Page 1

PNRV12ZBL01

GE Appliances

Reverse Osmosis

Filtration System

Part No. 215C1002P004–4 Pub. No. 49-5802-4

5-98 CG

7178901

Owner’s Manual

Faucet & Base

Reverse Osmosis Unit

Storage Tank

Tested and certified to ANSI/NSF

Standard 58 for TDS and cyst reduction.

Page 2

Operating Instructions Safety InstructionsCustomer Service Troubleshooting Tips

Congratulations!

You are Now Part of the GE Family.

Safety Information

. . . . . . . . . 3

Operating Instructions

. .4–10

Specification Guidelines . . . . . . . . . . . .4

Care and Cleaning of the Reverse

Osmosis System . . . . . . . . . . . . . . .7–10

Cartridge Replacement . . . . . . . . . . . .7

Prefilter and Postfilter Cartridge

Replacement . . . . . . . . . . . . . . . . . . . .7

Reverse Osmosis Cartridge

Replacement . . . . . . . . . . . . . . . . . . . .8

Sanitizing the Reverse Osmosis

System . . . . . . . . . . . . . . . . . . . . . . . .9

Flow Control and Screen . . . . . . . . .10

Purging the Reverse Osmosis

System . . . . . . . . . . . . . . . . . . . . . . .10

Troubleshooting Tips

Before You Call For Service

. . . . . .11, 12

Customer Service

Product Registration . . . . . . . . . . .13, 14

Warranty . . . . . . . . . . . . . . . . . . . . . . .15

Service Telephone

Numbers . . . . . . . . . . . . . . . . . . . . . . .16

2

Welcome to the GE family. We’re proud of our quality products and we are

committed to providing dependable service. You’ll see it in this easy-to-use Owner’s

Manual and you’ll hear it in the friendly voices of our customer service department.

Best of all, you’ll experience these values each time you use the water system. That’s

important, because your new system will be part of your family for many years. And

we hope you will be part of ours for a long time to come.

We thank you for buying GE. We appreciate your purchase, and hope you will

continue to rely on us whenever you need quality appliances for your home.

FOR YOUR RECORDS

Write the model and serial numbers here:

#

#

You can find them on the sump bracket.

Staple sales slip or cancelled check here.

Proof of the original purchase date is needed to obtain service under

the warranty.

Inside you will find many helpful hints on how to use and maintain

your water system properly. Just a little preventive care on your part

can save you a great deal of time and money over the life of your

system. A video has been included with the product containing

important use and care instructions.

You’ll find many answers to common problems in the

Before You Call

For Service

section. If you review our chart of

Troubleshooting Tips

first,

you may not need to call for service at all.

READ THIS MANUAL

IF YOU NEED SERVICE

If you do need service, you can relax knowing help is only a phone

call away. A list of toll-free customer service numbers is included in

the back section.

IMPORT ANT!

Fill out and return the Consumer Product Registration Card that is

packed with this product. If you cannot find it, please send in the

duplicate card printed in the back of this manual.

Page 3

Customer ServiceTroubleshooting TipsOperating InstructionsSafety Instructions

3

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

■Check with your state and local public works

department for plumbing and sanitation codes.

You must follow these guidelines as you install the

Reverse Osmosis system.

Using a qualified installer

is recommended

.

■If house water pressure is over the maximum (125

pounds per square inch), install a pressure reducing

valve in the water supply line to the Reverse Osmosis

system.

■Be sure the water supply conforms with the

Specification guidelines.

If the water supply conditions

are unknown, contact your municipal water company

or your local health department for a list of

contaminants in your area and a list of laboratories

certified by your state to analyze drinking water.

WARNING:

Before using the Reverse Osmosis

system for the first time, the system must be purged.

The Reverse Osmosis cartridge contains a food

grade preservative that must be purged from the

system. The preservative will give product water an

unpleasant taste and odor.

■This product reduces fluoride in drinking water.

Please consult your dentist if you have questions.

WARNING:

Do not use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before or after

the system. Systems certified for cyst reduction

may be used on disinfected water that may contain

filterable cysts. This Reverse Osmosis unit contains

a replaceable membrane cartridge treatment

component critical for effective reduction of

Total Dissolved Solids. The water should be tested

periodically to verify that the system is performing

satisfactorily. This system is acceptable for

treatment of influent concentrations of no more

than 27 mg/L nitrate and 3 mg/L nitrite in

combination measured as N and is certified for

nitrate/nitrite reduction only for water supplies

with a pressure of 280kPa (40 psig) or greater.

SAVE THESE INSTRUCTIONS

Read and follow this Safety Information carefully.

■Install or store where it will not be exposed to

temperatures below freezing or exposed to any

type of weather. Water freezing in the system will

break it. Do not attempt to treat water over 100°F.

■Do not install on

HOT WATER.

The temperature

of the water supply to the Reverse Osmosis system

must be between the minimum of 40°F. and the

maximum of 100°F. See the

Specification guidelines.

