Page 1

GE Appliances

Refrigerators

Side by side

Réfrigérateurs

Côte à côte

Refrigeradores

Lado a lado

Part No. 162D7734P009 Pub. No. 49-60008-1 11-99 JR

Profile Models 22–27

Owner’s Manual

Modèles Profile 22–27

Manuel d’utilisation

Modelos Profile 22–27

Manual del propietario

English section begins on page 2

La section française commence à la page 32

La sección en español empieza en la página 60

www.geappliances.com

Page 2

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation Instructions

Congratulations!

You Are Now Part of the GE Family.

Welcome to the GE family. We’re proud of our quality products and we are committed to providing

dependable service. You’ll see it in this easy-to-use

Owner’s Manual and you’ll hear it in the friendly

voices of our customer service department.

Best of all, you’ll experience these values each time

you use your refrigerator. That’s important, because

your new refrigerator will be part of your family for

many years. And we hope you will be part of ours for

a long time to come.

We thank you for buying GE. We appreciate your

purchase, and hope you will continue to rely on us

whenever you need quality appliances for your home.

GE & You, A Service Partnership.

Safety Information

Safety Precautions . . . . . . . . . . . .3

Use of Extension Cords . . . . . . . . .3

How to Connect Electricity . . . . . .4

Use of Adapter Plugs . . . . . . . . . .4

Operating Instructions

Controls . . . . . . . . . . . . . . . . . .5–8

Features . . . . . . . . . . . . . . . . .9–11

Ice Service . . . . . . . . . . . . . . . . . .12

Ice and Water Dispenser

. . . .12, 13

Care and Cleaning . . . . . . . . .14–16

Installation Instructions

Preparing to

Install the Refrigerator . . . . . . . .17

Water Line Installation . . . . .18–20

Troubleshooting Tips

Normal Operating Sounds . . . . . .21

Before You Call For Service

. .21–24

Customer Service

Warranty for Canadian Customers

24

Warranty for U.S. Customers . . .25

FXRC Cartridge

Performance Data Sheet . . . . . . .26

State of California Water

Treatment Device Certificate . . .27

Product Registration . . . . . . . . . .29

Service Telephone

Numbers . . . . . . . . . . . .Back Cover

FOR YOUR RECORDS

Write the model and serial numbers here:

#

#

You can find them on a label on the wall beside the top drawer

or at the bottom, just inside the fresh food compartment door.

Staple sales slip or cancelled check here.

Proof of the original purchase date is needed to obtain service

under the warranty.

Inside you will find many helpful hints on how to use and maintain

your refrigerator properly. Just a little preventive care on your part

can save you a great deal of time and money over the life of your

refrigerator.

READ THIS MANUAL

IF YOU NEED SERVICE

You’ll find many answers to common problems in the

Before You

Call For Service

section. If you review our chart of

Troubleshooting Tips

first, you may not need to call for service at all.

If you do need service, you can relax knowing help is only a phone

call away. A list of toll-free customer service numbers is included in

the back section. Or,

in the U.S.,

you can always call the GE Answer

Center® at 800.626.2000, 24 hours a day, 7 days a week.

In Canada,

call 1-800-361-3400.

2

IMPORTANT!

Fill out the Consumer Product Registration Card.

Two Easy Ways To Register Your Appliance!

■ Through the internet at www.geappliances.com.

■ Complete and mail the enclosed Product Registration Card.

Page 3

Customer ServiceTroubleshooting Tips

Operating Instructions

Safety Instructions Installation Instructions

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

Use this appliance only for its intended purpose as described in this Owner’s Manual.

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

■

■This refrigerator must be properly installed

and located in accordance with the Installation

Instructions before it is used.

■

■Do not allow children to climb, stand or hang

on the shelves in the refrigerator. They could

damage the refrigerator and seriously injure

themselves.

■

■Do not touch the cold surfaces in the freezer com-

partment when hands are damp or wet. Skin may

stick to these extremely cold surfaces.

■

■Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

■

■In refrigerators with automatic icemakers,

avoid contact with the moving parts of the

ejector mechanism, or with the heating element

that releases the cubes. Do not place fingers or

hands on the automatic icemaking mechanism

while the refrigerator is plugged in.

■

■Keep fingers out of the “pinch point” areas; clear-

ances between the doors and between

the doors and cabinet are necessarily small.

Be careful closing doors when children are

in the area.

■

■Unplug the refrigerator before cleaning and mak-

ing repairs.

NOTE: We strongly recommend that any servicing be performed

by a qualified individual.

■

■Turning the control to the

OFF or0

position does

not remove power to the light circuit.

■

■Do not refreeze frozen foods which have

thawed completely.

PROPER DISPOSAL OF THE REFRIGERATOR

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous…even if they will sit for “just a few

days.” If you are getting rid of your old refrigerator,

please follow the instructions below to help prevent

accidents.

Before You Throw Away Your Old Refrigerator

or Freezer:

■Take off the doors.

■Leave the shelves in place so that children may

not easily climb inside.

CFC Disposal

Your old refrigerator has a cooling system that used

CFCs (chlorofluorocarbons). CFCs are believed to

harm stratospheric ozone.

If you are throwing away your old refrigerator, make

sure the CFC refrigerant is removed for proper disposal by a qualified servicer. If you intentionally

release this CFC refrigerant you can be subject to

fines and imprisonment under provisions of environmental legislation.

USE OF EXTENSION CORDS

Because of potential safety hazards under certain conditions, we strongly recommend

against the use of an extension cord.

However, if you must use an extension cord, it is absolutely necessary that it be a UL-listed (in the United

States) or a CSA-listed (in Canada), 3-wire grounding type appliance extension cord having a grounding

type plug and outlet and that the electrical rating of the cord be 15 amperes (minimum) and 120 volts.

DANGER! RISK OF CHILD ENTRAPMENT

3

Page 4

4

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord. For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard 3-prong (grounding) wall outlet to minimize

the possibility of electric shock hazard from this

appliance.

Have the wall outlet and circuit checked by a qualified electrician to make sure the outlet is properly

grounded.

Where a standard 2-prong wall outlet is encountered, it is your personal responsibility and obligation to have it replaced with a properly grounded 3prong wall outlet.

The refrigerator should always be plugged into its

own individual electrical outlet which has a voltage

rating that matches the rating plate.

This provides the best performance and also prevents overloading house wiring circuits which could

cause a fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the

power cord. Always grip plug firmly and pull straight

out from the outlet.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end.

When moving the refrigerator away from the

wall, be careful not to roll over or damage the

power cord.

USE OF ADAPTER PLUGS

(Adapter plugs not permitted in Canada)

Because of potential safety hazards under certain conditions, we strongly recommend against

the use of an adapter plug.

However, if you must use an adapter, where local

codes permit, a

temporary connection

may be made

to a properly grounded 2-prong wall outlet by use

of a UL-listed adapter available at most local hardware stores.

The larger slot in the adapter must be aligned with

the larger slot in the wall outlet to provide proper

polarity in the connection of the power cord.

When disconnecting the power cord from the

adapter, always hold the adapter in place with one

hand while pulling the power cord plug with the

other hand. If this is not done, the adapter ground

terminal is very likely to break with repeated use.

If the adapter ground terminal breaks,

DO NOT USE

the refrigerator until a proper ground has been

established.

Attaching the adapter ground terminal to a wall outlet

cover screw does not ground the appliance unless the

cover screw is metal, and not insulated, and the wall outlet is grounded through the house wiring. You should have

the circuit checked by a qualified electrician to make sure

the outlet is properly grounded.

Read and follow this Safety Information carefully.

SAVE THESE INSTRUCTIONS

Page 5

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

About the controls on the refrigerator.

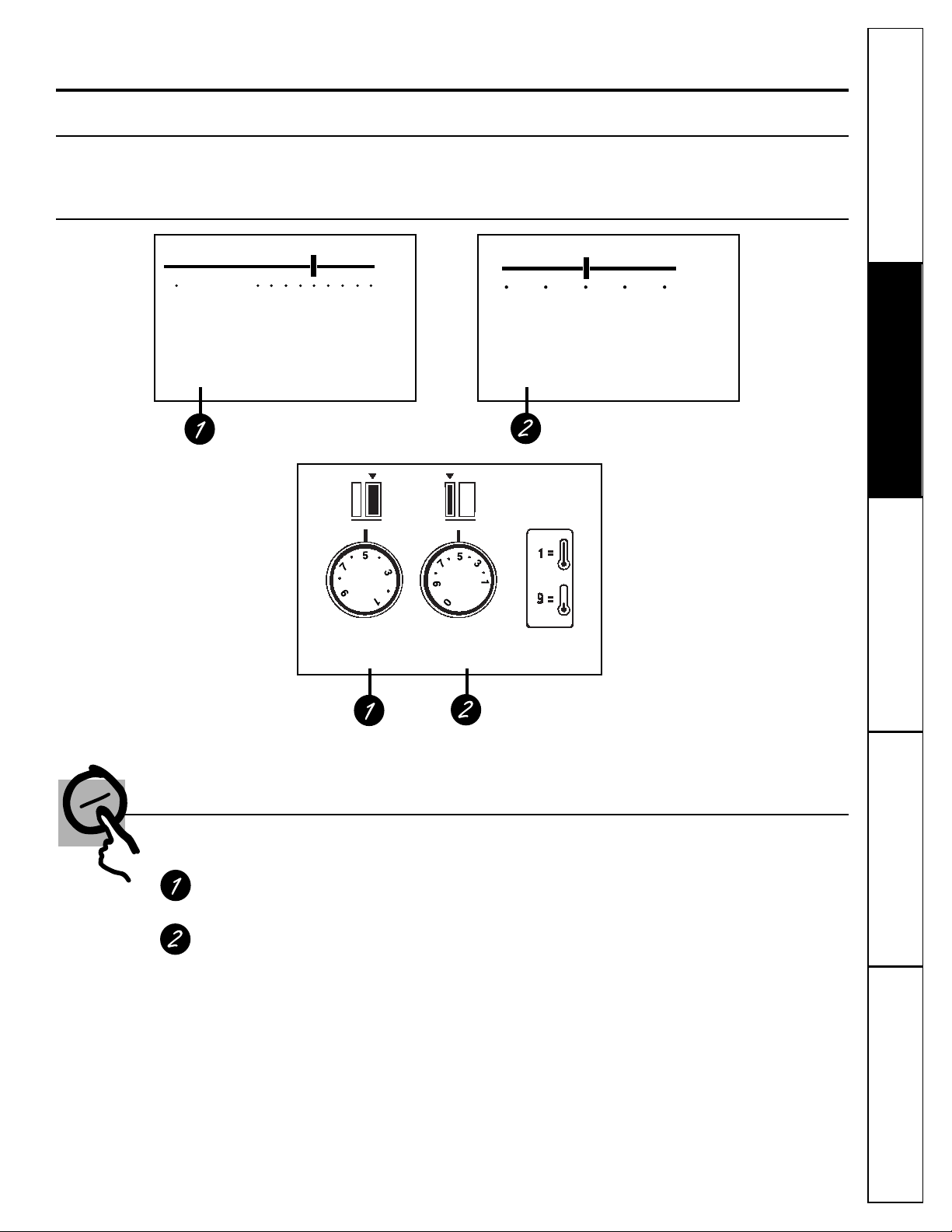

Fresh Food Control

5 is Initial Setting

9 is Coldest

OFF 13579

A B C D E

Freezer Control

C is Initial Setting

E is Coldest

Control Settings

Moving the control to

OFF

or 0stops cooling in both areas—fresh food and freezer—but does not shut off

power to the refrigerator.

Fresh Food Control

The fresh food control maintains the temperatures throughout the fresh food compartment.

Freezer Control

The freezer control maintains the temperatures throughout the freezer compartment.

How To Test Temperatures

Use the milk test for the fresh food compartment. Place a container of milk on the top shelf and check it a

day later. If the milk is too warm or too cold, adjust the temperature controls.

Use the ice cream test for the freezer compartment. Place a container of ice cream in the center of the freezer and check it after a day. If it’s too hard or too soft, adjust the temperature controls.

After changing the controls, allow 24 hours for the refrigerator to reach the temperature you have set.

Initially set the fresh food control at 5 and the freezer control at 5 or C.

If you want colder or warmer temperatures, adjust the

fresh food temperature first. When satisfied with that setting, adjust the freezer temperature.

The controls will look like one of the following.

5

Fresh Food

Control

Freezer

Control

Page 6

6

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

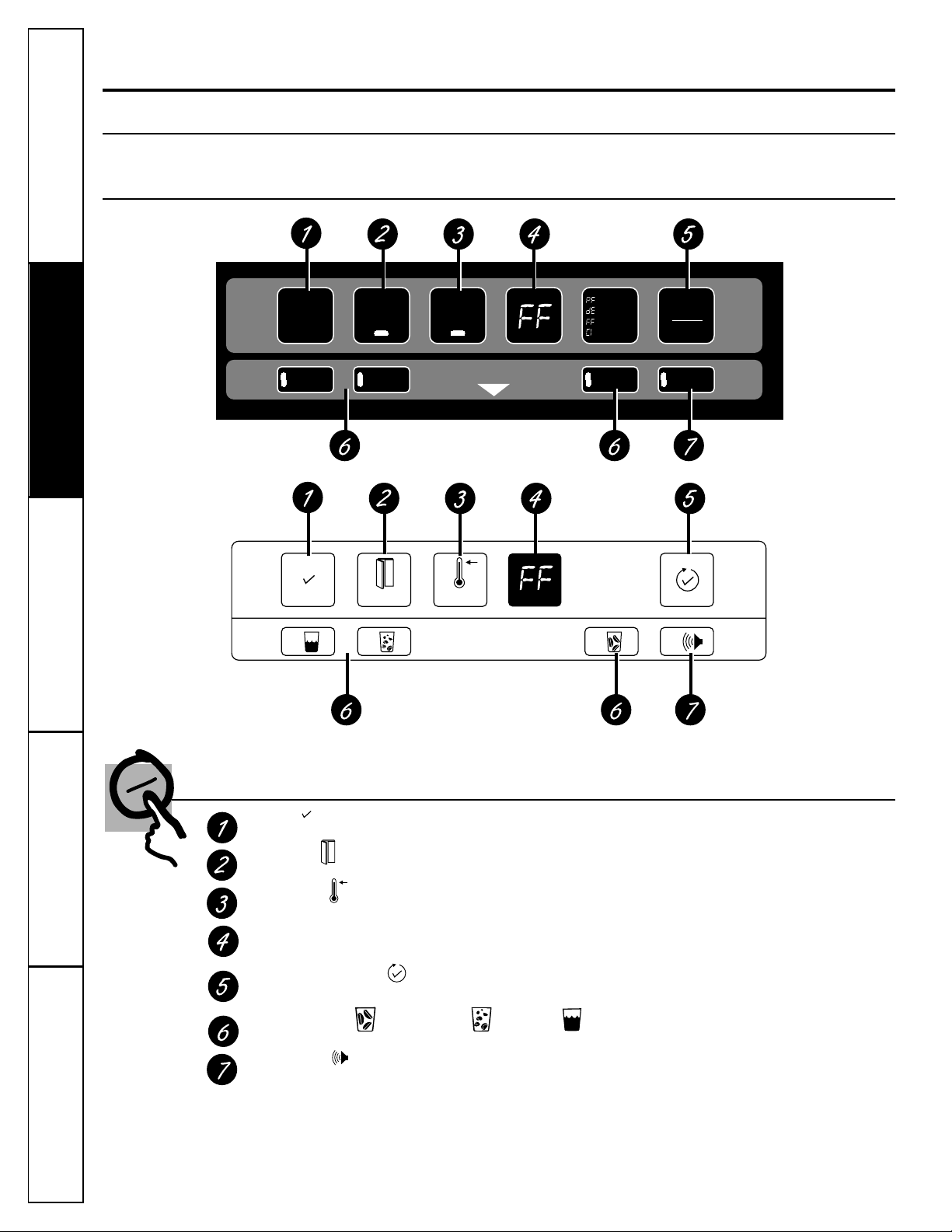

About the controls on the refrigerator.

