Page 1

GE Energy

Masoneilan* Valves

21000 Series

High-Performance Control Valves

Optimum control performance

for a wide range of automated

process control applications

• Single-ported design

configuration

• Advanced digital

positioning and control

Page 2

21000 Series

Globe Style Control Valves

Versatile

GE Energy offers the Masoneilan 21000 Series heavy top-guided globe valve for a wide range of automated process control

applications. The 21000 Series product line features a singleported design configuration, which permits numerous trim,

actuation, and instrumentation solutions including:

• Lo-dB

• Anti-Cavitation

• Reduced Capacity & Low Flow Trim

• Cryogenic Configuration

• Tight Shutoff

• Environmental Packing

• Advanced Digital Positioning & Control

Reliable

Rugged top-guiding of the plug promotes enhanced valve

stability under adverse conditions. The inherent ruggedness

of the 21000 Series is field-proven, with thousands of units

installed in process control plants around the world operating

successfully with various fluids under mild and extreme

conditions.

*

Noise Attenuation

High Performance

The combination of trim designs, actuator stability, shutoff

capabilities, and precise valve positioning offers optimum

control performance. GE’s 21000 Series is also available in

various materials, pressure ratings, and end connections

offering a complete high-performance valve platform.

The simple construction and flexible design

features of the 21000 Series help to lower

maintenance costs and extends product

life cycles. This versatile product line helps

customers to solve a multitude of control valve

application problems using a common platform.

2 | GE Energy

Page 3

Key Features

Model 87/88

Spring Diaphragm Actuator

• Compact Multi-Spring Design Reduces

Stem-Side Loading

• Field-Reversible Construction

• Rolling Diaphragm Helps to Reduce Friction and Wear

• Constant Effective Area for Smooth Linear Control

• Four Sizes Available Covering Large Thrust Range

• Four Standard Spring Ranges for Wider Application

Envelope

• Side-Mounted Handwheel Option

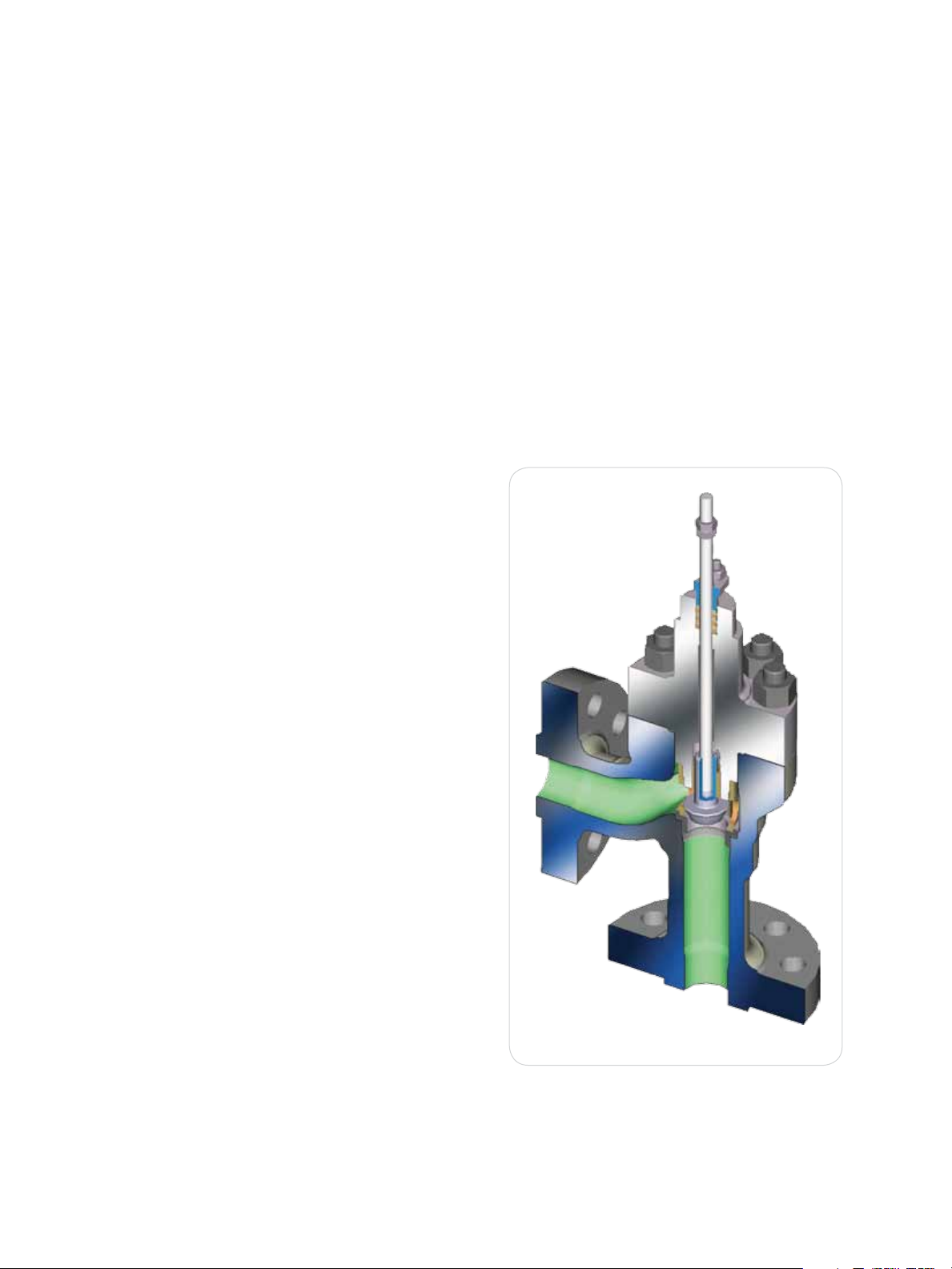

Heavy Top Guiding

• Larger Post Guide Area for Increased Stability

• Positioned Outside of Direct Fluid Flow Path

• Offers More Reliable Control Performance

Various Trim Options

• Single- and Double-Stage Low Noise and

Anti-Cavitation Trim

• Standard Hardened Trim (Stellited or

Equivalent Trim)

