Page 1

169

MOTOR MANAGEMENT RELAY

Instruction Manual

Software Rev: 169.E7.5

Manual P/N: 1601-0003-A4

Copyright 2000 GE Power Management

g

215 Anderson Avenue, Markham, Ontario, L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

www.GEindustrial.com/pm

GE Power Management

Page 2

INTENT

This manual describes the function, operation and use of the GE Power Management Model 169 and 169 Plus Motor

Management Relays.

REVISION HISTORY

Manual Part No. 169 / 169 Plus Software Revision Release Date (M/D/Y)

M17/03/86 - all Rev. A, B, C, Rev. D1 3/17/86

M01/08/86 - Rev. D2 8/1/86

M21/08/86 - Rev. E1 8/21/86

M14/10/86 - Rev. E2, E3 10/14/86

M17/07/87-E4 - Rev. E4 (preliminary) 7/17/87

M05/08/87-E4 - Rev. E4 8/5/87

M02/11/87-E4 - Rev. E4 (D/O hardware rev.) 11/2/87

M04/11/87-E4 - Rev. E4 11/4/87

M22/01/89-E5 - Rev. E5 1/22/89

M01/02/90-E5 - Rev. E5 1/2/90

M23/02/90-E6 - Rev. E6 2/23/90

M18/09/91-E7 - Rev. 169.E7.0 9/18/91

M30/10/91-E7.1 - Rev. 169.E7.1 10/30/91

M02/12/91-E7.2 - Rev. 169.E7.2 12/2/91

1601-0003-A1 - Rev. 169.E7.2 10/12/93

1601-0003-A2 - Rev. 169.E7.2 01/23/95

1601-0003-A3 - Rev. 169.E7.3 08/22/95

1601-0003-A4 - Rev. 169.E7.4 03/11/98

1601-0003-A4 - Rev. 169.E7.5 12/14/99

Page 3

TABLE OF CONTENTS

g

GE Power Management

1.1 Motor Protection Requirements

1.2 169 Relay Features

1.3 Typical Applications

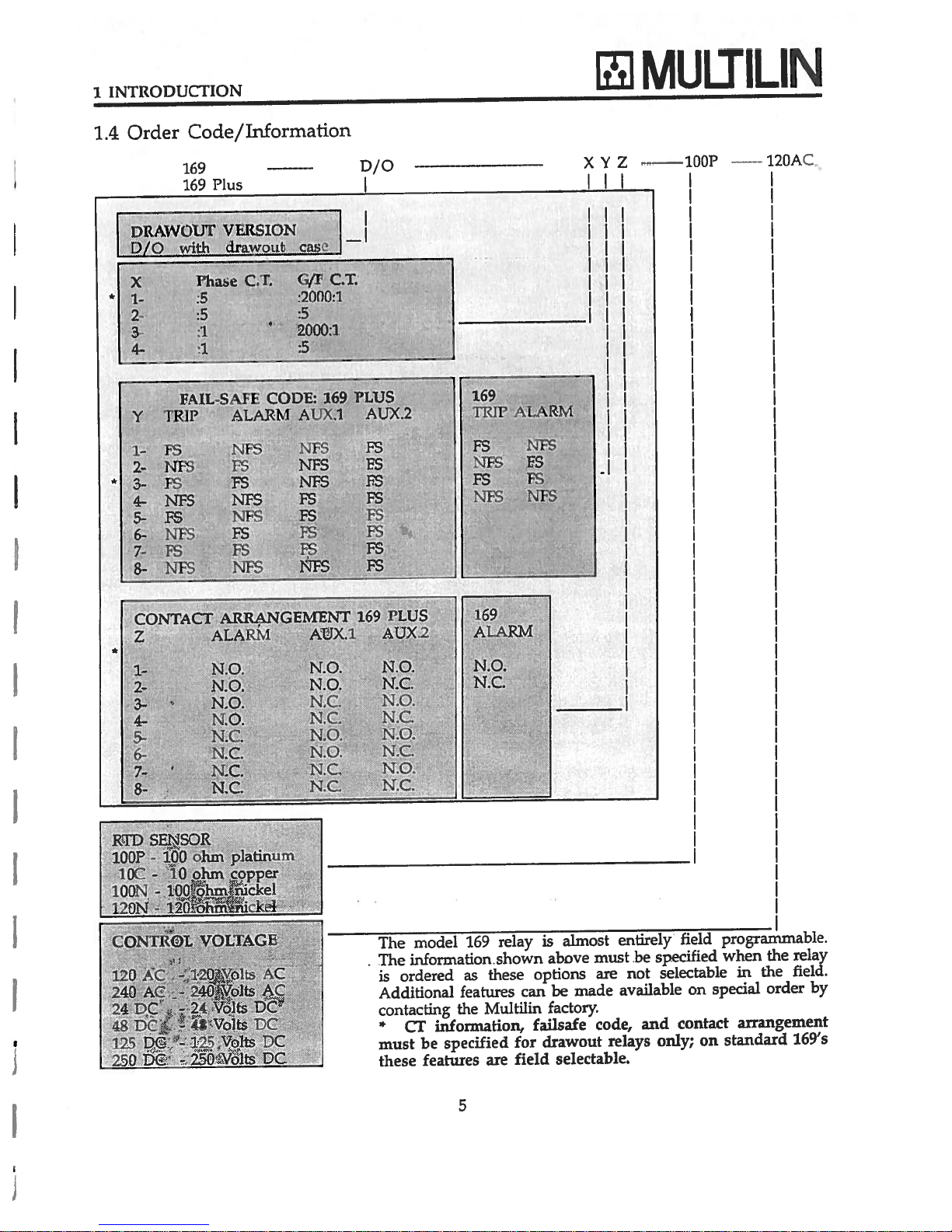

1.4 Technical Specifications

2.1 Physical Dimensions

2.2 Mounting

2.3 External Connections

2.4 Control Power

2.5 Phase C.T.s

2.6 Ground Fault C.T.

2.7 Trip Relay Contacts

2.8 Alarm Relay Contacts

2.9 Auxiliary Relay #1 Contacts (169 Plus)

2.10 Auxiliary Relay #2 Contacts (169 Plus)

2.11 RTD Sensor Connections

2.12 Emergency Restart Terminals

2.13 External Reset Terminals

................................................................................................................................................. 9

............................................................................................................................................ 15

................................................................................................................................. 1

............................................................................................................................... 3

....................................................................................................................... 4

............................................................................................................................. 7

.......................................................................................................................... 10

....................................................................................................................................... 15

................................................................................................................................. 16

.............................................................................................................................. 16

.......................................................................................................................... 16

........................................................................................................... 1

.................................................................................................................. 17

.......................................................................................................... 18

.................................................................................................................. 18

.............................................................................................. 17

............................................................................................ 17

2.14 Analog Output Terminals

2.15 Differential Relay Terminals (169 Plus)

2.16 Speed Switch Terminals (169 Plus)

2.17 Programming Access Terminals

2.18 RS-422 Serial Communications Terminals (169 Plus)

2.19 Display Adjustment

2.20 Front Panel Faceplate

2.21 Spare Input Terminals (169 Plus)

2.22 169 Drawout Relay

3.1 Controls and Indicators

3.2 169 Relay Display Modes

3.3 ACTUAL VALUES Mode......................................................................................................... ...............30

3.4 SETPOINTS Mode

3.5 HELP Mode

3.6 TRIP/ALARM Mode

3.7 Phase C.T. and Motor Full Load Current Setpoints

3.8 Acceleration Time Setpoint

................................................................................................................................41

.......................................................................................................................................... 58

................................................................................................................... 18

............................................................................................ 19

.................................................................................................. 19

...................................................................................................... 19

................................................................... 19

............................................................................................................................ 20

........................................................................................................................ 20

..................................................................................................... 20

............................................................................................................................. 21

....................................................................................................................... 26

.................................................................................................................... 30

............................................................................................................................... 58

.......................................................................... 61

................................................................................................................. 61

3.9 Number of Starts/Hour Setpoint

......................................................................................................... 61

i

Page 4

TABLE OF CONTENTS

g

GE Power Management

3.10 Unbalance Setpoints

3.11 Ground Fault (Earth Leakage) Setpoints

3.12 Undercurrent Setpoints

3.13 Rapid Trip / Mechanical Jam Setpoints

3.14 Short Circuit Setpoints

3.15 Immediate Overload Alarm Level Setpoint

3.16 Stator RTD Setpoints

3.17 Other RTD Setpoints

3.18 Overload Curve Setpoints

3.19 Phase Reversal Protection

3.20 Thermal Memory

3.21 Emergency Restart

3.22 Resetting The 169 Relay

3.23 169 Relay Self-Test

3.24 Statistical Data Features

3.25 Factory Setpoints

4.1 Primary Injection Testing

.......................................................................................................................... 62

..................................................................................................................... 63

........................................................................................... 64

...................................................................................................................... 64

......................................................................................................................... 64

.......................................................................................................................... 65

................................................................................................................. 65

................................................................................................................ 69

................................................................................................................................69

............................................................................................................................. 71

.................................................................................................................... 71

............................................................................................................................. 72

................................................................................................................... 72

............................................................................................................................... 73

..................................................................................................................... 76

......................................................................................... 63

...................................................................................... 64

4.2 Secondary Injection T esting

4.3 Phase Current Input Functions

4.4 Ground Fault Current Functions

4.5 RTD Measurement Tests

4.6 Power Failure Testing

4.7 Analog Current Output

4.8 Routine Maintenance Verification

5.1 Hardware

5.2 Firmware

6.1 169 Relay Powered from One of Motor Phase Inputs

6.2 Loss of Control Power Due to Short Circuit or Ground Fault

6.3 Example Using FLC Thermal Capacity Reduction Setpoint

............................................................................................................................................... 81

