Page 1

Operations Manual

Models: 268 Co-Current Conditioner

263 Three-Cycle Filter

Page 2

Table of Contents

How To Use This Manual 3

General Warnings And Safety Information 4

System Operation Cycle Functions 6

Equipment Installation 8

Valve Layout 8

Control Layout 9

Location Selection 10

Water Line Connection 12

Drain Line 14

Regenerant Line Connection 15

Overflow Line Connection 16

Electrical Connection 18

Valve Camshaft 19

Disinfection Of Water Conditioners 20

Ultramax Controller 22

Display Icons 23

Keypad — Buttons 24

Things You Might Need to Know 25

Programming Overview 26

Level I Programming 26

Level II Programming 28

Level III Programming 33

Placing Conditioner Into Operation 34

Performa Exploded View 37

Performa Parts List 38

Troubleshooting 39

2 Table of Contents

Rev A

Page 3

How To Use This Manual

This installation manual is designed to guide the installer through the

process of installing and starting conditioners featuring the Ultramax

series controllers.

This manual is a reference and will not include every system installation

situation. The person installing this equipment should have:

• Knowledge of water conditioning and how to determine proper

Left Side Right Side

Icons That Appear In This Manual

control settings

• Basic plumbing skills

• The directional instructions "left" and “right" are determined by looking

at the front of the unit.

Introduction

WARNING: Failure to follow this instruction can result in personal

injury or damage to the equipment.

NOTE: This will make the process easier if followed.

Inspect the unit for damage or missing parts. Contact your supplier if any

discrepancies exist.

How To Use This Manual 3

Rev A

Page 4

General Warnings And Safety Information

Electrical

There are no user-serviceable parts in the AC adapter, motor, or controller.

In the event of a failure, these should be replaced.

• All electrical connections must be completed according to local codes.

• Use only the power AC adapter that is supplied.

• The power outlet must be grounded.

• To disconnect power, unplug the AC adapter from its power source.

Mechanical

• Do not use petroleum based lubricants such as vaseline, oils, or

hydrocarbon based lubricants. Use only 100% silicone lubricants.

• All plastic connections should be hand tightened. Teflon tape may be

used on connections that do not use an O-ring seal. Do not use pliers

or pipe wrenches.

• All plumbing must be completed according to local codes.

• Soldering near the drain line should be done before connecting the

drain line to the valve. Excessive heat will cause interior damage to the

valve.

• Observe drain line requirements.

• Do not use lead-based solder for sweat solder connections.

• The drain line must be a minimum of 1/2-inch diameter. Use

3/4-inch pipe if the backwash flow rate is greater than 7 GPM

(26.5 Lpm) or the pipe length is greater than 20 feet (6 m).

• Do not support the weight of the system on the control valve fittings,

plumbing, or the bypass.

• It is not recommended to use sealants on the threads. Use Teflon*

tape on the threads of the 1-inch NPT elbow, the drain line

connections, and other NPT threads.

*Teflon is a trademark of E.I. duPont de Nemours.

4 General Warnings And Safety Information

Rev A

Page 5

General

• Observe all warnings that appear in this manual.

• Keep the media tank in the upright position. Do not turn upside down

or drop. Turning the tank upside down will cause media to enter the

valve.

• Operating ambient temperature is between 34°F (1°C) and 120°F

(49°C).

• Operating water temperature is between 34°F (1°F) and 100°F (38°C).

• Working water pressure range is 20 to 120 psi (1.38 to 8.27 bar). In

Canada the acceptable working water pressure range is 20 to 100 psi

(1.38 to 6.89 bar).

• Use only regenerant salts designed for water softening. Do not use ice

melting, block, or rock salts.

• Follow state and local codes for water testing. Do not use water that is

microbiologically unsafe or of unknown quality.

• When filling media tank, do not open water valve completely. Fill tank

slowly to prevent media from exiting the tank.

• When installing the water connection (bypass or manifold) connect to

the plumbing system first. Allow heated parts to cool and cemented

parts to set before installing any plastic parts. Do not get primer or

solvent on O-rings, nuts, or the valve.

General Warnings And Safety Information 5

Rev A

Page 6

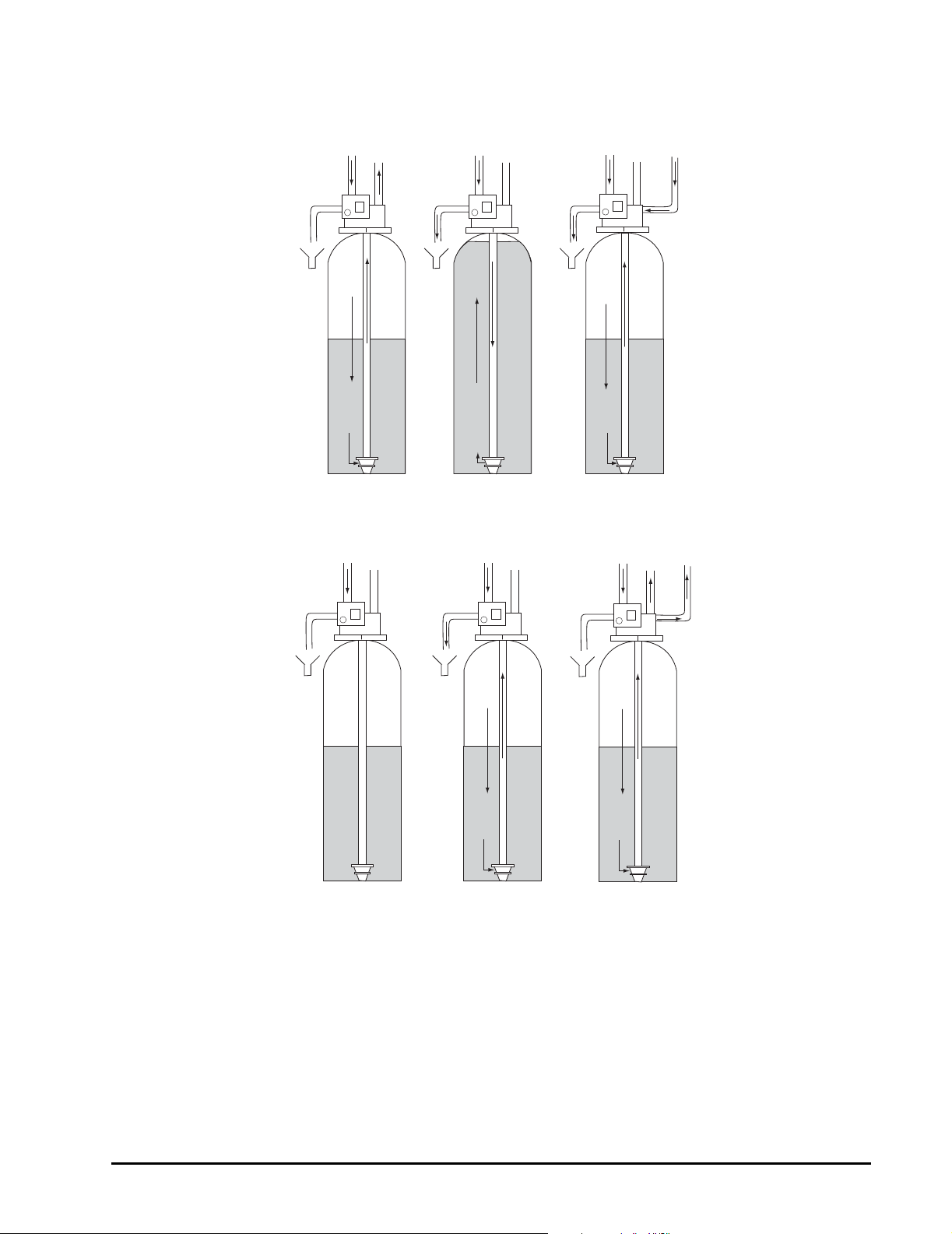

System Operation Cycle Functions

1. Service (Downflow)

Untreated water is directed down through the resin bed and up

through the riser tube. The hardness ions attach themselves to the

resin and are removed from the water. The water is conditioned as it

passes through the resin bed.

2. Backwash (Upflow)

The flow of water is reversed by the control valve and directed down

the riser tube and up through the resin bed. During the backwash

cycle, the bed is expanded and debris is flushed to the drain.

3. Brine/Slow Rinse (Downflow)

The control directs water through the brine injector and brine is drawn

from the regenerant tank. The brine is then directed down through the

resin bed and up through the riser tube to the drain. The hardness ions

are displaced by sodium ions and are sent to the drain. The resin is

regenerated during the brine cycle. Brine draw is completed when the

air check closes.

4. Repressurized Cycle (Hard Water Bypass Flapper Open)

This cycle allows the air and water to hydraulically balance in the

valve before continuing the regeneration.

