Page 1

ge.com

Refrigerators

Bottom Freezer

200D9366P004 49-60539 02-08 JR

Safety Instructions . . . . . . . . . . .2, 3

Operating Instructions

Automatic Icemaker . . . . . . . . . . . . . . .10

Care and Cleaning . . . . . . . . . . . . .11, 12

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Crispers and Pans . . . . . . . . . . . . . . . . . . .7

Freezer . . . . . . . . . . . . . . . . . . . . . . . . . . .8, 9

Replacing the Light Bulbs . . . . . . . . . .13

Shelves and Bins . . . . . . . . . . . . . . . . . . . .6

Water Filter . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Instructions

Installing the Refrigerator . . . . . . .15–19

Installing the Water Line . . . . . . . .28–30

Preparing to Install

the Refrigerator . . . . . . . . . . . . . . . . . . . .14

Removing and Replacing

the Doors (Double Door

Refrigerator Models only) . . . . . . .25–27

Removing and Replacing the

Freezer Drawer . . . . . . . . . . . . . . . . .20, 21

Reversing the Door Swing

(Single Door Refrigerator

Models only) . . . . . . . . . . . . . . . . . . .22–25

Troubleshooting Tips . . . . . .31–34

Normal Operating Sounds . . . . . . . . . .31

Consumer Support

Consumer Support . . . . . . . .Back Cover

Performance Data Sheet . . . . . . . . . . .41

Product Registration

for Canadian Customers . . . . . . . .37, 38

Product Registration

for U.S. Customers . . . . . . . . . . . . .35, 36

State of California Water

Treatment Device Certificate . . . . . . .42

Warranty for Canadian

Customers . . . . . . . . . . . . . . . . . . . . . . . . .40

Warranty for U.S. Customers . . . . . . .39

Réfrigérateurs

Congélateur inférieur

Refrigeradores

Congelador inferior

Write the model and serial

numbers here:

Model # ____________________

Serial #______________________

Find these numbers on a label

on the right side, near the top of the

refrigerator compartment.

Models 20, 22 and 23

Manuel d’utilisation

et d’installation

Owner’s Manual and

Installation Instructions

Manual del

propietario e

instalación

La section française commence à la page 43

La sección en español empieza en la página 81

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

Use this appliance only for its intended purpose as described in this Owner’s Manual.

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

■

■ This refrigerator must be properly installed

and located in accordance with the Installation

Instructions before it is used.

■

■ Do not allow children to climb, stand or hang

on the shelves in the refrigerator. They could

damage the refrigerator and seriously injure

themselves.

■

■ Do not touch the cold surfaces in the freezer

compartment when hands are damp or wet.

Skin may stick to these extremely cold surfaces.

■

■ Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

■

■ Keep fingers out of the “pinch point” areas;

clearances between the doors and between

the doors and cabinet are necessarily small.

Be careful closing doors when children are

in the area.

■

■ In refrigerators with automatic icemakers,

avoid contact with the moving parts of the

ejector mechanism, or with the heating element

that releases the cubes. Do not place fingers or

hands on the automatic icemaking mechanism

while the refrigerator is plugged in.

■

■ Unplug the refrigerator before cleaning and making

repairs.

NOTE: We strongly recommend that any servicing

be performed by a qualified individual.

■

■ Setting either or both controls to the Off position

does not remove power to the light circuit.

■

■ Do not refreeze frozen foods which have

thawed completely.

PROPER DISPOSAL OF THE REFRIGERATOR

Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous…even if they will sit for “just a few days.”

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent

accidents.

Before You Throw Away Your Old

Refrigerator or Freezer:

■ Take off the doors.

■ Leave the shelves in place so that children may not

easily climb inside.

Refrigerants

All refrigeration products contain refrigerants,

which under federal law must be removed prior

to product disposal. If you are getting rid of an

old refrigeration product, check with the company

handling the disposal about what to do.

USE OF EXTENSION CORDS

Because of potential safety hazards under certain conditions, we strongly recommend against

the use of an extension cord.

However, if you must use an extension cord, it is absolutely necessary that it be a UL-listed (in the United States)

or a CSA certified (in Canada), 3-wire grounding type appliance extension cord having a grounding type plug

and outlet and that the electrical rating of the cord be 15 amperes (minimum) and 120 volts.

DANGER! RISK OF CHILD ENTRAPMENT

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

2

Page 3

3

Consumer Support

Troubleshooting Tips

Operating InstructionsSafety Instructions

Installation

Instructions

ge.com

WARNING!

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped

with a 3-prong (grounding) plug which mates

with a standard 3-prong (grounding) wall outlet to

minimize the possibility of electric shock hazard from

this appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall outlet is encountered,

it is your personal responsibility and obligation to

have it replaced with a properly grounded 3-prong

wall outlet.

The refrigerator should always be plugged into its

own individual electrical outlet which has a voltage

rating that matches the rating plate.

This provides the best performance and also prevents

overloading house wiring circuits which could cause a

fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the

power cord. Always grip plug firmly and pull straight

out from the outlet.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end.

When moving the refrigerator away from the

wall, be careful not to roll over or damage the

power cord.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

USE OF ADAPTER PLUGS

Adapter plugs are not permitted in Canada.

Page 4

4

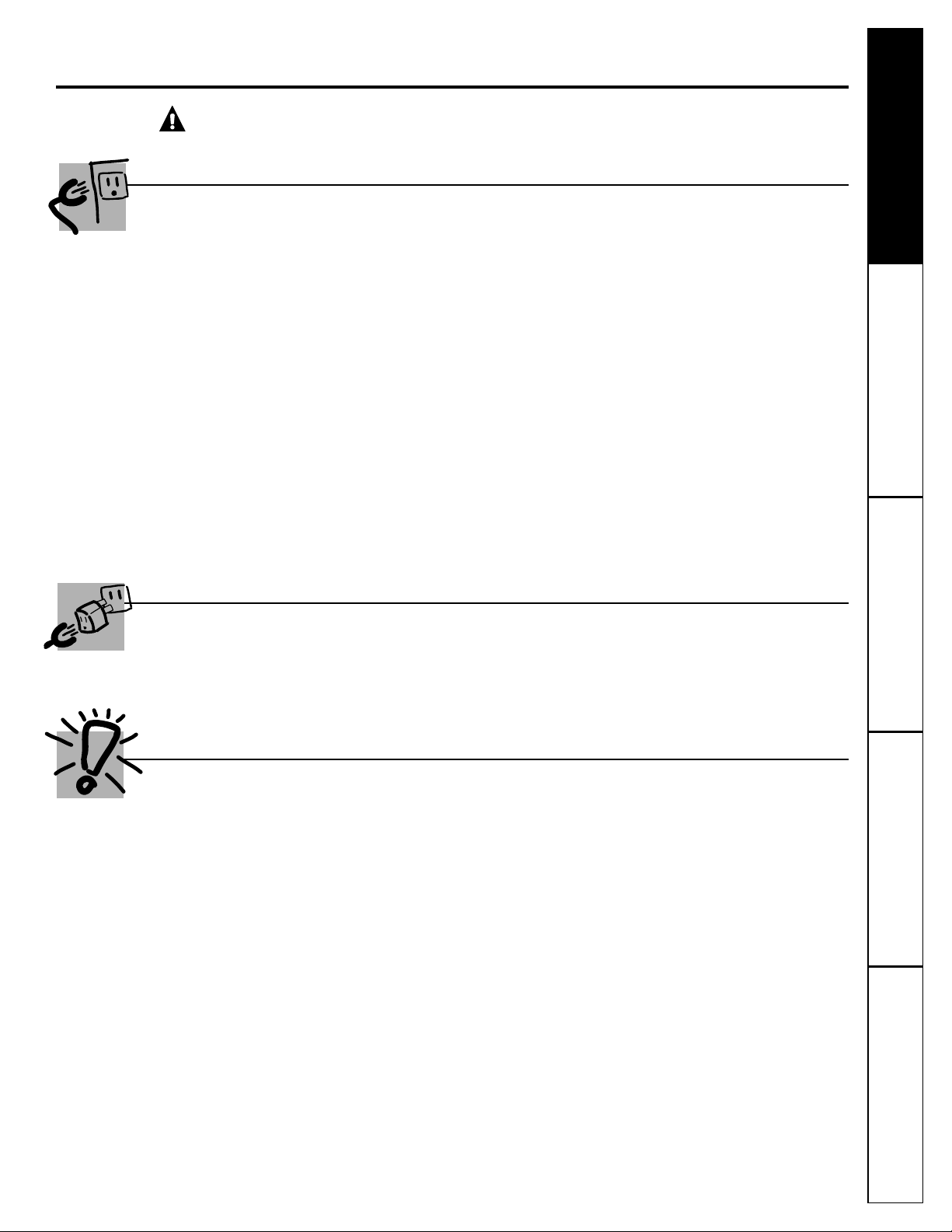

About the controls with temperature settings.

Initially, set the refrigerator control at 5 and the freezer control at 5. Allow 24 hours for

the temperature to stabilize. Several adjustments may be required. Adjust the controls

one increment at a time, and allow 24 hours after each adjustment for the refrigerator

to reach the temperature you have set.

Setting either or both controls to 0 for digital and 0 for the refrigerator control knob

stops cooling in both the refrigerator and freezer compartments, but does not shut

off electrical power to the refrigerator.

NOTE: The refrigerator is shipped with protective film covering the digital temperature controls.

If this film was not removed during installation, remove it now.

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

(on some models)

(on some models)