■

Do Not

open the water supply valve until the pipes

have been flushed.

■

Extended non-use of the Reverse Osmosis system

If the system is not used for one week or more,

open the RO water faucet, allow the system to

drain. Close the RO water faucet and allow the

system to regenerate the water supply.

WARNING:

Discard all unused parts and

packaging material after installation. Small parts

remaining after the installation could be a choke

hazard.

■

Sanitize upon installation of the Reverse Osmosis

system and after servicing inner parts, including

replacement of prefilter, postfilter and Reverse

Osmosis cartridge. It is important to have clean

hands while handling inner parts of the system.

See the

Sanitizing the Reverse Osmosis System

section.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of

property damage or personal injury.

SAFETY PRECAUTIONS

PROPER INSTALLATION AND MAINTENANCE

This Reverse Osmosis system must be properly installed and located in accordance with the Installation

Instructions before it is used. If you did not receive Installation Instructions, you can receive one by

calling us toll-free at the GE Answer Center

®

, 800.626.2000.

Page 4

4

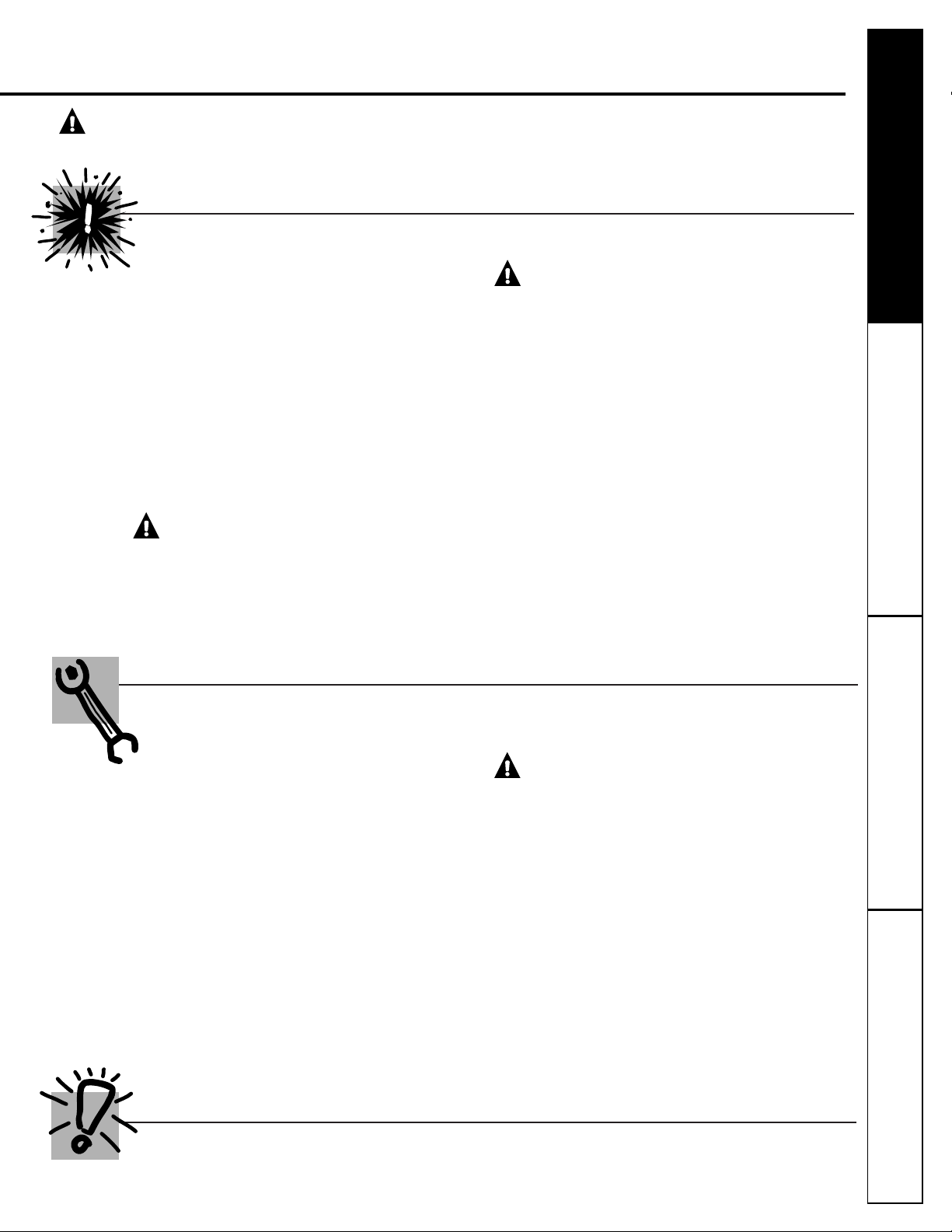

Specification guidelines.

About the reverse osmosis system.

What the Reverse Osmosis System Does

The system makes a good supply of drinking water each day. How much it will make depends primarily on

these things…

Feed water pressure—pounds per square inch (psi)

40–125

Feed water temperature limits—minimum/maximum degrees F.