The Electronic Monitor and Diagnostic System controls dispenser functions and monitors the operation of

your refrigerator.

On some models. The controls will look like one of the following.

Monitor and Diagnostic System

NORMAL

lights up to indicate that no failure has been detected by the diagnostic system.

DOOR OPEN

flashes when either door is open.

WARM TEMP

lights up when freezer food-keeping temperature is above normal.

Flashing diagnostic codes.

What these codes mean—and what to do when they appear—is explained

more thoroughly on the following pages.

SYSTEM CHECK-RESET

reviews the diagnosis of four coded functions and allows you to erase codes

from the display.

Select

CUBED ICE , CRUSHED ICE

or

WATER

and the signal light confirms your choice.

DOOR ALARM

lights up when the beeper has been set to sound after either door has been open 30

seconds.

DISPLAY

NORMAL

DOOR

OPEN

WARM

TEMP

POWER

DEFROST

FREEZER

ICE MAKER

SYSTEM

CHECK

RESET

CHILLED

WATER

CRUSHED

ICE

DISPENSER PUSH BELOW

CUBED

ICE

DOOR ALARM

ON/ OFF

Page 7

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

7

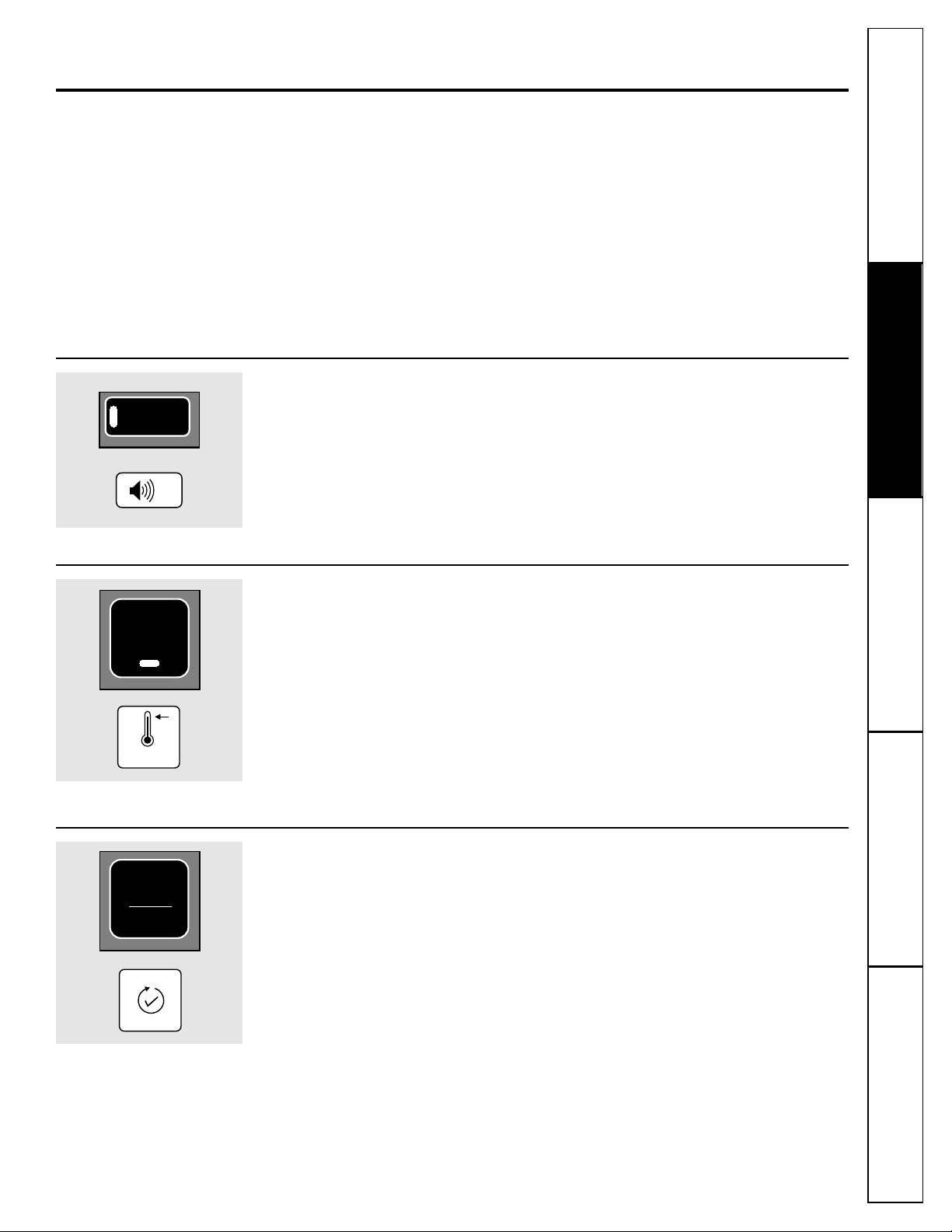

When Your Refrigerator Is First Plugged In

How the Monitor and Diagnostic System Works

All panel lights come on for five seconds,

a beep sounds, and lights go off except as

follows:

■

PF

flashes in the display. Touch

SYSTEM

CHECK-RESET

to erase it.

■

NORMAL

glows.

■

WARM TEMP

glows until the refrigerator

cools down. It goes off when proper foodkeeping temperature is reached.

■Door alarm beeper is activated and

DOOR

ALARM

glows.

■

CRUSHED ICE

glows.

■

DOOR OPEN

flashes if either door is open,

goes out when doors are shut.

■Night light in ice and water dispenser

is off.

How to Set the Door Alarm

To set the alarm press

DOOR ALARM

until it

glows.

The control beeps if either door is open for

more than 30 seconds.

The light goes out and the beeping stops

when you close the door.

Why the WARM TEMP Light Glows

At first, it’s probably because your newlyinstalled refrigerator hasn’t completely

cooled down yet. Wait a few hours for it to

cool, and then the light will go out.

From then on,

WARM TEMP

will glow whenever temperatures inside get too high for

proper food storage. If this happens, open

the doors only when absolutely necessary,

and close them as quickly as possible.

As soon as inside temperatures return to

normal, the light goes out.

If

WARM TEMP

reappears and stays on for

longer than 4 hours, call for service.

The diagnostic code flashes and the control

beeps when something starts to go wrong.

If more than one coded function requires

attention at the same time, the one with the

highest priority will be displayed first.

Pressing

SYSTEM CHECK-RESET

will erase

two codes immediately—PFand

CI.

The

dE

and FFcodes can only be erased by pressing

SYSTEM CHECK-RESET

after the condition

that caused the code to flash has been corrected.

SYSTEM CHECK-RESET

will also evaluate

all other coded functions. If

NORMAL

is

lit during the displaying of a code, that function is operating properly.

DOOR ALARM

ON/ OFF

WARM

TEMP

SYSTEM

CHECK

RESET

Page 8

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

About the controls on the refrigerator.

8

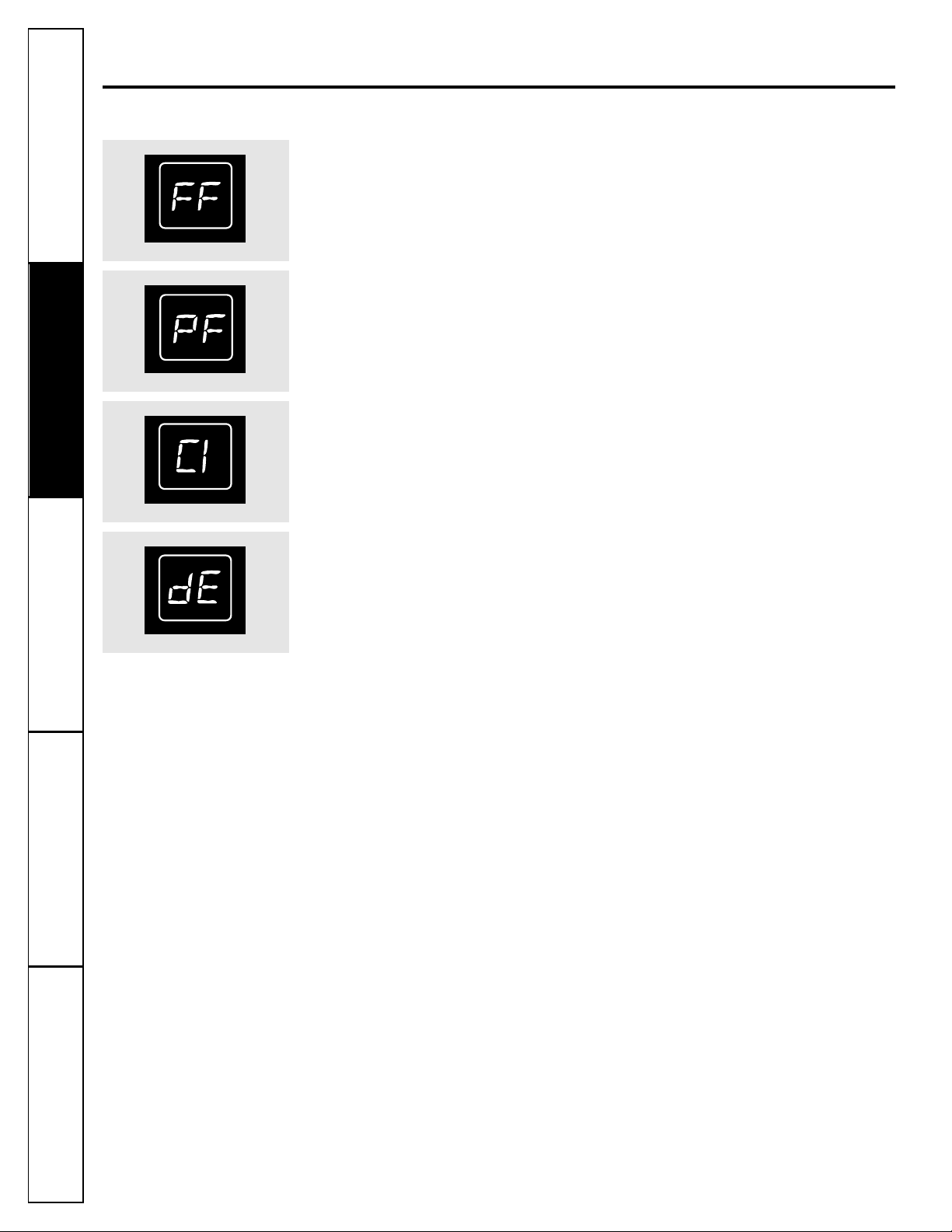

What the Codes Mean

Check your frozen food.

Has any of it started to thaw? A package may be holding the freezer

compartment door open. Don’t open the door more often than absolutely necessary while

this code is displayed. Touching

SYSTEM CHECK-RESET

after the freezer compartment tem-

perature has returned to normal will erase the code.

Power to the refrigerator has been interrupted for more than two seconds.

Check the condition

of food in both the fresh food and freezer compartments. Touch

SYSTEM CHECK-RESET

to erase the code.

There is no fault with the refrigerator when the PFcode flashes.

Check the icemaker.

Ice clumps in the storage bin may have stalled the icemaker. Follow cor-

rective measures described in

Troubleshooting Tips.

If water supply to the icemaker is

not connected or not turned on, make sure the icemaker feeler arm is in the

STOP

(up)

position. The code stops flashing when problem is corrected or

SYSTEM CHECK-RESET

is touched.

Something is wrong with the defrost system—keep doors closed to retain cold and call for service.

The code flashes until problem is corrected.

DISPLAY

Page 9

About the water filter cartridge.

Not all features are on all models.

On some models

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

About the refrigerator shelves and dishes.

