Page 1

SAFETY PRECASAFETY PRECA

SAFETY PRECA

SAFETY PRECASAFETY PRECA

SERSER

VICE VICE

SER

SERSER

Only qualified service technicians who are familiar with safety checks

and guidelines should perform service work. Before replacing parts,

disconnect power source to protect electrostatically sensitive parts. Do

not attempt to modify any circuit unless so recommended by the

manufacturer. When servicing the receiver, use an isolation transformer

between the line cord and power receptacle.

SERSER

SER

SERSER

Use EXTREME CAUTION when servicing the high voltage circuits. To

discharge static high voltage, connect a 10K ohms resistor in series with a

test lead between the receiver ground and CRT anode lead. DO NOT lift

the CRT by the neck. Always wear shatterproof goggles when handling

the CRT to protect eyes in case of implosion.

X-RAX-RA

X-RA

X-RAX-RA

Be aware of the instructions and procedures covering X-ray radiation. In

solid-state receivers and monitors, the CRT is the only potential source of

X-rays. Keep an accurate high voltage meter available at all times. Check

meter calibration periodically. Whenever servicing a receiver, check the

high voltage at various brightness levels to be sure it is regulating

properly. Keep high voltage at rated value, NO HIGHER. Excessive high

voltage may cause X-ray radiation or failure of associated components.

DO NOT depend on protection circuits to keep voltage at rated value.

When troubleshooting a receiver with excessive high voltage, avoid close

contact with the CRT. DO NOT operate the receiver longer than

necessary. To locate the cause of excessive high voltage, use a variable

AC transformer to regulate voltage. In present receivers, many electrical

and mechanical components have safety related characteristics which are

not detectable by visual inspection. Such components are identified by a

# on both the schematic and the parts list. For SAFETY, use only

equivalent replacement parts when replacing these components.

GENERAL GUIDELINESGENERAL GUIDELINES

GENERAL GUIDELINES

GENERAL GUIDELINESGENERAL GUIDELINES

Perform a final SAFETY CHECK before returning receiver to customer.

Check repaired area for poorly soldered connections, and check entire

circuit board for solder splashes. Check board wiring for pinched wires or

wires contacting any high wattage resistors. Check that all control knobs,

shields, covers, grounds, and mounting hardware have been replaced. Be

sure to replace all insulators and restore proper lead dress.

WARNINGWARNING

VICE

WARNING

VICE VICE

WARNINGWARNING

VICING VICING

VICING

VICING VICING

Y RADIAY RADIA

Y RADIA

Y RADIAY RADIA

THE HIGH THE HIGH

THE HIGH

THE HIGH THE HIGH

TION AND HIGH TION AND HIGH

TION AND HIGH

TION AND HIGH TION AND HIGH

VV

OLOL

V

OL

VV

OLOL

TT

AA

GE AND CRGE AND CR

T

A

GE AND CR

TT

AA

GE AND CRGE AND CR

VV

OLOL

TT

V

OL

T

VV

OLOL

TT

TT

T

TT

AA

GE LIMITSGE LIMITS

A

GE LIMITS

AA

GE LIMITSGE LIMITS

UTIONSUTIONS

UTIONS

UTIONSUTIONS

SAFETY CHECKS — FIRE AND SHOCK HAZARDSAFETY CHECKS — FIRE AND SHOCK HAZARD

SAFETY CHECKS — FIRE AND SHOCK HAZARD

SAFETY CHECKS — FIRE AND SHOCK HAZARDSAFETY CHECKS — FIRE AND SHOCK HAZARD

Cold LeakaCold Leaka

Cold Leaka

Cold LeakaCold Leaka

Unplug the AC cord, connect a jumper across the plug prongs, and turn

the power switch on (if applicable). Use an ohmmeter to measure the

resistance between the jumped AC plug and any exposed metal cabinet

parts such as antenna screw heads, control shafts, or handle brackets.

Exposed metal parts with a return path should measure between 1M

ohms and 5.2M ohms. Parts without a return path must measure infinity.

Hot LeakaHot Leaka

Hot Leaka

Hot LeakaHot Leaka

Plug the AC cord directly into an AC outlet. DO NOT use an isolation

transformer. Use a 1500 ohms, 10W resistor in parallel with a .15µF

capacitor to connect between any exposed metal parts on the receiver and

a good earth ground. (See figure below.) Use an AC voltmeter with at

least 5000 ohms per volt sensitivity to measure the voltage across the

resistor. Check all exposed metal parts and measure voltage at each point.

Voltage measurements should not exceed .75VAC, 500µA. Any value

exceeding this limit constitutes a potential shock hazard and must be

corrected. If the AC plug is not polarized, reverse the AC plug and repeat

exposed metal part voltage measurement at each point.

gg

e Chece Chec

e Chec

e Chece Chec

ks fks f

ks f

ks fks f

g

gg

gg

e Current Chece Current Chec

g

e Current Chec

gg

e Current Chece Current Chec

or Receiveror Receiver

or Receiver

or Receiveror Receiver

kk

k

kk

s with Isolated Grs with Isolated Gr

s with Isolated Gr

s with Isolated Grs with Isolated Gr

oundound

ound

oundound

4715

SET 4715SET 4715

SET 4715SET 4715

SET 4715

Y1/Y7)Y1/Y7)

Y1/Y7)Y1/Y7)

Y1/Y7)