5. Fast Rinse (Downflow)

The control directs water down through the resin bed and up through

the riser tube to the drain. Any remaining brine residual is rinsed from

the resin bed.

6. Brine Refill

Water is directed down through the resin bed to the regenerant tank

at a controlled rate, to create brine for the next regeneration.

6 System Operation Cycle Functions

Rev A

Page 7

Cycle Water Flows

From Regenerant

SERVICE BACKWASH BRINE/SLOW RINSE

To Regenerant

Tank

Tank

REPRESSURIZE

FAST RINSE

BRINE REFILL

System Operation Cycle Functions 7

Rev A

Page 8

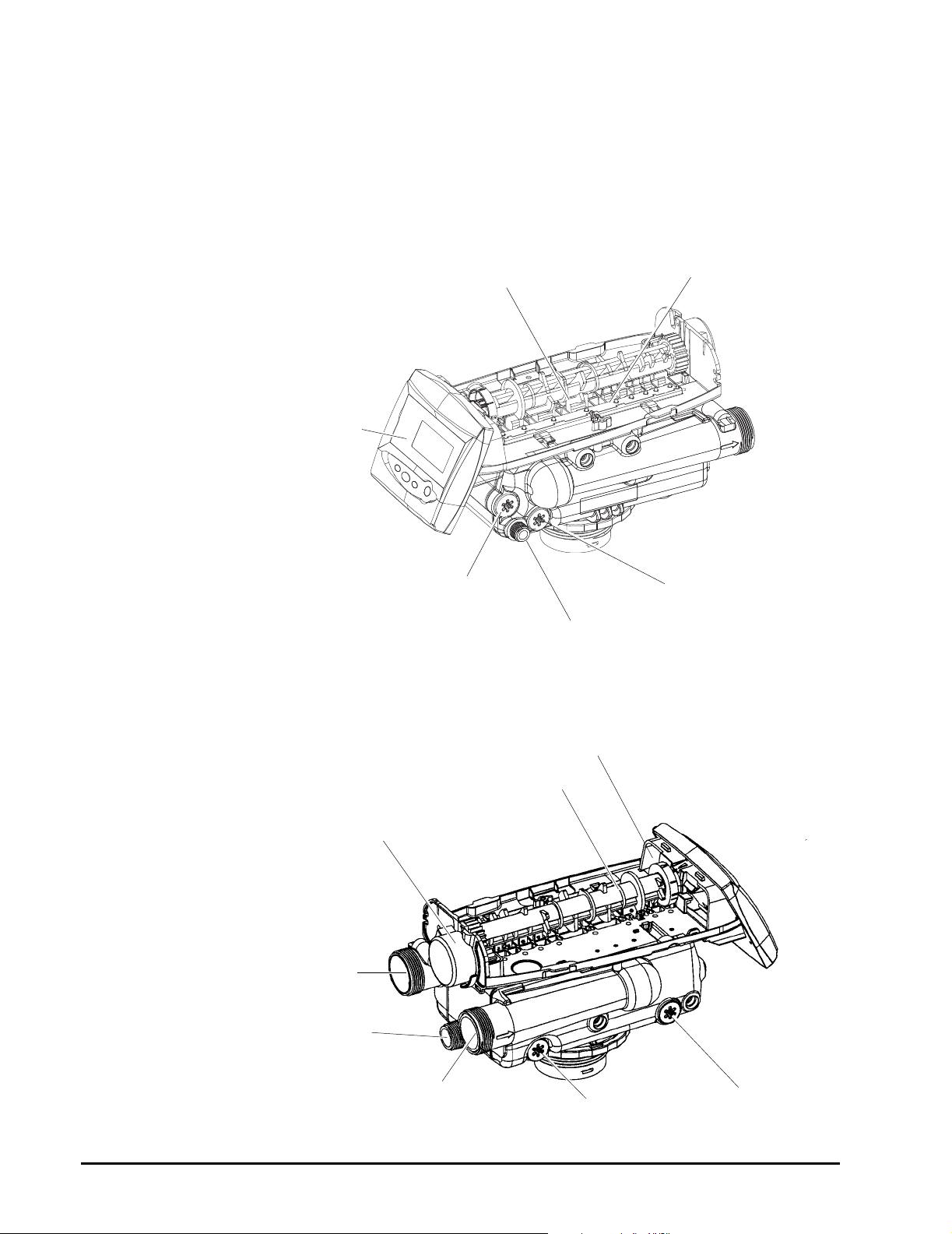

Equipment Installation

Valve Layout

Control Module

One Piece Valve

Disc Spring

Valve Discs

Mount

Outlet

Drain

Refill Controller

Motor

Injector and cap

Regenerant Tube Connection

Optical Sensor

Camshaft

Inlet

Backwash

Drain Control

Injector Screen

Filter

8 Equipment Installation

Rev A

Page 9

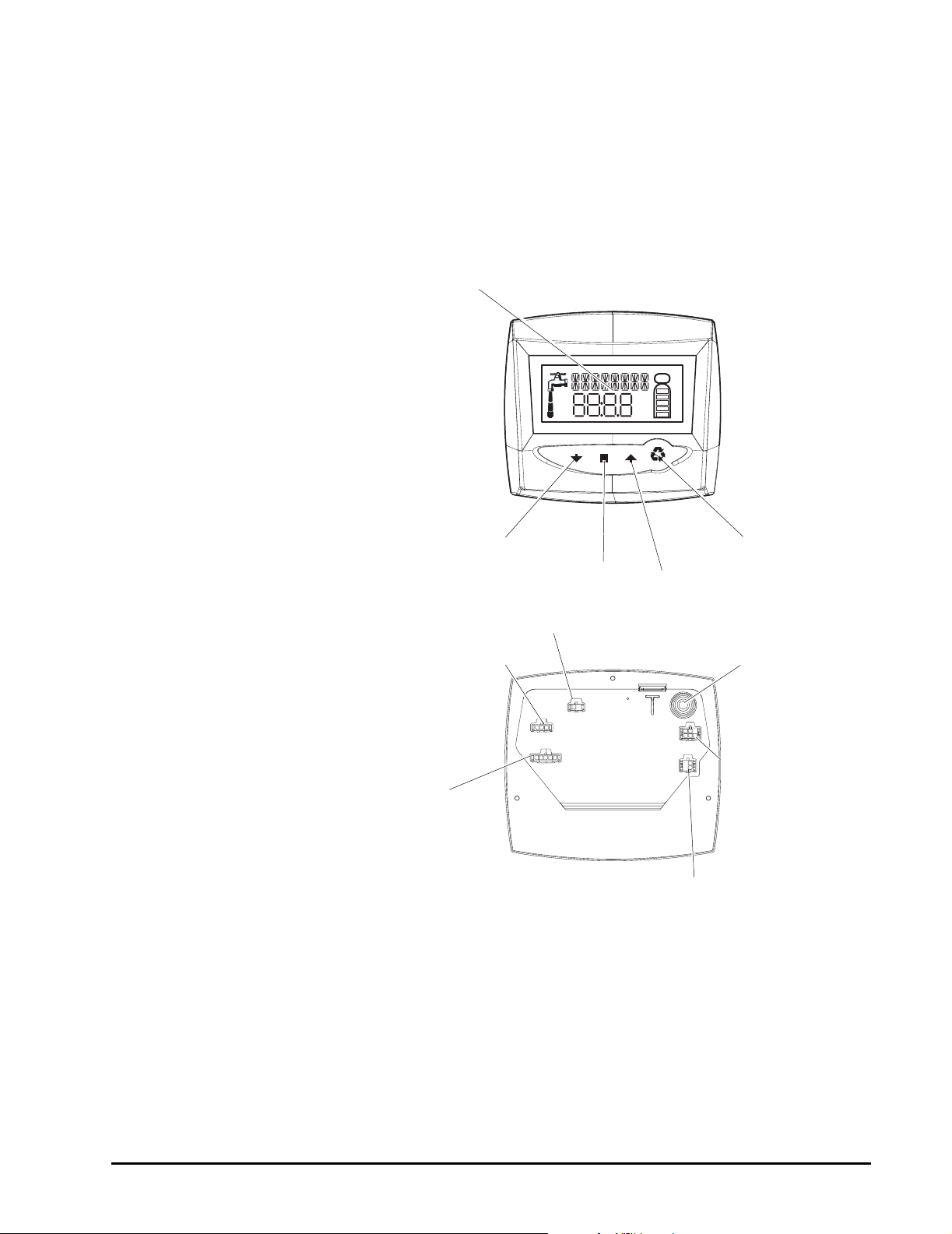

Control Layout

Ultramax Controller

LCD Display

PM

MIN

LBS

KG

x100

Lockout Connection

Secondary Valve

Motor Control

(not used)

Down Button

Set Button

Refill Sensor Probe Outlet

Turbine Input or Dry Contact Signal Input

Manual Regen Button

Up Button

AC Adapter

(low voltage)

Input

Main Motor &

Optical Sensor

Connection

Control Layout 9

Rev A

Page 10

Location Selection

Location of a water treatment system is important. The following

conditions are required:

• Level platform or floor

• Room to access equipment for maintenance and adding regenerant

(salt) to tank.