40–100

Water quality

Maximum Total Dissolved Solids (TDS)—parts per million (ppm)

2000

Maximum water hardness @ 6.9 pH—grains per gallon (gpg)

10

For water with hardness greater than 10 grains (at 6.9 pH) the use

of a softener is recommended. Failure to install a water softener

will reduce the life of the Reverse Osmosis membrane. See chart

for additional information on the possible need for a water softener.

Maximum iron, manganese, hydrogen sulfide (ppm)

<0.1

Chlorine in water supply

Allowable*

Feed water pH limits (pH)

4–10

Percent rejection of TDS, minimum (new membrane)**

92

*Chlorine removed (maximum of 2.0 ppm) by the Reverse Osmosis prefilter…regular changing of the prefilter is

required. Chlorine will destroy the Reverse Osmosis membrane.

**Feed water at 50 psig and 77°F. with 750 ppm sodium chloride. Quality water production, amount of waste water

and percent rejection all vary with changes in pressure, temperature and Total Dissolved Solids.

On average you should expect your Reverse Osmosis system to be able to deliver 12 gallons of product per day, as

tested by Water Quality Association Standard S-300. Output according to ANSI/NSF Standard 58 is 10 gallons per

day. Process water used per gallon of water produced is four gallons.

3

2

1

Product – height 16″ width 17″ depth 6″

Reverse Osmosis removes Total Dissolved Solids (TDS) and organic matter from water by diffusing it

through a special membrane. The membrane separates minerals and impurities from the water and they

are flushed to the drain. High quality product water goes directly to the drinking water faucet or to the

storage tank. The system makes a good supply of drinking water each day (see

Specification guidelines)

.

How much it makes depends on the feed water supply pressure, temperature, and quality.

The system includes an electronic faucet assembly with an integrated water testing feature. When water is

taken from the faucet, a green indicator light means TDS removal is within the specified limits, and that

water quality is good.

The prefilter and postfilter are replaceable cartridges. The carbon prefilter removes chlorine while also

filtering sediments. The postfilter removes any other undesirable tastes and odors before you use the water.

Operating Instructions Safety InstructionsCustomer Service Troubleshooting Tips

Water Softener Chart

Incoming Water ph

WATER SOFTENER RECOMMENDED

INCOMING WATER HARDNESS (GPG)

60

50

40

30

2010

8

6

7

7.5

6.5

Water Softener

not required

Page 5

5

Customer ServiceTroubleshooting TipsOperating InstructionsSafety Instructions

Prefilter

—Water from the cold supply pipe is directed to the prefilter cartridge, which is inside the sump.

The

prefilter is a replaceable sediment cartridge containing activated carbon. The cartridge removes sand, silt, dirt, other

sediments and up to 2.0 ppm of chlorine from the feed water. The prefilter reduces chlorine in the feed water because

CHLORINE DESTROYS THE REVERSE OSMOSIS MEMBRANE.

Filtered, clean, chlorine-reduced water flows from the

prefilter to the Reverse Osmosis cartridge.

Storage Tank—

The storage area holds up to 2.1 gallons of product water. A diaphragm inside the tank keeps water

pressurized, when the tank is full, for fast flow to the faucet when drinking water is needed.

Check Valve—

A check valve is built into one end of the Reverse Osmosis housing under the tee fitting. The check

valve prevents a backward flow of product water from the storage area. A backward flow could cause the Reverse

Osmosis membrane to rupture.

Automatic Shutoff Assembly—

To conserve water, the drinking water system has an automatic shutoff. When the storage

tank has filled to capacity and the drinking water faucet is closed, pressure closes the shutoff. Water flow to the Reverse

Osmosis housing is shut off until drinking water is used again, and pressure drops in the Reverse Osmosis system.

4

3

2

1

Sump

Sump

Postfilter

cartridge

Prefilter

cartridge

Inlet cover

Reverse Osmosis cartridge

Reverse Osmosis housing

Turn sump this way to remove

O-ring

inside

sump

Reverse Osmosis Cartridge—

The cartridge, inside the Reverse Osmosis housing, includes a tightly wound, special

membrane. Water is forced through the cartridge where the membrane removes the dissolved solids and organic

matter. High quality product water exits the Reverse Osmosis housing and goes to the storage tank. Reject water, with

the dissolved solids and organic matter, leaves the housing and is discharged to the drain through 1⁄4″tubing.

Postfilter—

After leaving the storage area, but before going to the system faucet, product water goes to the postfilter

which is inside the sump. The postfilter is also a replaceable sediment cartridge that contains activated carbon. Any

remaining tastes, odors, or sediments are removed from product water by the postfilter. Clean, high quality

drinking water flows through the tubing and to the system faucet.

Flow Control—

The flow control regulates the flow of water through the Reverse Osmosis cartridge at the required

rate to produce high quality water. The control is located in the elbow fitting at the Reverse Osmosis housing drain

port. A small, cone-shaped screen fits over the front end of the flow control to prevent clogging due to sediments in

the drain water.