............................................................................................................................................... 83

............................................................................................................... 76

.......................................................................................................... 76

........................................................................................................ 79

..................................................................................................................... 79

.......................................................................................................................... 79

........................................................................................................................ 80

...................................................................................................... 80

...................................................................... 85

......................................................... 85

........................................................... 86

ii

Page 5

LIST OF TABLES

Table 1-1 Model 169 and 169 Plus Relay Features..................................................................................................... 2

Table 2-1 169 External Connections.......................................................................................................................... 10

Table 3-1 Controls and Indicators............................................................................................................................... 26

Table 3-1 Controls and Indicators............................................................................................................................... 31

Table 3-3 SETPOINTS ............................................................................................................................................... 42

Table 3-5 Standard Overload Curve Trip Times (in seconds).................................................................................... 66

Table 3-6 PRE-STORED FACTORY SETPOINTS (169 SETPOINT PAGES 1-3)................................................... 74

Table 3-7 Preset Factory Relay Configurations and Functions .................................................................................75

Table 4-1 RTD Resistance vs. Temperature.............................................................................................................. 79

g

GE Power Management

Page 6

1 INTRODUCTION

g

GE Power Management

1.1 Motor Protection Requirements

Three phase AC motors have become standard in modern industry. These motors are generally rugged and very

reliable when used within their rated limits. Newer motors, however, tend to be designed to run much closer to these

operational limits and thus, there is less margin available for any type of abnormal supply, load, or operating

conditions.

To fully protect these motors, a modern protective device is required. Accurate stator and rotor thermal modeling is

necessary to allow the motor to operate within its thermal limits and still give the maximum desired output. As well,

other features can be incorporated into a modern relay to fully protect the motor, the associated mechanical system,

and the motor operator from all types of faults or overloads.

Motor thermal limits can be exceeded due to increased current from mechanical overloads or supply unbalance.

Unbalance can greatly increase heating in the rotor because of the large negative sequence current components

present during even small voltage unbalances. A locked or stalled rotor can cause severe heating because of the

associated large currents drawn from the supply. Many motor starts over a short period of time can cause

overheating as well. Phase-to-phase and phase-to-ground faults can also cause damage to motors and hazards to

personnel. Bearing overheating, loss of load, and phase reversal can cause damage to the mechanical load being

driven by the motor.

The ideal motor protection relay should monitor the rotor and stator winding temperatures exactly and shut off the

motor when thermal limits are reached. This relay should have an exact knowledge of the temperature and proper

operating characteristics of the motor and should shut down the motor on the occurrence of any potentially

damaging or hazardous condition.

The Multilin Model 169 Motor Management Relay uses motor phase current readings combined with stator RTD

temperature readings to thermally model the motor being protected. In addition, the 169 takes into account the

heating effects of negative sequence currents in the rotor, and calculates the cooling times of the motor. The relay

also monitors the motor and mechanical load for faults and problems.

1.2 169 Relay Features

The Multilin Model 169 Motor Management Relay is a modern microcomputer-based product designed to provide

complete, accurate protection for industrial motors and their associated mechanical systems. The 169 offers a wide

range of protection, monitoring, and diagnostic features in a single, integrated package. All of the relay setpoints

may be programmed in the field using a simple 12 position keypad and 48 character alphanumeric display. A built-in

"HELP" function can instruct the user on the proper function of each of the programming keys and on the meaning of

each displayed message.

One 169 relay is required per motor. Phase and ground fault currents are monitored through current transformers so

that motors of any line voltage can be protected. The relay is used as a pilot device to cause a contactor or breaker

to open under fault conditions; that is, it does not carry the primary motor current.

The relay comes in two different models, thus allowing for choice of the most cost effective relay for each application.

The 169 Plus has the following features which the model 169 does not: custom curve selectability, motor statistical

records, speed switch input, differential relay input, two auxiliary output relays, two additional RTD inputs, single shot

emergency restart feature, an RS 422 communications port, unbalance input to thermal memory, start inhibit feature,

and spare input terminals.

The custom curve feature of the model 169 Plus gives the user additional flexibility. If one of the eight standard

overload curves is not suitable for the application under consideration, the user can enter his own breakpoints to

form a custom curve. This means that the 169 Plus can offer optimum motor protection in situations where other

relays cannot. Such applications include induced fan drives where the motor stator and rotor thermal capacities can

differ significantly.

An important feature of the Multilin 169 Plus relay, is its ability to "learn" individual motor parameters. The relay

actually adapts itself to each application by "learning" values of motor inrush current, negative sequence current K

factor, cooldown rates, and acceleration time. These values may be used to improve the 169's protective

capabilities (when enabled) and are continually updated. The model 169 learns inrush current only.

The 169 Plus calculates both positive and negative sequence currents. The equivalent motor heating current is

calculated based on the "learned" K factor. This, combined with RTD temperature readings by a motor thermal

modeling algorithm, gives the 169 Plus a complete thermal model of the motor being protected. Thus, the 169 Plus

will allow maximum motor power output while providing complete thermal protection.

1

Page 7

1 INTRODUCTION

The 169 Plus relay provides a complete statistical record of the motor being protected. The total motor running

hours, the number of motor starts, and the total number of relay trips since the last commissioning are stored and

can be viewed on the display. As well, the number of short circuit, RTD, ground fault, unbalance, overload, start, and

rapid trips can be recalled by simple keypad commands. These values are stored along with all of the relay

setpoints in a non-volatile memory within the relay. Thus, even when control power is removed from the 169 Plus,

the statistical record and all relay setpoints will remain intact.

The 169 can provide one of various output signals for remote metering or programmable controller attachment.

Analog signals of motor current as a percentage of full load, hottest stator RTD temperature, percentage of phase

CT secondary current, or motor thermal capacity are available by simple field programming. A total of four output

relays are provided on the 169 Plus, including a latched trip relay, an alarm relay, and two auxiliary relays. The

model 169 provides a latched trip relay and an alarm relay. All output relays may be programmed via the keypad to

trip on specific types of faults or overloads.

When an output relay becomes active, the 169 will display the cause of the trip, and if applicable, the lock-out time

remaining. Pre-trip values of motor current, unbalance, ground fault current, and maximum stator RTD temperature

are stored by the 169 and may be recalled using the keypad.

The correct operation of the Multilin 169 relay is continually checked by a built-in firmware self-test routine. If any

part of the relay malfunctions under this self-test, an alarm indication will tell the operator that service is required.

Table 1-1 Model 169 and 169 Plus Relay Features

Protection Features

Overloads

•

Stator Winding Overtemperature (Alarm and Trip)

•

Multiple Starts

•

Short Circuit

•

Locked Rotor

•

Rapid Trip/Mechanical Jam

•

Unbalance/Single Phasing

•

Ground Fault (Alarm and Trip)

•

Phase Reversal

•

Bearing Overtemperature (Alarm and Trip)

•

Undercurrent

•

Variable Lock-Out Time

•

g

GE Power Management

Operational Features

Microcomputer controlled

•

Keypad programmable

•

48 character alphanumeric display

•

Built-in "HELP" function

•

Eight selectable standard overload curves

•

User defined custom overload curve capability (169 Plus)

•

Continual relay circuitry self-check

•

Monitoring and Display Features

Negative sequence phase current unbalance measurement

•

Ground fault (earth leakage) current measurement

•

Up to six stator RTD inputs

•

Two additional RTD inputs on the model 169, four on the 169 Plus

•

Monitoring of motor ambient air temperature

•

Display of all SETPOINTS or ACTUAL VALUES upon request

•

Display of relay TRIP/ALARM and HELP messages

•

2

Page 8

1 INTRODUCTION

Communications and Control Features

One latched, main trip relay

•

One alarm relay

•

Emergency restart capability

•

Pre-trip alarm warnings

•

4-20mA output of motor current as a percentage of full load, motor thermal capacity, hottest stator RTD

•

temperature, or percentage of phase CT secondary current

Two auxiliary relays (169 Plus)

•

Optional single-shot restart on running overload trip (169 Plus)

•

Speed switch, differential relay, and spare input (169 Plus)

•

RS 422 port for connection to programmable controllers and computers (169 Plus)

•

Statistical and Memory Features

Recall of all pre-trip motor values

•

Tamperproof setpoints stored in non-volatile memory

•

Microcomputer "learns" motor inrush current, acceleration time

•

current heating K factor* (* 169 Plus only)

Complete record of motor statistical data: motor running hours, number of starts, number and type of relay trips

•

(169 Plus)

*

, cooldown rates*, and negative sequence

g

GE Power Management

1.3 Typical Applications

The many features of the 169 make it an ideal choice for a wide range of motor protection applications. Versatile

features and controls allow the relay to protect associated mechanical equipment as well as the motor. The 169

should be considered for the following and other typical uses:

1. Protection of motors and equipment from operator abuse.

2. Protection of personnel from shock hazards due to winding shorts or earth leakage current from moisture.

3. Protection of gears, pumps, fans, saw mills, cutters, and compressors from mechanical jam.

4. Indication of loss of suction for pumps or loss of air flow for fans using the undercurrent feature.

5. Protection of motor and load bearings from excessive heat buildup due to mechanical wear.

6. Protection of motors operated in environments with varying ambient temperatures.

7. Communication with programmable controllers and computers for integrated plant control.

8. Protection of high inertia, long acceleration drive systems using a custom overload curve.

9. Statistical record-keeping for effective maintenance programs.

10. Complete protection, allowing maximum motor utilization with minimum downtime, for all AC motors.

3

Page 9

1 INTRODUCTION

g

1.4 Technical Specifications

Phase Current Inputs

conversion: calibrated RMS

range: 0.05 to 12 × phase CT primary amps setpoint

full scale: 12 × phase CT primary amps setpoint

accuracy: ±0.5% of full scale (0.05 to 2 X phase CT primary amps setpoint)

±1.0% of full scale (over 2 X phase CT primary amps setpoint)

Ground Fault Current Input

conversion: calibrated RMS

range: 0.1 to 1.0 X G/F CT primary amps setpoint (5 Amp secondary CT)

1.0 to 10.0 amps (2000:1 CT)

full scale: 1 × G/F CT primary amps setpoint (5 Amp secondary CT)

10 amps (2000:1 CT)

accuracy: ±4% of G/F CT primary amps setpoint (5 Amp secondary CT)

± 0.3 amps primary (2000:1 CT)

Overload Curves

trip time accuracy: ±1 sec. up to 13 sec.