Page 5

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

5

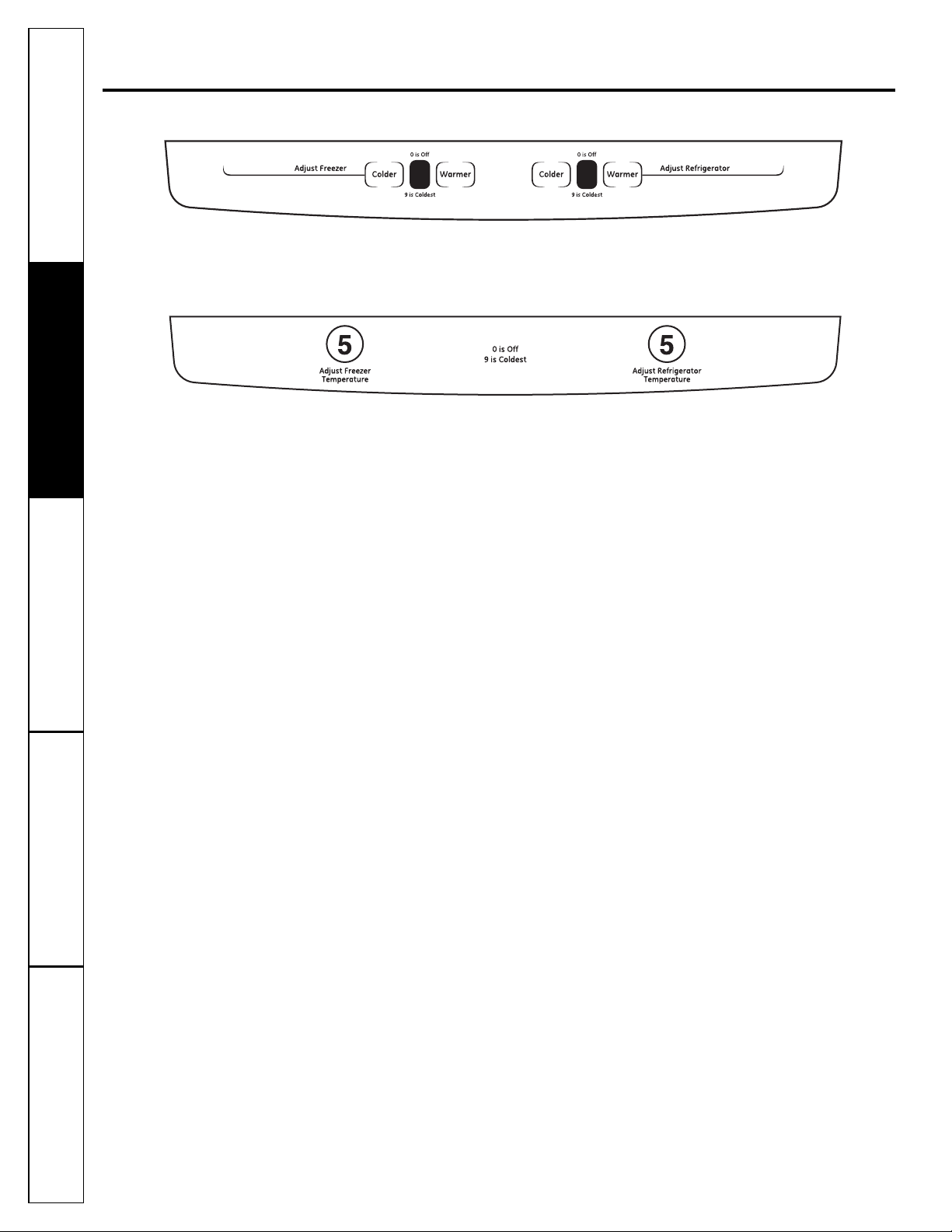

Water Filter Cartridge

The water filter cartridge is located in the

back upper right corner of the refrigerator

compartment.

When to Replace the Filter

The filter cartridge should be replaced

when the flow of water to the icemaker

decreases, or every six months.

Installing the Filter Cartridge

If you are replacing the cartridge, first

remove the old one. Open the cartridge

cover by pressing in on the tab at the

front and pulling down.

Remove the cartridge by slowly rotating

it counterclockwise. A small amount of

water may drip down.

CAUTION: If air has been

trapped in the system, the filter cartridge may

be ejected as it is removed. Use caution when

removing.

Remove the protective foil from the end

of the cartridge.

Lining up the arrow on the cartridge

and the cartridge holder, slowly rotate

the cartridge clockwise until it stops.

When the cartridge is properly installed,

you will feel it “click” as it locks into place.

The grip on the end of the cartridge

should be positioned vertically.

Do not overtighten.

Close the cartridge cover.

Filter Bypass Plug

You must use the filter bypass plug when a

replacement filter cartridge is not available.

The icemaker will not operate without the

filter or filter bypass plug.

Replacement Filters:

To order additional filter cartridges

in the United States, visit our Website,

ge.com, or call GE Parts and Accessories,

800.626.2002.

Filter Model GSWF

Customers in Canada should consult

the yellow pages for the nearest Mabe

Service Center.

About the water filter. (on some models) ge.com

Page 6

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

6

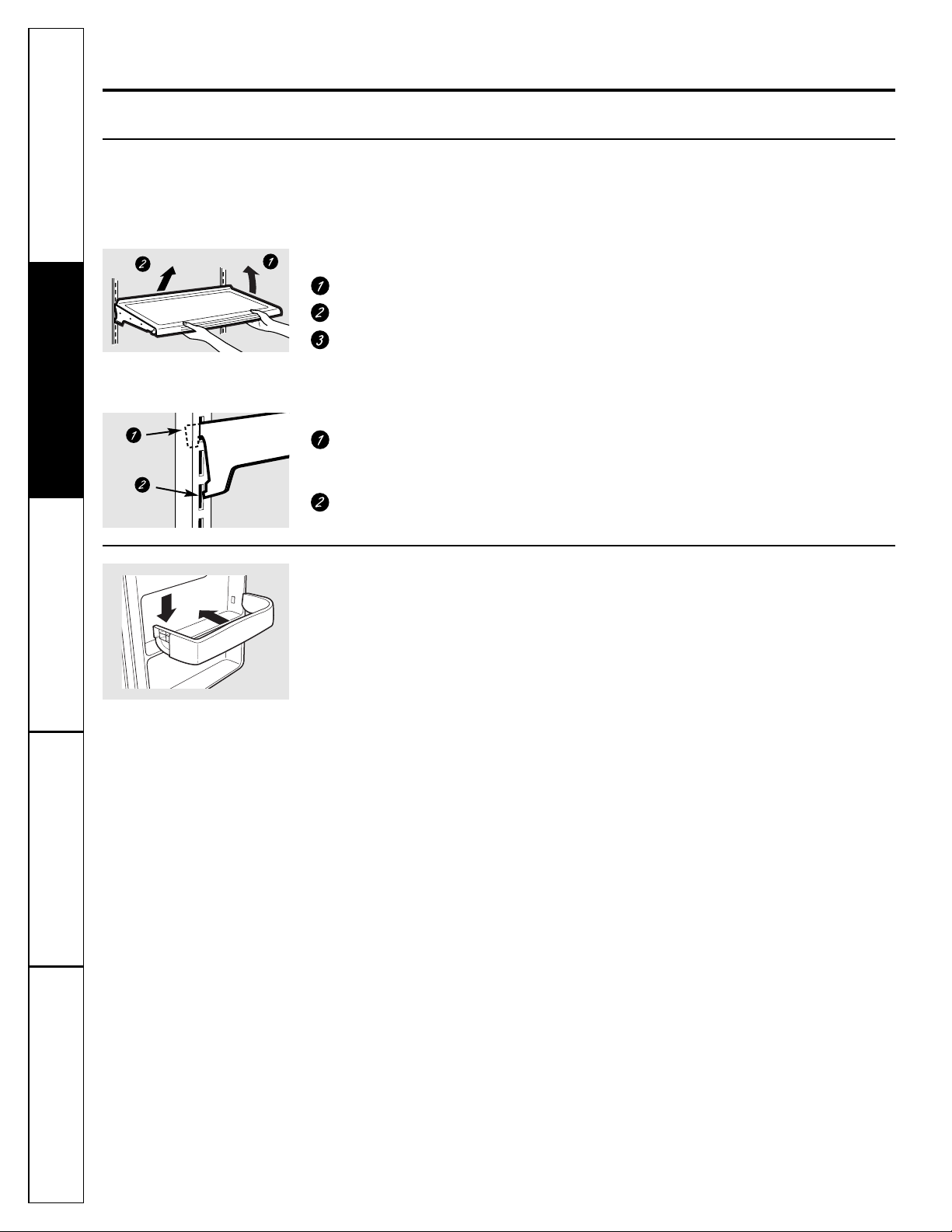

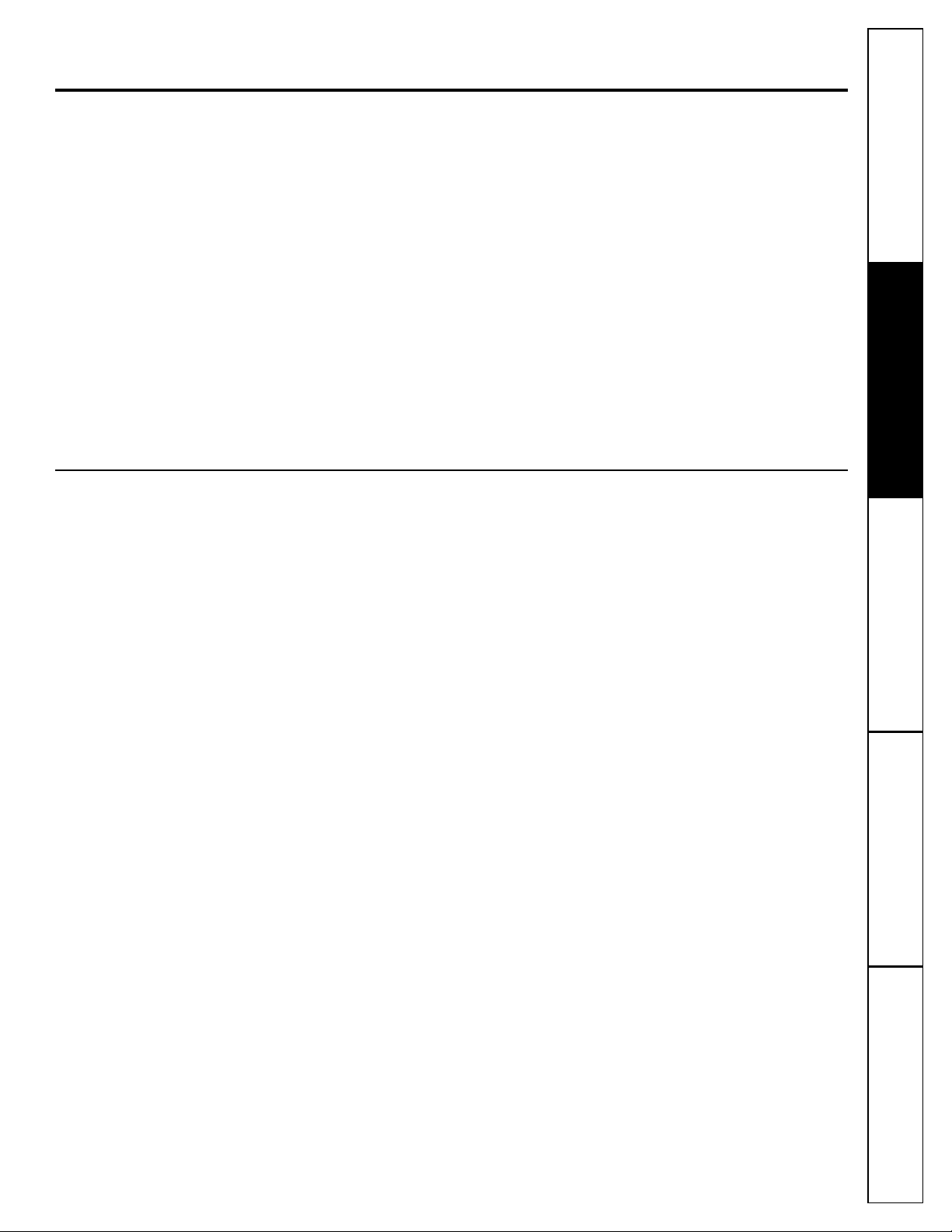

Rearranging the Shelves

To remove:

Remove all items from the shelf.

Tilt the shelf up at the front.

Lift the shelf up at the back and

bring the shelf out.

To replace:

While tilting the shelf up, insert the top

hook at the back of the shelf in a slot

on the track.

Lower the front of the shelf until the

bottom of the shelf locks into place.

About the shelves and bins.

Not all features are on all models.

Some models have wire shelves

that can be adjusted in the same

manner.

Shelves in the refrigerator compartment are adjustable.

Refrigerator Compartment

Non-Adjustable Shelves on the Door (on some models)

To remove: Lift the shelf straight up; then

pull out.

To replace: Engage the shelf in the molded

supports on the door and push down.

It will lock in place.

Page 7

Consumer Support

Troubleshooting Tips

Operating InstructionsSafety Instructions

Installation

Instructions

7

About the crispers and pans. ge.com

Not all features are on all models.