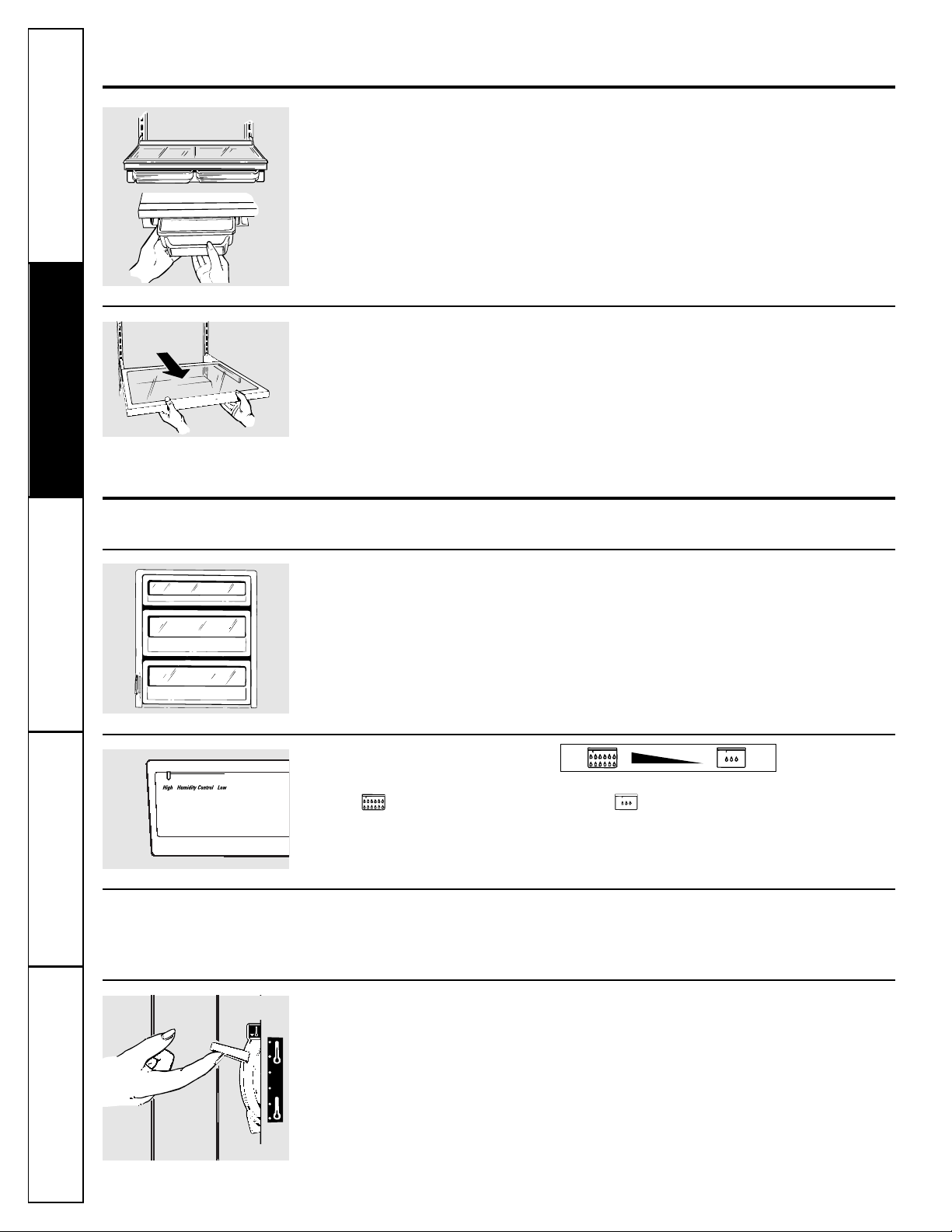

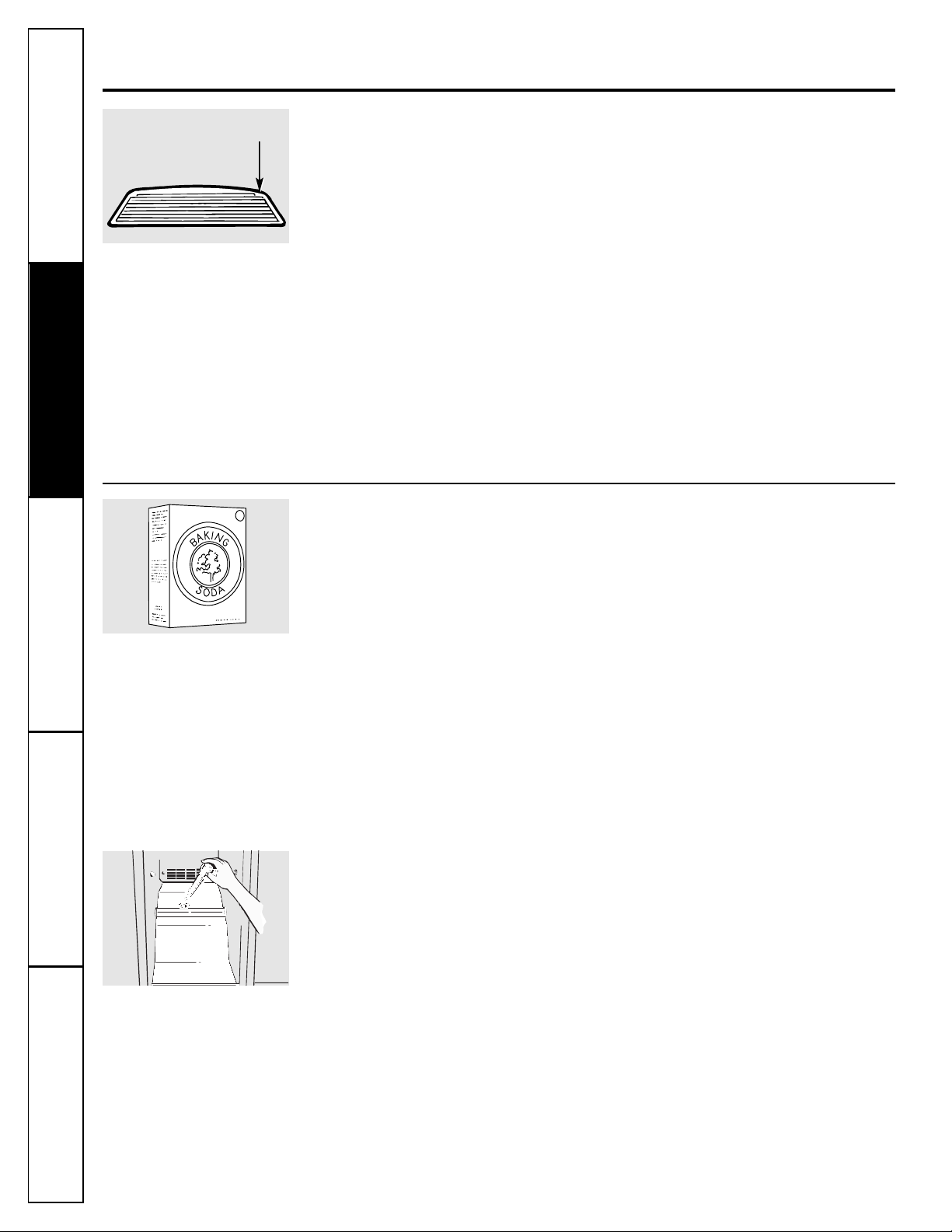

Rearranging the Shelves

Shelves in the fresh food and freezer compartments are adjustable.

To Remove

To Replace

Lift up and out

2

Insert

top hook

1

Lower to

lock in place

2

Tilt up

1

The water filter cartridge is located in the

upper right-hand corner of the fresh food

compartment, right below the temperature

controls.

The filter cartridge should be replaced

every

six months

or earlier if the flow of

water to the water dispenser or icemaker

decreases.

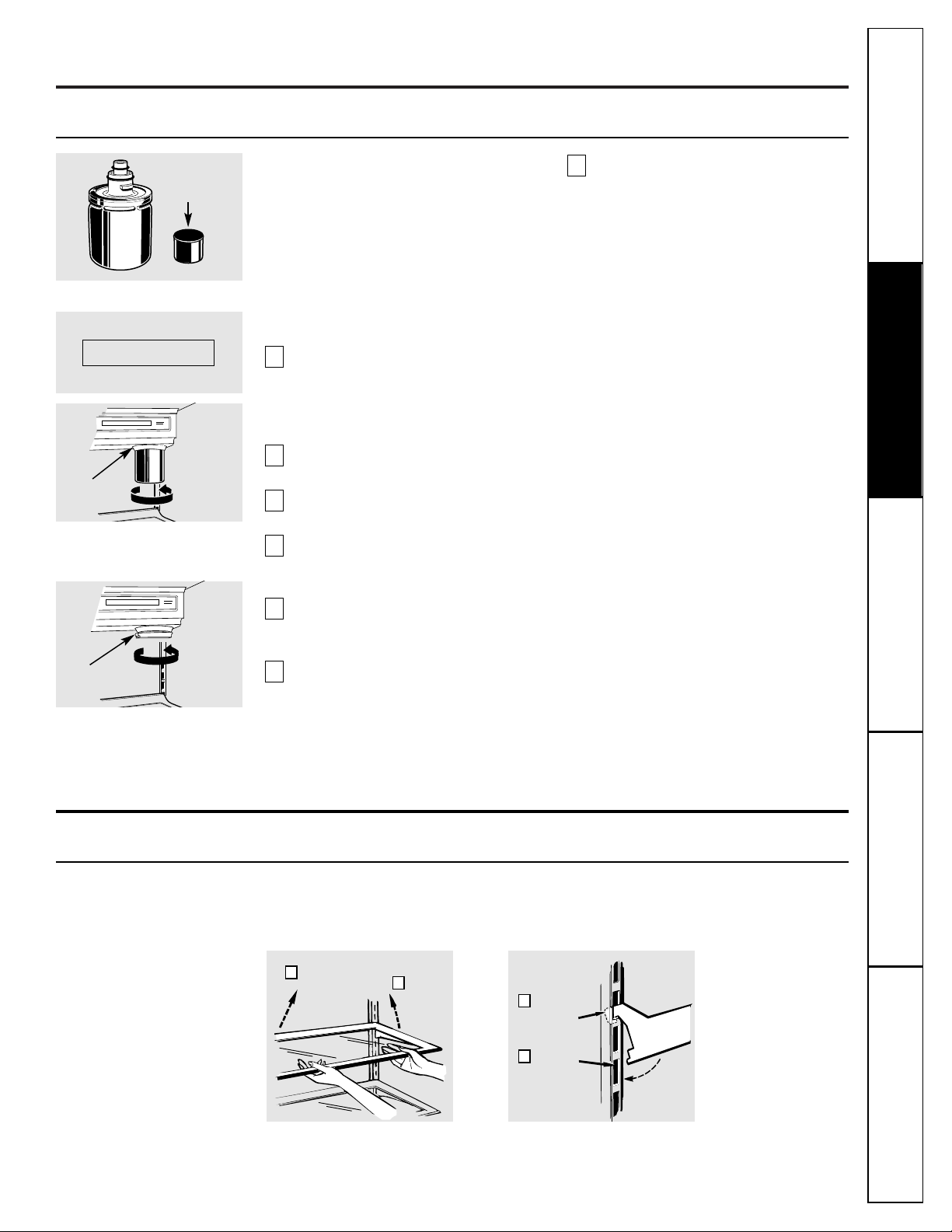

Installing the Filter Cartridge

If you are replacing the cartridge, first

remove the old one by slowly turning it

to the left.

Do not

pull down on the cartridge. A small amount of water may

drip down.

Remove and discard the plastic cap

from the new cartridge.

Fill the replacement cartridge with water

from the tap.

Apply the month and year sticker to the

cartridge to remind you to replace the

filter in

six months.

Place the top of the cartridge up inside

the cartridge holder.

Do not

push it up

into the holder.

Slowly turn it to the right until the filter

cartridge stops.

DO NOT OVERTIGHTEN.

As you turn the cartridge, it will automatically raise itself into position.

Run water from the dispenser for 1

minute (about a half gallon) to clear

the system and prevent sputtering.

NOTE:

A newly-installed water filter car-

tridge may

cause water to spurt

from

the dispenser.

Filter Bypass Plug

You must use the filter bypass plug

when a replacement filter cartridge is not

available. The dispenser and the icemaker

will not operate without the filter or filter

bypass plug.

Questions?…In the United States, call the

GE Answer Center® 800.626.2000.

Replacement Filters:

To order additional filter cartridges in the

United States, call GE Parts and Accessories,

800-626-2002.

FXRT—Chlorine, Taste and Odor

Suggested Retail $29.95

FXRC—Chlorine, Taste and Odor—

Lead and Cysts

Suggested Retail $34.95

Customers in Canada should consult the

yellow pages for the nearest Camco Service

Center.

7

6

5

4

3

2

1

Plastic Cap

Discard the plastic cap.

Place the top of the cartridge up

inside the cartridge holder and

slowly turn it to the right.

Filter Bypass Plug

Cartridge

Holder

REPLACE FILTER BY:

(month-year)

replace every 6 months

9

Page 10

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

About the refrigerator shelves and dishes.

10

About the storage drawers.

Not all features are on all models.

Quick Serve™ System

CAUTION: Dishes and lids are not

designed for use on the range top, broiler or in the regular oven. Such

use can be hazardous.

Quick Serve™ dishes fit into a space-saving

rack under the shelf. The rack can be relocated anywhere in the fresh food compartment.

Dishes and lids are safe for use in microwave

ovens, refrigerators and freezers.

Do not use when cooking high-fat foods,

such as bacon, and high-sugar foods, such

as candy and syrup. The high temperatures

of the fat and sugar can cause bubbles to

form on the inside of the dish.

Slide-Out Spillproof Shelf

The slide-out spillproof shelf allows you to

reach items stored behind others. The special edges are designed to help prevent

spills from dripping to lower shelves.

Make sure you push the shelves all the way back

in before you close the door.

Storage Drawers

Excess water that may accumulate in the

bottom of the drawers should be emptied

and the drawers wiped dry.

Adjustable Humidity Drawers

Slide the control all the way to the

High

or setting to provide high humidi-

ty recommended for most vegetables.

Slide the control all the way to the

Low

or

setting to provide lower humidity levels

recommended for most fruits.

Sealed Snack Pack

The sealed snack pack can be moved to the

most useful location for your family’s needs.

Convertible Meat Drawer

The convertible meat drawer has its own

cold air duct to allow a stream of cold air

from the freezer compartment to flow

around the drawer.

The variable temperature control

regulates

the air flow from the freezer compartment.

Set control lever

down

to the coldest setting

to store fresh meats. If lever is left in meat

position for a long period of time, some

frost may form on the inside of the drawer.

Set control lever

up

to convert the drawer to

normal refrigerator temperature and provide extra vegetable storage space. Cold air

duct is turned off. Variable settings between

these extremes can be selected.

Normal

Coldest

Page 11

About storage drawer removal.

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

11

Not all features are on all models.

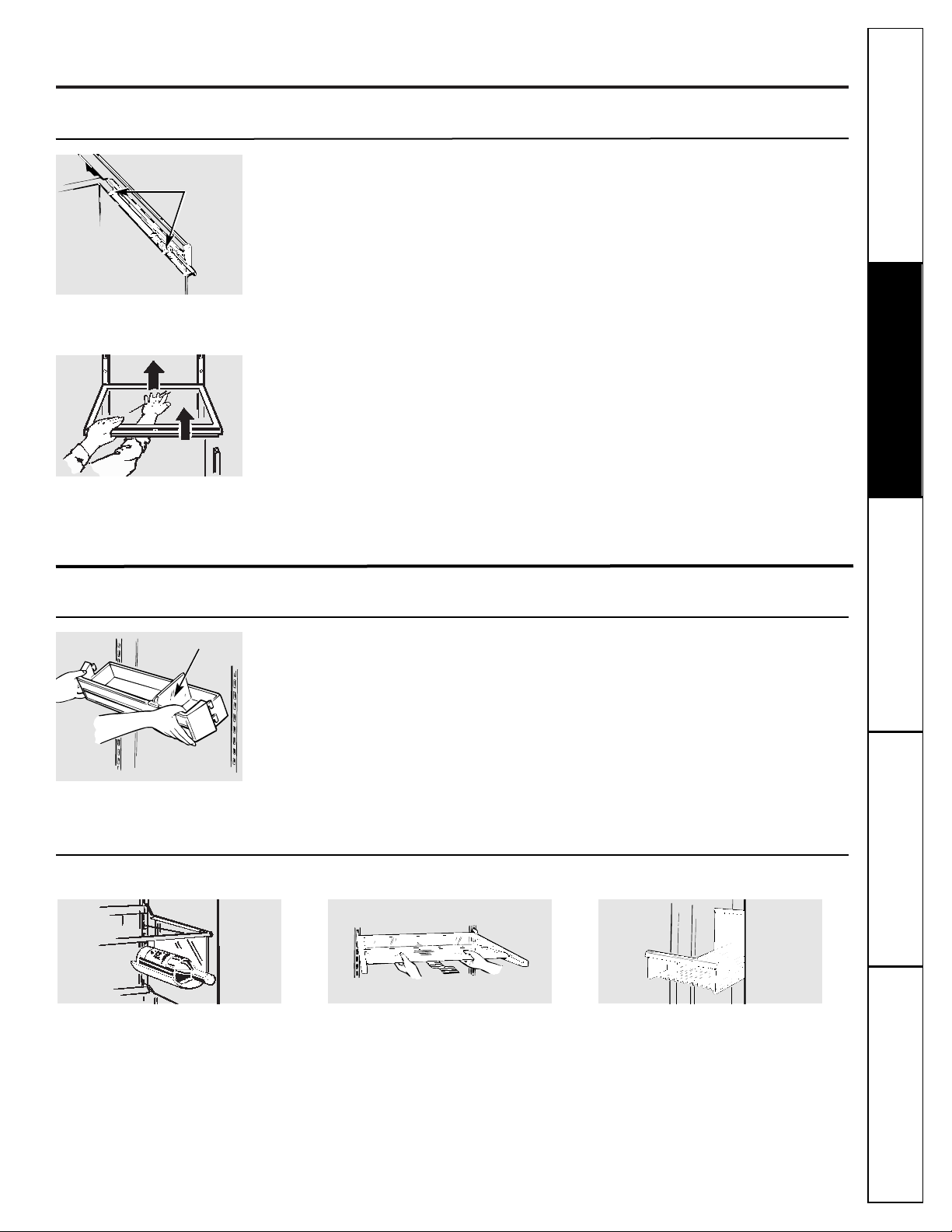

Drawer Removal

Drawers can easily be removed by tilting

up slightly and pulling past

stop

location.

Remove the door bins from the fresh food door

before removing the drawer.

To remove the shelf above the top drawer, first remove the top drawer and any

food on the shelf. Then tilt the shelf up at

the front and lift it up and out of the

tracks.

To replace the shelf, raise the shelf front

slightly and place the top hooks in the

lowest large track slots. Then lower the

front of the shelf until it is level.

To remove the drawers when the fresh

food compartment door cannot be

opened fully you need to roll the refrigerator forward until the door can be fully

opened. In some cases this will require

moving the refrigerator to the left as you

roll it out.

When replacing the drawers, make

sure you slide them through both

drawer guides on the right side.

Drawer

Guides

About the additional features.

Not all features are on all models.

Bins on the Fresh Food Compartment Door

Adjustable bins can easily be carried

from refrigerator to work area.

To remove:

Lift bin straight up until

mounting hooks disengage.