±8% of trip time over 13 sec.

detection level: ±1% of primary CT amps

GE Power Management

Unbalance

display accuracy: ±2 percentage points of true negative sequence unbalance (In/Ip)

Relay Lock-out Time

accuracy: +/- 1 minute with control power applied

+/- 20% of total lock-out time with no control power applied

Trip/Alarm Delay Times

accuracy: ±0.5 sec. or 2% of total time, whichever is greater with the exception of:

1. "INST."setpoints: less than 50 msec.

2. Ground Fault 0.5 Second delay: ±150 msec.

3. Ground Fault 250 msec delay: +75 msec, -150 msec.

Phase Reversal Trip Time

relay response time: within 3.5 sec. of motor start attempt

Differential Relay Input

relay response time: 100 msec. maximum (contact closure to output relay activation)

4

Page 10

1 INTRODUCTION

RTD Inputs

sensor types: 10 Ω copper

100 Ω nickel

120 Ω nickel

100 Ω platinum (specified with order)

display accuracy: ±2 C

trip/alarm setpoint range: 0 to 200°C

dead band: 3°C

maximum lead resistance: 25% of RTD 0°C resistance

Relay Contacts

type: form C

rated load: 10 A @ 250 VAC / 10 A @ 30 VDC (resistive load)

7.5 A @ 250 VAC / 5 A @ 30 VDC (inductive load)

0.5 A @ 125 VDC (resistive load)

0.3 A @ 125 VDC (inductive load)

maximum operating voltage: 380 VAC, 125 VDC

maximum operating current: 10 Amps

minimum permissible load: 5 VDC, 100 mA

NOTE: AC inductive load PF = 0.4

DC inductive load L/R = 7 msec.

g

GE Power Management

Analog Current Output (4-20 mA standard)

output: 4-20 mA / 0-20 mA / 0-1 mA

maximum load resistance: 300

maximum output (saturation): 20.2 mA 20.2 mA 1.01 mA

accuracy: ±1% of full scale reading

polarity: terminal 58 ("-") must be at ground potential (ie. output is not isolated)

Control Power

AC nominal: 120 VAC, range: 90-150 VAC

240 VAC, range: 180-270 VAC

frequency: 50/60 Hz

maximum power consumption: 40 VA

DC nominal: 24 VDC, range: 20-30 VDC

48 VDC, range: 30-55 VDC

125 VDC, range: 80-150 VDC

250 VDC, range: 160-300 VDC

maximum power consumption: 30 W

Environment

operating temperature range: –10°C to +60°C

display operational range: 0°C to +55°C

Ω

300

Ω

2000

Ω

5

Page 11

1 INTRODUCTION

CT Burden Due to Connection of 169 Relay

phase CT: 1 amp or 5 amp input: less than 0.50 VA at rated load

ground fault CT: 5 amp input: less than 0.50 VA at rated load

2000:1 input: can be driven by GE Power Management 2000:1 CT

Running Hours Counter

accuracy: ±1%

Note: It is recommended that all 169 relays be powered up at least once per year to avoid deterioration of

electrolytic capacitors in the power supply.

Due to updating technology, specifications may be improved without notice.