• Ambient temperatures over 34°F (1°C) and below 120°F (49°C).

• Water pressure below 120 psi (8.27 bar) and above 20 psi

(1.4 bar).

• In Canada the water pressure must be below 100 psi (6.89 bar).

• Constant electrical supply to operate the controller.

• Total minimum pipe run to water heater of ten feet (three meters) to

prevent backup of hot water into system.

• Local drain for discharge as close as possible.

• Water line connections with shutoff or bypass valves.

• Must meet any local and state codes for site of installation.

• Valve is designed for minor plumbing misalignments. Do not support

weight of system on the plumbing.

Outdoor Locations

• Be sure all soldered pipes are fully cooled before attaching plastic

valve to the plumbing.

When the water conditioning system is installed outdoors, several items

must be considered.

• Moisture — The valve and controller are rated for NEMA 3 locations.

Falling water should not affect performance.

The system is not designed to withstand extreme humidity or water

spray from below. Examples are: constant heavy mist, near corrosive

environment, upwards spray from sprinkler.

• Direct Sunlight — The materials used will fade or discolor over time in

direct sunlight. The integrity of the materials will not degrade to cause

system failures.

If it is necessary to locate the conditioner in direct sunlight, a

protective outdoor cover (PN 1242287) over the valve and controller is

necessary. A valve skirt (PN 1242286) that provides further protection

is available.

• Temperature — Extreme hot or cold temperatures will cause damage

to the valve or controller.

Freezing temperatures will freeze the water in the valve. This will cause

physical damage to the internal parts as well as the plumbing.

High temperatures will affect the controller. The display may become

unreadable but the controller should continue to function. When the

temperature drops down into normal operating limits the display will

10 Location Selection

Rev A

Page 11

return to normal. A protective cover should assist with high

temperature applications.

• Insects — The controller and valve have been designed to keep all but

the smallest insects out of the critical areas. Any holes in the top plate

can be covered with a metal foil ductwork tape. The top cover should

be installed securely in place.

• Wind — The Ultramax cover is designed to withstand a 30 mph

(48 Kph) wind when properly installed on the valve.

Location Selection 11

Rev A

Page 12

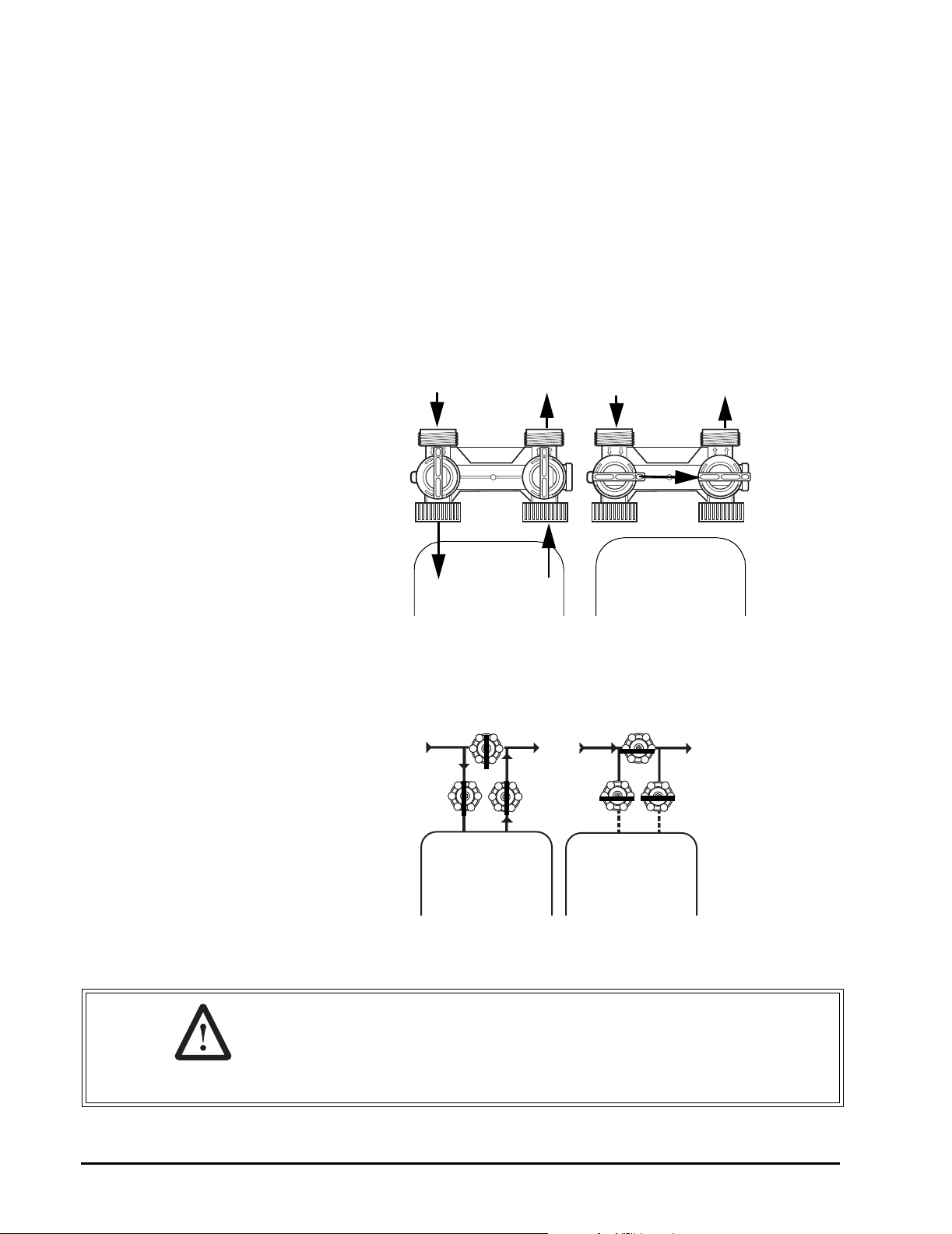

Water Line Connection

Figure 1

Autotrol Series 1265

bypass for use with

Performa

A bypass valve system should be installed on all water conditioning

systems. Bypass valves isolate the conditioner from the water system and

allow unconditioned water to be used. Service or routine maintenance

procedures may also require that the system is bypassed. The illustrations

below show the two common bypass methods.

Figure 2

Typical Globe Valve Bypass

System

Normal Operation

In

B

Y

P

A

S

S

Out

B

Y

P

A

S

S

In

A

P

S

Y

S

Water

Conditioner

Normal Operation In Bypass

In Bypass

B

Water

Conditioner

Out

S

S

A

P

Y

B

Water

Conditioner

Water

Water

Conditioner

Water

WARNING: The inlet water must be connected to the inlet port of the

valve. When replacing non-Autotrol valves, the inlet and outlet may be

reversed. It is also possible for the plumbing to be installed in an

opposite order.

Do not solder pipes with lead-based solder.

12 Water Line Connection

Rev A

Page 13

WARNING: Do not use tools to tighten plastic fittings. Over time,

stress may break the connections. When the 1265 bypass valve is used,

only hand tighten the nuts.

WARNING: Do not use petroleum grease on gaskets when connecting

bypass plumbing. Use only 100% silicone grease products when

installing any Autotrol brand valve. Non-silicone grease may cause

plastic components to fail over time.

WARNING: Several tube adapters are available to connect the valve

to the water plumbing. See Parts List.

