Page 1

Brine Valve PN 3020511

Installation Manual

• Unique mechanical structure developed according to

scientific principles providing the best reliability.

• Highly expandable interface with replacement

fittings, to coordinate different uses of the control

valve.

• Adjustments are designed for ease of use and fast set-

up.

• Flow control is regulated by the body. Brine valve is

suitable for most water conditioning systems.

Specifications

Dimensions:

32" high unit: 3.2" L x 2.8" W x 27.38" H

(80 mm x 71 mm x 695 mm)

Rated Pressure: 20 - 120 psi (0.14 - 0.83 MPa)

Temperature Range: 34 - 140°F (1 - 60°C)

Used Media: Clean municipal water or

brine

Max. Refill Water FLow: 1.2 GPM (4.5 L/m)

Thank you for choosing the GE Safety Brine Valve. For a

complete water conditioner system, a brine valve is

indispensable for system protection and regeneration, as

well as ensuring the best water conditions.

The innovative design of the Brine Valve provides safe and

reliable performance, and is suitable for household and

commercial conditioner systems. This manual will help

you better understand the structure and properties of the

valve and will guide you through the installation.

We urge you to read this manual carefully and refer to it

any time a malfunction occurs. The Troubleshooting Table

highlights minor problems that you can correct yourself.

Overview

The brine valve is suitable for household use. For a water

conditioner system, the brine valve has two principal

functions:

Air Check function - During system regeneration or a slow

rinse period, the brine valve prevents air from being pulled

into the resin tank, thereby ensuring the system’s

performance.

Max. Brine Flow: 1.0 GPM (3.7 L/m)

Materials:

Main Valve: ABS & PE

Seal: Chlorine/Chloramines

resistant silicone rubber

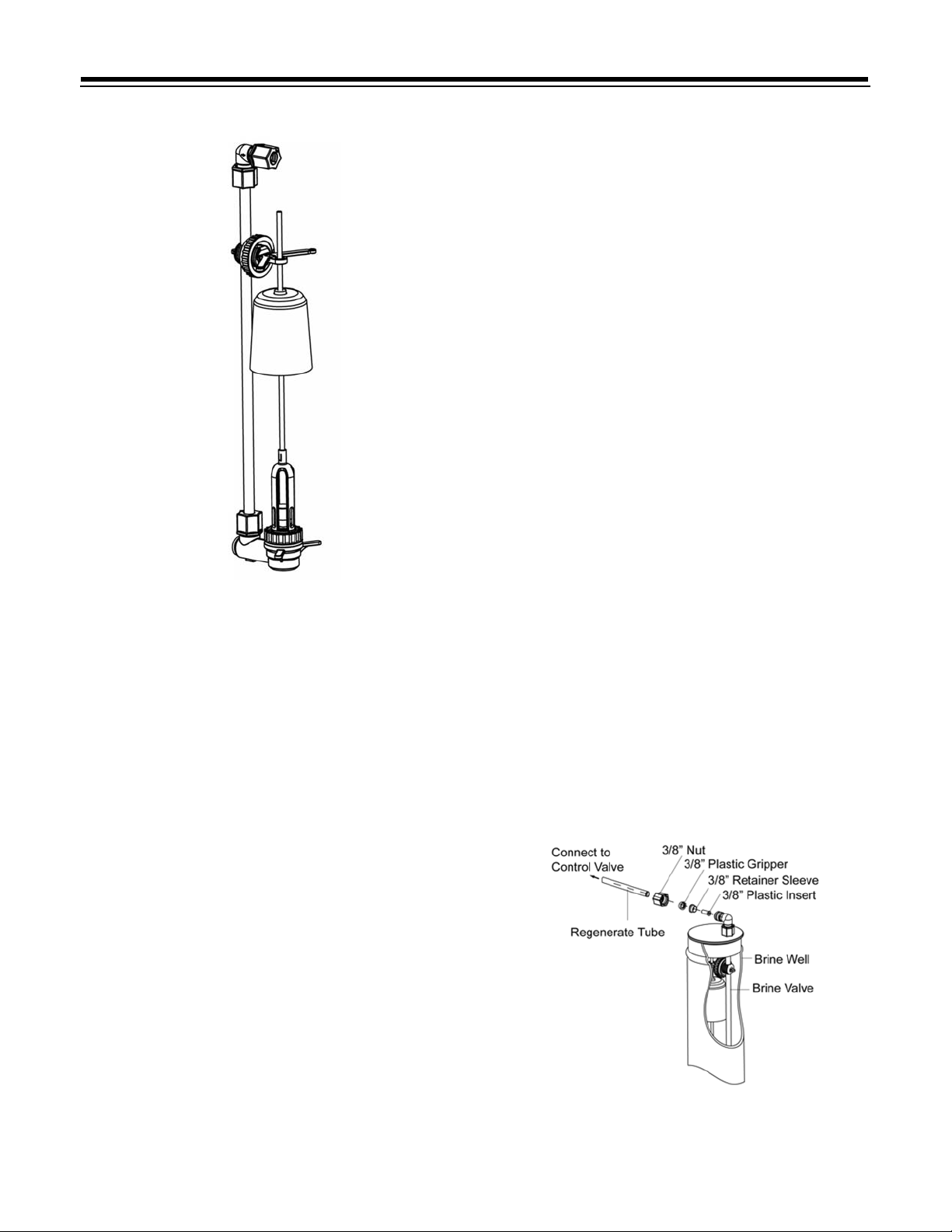

Regenerant Tube Connection

The brine valve is compatible with a 3.5" (90 mm) GE brine

well, see Figure 1. The regenerant tube links the control

valve and the brine valve. Place one end of the right angle

elbow through the hole of the brine well. Slide the nut,

retaining sleeve and plastic gripper over the regenerant

tube. Insert the inner tube support and connect the

regenerant tube to the elbow. Finally, connect the other

end of the regenerant tube to the control valve.

Refill Protection - “over-refill” may occur if the control

valve was set incorrectly or a system failure occurs. If this

happens, the brine valve is a protective device against

overfilling the brine tank.

Product Features

• Positive automatic opening and closing of the valve by

using vacuum or pressure.

Figure 1

Page 2

Brine Valve PN 3020511

Brine Well Installation

1. The brine well should be vertically installed in the

regenerant tank.

2. All connections should be manually tightened to

ensure a solid connection. DO NOT over tighten plastic

parts with a wrench, or you might damage plastic

components.

3. Set the postion of the brine valve float . The float

should be positioned 0.8" - 2" (20 - 50 mm) above the

brine surface level or as required for application.

CAUTION: DO NOT use petroleum based lubricants such as

vaseline, oils, or hydrocarbon based lubricants. Use only

100% silicone lubricant.