g

GE Power Management

6

Page 12

Page 13

2 INSTALLATION

g

GE Power Management

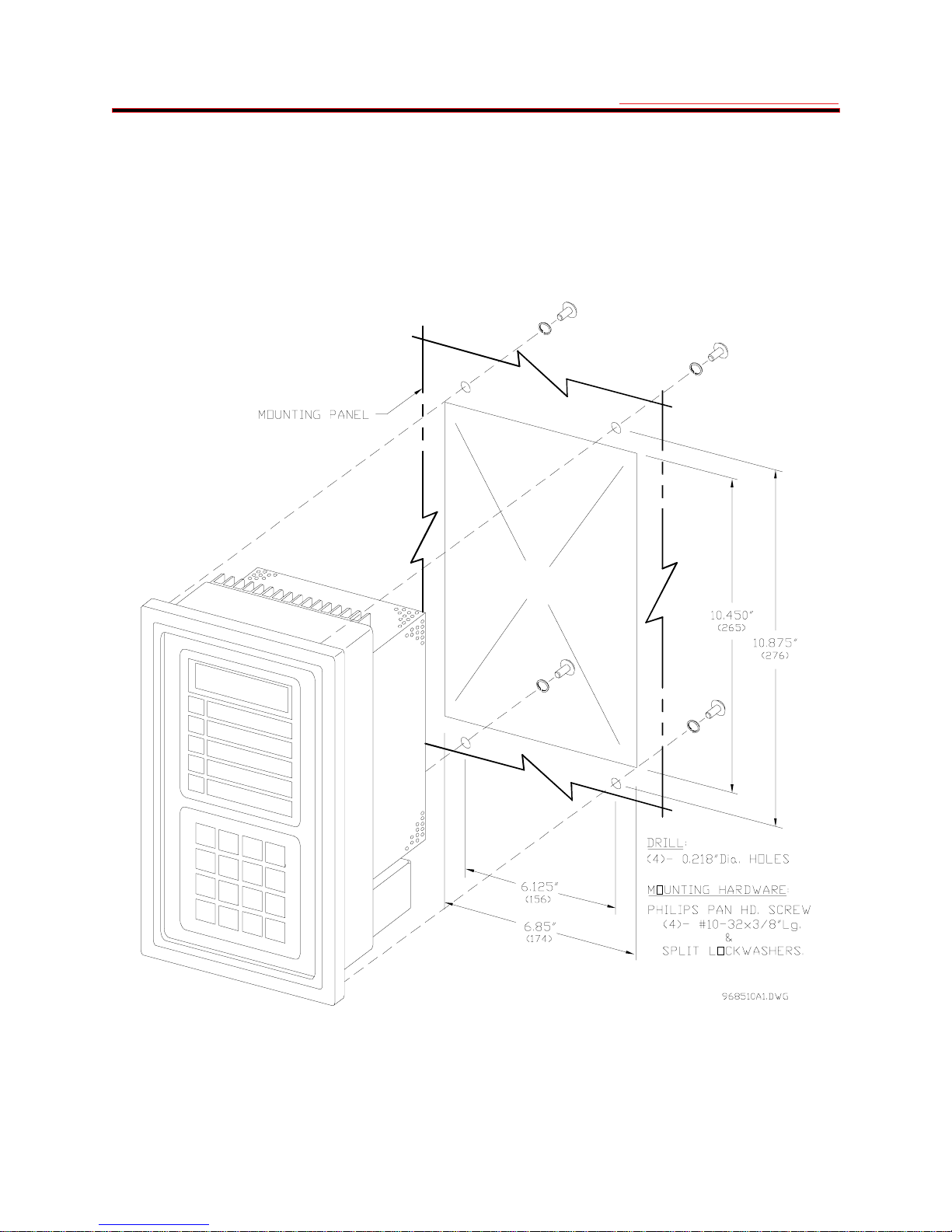

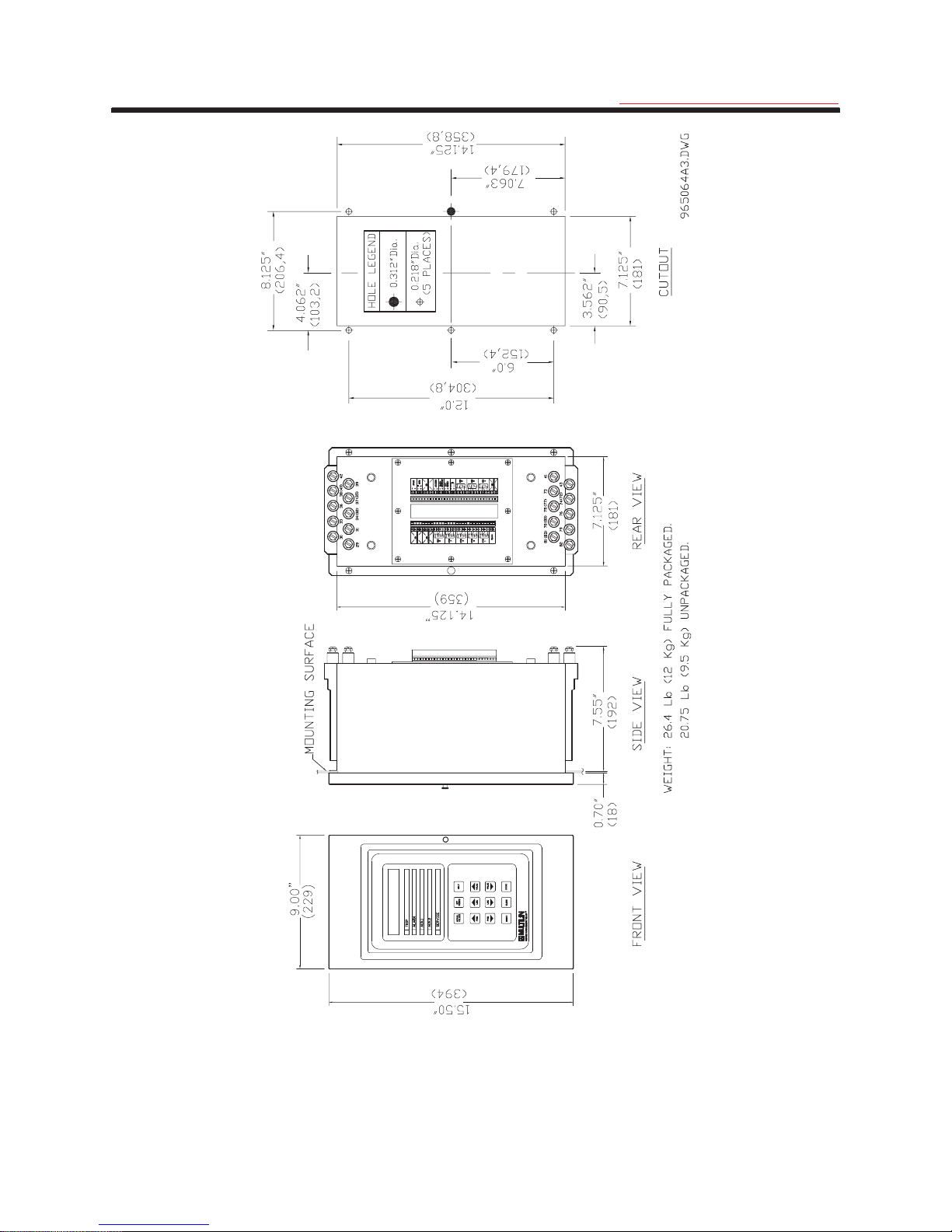

2.1 Physical Dimensions

The 169 relay is contained in a compact plastic and metal housing with the keypad, display, and all indicators located

on the front panel. The physical dimensions of the 169 unit are given in Figure 2-1.

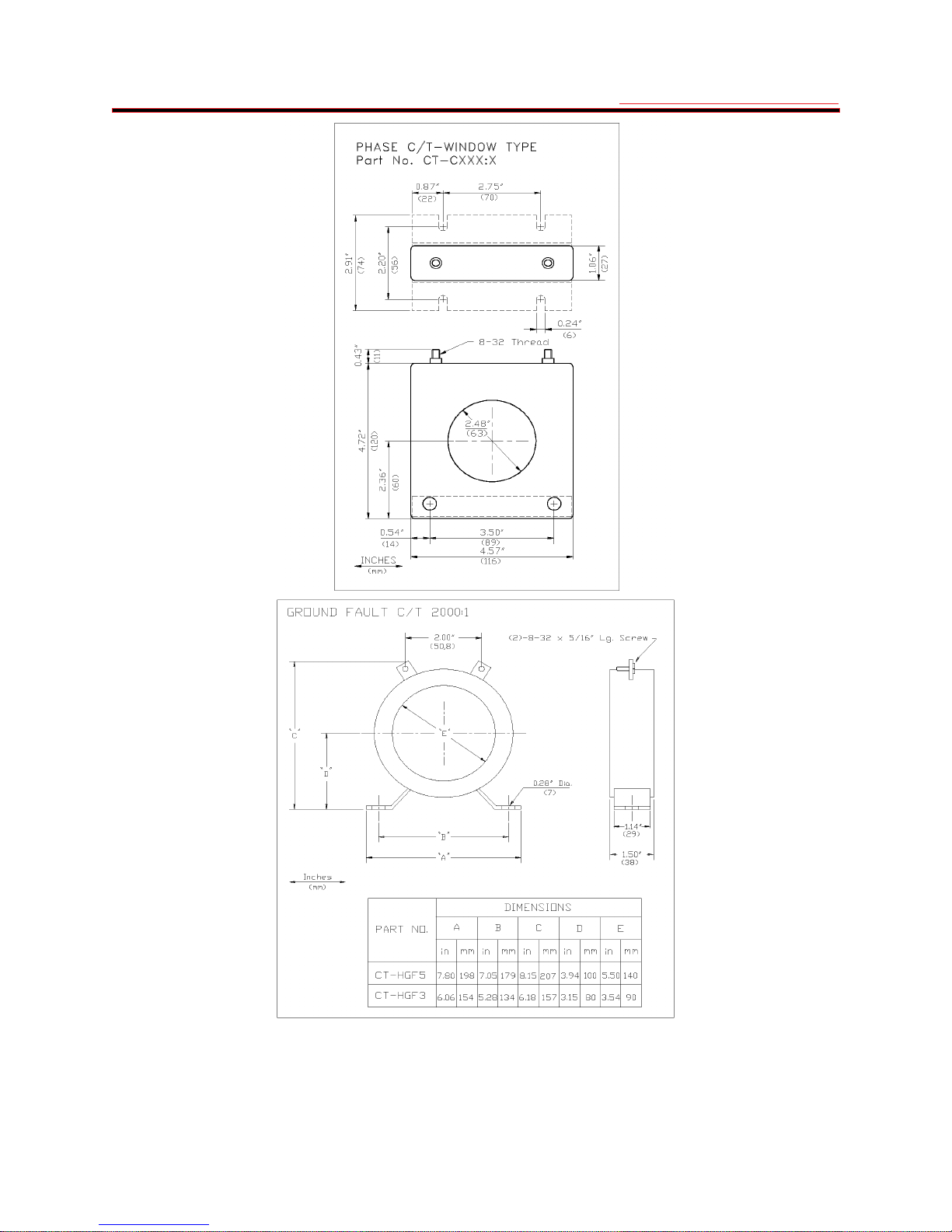

Multilin also provides phase and ground fault CTs if required. Dimensions for these are shown in Figure 2-2. Note:

Dimensions of Figure 2-2 are for 100:5 to 1000:5 phase CT's, for the dimensions of 50:5 and 75:5 CT's, consult

factory.

Figure 2-1 Physical Dimensions

7

Page 14

2 INSTALLATION

g

GE Power Management

Figure 2-2 CT Dimensions

8

Page 15

2 INSTALLATION

g

GE Power Management

2.2 Mounting

The 169 should be positioned so that the display is visible and the front panel keypad is accessible. A cut-out is

made in the mounting panel and the unit is mounted as shown in Figure 2-3. Four washers and 10-32 X 3/8"

mounting screws are provided.

Although the 169 circuitry is internally shielded, to minimize noise pickup and interference the relay should be placed

away from high current conductors or sources of strong magnetic fields.

Connections to the relay are made through terminal blocks and CTs located on the rear of the unit.