Water Line Connection 13

Rev A

Page 14

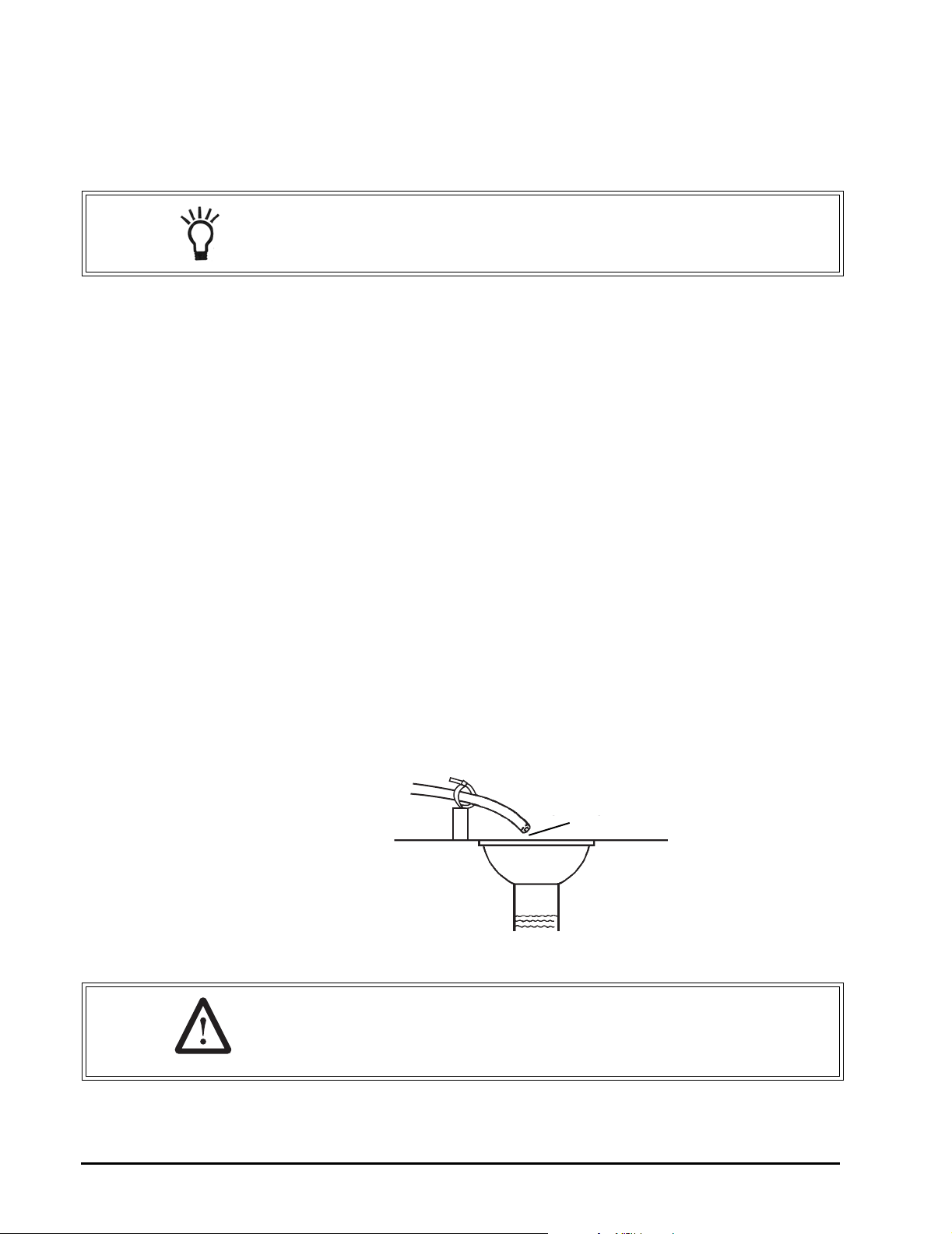

Drain Line

Drain Line Connection

NOTE: Standard commercial practices are expressed here. Local

codes may require changes to the following suggestions. Check with

local authorities before installing a system.

1. The unit should be above and not more than 20 feet (6.1 m) from the

drain. Use an appropriate adapter fitting to connect 1/2-inch (1.3 cm)

plastic tubing to the drain line connection of the control valve.

2. If the backwash flow rate exceeds 5 gpm (22.7 Lpm) or if the unit is

located 20-40 feet (6.1-12.2 m) from drain, use 3/4-inch (1.9 cm)

tubing. Use appropriate fittings to connect the 3/4-inch tubing to the

3/4-inch NPT drain connection on valve.

3. The drain line may be elevated up to 6 feet (1.8 m) providing the run

does not exceed 15 feet (4.6 m) and water pressure at the conditioner

is not less than 40 psi (2.76 bar). Elevation can increase by 2 feet (61

cm) for each additional 10 psi (.69 bar) of water pressure at the drain

connector.

4. Where the drain line is elevated but empties into a drain below the

level of the control valve, form a 7-inch (18-cm) loop at the far end of

the line so that the bottom of the loop is level with the drain line

connection. This will provide an adequate siphon trap.

Figure 3

Drain Line Connection

Where the drain empties into an overhead sewer line, a sink-type trap

must be used.

Secure the end of the drain line to prevent it from moving.

Right Wa y

Air Gap

Drain

WARNING: Never insert drain line directly into a drain, sewer line or

trap (Figure 3). Always allow an air gap between the drain line and the

wastewater to prevent the possibility of sewage being

back-siphoned into the conditioner.

14 Drain Line

Rev A

Page 15

Regenerant Line Connection

(not used with 3-cycle filter system)

The regenerant line from the tank connects to the valve. Make the

connections and hand tighten. Be sure that the regenerant line is secure

and free from air leaks. Even a small leak may cause the regenerant line to

drain out, and the conditioner will not draw regenerant from the tank. This

may also introduce air into the valve causing problems with valve

operation.

Ensure that pipe sealant (Teflon* tape) is applied to the 3/8-inch NPT

regenerant line connection.

Figure 4 Regenerant Line

Connection

Regenerant Line Connection

NOTE: When installing a 3-cycle filter (263 valve) use a cap on the

regenerant line connection to prevent water seepage from the port. See

Parts List for part number.

*Teflon is a trademark of E.I. duPont de Nemours.

Regenerant Line Connection 15

Rev A

Page 16

Overflow Line Connection

(not used with 3-cycle filter system)

In the event of a malfunction, the regenerant TANK OVERFLOW will direct

“overflow” to the drain instead of spilling on the floor. This fitting should be

on the side of the cabinet or regenerant tank. Most tank manufacturers

include a post for the tank overflow connector.

To connect the overflow line, locate hole on side of tank. Insert overflow

fitting into tank and tighten with plastic thumb nut and gasket as shown

(Figure 5). Attach length of 1/2-inch (1.3-cm) I.D. tubing (not supplied) to

fitting and run to drain. Do not elevate overflow line higher than overflow

fitting.

Do not tie into drain line of control unit. Overflow line must be a direct,

separate line from overflow fitting to drain, sewer or tub. Allow an air gap

as per drain line instructions.

Figure 5

Overflow Line Connection

Overflow Fitting

Drain Tubing

Secure hose in place

Air Gap

Drain

16 Overflow Line Connection

Rev A

Page 17

Figure 6

Regenerant Tank Check Valve*

(not used with 3-cycle filter system)

* Furnished as an option from system manufacturer.

Overflow Line Connection 17

Rev A

Page 18

Electrical Connection

All Ultramax controllers operate on 12-volt alternating current power

supply. This requires use of the GE Water Technologies supplied AC

adapter. A variety of AC adapters are available for different applications.

These AC adapters are available from your supplier. They include:

120 VAC AC Adapters:

Controller Location

AC Adapter

Standard wall-mount

AC adapter

Outdoor rated AC

adapter

Input

Voltage

120V 60Hz Standard indoor

120V 60Hz UL listed for

Application Part Number

1000811

application

1235448

outdoor

installations

Make sure power source matches the rating printed on the AC adapter.

NOTE: The power source should be constant. Be certain the AC

adapter is not on a switched outlet. Power interruptions longer than 8

hours may cause the controller to lose the time and day settings. When

power is restored, the day and time settings must then be re-entered.

The Ultramax controllers are designed to be mounted on the valve or

attached to a flat surface. Installations that do not provide easy access to

the valve can have the controller mounted for remote operation.

A remote mount connection, PN 1256257, is available for the Ultramax

Series controller.

18 Electrical Connection

Rev A

Page 19

Valve Camshaft

Figure 7

Camshaft Front End for

263 and 268 valve bodies

The front end of the camshaft has an indicator cup. The cup has slots in

the outer periphery and numbers on the inside face (Figure 7).

The numbers can be seen with the cover off, from the front over the top of

the controller. The number at the top indicates which regeneration cycle is

currently in progress.

Treated Water Indicator

(normal operation)

Treated Water Slot

The corresponding slot for the number is positioned at the optical sensor

which is approximately 90 degrees out of phase.

Regeneration Cycle Indicators

0 = Treated Water - normal operation mode

1 = Backwash Cycle

2 = Regenerant Draw Cycle (not used in filter mode)

3 = Slow Rinse Cycle (not used in filter mode)

4=System Pause

5=Fast Rinse Cycle 1

6 = Backwash Cycle 2 (not used in filter mode)

7 = Fast Rinse Cycle 2 (not used in filter mode)

8 = Regenerant Refill (not used in filter mode)

Valve Camshaft 19

Rev A

Page 20

Valve Disc Operation

Figure 8 - Ultramax Valve

4 Outlet Valve

6 Rinse Drain

2 Bypass Valve

Disinfection Of Water Conditioners

The materials of construction of the modern water conditioner will not

support bacterial growth, nor will these materials contaminate a water

supply. During normal use, a conditioner may become fouled with organic

matter, or in some cases with bacteria from the water supply. This may

result in an off-taste or odor in the water.