7

6

5

Screen

Flow control

To drain

1/4″

tubing

Compression nut

Check valve tee

Drain elbow

Automatic

shutoff

assembly

U-pin

Lock washer

Page 6

6

Operating Instructions Safety InstructionsCustomer Service Troubleshooting Tips

About the reverse osmosis system.

The Faucet and Indicator Lights

Faucet and Electronics—

The countertop faucet

dispenses filtered drinking water when

opened. It has a hand-operated, spring-loaded

lever to prevent waste. You can keep the faucet

open by pushing upward on the lever until it

locks against the faucet spout.

To comply with plumbing codes, an air gap is

built into the faucet drain water connection.

The electronic faucet provides an integrated

TDS monitor. As water is taken from

the faucet, the indicator lights show how

the Reverse Osmosis system is operating

to provide high quality drinking water.

Flashing Green Light—

The Reverse Osmosis

system is providing high quality drinking water.

NOTE:

If the Reverse Osmosis system is connected

to the refrigerator this light will also flash when

the icemaker or water dispenser is in use.

The green light may stop flashing when the

supply of Reverse Osmosis water is nearly gone

and flow from the RO water faucet decreases.

This is a normal condition.

Flashing Amber “FILTER” Light—

The prefilter

and postfilter cartridges need replacing after

six months or 900 gallons of product water. See

the

Care and Cleaning

section for prefilter and

postfilter cartridge replacement.

Flashing Amber “RO” Light—

The Reverse Osmosis

cartridge is no longer removing at least 75%

of the TDS from the supply water and needs

replacing.

See the

Care and Cleaning

section

for Reverse Osmosis cartridge replacement.

NOTE:

Disregard initial or short periods (a few

seconds) of the flashing “RO” light. Long

periods of limited or non use can cause the

TDS

levels to temporarily change.

Page 7

7

Customer ServiceTroubleshooting TipsOperating InstructionsSafety Instructions

Care and cleaning of the reverse osmosis system.

To obtain replacement filters, call GE Appliance Parts at 800-626-2002.

If the Reverse Osmosis filtration system is connected to your icemaker,

YOU MUST

turn off the

icemaker by raising the feeler arm before servicing or changing the filters, or when purging the

Reverse Osmosis system. Four hours after servicing, lower the feeler arm to resume icemaking.

When replacing cartridges you may lift the Reverse Osmosis assembly from the mounting

washers and lay it on the floor. You

can also remove the

Reverse Osmosis

housing by pulling it

out of the mounting clamps.

CAUTION:Before servicing the Reverse Osmosis system, close the shutoff valve on the storage

tank, close the water supply/saddle valve and open the RO water faucet. Allow the system to drain.