Figure 2-3 Relay Mounting

9

Page 16

2 INSTALLATION

g

GE Power Management

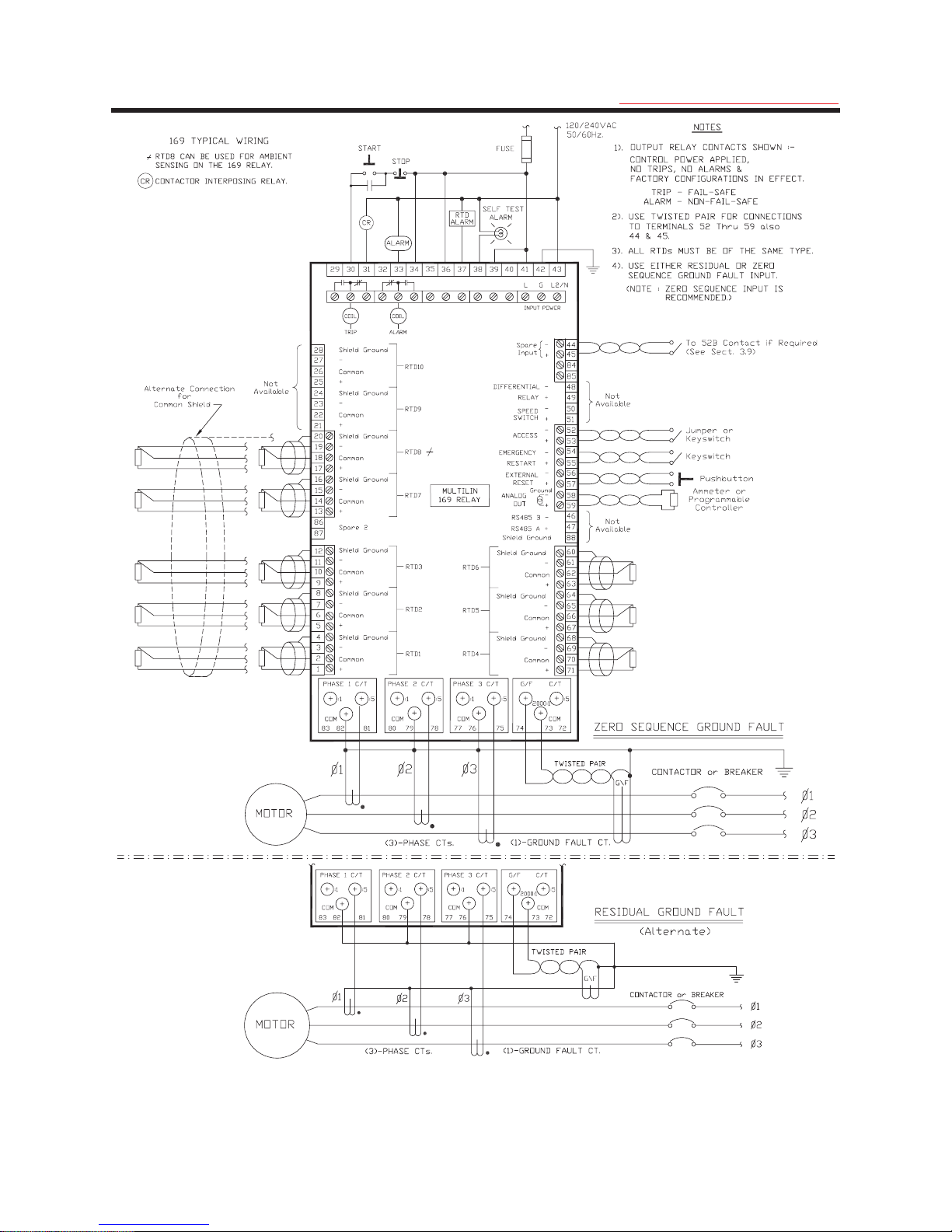

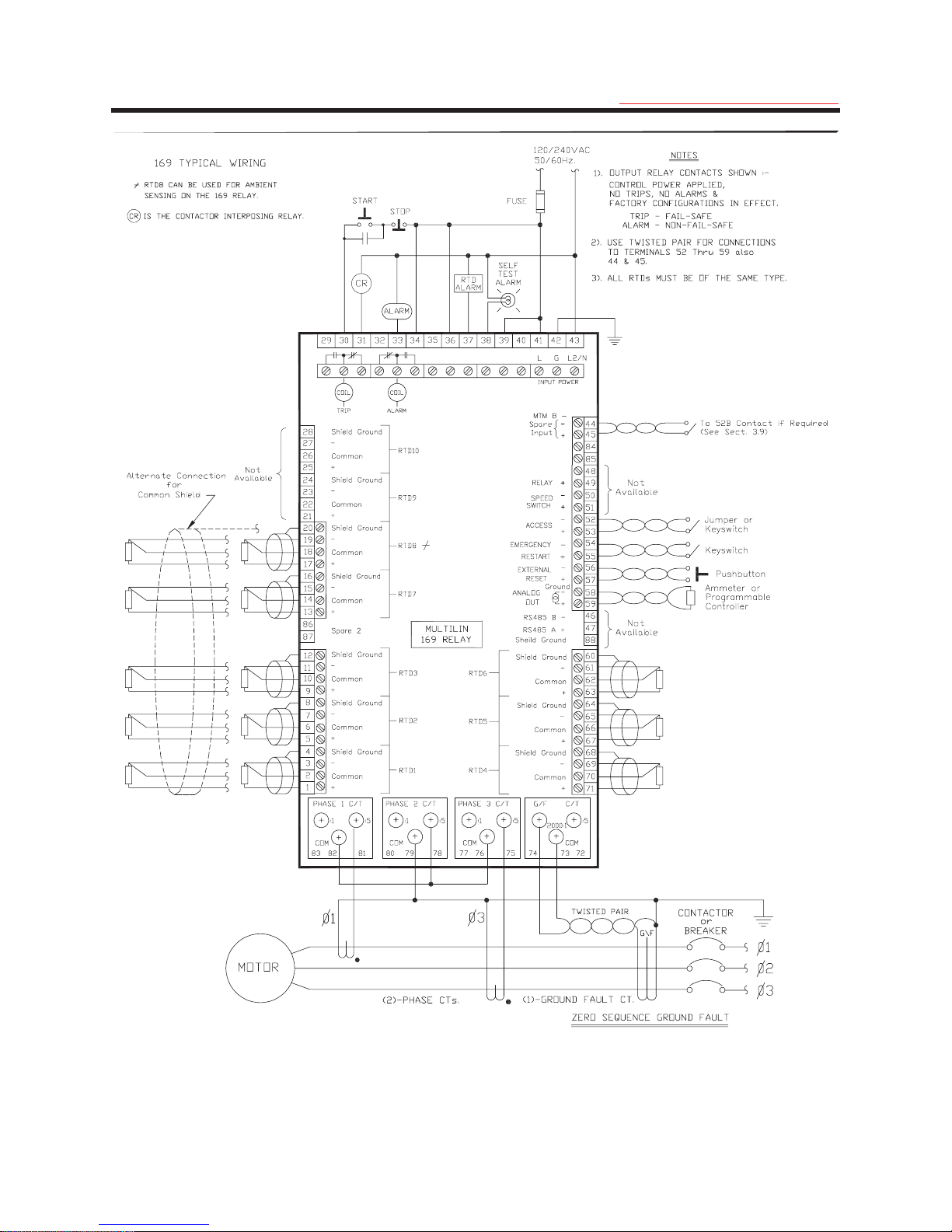

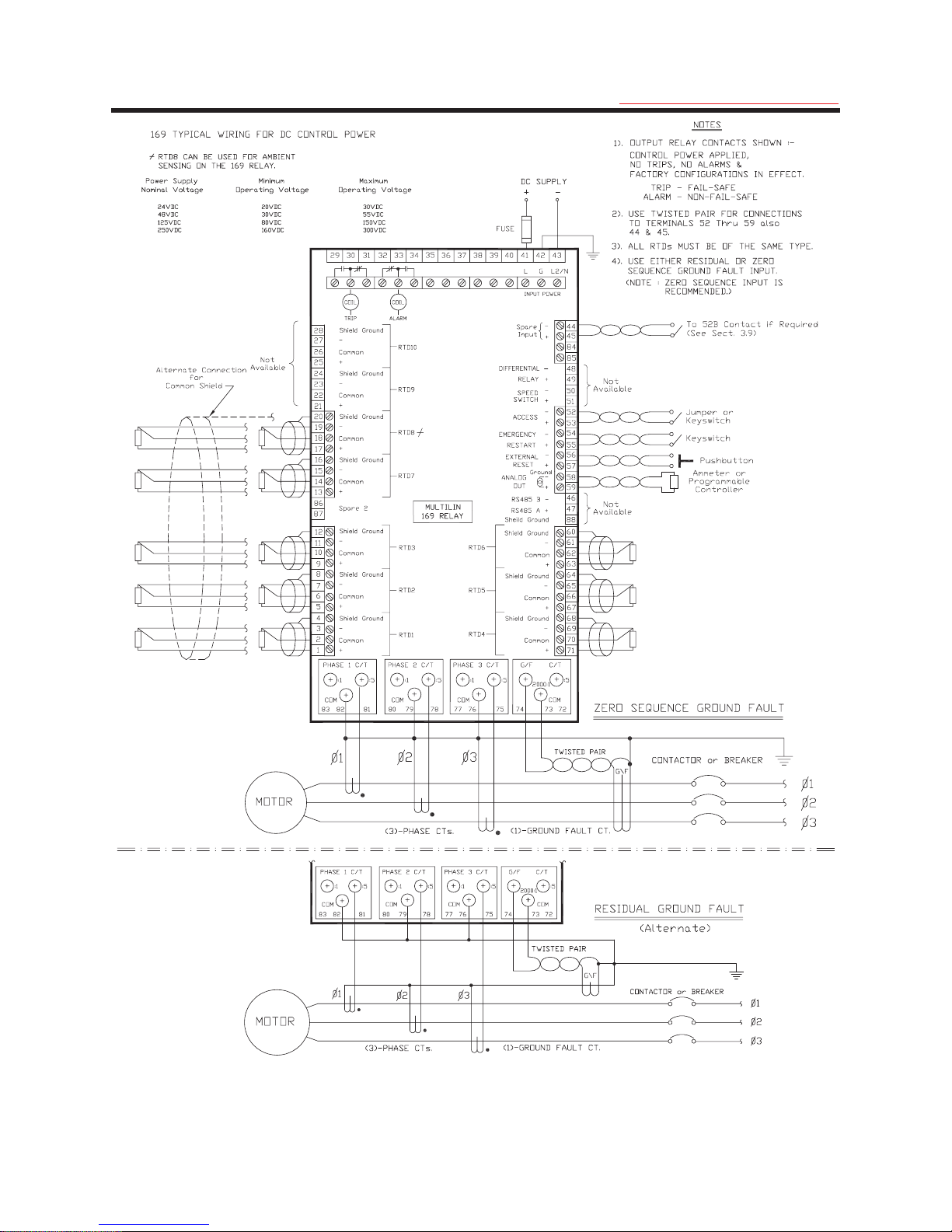

2.3 External Connections

The connections made to the 169 relay will vary depending on the programming of the unit. It is not necessary to

use all of the connections provided; a minimal configuration would include supply power, three phase current CT

inputs and the Trip relay contacts wired in series with the contactor control relay or circuit breaker shunt trip coil.

Connections to these and the other terminals outlined below will be explained in the following sections. Figures 2-4,

2-6, 2-7 show typical connections to the 169 relay.