Error Codes Chart .................................. 1

GridTrace Location

High Voltage Shutdown Test .................. 1

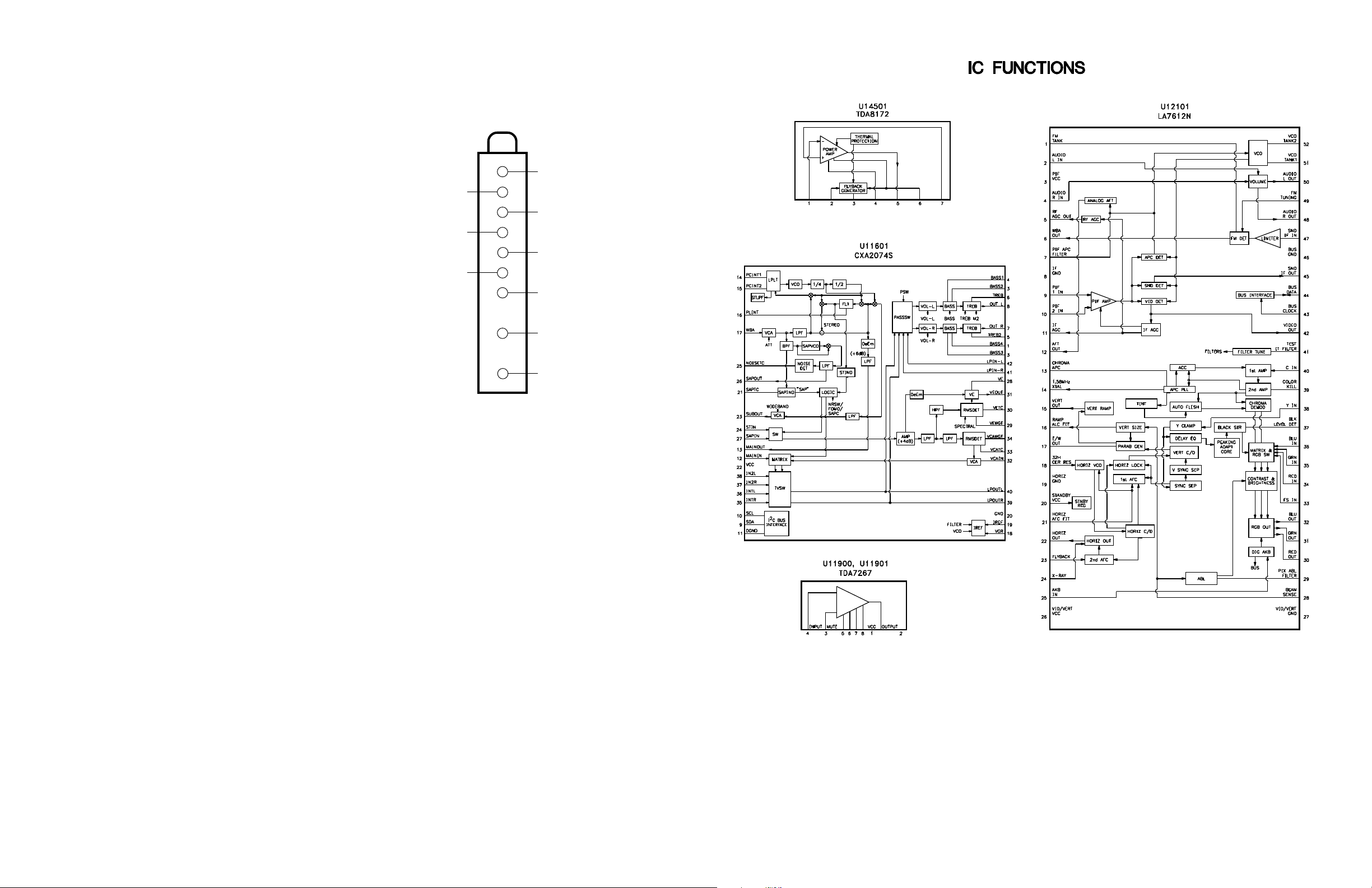

IC Functions ........................................... 1

Important Parts Information ................... 2

Miscellaneous Adjustments .................... 1

Parts List ................................................. 4

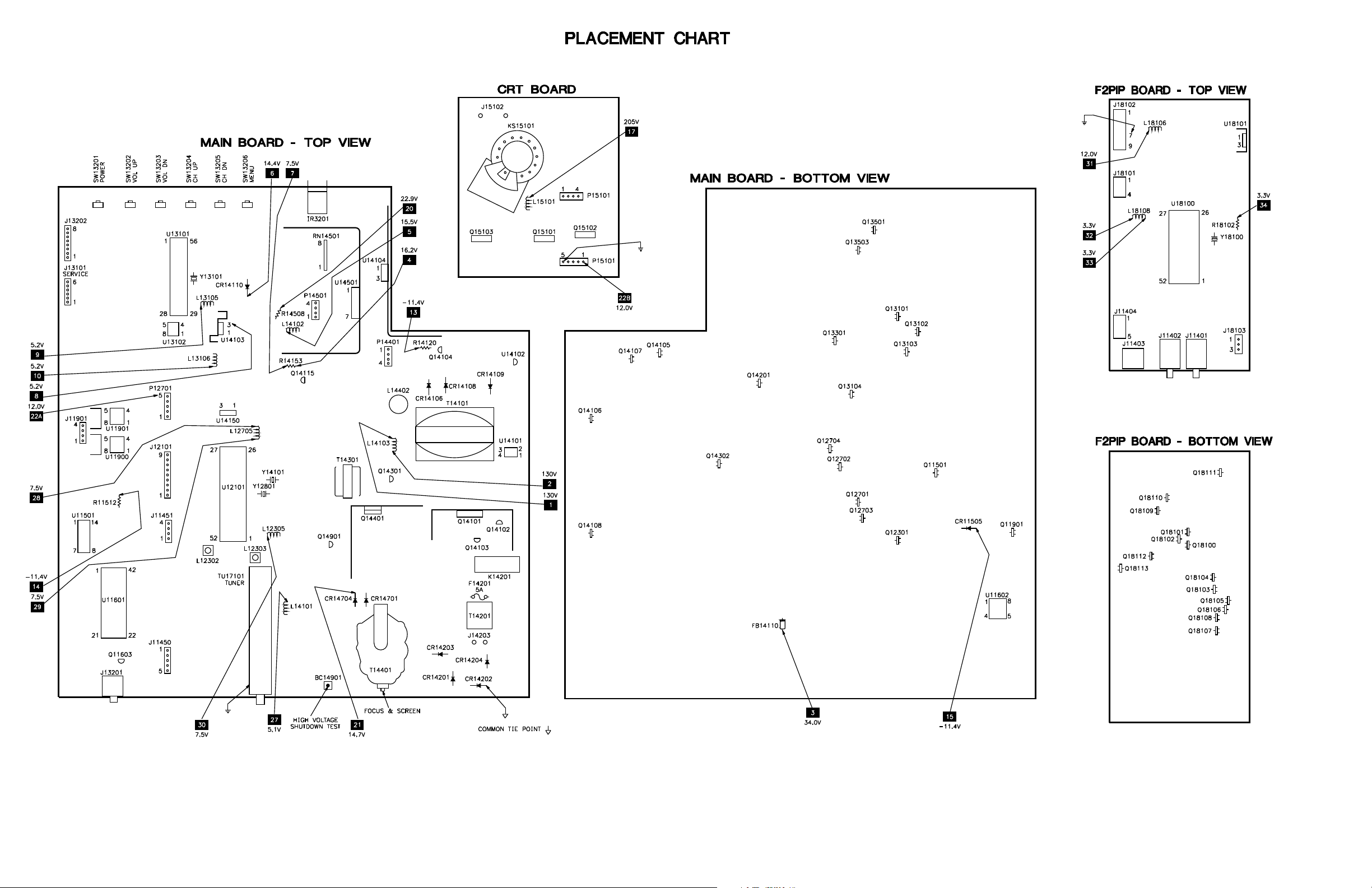

Placement Chart ..................................... 1

Safety Precautions .................................. 1

Schematic Component Location ............ 3

Schematic Notes ..................................... 2

Schematics

Test Equipment....................................... 2

Tuner Information .................................. 1

INDEXINDEX

INDEX

INDEXINDEX

Main Board ..................................... 4

Audio ............................................... 3

PIP ................................................... 3

Power Supply .................................. 2

System Control ................................ 3

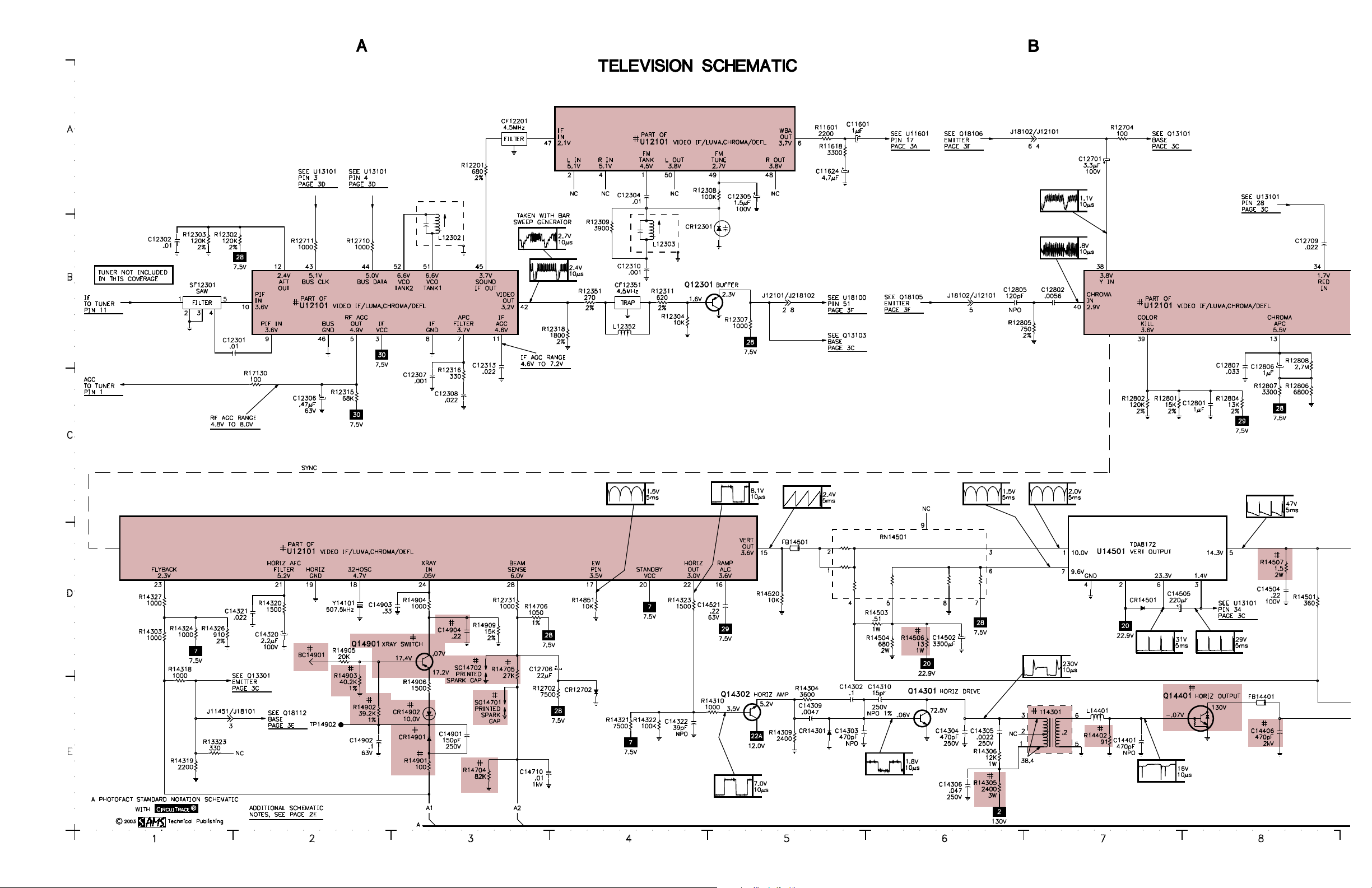

Television ........................................ 2

Technical Service Data

GEGE

GE

GEGE

Model 27GT716YX1 (Chassis CTC203AModel 27GT716YX1 (Chassis CTC203A

Model 27GT716YX1 (Chassis CTC203A

Model 27GT716YX1 (Chassis CTC203AModel 27GT716YX1 (Chassis CTC203A

Representative Model

ff

or seror ser

f

or ser

ff

or seror ser

Essential coEssential co

Essential co

Essential coEssential co

vicing a televicing a tele

vicing a tele

vicing a televicing a tele

ScSc

hematicshematics

•

Sc

hematics

ScSc

hematicshematics

veravera

gg

vera

veravera

vision receivervision receiver

vision receiver

vision receivervision receiver

ee

g

e

gg

ee

Y1/Y7)Y1/Y7)

Y1/Y7)

Y1/Y7)Y1/Y7)

......

...

......

4715

4715

HIGH HIGH

VV

OLOL

TT

AA

HIGH

V

HIGH HIGH

VV

Momentarily short BC14901 (see Q14901 base) to ground. The receiver should lose raster and sound. If

receiver does not lose raster and sound, the shutdown circuit should be repaired. To resume normal

operation, remove AC power for approximately 30 seconds and then turn the receiver on.

The listing of any available replacement part herein in no case constitutes a recommendation, warranty, or guarantee by

SAMS Technical Publishing as to the quality and suitability of such replacement part. The numbers of the listed parts have

been compiled from information furnished to SAMS Technical Publishing by the manufacturers of the specific type of

replacement part listed.