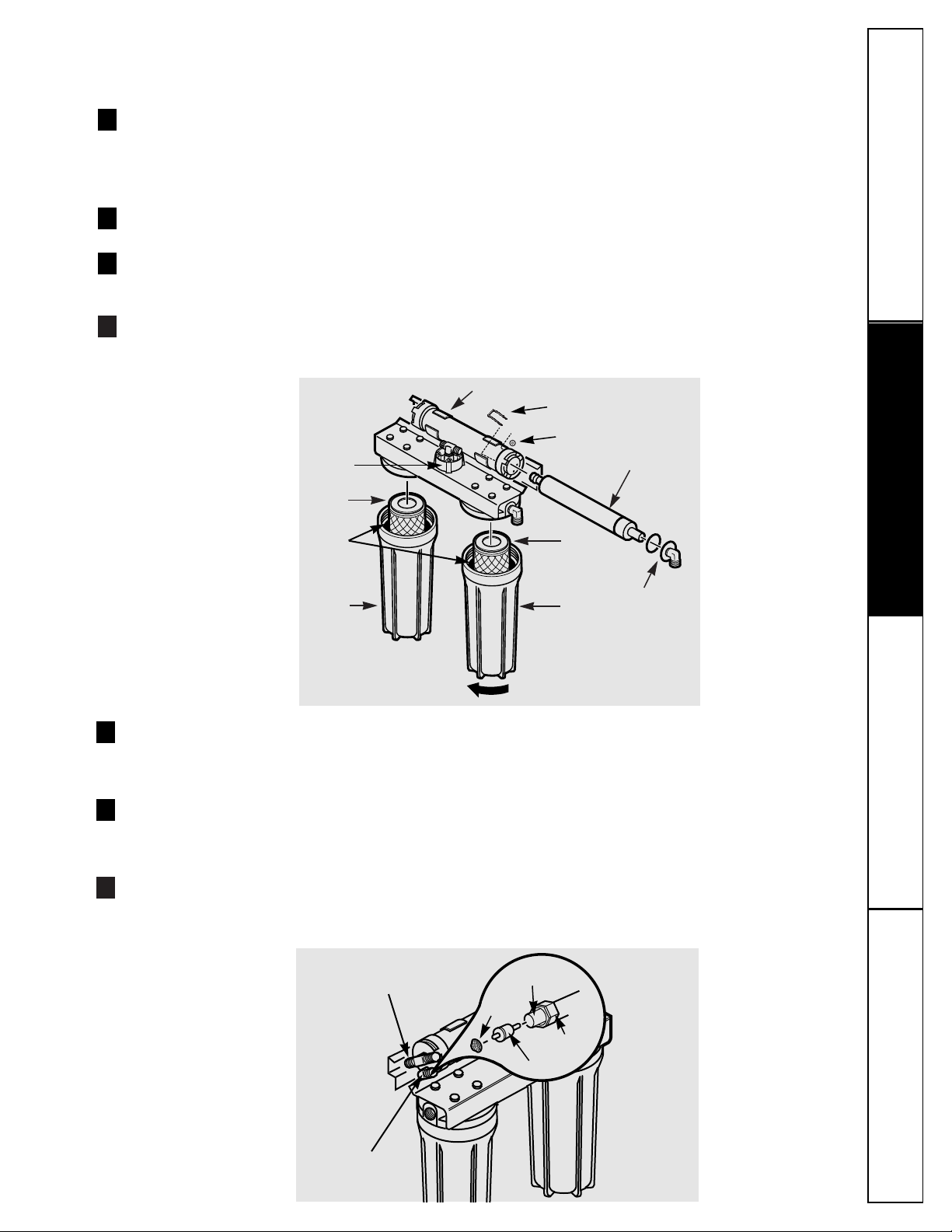

Prefilter/Postfilter Cartridge Replacement FX12P Activated Carbon

Reverse Osmosis Cartridge Replacement FX12M Thin Film Polyamide

Prefilter and Postfilter Cartridge Replacement

When the amber “FILTER” light flashes the prefilter and postfilter cartridges must be replaced.

The batteries in the control box must also be replaced.

Follow the steps in the

Sanitizing the Reverse Osmosis System

section except discard the old

filters and replace with new filters.

Replace the “AA” alkaline batteries

in the control box. Good batteries are needed to ensure

proper indicator light operation.

NOTE:

Lights may not operate properly until system has been

allowed to refill the storage tank. Weak batteries may give a false indication. Changing the

batteries resets the six month

or 900 gallon period.

2

1

Page 8

8

Operating Instructions Safety InstructionsCustomer Service Troubleshooting Tips

Care and cleaning of the reverse osmosis system.

NOTE: When replacing the Reverse Osmosis

cartridge, also install a new flow control and

screen. See the Flow Control and Screen section.

If the Reverse Osmosis Filtration system is

connected to your icemaker YOU MUST turn

off the icemaker by raising the feeler arm

before servicing the filter, changing the filters,

or purging the filtration system. Four hours

after servicing your unit, lower the feeler arm

to resume icemaking.

When replacing cartridges you may lift the

Reverse Osmosis assembly from the mounting

washers and lay it on the floor. You can also

remove the Reverse Osmosis housing by

pulling it out of the mounting clamps.

When the amber “RO” light flashes the

Reverse Osmosis cartridge must be replaced.

NOTE:

Disregard initial or short periods (a few

seconds) of the flashing “RO” light. Long

periods of limited or non use can cause TDS

levels to temporarily change.

Be sure you clean your hands with anti-bacterial

soap before handling inner parts of the system.

Be sure the water supply valve to the

Reverse Osmosis system is turned off, and

the RO water faucet and storage tank are

open. Allow the system to drain completely

(this takes several minutes).

Pull the Reverse Osmosis system out away

from cabinet. Leave tubing connected.

Place a dry towel under the Reverse Osmosis

unit.

Using pliers remove the lock washer,

pull the u-pin and remove the Reverse

Osmosis housing inlet cover. Save the lock

washer for final assembly.

CAUTION:Failure to close the water supply

valve or tank shutoff valve will cause water

to spray or run when sumps are removed.

Remove the lock washer, pull the u-pin and

remove the inlet cover from the housing.

Use pliers to pull the cartridge from the

housing and discard the cartridge.

Sanitize the system. Go to the

Sanitizing the

Reverse Osmosis System

section and follow

steps 4 through 11.

Install new flow control and screen. Go

to the

Flow Control and Screen

section for

directions.

Pull the u-pin and remove the inlet cover

from the housing.

Install the new Reverse Osmosis cartridge.

NOTE:

The Reverse Osmosis cartridge o-ring

end is notched and may need to be rotated

during reinstallation for proper fit.

Replace the inlet cover. Lightly lubricate the

o-ring seal with only clean silicone grease.

Insert the u-pin and install the lock washer.

Turn on the water supply. Check for leaks.

Purge the Reverse Osmosis system. Go to

the

Purging the Reverse Osmosis System

section.