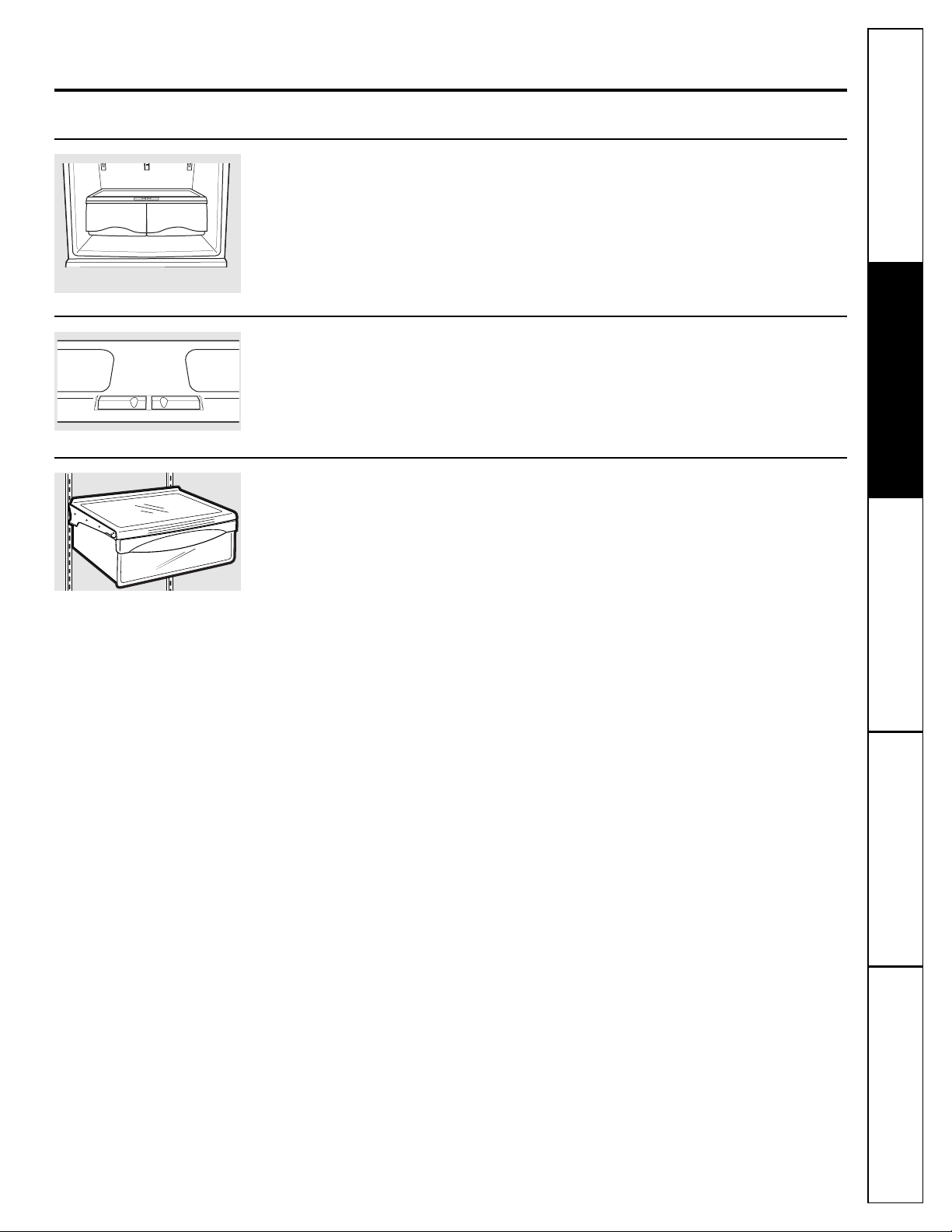

Fruit and Vegetable Crisper

Excess water that may accumulate in the

bottom of the drawers or under the drawers

should be wiped dry.

Adjustable Humidity Crisper (on some models)

Slide the control all the way to the

HIGH setting to provide high humidity

recommended for most vegetables.

Slide the control all the way to the LOW

setting to provide lower humidity levels

recommended for most fruits.

Snack Pan (on some models)

This pan can be moved to the most useful

location for your family’s needs.

To remove, slide the pan out to the stop

position, lift the pan up and past the stop

position and lift it out.

Page 8

8

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

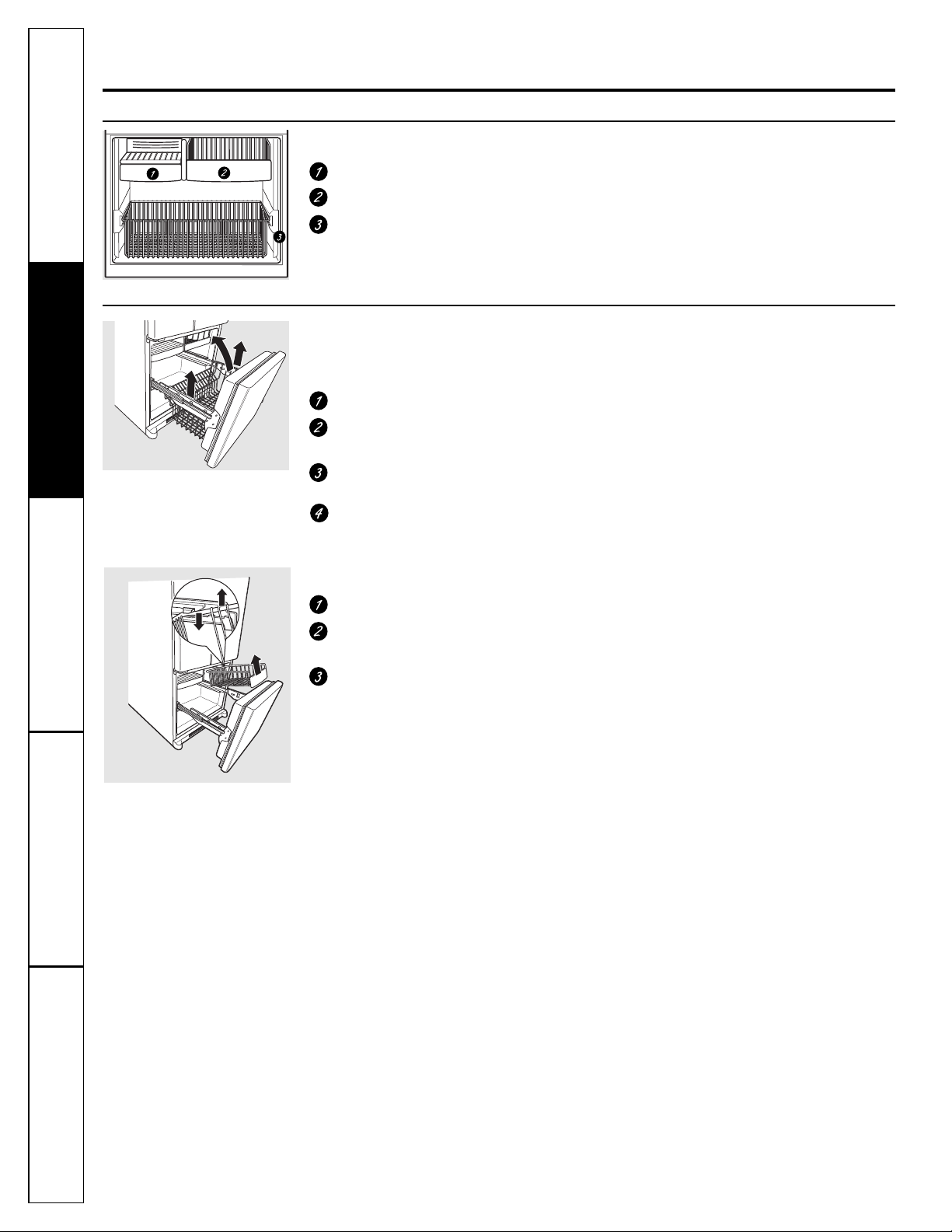

Freezer Shelves and Baskets

A shelf above the ice storage bin

A half-width basket

A deep full-width basket

NOTE: Do not fill baskets higher than the rim

of the basket. This may cause baskets to stick

or jam when opening or closing.

Basket Removal

To remove the deep full-width basket on

freezer drawer models:

Open the freezer drawer until it stops.

The freezer basket rests on the inside

tabs on the drawer slides.

Lift the basket so that it is out of all

6 slide bracket tabs.

Tilt the basket and lift out of the drawer.

When replacing the deep full-width basket:

Tilt the basket back and lower it down

into the drawer. Rotate the basket to a

horizontal position and press it down into

the 6 alignment tabs.

NOTE: Always be sure that the basket is

seated in all 6 slide bracket tabs before sliding

back into the freezer. The basket can be

turned in either direction front to back and

installed into the freezer.

To remove the half-width basket:

Pull the basket out to the stop location.

Lift the basket up at the front to release

it from the stop hooks on each side.

Lift the basket out to remove it from

the sides.

When replacing the basket, make sure that

the basket goes under the stop hooks on

each side.

NOTE: Always be sure to fully close this

basket.

About the freezer drawer. (on some models)

Not all features are on all models.

Appearance and features may vary

Appearance may vary

Appearance may vary

Page 9

9

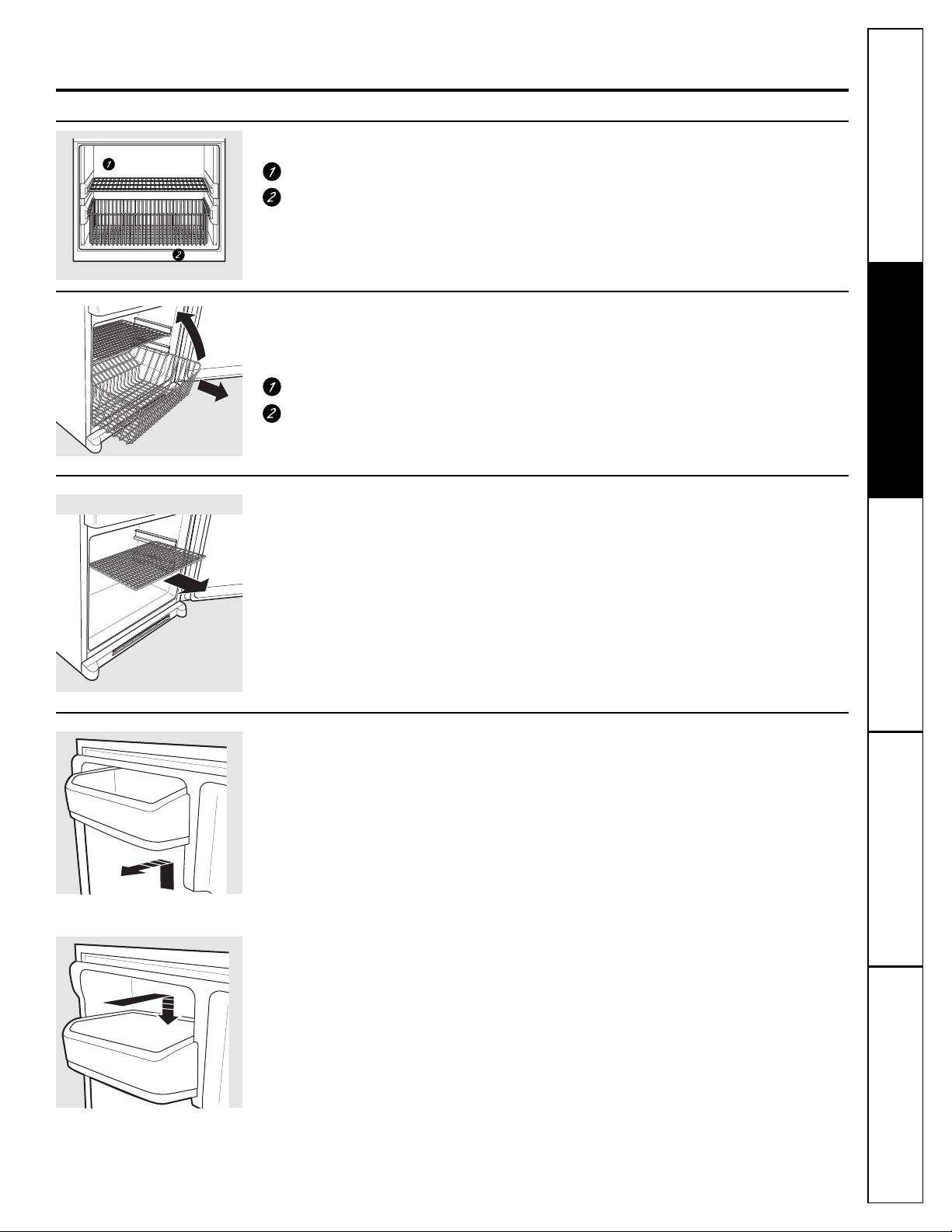

Freezer Shelf and Basket

A full-width fixed wire shelf

A full-width sliding wire basket

NOTE: Do not fill basket higher than the rim of

the basket. This may cause basket to stick or

jam when opening or closing.