To replace or relocate:

Select desired shelf

height, engage bin’s hook in slots on the

tracks of the door, and push in. Bin will

lock in place.

The divider

helps prevent tipping, spilling

or sliding of small items stored on the

door shelf. Place a finger on either side

of the divider near the front and move it

back and forth to fit your needs.

Divider

Removable Wine Rack Quick Space Shelf

This shelf splits in half and slides

under itself for storage of tall items

on the shelf below.

Freezer Baskets

Page 12

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

About ice service.

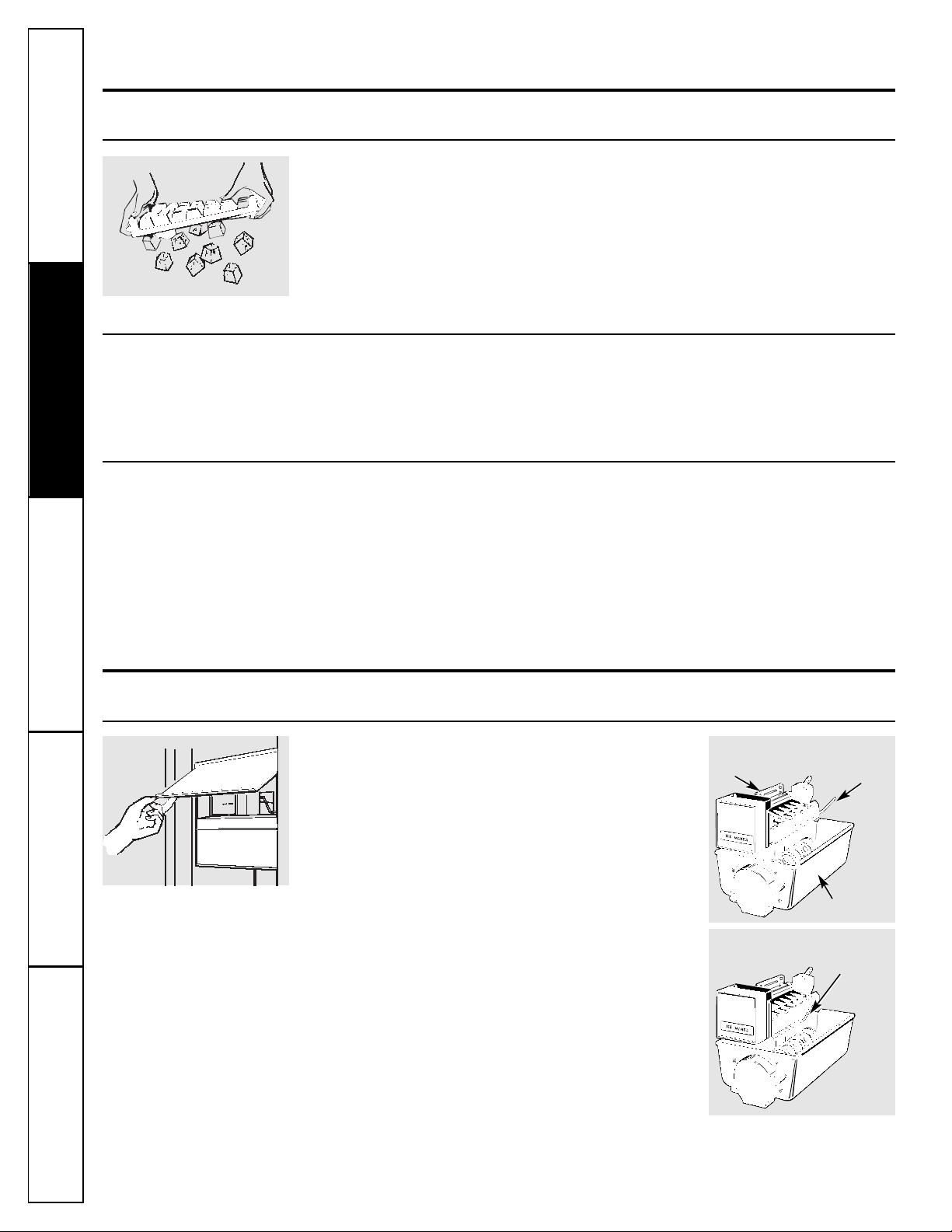

Automatic Icemaker

(on some models)

The icemaker will produce eight cubes per cycle—approximately 120 cubes in a 24-hour period, depending on freezer compartment temperature, room temperature, number

of door openings and other use conditions.

If the refrigerator is operated before the water connection

is made to the icemaker, raise the ice access door and make

sure the feeler arm is in the

STOP

(up) position.

When the refrigerator has been connected to the water

supply, move the feeler arm to the

ON

(down) position.

The icemaker will fill with water when it cools to freezing. A

newly-installed refrigerator may take 8 to 12 hours to begin

making ice cubes.

Throw away the first few batches of ice to allow the water

line to clear.

Be sure nothing interferes with the swing of the feeler arm.

It is normal for several cubes to be joined together.

If ice is not used frequently, old ice cubes will become

cloudy and taste stale.

About the automatic icemaker.

A newly-installed refrigerator may take 8 to 12 hours to begin making ice.

Icemaker

Ice Storage Bin

Feeler arm

in the

STOP

(up) position

Feeler arm

in the

ON

(down) position

12

On some models

Icemaker Accessory Kit

If your refrigerator did not come already equipped with an automatic icemaker, an

icemaker accessory kit is available at extra cost. Check the back of the refrigerator for

the specific icemaker kit needed for your model.

Water Supply Kit

A kit containing copper tubing, shutoff valve, fittings and instructions needed to connect the icemaker to your cold water line is available at extra cost from your dealer or

from Parts and Accessories, 800-626-2002.

See the Preparing to install the refrigerator section.

Ice Trays

To release ice cubes, turn the tray upside

down, hold it over a container, and twist

both ends.

For only one or two ice cubes, leave the

tray right-side up, twist both ends slightly,

and remove as many cubes as you want.

Wash ice trays in lukewarm water only—do not

put them in an automatic dishwasher.

Page 13

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

About the ice and water dispenser.

On some models

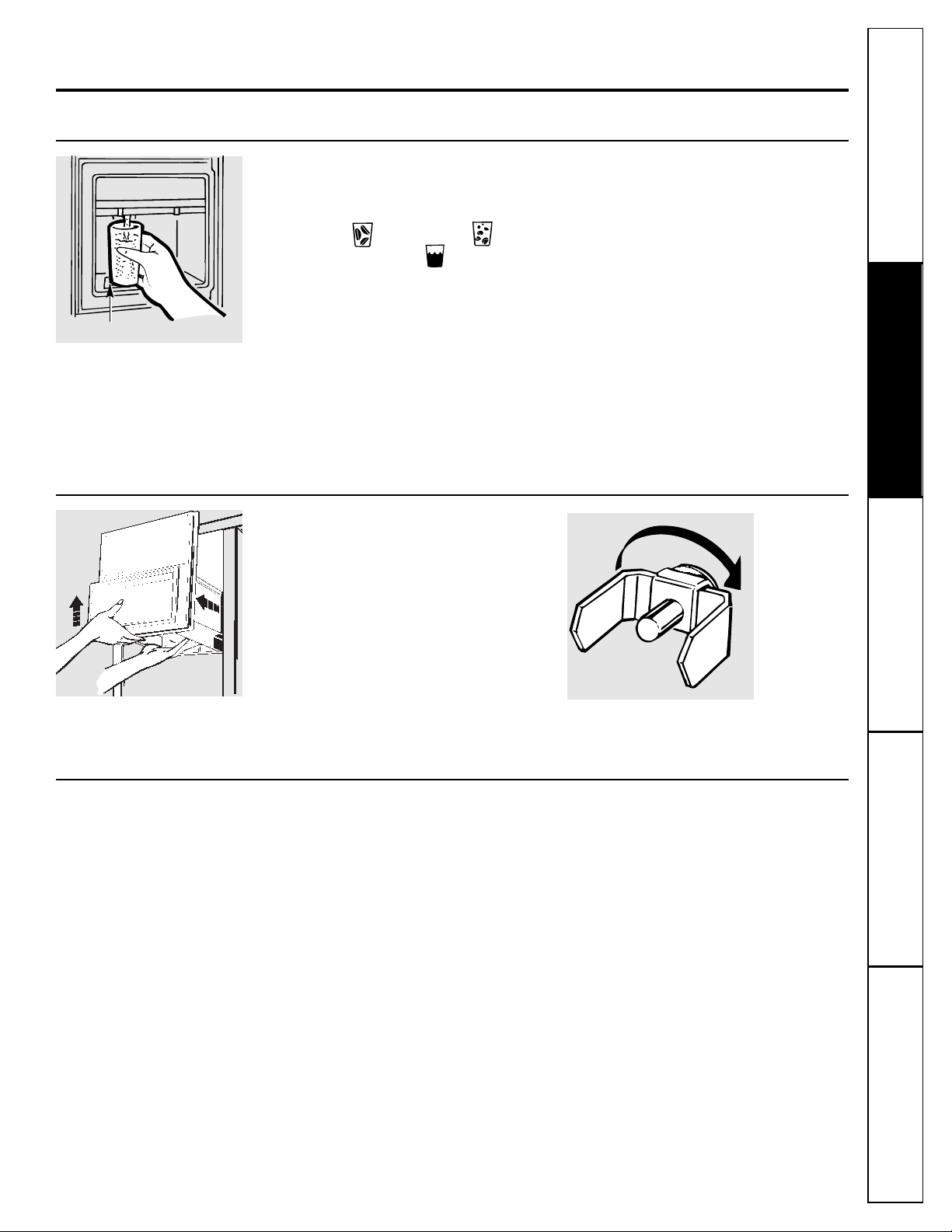

To Use the Dispenser

Press the rim of the glass gently against the

dispenser pad.

Select

CUBES , CRUSHED ICE

(on

some models) or

WATER .

The spill shelf is not self-draining. To

reduce water spotting, the shelf and its grille

should be cleaned regularly.

If no water is dispensed when the refrigerator is

first installed, there may be air in the water line

system. Press the dispenser pad for at least two

minutes to remove trapped air from the water

line and to fill the water system. To flush out

impurities in the water line, throw away the first

six glassfuls of water.

A light switch (on some models) turns the

night light

in the dispenser on or off. The

light also comes on when the dispenser pad

is pressed. The light in the dispenser should

be replaced with a 7-watt maximum bulb

when it burns out.

CAUTION: Never put fingers or any other

objects into the ice crusher discharge

opening.

Spill Shelf

Ice Storage Bin

To remove:

Lift the left corner to free the bin from the

shelf and pull the bin straight out while supporting it at front and rear.

To replace:

Slide the bin back until the tab on the bin

locks into the slot on the shelf. If the bin

does not go all the way back, remove it and

rotate the drive mechanism 1/4 turn. Then

push the bin back again.

Rotate

Drive

Mechanism

Important Facts About Your Dispenser

■Add ice before filling the glass with a bev-

erage. This will prevent splashing, which

could cause the ice selector switch

to stick or bind.

■Do not add ice from trays or bags to

the storage bin. It may not crush or dispense well.

■Avoid overfilling glass with ice and use of

narrow or extra-tall glasses. Backed-up ice

can jam the chute or cause the door in

the chute to freeze shut. If ice is blocking

the chute, poke it through with a wooden

spoon.

■Beverages and foods should not be

quick-chilled in the ice storage bin.

Cans, bottles or food packages in the storage bin may cause the icemaker or auger

to jam.

■Some crushed ice may be dispensed even

though you selected

CUBES.

This happens occasionally when a few cubes accidentally get directed to the crusher.

■After crushed ice is dispensed, some

water may drip from the chute.

■Sometimes a mound of snow will form on

the door in the ice chute. This condition

is normal and usually occurs when you

have dispensed crushed ice repeatedly.

The snow will eventually evaporate.

■Dispensed water is not ice cold. For cold-

er water, simply add crushed ice or cubes

before dispensing water.

13

Page 14

14

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Care and cleaning of the refrigerator.

Cleaning the Outside

The dispenser well

(on some models),

beneath the grille, should be wiped dry. Water

left in the well may leave deposits. Remove

the deposits by adding undiluted vinegar to

the well. Soak until the deposits disappear

or become loose enough to rinse away.

The dispenser pad

(on some models). Clean

with warm water and baking soda solution—

about a tablespoon (15 ml) of baking soda

to a quart (1 l) of water. Rinse thoroughly

and wipe dry.

HINT: Open the freezer door part way to prevent

dispensing of ice or water when cleaning.

The door handles and trim.

Clean with a

cloth dampened with soapy water. Dry with

a soft cloth.

The stainless steel panels and door handles

(on some models) can be cleaned with a

commercially available stainless steel cleaner using a clean, soft cloth.

Keep the outside clean.

Wipe with a clean

cloth lightly dampened with kitchen appliance wax or mild liquid dish detergent. Dry

and polish with a clean, soft cloth.

Do not wipe the refrigerator with a soiled dish

cloth or wet towel. These may leave a residue

that can erode the paint. Do not use scouring

pads, powdered cleaners, bleach or cleaners containing bleach because these products can

scratch and weaken the paint finish.

Press here to

remove grille.

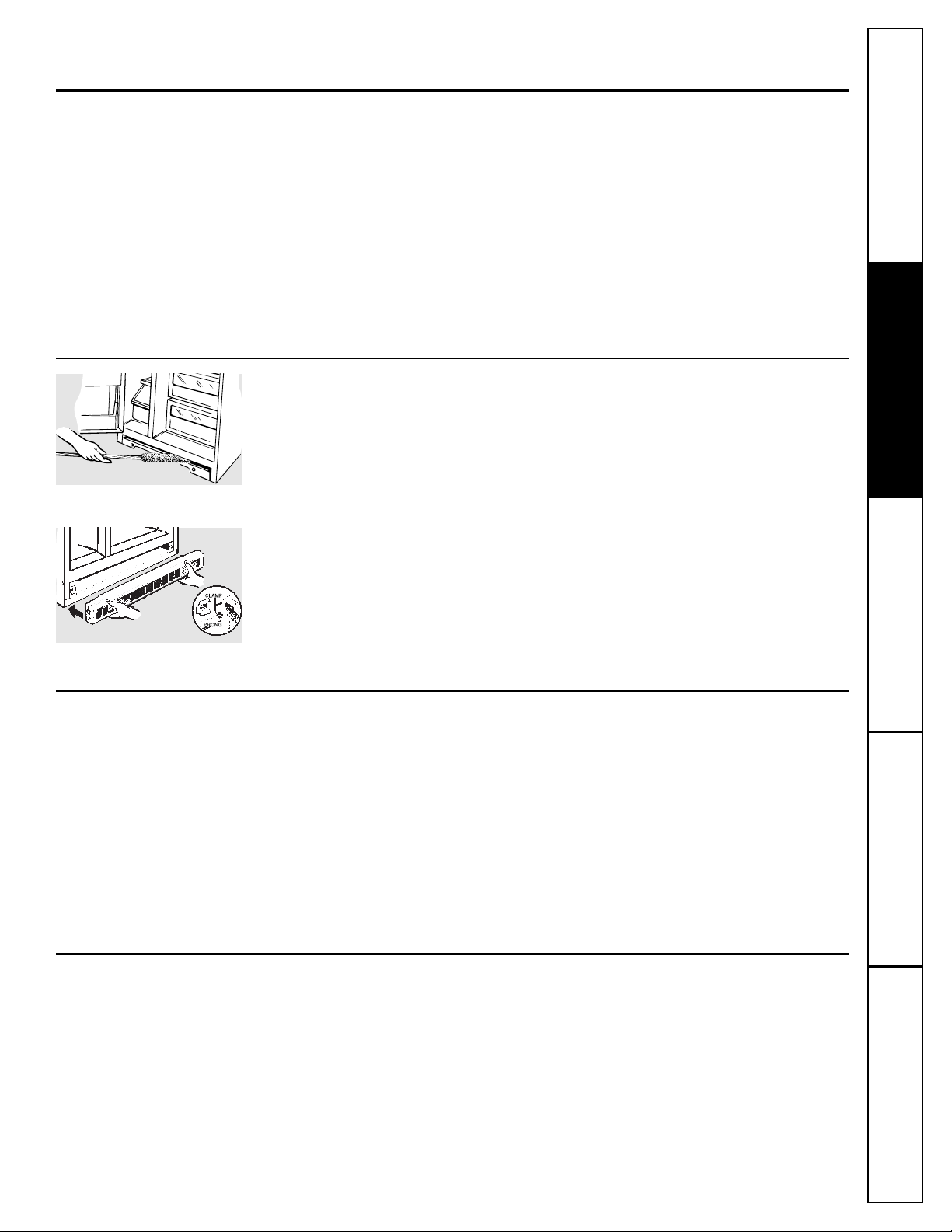

Cleaning the Inside

To help prevent odors,

leave an open box of

baking soda in the fresh food and freezer

compartments.