Some conditioners may need to be disinfected after installation and some

conditioners will require periodic disinfection during their normal life.

Depending upon the conditions of use, the style of conditioner, the type of

ion exchanger, and the disinfectant available, a choice can be made

among the following methods.

Sodium or Calcium Hypochlorite

Application

These materials are satisfactory for use with polystyrene resins, synthetic

gel zeolite, greensand and bentonites.

3 Inlet Valve

7 Backwash Drain Valves

5 Refill Valve

1 Regenerant Valve

5.25% Sodium Hypochlorite

These solutions are available under trade names such as Clorox*. If

stronger solutions are used, such as those sold for commercial laundries,

adjust the dosage accordingly.

1. Dosage

A. Polystyrene resin; 1.2 fluid ounce (35.5 mL) per cubic foot.

B. Non-resinous exchangers; 0.8 fluid ounce (23.7 mL) per cubic foot.

2. Brine tank conditioners

A. Backwash the conditioner and add the required amount of

hypochlorite solution to the well of the regenerant tank. The

regenerant tank should have water in it to permit the solution to be

carried into the conditioner.

B. Proceed with the normal regeneration.

*Clorox is a trademark of the Clorox Company.

20 Disinfection Of Water Conditioners

Rev A

Page 21

Calcium Hypochlorite

Calcium hypochlorite, 70% available chlorine, is available in several forms

including tablets and granules. These solid materials may be used directly

without dissolving before use.

1. Dosage

A. Two grains (approximately 0.1 ounce [3 mL]) per cubic foot.

2. Regenerant tank conditioners

A. Backwash the conditioner and add the required amount of

hypochlorite to the well of the regenerant tank. The regenerant tank

should have water in it to permit the chlorine solution to be carried

into the conditioner.

B. Proceed with the normal regeneration.

Disinfection Of Water Conditioners 21

Rev A

Page 22

Ultramax Controller

Power Loss Memory Retention

The Ultramax series controllers feature battery-free time and date

retention during the loss of power. This is designed to last a minimum of 8

hours depending on the installation. The controller will continue to keep

time and day in dynamic memory while there is no AC power.

The controller will not track water usage on volumetric demand controls in

the event of a power failure.

All programmed parameters are stored in the Ultramax series static

memory and will not be lost in the event of a power failure. These settings

are maintained separately from the time and day settings.

Motor

The Ultramax series controller uses a standard 12-volt AC motor that

works with either 50 Hz or 60 Hz. The same motor is used worldwide and

does not need to be changed for different power conditions.

Controller Memory

Information entered or calculated by the controller is stored in two

different ways.

Variable Reserve Function

A static memory will store:

Model number

Regenerant setting

Time of regeneration

Days between regeneration

Filter mode

A dynamic memory with 8 hour retention will store:

Current day of week

Running clock

NOTE: Water flow to the valve can be turned on or bypassed when the

controller is powered up for the first time.

The Ultramax metered-demand volumetric controllers are designed with a

variable reserve feature. This feature automatically adjusts the reserve to

the end-user’s water usage schedule.

A variable reserve saves salt and water by only regenerating when

absolutely necessary, and ensures enough soft water for typical

high-water usage days.

Each day of regeneration the controller reviews the last four weeks of

water usage for the same day of the week to determine if the remaining

capacity is adequate for the next day of the week. If not, it will initiate an

automatic regeneration.

22 Ultramax Controller

Rev A

Page 23

Display Icons

Figure 9

10

9

2

PM

MIN

LBS

KG

x100

7

6

8

3

4

5

NOTE: In normal operation and during programming, only a few of the

icons will actually be displayed.

1. Displays amount of conditioning capacity remaining.

2. "PM" indicates that the time displayed is between 12:00 noon and

12:00 midnight (there is no AM indicator). PM indicator is not used if

clock mode is set to 24-hour.

1

4

3. When "MIN" is displayed, the value entered is in minute increments.

4. When "LBS" is displayed, the value entered is in pounds.

5. When "Kg" is displayed, the value entered is in kilograms or kilograins.

6. Four digits used to display the time or program value. Also used for

error codes.

7. Colon flashes as part of the time display. Indicates normal operation.

8. X100 multiplier for large values.

9. Shows when water is flowing through the valve.

10. Banner display.

Display Icons 23

Rev A

Page 24

Keypad — Buttons

Programming Conventions

21

3

4

1. DOWN arrow. Generally used to scroll down or increment through a

group of choices.

2. SET. Used to accept a setting that normally becomes stored in

memory. Also used together with the arrow buttons.

3. UP arrow. Generally used to scroll up or increment through a group of

choices.

4. Regen. Used to command the controller to regenerate.

The Ultramax controller is programmed using the buttons on the keypad.

The programming instructions will be described two ways whenever a

section has keypad input.

First, a table shows simplified instructions. Second, text follows that

describes the action. In each table:

"Action" lists the event or action desired.

"Keys" are listed as:

UP for up arrow

DOWN for down arrow

SET for set

REGEN for regeneration

"Duration" describes how long a button is held down:

P/R for press and release

HOLD for press and hold

X sec for a number of seconds to press the button and hold it down

"Display" calls out the display icons that are visible.

24 Keypad — Buttons

Rev A

Page 25

Things You Might Need to Know

• When the controller is first plugged in, it may display a flashing Err 3

and scrolling "Call Dealer for Service" message. This means that the

controller is rotating to the home position. The Err 3 will clear when the

control reaches the home position.

• The preset default time of regeneration is 2:00 AM. If you want to

change it, see the Level II Programming section.

• The controller can be programmed to regenerate on specific days of

the week. See Level II Programming section.

• If electrical power is not available, the camshaft can be rotated

counterclockwise by hand if the motor is removed.

• The Ultramax series controller sends commands to the motor for

camshaft movement. However, water pressure/flow are required

during the regeneration cycle for backwash, purge and refill, and brine

draw to actually take place.

• Make sure control power source is plugged in. The transformer should

be connected to a non-switched power source.

Things You Might Need to Know 25

Rev A

Page 26

Programming Overview

The Ultramax Series controller is designed to operate by setting the Time

of Day, Day of the Week, and the Hardness. The remaining settings are set

at the factory using a Model Number.

The controller menu has three levels:

Level I Basic — This level is easily accessed by the user. Only the Time of

Day, Day of Week and Time of Regeneration can be changed in Level I.

Level II Professional — This level allows the installer to change settings

such as hardness, capacity, and cycle times.

Level III History — This operation history and the program are viewable.

This information is used to troubleshoot and maintain the system.

NOTE: If a button is not pushed for thirty seconds, the controller

returns to normal operation mode.

NOTE: Any setting that is a time display will not show "AM" for times

between 12:00 midnight and 12:00 noon. "PM" is displayed to the right

of the time for times between 12:00 noon and 12:00 midnight. When

using the 24 hour clock "PM" is not displayed.

Level I Programming

Level I program parameters are those that can be accessed by the end

user by pressing the SET button. They include:

Time of Day

Day of Week

Time of Regeneration

• Setting Time of Day

Upon initial start up of the controller, you will need to set the time of

day. The words “Time of Day” will scroll across the banner display and

the currently programmed time of day will be flashing below. If time is

not flashing, press the SET button. To change the time of day, press

and hold the UP or DOWN button until the correct time of day is

displayed. Press the SET button to accept the selection.

NOTE: When the controller is set up for a twelve hour clock a PM

indicator will illuminate when the displayed time is in the PM hours.

There is no AM indicator

26 Programming Overview

Rev A

Page 27

• Setting Day of Week

After setting the Time of Day the banner display will show the word

“Day” followed by an abbreviated day of the week.

SU = Sunday

MO = Monday

TU = Tuesday

WE = Wednesday

TH = Thursday

FR = Friday

SA = Saturday

Use the UP or DOWN arrow buttons to change the flashing day of

week. Press the SET button when the current day of week is flashing.

• Setting Regeneration Time

The "Regeneration Time" is the setting which allows the programmer

to select the time of day that regeneration should occur. The words

“Regeneration Time” will scroll through the banner display. To change

the regeneration time press and hold the UP or DOWN button until the

desired regeneration time is displayed. Press SET to lock this time into

memory.

NOTE: When the controller is set up for a twelve hour clock a PM

indicator will illuminate when the displayed time is in the PM hours.

There is no indicator for the AM times.