Basket Removal

To remove the full-width sliding wire basket

on door models:

Open the basket out to its full extension.

Lift up the front of the basket and pull

straight out to remove.

When replacing the full-width sliding

wire basket:

Insert the wire basket into the lower liner’s

rails and push back into place.

NOTE: The full-width wire shelf is not intended

to slide.

To remove for cleaning:

Hold the shelf at the front and pull it firmly

forward.

When replacing the full-width sliding wire

shelf:

Insert the wire shelf into the upper liner’s rails

and push back into place.

About the freezer compartment. (on some models) ge.com

Not all features are on all models.

Fixed Shelf Removal

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

To remove: Lift the shelf straight up;

then pull out.

To replace: Engage the shelf in the molded

supports on the door and push down. It will

lock in place.

Non-Adjustable Shelf on Freezer Door

To remove

To replace

Page 10

10

About the automatic icemaker. (on some models)

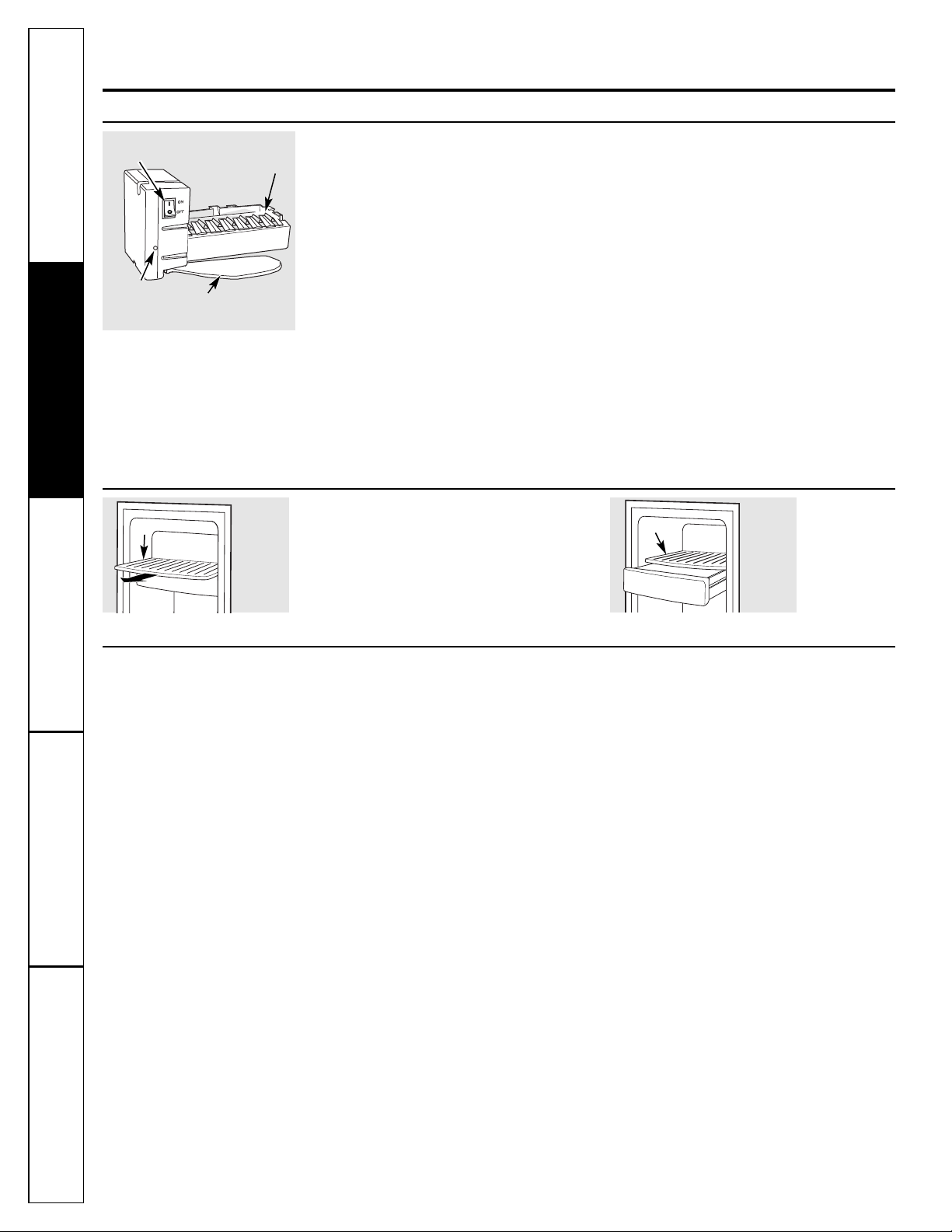

Automatic Icemaker

The icemaker will produce seven cubes per cycle—

approximately 100–130 cubes in a 24-hour period,

depending on freezer compartment temperature,

room temperature, number of door openings and

other use conditions.

See below for how to access ice and reach the

power switch.

If the refrigerator is operated before the water

connection is made to the icemaker, set the power

switch in the O (off) position.

When the refrigerator has been connected to

the water supply, set the power switch to the l (on)

position. The icemaker power light will turn green

when the freezer light switch is pressed in or when

the freezer door is closed.

The icemaker will fill with water when it cools to

15°F (–10°C). A newly installed refrigerator may

take 12 to 24 hours to begin making ice cubes.

You will hear a buzzing sound each time

the icemaker fills with water.

Throw away the first few batches of ice to allow

the water line to clear.

Be sure nothing interferes with the sweep

of the feeler arm.

When the bin fills to the level of the feeler arm,

the icemaker will stop producing ice. It is normal

for several cubes to be joined together.

If ice is not used frequently, old ice cubes will

become cloudy, taste stale and shrink.

NOTE: In homes with lower-than-average water

pressure, you may hear the icemaker cycle multiple

times when making one batch of ice.

NOTE: Set the power switch to the O (off) position

if the water supply is shut off.

A newly installed refrigerator may take 12 to 24 hours to begin making ice.

Icemaker

Feeler Arm

Power

Switch

Green

Power

Light

Accessing Ice and Reaching

the Power Switch

To reach the icemaker power switch, pull

the shelf above the ice bin straight out. Always

be sure to replace the shelf.

To access ice, simply pull the bin forward.

To access ice.

Shelf

Ice Bin

To reach the power switch.

Shelf

Ice Bin

Icemaker Accessory Kit

If your refrigerator did not come already equipped

with an automatic icemaker, an icemaker

accessory kit is available at extra cost.

Check the back of the refrigerator for the specific

icemaker kit needed for your model.

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Page 11

Care and cleaning of the refrigerator. ge.com

Cleaning the Outside

The door handles and trim. Clean with a

cloth dampened with soapy water. Dry with

a soft cloth. Do not use wax on the door

handles and trim.

Keep the outside clean. Wipe with

a clean cloth lightly dampened with kitchen

appliance wax or mild liquid dish detergent.

Dry and polish with a clean, soft cloth.

Do not wipe the refrigerator with a soiled

dish cloth or wet towel. These may leave

a residue that can erode the paint. Do not

use scouring pads, powdered cleaners,

bleach or cleaners containing bleach

because these products can scratch

and weaken the paint finish.

The stainless steel panels and door

handles. Stainless steel (on some models)

can be cleaned with a commercially

available stainless steel cleaner. A spray-on

stainless steel cleaner works best.

Do not use appliance wax or polish

on the stainless steel.

Cleaning the Inside

To help prevent odors, leave an open box

of baking soda in the refrigerator and freezer

compartments.

Unplug the refrigerator before cleaning.

If this is not practical, wring excess moisture

out of sponge or cloth when cleaning around

switches, lights or controls.

Use an appliance wax polish on the inside

surface between the doors.

Use warm water and baking soda solution—

about a tablespoon (15 ml) of baking soda to

a quart (1 liter) of water. This both cleans and

neutralizes odors. Rinse and wipe dry.

After cleaning the door gaskets, apply a thin

layer of petroleum jelly to the door gaskets

at the hinge side. This helps keep the gaskets

from sticking and bending out of shape.

Avoid cleaning cold glass shelves with hot

water because the extreme temperature

difference may cause them to break.

Handle glass shelves carefully. Bumping

tempered glass can cause it to shatter.

Do not wash any plastic refrigerator parts

in the dishwasher.

11

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Page 12

12

For long vacations or absences, remove

food and unplug the refrigerator. Clean the

interior with a baking soda solution of one

tablespoon (15 ml) of baking soda to one

quart (1 liter) of water. Leave the doors open.

Set the icemaker power switch to the O (off)

position and shut off the water supply to

the refrigerator.

If the temperature can drop below freezing,

have a qualified servicer drain the water

supply system (on some models) to prevent

serious property damage due to flooding.

Care and cleaning of the refrigerator.

Preparing for Vacation

Preparing to Move

Secure all loose items such as base grille,

shelves and drawers by taping them

securely in place to prevent damage.

When using a hand truck to move the

refrigerator, do not rest the front or back

of the refrigerator against the hand truck.

This could damage the refrigerator. Handle

only from the sides of the refrigerator.

Be sure the refrigerator stays in an upright

position during moving.

Behind the Refrigerator

Be careful when moving the refrigerator

away from the wall. All types of floor

coverings can be damaged, particularly

cushioned coverings and those with

embossed surfaces.

Raise the leveling legs located at the bottom

front of the refrigerator.

Pull the refrigerator straight out and return it

to position by pushing it straight in. Moving

the refrigerator in a side direction may

result in damage to the floor covering

or refrigerator.

Lower the leveling legs until they touch

the floor.

When pushing the refrigerator back, make

sure you don’t roll over the power cord or

icemaker supply line (on some models).