Unplug the refrigerator before cleaning.

If this

is not practical, wring excess moisture out of

sponge or cloth when cleaning around

switches, lights or controls.

Use warm water and baking soda solution—

about a tablespoon (15 ml) of baking soda

to a quart (1 l) of water. This both cleans

and neutralizes odors. Rinse and wipe dry.

After cleaning the door gaskets, apply a thin

layer of petroleum jelly to the door gaskets

at the hinge side. This helps keep the gaskets from sticking and bending out of

shape.

Drain opening in freezer compartment.

During

yearly cleaning, remove bottom freezer basket and flush a solution of baking soda—1

teaspoon (5 ml) and 2 cups (500 ml) of hot

(not boiling) water—through the drain

line with the help of a meat baster. This will

help eliminate odor and reduce the likelihood of a clogged drain line. If drain

becomes clogged, use a meat baster and

baking soda solution to force the clog

through the drain line.

Avoid cleaning cold glass shelves (on

some models) with hot water because

the extreme temperature difference may

cause them to break. Handle glass

shelves carefully. Bumping tempered

glass can cause it to shatter.

Do not wash any plastic refrigerator parts in

the dishwasher except Quick Serve dishes

and lids.

Page 15

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

15

Behind the Refrigerator

Be careful when moving the refrigerator

away from the wall. All types of floor coverings can be damaged, particularly cushioned coverings and those with embossed

surfaces.

Pull the refrigerator straight out and return

it to position by pushing it straight in.

Moving the refrigerator in a side direction

may result in damage to the floor covering

or refrigerator.

When pushing the refrigerator back,

make sure you don’t roll over the power

cord or icemaker supply line (on some

models).

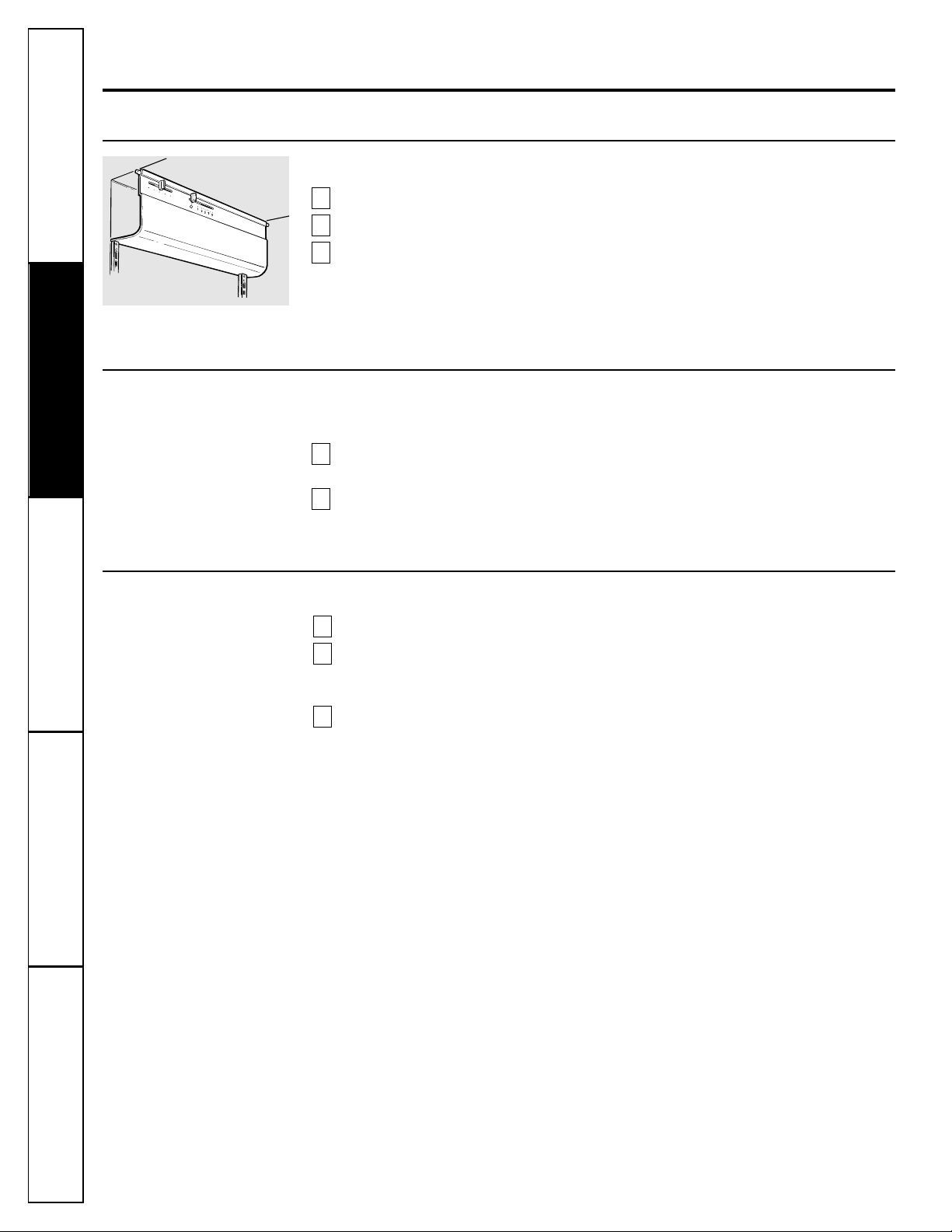

Under the Refrigerator

For most efficient operation, keep the

area under the refrigerator clean. Remove

the base grille and sweep away or vacuum

up dust.

For best results, use a brush specially

designed for this purpose. It is available at

most appliance parts stores.

To remove the base grille,

open both doors,

grasp the bottom of the grille and pull it out.

To replace base grille,

line up the clips on the

back of the grille with the openings in the

base plate and push the grille forward until

it snaps into place.

Clean the condenser coils at least

once a year.

Preparing for Vacation

For long vacations or absences, remove

food and unplug the refrigerator. Move

the control to the

OFF

or 0position, and

clean the interior with a baking soda solution of one tablespoon (15 ml) of baking

soda to one quart (1 l) of water. Leave the

doors open.

Move the icemaker feeler arm (on some

models) to the

STOP

(up) position and shut

off the water supply to the refrigerator.

If the temperature can drop below freezing,

have a qualified servicer drain the water

supply system (on some models) to prevent

serious property damage due to flooding.

Preparing to Move

Secure all loose items such as grille, shelves and drawers by taping them securely

in place to prevent damage.

Be sure the refrigerator stays in an upright position during moving.

Page 16

16

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Replacing the light bulbs.

Turning the control to the OFF or 0 position does not remove power to the light circuit.

Fresh Food Compartment—Upper Light

Unplug the refrigerator.

Pull off the temperature control knobs.

Pull bottom of the light shield down and

forward, then rotate the top up and off.

After replacing with an appliance bulb of the

same or lower wattage, reinstall the light shield

and plug the refrigerator back in.

3

2

1

Fresh Food Compartment—Two Lower Lights

(on some models)

These lights are located behind the top drawer.

Unplug the refrigerator and remove the

top drawer and cover.

Grasp the bottom edge of the shield

and pull forward and up to free its bottom edge.

After replacing with an appliance bulb of the

same or lower wattage, replace the shield, drawer and cover and plug the refrigerator

back in.

2

1

Freezer Compartment

Unplug the refrigerator.

Remove the shelf just below light shield.

(The shelf will be easier to remove if it is

emptied first.)

Pull the light shield toward you to reach

the bulb.

After replacing with an appliance bulb of the

same or lower wattage, reinstall the shield

and shelf and plug the refrigerator back in.

3

2

1

13579

Page 17

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

Preparing to install the refrigerator.

Read these instructions completely and carefully.

Water Supply to the Icemaker

(on some models)

If the refrigerator has an icemaker, it will have to be

connected to a cold water line.

A water supply kit (containing copper tubing, shutoff valve, fittings and instructions) is available

at extra cost from your dealer or from Parts and

Accessories, 800-626-2002.

Refrigerator Location

Do not install the refrigerator where the temperature will go below 60°F (16°C)

because it will not run often enough to maintain

proper temperatures.

Install it on a floor strong enough to support it

fully loaded.

Clearances

Allow the following clearances for ease of installation, proper air circulation and

plumbing and electrical connections:

Sides 5/8″(15 mm)

Top 1″(25 mm)

If built-in, allow 7/8″(22 mm) for hinge covers.

Back 1″(25 mm)

If the refrigerator is against a wall

on either side, allow the following

door clearances for a 90° door opening:

22′– 25′models 3/4″(19 mm)

27′models 11/2″(38 mm)

Rollers

The rollers have 3 purposes:

Rollers adjust so the door closes easily when

opened about halfway. [Raise the front about

5/8″(15 mm) from the floor.]

To assure that the doors will close automatically

from a halfway open position, there is a built-in tilt

from the front to the back of the cabinet. Side-byside refrigerators also have specially designed door

hinges that lift both doors slightly when opened,

allowing the force of gravity to help close them

securely.

Rollers adjust so the refrigerator is firmly positioned on the floor and does not wobble.

Rollers allow you to move the refrigerator away

from the wall for cleaning.

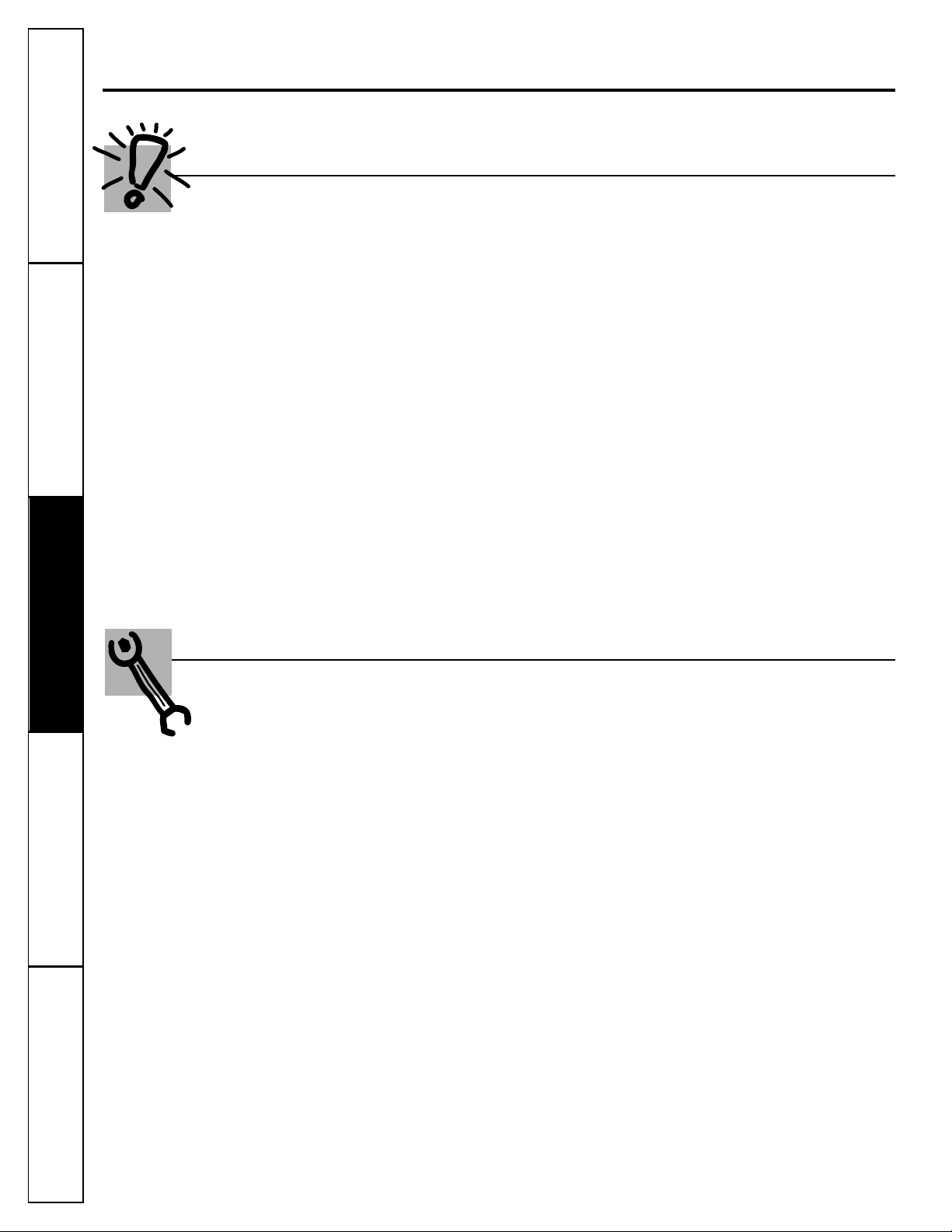

To adjust the rollers,

remove the base grille by pulling

it out at the bottom.

Turn the roller adjusting screws

clockwise to raise

the refrigerator,

counterclockwise to lower

it. Use

an adjustable wrench (3/8″hex head bolt) or pliers.

To replace base grille,

align prongs on back of grille

with clamps in cabinet and push forward until grille

snaps into place.

3

2

1

17

90°

Page 18

18

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Installing the water line.

Read these instructions completely and carefully.

Before You Begin

When connecting a GE Reverse Osmosis Water System to your refrigerator, the only

approved installation is with a GE RVKIT.

If the water supply to the refrigerator is from a Reverse Osmosis Water Filtration System

AND the refrigerator also has a water filter, use the refrigerator’s filter bypass plug. Using

the refrigerator’s water filtration cartridge in conjunction with the RO filter can result in hollow ice cubes and slower water flow from the water dispenser.

This water line installation is not warranted by the refrigerator or icemaker manufacturer.

Follow these instructions carefully to minimize the risk of expensive water damage.

Water hammer (water banging in the pipes) in house plumbing can cause damage

to refrigerator parts and lead to water leakage or flooding. Call a qualified plumber

to correct water hammer before installing the water supply line to the refrigerator.

To prevent burns and product damage, do not hook up the water line to the

hot water line.

If you use your refrigerator before connecting the water line, make sure the

icemaker feeler arm is kept in the STOP (up) position.

Do not install the icemaker tubing in areas where temperatures fall below freezing.

When using any electrical device (such as a power drill) during installation, be sure

the device is insulated or wired in a manner to prevent the hazard of electric shock.

All installations must be in accordance with local plumbing code requirements.

What You Will Need

To determine how much copper tubing you need:

Measure the distance from the water valve on the back of the refrigerator to the

water supply pipe. Then add 8 feet (244 cm). Be sure there is sufficient extra tubing

[about 8 feet (244 cm) coiled into 3 turns of about 10 inches (25 cm) diameter] to allow

the refrigerator to move out from the wall after installation.

