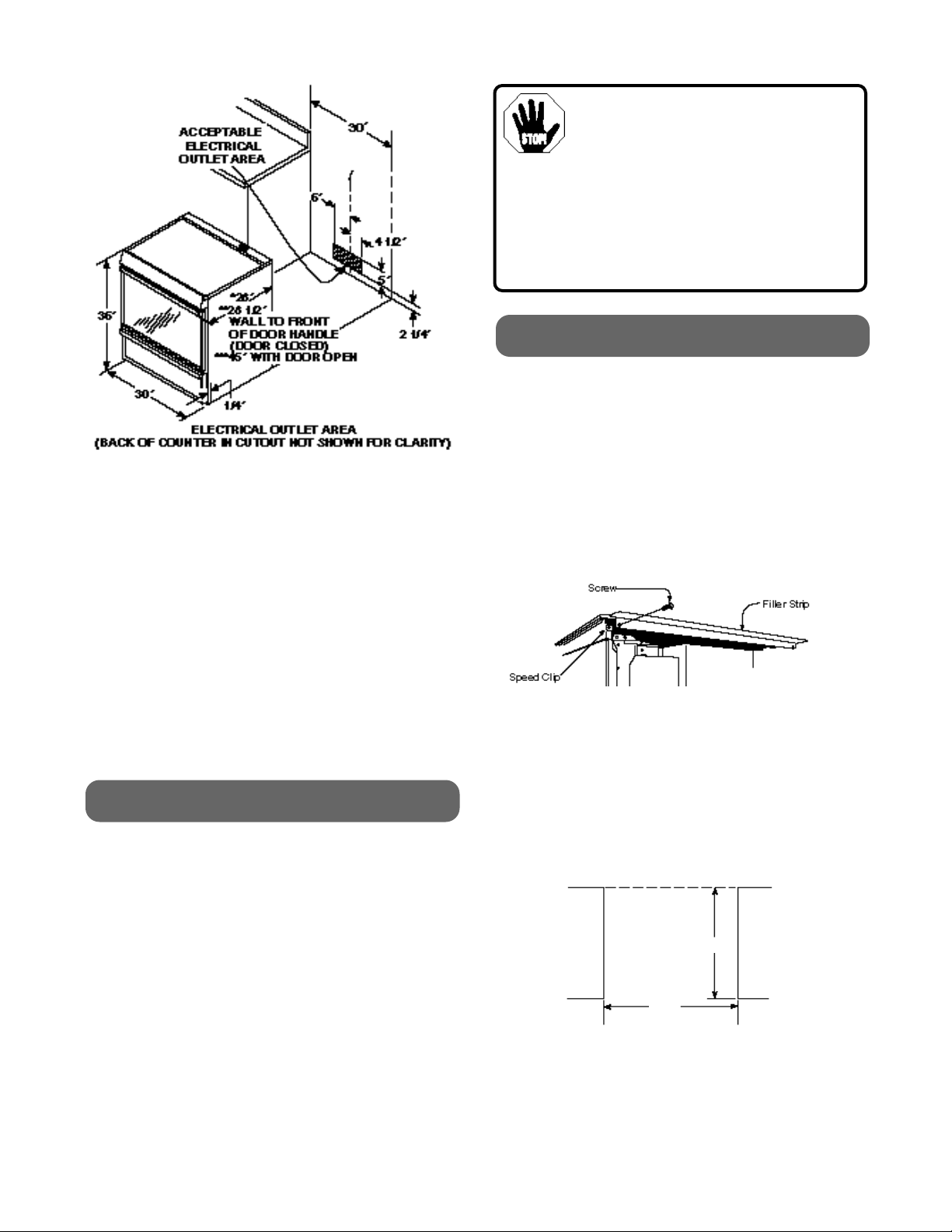

PREPARING THE COUNTER

FIG. 7

• The distance from the floor to the top of the

counter must be at least 35 7/8". The

maximum countertop height is 38".

Make sure the wall coverings, countertop and

cabinets around the cooktop can withstand the

heat (up to 200°F) generated by the range.

NOTE: Dimension for Wall to Front of Door

Handle (door closed).

*-28" FOR MODELS- JSP26, JSS26, JSC26,

JSS16, RS734, RS504

**- 28 1/2" FOR MODELS- JSP39, JSP38,

JSP31, JSP28,

RS744, RS622,

JS960, JSP40,

JSP34

PREPARATION

• Remove all tape and packaging. Be sure to

remove clear plastic film that covers some

chrome parts (around glass oven doors, side

trim) and any tape and packaging from inside

the oven.