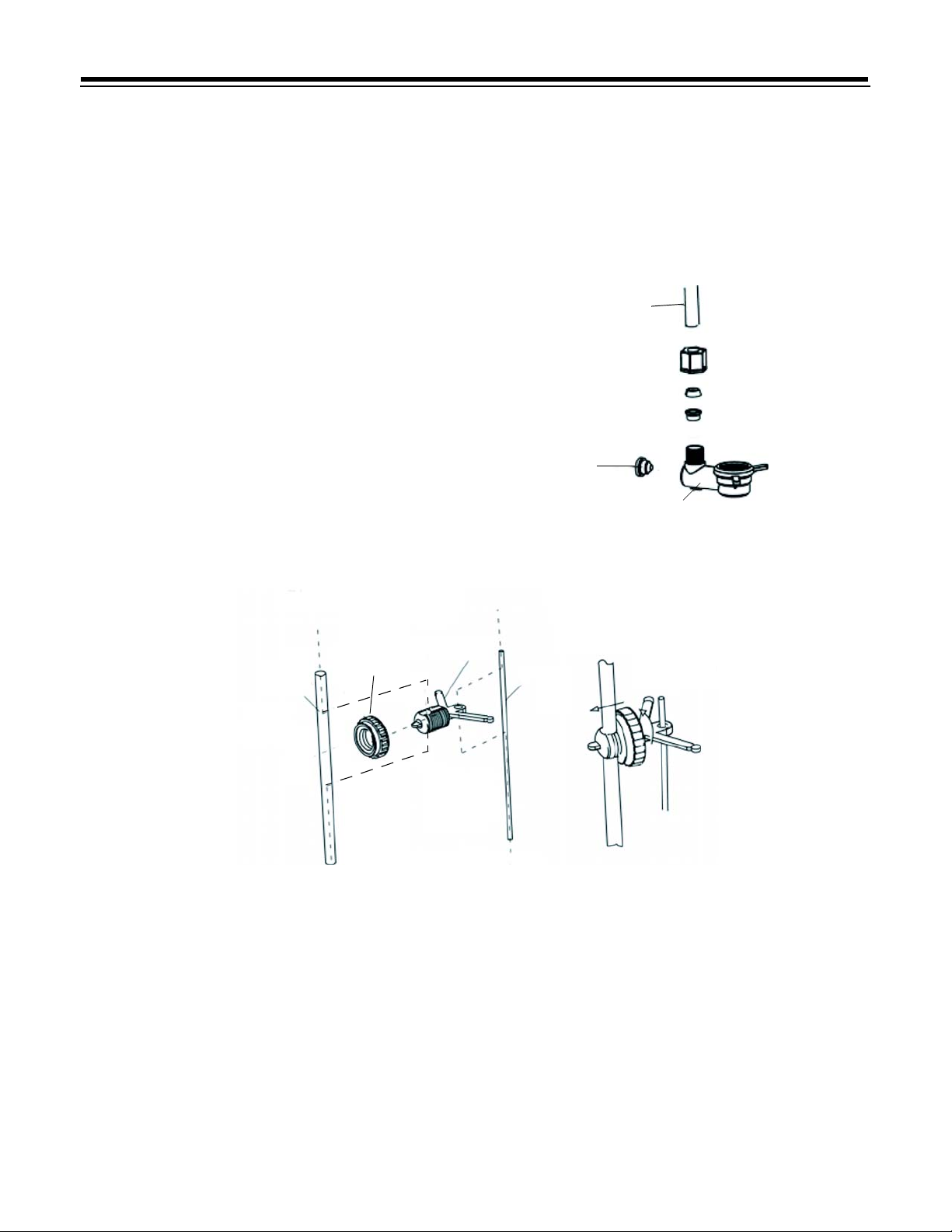

Operation

The brine valve will work with the control valve to

automatically control the water level in the brine tank.

Another unique feature of the brine valve is the ability to

adjust the top support. The top bracket can be moved up

or down by loosening the lock nut. Hand tighten the

locknut.

Regenerant Tube

Base Plug

Valve Base

Figure 2

Regenerant Tube - 3/8"

Disassembly

Adjust Bracket

1/2” Lock Nut

Figure 3

Plastic Tube

Assembly

Arrow Direction to T ighten

2

Page 3

Troubleshooting

Problem Possible Cause Solutions

Brine Valve PN 3020511

No water refill into the

salt tank

Excessive refill Seal leak or failure Check for debris on seal.

System uses less brine

than the regnerate

setting

Brine valve not operating Check that the brine valve is vertical and

moving freely.

Water flow is greater than 1.2 gpm

(4.5 L/m). Replace the refill control

washer with a smaller inside diameter

washer.

Check to see if there is too much air in

the resin tank.

Obstruction in regenerant tube or valve Inspect pipline, remove any debris.

Damaged brine valve Replace brine valve.

Replace the seal.

The float does not close off incoming water Float is restricted by the bracket. Raise

top bracket to allow more space for float

movement .

Damaged brine valve Replace brine valve.

Air leak Inspect pipeline and repair leaks.

Regenerant tube is too long Be sure the length is less than 6.6 ft (2 m).

Brine valve is set incorrectly Check and adjust floater to appropriate

height.

Be sure the refill controller is an

appropriate size.

The check ball was pulled at wrong time Remove the check ball enclosure.

3

Page 4

Parts

Brine Valve PN 3020511

9

10

11

No. Description No. Description

1 Threaded connector 13 1/2-inch Lock nut

2 O-Ring, 22 x 1.8 14 3/8-inch Elbow

3 Regenerant tube 15 Pole base

4 Air check seal 16 Check ball

5 Float 17 Plastic pole

6 Rubber stop 18 Inner air check seal

7 Valve base 19 Inner connector

8 Base plug 20 Inner check ball enclosure

9 3/8-inch Retainer sleeve 21 Inner tube support

10 3/8-inch Plastic gripper 22 Fastener ring

11 3/8-inch Nut 23 Inner check seal retainer

12 Support bracket

© Copyrig ht 2007 GE Water & Process Technologies

P/N 3020 577 Rev C

Loading...

Loading...