Level I Programming 27

Rev A

Page 28

Level II Programming

Level II program parameters are those parameters used to fine-tune a

conditioners operation. These are accessible by pressing and holding the

UP and DOWN buttons until the display goes blank. Then release the

buttons. Calendar Override is the first Level II parameter displayed. Level II

program parameters include:

268 Conditioner Operation Type 263 Filter Operation Type

CALENDAR OVERRIDE CALENDAR OVERRIDE

SALT AMOUNT REGEN SU

CAPACITY K GRAIN REGEN MO

HARDNESS GPG REGEN TU

SELECT LANGUAGE REGEN WE

CLOCK MODE REGEN TH

UNITS OF MEASURE REGEN FR

INJECTOR SELECTION* REGEN SA

BACKWASH 1 CAPACITY GAL

SLOW RINSE SELECT LANGUAGE

FAST RINSE 1 CLOCK MODE

BACKWASH 2 UNITS OF MEASURE

FAST RINSE 2 BACKWASH

OPERATION TYPE 268* FAST RINSE

SERVICE INTERVAL OPERATION TYPE 263*

CHLORINE GENERATOR SERVICE INTERVAL

CHLORINE GENERATOR

*View only.

Level II parameters will, in almost all cases, be preset to meet your

configuration needs. The predefined system number will preprogram all of

the Level II parameters to the selected default values.

• Setting the Calendar Override

Calendar Override allows the programmer to set the maximum days

between regenerations. A setting of 0 (zero) means the calendar

override is disabled. To change the calendar override, press the SET

button while the words “CALENDAR OVERRIDE" appear on the banner

display. The blinking digit can be changed to the desired numbers of

days. To lock in the parameter, press the SET button.

WARNING: Setting days between regeneration to zero will cause the

system to not regenerate. This setting is used for selecting regeneration

on specific days or to use with a remote regeneration input. See below.

28 Level II Programming

Rev A

Page 29

NOTE: Regeneration on specific day is used to provide regeneration

when water demands are not steady. Example: If the weekdays have

low usage and the weekend is high, then regeneration every three days

will not meet the requirements.

The calendar override days between regeneration must be set to zero

to enable regeneration on specific days.

• Setting Backwash Days (263 filter only)

The 263 filter controller can be programmed to regenerate on an elapsed

time period (calendar override) or by the day of the week. If you would like

to regenerate on specific days select a 0 (zero) for the calendar override

setting, the 263 filter will prompt you to select the days of the week in

which you would like the unit to regenerate/backwash. For example, the

unit could be programmed to regenerate every Monday, Wednesday and

Friday.

• Setting the Salt Amount (268 softener only)

Is selected by the system model number. Your Ultramax Water Treatment

Dealer enters the model numbers based on the specific application

requirements.

• Setting Capacity

Softener Default Capacity Setting

The default capacity setting is accurately calculated when the model

number is entered by the factory. The capacity can be changed to

operate "custom systems". Contact your Ultramax Water Treatment

Dealer before adjusting the capacity setting. Default capacities are

shown in Table 1.

Filter Capacity

Filter capacity is set in gallons or cubic meters. It is programmable

from 100 to 14000 gallons or 1 to 140 cubic meters of capacity. Press

the SET button and the digits will begin flashing. Change the capacity

by using the up and down arrows to adjust the setting. To accept the

setting, press the SET button.

NOTE: (Conditioners only) A different model number must be selected

to change the default capacity and salt dosage.

• Setting the Hardness (conditioner only)

Hardness is set in grains per gallon (gpg) or parts per million (ppm) and

should be programmed to the total hardness level of the incoming

water supply. Press the SET button to make the display flash. Use the

UP and DOWN buttons to adjust the hardness setting. Press the SET

button when the desired setting has been reached.

• Setting the Language

Level II Programming 29

Rev A

Page 30

The controller is capable of displaying 6 different languages. They are

as follows:

1 = English

2 = Spanish

3 = French

4 = Italian

5 = Flemish

6 = German

Press the SET button and select the desired language using the UP or

DOWN buttons. Press the SET button to accept the selection.

•Setting Clock Mode

The controller can be programmed to operate with a 12- or 24-hour

clock. Program the clock mode to "12" for a 12-hour clock or "24" for a

24-hour clock. When the controller is programmed as a 12-hour clock

the PM indicator will illuminate during the PM hours. There is no AM

indicator.

•Setting Units of Measure

The controller can be programmed to operate in U.S. or Metric units.

Program the Units of Measure to 0 (zero) for U.S. units or 1 for Metric

units.

•Viewing the Injector Type

Is selected by system model number and cannot be changed.

• Adjusting the Cycle Times

Conditioner Cycle Times

The following cycle times are adjustable.

268 Conditioner

Cycle Range

Backwash 1 1-60 minutes

Slow Rinse * 1-125 minutes

Fast Rinse 1 1-30 minutes

Backwash 2 0-30 minutes

Fast Rinse 2 0-30 minutes

263 Filter Cycle Times

Cycle Range

Backwash 1-50 minutes

Fast Rinse 1-30 minutes

Refill time does not appear as this cycle time is determined by the salt

setting.

*The controller calculates the Slow Rinse default time on injector type,

system size and salt dosage. The cycle times can be adjusted for

custom applications. Please contact your Ultramax Water Treatment

Dealer before attempting to adjust the Slow Rinse time.

30 Level II Programming

Rev A

Page 31

•Operation Type

This parameter displays the controller type and is preset at the

factory: 268 softener, 263 filter.

• Setting the Service Interval

The service interval feature is an option that will allow the installer to

program the unit to ask for maintenance after a programmed

duration. The feature is programmed from 0 (zero) to 99 months. When

the programmed length of time has been reached the words "CALL

DEALER FOR SERVICE" will appear in the banner display to signal the

end user that regular maintenance may be required. If it is set to 0

(zero) the function is disabled. If you wish to enable this function

program the desired service interval duration.

Level II Programming 31

Rev A

Page 32

• Setting the Chlorine Generator/Salt Check (conditioner only)

The controller has the capability to produce a low level of chlorine

during the brine draw stage of regeneration. It can also sense if there

is any brine present during the time when brine draw is occurring. This

parameter can be adjusted to the following:

0 = Chlorine Generator with Salt Check disabled

1 = Chlorine Generator with Salt Check enabled

2 = Salt Check only

A refill sensor probe kit (P/N 3002122) must be installed for this

function to work properly. After it is installed, select the desired

parameter and push SET to accept the selection.

32 Level II Programming

Rev A

Page 33

Level III Programming

Scrolling Display Readout Range/Values

Historical information can be retrieved from the controller be pressing the

SET and DOWN buttons simultaneously, with the controller in the home

position. Release both buttons when the controller displays MODEL

NUMBER. Press the UP or DOWN buttons to navigate to each setting. The

readout will scroll across the top of the display and the value will be

displayed below the readout. Upon completing the initial programming

procedure the average daily usages will display the same value. These

values will changes as the unit logs water usage.

Valve Type

268 263

MODEL NUMBER

a

See Salt/Capacity Table X X

DAYS SINCE REGENERATION 0 to 255 days X X

PEAK FLOW RATE - DAY AND TIME Language/Clock Mode Dependant X

PEAK FLOW RATE GPM

a

0 to 47 GPM X

WATER TREATED TODAY GAL 0 to 65536 gal. X

WATER SINCE REGENERATION GAL 0 to 65536 gal. X

SUNDAY AVERAGE USAGE GAL 0 to 65536 gal. X

MONDAY AVERAGE USAGE GAL 0 to 65536 gal. X

TUESDAY AVERAGE USAGE GAL 0 to 65536 gal. X

WEDNESDAY AVERAGE USAGE GAL 0 to 65536 gal. X

THURSDAY AVERAGE USAGE GAL 0 to 65536 gal. X

FRIDAY AVERAGE USAGE GAL 0 to 65536 gal. X

SATURDAY AVERAGE USAGE GAL 0 to 65536 gal. X

TOTAL WATER USED GAL X 100

a

TOTAL WATER USED GAL X 1000000

0 TO 999900 gal.

a

0 to 42,940,000 gal.

a

a

X

X

MONTHS SINCE SERVICE

a

0 to 2184 months

a

XX

a. Bold text indicates that specif ic values can be reset. Press and hold the SET button for 5 seconds to reset

the value.

Level III Programming 33

Rev A

Page 34

Placing Conditioner Into Operation

Conditioner and Filter Start-Up

After you have performed the previous initial power-up steps, you will

need to place the conditioner into operation. Follow these steps carefully,

as they differ from previous Autotrol valve instructions.

NOTE: The control valve can be started-up even if power is not yet

available to the controller. The valve must be connected to the water

supply. The motor can be unmounted from the valve, and the camshaft

can be indexed manually counterclockwise by hand. This will allow the

tank to be filled and allows regenerant draw to be tested.