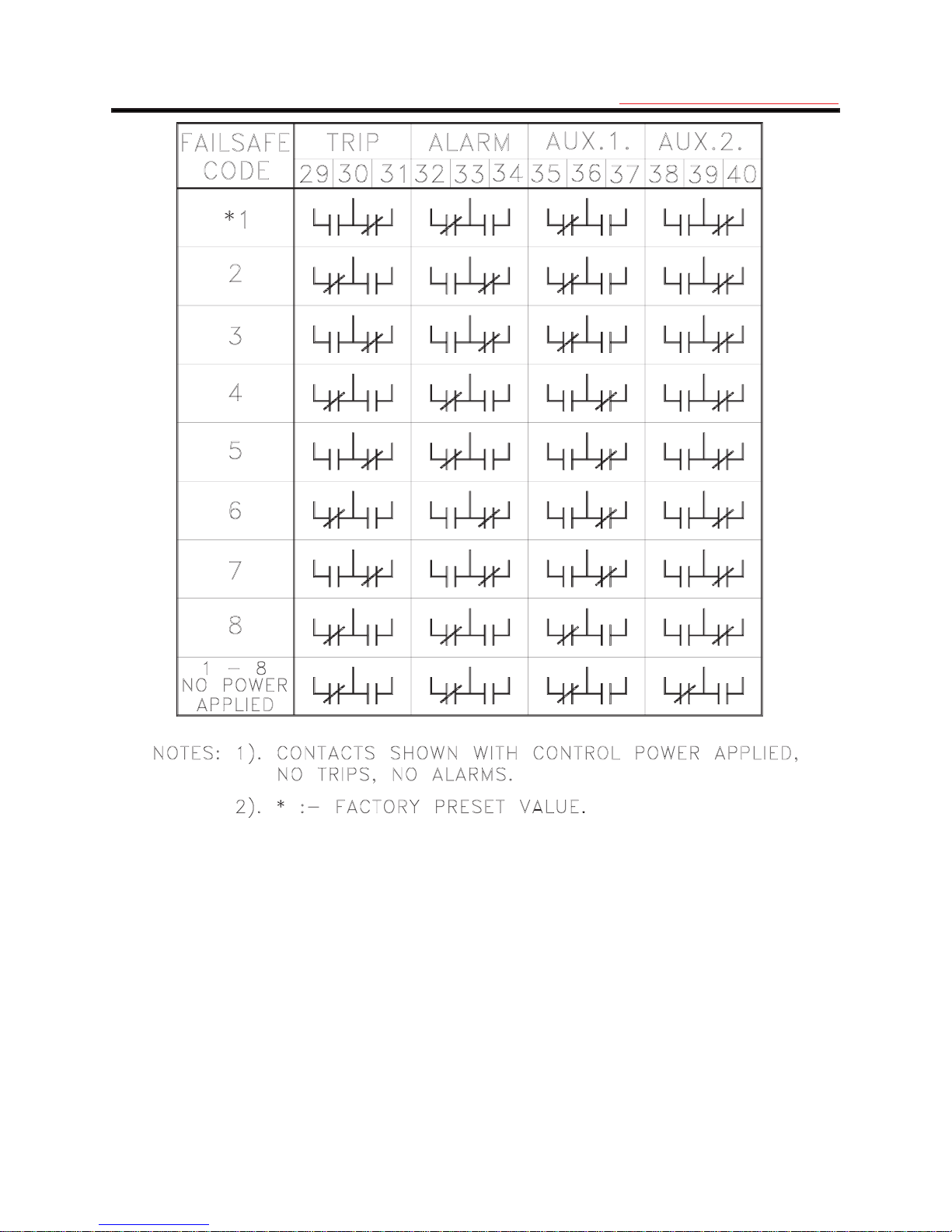

NOTE: The rear of the 169 relay shows output relay contacts in their power down state. Figures 2-4, 2-6, 2-7 show

output relay contacts with power applied, no trips or alarms, Factory Configurations, i.e. TRIP - fail-safe, ALARM non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe). See Figure 2-5 for a complete list of all possible output relay

contact states. See page 62 for a description of the RELAY FAILSAFE CODE.

Table 2-1 169 External Connections

Inputs

Supply Power L, G, N

•

Phase CTs

•

Ground Fault CTs

•

6 Stator RTDs

•

2 additional RTDs on the 169, 4 on the 169 Plus

•

Emergency Restart keyswitch

•

External Reset pushbutton

•

Programming Access jumper or keyswitch

•

Speed Switch input on the 169 Plus

•

Differential Relay input on the 169 Plus

•

Spare Input on the 169 Plus

•

Outputs

2 Sets of Relay Contacts (NO/NC) on the 169, 4 on the 169 Plus

•

Programmable Analog Current Output Terminals

•

RS 422 Serial Communication Port on the 169 Plus

•

10

Page 17

2 INSTALLATION

g

GE Power Management

Figure 2-4 Relay Wiring Diagram (AC control power)

11

Page 18

2 INSTALLATION

g

GE Power Management

WARNING: In locations where system voltage disturbances cause voltage levels to dip below the range

specified in specifications (1.5), any relay contact programmed failsafe may change state. To avoid tripping

the motor in this case, trip relay contacts should be programmed non-failsafe.

Figure 2-5 Output Relay Contact States

12

Page 19

2 INSTALLATION

g

GE Power Management

Figure 2-6 Relay Wiring Diagram (Two Phase CTs)

13

Page 20

2 INSTALLATION

g

GE Power Management

Figure 2-7 Relay Wiring Diagram (DC Control Power)

14

Page 21

2 INSTALLATION

g

GE Power Management

2.4 Control Power

Control power for the relay is nominally either 120/240 VAC at 50 Hz/60 Hz or either 24, 48, 125, or 250 VDC. The

AC voltage is selected by means of a slide switch on the power supply circuit board as shown in Figure 2-8. If an

alternative voltage is selected, ensure that the control power label on the back of the 169 Relay reflects the change.

This board is accessed by removing the perforated cover on the rear of the unit. The switch must be correctly set

before control power is applied to the 169. Maximum power consumption for the unit is 40 VA (AC version) or 30 W

(DC version).

The 169 will operate properly over a wide range of supply voltages typically found in industrial environments (see

control power specifications in section 1.5). When the supply voltage drops below the minimum, the output relays

will return to their power down states but all setpoints and statistical data will remain stored in the relay memory.

Motor lock-out time will be adhered to with or without control power applied.

Control power must be applied to the 169 relay, and the relay programmed, before the motor is energized. Power is

applied at terminals 41, 42, and 43 which is a terminal block having #6 screws.

NOTE: Chassis ground terminal 42 must be connected directly to the dedicated cubicle ground conductor to

prevent transients from damaging the 169/169 Plus resulting from changes in ground potential within the

cubicle.

Figure 2-8 AC Voltage Selection (120/240 VAC models only)

2.5 Phase CTs

One CT for each of the three motor phases is required to input a current into the relay proportional to the motor

phase current. The phase sequence must be as shown in Figures 2-4 and 2-7 in order for the phase reversal

function to operate properly. If two phase CTs are used as shown in Figure 2-6 the phase reversal function cannot

be used (see section 3.19). The CTs used can have either a 1 amp or 5 amp secondary and should be chosen so

that the motor full load current is between 50 and 95 percent of the rated CT primary amps. The CT ratio should

thus be of the form n:1 or n:5 where n is between 20 and 1500. The ratio of the CT used must be programmed into

the 169 (see section 3.7).

The CT connections to the relay are made between the ":1" and "COM" terminals for 1 amp CTs or between the ":5"

and "COM" terminals for CTs with a 5 amp secondary. The connections to the 169 internal phase CTs are made

directly via #10 screws.

AC VOLTAGE SELECTION SWITCH

A100 PC BOARD

15

Page 22

2 INSTALLATION

g

GE Power Management

2.6 Ground Fault CT

All current carrying conductors must pass through a separate ground fault CT in order for the ground fault function to

operate correctly. If a safety ground is used it should pass outside the CT window.

The ground fault CT is connected to terminals 73 and 72 for 5 amp secondary CTs or to terminals 73 and 74 for

Multilin 2000:1 CTs. as shown in Figures 2-4, 2-6, 2-7. The polarity of the ground fault CT connection is not

important. It is recommended that the two CT leads be twisted together to minimize noise pickup. If a 2000:1 ground

fault CT is used, the secondary output will be a low level signal which allows for sensitive ground fault detection.

The zero sequence ground fault connection is recommended. If the residual ground fault method is used the 169

relay will not display ground fault current in direct primary amps.

The connections to the 169 internal ground fault CT are made directly via #10 screws.

2.7 Trip Relay Contacts

The main control relay or shunt trip coil of the motor starter or circuit breaker should be connected to the Trip relay

contacts of the 169. These contacts are available as normally open (NO), normally closed (NC), and can switch up

to 10 amps at either 250 VAC or 30 VDC with a resistive load. Silver cadmium oxide contacts are used because of

their ability to handle high inrush currents on inductive loads. Contact Multilin if these contacts are to be used for

carrying low currents since they are not recommended for use below 0.1 amps. Connection to the motor contactor

or breaker is shown in Figures 2-4, 2-6, 2-7.

The Trip output relay will remain latched after a trip. This means that once this relay has been activated it will remain

in the active state until the 169 is manually reset. The Trip relay contacts may be reset by pressing the RESET key

(see section 3.1) if motor conditions allow, or by using the Emergency Restart feature (see section 2.12). An

optional single shot restart can be selected on the 169 Plus to automatically reset the relay after a running

OVERLOAD TRIP. This feature is selected or defeated in page 5 of SETPOINTS mode.

The Trip relay may be programmed to be fail-safe or non-fail-safe. W hen in the fail-safe mode, relay activation or a

loss of power condition will cause the relay contacts to go to their power down state. Thus, in order to cause a trip

on loss of power to the 169, output relays should be programmed as fail-safe.

The Trip relay cannot be reset if a lock-out is in effect. Lock-out time will be adhered to regardless of whether control

power is present or not.

The Trip relay can be programmed to activate on any combination of the following trip conditions: overload, stator

RTD overtemperature, rapid trip, unbalance, ground fault, short circuit, RTD overtemperature, phase reversal,

acceleration time, number of starts per hour, single phase, speed switch closure on start, differential relay closure,

spare input closure, and start inhibit (see section 3.4 for factory preset configurations). Connections to the Trip relay

contacts are made via a terminal block which uses #6 screws.

NOTE: The rear of the 169 relay shows output relay contacts in their power down state. Figures 2-4, 2-6, 2-7

show output relay contacts with power applied, no trips or alarms, and Factory Configurations in effect (i.e.

TRIP - fail-safe, ALARM - non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe). See Figure 2-5 for a list of all

possible contact states.

2.8 Alarm Relay Contacts

These contacts are available as normally open (NO), normally closed (NC), with the same ratings as the Trip relay

but can only be programmed to activate when alarm setpoint levels are reached. (On a Draw-out version of 169,

only one set of alarm contacts is available and the user must specify normally open or normally closed when

ordering). Thus these contacts may be used to signal a low level fault condition prior to motor shut-down.