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Page 13

13

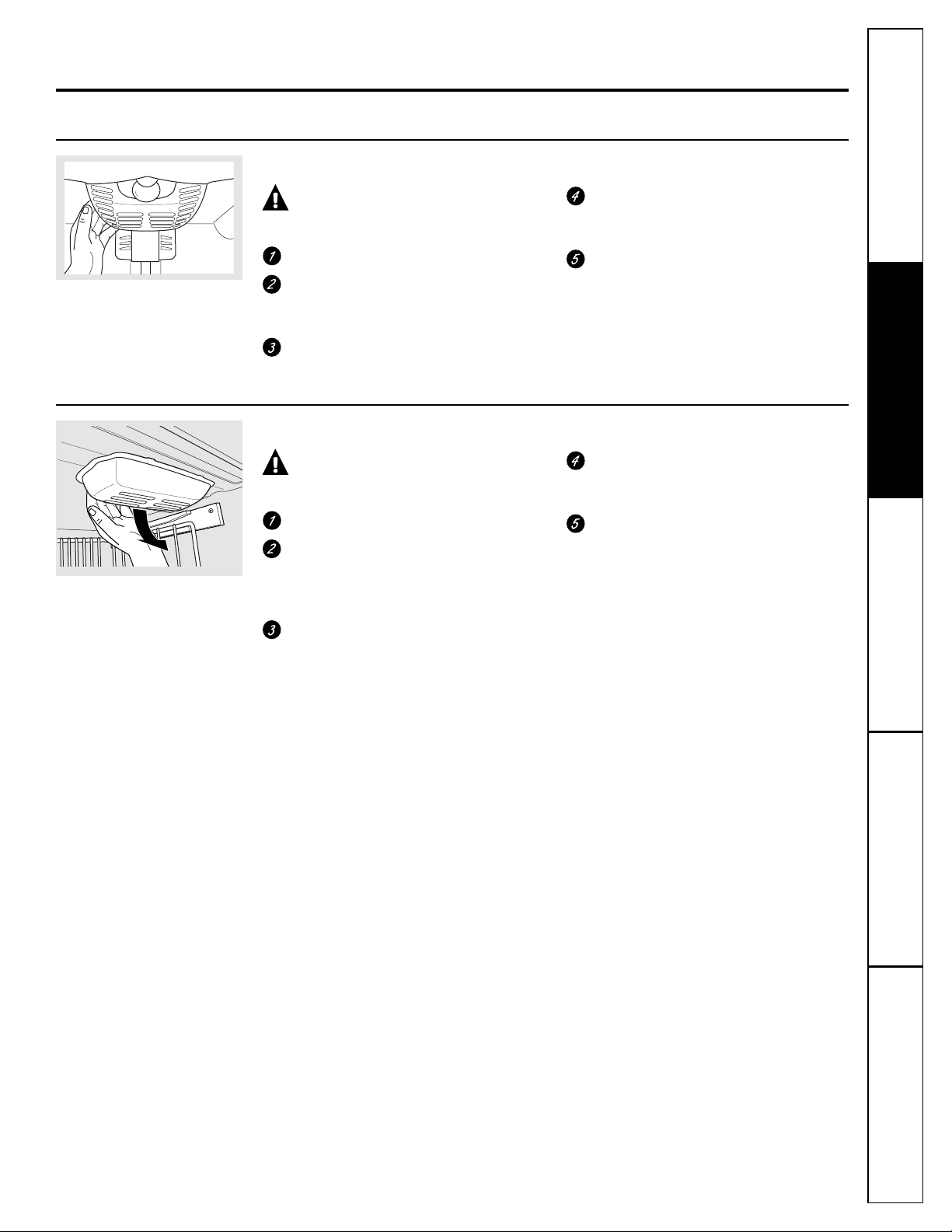

Refrigerator Lights

CAUTION: Light bulbs may

be hot.

Unplug the refrigerator.

To remove the light shield, grasp the

shield at the back and pull out to release

the tabs at the back.

Rotate the shield down and then forward

to release the tabs at the front of the

shield.

After replacing with an appliance bulb

of the same or lower wattage, replace

the shield.

Plug the refrigerator back in.

NOTE: Appliance bulbs may be ordered from

GE Parts and Accessories, 800.626.2002.

Freezer Light

Replacing the light bulbs. ge.com

Turning the control to the 0ff position does not remove power to the light circuit.

Appearance may vary

CAUTION: Light bulbs may

be hot.

Unplug the refrigerator.

The bulb is located at the top of the

freezer inside a light shield. To remove the

shield, grasp the shield at the back and

pull out to release the tabs at the back.

Rotate the shield down and then forward

to release the tabs at the front of the

shield.

After replacing with an appliance bulb

of the same or lower wattage, replace

the shield.

Plug the refrigerator back in.

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Page 14

Installation

Refrigerator

Instructions

Models 20 and 22

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.com

In Canada, call 1.800.561.3344 or Visit our Website at: www.geappliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT — Save these instructions

for local inspector’s use.

•

IMPORTANT — Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions for

future reference.

• Skill level – Installation of this appliance requires

basic mechanical skills.

• Completion time – Refrigerator Installation

20 minutes

Water Line Installation

30 minutes

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

PREPARATION

MOVING THE REFRIGERATOR INDOORS

If the refrigerator will not fit through a doorway,

the refrigerator door and freezer drawer can be

removed.

• To remove the refrigerator door, see Step 1 in

the Reversing the Door Swing section.

• To remove the freezer drawer, see the Removing

the Freezer Drawer section.

WATER SUPPLY TO THE ICEMAKER AND DISPENSER

(ON SOME MODELS)

If the refrigerator has an icemaker, it will have

to be connected to a cold water line. A GE water

supply kit (containing tubing, shutoff valve, fittings

and instructions) is available at extra cost from

your dealer, by visiting our Website at ge.com

(in Canada at www.geappliances.ca) or from

Parts and Accessories, 800.626.2002

(In Canada 1.888.661.1616).

TOOLS YOU MAY NEED

Adjustable Wrench

1/4″ Outer Diameter

Compression Nut

and Ferrule (sleeve)

(icemaker models only)

Phillips Head Screwdriver

14

3/8″ and 5/16″ Socket

Ratchet/Driver

3/32″, 1/8″ and 3/16″ Allen

wrenches

Pencil

1/8″ Drill Bit and

Electric or Hand Drill

Tape measure

1/4″ Nut Driver

Wire Cutters

Level

Page 15

Installation Instructions

INSTALLING THE REFRIGERATOR

REFRIGERATOR LOCATION

• Do not install the refrigerator where the temperature

will go below 60°F (16°C) because it will not run often

enough to maintain proper temperatures.

• Do not install the refrigerator where the temperature

will go above 100°F (37°C) because it will not perform

properly.

• Install it on a floor strong enough to support it fully

loaded.

CLEARANCES

Allow the following clearances for ease of installation,

proper air circulation and plumbing and electrical

connections.

Standard Depth

Models

Sides 1/8″ (3 mm)

Top 1″ (25 mm)

Back 1″ (25 mm)

CONNECTING THE REFRIGERATOR

TO THE HOUSE WATER LINE

(icemaker models)

A cold water supply is required for automatic

icemaker operation. If there is not a cold water

supply, you will need to provide one. See Installing

the Water Line section.

NOTES:

• Before making the connection to the refrigerator,

be sure the refrigerator power cord is not plugged

into the wall outlet.

• If your refrigerator does not have a water filter, we

recommend installing one if your water supply has

sand or particles that could clog the screen of the

refrigerator’s water valve. Install it in the water line

near the refrigerator. If using GE SmartConnect

™

Refrigerator Tubing Kit, you will need an additional

tube (WX08X10002) to connect the filter. Do not cut

plastic tube to install filter.

1

REMOVE TOP CAP (on some models)

•

IMPORTANT NOTE: This refrigerator is 34-1/2″ deep.

Doors and passageways leading to the installation

location must be at least 36″ wide in order to leave

the doors and handles attached to the refrigerator

while transporting it into the installation location. If

passageways are less than 36″, the refrigerator doors

and handles can easily be scratched and damaged.

The top cap and doors can be removed to allow the

refrigerator to be safely moved indoors. Start with Step A.

•If it is not necessary to remove doors, skip Step A.

Leave tape and all packaging on doors until the

refrigerator is in the final location.

•SKID REMOVAL: Tilt refrigerator to each side to

remove skid.

•NOTE: Use a padded hand truck to move this

refrigerator. Place the refrigerator on the hand truck

with a side against the truck. We strongly recommend

that TWO PEOPLE move and complete this installation.

Locate and remove the two Phillips head screws on

the top of the refrigerator. Remove the two screws

on each side at the rear of the top cap. Lift off and

remove top cap.

Remove the fresh-food door(s). Refer to Steps 1 and 3

of “Reversing the Door Swing” section or Steps 1 and

2 of “Removing the Doors” section.

Remove the bottom freezer drawer or door. Refer to

“Removing Freezer Drawer” section or Step 2 of

“Reversing the Door Swing” section.

Move refrigerator to the installation location.

A

B

C

D

15

REMOVE TOP CAP (cont.) (on some models)

REINSTALL DOORS, DRAWERS AND TOP CAP

Carefully lower the door(s) onto the center hinge(s).

Reinstall top hinge(s). NOTE: Ensure the door is

properly aligned to the case top to avoid

readjustment of the door during top cap

reinstallation.

Place cap over the top of the refrigerator. Reinstall

the original screws in the top and back of the cap.

Reinstall the bottom freezer drawer or door. Refer to

“Replacing the Freezer Drawer” section or Step 8 of

“Reversing the Door Swing” section.

E

F

G

A

Top Hinge B

Page 16

CONNECTING THE REFRIGERATOR TO

THE HOUSE WATER LINE

(cont.)

If you are using copper tubing, place a

compression nut and ferrule (sleeve) onto the

end of the tubing coming from the house cold

water supply.

If you are using the GE SmartConnect

™

tubing, the nuts are already assembled to

the tubing.

If you are using copper tubing, insert

the end of the tubing into the refrigerator

connection, at the back of the refrigerator,

as far as possible. While holding the tubing,

tighten the fitting.

If you are using GE SmartConnect

™

tubing,

insert the molded end of the tubing into the

refrigerator connection, at the back of the

refrigerator, and tighten the compression

nut until it is hand tight. Then tighten one

additional turn with a wrench. Overtightening

may cause leaks.

Fasten the tubing into the clamp provided to

hold it in position. You may need to pry open

the clamp.

One of the illustrations below will look like

the connection on your refrigerator.

Icemaker-Ready models

Icemaker-Installed Models

16

Installation Instructions

1

A

B

C

1/4″ Tubing

Tubing Clamp

1/4″

Compression

Nut

Ferrule

(sleeve)

SmartConnect

™

Tubing

Refrigerator

Connection

TURN ON THE WATER SUPPLY

(icemaker models)

Turn the water on at the shutoff valve (house

water supply) and check for any leaks.

2

PLUG IN THE REFRIGERATOR

On models with an icemaker, before plugging in

the refrigerator, make sure the icemaker power

switch is set to the O (off) position.

See the grounding information attached to the

power cord.

3

PUT THE REFRIGERATOR IN PLACE

Move the refrigerator to its final location.

4

1/4″ Copper

Tubing

1/4″

Compression

Nut

Ferrule

(sleeve)

SmartConnect

™

Tubing

Refrigerator

Connection

Tubing

Clamp

LEVEL THE REFRIGERATOR

Adjustable legs at the front corners of the

refrigerator should be set so the refrigerator is

firmly positioned on the floor, and the front is

raised just enough that the door closes easily

when opened about halfway.

To adjust the leveling legs, turn the legs

clockwise to raise the refrigerator,

counterclockwise to lower it.

5

INSTALLING THE REFRIGERATOR (cont.)