Reproduction or use, without express permission, of editorial or pictorial content, in any manner, is prohibited. No patent

liability is assumed with respect to the use of the information contained herein.

© 2003

5436 West 78th Street

Indianapolis, IN 46268-4149

Printed in the United States of America 5 4 3 2 1

PP

aa

gg

e 1e 1

a

g

e 1

aa

gg

e 1e 1

SET 4715 SET 4715

SET 4715

SET 4715 SET 4715

P

PP

GE SHUTDOGE SHUTDO

OL

T

A

GE SHUTDO

OLOL

TT

AA

GE SHUTDOGE SHUTDO

WN WN

TESTTEST

WN

TEST

WN WN

TESTTEST

03PF02087

UPC

HERE

MODEL 27GT716YX1 (CHASSIS CTC203AMODEL 27GT716YX1 (CHASSIS CTC203A

MODEL 27GT716YX1 (CHASSIS CTC203AMODEL 27GT716YX1 (CHASSIS CTC203A

MODEL 27GT716YX1 (CHASSIS CTC203A

GEGE

GEGE

GE

For Supplier AdFor Supplier Ad

For Supplier Ad

For Supplier AdFor Supplier Ad

See PHOSee PHO

See PHO

See PHOSee PHO

TT

T

TT

OFOF

OF

OFOF

AA

CT AnnCT Ann

A

CT Ann

AA

CT AnnCT Ann

dress,dress,

dress,

dress,dress,

ual Indeual Inde

ual Inde

ual Indeual Inde

xx

x

xx

Component locationsComponent locations

•

Component locations

Component locationsComponent locations

PP

arar

ts listts list

•

P

ar

ts list

PP

arar

ts listts list

APRIL APRIL

APRIL

APRIL APRIL

2003 SET 4715 2003 SET 4715

2003 SET 4715

2003 SET 4715 2003 SET 4715

Page 2

PP

aa

gg

e 1e 1

g

e 1

gg

e 1e 1

SET 4715 SET 4715

SET 4715

SET 4715 SET 4715

P

a

PP

aa

TUNER INFORMATION

TUNER TUNER

TUNER

TUNER TUNER

PinPin

Pin

PinPin

(1) AGC 2.4V 2.3V 2.8V

(2) TU 1.3V 4.2V 5.5V

(3) +5V 5.1V 5.1V 5.1V

(4) CLK 5.1V 5.1V 5.1V

(5) DATA 5.1V 5.1V 5.1V

(6) +5V 5.1V 5.1V 5.1V

(7) +5V 5.1V 5.1V 5.1V

(9) +32V 34.0V 34.0V 34.0V

(11) IF 0V 0V 0V

NOTE: VHF Low Band voltages taken on channel 2.

VHF LoVHF Lo

VHF Lo

VHF LoVHF Lo

VHF High Band voltages taken on channel 7.

UHF Band voltages taken on channel 14

w Bandw Band

w Band

w Bandw Band

VV

OLOL

TT

V

OL

T

VV

OLOL

TT

AA

GE CHARGE CHAR

A

GE CHAR

AA

GE CHARGE CHAR

VHF High BandVHF High Band

VHF High Band

VHF High BandVHF High Band

TT

T

TT

UHF BandUHF Band

UHF Band

UHF BandUHF Band

TUNER TUNER

TUNER

TUNER TUNER

(2)

(4)

(6)

TERMINAL GUIDETERMINAL GUIDE

TERMINAL GUIDE

TERMINAL GUIDETERMINAL GUIDE

(1)

τ

τ

(3)

τ

τ

(5)

τ

τ

(7)

τ

(9)

τ

(11)

τ

Page 3

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 1e 1

a

g

e 1

aa

gg

e 1e 1

MISCELLANEOUS ADJUSTMENTS

NOTE: All procedures require an antenna connected and power applied to

the set.

HIGH HIGH

VV

OLOL

TT

AA

HIGH

V

HIGH HIGH

VV

Tune in a picture. Set brightness, contrast, and color to minimum. Connect

a high voltage probe to the CRT anode. High voltage should be 27kV to

29kV.

SERSER

VICE MENUVICE MENU

SER

VICE MENU

SERSER

VICE MENUVICE MENU

The following adjustment procedures are accessed thru a service menu. To access the service menu, turn the receiver on, press the menu button and hold it

down while pressing the power button. While holding down the menu button, release the power button and press the volume + button. The screen will

display a one line menu, on the left the parameter P0, and on the right the value of that parameter V0. Release buttons. Adjustments are made by selecting

the proper parameter and changing the value of that parameter. To change the parameter number use channel up and down buttons. To adjust the current

value of that parameter use volume + and - buttons. To access and change any of the adjustments, the proper parameter pass number must be entered. This

information is listed at the beginning of the alignment. When these parameters are modified, the T-Chip and the corresponding EEPROM are updated. All

service adjustments are bus controlled, except focus and screen.

NOTE: In order to adjust the RF AGC, audio or video levels, tuner, PIP, or stereo circuits, the Chipper Check hardware and software must be used. This

can be purchased from Thomson Electronics. Before making any changes to any of the values, record the On-Set values.

VICE ADJUSTMENT PARAMETERSVICE ADJUSTMENT PARAMETERS

SERSER

VICE ADJUSTMENT PARAMETERS

SER

VICE ADJUSTMENT PARAMETERSVICE ADJUSTMENT PARAMETERS

SERSER

PP

arameterarameter

P

arameter

PP

arameterarameter

No.No.

No.

No.No.

0 Pass number for service Must set to 76 - May not advance until value is set to 76.

1 Error Code 1 0 0 - 255 Displays the first error detected. Set to 0 before exiting.

2 Error Code 2 0 0 - 255 Displays the second error detected. Set to 0 before exiting.

3 Error Code 3 0 0 - 255 Displays the last error detected. Set to 0 before exiting.

4 Horizontal Phase 10 0 - 15 Tune in a crosshatch pattern, adjust to center the pattern

5 EW DC (Width) 16 0 - 31 Tune in a crosshatch pattern, adjust for slight horizontal

6 EW Amplitude 8 0 - 15 Set value to 8.

7 EW Tilt 8 0 - 15 Set value to 8.

8 Top Corner Pin Correction 2 0 - 7 Set value to 2.

9 Bottom Corner Pin Correction 2 0 - 7 Set value to 2.

10 Vertical DC 33 0 - 63 Tune in a crosshatch pattern, adjust to center vertically.

11 Vertical Size 84 0 - 127 Tune in a crosshatch pattern, adjust for slight vertical overscan.

12 Vertical Countdown Mode 0 0 - 3 Set value to 0. (0 = Standard, 1 = Non-Standard, 2 = 50Hz,

13 Red Bias 30 0 - 127 Press menu button on the TV set for setup line.

14 Green Bias 15 0 - 127 Press menu button on the TV set for setup line.

15 Blue Bias 34 0 - 127 Press menu button on the TV set for setup line.

16 Red Drive 41 0 - 63 17 Green Drive 33 0 - 63 18 Blue Drive 32 0 - 63 19 Gemstar Horizontal OSD Position 166 0 - 255 Set value to 166.

20 Gemstar Vertical OSD Position 68 0 - 255 Set value to 68.

21 Gemstar PIP Horizontal Position 40 0 - 255 Set value to 40.

22 Gemstar PIP Vertical Position 43 0 - 255 Set value to 43.

23 Gemstar PIP Window Vertical Size 3 0 - 13 Set value to 3.

OL

OLOL

T

A

TT

AA

PP

P

PP

GE CHECKGE CHECK

GE CHECK

GE CHECKGE CHECK

arameter Namearameter Name

arameter Name

arameter Namearameter Name

adjustment parameters.

On-SetOn-Set

On-Set

On-SetOn-Set

VV

aluealue

V

alue

VV

aluealue

COLOR COLOR

COLOR

COLOR COLOR

NOTE: See Service Adjustment Parameters to change drive and bias values.

Press menu button for collapsed raster service line. Disconnect the antenna.

Preset the red, green, and blue drive values to 32. Adjust screen control for

a service line that is just visible. Adjust red, green, and blue drives to obtain

a white raster. Check the low light to high light gray scale tracking. Repeat

the procedure, if necessary, to obtain the best performance.

VV

aluealue

V

alue

VV

aluealue

RangRang

ee

Rang

e

RangRang

ee

TEMPERATEMPERA

TEMPERA

TEMPERATEMPERA

CommentComment

Comment

CommentComment

See Error Codes Chart.

See Error Codes Chart.

See Error Codes Chart.

on the screen.

overscan.

3 = 48Hz)

TURETURE

TURE

TURETURE

ERROR CODES CHART

ErrErr

or Codeor Code

Err

or Code

ErrErr

or Codeor Code

DECDEC

HEXHEX

DEC

HEX

DECDEC

HEXHEX

0 00 No error code 1 01 16.0V fault 16.0V STBY source is failing.

3 03 12.0V run fault 12.0V source is failing.

4 04 T4 Chip Run supply failed.

8 08 T4 Chip X-ray protection caused high voltage shutdown.

9 09 T4 Chip (POR) Power supply problem at (POR) power on reset.

10 0A F2 PIP module error (POR) Power supply problem at (POR) power on reset/PIP.

11 0B Stereo decoder (POR) Power supply problem at reset/Stereo decoder.

16 10 Run IIC Bus held low Run IIC clock or data held low.

18 12 Standby IIC Bus held low Standby IIC clock or data held low.

23 17 Gemstar 4 Board Guide fatal error on set using Gemstar 4 Board.