■

A water supply kit

(containing copper tubing, shutoff valve and fittings listed below) is avail-

able at extra cost from your dealer or from Parts and Accessories, 800-626-2002.

■

Cold water supply.

The water pressure must be between 20 and 120 p.s.i. (1.4–8.2 bar) on

models without a water filter and between 40 and 120 p.s.i. (2.8–8.2 bar) on models with

a water filter.

■

Power drill.

■

Copper tubing,

1/4″outer diameter to connect the refrigerator to the water supply. Be sure

both ends of the tubing are cut square.

Do not use plastic tubing or plastic fittings because the water supply line is under

pressure at all times. Certain types of plastic tubing may become brittle with age and

crack, resulting in water leakage.

■

Two 1/4″outer diameter compression nuts and 2 ferrules (sleeves)—

to connect the copper

tubing to the shutoff valve and the refrigerator water valve.

■If your existing water line has a flared fitting at the end, you will need an

adapter

(available at

plumbing supply stores) to connect the water line to the refrigerator

OR

you can cut off the

flared fitting with a

tube cutter

and then use a compression fitting.

■

Shutoff valve

to connect to the cold water line. The shutoff valve should have a water inlet

with a minimum inside diameter of 5/32″at the point of connection to the

COLD WATER

LINE.

Saddle-type shutoff valves are included in many water supply kits. Before purchasing,

make sure a saddle-type valve complies with your local plumbing codes.

Page 19

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

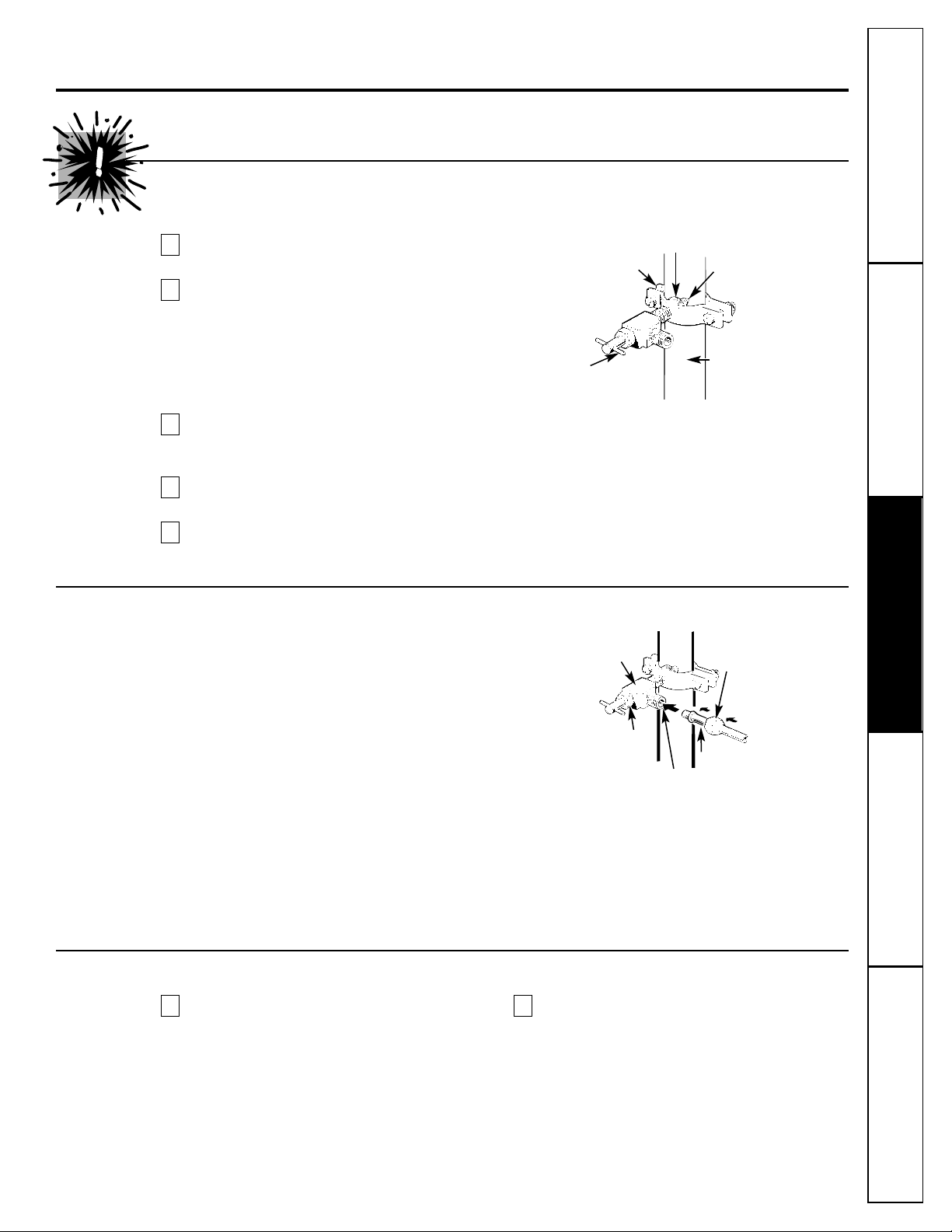

Shut Off the Main Water Supply

Turn on the nearest faucet long enough to clear the line of water.

Install the Shutoff Valve

Install the shutoff valve on the nearest frequently used drinking water line.

Choose a location for the valve that is easily

accessible. It is best to connect into the side of a

vertical water pipe. When it is necessary to connect into a horizontal water pipe, make the connection to the top or side, rather than at the bottom, to avoid drawing off any sediment from the

water pipe.

Drill a 1/4″hole in the water pipe, using a sharp

bit. Remove any burrs resulting from drilling the

hole in the pipe.

Fasten the shutoff valve to the cold water pipe

with the pipe clamp.

Tighten the clamp screws until the sealing washer begins to swell.

Do not overtighten or you may crush the copper

tubing.

NOTE: Commonwealth of Massachusetts Plumbing Codes

248CMR shall be adhered to. Saddle valves are illegal and

use is not permitted in Massachusetts. Consult with your

licensed plumber.

5

4

3

2

1

19

Route the Copper Tubing and Connect It to the Shutoff Valve

Route the copper tubing between the cold water

line and the refrigerator.

Route the tubing through a hole drilled in the wall

or floor (behind the refrigerator or adjacent base

cabinet) as close to the wall as possible.

Be sure there is sufficient extra tubing [about 8

feet (244 cm) coiled into 3 turns of about 10

″

(25 cm) diameter] to allow the refrigerator to

move out from the wall after installation.

Place the compression nut and ferrule (sleeve)

onto the end of the tubing and connect it to the

shutoff valve.

Make sure the tubing is fully inserted into the valve.

Tighten the compression nut securely.

NOTE: Commonwealth of Massachusetts Plumbing Codes

248CMR shall be adhered to. Saddle valves are illegal and

use is not permitted in Massachusetts. Consult with your

licensed plumber.

Turn On the Water and Flush Out the Tubing

Turn the main water supply on and flush out the

tubing until the water is clear.

Shut the water off at the water valve after about

one quart (1 L) of water has been flushed

through the tubing.

21

Washer

Inlet End

Pipe Clamp

Vertical Cold Water Pipe

Saddle-Type

Shutoff Valve

Saddle-Type Shutoff Valve

Compression Nut

Packing Nut

Outlet Valve

Ferrule (sleeve)

Page 20

20

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Installing the water line.

Read these instructions completely and carefully.

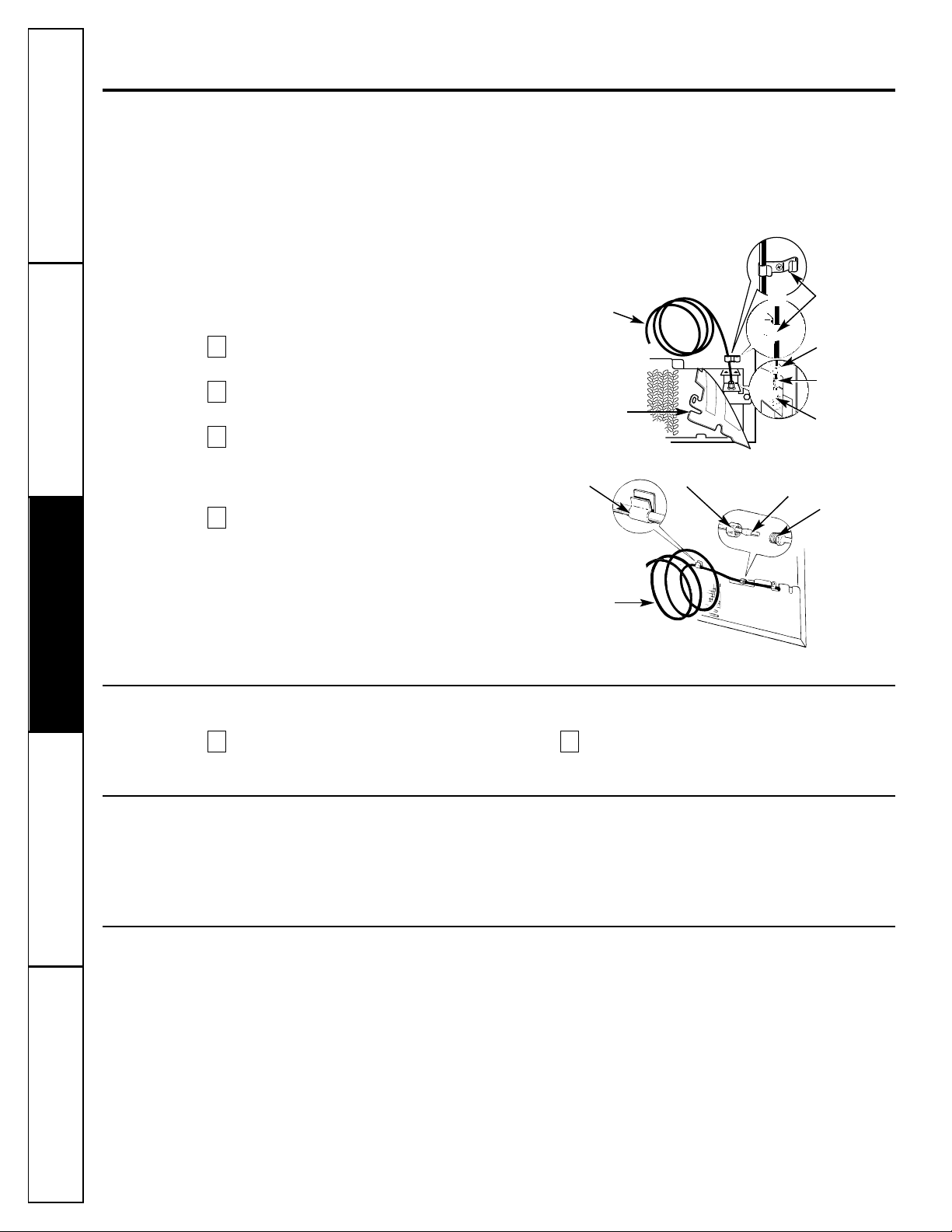

Connect the Tubing to the Refrigerator

Before making the connection to the refrigerator, be sure the refrigerator power

cord is not plugged into the wall outlet.

We recommend installing a water filter if your water

supply has sand or particles that could clog the

screen of the refrigerator’s water valve. Install it in

the water line near the refrigerator.

Remove the plastic flexible cap from the water

valve (refrigerator connection).

Place the compression nut and ferrule (sleeve)

onto the end of the tubing as shown.

Insert the end of the copper tubing into

the water valve refrigerator connection as far

as possible. While holding the tubing, tighten

the fitting.

Fasten the copper tubing into the clamp provided to hold it in position. You may

need to pry open the clamp.

One of the illustrations below will look like the connection

on your refrigerator.

4

3

2

1

Turn the Water On at the Shutoff Valve

Tighten any connections that leak. Replace the access cover and screws (on some

models).

21

Plug In the Refrigerator

Arrange the coil of copper tubing so that it does not

vibrate against the back of the refrigerator or against

the wall.

Push the refrigerator back to the wall.

Start the Icemaker

Set the icemaker feeler arm to the

ON

(down) position. The icemaker will not begin to operate until it

reaches its operating temperature of 15°F

(-9°C) or below. It will then begin operation automatically if the icemaker feeler arm is in the

ON

(down) position.

NOTE: The icemaker may double-cycle when it first starts,

causing some water spillage from the icemaker into the

ice bucket. This is normal and should not happen again.

1/4″

Compression

Nut

1/4″Copper

Tubing

Remove screws

and fold back

access cover.

Ferrule

(sleeve)

Tubing Clamp

Refrigerator

Connection

OR

1/4″Compression Nut

1/4″Copper

Tubing

Ferrule (sleeve)

Tubing Clamp

Refrigerator

Connection

Page 21

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

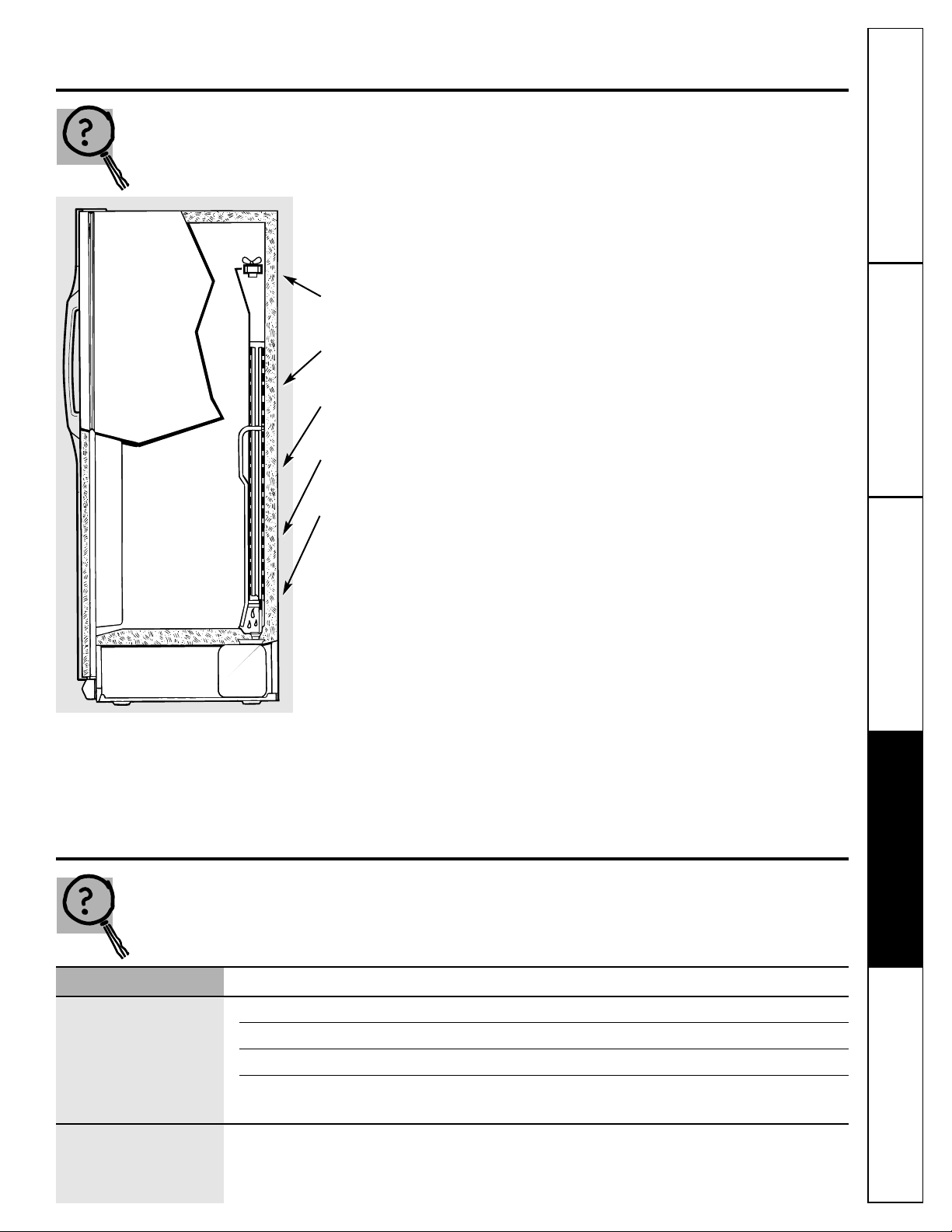

Normal operating sounds.