Conditions which can be programmed to activate the relay are alarm levels for the following functions: immediate

overload, unbalance, undercurrent, ground fault, stator RTD overtemperature, RTD overtemperature, broken RTD

sensor, spare input alarm, self-test alarm, and start inhibit (see section 3.4 for factory preset configurations). The

relay can be configured as latched or unlatched and fail-safe or non-fail-safe. Connections to the Alarm relay

contacts are made via a terminal block which uses #6 screws.

NOTE: The rear of the 169 relay shows output relay contacts in their power down state. Figures 2-4, 2-6, 2-7 show

output relay contacts with power applied, no trips or alarms, and Factory Configurations in effect (i.e. TRIP - fail-safe,

ALARM - non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe). See Figure 2-5 for a list of all possible contact

states.

16

Page 23

2 INSTALLATION

g

GE Power Management

2.9 Auxiliary Relay #1 Contacts (169 Plus)

Auxiliary relay #1 is provided to give an extra set of NO/NC contacts which operate independently of the other relay

contacts. (On a Draw-out version of 169, only one set of Aux.1 contacts is available and the user must specify

normally open or normally closed when ordering). This auxiliary relay has the same ratings as the Trip relay.

Auxiliary relay #1 can be configured as latched or unlatched and fail-safe or non-fail-safe. The conditions that will

activate this relay can be any trip or alarm indications (see section 3.4 for factory preset configurations).

These contacts may be used for alarm purposes or to trip devices other than the motor contactor. For example, the

ground fault and short circuit functions may be directed to Auxiliary relay #1 to trip the main circuit breaker rather

than the motor starter.

Connections to the relay contacts are made via a terminal block which uses #6 screws.

NOTE: The rear of the 169 relay shows output relay contacts in their power down state. Figures 2-4, 2-6, 2-7

show output relay contacts with power applied, no trips or alarms, and Factory Configurations in effect (i.e.

TRIP - fail-safe, ALARM - non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe). See Figure 2-5 for a list of all

possible contact states.

2.10 Auxiliary Relay #2 Contacts (169 Plus)

This relay provides another set of NO/NC contacts with the same ratings as the other relays. (On a Draw-out version

of 169, only one set of Aux.2 contacts is available and the user must specify normally open or normally closed when

ordering). This relay is different from the others in the fact that it is permanently programmed as latched and failsafe.

This relay may be programmed to activate on any combination of alarm conditions (see section 3.4 for factory preset

configurations). The feature assignment programming is thus the same as for the Alarm relay.

Connections to the relay contacts are made via a terminal block which uses #6 screws.

NOTE: The rear of the 169 relay shows output relay contacts in their power down state. Figures 2-4, 2-6, 2-7

show output relay contacts with power applied, no trips or alarms, and Factory Configurations in effect (i.e.

TRIP - fail-safe, ALARM - non-fail-safe, AUX.1 - non-fail-safe, AUX.2 - fail-safe). See Figure 2-5 for a list of all

possible contact states.

2.11 RTD Sensor Connections

Up to six resistance temperature detectors (RTDs) may be used for motor stator temperature monitoring. The

remaining RTD inputs may be used for motor and load bearing, or other temperature monitoring functions. All RTDs

must be of the same type. RTD #8 (RTD #10 on the 169 Plus) may be used to monitor ambient air temperature.

This is done to enhance protection in environments where the ambient temperature varies considerably. Use of

stator RTDs will allow the 169 to "learn" the actual cooling times of the motor. W hen no stator RTDs are used the

169 will not learn the actual motor cooling times, but will rely on the user defined preset values. The number of

stator RTDs used together with RTD trip and alarm temperatures must be programmed into the 169 (see sections

3.16, 3.17). The RTD type to be used must be specified when ordering the 169 relay. If the type of RTD in use is to

be changed, the 169 must be returned to the factory.

Each RTD has four connections to the 169 relay as shown in Figures 2-4, 2-6, 2-7. Since the RTD indicates

temperature by the value of its resistance, it is necessary to compensate for the resistance of the connecting wires,

which is dependent on lead length and ambient temperature. The 169 uses a circuit to cancel this resistance and

read only the actual RTD resistance. Correct operation will occur providing all three wires are of the same length and

the lead resistance is not greater than 25% of the RTD 0 C resistance. This can be accomplished by using identical

lengths of the same type of wire. If 10 copper RTDs are to be used special care should be taken to keep the lead

resistance as low as possible.

If RTD #8 (RTD #10 on the 169 Plus) is to be used for ambient air temperature measurement the RTD should be

placed and mounted somewhere in the motor cooling air intake flow. The sensor should be in direct contact with the

cooling air but not with any surface that is at a temperature other than the cooling air. This RTD is selected for

ambient temperature use in page 5 of SETPOINTS mode.

If no RTD sensor is to be connected to any of the RTD terminals on the 169, the terminals may be left open.

If fewer than 6 stator RTDs are to be employed, they should be connected to the lowest numbered relay RTD

connections. For example, if 3 stator RTDs are to be used they should be connected to the terminals for RTD1,

17

Page 24

2 INSTALLATION

RTD2, and RTD3 (terminals #1-12). Other RTDs should be connected to the terminals for RTD7-RTD10 (terminals

#13-28) as shown in Figure 2-4.

The connections are made via terminal blocks which can accommodate up to #12 AWG multi-strand wire.

Note: Shielded, three wire cable must be used in industrial environments to prevent noise pickup. Wherever

possible, the RTD leads should be kept close to grounded metal casings and avoid areas of high

electromagnetic or radio frequency fields. RTD leads should not run adjacent to, or in the same conduit as

high current carrying wires. It is recommended to use a three wire shielded cable of #18 AWG copper

conductors. The shield connection of the RTD should not be grounded at the sensor end as there is an

internal ground on the 169. This arrangement prevents noise pickup that would otherwise occur from

circulating currents due to differences in ground potentials on a doubly grounded shield.

g

GE Power Management

2.12 Emergency Restart Terminals

If it is desired to occasionally override relay trips or lock-outs and restart the motor, a normally open keyswitch

should be installed between terminals 54 and 55. Momentarily shorting these terminals together will cause the

thermal memory of the 169 to discharge to 0% (if RTD input to thermal memory is enabled, thermal memory can be

reduced to 0% by keeping terminals 54 and 55 shorted together for more than 11 seconds; see section 3.20). The

Emergency Restart terminals can thus be used to override an OVERLOAD TRIP. Shorting the Emergency Restart

terminals together will also decrement the relay's internal starts/hour counter by 1 and therefore allow the operator to

override a STARTS/HOUR TRIP.

Note: This option should be used only when an immediate restart after a lock-out trip is required for process

integrity or personnel safety. Discharging the thermal memory of the 169 gives the relay an unrealistic value

for the thermal capacity remaining in the motor and it is possible to thermally damage the motor by

restarting it. Thus, complete protection may be compromised in order to restart the motor using this feature.

A twisted pair of wires should be used. Connection to the 169 is made via a terminal block which can accommodate

up to #12 AWG multi-strand wire.

2.13 External Reset Terminals

An external reset switch, which operates similarly to the keypad RESET key (see section 3.1), can be connected to

terminals 56 and 57 for remote reset operation. The switch should have normally open contacts. Upon closure of

these contacts the relay will be reset. This external reset is normally equivalent to pressing the keypad RESET key

but a special reset feature can be selected on page 5 of setpoints mode, so that the keypad RESET key will not

cause Auxiliary relay #1 to be reset (see section 3.22). Keeping the External Reset terminals shorted together will

cause the 169 to be reset whenever motor conditions allow.

A twisted pair of wires should be used. Connection to the 169 is made via a terminal block which can accommodate

up to #12 AWG multi-strand wire.

2.14 Analog Output Terminals (Non-Isolated)

Terminals 58 and 59 of the 169 are available for an analog current output representing one of percentage of motor

thermal capacity used, motor current as a percentage of full load (i.e. 0-1 XFLC), hottest stator RTD temperature as

a percentage of 200 C or CT secondary current as a percentage of CT secondary amps rating. The choice of output

is selected in page 5 of SETPOINTS mode. This selection can be made or changed at any time without affecting the

protective features of the relay.

The output current range is standard at 4-20 mA. Contact Multilin if a different current range is required. 4 mA

output corresponds to a low scale reading (i.e. 0% thermal capacity used, 0 XFLC phase current, 0 C hottest stator

RTD temperature, or 0 A phase CT secondary current). 20 mA output current corresponds to a high scale reading

(i.e. 100% thermal capacity used, 1 XFLC or greater phase current, 200 C or greater hottest stator RTD temperature,

or either 1 A (or greater) or 5 A (or greater) phase CT secondary depending on the CT used).

This output is a current source suitable for connection to a remote meter, chart recorder, programmable controller, or

computer load. Current levels are not affected by the total lead and load resistance as long as it does not exceed

300 for the 4-20 mA range. For readings greater than 100% of full scale the output will saturate at 20.2 mA.

This analog output is not isolated. Terminal 58 is internally connected to system ground. Consequently the negative

terminal of the connected load device must be at ground potential.

18

Page 25

2 INSTALLATION

A twisted pair of wires should be used. Connection to the 169 is made via a terminal block which can accommodate

up to #12 AWG multi-strand wire.

g

GE Power Management

2.15 Differential Relay Terminals (169 Plus)

Terminals 48 and 49 are provided for connection to a differential relay. This allows an external differential relay to be

connected to a 169 Plus relay. A contact closure between these terminals will cause an immediate activation of the

output relay assigned to the differential relay input function. After a DIFFERENTIAL INPUT TRIP terminals 48 and

49 must be open circuited in order to reset the relay.

If no differential relay is to be used terminals 48 and 49 should be left open.