• Take the accessory pack out of the oven.

• Check to be sure that no range parts have

come loose during shipping.

If you have an existing 30" wide cutout that goes

all the way to the wall, you have the option to buy

a 4" Backguard, Model #JXS31 (white), JXS32

(chrome), JXS33 (almond), JXS34 (black), or

JXS35 (bisque) or a Main Top Rear Filler Kit,

Model # JXS62BB (black), JXS63WW (white),

JXS64AA (almond), or JXS65CC (bisque).

These kits are available through your GE dealer,

if the existing cutout is in a counter that has a

backsplash (postformed top) we recommend that

you use the 4" backguard kit.

FIG. 8

Determine the dimension of your cutout. See

Fig. 9 and Fig. 10. Dimensions given are from

front of counter and not from cabinet face. To

minimize chipping you may want to apply

masking tape to the counter and mark the cut on

top of the tape. Use a hand or saber saw to

make the cut. For best appearance it is

important that the cut be smooth and straight.

If you are NOT using the Filler or Backguard:

23 3/16"

30"

FIG. 9

If you have a countertop deeper than 25" and

you wish to set the range further back into the

counter, the cutout may be cut deeper (up to 24

1/2"), but there must be at least 24 1/2" from the

front edge of the countertop and back wall.

3

Page 4

If you are using the Filler or Backguard:

25"

30"

NOTE: If the distance from the back wall to the

front of the counter backsplash (Dimension A in

Fig. 11) is greater than the standard 1 1/8", there

will be a small gap between the wall behind the

range and the backguard. This is normal and

should not be visually objectionable.

Fig.10

FIG. 11

SIDE TRIM EXTENSION KIT

If there is a small gap between the sides of the

range and the cabinets (up to 1/4" each side),

you can order a side trim extension kit,

Pub, #3-A040, through the GE service center.

ELECTRICAL CONNECTION

We recommend that you have the electrical

hookup of your range done by a qualified

electrician. Have the electrician show you

where your range disconnect is located.

Call your Electric Company and ask which

codes apply in your area. If there are no codes,

you must follow the NATIONAL ELECTRICAL

CODE, ANSI/NFPA NO. 70-Latest Edition.You

can get a copy by writing:

National Fire Protection Association

Battermarch Park

Quincy, MA 02269

Effective January 1, 1996, the National Electrical

Code requires that new or rewired construction

utilize a 4 conductor connection to an electric

range. When installing an electric range in a

new construction, follow the instructions in NEW

CONSTRUCTION AND FOUR-CONDUCTOR

BRANCH CIRCUIT CONNECTION.

If you fail to wire your range in accordance with

governing codes, you may create a hazardous

condition.

You must use a three-wire, single-phase AC

120/240 Volt or 208Y/120 Volt, 60 Hertz

electrical system to operate your range.

Use #8 wire and 40 Amp fuse or circuit breaker

for 120/240 Volt and 208Y/120 Volt systems.

The range connector block is approved for

copper wire connection only. If you are

connecting to aluminum house wiring, you must

use a special U.L. approved connector for

joining copper to aluminum.

4

Page 5

TO MAKE ELECTRICAL

CONNECTION

• Remove the junction block access cover (on

range back). See Fig. 12A or 12B. SOME

MODELS will have a one-piece wire cover

shown in Fig.12B. When re-installing one-piece

wire cover, make sure that wire does not

become pinched between wire cover and

mainback.

• Connect the red and black lead to the outside

terminals and the white lead to the center

terminal.

• Push the strain relief upward (to relieve

strain), while tightening the strain relief clamp.

• Re-install the junction block access cover

making sure that wire does not become

pinched between wire cover and mainback.

Fig. 13

Fig.12A

• All new constructions, mobile homes and

installations where local codes do not allow

grounding through neutral, require a four-wire

flexible cord kit. If the range is rated between

8,750 and 16,500 watts, the cord kit must be

rated for 40 Amps-125/250 volts. If the range is

rated between 16,501 and 22,500 watts, the

cord kit must be rated for 50 Amps-125/250

volts. For existing construction, a three wire

flexible cord kit may be used, and the same

ratings apply as described above.