• Quick-Change or Threaded Seat Rings

• Reduced Capacities and Low-Flow Trims

• Equal Percentage and Linear Characteristics

• UOP Lockhopper Trim

• Soft-Seat Design

Design Flexibility

• Multiple End Connections

• Various Materials

• Angle Body Configuration

• Bellows Seal Design

• Piston Actuation Option

• Extension Bonnets

• Cryogenic Configuration

• Low-Emissions Packing

• DIN Version Available

21000 Series High Performance Globe Style Control Valves | 3

Page 4

Customer Benefits

Reduced Noise Levels

The optional Lo-dB trim designs offer single-stage and doublestage noise attenuation benefits. Noise reduction levels of up

to 25 dBA are possible, depending on the specific operating

conditions.

Extended Life Cycle

Optional Anti-Cavitation trim is also available in single-stage

and double-stage configurations. Proper control of dynamic

cavitation conditions is extremely important for maintaining the

continuous high performance and reliability of control valves.

Lower Costs

Dependable tight shutoff of a control valve helps to reduce

the loss of process fluids, and can help eliminate the need for

separate isolation valves. The optional soft-seat design provides

bubble-tight shutoff capabilities in accordance with ANSI/FCI

and IEC requirements.

Single-stage trim Double-stage trim

4 | GE Energy

Page 5

Clean Air Compliance

The optional LE Packing system helps to reduce atmospheric

emissions from the stem seal area. This unique feature helps to

promote compliance with environmental safety and emissions

control requirements.

Hazardous Emissions Control

The optional Bellows Seal configuration is well-suited for

applications involving highly toxic and dangerous fluids. Positive

sealing and extended life-cycle operation combine to promote

reliable and safe operation.

Low Temperature Operation

The 21000 Series from GE is also available in a cryogenic

configuration for effective process control performance at

extremely low temperature conditions. This is accomplished

by using a combination of extended bonnets and construction

materials.

Improved Process Yields

Spring

Loaded

Follower S/A

Packing Set

PFE/PTFE

5 Pieces

Spacer

LE Packing

The 21000 Series can be equipped with various Masoneilan

advanced digital positioners and controllers for enhanced

performance and control. This results in improved process yields

and real-time diagnostics capabilities to support predictive

plant maintenance programs. GE offers the Masoneilan SVI*

II AP (Advanced Performance) with HART® communications

and the Masoneilan FVP* for Foundation Fieldbus applications.

Both instruments are available in single- or double-acting

configurations and offer advanced control technology to provide

enhanced precision for pneumatically actuated control valves.

We also offer the Masoneilan ValVue* Software Suite for PCbased communications with these advanced devices..

21000 Series

Globe-style

SVI II AP

FVP

21000 Series High Performance Globe Style Control Valves | 5

Page 6

Product Specifications

Operating Range

Sizes 3/4” to 8” (20mm to 200mm)

Body Ratings ASME Class 150 to 2500 (Equivalent PN)

Leakage ANSI/FCI/IEC Class IV, V and VI

Cv Range 0.1 to 640

Temperature Range

°

F to +800°F (-196°C to +427°C)

-320

Connections

RF Flanged

Socket Weld

Threaded

RT Joint

Butt Weld

End Connections

Valve Sizes

3/4” to 2”

(20mm to 50mm)

• •

•

•

• •

• •

3” to 8”

(80mm to 610mm)

6 | GE Energy

Page 7

Materials of Construction

5

7

1

8

9

2

6

3

4

Materials of Construction

1 Body Carbon Steel, Stainless Steel, Chrome-Moly, Other Alloys

2 Bonnet Carbon Steel, Stainless Steel, Chrome-Moly, Other Alloys

3 Plug

4 Seat Ring Stainless Steel, Stainless Steel with Hardfacing

5 Stem Stainless Steel

6 Cage Stainless Steel

7 Guide Bushing Stainless Steel

8 Gaskets Stainless Steel with Flexible Graphite Filler

9 Packing PTFE, Flexible Graphite, LE Packing

Stainless Steel, Stainless Steel with Hardfacing, Stellite or Equivalent,

PTFE Soft Seat

Note: Consult factory for availability of other materials, ratings and connections.

21000 Series High Performance Globe Style Control Valves | 7

Page 8

DIRECT SALES OFFICE LOCATIONS

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

California

Phone: +1-562-941-7610

Fax: +1-562-941-7810

* Masoneil an, SVI, FVP, ValVue, Lod B, MARC, ValSpeQ, Val vKeep and ValSco pe are register ed trademark s of the General E lectric Com pany.

Other company names and product names used in this document are the registered trademarks or trademarks of their respective owners.

© 2011 General Ele ctric Comp any. All rights re served

GEA19532 07/2012

[Former ly Masoneila n BH21000 03/10]

Loading...

Loading...