Function Display Text (268) Display Text (263)

Treated Water Ultramax (268) Ultramax (263)

Regeneration Backwash

Brine Draw/Slow Rinse

Pause - Please Wait

Fast Rinse 1

Backwash 2

Fast Rinse 2

Brine Tank Refill

Backwash

Pause - Please Wait

Fast Rinse

1. Remove the cover from the valve. Removing the cover will allow you to

see that the camshaft is turning, and in which cycle the camshaft is

currently positioned.

2. With the supply water for the system still turned off, position the

bypass valve to the “not in bypass” (normal operation) position.

3. Press and release the REGEN button on the controller. The scrolling

text on the display will show "DELAYED REGENERATION". Press UP to

navigate to "IMMEDIATE REGENERATION".

4. Press and release SET and UP to begin regeneration. The display will

show eight LEDs moving from left to right on the banner display

indicating that the motor is running. Additionally, the display will show

the total regeneration time remaining.

Pressing SET when the motor has stopped displays the cycle

description and cycle time remaining.

5. Press and release SET and UP simultaneously to advance to each

cycle.

6. Advance the control to the Backwash. See below for the cycle

sequences.

7. Fill the media tank with water.

A. While the controller is in cycle (Backwash), open the water supply

valve very slowly to approximately the 1/4 open position.

34 Placing Conditioner Into Operation

Rev A

Page 35

WARNING:

tank into the valve or the plumbing. In the ¼ open position, you should hear air

slowly escaping from the valve drain line.

If opened too rapidly or too far, media may be lost out of the

B. When all of the air has been purged from the media tank (water

begins to flow steadily from the drain line), open the main supply

valve all of the way. This will purge the final air from the tank.

C. Allow water to run to drain until the water runs clear from the drain

line. This purges any refuse from the media bed.

D. Turn off the water supply and let the system stand for about five

minutes. This will allow any air trapped to escape from the tank.

NOTE: 263 Filter - advance control back to the treated water position,

proceed to Step 12.

8. Add water to the regenerant tank (initial fill) (conditioner only).

A. With a bucket or hose, add approximately 4 gallons (15 liters) of

water to the regenerant tank.

If the tank has a salt platform in the bottom of the tank, add water

until the water level is approximately 1 inch (25 mm) above the

platform.

NOTE: We recommend that you do not put regenerant into the tank until

after the control valve has been put into operation. With no regenerant in the

tank, it is much easier to view water flow and motion in the tank.

Action Key Duration Display

Display current

cycle

Advance to next

cycle

Cancel

regeneration

SET 5 Sec. Current cycle

SET and UP Press and

release

SET and UP 5 Sec. Regeneration

Next cycle

canceled

Placing Conditioner Into Operation 35

Rev A

Page 36

9. Engage the refill cycle to prime the line between the regenerant tank

and the valve (conditioner only).

A. Slowly open the main water supply valve again, to the fully open

position. Be sure not to open too rapidly as that would push the

media out of the media tank.

B. Advance the controller to the regenerant tank Refill position. From

the Backwash 1 cycle, press and hold the SET button. This will

display the current cycle.

NOTE: As you advance through each cycle there will be a slight delay

before you can advance to the next cycle. There will be a pause after

the brine draw and slow rinse cycles (system pause). This cycle allows

the water/air pressure to equalize on each side of the valve discs before

moving on.

C. With the water supply completely open, when you arrive at the

regenerant tank refill cycle, the controller will direct water down

through the line to the regenerant tank. Let the water flow through

the line until all air bubbles have been purged from the line.

D. Do not let the water flow down the line to the tank for more than one

to two minutes, or the tank may overfill.

E. Once the air is purged from the line, press the SET button and the UP

button simultaneously to advance to Treated Water position.

10. Draw water from the regenerant tank.

A. From the treated water position initiate a manual regeneration.

The controller will begin a manual regen, and advance the control

valve to the backwash cycle. Press the SET and UP button to

advance to brine draw/slow rinse cycle.

B. With the controller in this position, check to see that the water in the

regenerant tank is being drawn out of the tank. The water level in

the tank should recede very slowly.

C. Observe the water being drawn from the regenerant tank for at

least three minutes. If the water level does not recede, or goes up,

check all hose connections. C2 should be displayed.

11. If the water level is receding from the regenerant tank you can then

advance the controller back to the treated water position by pressing

SET and the UP buttons simultaneously.

12. Finally, turn on a faucet plumbed after the water conditioner. Run the

faucet until the water runs clear.

36 Placing Conditioner Into Operation

Rev A

Page 37

Performa Exploded View

4

20

7

22

23

6

5

3

8

17

1

2

15

11

10A

11

10B

18

16

12

9

14

21

19

13

Warning: Do not use the flow control ball with #10A.

Performa Exploded View 37

Rev A

Page 38

Performa Parts List

Part

Code

10A 1000222 Regenerant Refill C ontroller, No Ball 1 * 1239753 Switch Kit, Top Plate Mount, 0.1 amp

10B 1243510 Regenerant Refill Controller * 1239754 Switch Kit, Top Plate Mount, 5 amp

11 1030502 Ball, Refill Flow Control * 1242286 Valve Skirt

12 1002449 Drain Fitting Elbow (3/4-inch hose 1 * 1242287 Cover with Shield

13 1010428 O-Ring 1 * 1233187 Motor Locking Pin

14 1000269 Injector Cap with O-Ring 1 * 3002122 Refill Sensor Probe Kit

15 1035 62 2 Tank Ring 1 * 123 9760 Blending Valve Kit Ult ram a x

No. Description Qty. Code

1 1244651 Valve Assembly w/o Flow Controls 1 16 Plumbing Adapter Kits: 1

2 1235338* Top Plate, Ultramax Series Valves 1 1001606 3/4-inch Copper Tube Adapter Kit

3 1235339 Valve Disc Spring, One Piece, Performa 1 1001670 1-inch Copper Tube Adapter Kit

Valve 1001608 22-mm Copper Tube Adapter Kit

4 1242282 Cover, V alve, Ultramax Series 1 1001613 3/4-inch CPVC Tube Adapter Kit

Controller 1001614 1-inch CPVC Tube Adapter Kit

5 1235352* Cam, 263-268 Ultramax Series Valve, STD, 1 1001615 25-mm CPVC Tube Adapter Kit

Black 1001769 3/4-inch NPT Plastic Pipe Adapter Kit

6 Drain Con trol Assembly: 1 1001603 1-inch NPT Plastic Pipe Adapter Kit

1000212 No. 10 (2.5 gpm; 9.5 Lpm) 1001604 3/4-inch BSPT Plastic Pipe Adapter Kit

1000213 No. 12 (3.5 gpm; 13.2 Lpm) 1001605 1-inch BSPT Plastic Pipe Adapter Kit

1000214 No. 13 (4.1 gpm; 15.5 Lpm) 1001611 3/4-i nch BSPT Brass Pipe Adapt er Kit

1000215 No. 14 (4.8 gpm; 18.2 Lpm) 1001610 1-inch NPT Brass Pipe Adapter Kit

7 12352 69 Motor/ O ptical C able Assembly, Ult ramax

Series

Controller 17 1235373 Module, Sensor, Photo Interrupter 1

8 10002 26 Scr een/ Cap Assembl y w/ O-Ri ng 1 18 1235361 Motor w/S pa cer & Pin ion, Ult rama x Seri es 1

9 Injector (High Efficiency) Options: Controller, 12 V, 50/60 Hz

10357 33 “H” Injector (High Efficiency) - Lt Purple 19 1001986 13/16 inch Rubber Insert (Optional) 1

(9-inch tank) 20 12354 46 Turbine C ab le 1

10357 34 “J” In jector (High Eff iciency) - Lt Blue 21 1010154 Tank O-Ring 1

(10-inch tank) 22 1000811 AC Adapter, North American 1

1030413 “K” Injector (High Efficiency) - Pink 23 1238362 Ultramax Controller 1

(12-inch tank) (unprogrammed)

1035736 “L” Injector (High Efficiency) - Orange * 1033444 Turbine Assembly

(13 & 14-inch tank) * 1239979 Cable Harness, Remote Regen 740F

1032978 Plugged Injector for 263 Filter * 1239711 Switch Kit, Front Mount, 0.1 amp

103298 5 Plugged Injector Cap * 1 23 97 52 Switch Kit, Fro nt Mount, 5 amp

barbed) * 1033444 Internal Turbine Meter

1 1001612 1-inch BSPT Brass Pipe Adapter Kit

Part

No. Description Qty.