24 18 Gemstar 4 Board Task monitor error on set using Gemstar 4 Board.

25 19 Gemstar 4 Board Watchdog error on set using Gemstar 4 Board.

34 22 Gemstar 4 Board Gemstar 4 fails to acknowledge.

44 2C F2PIP module error F2PIP fails to acknowledge.

102 66 Octal DAC Octal DAC fails to acknowledge.

128 80 Stereo decoder Stereo decoder fails to acknowledge.

160 A0 Main or PIP tuner EEPROM Main or PIP tuner EEPROM fails to acknowledge.

186 BA T4 Chip T4 Chip fails to acknowledge.

196 C4 Main tuner PLL/DAC Main tuner PLL IC fails to acknowledge.

198 C6 Main tuner PLL/DAC Main tuner DAC IC fails to acknowledge.

ERRERR

OR CODESOR CODES

ERR

OR CODES

ERRERR

OR CODESOR CODES

If certain failures occur, the matching error codes will be stored in the

EEPROM. These error codes will be displayed in parameters 1, 2, and 3.

The first failure error code will be stored at parameter 1 and the second

failure error code will be stored at parameter 2. Parameter 3 will be updated

to display the most recent failure occurred in the chassis. If a failure of a

bus IC occurred, the normal acknowledgment checking of that bus will be

disabled in the service mode and the address of that IC which failed will be

stored in one of the error code parameters. After every repair is done to the

chassis it is recommended to check the error code parameters and reset

them back to value 0.

ErrErr

or Locationor Location

Err

or Location

ErrErr

or Locationor Location

Condition IndicatedCondition Indicated

Condition Indicated

Condition IndicatedCondition Indicated

Page 4

GE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

Y1/Y7)

Y1/Y7)Y1/Y7)

Y1/Y7)Y1/Y7)

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 1e 1

a

g

e 1

aa

gg

e 1e 1

Page 5

PP

aa

gg

e 2e 2

g

gg

e 2

e 2e 2

SET 4715 SET 4715

SET 4715

SET 4715 SET 4715

P

a

PP

aa

Page 6

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 2e 2

a

g

e 2

aa

gg

e 2e 2

Page 7

PP

aa

gg

e 2e 2

a

g

e 2

aa

gg

e 2e 2

SET 4715 SET 4715

SET 4715

SET 4715 SET 4715

P

PP

Page 8

ImporImpor

tant Ptant P

arar

ts Infts Inf

Impor

tant P

ImporImpor

ν The parts listed here are those not usually available from a well-stocked supply cabinet or bin.

ν Where items may be replaced with equivalent parts, several alternates are shown from participating vendors.

ν On the parts lists, safety items are marked with a

these items.

ν When ordering parts, state the model number, part number, and description.

ar

tant Ptant P

arar

# #

# to remind you that only exact replacements are recommended for

# #

ts Inf

ts Infts Inf

ormationormation

ormation

ormationormation

Obtaining PObtaining P

Obtaining P

Obtaining PObtaining P

Many of these parts are available from your local Sams authorized distributor or the manufacturer of the equipment. Call

Sams for the name of your nearest distributor:

arar

ar

arar

tsts

ts

tsts

800-428-7267

Or consult the Sams

Information on test equipment and replacement parts is listed in these pages for the following participating vendors.

Consult the Sams

ν NTE Electronics, Inc. (NTE)

Test equipment listed by participating manufacturer illustrates typical or equivalent equipment used by Sams engineers to obtain

measurements. This equipment is compatible with most types used by field service technicians.

Annual Index

Annual Index

for the address of the original equipment manufacturer.

PP

arar

ticipating ticipating

P

ar

ticipating

PP

arar

ticipating ticipating

for their current address.

TEST EQTEST EQ

TEST EQ

TEST EQTEST EQ

VV

endorendor

V

endor

VV

endorendor

ν Sencore, Inc.

UIPMENTUIPMENT

UIPMENT

UIPMENTUIPMENT

ss

s

ss

GE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

EquipmentEquipment

Equipment

EquipmentEquipment

Oscilloscope SC3100

Generators

RGB CM2125

Multiburst Signal VG91

Color Bar VG91

TV Stereo VG91

Digital VOM SC3100

Frequency Meter SC3100

Hi-Voltage Probe HP200

Accessory Probes TP212

Sencore No.Sencore No.

Sencore No.

Sencore No.Sencore No.

EquipmentEquipment

Equipment

EquipmentEquipment

Isolation Transformer PR570

Capacitance Analyzer LC102

CRT Analyzer CR7000

AC Leakage Tester PR570

Inductance Analyzer LC102

Flyback Yoke Tester TVA92

Field Strength Meter SL753

Transistor Tester TF46

Horizontal Analyzer HA-2500

Video Analyzer VG91, TVA92

Sencore No.Sencore No.

Sencore No.

Sencore No.Sencore No.

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

a

g

aa

gg

Y1/Y7)

Y1/Y7)Y1/Y7)

Y1/Y7)Y1/Y7)