Depending on the placement of the refrigerator in your kitchen,

you may want to place a piece of rubber backed carpet under

the refrigerator to reduce noise.

The new high efficiency compressor runs faster and will have a higher pitch hum

or pulsating sound while operating.

Defrost timer and refrigerator control click on and off.

The fan circulating air inside the freezer which keeps the temperatures throughout.

Water dropping on the defrost heater causing a sizzling, hissing or popping

sound during the defrost cycle.

The flow of refrigerant through the freezer cooling coils sounds like boiling

water or a gurgling noise.

Cracking or popping of cooling coils caused by expansion and contraction

during defrost and refrigeration following defrost.

Water dripping as it melts from the evaporator and flows to the drain pan

during the defrost cycle.

Icemaker

(on some models)

The icemaker water valve will buzz when the icemaker fills with water. If the feeler

arm is in the

ON

(down) position it will buzz even if it has not yet been hooked up

to water. Keeping the feeler arm in the

ON

(down) position before it is hooked up

to water can damage the icemaker. To prevent this, raise the feeler arm to the

STOP

(up) position. This will stop the buzzing.

The sound of cubes dropping into the bin and water running in pipes as

icemaker refills.

Before you call for service…

Troubleshooting Tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

Problem Possible Causes What To Do

Refrigerator does not

Refrigerator in defrost cycle. • Wait about 30 minutes for defrost cycle to end.

operate

Control in

OFF

or 0position. • Move the control to a temperature setting.

Refrigerator is unplugged. • Push the plug completely into the outlet.

The fuse is blown/circuit • Replace fuse or reset the breaker.

breaker is tripped.

Vibration or rattling

Rollers need adjusting. • See

Rollers.

(slight vibration

is normal)

These sounds are normal

and are due mostly to highly

efficient operation.

21

Page 22

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Before you call for service…

Problem Possible Causes What To Do

Motor operates for

Normal when refrigerator • Wait 24 hours for the refrigerator to completely

long periods or cycles

is first plugged in. cool down.

on and off frequently.

Often occurs when large • This is normal.

(Modern refrigerators

amounts of food are

with more storage

placed in refrigerator.

space and a larger

Door left open. • Check to see if package is holding door open.

freezer require more

Hot weather or frequent • This is normal.

operating time. They

door openings.

start and stop often

Temperature controls • See

About the controls.

to maintain even

set at the coldest setting.

temperatures.)

Grille and condenser • See

Care and cleaning.

need cleaning.

Fresh food or freezer

Temperature control not set • See

About the controls.

compartment too warm

cold enough.

Warm weather or frequent • Set the temperature control one step colder.

door openings. See

About the controls.

Door left open. • Check to see if package is holding door open.

Frost or ice crystals

Door left open. • Check to see if package is holding door open.

on frozen food

Too frequent or too long

(frost within package

door openings.

is normal)

Divider between fresh

Automatic energy saver • This helps prevent condensation on the outside.

food and freezer

system circulates warm

compartments feels warm

liquid around front edge

of freezer compartment.

Automatic icemaker

Icemaker feeler arm in • Move the feeler arm to the

ON

(down) position.

does not work

the

STOP

(up) position.

• Cubes may have fused to the side of the mold. Move the

(on some models)

feeler arm to the

STOP

(up) position, then remove

these cubes.

Water supply turned off or •See

Installing the water line.

not connected.

Freezer compartment • Wait 24 hours for the refrigerator to completely

too warm. cool down.

Piled up cubes in the storage bin • Level cubes by hand.

cause the icemaker to shut off

Ice cubes have

Ice storage bin needs cleaning. •Empty and wash bin. Discard old cubes.

odor/taste

Food transmitting odor/taste • Wrap foods well.

to ice cubes.

Interior of refrigerator •See

Care and cleaning.

needs cleaning.

Poor-tasting incoming water. • Install a water filter.

Small or hollow cubes

Water filter clogged. • Replace filter cartridge with new cartridge or with plug.

Door not closing

Door gasket on hinge side • Apply petroleum jelly on face of gasket.

properly

sticking or folding over.

Orange glow in

Defrost heater is on. • This is normal.

the freezer

22

Page 23

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

Problem Possible Causes What To Do

Slow ice cube freezing

Door left open. • Check to see if package is holding door open.

Temperature control not set • See

About the controls.

cold enough.

Cube dispenser does not

Icemaker turned off or • Turn on icemaker or water supply.

work (on some models)

water supply turned off.

Ice cubes are frozen to • Remove cubes and move the feeler arm to the

icemaker feeler arm.

ON

(down) position.

Irregular ice clumps in • Break up with fingertip pressure and discard

storage container. remaining clumps.

• Freezer may be too warm. Adjust the freezer control

to a colder setting, one position at a time, until

clumps do not form.

Water has poor taste/odor

Water dispenser has not been •Dispense water until all water in system is replenished.

(on some models)

used for a long time.

Water dispenser does

Water supply line turned • See

Installing the water line.

not work (on some models)

off or not connected.

Water filter clogged. • Replace filter cartridge or remove filter and install plug.

Air may be trapped in the • Press the dispenser pad for at least two minutes.

water system.

Water spurting from

Newly-installed filter cartridge. • Run water from the dispenser for 1 minute (about a

dispenser (on some models)

half gallon).

Water is not dispensed

Water in reservoir is • Call for service.

but icemaker is working

frozen.

(on some models)

No water or ice cube

Supply line or shutoff • Call a plumber.

production

(on some

valve is clogged.

models)

Water filter clogged. • Replace filter cartridge or remove filter and install plug.

Refrigerator has odor

Foods transmitting • Foods with strong odors should be tightly wrapped.

odor to refrigerator.

• Keep an open box of baking soda in the refrigerator;

replace every three months.

Interior needs cleaning. • See

Care and cleaning.

Defrost water drainage • See

Care and cleaning.

system needs cleaning.

Moisture forms on

Not unusual during • Wipe surface dry.

outside of refrigerator

periods of high humidity.

Moisture collects inside

Too frequent or too

(in humid weather, air

long door openings.

carries moisture into

refrigerator when doors

are opened)

Interior light does

No power at outlet. • Replace fuse or reset the breaker.

not work

Light bulb burned out. •See

Replacing the light bulbs.

Water on kitchen floor or

Drain in the bottom of • See

Care and cleaning.

on bottom of freezer

the freezer clogged.

Cubes jammed in chute. • Poke ice through with a wooden spoon.

23

Page 24

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

24

Before you call for service…

Problem Possible Causes What To Do

Hot air from bottom

Normal air flow cooling • Your floor covering supplier should be consulted if you

of refrigerator

motor. In the refrigeration object to this discoloration.

process, it is normal that

heat be expelled in the

area under the refrigerator.

Some floor coverings will

discolor at these normal

and safe temperatures.

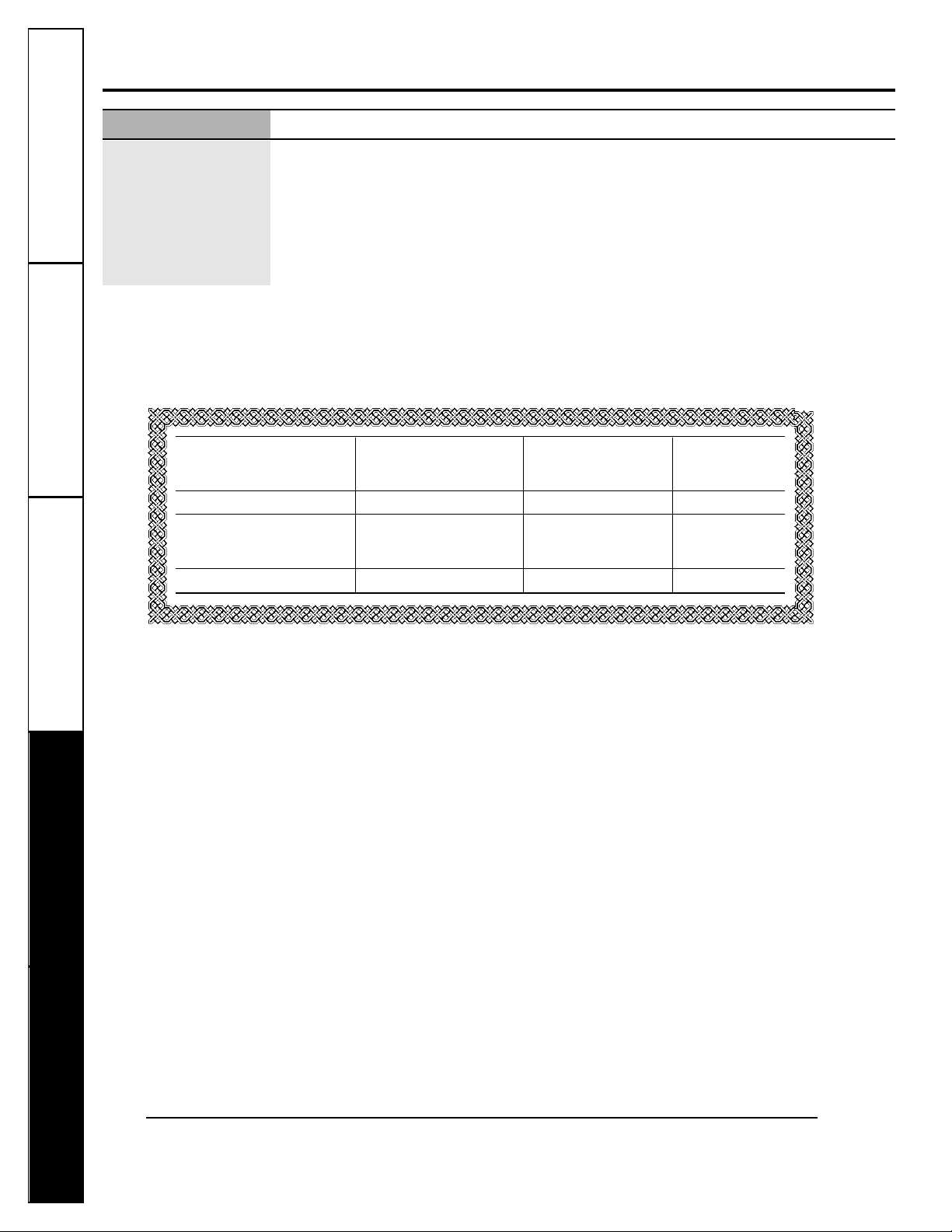

CONSUMER WARRANTY

(for customers in Canada)

Your refrigerator is warranted to be free of defects in material and workmanship.

What is covered How Long Warranted Parts Labour

(From Date of Sale) Repair or Replace

at Camco’s Option

Compressor Ten (10) Years Ten (10) Years Ten (10) Years

Sealed System (including Five (5) Years Five (5) Years Five (5) Years

evaporator, condenser

tubing and refrigerant)

All Other Parts One (1) Year One (1) Year One (1) Year

TERMS AND CONDITIONS:

This warranty applies only for single

family domestic use in Canada when the

Refrigerator has been properly installed

according to the instructions supplied by

Camco and is connected to an adequate

and proper utility service.

Damage due to abuse, accident, commercial

use, and alteration or defacing of the serial

plate cancels all obligations of this warranty.

Service during this warranty must be performed

by an Authorized Camco Service Agent.

Neither Camco nor the Dealer is liable for any

claims or damages resulting from any failure

of the Refrigerator or from service delays

beyond their reasonable control.

To obtain warranty service, purchaser must

present the original bill of sale. Components

repaired or replaced are warranted through the

remainder of the original warranty period only.

This warranty is in addition to any statutory

warranty.

WHAT IS NOT COVERED:

• Service trips to your home to teach you how

to use the product.

• Damage to finish after delivery.

• Improper installation—proper installation

includes adequate air circulation to the

refrigeration system, adequate electrical,

plumbing and other connecting facilities.

• Replacement of house fuses or resetting of

circuit breakers.

• Replacement of light bulbs.

• Damage to product caused by accident, fire,

floods or acts of God.

• Loss of food due to spoilage.

• Proper use and care of product as listed

in the owner’s manual, proper setting of controls.

• WARRANTOR IS NOT RESPONSIBLE

FOR CONSEQUENTIAL DAMAGES.

IMPORTANT

Keep this warranty and your bill of sale as proof of original purchase and purchase date.

Camco Service is available coast to coast.

If further help is needed concerning this warranty, contact:

Manager, Consumer Relations, Camco Inc.,

Suite 310, 1 Factory Lane, Moncton, N.B. E1C 9M3

Page 25

25

Customer ServiceTroubleshooting Tips

Operating InstructionsSafety Instructions

Installation Instructions

Refrigerator Warranty

(For customers in the United States)

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care® technician. For service,

call 800-GE-CARES.

For The Period Of: GE Will Replace:

One Year Any part

of the refrigerator (excluding water filter cartridge) which fails due to a

From the date of the

defect in materials or workmanship. During this

full one-year warranty,

GE will also

original purchase

provide,

free of charge,

all labor and in-home service to replace the defective part.

Five Years Any part of the sealed refrigerating system

(the compressor, condenser, evaporator

From the date of the

and all connecting tubing) which fails due to a defect in materials or workmanship.

original purchase

During this

five-year warranty,

GE will also provide,

free of charge,

all labor and

in-home service to replace the defective part.

Lifetime Any see-through pan or drawer

furnished with the refrigerator if the pan or drawer

From the date of the

breaks during normal household use. Drawer covers are not included.

original purchase

Thirty Days Any part

of the water filter cartridge which fails due to a defect in materials or

From the date of the

workmanship. During this

full thirty-day warranty,

we will also provide,

free of charge,

original purchase

all labor and in-home service to replace the defective part.

■Service trips to your home to teach you how to use the

product.

■Improper installation.

■Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■Loss of food due to spoilage.

■Replacement of house fuses or resetting of circuit break-

ers.

■Replacement of the water filter cartridge due to water

pressure that is outside the specified operating range or

due to excessive sediment in the water supply.

■Damage to the product caused by accident, fire, floods or

acts of God.