* Drain Line Flow Control 1

1030355 Drain Line F low Control, 5 gpm (19 Lpm)

1030356 Drain Line F low Control, 6 gpm (22.5

Lpm)

1030357 Drain Line F low Control, 7 gpm (26.5

Lpm)

1030358 Drain Line F low Control, 8 gpm (30 Lpm)

1030359 Drain Line F low Control, 9 gpm (34 Lpm)

1030360 Drain Line Flow Control, 10 gpm (3 8 Lpm)

* 1030334 Plugged Refill Flow Control - for 263

Valve

* 1041174 Valve Disc Kit

*Not shown on drawing.

38 Performa Parts List

Rev A

Page 39

Troubleshooting

Ultramax Series Controller Troubleshooting

Problem Possible Cause Solution

ERR 1 is displayed. Program settings have been corrupted. Press any key and reset model number.

ERR 3 is displayed. Controller does not know the position of

the camshaft. Camshaft should be

rotating to find Home position.

Camshaft is not turning during ERR 3

display.

If camshaft is turning for more than five

minutes to find Home position:

Wait for two minutes for the controller to

return to Home position. The hourglass

should be flashing on the display

indicating the motor is running.

Check that motor is connected.

Verify that motor wire harness is

connected to motor and controller

module.

Verify that optical sensor is connected

and in place.

Verify that motor gear has engaged cam

gear.

If everything is connected, try replacing

in this order:

—Wire harness

—Motor

—Optical sensor

—Controller

Verify that optical sensor is in place and

connected to wire.

Verify that camshaft is connected

appropriately.

Verify that no dirt or rubbish is clogging

any of the cam slots.

If motor continues to rotate indefinitely,

replace the following components in this

order:

—Wire harness

—Motor

—Optical sensor

—Controller

Time of Day incorrect. Power failure occurred. Press SET to reset the time display.

Troubleshooting 39

Rev A

Page 40

System Troubleshooting

Problem Possible Cause Solution

1. Brine tank

overflow.

2. Flowing or

dripping water at

drain or brine line

after

regeneration.

3. Hard water

leakage after

regeneration.

4. Control will not

draw brine.

5. Control will not

regenerate

automatically.

6. Control

regenerates at

wrong time of

day.

7. Valve will not

draw brine.

8. System using

more or less salt

than regenerant

setting.

a. Uncontrolled brine refill flow rate.

b. Air leak in brine line to air check.

c. Drain control clogged with resin

or other debris.

a. Valve stem return spring weak.

b. Debris is preventing valve disc

from closing.

a. Improper regeneration.

b. Leaking of external bypass valve.

c. O-ring around riser pipe

damaged.

d. Incorrect capacity.

a. Low water pressure.

b. Restricted drain line.

c. Injector plugged.

d. Injector defective.

e. Valve disc 2 and/or 3 not closed.

f. Air check valve prematurely

closed.

a. AC adapter or motor not

connected.

b. Defective motor.

a. Controller set incorrectly. a. Correct time setting according to

a. Low water pressure.

b. Restricted drain line.

c. Injector plugged.

d. Injector defective.

e. Air check valve closes

prematurely on brine pickup

tube.

a. Foreign matter in valve causing

incorrect flow rates.

a. Remove brine control to clean ball and seat.

b. Check all connections in brine line for leaks.

Refer to instructions.

c. Clean drain control.

a. Replace spring. (Contact dealer.)

b. Remove debris.

a. Repeat regeneration after making certain

correct regenerant dosage was set.

b. Replace bypass valve. (Contact dealer.)

c. Replace O-ring. (Contact dealer.)

d. Verify appropriate regenerant amount and

system capacity. (Contact dealer.)

a. Make correct setting according to

instructions.

b. Remove restriction.

c. Clean injector and screen.

d. Replace injector and cap. (Contact dealer.)

e. Remove foreign matter from disc and check

disc for closing by pushing in on stem.

Replace if needed. (Contact dealer.)

f. Put control momentarily into brine refill.

Replace or repair air check if needed.

(Contact dealer.)

a. Connect power.

b. Replace motor. (Contact dealer.)

instructions.

a. Set pump to maintain 20 psi at softener.

b. Change drain to remove restriction.

c. Clean injector and screen.

d. Replace injector. (Contact dealer.)

e. Put control momentarily into brine/slow

rinse. Replace or repair air check if needed.

(Contact dealer.)

a. Remove brine control and flush out foreign

matter. Advance control to brine/slow rinse,

to clean valve (after so doing position

control to "fast rinse” to remove regenerant

from tank).

40 Troubleshooting

Rev A

Page 41

9. Intermittent or

irregular

regenerant draw.

10. No conditioned

water after

regeneration.

11. Backwashes or

purges at

excessively low

or high rate.

12. No water flow

display when

water is flowing.

a. Low water pressure.

b. Defective injector.

a. No regenerant in regenerant

tank.

b. Injector plugged.

c. Air check valve closes

prematurely.

a. Incorrect drain controller used.

b. Foreign matter affecting valve

operation.

a. Bypass valve in bypass.

b. Meter probe disconnected or not

fully connected to meter

housing.

c. Restricted meter turbine rotation

due to foreign material in meter.

a. Set pump to maintain 20 psi at conditioner.

b. Replace injector. (Contact dealer.)

a. Add regenerant to regenerant tank.

b. Clean injector and screen.

c. Put control momentarily into brine/slow

rinse. Replace or repair air check if needed.

(Contact dealer.)

a. Replace with correct size controller. (Contact

dealer.)

b. Remove drain controller and clean ball and

seat.

a. Shift bypass valve to not-in-bypass position.

b. Fully insert probe into meter housing.

c. Remove meter housing, free up turbine and

flush with clean water. Turbine should spin

freely. If not, replace meter. (Contact dealer.)

13. Run out of

conditioned

water between

regenerations.

14. Regenerant tank

overflow.

a. Improper regeneration.

b. Incorrect regenerant setting.

c. Incorrect hardness or capacity

settings.

d. Water hardness has increased.

e. Restricted meter turbine rotation

due to foreign material in meter.

a. Regenerant valve disc 1 being

held open by foreign matter.

b. Valve disc 2 not closed during

regenerant draw causing brine

refill.

c. Air leak in regenerant line to air

check.

d. Improper drain control for

injector.

e. Drain control clogged with resin

or other debris.

a. Repeat regeneration, making certain that

correct regenerant dosage is used.

b. Set P6 to proper level. See salt setting chart .

c. Set to correct values. See Programming

section.

d. Set hardness to new value. See

Programming section.

e. Remove meter housing, free up turbine and

flush with clean water. Turbine should spin

freely; if not, replace meter. (Contact dealer.)

a. Manually operate valve stem to flush away

obstruction.

b. Flush out foreign matter holding disc open

by manually operating valve stem.

c. Check all connections in regenerant line for

leaks. Refer to instructions.

d. Too small of a drain control with a larger

injector will reduce draw rates.

e. Clean drain control.

Troubleshooting 41

Rev A

Page 42

42 Troubleshooting

Rev A

Page 43

UltraMax System Configurations

Upon initial start-up of the UltraMax controller, the software will request a

pre-determined model number. This model number populates the default

values within the controller, allowing for quick and easy set-up of the

software without entering several levels of data. The table below shows

the pre-determined model numbers for the controller and the associated

primary valve functions for each number.

Use the UP and DOWN buttons to scroll through the available model

numbers. Press the SET button to select the number and move to the

standard programming value.

Controller Reset:

Model

Number

10 1.0 cu ft Conditioner 268 Valve 15 Kgrains 3.0 lbs

15 1.5 cu ft Conditioner 268 Valve 23 Kgrains 4.5 lbs

20 2.0 cu ft Conditioner 268 Valve 31 Kgrains 6.0 lbs

93 Generic Filter 263 Valve N/A N/A

98 Generic Conditioner 268 Valve 25 Kgrains 9.0 lbs

System Description

Operation

Type

System

Capacity

Salt

Amount

If the incorrect model number is accidentally selected for the controller,

you can easily reset the controller to the factory default mode. When the

controller is in normal operating mode showing the time of day, perform

the following steps.

1. Press the DOWN and SET buttons simultaneously and hold for 5

seconds.

2. After 5 seconds the controller will go blank. Release the buttons and

the controller will scroll "MODEL NUMBER " and the selected model will

be displayed.

3. If the number is correct, wait 30 seconds and the controller will

automatically go back to normal operation mode.

4. If the model number is incorrect, press and hold the SET button for 5

seconds. This will default the controller back to the factory default

setting. The controller will scroll "MODEL NUMBER " and the factory

model number will begin flashing, meaning it can be changed. USe the

UP or DOWN buttons to scroll to the correct model number. Select that

number by pressing the SET button.

UltraMax System Configurations 43

Rev A

Page 44

© Copyright 2005 General Electric Company

Printed in USA P/N 3002774 Rev. A

Loading...

Loading...