e 2e 2

e 2

e 2e 2

Page 9

PP

aa

gg

e 3 SET 4715e 3 SET 4715

P

a

g

e 3 SET 4715

PP

aa

gg

e 3 SET 4715e 3 SET 4715

Page 10

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 3e 3

a

g

e 3

aa

gg

e 3e 3

Page 11

PP

aa

gg

e 3e 3

a

g

e 3

aa

gg

e 3e 3

SET 4715 SET 4715

SET 4715

SET 4715 SET 4715

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 3e 3

a

g

e 3

aa

gg

e 3e 3

P

PP

Page 12

SCHEMASCHEMA

SCHEMA

SCHEMASCHEMA

TIC COMPONENT LOCATIC COMPONENT LOCA

TIC COMPONENT LOCA

TIC COMPONENT LOCATIC COMPONENT LOCA

TION GUIDETION GUIDE

TION GUIDE

TION GUIDETION GUIDE

C11401 B46

C11402 C46

C11403 B46

C11450 B30

C11451 B30

C11453 C35

C11454 D35

C11455 C35

C11456 D35

C11501 D32

C11502 D32

C11503 D35

C11504 D35

C11506 D30

C11507 E30

C11601 A5

C11602 C30

C11603 C30

C11604 C32

C11605 D32

C11606 C32

C11607 C32

C11608 B30

C11609 B30

C11610 C30

C11611 B30

C11612 D30

C11613 D30

C11614 C30

C11615 C30

C11616 C29

C11617 A30

C11618 D30

C11619 A30

C11620 C32

C11621 B32

C11622 B32

C11623 D32

C11624 A5

C11625 D32

C11626 A31

C11627 A31

C11628 A33

C11629 B31

C11630 A33

C11631 A33

C11701 E29

C11702 D30

C11703 D30

C11704 E30

C11705 E30

C11906 A34

C11907 B34

C11908 C35

C11909 B35

C11910 A34

C11912 B34

C11913 A36

C11914 B36

C12301 C1

C12302 B1

C12303 D37

C12304 A4

C12305 A5

C12306 C2

C12307 C3

C12308 C3

C12310 B4

C12312 C28

C12313 C3

C12314 C28

C12701 A7

C12702 C10

C12703 C10

C12704 C9

C12706 D4

C12707 C28

C12708 C28

C12709 B8

C12710 B9

C12711 B11

C12712 A28

C12713 C10

C12714 C13

C12715 B13

C12716 B13

C12717 C9

C12718 C10

C12801 C8

C12802 B7

C12803 C9

C12805 B6

C12806 C8

C12807 C8

C13102 C37

C13103 C38

C13104 E39

C13105 C38

C13106 C41

C13107 D41

C13108 B38

C13109 C38

C13110 B38

C13111 B38

C13113 C24

C13114 D38

C13115 C24

C13119 B43

C13129 B41

C13141 D41

C13144 C41

C13163 B24

C13165 C24

C13169 B41

C13170 C40

C13201 A37

C13202 A37

C13301 A41

C13302 E41

C13312 E41

C13501 E40

C13502 E40

C13503 D40

C13504 D39

C14101 B19

C14102 B20

C14103 B19

C14104 C19

C14105 C19

C14106 C20

C14107 C20

C14108 A20

C14109 A22

C14110 A24

C14111 B23

C14112 B23

C14113 B21

C14114 B24

C14115 C21

C14116 D23

C14118 A28

C14119 B24

C14121 B24

C14122 A24

C14123 D21

C14124 A22

C14125 B20

C14126 C19

C14127 C20

C14150 C28

C14151 C26

C14152 B24

C14153 B24

C14154 B27

C14155 B28

C14158 B24

C14159 B23

C14160 B27

C14201 A17

C14203 A19

C14204 A19

C14205 A20

C14206 A20

C14207 B18

C14208 A17

C14302 E5

C14303 E5

C14304 E6

C14305 E6

C14306 E6

C14309 E5

C14310 E5

C14320 D2

C14321 D2

C14322 E4

C14401 E7

C14402 E9

C14403 D9

C14404 D9

C14405 D10

C14406 E8

C14502 D6

C14504 D8

C14505 D7

C14506 E21

C14507 E21

C14521 D5

C14701 E20

C14702 D19

C14703 D19

C14704 D19

C14706 E20

C14710 E3

C14711 E21

C14901 E3

C14902 E2

C14903 D3

C14904 D3

C15101 D15

C17416 B43

C17417 C43

C18101 A47

C18102 A47

C18103 B51

C18104 D45

C18105 B47

C18106 C47

C18107 B48

C18109 E49

C18110 E50

C18111 E50

C18112 D49

C18113 D45

C18114 D49

C18115 E48

C18116 C50

C18117 D48

C18118 D48

C18119 D50

C18120 D50

C18121 C51

C18122 C49

C18124 C49

C18125 E48

C18126 E48

C18127 B49

C18129 B49

C18130 B49

C18131 C49

C18132 A50

C18133 B50

C18134 B48

C18137 B49

C18138 B49

C18139 A49

C18142 A49

C18143 A49

C18144 D48

C18145 E50

C18146 D28

C18147 D27

C18148 D28

C18149 D27

C18150 D27

C18151 D27

C18152 D25

C18153 D26

C18154 D28

C18159 D28

C18161 D28

C18162 C47

C18163 D47

C18171 D27

C18172 D26

CF12201 A3

CF12351 B4

CR11401 B46

CR11402 B46

CR11403 C47

CR11501 D33

CR11502 D33

CR11503 D35

CR11504 E23

CR11505 E24

CR11601 B33

CR11602 C29

CR11603 C29

CR12301 B5

CR12702 E4

CR13501 E40

CR14101 B18

CR14102 B19

CR14103 C19

CR14104 C19

CR14105 C19

CR14106 A22

CR14107 B23

CR14108 B21

CR14109 B21

CR14110 B23

CR14111 D21

CR14113 E24

CR14114 E24

CR14115 C27

CR14117 C19

CR14201 A19

CR14202 A18

CR14203 A19

CR14204 A18

CR14205 B17

CR14301 E5

CR14401 D10

CR14501 D7

CR14701 E19

CR14702 D19

CR14704 E20

CR14901 E3

CR14902 E3

CR18101 D46

CR18102 D46

CR18103 B51

DY1 D9

F14201 A17

FB13101 E24

FB14106 B22

FB14107 A22

FB14108 A22

FB14109 B20

FB14110 A24

FB14114 B21

FB14401 E8

FB14501 D5

FB18101 E50

FB18102 B52

FB18103 A52

IR13201 A37

J11401 B29

J11401 B29

J11401 B45

J11402 C36

J11402 D36

K14201 A18

K14201 B17

L12302 B3

L12303 B4

L12305 C27

L12352 B4

L12705 C27

L13105 C24

L13106 C23

L14101 B28

L14102 B22

L14103 A24

L14105 A23

L14200 A18

L14401 E7

L14402 D9

L15101 D20

L18100 C49

L18101 B49

L18102 B48

L18103 B49

L18104 A49

L18105 A49

L18106 D25

L18108 D26

L18111 D26

PW14201 A17

Q11501 D23

Q11603 C30

Q11901 C33

Q12301 B4

Q12701 C13

Q12702 A13

Q12703 B13

Q12704 B13

Q13101 C37

Q13102 C38

Q13103 D38

Q13104 B43

Q13301 D37

Q13501 D40

Q13503 D40

Q14101 B20

Q14102 B19

Q14103 B19

Q14104 A25

Q14105 A25

Q14106 D20

Q14107 D21

Q14108 B19

Q14115 B27

Q14201 B17

Q14301 E6

Q14302 E5

Q14401 E7

Q14901 D3

Q15101 A14

Q15102 C14

Q15103 B14

Q18100 C46

Q18101 D46

Q18102 D45

Q18103 C49

Q18104 B49

Q18105 B51

Q18106 A51

Q18107 B49

Q18108 A49

Q18109 E46

Q18110 E45

Q18111 B51

Q18112 D46

Q18113 D47

R5050 D12

R11401 B29

R11402 B30

R11403 B29

R11404 B30

R11405 B45

R11406 B45

R11407 C35

R11408 C35

R11409 D35

R11410 D35

R11411 B46

R11412 B46

R11413 C46

R11414 C46

R11460 B30

R11461 B30

R11462 C35

R11463 D35

R11501 D32

R11502 D32

R11503 D32

R11504 D32

R11505 D33

R11506 D32

R11507 D33

R11508 D34

R11509 D34

R11510 D34

R11511 D30

R11512 E30

R11513 E23

R11514 D23

R11601 A5

R11602 D31

R11603 C31

R11604 C31

R11605 B30

R11606 D30

R11607 D30

R11608 D30

R11609 D30

R11611 A32

R11612 A32

R11613 B32

R11614 A33

R11615 C30

R11616 C30

R11617 B30

R11618 A5

R11619 C29

R11620 C29

R11621 B32

R11622 B32

R11623 B33

R11624 B33

R11625 A33

R11626 A33

R11627 C30

R11701 D29

R11702 E29

R11703 D29

R11704 D30

R11705 D30

R11706 E30

R11707 E31

R11708 D29

R11709 E29

R11909 C35

R11910 A34

R11911 A34

R11912 B34

R11913 B34

R11915 B33

R11917 C33

R11918 C33

R11919 C33

R11920 A36

R11921 B36

R12201 A3

R12302 B2

R12303 B1

R12304 B4

R12305 D37

R12306 E24

R12307 B5

R12308 A5

R12309 B4

R12311 B4

R12315 C2

R12316 C3

R12318 B4

R12351 B4

R12701 C10

R12702 E4

R12703 C10

R12704 A7

R12705 C9

R12706 C12

R12707 A12

R12708 B12

R12710 B2

R12711 B2

R12712 B12

R12713 B12

R12714 B10

R12715 C13

R12716 C13

R12717 C13

R12718 C13

R12719 A13

R12720 A13

R12721 A13

R12722 A13

R12723 B13

R12724 B13

R12725 B13

R12726 C10

R12727 B13

R12731 D3

R12801 C7

R12802 C7

R12803 C9

R12804 C8

R12805 B7

R12806 C8

R12807 C8

R12808 C8

R13101 C37

R13102 C37

R13103 C38

R13104 C38

R13105 C38

R13106 D38

R13107 C41

R13108 C37

R13109 D38

R13110 D37

R13111 D38

R13112 D38

R13113 C38

R13114 B38

R13115 C38

R13116 B38

R13117 B38

R13118 B39

R13119 B39

R13120 A39

R13121 E40

R13122 A38

R13123 B41

R13124 B41

R13126 B39

R13127 E40

R13128 B43

R13130 C42

R13131 B42

R13132 B41

R13134 A43

R13135 A43

R13136 B43

R13137 B43

R13138 A43

R13139 A44

R13140 C42

R13141 A43

R13142 A43

R13143 D40

R13144 D40

R13145 B41

R13147 E43

R13148 E42

R13150 A39

R13151 D43

R13152 D40

R13153 A38

R13154 C43

R13161 D42

R13162 E43

R13165 A40

R13166 B42

R13167 E40

R13168 C40

R13169 C42

R13170 C39

R13171 E40

R13175 C41

R13176 B43

R13181 B43

R13182 E38

R13183 E39

R13184 D43

R13185 D43

R13186 E42

R13188 C38

R13189 B38

R13190 B38

R13191 B38

R13194 D43

R13195 D43

R13196 D42

R13197 D42

R13198 A40

R13199 D43

R13201 A38

R13202 A37

R13205 E41

R13207 E41

R13301 E41

R13302 A41

R13306 A39

R13307 B39

R13308 B39

R13309 B39

R13310 B40

R13311 B40

R13312 B40

R13313 B40

R13314 E38

R13315 D37

R13316 D38

R13317 D38

R13318 D37

R13319 D37

R13320 E37

R13321 E37

R13322 E37

R13323 E1

R13501 E40

R13503 D41

R13504 D41

R13505 D41

R13507 D41

R13508 D40

R13510 D41

R13511 D40

R13512 D39

R14101 B18

R14102 B18

R14103 B19

R14104 B19

R14105 C20

R14106 B19

R14107 B19

R14108 B20

R14109 B20

R14110 B19

R14111 C19

R14112 C19

R14113 C20

R14114 C20

R14115 D20

R14116 D20

R14117 A20

R14118 A24

R14119 A23

R14120 D23

R14121 A40

R14122 A25

R14123 A25

R14124 B22

R14126 D20

R14127 D21

R14128 D21

R14129 C20

R14130 D23

R14135 D20

R14151 C26

R14153 B23

R14155 B27

R14157 B27

R14158 B27

R14159 B27

R14201 A17

R14202 A18

R14204 A20

R14205 A17

R14206 A40

R14286 C40

R14287 C40

R14303 D1

R14304 E5

R14305 E6

R14306 E6

R14309 E5

R14310 E4

R14318 E1

R14319 E1

R14320 D2

R14321 E4

R14322 E4

R14323 D4

R14324 D1

R14326 D1

R14327 D1

R14401 D10

R14402 E7

R14403 E10

R14501 D8

R14503 D5

R14504 D6

R14506 D6

R14507 D8

R14508 E20

R14509 E21

R14520 D5

R14701 D19

R14702 D20

R14703 A16

R14704 E3

R14705 E3

R14706 D3

R14851 D4

R14901 E3

R14902 E2

R14903 E2

R14904 D3

R14905 D2

R14906 E3

R14909 D3

R15101 A15

R15102 C15

R15103 B15

R15104 A15

R15105 C15

R15106 B15

R15107 A14

R15108 C14

R15109 B14

R15118 D16

R17130 C2

R17402 B44

R17403 C44

R17409 B44

R17411 D44

R18101 D49

R18102 D27

R18103 E50

R18104 D49

R18106 D47

R18107 C46

R18108 C46

R18109 C47

R18110 D46

R18111 D45

R18112 D47

R18113 D47

R18114 C48

R18115 C49

R18116 C51

R18117 B48

R18118 B49

R18119 B51

R18120 A51

R18121 B49

R18122 B49

R18123 A48

R18124 A50

R18125 D25

R18128 A47

R18129 E45

R18130 D45

R18131 E46

R18132 C47

R18133 D46

R18134 D46

R18135 B46

R18136 D50

R18137 D45

R18139 B46

R18140 C47

R18141 C47

R18142 D47

R18143 D47

R18144 B51

R18146 D46

R18147 D46

R18148 D47

R18149 B52

R18150 B51

R18151 B51

R18152 D49

R18153 B50

R18154 D47

R18156 B51

R18157 A51

R18158 D26

R18159 D26

R18163 B47

R18164 C47

R18165 B47

R18166 C47

R18167 D50

RN14501 D5

RT14201 A18

SF12301 B1

SP1 A36

SP2 B36

SW13201 B37

SW13202 B37

SW13203 B37

SW13204 B37

SW13205 B37

SW13206 B37

T14101 A21

T14201 A17

T14301 E7

T14401 D11

T14401 E18

U11501 D29

U11501 D33

U11501 D34

U11501 E29

U11601 A31

U11602 A33

U11602 B33

U11900 A35

U11901 B35

U12101 A4

U12101 B2

U12101 B7

U12101 D2

U13101 C40

U13102 A44

U14101 C19

U14102 D19

U14103 B23

U14104 A26

U14150 C27

U14501 D7

U18100 C49

U18101 D26

V101 C16

Y12801 B9

Y13101 C41

Y14101 D2

Y18100 D50

GE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

Y1/Y7)

Y1/Y7)Y1/Y7)

Y1/Y7)Y1/Y7)