Page 17

Installation Instructions

REMOVE THE FRESH FOOD

DOOR HANDLE

(For placement in the installation location

or reversal of the handles – on some

models)

Stainless steel (on

some models):

REMOVING

THE DOOR

HANDLE: Loosen

the set screws

with the 3/32″

Allen wrench

and remove

the handle.

NOTE: For

Double Door

models follow

the same

procedure on

the opposite door.

Plastic handle

(on some models):

REMOVING THE DOOR HANDLE: Depress the

tab on the underside of the handle and slide

the handle up and off of the mounting

fasteners.

REVERSING THE

DOOR HANDLE

(on some

models):

• Remove

the handle

mounting

fasteners with

a 3/16″ Allen

wrench and

transfer

the handle

mounting

fasteners to

the right side.

• Remove the logo badge.

• Remove and transfer the plug button to

the left side of the fresh food door. NOTE:

Use a flat plastic edge to prevent damaging

the door. Remove any adhesive on the door

with a mild detergent. Remove the paper

covering on the adhesive backing on

the logo badge prior to carefully attaching

the badge to the door.

6

A

B

A

B

Mounting

Fasteners

Mounting

Fasteners

Badge

Badge

(appearance may vary)

(appearance may vary)

REMOVE THE FREEZER DOOR HANDLE

Stainless steel and plastic handles:

Loosen the set screws located on the

underside of the handle with the 1/8″ Allen

wrench and remove the handle.

NOTE: If the handle mounting fasteners need

to be tightened or removed, use a 3/16″ Allen

wrench.

7

17

A

A

A

A

Page 18

ATTACH THE FREEZER DOOR HANDLE

Stainless steel and plastic handles:

Attach the handle firmly to the mounting

fasteners and tighten the set screws on

the bottom of the handle with a 1/8″ Allen

wrench.

Installation Instructions

18

ATTACH THE FRESH FOOD

DOOR HANDLE

Stainless steel handle:

Attach the

handle to the

handle mounting

fasteners and

tighten the set

screws with a

3/32″ Allen

wrench.

NOTE: For

Double Door

models follow

the same

procedure on the

opposite door.

Plastic handle:

Attach the handle to the handle mounting

fasteners by aligning the slots with the

handle mounting fasteners.

Slide it down until it is firmly locked into

position.

8

A

Mounting

Fasteners

(appearance may vary)

(appearance may vary)

Mounting

fasteners

Slots on back of

handle

9

(appearance may vary)

INSTALLING THE REFRIGERATOR (cont.)

A

A

A

A

A

A

Page 19

LEVEL THE REFRIGERATOR

The leveling legs have 2 purposes:

1) Leveling legs adjust so the refrigerator is

firmly positioned on the floor and does not

wobble.

2) Leveling legs serve as a stabilizing brake

to hold the refrigerator securely in position

during operation and cleaning. The leveling

legs also prevent the refrigerator from

tipping.

Remove the grille by removing the two Phillips

head screws.

Turn the leveling legs clockwise to raise

the refrigerator, counterclockwise to lower it.

CAUTION: To avoid possible

personal injury or property damage,

the leveling legs must be firmly touching

the floor.

Replace the base grille by inserting the two

Phillips head screws.

10

A

Installation Instructions

SET THE CONTROLS

Set the controls to the recommended setting.

11

REMOVE PACKAGING, START

ICEMAKER

(icemaker models)

A) Remove all tape, foam and protective

packing from shelves and drawers.

B) Remove the tie downs from the freezer

baskets.

C) Place half width basket onto drawer slides.

See About the freezer section for instructions.

Set the icemaker power switch to the I (on) position.

The icemaker will not begin to operate until it

reaches its operating temperature of 15°F (–9°C) or

below. It will then begin operation automatically. It

will take 2–3 days to fill the ice bin.

NOTE: In lower water pressure conditions, the

water valve may turn on up to 3 times to

deliver enough water to the icemaker.

12

Power

switch

B

C

19

Page 20

20

Installation Instructions

REMOVE THE BASE GRILLE

(if needed)

If, after removing the freezer drawer and

refrigerator door, the refrigerator will still not

fit through a doorway, the base grille can be

removed.

Remove the base grille by removing the

screws.

3

A

REMOVING THE FREEZER DRAWER (on some models)

REMOVE THE BASKET

Open the freezer drawer until it stops.

The freezer basket rests on a frame inside the

freezer drawer. Lift the basket up at the back.

Lift the front up and lift the entire basket up

and out of the drawer.

1

A

B

C

The freezer drawer can be removed, if needed,

to fit through tight areas.

Read these instructions completely and carefully.

REMOVE THE DRAWER FRONT

Remove the screw on each side of the railing.

2

A

REMOVE THE DRAWER FRONT (cont.)

Lift up on both sides of the freezer drawer

handle to separate the drawer railings from

the rail assemblies.

Set the drawer front on a non-scratching

surface.

Push the rail assemblies back into locking

position.

2

B

C

D

Rail Assembly

Drawer

Assembly

A

Screw

Page 21

21

Installation Instructions

REPLACING THE FREEZER DRAWER (on some models)

ATTACH AND SECURE THE DRAWER

FRONT TO THE SLIDES

Pull out the rail assemblies to the full length

on each side of the cabinet.

Locate the slots on the inside of the rail

assemblies near the back.

Insert the hooks at the back of the drawer

railings into the slots on the rail assemblies.

Lower the front of the drawer, making sure the

tabs on the sides of the railings fit into the front

slots in the rail assemblies.

1

A

B

D

C

REPLACE THE FREEZER BASKET

Replace the lower freezer basket by lowering it

into the frame.

2

Two people may be required to complete

this procedure.

ATTACH AND SECURE THE DRAWER

FRONT TO THE SLIDES

(cont.)

Replace the screws on both rail assemblies.

1

Slot

Rail assembly

Slot

Tab

Hook

E

Screw

Page 22

TOOLS YOU WILL NEED

Installation Instructions

REVERSING THE DOOR SWING (Single Door Refrigerator Models only)

IMPORTANT NOTES

When reversing the door swing:

NOTE: Door swing is not reversible on stainless

steel models.

• Read the instructions all the way through before

starting.

• Parts are included in the door hinge kit.

• Handle parts carefully to avoid scratching paint.

• Set screws down by their related parts to avoid

using them in the wrong places.

• Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is completed.

These instructions are for changing the hinges

from the right side to the left side—if you ever want

to change the hinges back to the right side, follow

these same instructions and reverse all references

to left and right.

• Once door swing is finalized, ensure the logo

badge is properly aligned and permanently

secured to the door by removing the adhesive

cover on the back side. NOTE: A replacement

logo badge is included in the hinge kit.

Unplug the refrigerator from its electrical outlet.

Empty all door shelves, including the dairy

compartment.

Thin-blade Screwdriver

Masking Tape

Adjustable Wrench

5/16

″ Socket

Ratchet/Driver

REMOVE THE

REFRIGERATOR DOOR

Tape the door shut with masking tape.

Remove the hinge cover on top of the

refrigerator door by carefully prying it up with

a putty knife, if necessary.

Using a 5/16″ socket ratchet/driver, remove

the bolts securing the top hinge to the cabinet.

Then lift the hinge straight up to free the hinge

pin from the socket in the top of the door.

Carefully remove the door thimble from inside

the socket. This will be used again when

reinstalling the door on the other side.

Remove the tape and tilt the door away from

the cabinet. Lift the door off the center hinge

pin. Ensure that the plastic hinge pin thimble

remains on the hinge pin or inside door hinge

pin hole located in the bottom of the door.

Set the door on a non-scratching surface with

the inside up.

1

A

B

C

Hinge Cover

Top Hinge

Phillips Screwdriver

22

Torx T-20 Driver

E

F

D

Door Thimble

Page 23

Installation Instructions

TRANSFER CENTER HINGE

BRACKET

(cont.)

Transfer the plug button and screw hole

cover in the hinge holes on the left side

to the right side.

Install the new center hinge bracket from the

kit on the left side.

3

C

REMOVE THE FREEZER DOOR

Tape the door shut with masking tape.

Remove hinge pin from hinge bracket. This will

be used again with the new hinge bracket for

the other side.

Remove the tape and tilt the door away from

the cabinet. Lift the door off the bottom

hinge pin.

Remove the button plug from the left side of

the door. Remove the door thimble from the

right side of the door. Install the door thimble

into the hole on the left and the button plug

into the hole on the right.

Set the door on a non-scratching surface, with

the inside up.

2

A

B

C

D

TRANSFER CENTER HINGE BRACKET

Using a 5/16″ socket ratchet/driver, remove the

bolts securing the center hinge to the cabinet.

3

A

B

REMOVE BOTTOM HINGE AND

LEVELING LEG

Using a 1/2″ socket ratchet/driver, remove the

nut and hinge pin from the hinge bracket with

leveling leg. Using a 5/16″ socket ratchet/driver,

remove the screws from the bottom hinge

bracket. These will be reinstalled on the

other side.

Using a 5/16″ socket ratchet/driver, remove

the screws from the leveling leg bracket on

the other side. These will be reinstalled on the

opposite side.

4

A

B

23

Bottom Hinge

Bracket

Leveling Leg

Bracket

E

Page 24

TRANSFER REFRIGERATOR AND

FREEZER DOOR STOPS

Remove the door stop on the right side of the

bottom of the door by removing the two screws.

Move the plastic hinge hole thimble to the

opposite hole.

Install the door stop on the left side, making

sure to line up the screw holes in the door stop

with the holes in the bottom of the door.

6

A

B

C

Bottom of Door (Right Side) Bottom of Door (Left Side)

A

TRANSFER REFRIGERATOR

DOOR HANDLE TO RIGHT

Refer to Remove the Fresh Food Door Handle

and Attach the Fresh Food Door Handle

sections for instructions.

7

Installation Instructions

INSTALL BOTTOM HINGE AND

LEVELING LEG

Using a 1/2″ socket ratchet/driver, install the

hinge pin and nut in the opposite hole on the

hinge bracket with leveling leg.

Using a 5/16″ socket ratchet/driver, install the

hinge bracket with leveling leg on the left side

of the refrigerator. The pin will be toward the

outside of the refrigerator.

Using a 5/16″ socket ratchet/driver, install the

leveling leg bracket on the right side of the

refrigerator.

5

A

B

C

REHANG FREEZER DOOR

Lower the freezer door onto the bottom hinge pin.

Ensure that the plastic hinge pin thimble is on the

hinge pin or inside the door hinge pin hole located

in the bottom of the door.

Straighten the door and line it up with the

center hinge bracket.

Install the center hinge pin with a 3/4″ socket

ratchet/driver. Turn it until it extends through

the hinge bracket and into the freezer door.

8

A

B

C

REVERSING THE DOOR SWING (cont.)

24

Page 25

Installation Instructions

REMOVING THE DOORS

(Double Door Refrigerator Models only)

IMPORTANT NOTES

NOTE: Door swing is not reversible.

• Read the instructions all the way through before

starting.

• Handle parts carefully to avoid scratching paint.

• Set screws down by their related parts to avoid

using them in the wrong places.

• Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move

the cabinet.

These instructions are for removing the doors.

Unplug the refrigerator from its electrical outlet.

Empty all door shelves, including the dairy

compartment.

TOOLS YOU WILL NEED

Thin-blade Screwdriver

Masking Tape

Adjustable Wrench

3/8

″ and 10 mm Socket

Ratchet/Driver

Phillips Screwdriver

REHANG REFRIGERATOR DOOR

Lower the refrigerator door onto the center hinge

pin. Ensure that the plastic hinge pin thimble is on

the center hinge pin or inside door hinge pin hole

located in the bottom of the door.