CAUTION:The Reverse Osmosis cartridge

contains a food grade preservative that should

be purged from the system before first use or

whenever the Reverse Osmosis cartridge is

replaced. The preservative will give product

water an unpleasant taste

and odor. After the

tank has filled (takes about four hours), open the

system faucet until the bladder is empty. After

four of these drainings, the system is ready to

make product water for your use

.

NOTE:Lights may not operate properly until the

system has been allowed to refill the tank.

12

11

10

9

8

7

6

5

4

3

2

1

Reverse Osmosis Cartridge Replacement

Page 9

Customer ServiceTroubleshooting TipsOperating InstructionsSafety Instructions

Sanitizing the Reverse Osmosis System

Sanitize upon installation of the Reverse Osmosis

system and after servicing inner parts, including

replacement of prefilter, postfilter and the

Reverse Osmosis cartridge.

Be sure you clean your

hands with anti-bacterial soap before handling

inner parts of the system.

CAUTION:

Before sanitizing, be sure to remove

all cartridges as follows.

Chlorine will destroy

the Reverse Osmosis cartridge.

Be sure the water supply valve to the Reverse

Osmosis system is turned off, and the RO

water faucet and storage tank are open. Allow

the system to drain completely (this takes

several minutes).

Pull the Reverse Osmosis system out away

from cabinet. Leave tubing connected.

Place a dry towel under the Reverse Osmosis

unit. Using pliers remove the lock washer,

pull the u-pin clip and remove the

Reverse

Osmosis

housing inlet cover. Save the lock

washer for final assembly.

Remove (using pliers) the Reverse Osmosis

cartridge from the housing. Place the

cartridge in a clean plastic bag.

Replace the inlet cover and u-pin, making

sure the o-ring is in place.

Remove the POSTFILTER sump by turning

it to the left using the sump wrench tool

provided. Be careful, the sump is full of water.

Remove the cartridge from the sump and

place in a clean plastic bag. Make sure the

o-ring is seated in the top of the sump. With

the o-ring seal in position, replace the sump

and tighten securely by hand.

Remove the PREFILTER sump and

cartridge. Place this cartridge in a clean

plastic bag.

Fill the prefilter sump with cold water to

about 1″ from the o-ring. Add 1 ounce (2

tablespoons)

of ordinary 5.25% household

chlorine bleach and mix into the water.

Do

not add chlorine first. Concentrated chlorine

may damage plastic.

Carefully replace the sump (make sure the

o-ring valve seal is in place) on the prefilter

head and tighten securely by hand.

Close the RO water faucet. Open the water

supply valve (turn counterclockwise) to the

Reverse Osmosis system. Allow system to fill

for one minute.

Open the RO water faucet and allow water

to flow for 10 minutes through the Reverse

Osmosis system. Close RO water faucet for

one minute and then open faucet and allow

water to flow (approximately 10 minutes)

until bleach odor is gone.

Turn off the water supply valve (turn

clockwise) to the Reverse Osmosis system.

After water flow stops, leave the RO water

faucet open.

Be sure hands have been cleaned with

anti-bacterial soap.

Repeat steps 1–6 and 8;

however, reinstall the cartridges instead

of removing them.

NOTE:

The Reverse Osmosis cartridge o-ring

end is notched and may need to be rotated

during reinstallation for proper fit.

After installing/reinstalling cartridges,

close RO water faucet and open water

supply valve (turn counterclockwise). Check

for leaks.

13

12

11

10

9

8

7

6

5

4

3

2

1

9

Sump

Sump

Postfilter

cartridge

O-ring end

Prefilter

cartridge

Inlet cover

Reverse Osmosis cartridge

Reverse Osmosis housing

Turn sump this way to remove

O-ring

inside

sump

Automatic

shutoff

assembly

U-pin

Lock washer

Sump Wrench

Loosen

Page 10

Care and cleaning of the reverse osmosis system

Operating Instructions Safety InstructionsCustomer Service Troubleshooting Tips

10

Flow Control and Screen

The flow control regulates the flow of water

through the Reverse Osmosis cartridge at the

required rate so high quality product water is

produced.

When servicing the Reverse Osmosis cartridge,

check the flow control and tubing, to make sure

the tube and surrounding surfaces are clean and

unrestricted. A small, cone-shaped screen is

located in front of the flow control to help keep it

clean. If the flow control is plugged with foreign

particles, the Reverse Osmosis cartridge cannot

discharge minerals and impurities to the drain. If

this happens, it will only take a short time for the

system to plug.

Make sure tank shutoff valve is closed, water

supply valve is closed (turn clockwise), and the

RO water faucet is open. Drain system until

water stops flowing.

Locate the plastic drain elbow, next to the

brass check valve tee.

Unscrew the compression nut.

Remove flow control with a clean knife edge.

Remove screen; a toothpick may be needed.

If you are replacing the flow control and

screen,

discard them. If you are checking the

flow control,

screen and tubing for blockage,

clean these parts of any debris. Do not blow

through the flow control, it will contaminate

the part.

Replace the screen by placing the cone end

into the elbow cap and carefully push it in.