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 3e 3

a

g

e 3

aa

gg

e 3e 3

Page 13

PP

aa

gg

e 4e 4

g

e 4

gg

e 4e 4

SET 4715 SET 4715

SET 4715

SET 4715 SET 4715

P

a

PP

aa

MAIN BOMAIN BO

MAIN BO

MAIN BOMAIN BO

ARD - ARD -

ARD -

ARD - ARD -

TT

OP OP

T

TT

VIEWVIEW

OP

VIEW

OP OP

VIEWVIEW

MAIN BOMAIN BO

MAIN BO

MAIN BOMAIN BO

BC14901 O7

C11450 O2

C11451 O2

C11504 K1

C11506 K1

C11507 J2

C11601 N2

C11602 N2

C11603 N2

C11604 M3

C11605 L3

C11611 M2

C11614 N2

C11616 N1

C11617 N3

C11618 M2

C11619 M3

C11620 M3

C11623 L3

C11624 N1

C11628 K1

C11630 K2

C11703 K2

C11705 J2

C11908 I2

C11909 H2

C11913 I1

C11914 G1

C12305 K5

C12306 O6

C12310 G8

C12314 K6

C12701 I4

C12702 I4

C12703 H5

C12704 I3

C12706 F6

C12707 H5

C12713 H4

C12806 J6

C13105 D3

C13115 E4

C13144 D2

C13202 A7

C14101 K11

C14102 H10

C14104 J12

C14105 J12

C14108 H11

C14109 F10

C14110 E10

C14111 D12

C14112 D11

C14113 F11

C14114 F11

C14115 F11

C14116 E11

ARD - ARD -

ARD -

ARD - ARD -

TT

OP OP

VIEWVIEW

T

TT

OP

OP OP

,,

VIEW

,

VIEWVIEW

,,

C14118 E9

C14119 F5

C14121 F12

C14122 H9

C14124 F10

C14125 I11

C14150 H5

C14151 H5

C14152 H6

C14155 M5

C14158 L6

C14201 M12

C14203 O10

C14204 O11

C14205 L10

C14206 M10

C14207 O11

C14208 N12

C14304 H8

C14305 H8

C14306 H8

C14310 G8

C14320 I6

C14402 K8

C14403 F8

C14404 F7

C14405 F8

C14406 J8

C14502 B7

C14504 B6

C14505 C7

C14506 C7

C14521 H5

C14701 M7

C14703 E9

C14704 E8

C14710 N9

C14711 L8

C14901 E8

C14902 E8

CF12201 J4

CR11503 K1

CR11504 G2

CR11602 N2

CR12702 G6

CR13501 B3

CR14101 K10

CR14103 H12

CR14104 H12

CR14105 J11

CR14106 F10

CR14107 D12

CR14108 F10

CR14109 G11

CR14110 D5

CR14111 D12

CR14115 F6

GRIDTRA GRIDTRA

GRIDTRA

GRIDTRA GRIDTRA

CE LOCACE LOCA

CE LOCA

CE LOCACE LOCA

CR14117 I12

CR14201 O10

CR14202 O11

CR14203 N10

CR14204 N11

CR14205 D11

CR14301 G9

CR14401 F8

CR14501 C7

CR14701 M8

CR14702 F8

CR14704 M8

CR14901 E7

CR14902 J7

F14201 L11

FB13101 E4

FB14106 F10

FB14107 F10

FB14108 F10

FB14109 I11

FB14114 F10

FB14401 J8

FB14501 I6

IR13201 A6

J11450 O3

J11451 K3

J11901 H1

J13101 D1

J13202 C1

J14203 M11

K14201 K11

L12302 K4

L12303 K5

L12305 J6

L12705 H5

L13105 E4

L13106 F5

L14101 M6

L14102 D6

L14103 G9

L14105 D11

L14401 I8

L14402 F9

P12701 G3

P14401 D8

P14501 C6

Q11603 O2

Q14101 J11

Q14102 J11

Q14103 J11

Q14104 D10

Q14115 E6

Q14301 H9

Q14401 J8

Q14901 K7

R11511 J1

R11512 J2

TION GUIDETION GUIDE

TION GUIDE

TION GUIDETION GUIDE

R11613 L12

R11627 F2

R11705 K2

R11707 K2

R11909 G3

R11917 F2

R12702 G5

R12704 I3

R12710 K4

R12711 K4

R12717 G3

R12721 G3

R12725 M3

R12731 H4

R13103 D2

R13120 D5

R13188 B1

R13189 B1

R13190 B1

R13191 B1

R13201 A6

R13306 F2

R13307 E2

R13308 E2

R13309 E2

R13320 D5

R13322 F4

R14101 J10

R14102 K10

R14103 K10

R14104 K11

R14105 H11

R14106 K11

R14107 J11

R14108 J11

R14109 J11

R14110 I11

R14111 I12

R14113 F11

R14115 E11

R14116 E12

R14117 I10

R14118 E11

R14119 D12

R14120 D9

R14122 D10

R14123 D10

R14124 D9

R14130 E12

R14135 E12

R14151 G5

R14153 E6

R14155 E6

R14157 E6

R14158 F6

R14159 F6

R14201 N12

R14202 O11

R14204 N10

R14205 N12

R14303 H6

R14305 I8

R14306 H8

R14309 G8

R14310 H7

R14318 D6

R14319 D6

R14401 G8

R14402 I8

R14403 G9

R14501 C6

R14503 B6

R14504 D7

R14506 D6

R14507 C6

R14508 D5

R14509 D7

R14701 N7

R14702 E8

R14703 E7

R14705 L9

R14706 G5

R14901 E7

R14902 K7

R14903 N7

R14904 G6

R14905 O7

R17409 L5

R17411 L5

RN14501 B7

RT14201 L10

SF12301 J5

SW13201 A2

SW13202 A2

SW13203 A3

SW13204 A4

SW13205 A4

SW13206 A5

T14101 G11

T14201 M11

T14301 H8

T14401 N8

TU17101 N5

U11501 J2

U11601 L2

U11900 I2

U11901 H2

U12101 J5

U13101 C3

U13102 E3

U14101 H12

U14102 E12

U14103 E5

U14104 C8

U14150 G5

U14501 C7

Y12801 I6

Y13101 D4

Y14101 I6

Page 14

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 4e 4

a

g

e 4

aa

gg

e 4e 4

MAIN BOMAIN BO

MAIN BO

MAIN BOMAIN BO

ARD - BOARD - BO

ARD - BO

ARD - BOARD - BO

TTTT

OM OM

OM

OM OM

VIEWVIEW

VIEW

VIEWVIEW

TT

TTTT

MAIN BOMAIN BO

MAIN BO

MAIN BOMAIN BO

C11453 O11

C11454 O10

C11455 N10

C11456 N10

C11501 K11

C11502 K11

C11503 K12

C11606 M11

C11607 M11

C11608 M11

C11609 M11

C11610 M11

C11612 M11

C11613 M11

C11615 M11

C11621 L11

C11622 L11

C11625 L11

C11626 L11

C11627 L11

C11629 L11

C11631 L12

C11701 J11

C11702 K11

C11704 J10

C11906 H11

C11907 G11

C11910 H11

C11912 G11

C12301 J8

C12302 J8

C12303 J9

C12304 K8

C12307 J8

C12308 J8

C12312 J8

C12313 J8

C12708 H8

C12709 I9

C12710 I9

C12711 I9

C12712 G10

C12714 G9

C12715 G9

C12716 H9

C12717 J8

C12718 I8

C12801 I8

C12802 J9

C12803 I7

C12805 J9

C12807 I8

C13102 C11

C13103 D11

C13104 E9

C13106 D10

C13107 D10

C13108 B11

C13109 C11

C13110 C11

C13111 C11

C13113 E9

C13114 D11

C13119 E10

C13129 C9

ARD - BOARD - BO

ARD - BO

ARD - BOARD - BO

TTTT

OM OM

VIEWVIEW

,,

VIEW

VIEWVIEW

GRIDTRA GRIDTRA

,

GRIDTRA

,,

GRIDTRA GRIDTRA

TT

OM

TTTT

OM OM

C13141 C10

C13163 E9

C13165 D11

C13169 D10

C13170 B9

C13201 A6

C13301 D9

C13302 E9

C13312 D9

C13501 B10

C13502 B10

C13503 B10

C13504 B9

C14103 K2

C14106 H2

C14107 F1

C14123 D2

C14126 H1

C14127 H1

C14153 I8

C14154 F7

C14159 L7