Insert the door thimble into the hinge hole

on top of the refrigerator door and then

insert the top hinge pin. Make sure the door

is aligned with the cabinet. Attach the hinge

to the top of the cabinet loosely with the bolts.

Make sure the gasket on the door is flush against

the cabinet and is not folded. Support the door on

the handle side and make sure the door is straight

and the gap between the doors is even across the

front. While holding the door in place, tighten the

top hinge bolts. Replace the hinge cover.

9

A

B

C

INSTALL THE LOGO BADGE

Remove the adhesive backing paper

and align the pins on the back of the badge

with the holes in the door. Apply pressure to

the badge to ensure it sticks to the door.

10

25

Page 26

REMOVE THE REFRIGERATOR DOORS

(cont.)

Remove the tape and tilt the door away from

the cabinet. Lift the door off the center hinge

pin. Ensure that the plastic hinge pin thimble

remains on the hinge pin or inside door hinge

pin hole located in the bottom of the door.

Set the door on a non-scratching surface with

the inside up.

Installation Instructions

REMOVE OPPOSITE DOOR

Follow the same procedure on the opposite

door. There are no center hinge covers on the

opposite side.

3

REMOVE FREEZER DRAWER

Refer to the Removing the Freezer Drawer

section for instructions.

4

REMOVE THE

REFRIGERATOR DOORS

Tape the doors shut with masking tape.

Start with left-hand door first: Remove

the screw securing the center hinge cover, lift

the hinge cover and place to the side on top of

the refrigerator.

Remove the hinge cover on top of the

refrigerator door by removing the Phillips head

screw and pulling the cover up.

Using a 5/16″ socket ratchet/driver, remove

the bolts securing the top hinge to the cabinet.

Then lift the hinge straight up to free the hinge

pin from the socket in the top of the door.

1

A

B

E

F

Remove hinge cover

(1 Phillips screw)

1

REMOVE CENTER HINGE

Using a 5/16″ socket ratchet/driver, remove the

bolts securing the center hinge to the cabinet.

Set the hinge and bolts aside.

2

26

C

D

Hinge Cover

Top Hinge

REMOVING THE DOORS (Double Door Refrigerator Models only)

Page 27

Installation Instructions

REPLACING THE DOORS (Double Door Refrigerator Models only)

INSTALL CENTER HINGE

Install the center hinge on each side.

REHANG REFRIGERATOR DOORS

Lower the refrigerator door onto the center

hinge pin. Ensure that the plastic hinge pin

thimble is on the center hinge pin or inside

door hinge pin hole located in the bottom

of the door.

Securely tape the door shut with masking tape

or have a second person support the door.

Insert the top hinge pin into the hinge hole on

top of the refrigerator door. Make sure the door

is aligned with the cabinet and opposite door.

Attach the hinge to the top of the cabinet

loosely with the bolts.

Make sure the gasket on the door is flush

against the cabinet and is not folded. Make

sure the door is straight and the gap between

the doors is even across the front. While

holding the aligned door in place, tighten

the top hinge bolts. Replace the hinge cover

and screw.

A

B

C

Hinge Pin

ALIGN DOUBLE DOORS

If the top of the doors are uneven, first try to

raise the lowest door by turning the leveling leg

on the same side as the door until the doors

are even. If the unit rocks, re-adjust the leveling

legs to the extent that the unit is stable.

If the doors remain uneven, turn the adjustable

pin to raise, or lower, the left door to match

the right door. Use a 1/4″ Allen wrench to turn

the pin.

Adjustable pin

REPLACE FREEZER DRAWER

Refer to the Replacing the Freezer Drawer

section for instructions.

5

27

REPLACE OPPOSITE DOOR

Follow the same procedure on the opposite

door. There is no water line or hinge cover.

4

3

2

1

D

Top Hinge Bolts

Hinge Cover

(appearance may vary)

Page 28

Installation Instructions

28

INSTALLING THE WATER LINE (ICEMAKER MODELS)

Recommended copper water supply kits are

WX8X2, WX8X3 or WX8X4, depending on the

amount of tubing you need. Approved plastic

water supply lines are GE SmartConnect

™

Refrigerator Tubing (WX08X10006, WX08X10015

and WX08X10025).

When connecting your refrigerator to a GE Reverse

Osmosis Water System, the only approved

installation is with a GE RVKit. For other reverse

osmosis water systems, follow the manufacturer’s

recommendations.

If the water supply to the refrigerator is from

a Reverse Osmosis Water Filtration System

AND the refrigerator also has a water filter,

use the refrigerator’s filter bypass plug. Using

the refrigerator’s water filtration cartridge in

conjunction with the RO filter can result in hollow

ice cubes.

This water line installation is not warranted by

the refrigerator or icemaker manufacturer. Follow

these instructions carefully to minimize the risk of

expensive water damage.

Water hammer (water banging in the pipes) in

house plumbing can cause damage to refrigerator

parts and lead to water leakage or flooding. Call a

qualified plumber to correct water hammer before

installing the water supply line to the refrigerator.

To prevent burns and product damage, do not hook

up the water line to the hot water line.

If you use your refrigerator before connecting

the water line, make sure the icemaker power

switch is in the O (off) position.

Do not install the icemaker tubing in areas where

temperatures fall below freezing.

When using any electrical device (such as a power

drill) during installation, be sure the device is double

insulated or grounded in a manner to prevent the

hazard of electric shock, or is battery powered.

All installations must be in accordance with local

plumbing code requirements.

BEFORE YOU BEGIN

WHAT YOU WILL NEED

• Copper or GE SmartConnect™Refrigerator

Tubing kit, 1/4″ outer diameter to connect the

refrigerator to the water supply. If using copper,

be sure both ends of the tubing are cut square.

To determine how much tubing you need: measure

the distance from the water valve on the back

of the refrigerator to the water supply pipe.

Be sure there is sufficient extra tubing to allow

the refrigerator to move out from the wall after

installation.

GE SmartConnect

™

Refrigerator Tubing Kits

are available in the following lengths:

6′ (1.8 m) – WX08X10006

15′ (4.6 m) – WX08X10015

25′ (7.6 m) – WX08X10025

Page 29

NOTE: The only GE approved plastic tubing

is that supplied in GE SmartConnect

™

Refrigerator Tubing kits. Do not use any other

plastic water supply line because the line is

under pressure at all times. Certain types of

plastic will crack or rupture with age and cause

water damage to your home.

• A GE water supply kit (containing tubing,

shutoff valve and fittings listed below) is available

at extra cost from your dealer or from Parts and

Accessories, 800.626.2002 (in Canada

1.888.261.3055).

• A cold water supply. The water pressure must

be between 20 and 120 p.s.i. (1.4–8.1 bar).

• Power drill.

• 1/2″ or adjustable wrench.

• Straight and Phillips blade screwdriver.

• Two 1/4″ outer diameter compression nuts

and 2 ferrules (sleeves)—to connect the copper

tubing to the shutoff valve and the refrigerator

water valve.

OR

• If you are using a GE SmartConnect

™

Refrigerator Tubing kit, the necessary fittings

are preassembled to the tubing.

• If your existing copper water line has a flared

fitting at the end, you will need an adapter

(available at plumbing supply stores) to connect

the water line to the refrigerator OR you can cut

off the flared fitting with a tube cutter and then

use a compression fitting. Do not cut formed end

from GE SmartConnect

™

Refrigerator tubing.

• Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with

a minimum inside diameter of 5/32″ at the point

of connection to the COLD WATER LINE. Saddle-

type shutoff valves are included in many water

supply kits. Before purchasing, make sure a

saddle-type valve complies with your local

plumbing codes.

WHAT YOU WILL NEED (CONT.)

SHUT OFF THE MAIN WATER SUPPLY

Turn on the nearest faucet long enough

to clear the line of water.

Install the shutoff valve on the nearest frequently

used drinking water line.

1

Choose a location for the valve that is easily

accessible. It is best to connect into the side

of a vertical water pipe. When it is necessary

to connect into a horizontal water pipe, make

the connection to the top or side, rather than at

the bottom, to avoid drawing off any sediment

from the water pipe.

CHOOSE THE VALVE LOCATION

2

DRILL THE HOLE FOR THE VALVE

3

Drill a 1/4″ hole in the water pipe (even if using

a self-piercing valve), using a sharp bit. Remove

any burrs resulting from drilling the hole in

the pipe.

Take care not to allow water to drain into the

drill.

Failure to drill a 1/4″ hole may result in reduced

ice production or smaller cubes.

Installation Instructions

29

Page 30

Installation Instructions

Place the compression nut and ferrule (sleeve)

for copper tubing onto the end of the tubing and

connect it to the shutoff valve.

Make sure the tubing is fully inserted into

the valve. Tighten the compression nut securely.

For plastic tubing from a GE SmartConnect

™

Refrigerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then

tighten one additional turn with a wrench.

Overtightening may cause leaks.

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR shall be adhered to.

Saddle valves are illegal and use is not permitted

in Massachusetts. Consult with your licensed

plumber.

CONNECT THE TUBING TO THE VALVE

7

Saddle-Type

Shutoff Valve

Compression Nut

Packing Nut

Outlet Valve

Ferrule (sleeve)

Turn the main water supply on and flush out

the tubing until the water is clear.

Shut the water off at the water valve after

about one quart (1 liter) of water has been

flushed through the tubing.

FLUSH OUT THE TUBING

8

SmartConnect

™

Tubing

Fasten the shutoff valve to the cold water pipe

with the pipe clamp.

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR shall be adhered to.

Saddle valves are illegal and use is not permitted

in Massachusetts. Consult with your licensed

plumber.

FASTEN THE SHUTOFF VALVE

4

Tighten the clamp screws until the sealing

washer begins to swell.

NOTE: Do not overtighten or you may crush

the tubing.

TIGHTEN THE PIPE CLAMP

5

Pipe Clamp

Vertical Cold Water Pipe

Saddle-Type

Shutoff Valve

Washer

Inlet End

Pipe Clamp

Clamp

Screw

Route the tubing between the cold water line

and the refrigerator.

Route the tubing through a hole drilled in the

wall or floor (behind the refrigerator or adjacent

base cabinet) as close to the wall as possible.

ROUTE THE TUBING

6

To complete the installation of the refrigerator,

go back to Step 1 in Installing the Refrigerator.

30

INSTALLING THE WATER LINE (CONT.)

Page 31

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Normal operating sounds. ge.com

Before you call for service…

Troubleshooting Tips

Save time and money! Review the charts on

the following pages first and you may not need to call

for service.

Newer refrigerators sound different from older refrigerators.

Modern refrigerators have more features and use newer technology.

HUMMM...

WHOOSH...

■

The new high efficiency compressor may run faster

and longer than your old refrigerator and you may

hear a high-pitched hum or pulsating sound while

it is operating.

■

You may hear a whooshing sound when the

doors close. This is due to pressure equalizing within

the refrigerator.

■

You may hear the fans spinning at high speeds.

This happens when the refrigerator is first plugged in,

when the doors are opened frequently or when a large

amount of food is added to the refrigerator or freezer

compartments. The fans are helping to maintain the

correct temperatures.

■

The fans change speeds in order to provide optimal

cooling and energy savings.

CLICKS, POPS,

CRACKS and SNAPS

■

You may hear cracking or popping sounds when

the refrigerator is first plugged in. This happens as

the refrigerator cools to the correct temperature.

■

The freezer control will click when starting or stopping

the compressor.