CAUTION:

Do not force in further after you feel

resistance. Visually check to be sure it is

properly positioned.

Install flow control and tighten compression

nut by hand, then another 1⁄4 turn with

pliers.

DO NOT OVERTIGHTEN AND DISTORT OR

CRUSH THE TUBING AND FLOW CONTROL.

If you are replacing the Reverse Osmosis

cartridge, return to the

Reverse Osmosis

Cartridge Replacement

instructions. Otherwise,

open the tank valve and the water supply valve

(turn counterclockwise). Close the RO water

faucet.

8

7

6

5

4

3

2

1

Purging the Reverse Osmosis System

The Reverse Osmosis system

MUST BE PURGED

AFTER INSTALLATION

and

WHEN THE REVERSE

OSMOSIS CARTRIDGE IS REPLACED.

Make sure all tubing connections are

tightened.

Make sure the tank shutoff valve is open.

Turn

on the water supply by slowly opening

the water supply valve (turn counterclockwise)

to the Reverse Osmosis system. Carefully

check system for leaks.

Wait approximately four hours for storage

tank

to fill.

At that time,

carefully check all

fittings and tubing connections again for any

water leaks.

Open the RO water faucet until the tank is

empty and flow stops.

After filling and emptying the storage tank

four times, the system is ready to make

product water for your use.

WARNING:The Reverse Osmosis cartridge

contains a food grade preservative that

should be purged from the system before

use. The preservative will give product water

an unpleasant taste and odor.

5

4

3

2

1

REVERSE OSMOSIS SYSTEM

Battery

holder

Storage tank

1/4² tubing,

marked WATER

SUPPLY

RO product water faucet

Drain line

Water supply valve

Hot

Cold

Sink p-trap

Electronics

box

Leadwire

connection

3/8² tubing, marked

FAUCET

Storage tank

shutoff valve

Drain elbow

To drain

Screen

Compression

nut

1/4² tubing

Flow control

Check valve tee

Page 11

Problem Possible Causes What To Do

Sounds you might hear

Running water from the unit • This is normal.

to a drain.

Water has air bubbles

Air in system after installation. • Will go away after water runs for a while.

and is cloudy

Amber “FILTER” light

Six months or 900 gallons • Replace the prefilter, postfilter, and batteries in the

on the faucet base

of product water usage has electronics box.

is flashing

occurred.

Amber “RO” light flashing.

Low usage of the Reverse • Open the RO water faucet and allow the system to drain.

NOTE: Disregard initial or

Osmosis product water Close the RO water faucet and allow the system to

occasional short periods

regenerate the water supply.

of this flashing light.

The Reverse Osmosis •Replace the Reverse Osmosis cartridge, flow control

cartridge is no longer and screen.

removing the required amount

of Total Dissolved Solids.

Water supply to the Reverse • Increase water pressure, precondition the water,

Osmosis system not within etc., as needed to conform before doing maintenance

specifications. on the Reverse Osmosis system.

Indicator lights on faucet

Faucet base leadwire not • Connect.

base not working

connected to electronics

box leadwire.

Battery pack not connected • Connect.

to electronics box.

Batteries installed • Make sure batteries are installed correctly.

incorrectly.

Batteries are weak. • Replace batteries.

Leadwires damaged. • Inspect and repair as needed.

Customer ServiceTroubleshooting TipsOperating InstructionsSafety Instructions

11

Before you call for service…

Troubleshooting Tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

Page 12

Operating Instructions Safety InstructionsCustomer Service Troubleshooting Tips

12

Before you call for service…

Problem Possible Causes What To Do

Chlorine taste and/or

The ppm of chlorine in your

• If the water supply contains more than 2.0 ppm of chlorine,

odor in the Reverse

water supply exceeds maximum additional filtering of the water supply to the Reverse

Osmosis product water

limits and has destroyed the Osmosis is needed. Correct this condition before doing

Reverse Osmosis membrane. maintenance on the Reverse Osmosis system.

The prefilter is no longer • Replace the Reverse Osmosis membrane cartridge,

removing chlorine from control, screen, prefilter, postfilter and batteries in the

the water supply. electronics box.

Other taste and/or odor

High quality product water • This is normal.

may have a different taste

than what you’re used to.

Low water usage • Completely drain system and allow to refill.

Contamination in product

•

Use sanitizing procedures.

water storage.

Prefilter and postfilter

• Replace the prefilter and postfilter.

need to be changed.

Water leaking from

Drain side of faucet air gap • Inspect and eliminate restriction or plug. It is important

faucet air gap hole

(3/8² tubing) plugged, restricted that there are no dips, loops or low spots in the drain line

or incorrectly connected to the from the faucet air gap to the drain pipe. Refer to

drain point. Installation Instructions for proper drain connection. If

drain line adapter was used as the drain point, periodic

inspection/cleaning is recommended.