C14160 L7

C14302 G5

C14303 G5

C14309 G5

C14321 I8

C14322 I7

C14401 J5

C14507 C6

C14702 M5

C14706 M5

C14903 I8

C14904 K7

C17416 K9

C17417 K9

CR11501 J12

CR11502 J12

CR11505 J11

CR11601 L12

CR11603 O12

CR12301 K9

CR14102 K10

CR14113 O10

CR14114 O10

FB14110 L7

Q11501 G11

Q11901 J12

Q12301 J9

Q12701 H9

Q12702 G9

Q12703 H9

Q12704 G9

Q13101 C11

Q13102 D11

Q13103 D11

Q13104 E9

Q13301 D9

Q13501 B10

Q13503 C10

Q14105 D3

Q14106 E1

Q14107 D2

Q14108 J2

Q14201 D6

CE LOCACE LOCA

CE LOCA

CE LOCACE LOCA

Q14302 G5

R11460 O10

R11461 O10

R11462 O10

R11463 O10

R11501 K10

R11502 K10

R11503 J11

R11504 K10

R11505 J12

R11506 K10

R11507 J12

R11508 K11

R11509 K12

R11510 K12

R11513 G11

R11514 G11

R11601 M11

R11602 L10

R11603 M11

R11604 M11

R11605 M11

R11606 M11

R11607 M11

R11608 M11

R11609 M9

R11611 L12

R11612 L11

R11614 L11

R11615 M11

R11616 M11

R11617 M10

R11618 N11

R11619 O12

R11620 O11

R11621 L12

R11622 L12

R11623 L12

R11624 L12

R11625 L12

R11626 K11

R11701 K11

R11702 K11

R11703 K11

R11704 J11

R11706 J10

R11708 K11

R11709 K11

R11910 I11

R11911 H11

R11912 H11

R11913 H11

R11915 J12

R11918 J12

R11919 J12

R11920 I12

R11921 G12

R12201 J9

R12302 J7

R12303 J8

R12304 J9

R12305 J9

R12306 J8

R12307 J10

R12308 K9

TION GUIDETION GUIDE

TION GUIDE

TION GUIDETION GUIDE

R12309 K8

R12311 J9

R12315 J8

R12316 J8

R12318 K9

R12701 I9

R12703 I9

R12705 I8

R12706 I9

R12707 I9

R12708 I9

R12712 H10

R12713 G9

R12714 I9

R12715 G9

R12716 G9

R12718 G10

R12719 G9

R12720 G9

R12722 G10

R12723 H9

R12724 H9

R12726 H9

R12727 G10

R12801 I8

R12802 I8

R12803 J7

R12804 I9

R12805 J9

R12806 J7

R12807 J7

R12808 J7

R13101 C11

R13102 D11

R13104 D11

R13105 D11

R13106 D11

R13107 C9

R13108 D11

R13109 D11

R13110 D11

R13111 D11

R13112 D10

R13113 C10

R13114 C10

R13115 C10

R13116 C11

R13117 C11

R13118 C10

R13119 C10

R13121 D8

R13122 D9

R13123 C9

R13124 C9

R13126 C10

R13127 C9

R13128 E10

R13130 B10

R13131 C10

R13132 C10

R13134 D10

R13135 D10

R13136 F10

R13137 B11

R13138 D10

R13139 E11

R13140 B11

R13141 D10

R13142 D11

R13143 D10

R13144 C10

R13145 D9

R13147 B10

R13148 B10

R13150 C9

R13151 B11

R13152 C9

R13153 C9

R13154 B11

R13161 C11

R13162 C11

R13165 D10

R13166 C11

R13167 C9

R13168 C9

R13169 C11

R13170 C9

R13171 E9

R13175 D10

R13176 E10

R13181 D10

R13182 D9

R13183 D9

R13184 C11

R13185 C11

R13186 C10

R13194 C12

R13195 C12

R13196 C10

R13197 D10

R13198 D10

R13199 D12

R13202 A7

R13205 B9

R13207 C9

R13301 E9

R13302 D9

R13310 E11

R13311 E11

R13312 E11

R13313 E11

R13314 D9

R13315 D9

R13316 D9

R13317 D9

R13318 D9

R13319 D9

R13321 E9

R13323 E12

R13501 B9

R13503 B9

R13504 C10

R13505 C10

R13507 C10

R13508 C10

R13510 C10

R13511 C10

R13512 B10

R14112 H1

R14114 E1

R14121 D3

R14126 E1

R14127 D3

R14128 E4

R14129 G1

R14206 D6

R14286 C8

R14287 C8

R14304 G5

R14320 I8

R14321 H7

R14322 I7

R14323 I8

R14324 H7

R14326 H7

R14327 H7

R14520 I8

R14851 I8

R14906 J7

R14909 K7

R17130 O7

R17402 K8

R17403 K8

U11602 L12

Page 15

PARTS LIST

Item No.Item No.

Item No.

Item No.Item No.

CR11401 - 232710 CR11402 - 220638 NTE5014A

CR11403 - 232710 CR11501, 02 - 232709 CR11503 - 215488 NTE136A

CR11504 - 226463 CR11505 - 232709 CR11601 - 232709 -

# CR11602 - 159429 NTE5019T1

CR11603 - 232709 CR12301 - 227051 CR12702 - 198589 NTE519

CR13501 - 164874 NTE177

CR14101 - 232221 CR14102 - 198589 NTE519

CR14103, 04 - 139706 NTE177

CR14105 - 198589 NTE519

CR14106 - 243636 CR14107 - 217306 CR14108 - 243636 CR14109 - 176296 NTE552

CR14110 - 155276 NTE116

CR14111 - 198589 NTE519

CR14113, 14 - 232709 CR14115 - 215488 NTE136A

# CR14117 - 244224 -

CR14201 Thru

CR14204 - 147015 NTE125

CR14205 - 198589 NTE519

CR14301 - 176296 NTE552

# CR14401 - 140971 NTE558

CR14501 - 155276 NTE116

CR14701 - 241304 CR14702 - 176296 NTE552

CR14704 - 208878 -

# CR14901 - 157301 NTE177

# CR14902 - 159429 NTE5019T1

CR18101, 02, 03 - 232709 Q11501 - 215495 Q11603 - 177788 NTE31

Q11901 - 215495 Q12301 - 215496 Q12701, 02, 03 - 215495 Q12704 - 215496 Q13101 - 215495 Q13102, 02, 03 - 215496 Q13301 - 215496 Q13501 - 215496 Q13503 - 215495 -

# Q14101 - 244223 # Q14102 - 147665 NTE159

Q14103 - 232218 Q14104 - 243955 Q14105, 06, 07 - 215495 -

# Q14108 - 215496 -

Q14115 - 177788 NTE31

Q14201 - 219412 Q14301 - 146851 NTE287

Q14302 - 215495 -

# Q14401 - 242224 # Q14901 - 147665 NTE159

Q15101, 02, 03 - 215497 NTE2501

Q18100, 01 - 215495 Q18102 - 219412 Q18103, 04 - 215495 Q18105, 06 - 215496 Q18107, 08 - 215495 Q18109 - 215496 Q18110 - 215495 Q18111, 11, 12 - 215495 U11501 MC3403N 241785 NTE987

U11601 CXA2074S 237930 U11602 - 237474 U11900, 01 TDA7267 244225 -

TT

ype No.ype No.

T

ype No.

TT

ype No.ype No.

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NTE PNTE P

NTE P

NTE PNTE P

arar

ar

arar

t No.t No.

t No.

t No.t No.

Item No.Item No.

Item No.

Item No.Item No.

# U12101 LA7612N 241266 -

U13101 (1) ST9296N9B1/JBT 247619 U13101 (2) - 251833 U13102 24C08 244878 -

# U14101 - 223653 -

U14102 - 231525 U14103 L7852CV 241752 U14104 KA7812 162394 NTE966

U14150 L78S75CV 231526 U14501 (1) TDA8172 215531 NTE1788

U14501 (2) - 232109 NTE1788

U18100 - 248620 U18101 - 214704 NTE956

Item No.Item No.

Item No.

Item No.Item No.