■

Defrost timer snapping in and out of the defrost cycle.

■

Expansion and contraction of cooling coils during and

after defrost can cause a cracking or popping sound.

■

On models with an icemaker, after an icemaking cycle,

you may hear the ice cubes dropping into the ice

bucket.

■

On models with a dispenser, during water dispense,

you may hear the water lines move at initial dispense

and after dispenser button is released.

WATER SOUNDS

■

The flow of refrigerant through the freezer cooling coils

may make a gurgling noise like boiling water.

■

Water dropping on the defrost heater can cause a

sizzling, popping or buzzing sound during the defrost

cycle.

■

A water dripping noise may occur during the defrost

cycle as ice melts from the evaporator and flows into

the drain pan.

■

Closing the door may cause a gurgling sound due to

pressure equalization.

Do you hear what I hear? These sounds are normal.

Problem Possible Causes What To Do

Refrigerator does not Refrigerator in defrost cycle. • Wait about 30 minutes for defrost cycle to end.

operate

Control in

0ff position. • Move the control to a temperature setting.

Refrigerator is unplugged. • Push the plug completely into the outlet.

The fuse is blown/circuit • Replace fuse or reset the breaker.

breaker is tripped.

Vibration or rattling Leveling legs need adjusting. • See Level the Refrigerator.

(slight vibration

is normal)

For additional information on normal

icemaker operating sounds, see the

About the automatic icemaker section.

31

Page 32

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

32

Problem Possible Causes What To Do

Motor operates for Normal when refrigerator • Wait 24 hours for the refrigerator to completely

long periods or cycles is first plugged in. cool down.

on and off frequently.

Often occurs when large • This is normal.

(Modern refrigerators

amounts of food are

with more storage

placed in refrigerator.

space and a larger

Door left open. • Check to see if package is holding door open.

freezer require more

Hot weather or frequent • This is normal.

operating time. They

door openings.

start and stop often

Temperature control • See About the controls.

to maintain even

set at the coldest setting.

Refrigerator or freezer Temperature controls not set • See About the controls.

compartment too warm cold enough.

Warm weather or frequent • Set the temperature control one step colder.

door openings. See About the controls.

Door left open. • Check to see if package is holding door open.

Frost or ice crystals Door left open. • Check to see if package is holding door open.

on frozen food

Door openings too frequent • This is normal.

(frost within package

or too long.

is normal)

Frequent “buzzing” Icemaker power switch is in • Set the power switch to the 0 (off) position. Keeping it

sound the I (on) position, but the in the I (on) position will damage the water valve.

water supply to the refrigerator

has not been connected.

Small or hollow cubes Water filter clogged. • Replace filter cartridge with new cartridge or with plug.

Automatic icemaker Icemaker power switch is • Set the power switch to the I (on) position.

(on some models) not on. The icemaker power light will turn green when the

does not work freezer light switch is pressed in or when the freezer

door is closed.

Water supply turned off or • See Installing the water line.

not connected.

Freezer compartment • Wait 24 hours for the refrigerator to completely

too warm. cool down.

Piled up cubes in the storage • Level cubes by hand.

bin cause the icemaker

to shut off.

Ice cubes stuck in icemaker. • Turn off the icemaker, remove cubes and turn

(Green power light on the icemaker back on.

icemaker blinking.)

Icemaker light is not lit. • This is normal when the freezer door is open. The

icemaker power light will turn green when the freezer

light switch is pressed in or when the freezer door is

closed.

temperatures.)

Before you call for service…

Troubleshooting Tips

Page 33

ge.com

Consumer Support

Troubleshooting Tips

Operating InstructionsSafety Instructions

Installation

Instructions

33

Problem Possible Causes What To Do

Ice cubes have Food transmitting odor/taste • Wrap foods well.

odor/taste to ice cubes.

Interior of refrigerator • See Care and cleaning.

needs cleaning.

• Keep an open box of baking soda in the refrigerator;

replace every three months.

Slow ice cube freezing Door left open. • Check to see if package is holding door open.

Freezer control not set • See About the controls.

cold enough.

Refrigerator has odor Foods transmitting • Foods with strong odors should be tightly wrapped.

odor to refrigerator.

• Keep an open box of baking soda in the refrigerator;

replace every three months.

Interior needs cleaning. • See Care and cleaning.

Moisture forms on Not unusual during • Wipe surface dry and reset the refrigerator control

outside of refrigerator periods of high humidity. one setting colder.

Moisture collects inside Too frequent or too • This is normal.

(in humid weather, air long door openings.

carries moisture into

refrigerator when

doors are opened)

Refrigerator or freezer No power at outlet. • Replace fuse or reset the breaker.

compartment light

Light bulb burned out or loose. • See Replacing the light bulbs.

does not work

Door/drawer does not Leveling legs need adjusting. • See Installing the Refrigerator.

close by itself

Freezer door/drawer This is normal if, after popping • This indicates that there is a good seal on the freezer

pops open when open, the freezer door/drawer door/drawer. If the freezer door/drawer does not

refrigerator door closed on its own. automatically close after popping open, then see the

is closed Problem: Door/drawer does not close by itself, above.

Hot air from bottom Normal air flow cooling

of refrigerator motor. In the refrigeration

process, it is normal that

heat be expelled in the

area under the refrigerator.

Some floor coverings will

discolor at these normal

and safe temperatures.

Food freezing in Food too close to the air vent • Move the food away from the air vent.

the refrigerator at the back of the refrigerator.

Refrigerator control is set • Move the refrigerator control to a warmer

too cold. temperature setting one increment at a time.

Orange glow Defrost heater is on. • This is normal.

in the freezer

Page 34

34

Consumer Support

Troubleshooting Tips

Operating Instructions

Safety Instructions

Installation

Instructions

Before you call for service…

Troubleshooting Tips

Problem Possible Causes What To Do

No ice cube Supply line or shutoff valve • Call a plumber.

production is clogged.

(on some models)

Water filter clogged. • Replace filter cartridge or remove filter and install plug.

Filter cartridge not • Remove and reinstall filter cartridge, being certain that

properly installed. it locks into place. The blade on the end of the cartridge

should be positioned vertically.

Handle is loose / Handle needs adjusting. • See Attach the Fresh Food Door Handle and Attach the

handle has a gap Freezer Door Handle sections for detailed instructions.

Refrigerator beeping This is the door alarm. • Close door.

Control setting is On some models, the light bulbs • If the control settings do not light up, check to see if

not lit at the top of the refrigerator the light bulbs are burned out, and replace if necessary.

compartment light up the

temperature control settings.

Refrigerator doors are Doors need realigning. • See Align Double Doors section located under

not even (on Double Replacing the Door (Double Door Refrigerator Models

Door models only) only).

Baskets stick or jam Baskets are too full. • To open: remove some of the products from

when opening or the basket when opened as far as possible.

closing Readjust the products left in the basket and

try to open the basket again.

• To close: readjust products in the basket or remove

any product that is above the rim of the basket and

close the basket.

Page 35

35

General Electric Company

Warranty Registration Department

P.O. Box 32150

Louisville, KY 40232-2150

GE Service Protection Plus

™

GE, a name recognized worldwide for quality and dependability together with Assurant Solutions, offers you

Service Protection Plus

™

—comprehensive protection on your appliances.*

Benefits Include:

• Prompt, reliable service from GE Authorized Servicers

• Convenient hours designed to suit your busy schedule

• Quality replacement parts

• The dependability of GE, a name recognized and trusted worldwide

• Ask about our interest-free payment plans

With Service Protection Plus you can expect:

• An extended service plan that limits unexpected repair bills

• Service coverage for most major brands

• Unlimited service calls for the length of your contract, or credit toward a replacement product

• Service coverage for covered operating parts and labor on appliances and home electronics that fail during normal single family

household use

• Your satisfaction is our goal. We strive to provide you with excellent service in a professional and timely manner.

Place your confidence in GE and call us in the U.S. toll-free at 1.800.626.2224 for more information.

*Most brands covered up to 15 years old in the continental U.S.

SPP is a trademark of General Electric Company.

Please place in envelope and mail to:

✁

Cut here

Page 36

Consumer Product Ownership Registration

Important

Mail

Today!

GE Consumer & Industrial

Appliances

General Electric Company

Louisville, KY 40225

ge.com

First

Name

Mr. ■■ Ms. ■■ Mrs. ■■ Miss ■■

Street

Address

City

State

Date Placed

In Use

Month

Day

Year

Zip

Code

Apt. #

Last

Name

Phone

Number

_

_

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our product and thank you for placing your confidence in us.

We are proud to have you as a customer!

Follow these three steps to protect your new appliance investment:

Important: If you did not get a registration card with your

product, detach and return the form below to

ensure that your product is registered, or register

online at ge.com.

1

23

Model Number

Serial Number

✁

Cut here

Complete and mail

your Consumer

Product Ownership

Registration today.

Have the peace of

mind of knowing we

can contact you in

the unlikely event of

a safety modification.

After mailing the

registration below,

store this document

in a safe place. It

contains information

you will need should

you require service.

Our service number is

800 GE CARES

(800.432.2737).

Read your Owner’s

Manual carefully.

It will help you

operate your new

appliance properly.

Model Number Serial Number

E-mail Address*

36

* Please provide your e-mail address to receive, via e-mail, discounts, special offers and other important

communications from GE Appliances (GEA).

■■ Check here if you do not want to receive communications from GEA’s carefully selected partners.

FAILURE TO COMPLETE AND RETURN THIS CARD DOES NOTDIMINISH YOUR WARRANTY RIGHTS.

For information about GEA’s privacy and data usage policy, go to ge.com and click on “Privacy Policy”

or call 800.626.2224.

Page 37

37

Please place in envelope and mail to:

Veuillez mettre dans une enveloppe et envoyez à :

OWNERSHIP REGISTRATION

P.O. BOX 1780

MISSISSAUGA, ONTARIO

L4Y 4G1

(FOR CANADIAN CONSUMERS ONLY)

Page 38

38

Page 39

Refrigerator Warranty. (For customers in the United States)

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule service,

on-line, visit us at ge.com, or call 800.GE.CARES (800.432.2737).

Please have serial number and model number available when

calling for service.

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■ Loss of food due to spoilage.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage caused after delivery.

■ Replacement of the water filter cartridge, if included, due

to water pressure that is outside the specified operating

range or due to excessive sediment in the water supply.

■ Replacement of the light bulbs, if included, or water filter

cartridge, if included, other than as noted above.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

■ Product not accessible to provide required service.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA. If the product is located in an area where service by a GE Authorized Servicer

is not available, you may be responsible for a trip charge or you may be required to bring the product to an

Authorized GE Service location for service. In Alaska, the warranty excludes the cost of shipping or service calls

to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided

in this Limited Warranty. Any implied warranties, including the implied warranties of merchantability

or fitness for a particular purpose, are limited to one year or the shortest period allowed by law.

Consumer Support

Troubleshooting Tips

Operating InstructionsSafety Instructions

Installation

Instructions

39

For The Period Of: GE Will Replace:

GE and GE PROFILE MODELS:

One Year Any part of the refrigerator which fails due to a defect in materials or workmanship.

From the date of the During this limited one-year warranty, GE will also provide, free of charge, all labor and

original purchase related service to replace the defective part.

Thirty Days Any part of the water filter cartridge which fails due to a defect in materials or workmanship.

(Water filter, if included) During this limited thirty-day warranty, GE will also provide, free of charge, a replacement water

From the original filter cartridge.

purchase date of