■Incidental or consequential damage to personal property

caused by possible defects with this appliance.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Page 26

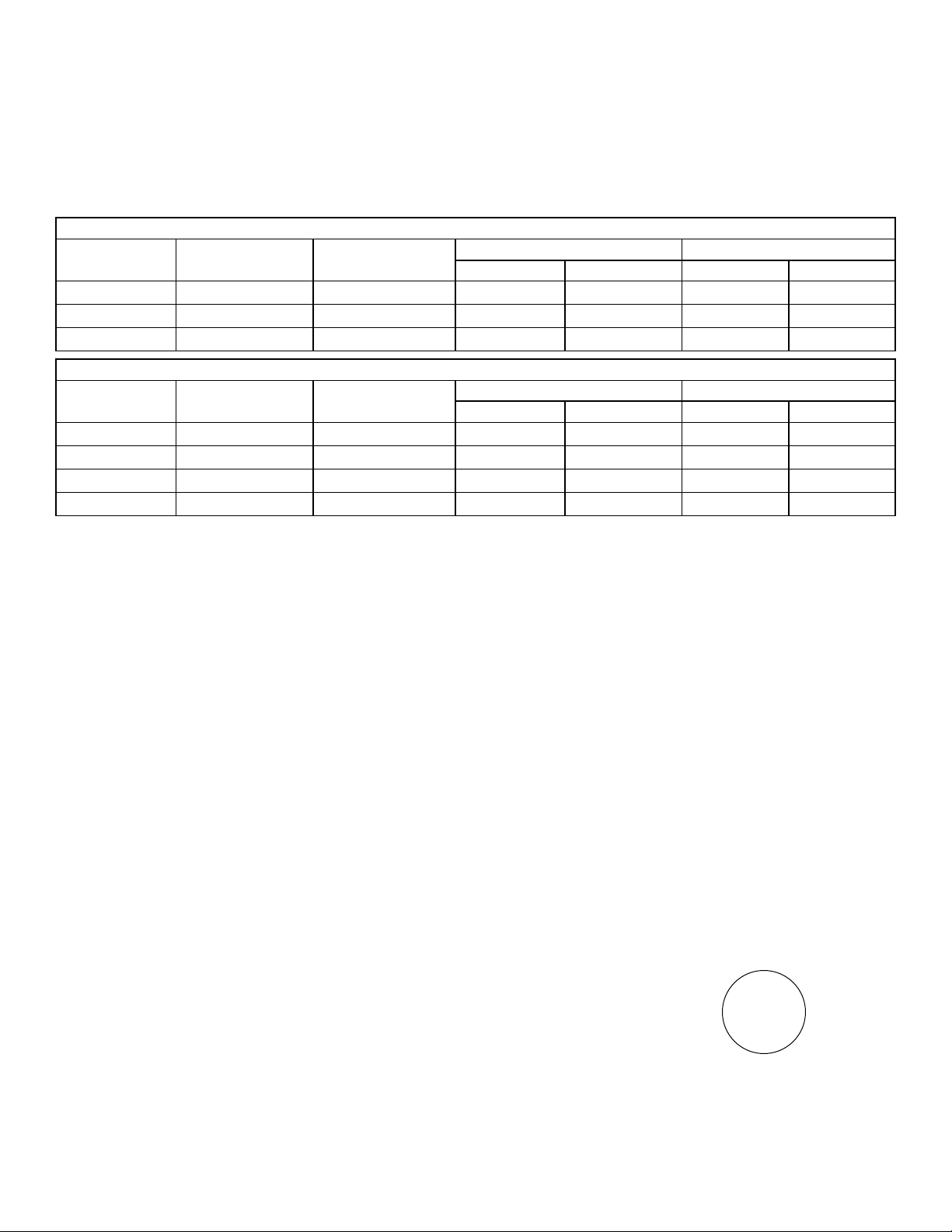

Performance Data Sheet

GE

Water by Culligan Filtration System

FXRC Cartridge

Health Claim Performance Certified by NSF/ANSI*

(100% safety factors built in for unmetered usage)

Standard No. 42: Aesthetic Effects

Parameter USEPA Influent Effluent % Reduction

MCL Challenge Average Maximum Average Minimum

Chlorine — 2.06 ppm 0.14 ppm 0.3 ppm 93 85

T & O ——————

Particulate** — 3,100,064 519 2425 99.98 99.92

Standard No. 53: Health Effects

Parameter USEPA Influent Effluent % Reduction

MCL Challenge Average Maximum Average Minimum

Turbidity 1 NTU*** 23.25 NTU 0.10 NTU 0.17 NTU 99.6 99.3

Cysts 99.95% Reduction 494,169 92 179 99.98 99.96

Lead at pH 6.5 15 ppb 157 ppb 3 ppb 3 ppb >98 >98

Lead at pH 8.5 15 ppb 162 ppb 3 ppb 3 ppb >98 >98

* Tested using a flow rate of 0.5 gpm; pressure of 60 psig; pH of 7.5 ± 0.5; temp. of 20° ± 2.5° C.

** Measurement in Particles/ml

*** NTU=Nephelometric Turbidity units

Operating Specifications

■Capacity: certified for up to 200 gallons (757 L)

■Pressure requirement: 40–120 psi (2.8–8.2 bar), non-shock

■Temperature: 33°–100° F. (0.6°–38° C.)

■Flow rate: 0.5 gpm (1.9 Lpm)

General Installation/Operation/Maintenance Requirements

■Flush new cartridge at full flow for 60 seconds to purge out trapped air.

■Replace cartridge when flow becomes too slow; at least every six months.

Special Notices

■

Installation instructions, parts and service availability, and standard warranty are included with the product when shipped.

■This drinking water system must be maintained according to manufacturer’s instructions, including replacement of filter

cartridges.

■Do not use where the water is microbiologically unsafe, or with waters of unknown quality without adequate disinfection

before or after the system; system may be used on disinfected water that may contain filterable cysts.

■

The contaminants or other substances removed or reduced by this water treatment system are not necessarily in your water.

■Check for compliance with the state and local laws and regulations.

NSF International Standards

Standard No. 42: Aesthetic Effects Standard No. 53: Health Effects

Chemical Unit Chemical Reduction Unit

Taste and Odor Reduction Lead Reduction

Chlorine Reduction, Class I Mechanical Filtration Unit

Mechanical Filtration Unit Cyst Reduction

Particulate Reduction, Class I Turbidity Reduction

The Water by Culligan Filtration System and FXRC cartridge have been

tested and Certified by NSF only for the functions listed immediately above.

Made by: Culligan International, Westmont, IL 60559, T:(630) 654-4000

General Electric, Appliance Park, Louisville, KY 40225 © 1997 GE

Tested & Certified

to ANSI/NSF

Standards 42 & 53

NSF

®

26

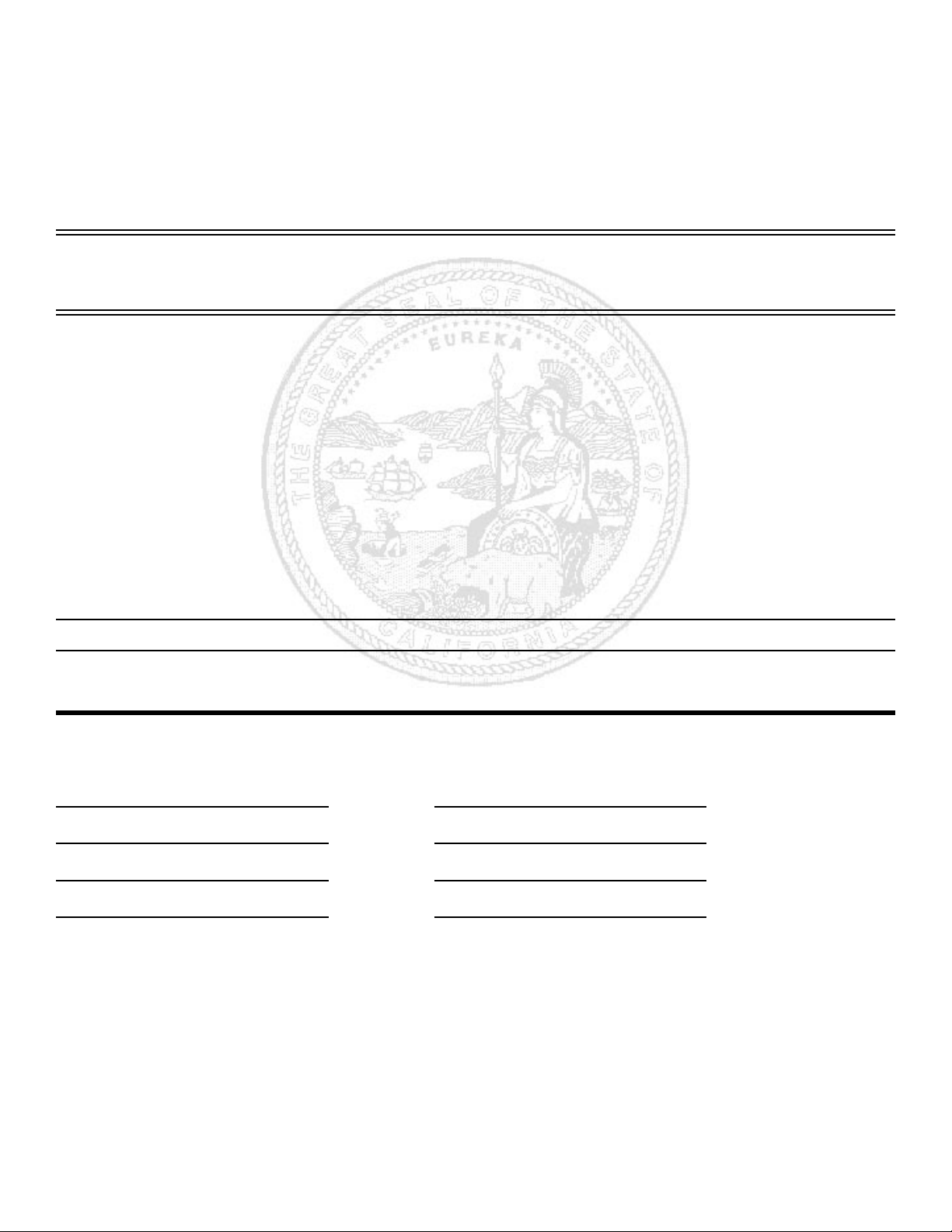

Page 27

27

State of California

Department of Health Services

Water Treatment Device

Certificate Number

97-1291

Date Issued: June 10, 1997

Trademark/Model Designation Replacement Elements

GE Water by Culligan Filtration System FXRC None

Manufacturer:

Culligan International Company

The water treatment device(s) listed on this certificate have met the testing requirements pursuant to Section 116830 of the

Health and Safety Code for the following health related contaminants:

Microbiological Contaminants Inorganic/Radiological

and Turbidity Contaminants

Cysts (protozoan) Lead

Turbidity

Organic Contaminants

None

Rated Service Capacity:

200 gallons

Rated Service Flow:

0.5 gpm

Do not use where water is microbiologically unsafe or with water of unknown quality, except that systems claiming cyst reduction may be

used on water containing cysts.

For Purchases Made In Iowa:

This form must be signed and dated by the buyer and seller prior to the consummation of this

sale. This form should be retained on file by the seller for a minimum of two years.

BUYER: SELLER:

Name Name

Address Address

City State Zip City State Zip

Signature Date Signature Date

Page 28

28

Customer Service Troubleshooting Tips

Operating Instructions

Safety InstructionsInstallation InstructionsCustomer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Customer Service Troubleshooting Tips Installation Instructions Safety Instructions

Operating Instructions

Notes

Page 29

29

General Electric Company

Warranty Registration Department

P.O. Box 32150

Louisville, KY 40232-2150

GE Service Protection Plus

™

GE, a name recognized worldwide for quality and dependability, offers you

Service Protection Plus

™

—comprehensive protection on all your appliances—

No Matter What Brand!

Benefits Include:

• Backed by GE

• All brands covered

• Unlimited service calls

• All parts and labor costs included

• No out-of-pocket expenses

• No hidden deductibles

• One 800 number to call

You will be completely satisfied with our service protection or you may request your money back

on the remaining value of your contract. No questions asked. It’s that simple.

Protect your refrigerator, dishwasher, washer and dryer, range, TV, VCR and much more—any brand!

Plus there’s no extra charge for emergency service and low monthly financing is available. Even icemaker

coverage and food spoilage protection is offered. You can rest easy, knowing that all your valuable

household products are protected against expensive repairs.

Place your confidence in GE and call us in the U.S. toll-free at 800-626-2224

for more information.

*All brands covered, up to 20 years old, in the continental U.S.

We’ll Cover Any Appliance.

Anywhere. Anytime.*

Please place in envelope and mail to:

✁

Cut here

Page 30

30

Consumer Product Ownership Registration

Important

Mail

Today!

First

Name

Mr. ■■ Ms. ■■ Mrs. ■■ Miss ■■

Street

Address

City

State

Date Placed

In Use

Month

Day

Year

Zip

Code

Apt. #

Last

Name

Phone

Number

_

_

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our product and thank you for placing your confidence in us.

We are proud to have you as a customer!

Follow these three steps to protect your new appliance investment:

Important: If you did not get a registration card with your

product, detach and return the form below to

ensure that your product is registered, or register

online at www.geappliances.com.

1

23

Model Number Serial Number

✁

Cut here

Complete and mail

your Consumer

Product Ownership

Registration today.

Have the peace of

mind of knowing we

can contact you in

the

unlikely event of

a

safety modification.

After mailing the registration below,

store this document

in a safe place. It contains information you

will need should

you require service.

Our service number is

800 GE CARES

(800-432-2737).

Read your Owner’s

Manual carefully.

It will help you

operate your new appliance properly.

If you have questions,

or need more

information, call the

GE Answer Center

®

800.626.2000.

Model Number Serial Number

E-mail Address

Occasionally, we may allow selected companies to send you information.

■■ Check here if you do not want this information.

Page 31

31

Page 32

Service à la clientèle Conseils de dépannage

Fonctionnement

Mesures de sécuritéInstallation

Félicitations!

Désormais vous faites partie de la famille GE.

Bienvenue dans la famille GE. Nous sommes fiers de

la qualité de nos produits et de la fiabilité de notre

service après-vente. Vous le constaterez dans le

présent manuel, facile à utiliser, et dans la voix

amicale de notre personnel du service à la clientèle.

Mais, surtout, vous le constaterez chaque fois que

vous vous servirez de votre réfrigérateur. C’est

important, car votre nouveau réfrigérateur fera

partie de votre famille pendant des années. Et nous

espérons que vous ferez partie de la nôtre pendant

longtemps aussi.

Nous vous remercions de votre achat GE, et espérons

qu’à l’avenir vous penserez à nous chaque fois que

vous aurez besoin d’un électroménager de qualité.

GE et vous, un partenariat de service.

Mesures de sécurité

Mesures de sécurité . . . . . . . . . .33

Cordons prolongateurs . . . . . . . .33

Raccordement électrique . . . . . .34

Fiche d’adaptation . . . . . . . . . . . .34

Fonctionnement

Commandes . . . . . . . . . . . . .35–38

Caractéristiques . . . . . . . . . .39–41

Service à glaçons . . . . . . . . . . . .42

Distributeur d’eau

et de glaçons . . . . . . . . . . . . .42, 43

Entretien et nettoyage . . . . .44–46

Installation

Préparation . . . . . . . . . . . . . . . . .47

Installation de la

conduite d’eau . . . . . . . . . . . .48–50

Conseils de dépannage

Bruits de fonctionnement

normaux . . . . . . . . . . . . . . . . . . . .51

Avant d’appeler

un réparateur . . . . . . . . . . . .51–54

Service à la clientèle

Garantie pour

la clientèle au Canada . . . . . . . . .55

Numéros de service . . . . . . . . . . .56

Feuillet de données relatives

à la performance de la

cartouche FXRC . . . . . . . . . . . . . .57

À CONSERVER SOIGNEUSEMENT

Transcrivez les numéros de modèle et de série ici.

#

#

Ils figurent sur l’étiquette qui se trouve soit sur la paroi du

réfrigérateur à côté du bac supérieur, soit à la partie inférieure

de la contre-porte du compartiment réfrigérateur.

Agrafez ici votre facture ou une copie de votre chèque.

Pour bénéficier de réparations sous garantie, il faut fournir une

preuve de la date d’achat d’origine.

Vous y trouverez de nombreux conseils pour l’utilisation et

l’entretien de votre réfrigérateur. Ces quelques mesures préventives

vous permettront d’économiser du temps et de l’argent, et, ainsi, de

prolonger la vie de votre réfrigérateur.

LISEZ VOTRE MANUEL