C11612, 13 22pF 5% 50V NPO 194903 C12303 120pF 5% 50V NPO 194902 C12714, 15, 16 470pF 5% 50V NPO 214732 C12718 100pF 5% 50V NPO 193340 C12803 15pF 5% 50V NPO 200538 C12805 120pF 5% 50V NPO 194902 C13102, 03 120pF 5% 50V NPO 194902 C13106, 07 56pF 5% 50V NPO 214741 C13170 220pF 5% 50V NPO 205551 C13312 100pF 5% 50V NPO 193340 -

# C14102 .0168 1.6kV 237355 -

# C14108 .0011 1.6kV 244208 -

# C14111 100µF 20% 63V 237425 -

# C14112 .01 10% 50V 240934 -

C14113, 15 680pF 10% 1kV 190538 C14159, 60 100pF 5% 50V NPO 193340 -

# C14201 .22 20% 125VAC 231451 -

# C14203, 04 680pF 10% 1kV 190538 -

# C14205 680µF 20% 200V 190560 -

# C14207 .0034 20% 120V 223330 -

# C14208 470pF 10% 250VAC 250102 -

C14303 470pF 5% 50V NPO 214732 C14310 15pF 1% 250V NPO 223899 C14322 39pF 5% 50V NPO 202905 C14401 470pF 5% 50V NPO 195918 -

# C14402 .0127 1.6kV 246497 -

# C14403 .41 5% 250V 214752 -

# C14404 2.2µF 20% 200V 247673 -

# C14405 .0047 10% 250V 142765 -

# C14406 470pF 5% 2kV 227068 -

C14702 470pF 10% 500V NPO 227050 C14704 680pF 10% 1kV 190538 C14706 470pF 10% 500V NPO 227050 C14710 .01 20% 1kV 137583 -

# C14904 .22 +80% -20% 25V 217298 -

C15101 .001 10% 3kV 120696 C17416, 17 43pF 5% 50V NPO 214029 C18102 180pF 5% 50V NPO 211039 C18103 100pF 5% 50V NPO 193340 C18104 220pF NPO 205551 C18107 180pF 5% 50V NPO 211039 C18112 10pF NPO 200537 C18113 470pF NPO 214732 C18114 20pF 5% 50V NPO 220150 C18122 47pF 5% 50V NPO 210689 C18124 100pF 5% 50V NPO 174412 C18127 18pF 5% 50V NPO 214028 C18129 100pF 5% 50V NPO 193340 C18134 82pF NPO 214741 C18137 220pF NPO 214032 C18138 330pF NPO 205551 C18139 27pF 5% 50V NPO 197604 C18142 91pF 5% 50V NPO 192057 C18143 27pF 5% 50V NPO 197604 C18162, 63 100pF 5% 50V NPO 193340 CF12201 Filter 195702 4.5MHz

CF12351 Trap 181125 4.5MHz

TT

ype No.ype No.

T

ype No.

TT

ype No.ype No.

LA7612A 252842 -

Function/RatingFunction/Rating

Function/Rating

Function/RatingFunction/Rating

MfrMfr

Mfr

MfrMfr

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NTE PNTE P

NTE P

NTE PNTE P

NotesNotes

Notes

NotesNotes

arar

ar

arar

t No.t No.

t No.

t No.t No.

PP

aa

gg

e 4e 4

g

e 4

gg

e 4e 4

SET 4715 SET 4715

SET 4715

SET 4715 SET 4715

P

a

PP

aa

Page 16

PARTS LIST continued

Item No.Item No.

Item No.

Item No.Item No.

# DY1 (3) Yoke - Horiz 1.3mH, Vert 10mH

# F14201 Fuse 175425 5Amp, 125V, Fast Acting

FB13101 Ferrite Bead 226467 FB14106, 07, 08 Ferrite Bead 237504 FB14109 Ferrite Bead 226467 FB14110 Ferrite Bead 215546 FB14114 Ferrite Bead 237504 FB14401 Ferrite Bead 161237 FB14501 Ferrite Bead 215547 FB18101 Ferrite Bead 239201 FB18102, 03 Ferrite Bead 240150 IR13201 Receiver 244227 IR

J11401 Jack 239389 Assembly

J11402 Jack 245283 Assembly

J11403 Jack 195705 S Video Input

# K14201 Relay 190490 Degaussing

# KS15101 Socket 233120 CRT

L12302 VCO 215502 L12303 FM 233056 L12305 10µH 175409 L12352 18µH 195711 L12705 10µH 175409 L13105, 06 4.7µH 237451 L14101 100µH 160186 L14102 27µH 190017 L14103 22µH 215504 L14105 47µH 244222 -

# L14200 Degaussing 218764 -

L14401 6.8µH 191141 -

# L14402 Horizontal Linearity 192844 -

L15101 100µH 160186 L18100 15µH 197613 L18101 18µH 195711 L18102 8.2µH 149170 L18103 12µH 210687 L18104 10µH 160518 L18105 - 197615 L18106 - 190017 L18108 4.7µH 237451 L18111 - 244254 -

# PW14201 Line Cord 241251 AC, Polarized

# R11401, 03 2200 5% 1/2W 246613 -

# R11406 56 5% 1/2W 247610 -

# R11407, 09 2200 20% 1/4W 237429 -

# R11412, 14 56 247610 -

# R11511, 12 100 5% 1/4W Nonflammable 198667 -

R11616 61.9K 1% 1/10W 225705 -

# R11627 10 5% 1/4W Nonflammable 241259 -

# R11909 16 5% 3W 244213 -

R12201 680 2% 1/10W 195939 R12302, 03 120K 2% 1/10W 207834 R12311 620 2% 1/10W 205339 R12318 1800 2% 1/10W 197903 R12351 270 2% 1/10W 197623 R12713 620 2% 1/10W 205339 R12717, 21, 25 220 2% 1/4W 175324 R12801 15K 2% 1/10W 205354 R12802 120K 2% 1/10W 207834 R12804 13K 2% 1/8W 178285 R12805 750K 2% 1/10W 202914 R13111 27K 2% 1/10W 205245 R13123 100K 1% 1/10W 215221 R13124 47.5K 1% 1/10W 237430 R13507 27K 2% 1/10W 205245 -

# R14101 47K 5% 3W 232213 -

# R14102 6800 5% 1/2W 179248 -

# R14105 68 5% 1/4W 175039 -

# R14106 2000 5% 1/4W 175321 -

# R14107 43 5% 1/4W 244214 -

# R14108 .1 5% 3W 244215 -

# R14109 750 5% 1/4W 179317 -

R14112 680 2% 1/10W 195939 R14114 270K 2% 1/10W 205375 -

Function/RatingFunction/Rating

Function/Rating

Function/RatingFunction/Rating

270K 5% 1/10W 195934 -

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NotesNotes

Notes

NotesNotes

Item No.Item No.

Item No.

Item No.Item No.

R14115 143K .1% 1/4W 249013 R14116 2800 .1% 1/4W 244217 -

# R14117 160 5% 7W 227958 -

R14118 33K 5% 3W 243805 -

# R14124 3.3 5% 2W Nonflammable 223680 -

R14126 37.4K 1% 1/10W 215215 R14135 3010 1% 1/4W 248594 -

# R14151 8.2 5% 1W 235378 -

# R14201 2.7M 10% 1/2W 217662 -

# R14202 1.8 10% 15W 200444 -

# R14205 120K 20% 1/2W 238903 -

# R14305 2400 2% 3W 235380 -

R14326 910 2% 1/10W 197627 -

# R14401 15K 5% 1W 190557 -

# R14402 91 5% 1/2W 227249 -

# R14403 820 5% 1W 175349 -

# R14506 13 5% 1W 231508 -

# R14507 1.5 5% 2W 237441 -

# R14508 1 10% 2W 215577 -

# R14701 10 20% 1/2W 241261 -

# R14703 .68 5% 3W 244221 -

# R14704 82K 10% 1/2W 239116 -

# R14705 27K 10% 1/2W 238958 -

R14706 1050 1% 1/4W 231511 -

# R14901 100 5% 1/4W Nonflammable 198667 -

# R14902 39.2K 1% 1/4W 190469 -

# R14903 40.2K 1% 1/4W 219026 -

R14909 15K 2% 1/10W 205354 -

# R15101, 02, 03 10K 5% 2W Nonflammable 176656 -

# R15104, 05, 06 2200 5% 1/2W 247669 -

# R15118 2200 5% 1/2W 247669 -

# R18125 30 5% 3W 247611 -

R18158 243 1% 1/10W 214132 R18159 392 1% 234552 RN14501 Network 215499 -

# RT14201 8 Cold PTC 207768 -

SF12301 Filter 217318 SAW

SP1, 2 Speaker 243893 60mm, X 90mm, 8 Ohms

SW13201 Switch 215500 Power

SW13202 Switch 215500 Volume Up

SW13203 Switch 215500 Volume Down

SW13204 Switch 215500 Channel Up

SW13205 Switch 215500 Channel Down

SW13206 Switch 215500 Menu

# T14101 SMT 244228 -

# T14201 Line Filter 190507 -

# T14301 (1) Horizontal Drive 215541 -

# T14301 (2) Horizontal Drive 252843 -

# T14401 (4) Horizontal Output 244229 -

# TU17101 Tuner 247225 CTT5050S

# V101 CRT HA68ADT275 A68ADT27X05

Y12801 Crystal 161235 3.58MHz

Y13101 Crystal 230708 4MHz

Y14101 Resonator 227064 507.5kHz

Y18100 Crystal 197652 14.318MHz

# Fuse Holder 176642 For F14201 (2 Used)

# For SAFETY use only equivalent replacement part.

(1) Used in chassis CTC203AY1.

(2) Used in chassis CTC203AY7.

(3) Bonded part of CRT.

(4) Screen and focus controls are part of T14401.

Function/RatingFunction/Rating

Function/Rating

Function/RatingFunction/Rating

PC Board 251838 4.5MHz Trap

PC Board 244468 CRT

PC Board 247480 F2PIP

Transmitter 247621 Remote, CRK76TN1

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NotesNotes

Notes

NotesNotes

GE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

GE MODEL 27GT716YX1 (CHASSIS CTC203AGE MODEL 27GT716YX1 (CHASSIS CTC203A

Y1/Y7)

Y1/Y7)Y1/Y7)

Y1/Y7)Y1/Y7)

SET 4715 PSET 4715 P

SET 4715 P

SET 4715 PSET 4715 P

aa

gg

e 4e 4

a

g

e 4

aa

gg

e 4e 4

Loading...

Loading...