System makes product

This is normal. • Water flow rate will be lower than your regular faucet.

water slowly

Water supply to the Reverse • Increase water pressure, precondition the water, etc., as

Osmosis system not within needed to conform before doing maintenance on the

specifications. Reverse Osmosis system.

Prefilter cartridge plugged • Replace the prefilter.

If rate does not increase,

replace the

with sediments and/or the postfilter, Reverse Osmosis cartridge, flow control, screen

Reverse Osmosis cartridge and batteries in the electronics box.

plugged with sediments.

Page 13

13

General Electric Company

Warranty Registration Department

P.O. Box 34070

Louisville, KY 40232-4070

GE Service Protection Plus

™

GE, a name recognized worldwide for quality and dependability, offers you Service

Protection Plus

™

—comprehensive protection on all your appliances—No Matter

What Brand!

Benefits Include:

•Backed by GE

•All brands covered

• Unlimited service calls

•All parts and labor costs included

•No out-of-pocket expenses

•No hidden deductibles

•One 800 number to call

You will be completely satisfied with our service protection or you may request your money back

on the remaining value of your contract. No questions asked. It’s that simple.

Protect your refrigerator, dishwasher, washer and dryer, range, TV, VCR and much more—any brand!

Plus there’s no extra charge for emergency service and low monthly financing is available. Even icemaker

coverage and food spoilage protection is offered. You can rest easy knowing that all your valuable

household products are protected against expensive repairs.

Place your confidence in GE and call us in the U.S. toll-free at 800-626-2224

for more information.

*All brands covered, up to 20 years old, in the continental U.S.

We’ll Cover Any Appliance.

Anywhere. Anytime.*

Please place in envelope and mail to:

✁

Cut here

Page 14

14

Consumer Product Ownership Registration

Model Number Serial Number

Important

Mail

Today!

GE Appliances

General Electric Company

Louisville, Kentucky 40225

First

Name

Mr. ■■ Ms. ■■ Mrs. ■■ Miss ■■

Street

Address

City

State

Date Placed

In Use

Month

Day

Year

Zip

Code

Apt. #

Last

Name

Phone

Number

_ _

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our product and thank you for placing your

confidence in us. We are proud to have you as a customer!

Follow these three steps to protect your new appliance investment:

Complete and mail

your Consumer

Product Ownership

Registration today.

Have the peace of

mind of knowing we

can contact you in

the unlikely event of

a safety modification.

After mailing

the registration

below, store this

document in a safe

place. It contains

information you

will need should

you require service.

Our service number

is 800-GE-CARES

(800-452-2737).

Read your Owner’s

Manual carefully.

It will help you

operate your new

appliance properly.

If you have questions,

or need more

information call the

GE Answer Center

®

800.626.2000.

Important: If you did not get a registration card with your product,

detach and return the form below to ensure that your

product is registered.

1

2 3

Model Number Serial Number

✁

Cut here

Page 15

For The Period Of: GE Will Replace, At No Charge To You:

One Year Any part

of the Reverse Osmosis Filtration System which fails due to a defect in materials or

From the date of the

workmanship. During this

full one-yearwarranty,

GE will also provide,

free of charge,

all labor

original purchase

and in-home service to replace the defective part.

Customer ServiceTroubleshooting TipsOperating InstructionsSafety Instructions

15

GE Reverse Osmosis System Warranty

All warranty service provided by our Factory Service Centers, or an authorized Customer Care®technician.

For service, call 800-GE-CARES.

■ Service trips to your home to teach you how to use the

product.

■ Improper installation.

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■ Filters, membranes or batteries.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage to the product caused by accident, fire, floods or

acts of God.

■ Incidental or consequential damage to personal property

caused by possible defects with this appliance.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your legal

rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Page 16

Printed in Louisville, KY

16

Service Telephone Numbers.

GE Answer Center

®

800.626.2000

The GE Answer Center® is open 24 hours a day, 7 days a week.

In-Home Repair Service

800-GE-CARES (800-432-2737)

Expert GE repair service is only a phone call away.

Special Needs Service

800.626.2000

800-TDD-GEAC (800-833-4322)

GE offers, free of charge, a brochure to assist in planning a barrier-free kitchen for persons

with limited mobility.

Service Contracts

800-626-2224

Purchase a GE service contract while your warranty is still in effect and you’ll receive a

substantial discount. GE Consumer Service will still be there after your warranty expires.

Parts and Accessories

800-626-2002

Individuals qualified to service their own appliances can have parts or accessories sent directly

to their homes (VISA, MasterCard and Discover cards are accepted).

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since

improper servicing may cause unsafe operation.

Service Satisfaction

If you are not satisfied with the service you receive from GE:

First,

contact the people who serviced your appliance.

Next,

if you are still not pleased, write all the details—including your phone number—to:

Manager, Consumer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

Finally,

if your problem is still not resolved, write:

Major Appliance Consumer Action Program

20 North Wacker Drive

Chicago, IL 60606

Operating Instructions Safety InstructionsCustomer Service Troubleshooting Tips

Loading...

Loading...