• When using a cord rated 40 Amps, remove the

next to outermost knockout (1 3/8" diameter) in

the connection plate. Likewise, when using a

cord rated 50 Amps, remove the outermost

knockout (1 3/4" diameter) in the plate.

• Terminations shall be either closed loop

terminals or open-end spade lugs with

upturned ends. You must use a clamp or

strain relief to hold the cord.

Fig.12B

NEW CONSTRUCTION AND

FOUR-WIRE CORD CONNECTION

THREE-WIRE CORD CONNECTION

• Remove the screws on the terminal block.

• Install the three-wire cord and the strain relief

in the hole in the strain relief bracket.

• Connect the outer leads to the outer terminals

and the center lead to the center terminal.

• Push the cord upward, (to relieve strain), while

tightening the strain relief clamp.

If local codes require an ungrounded neutral:

a. Remove ground strap.

b. Fasten the white wire to the center terminal.

c. Use grounding terminal or lead to ground unit

in accordance with local codes.

• Re-install the wire cover making sure that the

wire does not become pinched between wire

cover and mainback.

Fig. 14

• Remove the screws on the terminal block.

• Remove the ground screw, then remove the

ground strap.

• Install the four-wire cord and strain relief in the

hole in the strain relief bracket.

• Attach the green lead below the junction block

with the ground screw that was removed earlier

5

Page 6

OVEN DOOR REMOVAL

LEVELING THE RANGE

Before installing the range, you may remove the

oven door to lessen the weight of the unit. DO

NOT lift unit by door handle.

To remove oven door:

1. Open the door to the stop position. See

Fig. 15A.

2. Grasp the door at each side and lift up and off

the hinges. See Fig. 15B.

Fig. 15A

Fig. 15B

For proper cooking and baking the range must

be leveled. Do not place range in cutout until

you are sure that the flanges below the sides of

the cooktop are above the top of the counter.

Lift cooktop to see flanges. Damage to the

cooktop could result if adjusted improperly.

a. Install the oven racks (see use and care

section for instructions).

b. Use a 1 3/8" open end wrench or an

adjustable wrench to equally back out

the four leg levelers until the flanges

(rims) below the sides of the maintop are

above the top of the counter. Check by

measuring the height of the counter and

comparing it with the measurement from

the floor to the flanges below the sides of

the cooktop. Place range in cutout when

adjustments are complete.

CAUTION: When the door is

removed and hinge arms are at

stop position, do not bump or

try to move the hinge arms.

The hinges could snap back

causing an injury to the hands or damage to the porcelain on the front of the

oven. Cover the hinges with toweling or

insert empty towel rolls behind the

hinges while working in the oven area.

Fig. 16

c. Put a spirit level or a glass measuring

cup partially filled with water on one of

the oven racks. See Fig. 17.

d. Use the wrench to adjust the leg levelers.

Level range front to back and side to

side. See Fig. 16.

Fig. 17

6

Page 7

IMPORTANT INSTALLATION INSTRUCTIONS FOR

Build the filler as shown in Fig.19. Make sure to

provide the 3/4" gap at the top and the 5/16" gap

at the bottom. These gaps will provide the

proper ventilation as mentioned before.

If you wish to attach the filler to the floor or

adjacent cabinets, use screws or other

removable fasteners, so that the range can be

readily removed if necessary.

RANGES USED WITH COUNTERTOP HEIGHTS UP TO 38"

The height of the range must be adjusted to the

countertop height. For countertop heights

greater than 37", additional measurements may

need to be taken as detailed below.

When the range is elevated to the maximum

height, there is a large space between the

bottom of the range and the floor, referred to as

the toe space. This may be visually

objectionable. The legs should not be extended

any further than to provide a maximum of 3" toe

space. See Fig. 18.

The range is designed to provide a minimum of

1" air gap at the bottom of the range. See Fig.

19. (Example: When legs are screwed all the

way into the base rail.)

Fig. 19

Fig. 20

1" MIN. HEIGHT

Fig. 18

This gap is very important to the proper

ventilation of the range and must be maintained

when treating the appearance of the toe space.

The following is a suggested method of making a

filler for the toe space when the legs are

extended as mentioned before.

After the range is installed with the longer legs

and is in position and level, measure from the

bottom of the bodyside to the floor. This will be

the required height of the toe space filler. See

Fig. 19. This height may range from 2 1/16" to

3". Any height less than 2 1/16" may not be

visually objectionable and not need the filler.

3" MAX. HEIGHT

7

Loading...

Loading...