A twisted pair of wires should be used. Connection to the 169 is made via a terminal block which can accommodate

up to #12 AWG multi-strand wire.

2.16 Speed Switch Terminals (169 Plus)

Terminals 50 and 51 are provided for connection to an external speed switch. This allows the 169 Plus relay to

utilize a speed device for locked rotor protection.

terminals 50 and 51 occurs within the "SPEED SWITCH TIME DELAY" (SETPOINTS, page 5) the output relay

assigned to the speed switch function will activate. This function must be enabled in order for operation to occur

(SETPOINTS, page 5). After a SPEED SWITCH TRIP terminals 50 and 51 must be open circuited in order to reset

the relay.

If no speed switch is to be used terminals 50 and 51 should be left open.

A twisted pair of wires should be used. Connection to the 169 is made via a terminal block which can accommodate

up to #12 AWG multi-strand wire.

During a motor start attempt

if no contact closure between

2.17 Programming Access Terminals

When a jumper wire is connected between ACCESS terminals 52 and 53 all setpoints and configurations can be

programmed using the keypad. Once programming is complete the jumper will normally be removed from these

terminals. When this is done all actual and setpoint values can still be accessed for viewing; however, if an attempt

is made to store a new setpoint value the message "ILLEGAL ACCESS" will appear on the display and the previous

setpoint will remain intact. In this way all of the programmed setpoints will remain secure and tamperproof.

Alternatively, these terminals can be wired to an external keyswitch to permit setpoint programming upon closure of

the switch.

A twisted pair of wires should be used for connection to an external switch. Connection to the 169 is made via a

terminal block which can accommodate up to #12 AWG multi-strand wire.

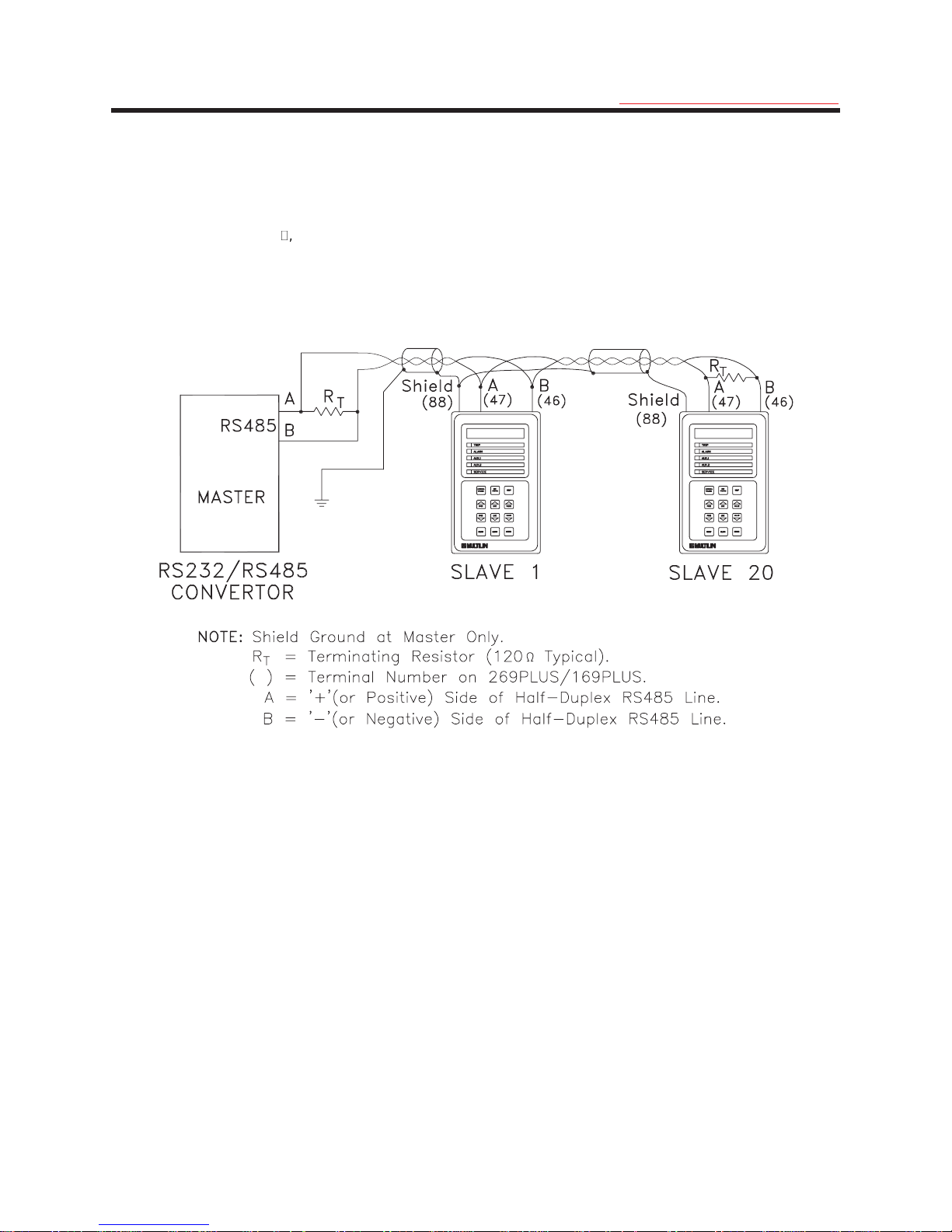

2.18 RS-422 Serial Communications Terminals (169 Plus)

Terminals 46 and 47 are provided for a digital serial communication link with other 169 Plus relays, computers, or

programmable controllers. Up to 20 169 Plus "SLAVES" can be connected to one "MASTER" (169 Plus or other

device) as shown in Figure 2-9. If devices other than 169 Plus relays are to be connected in the serial link a copy of

the "Multilin 169 Plus Relay Communication Protocol" will be required. This can be obtained by contacting Multilin.

Note that when using a device other than a 169 Plus to program a 169 Plus SLAVE, setpoints sent to the SLAVE

must be within the ranges listed in Table 3-3.

Each communication link must have only one MASTER. If the MASTER is a 169 Plus this relay cannot be used for

motor protection. Only relays programmed as SLAVEs can be used for motor protection. The MASTER should be

centrally located and can be used to view ACTUAL VALUES and SETPOINTS from each relay SLAVE. SETPOINTS

in each SLAVE can also be changed from the MASTER. In order to do this the MASTER relay must have its Access

terminals (52,53) shorted together.

Relays are programmed as MASTER or SLAVE using the last 2 setpoints of page 5 of SETPOINTS mode (see

section 3.4). Each SLAVE in the communication link must be programmed with a different SLAVE ADDRESS.

When a relay is programmed as a MASTER it will display all of the ACTUAL VALUES and SETPOINTS of the SLAVE

relay it is addressing. To view data from a different SLAVE the ADDRESSED SLAVE setpoint must be changed.

To avoid contention and improper reading of data ensure that the following conditions are met:

1. Each communication link has only one MASTER.

2. Each 169 Plus SLAVE in the link has a different SLAVE ADDRESS.

19

Page 26

2 INSTALLATION

The wires joining relays in the communication link should be a twisted pair. These wires should be routed away from

high power AC lines and other sources of electrical noise. The total length of the communications link should not

exceed 4000 feet. When connecting units in a communication link each 169 Plus relay must have terminal 47

connected to terminal 47 of the next unit in the link, and terminal 46 connected to terminal 46.

As shown in Figure 2-9 the first and last devices in the link should have a terminating resistor placed across

terminals 46 and 47. The value of these resistors should match the characteristic impedance of the line wire being

used. A typical value is 50 , 1/4 watt.

Connection to the 169 is made via a terminal block which can accommodate up to #12 AWG multi-strand wire.

Note: The difference in potentials between serial master ground and the 169 Plus slave (terminal 42) must

not exceed 10 volts. If a large difference in ground potentials does exist, communication on the serial

communication link will not be possible. In addition damage to the 169 Plus may result.

g

GE Power Management

Figure 2-9 Serial Communication Link Wiring

2.19 Display Adjustment

Once the 169 relay has been installed and input power applied, the contrast of the LCD display may have to be

adjusted. This adjustment has been made at the factory for average lighting conditions and a standard viewing

angle but can be changed to optimize the display readability in different environments. To alter the display contrast

the trimpot on the rear of the unit marked "CONTRAST" must be adjusted with a small slotted screwdriver.

2.20 Front Panel Faceplate

The front panel faceplate is composed of a polycarbonate material that can be cleaned with isopropyl or denatured

alcohol, freon, naphtha, or mild soap and water.

2.21 Spare Input Terminals (169 Plus)

Terminals 44 and 45 are provided for an additional relay contact input. A contact closure between these terminals

will cause a "SPARE INPUT TRIP" and/or a "SPARE INPUT ALARM" after the appropriate time delay (page 5 of

SETPOINTS). These terminals must be open circuited in order to reset the relay after a SPARE INPUT TRIP or

ALARM.

A twisted pair of wires should be used. Connection to the 169 is made via a terminal block which can accommodate

up to #12 AWG multi-strand wire.

20

Page 27

2 INSTALLATION

g

GE Power Management

2.22 169 Drawout Relay

The model 169 and 169 Plus relays are available in a drawout case option. The operation of the relay is the same

as described elsewhere in this manual except for the differences noted in this section. The physical dimensions of

the drawout relay are as shown in Figure 2-10. The relay should be mounted as shown in Figure 2-11.

The drawout 169 relay can be removed from service without causing motor shut-down. This can be useful for

replacing, calibrating, or testing units.

RELAY MOUNTING - Make cutout as shown and drill six 7/32" holes on mounting panel. Approximately 2-1/2"

should be clear at the top and bottom of the cutout in the panel for the hinged door. Ensure that the five #6-32 nuts

are removed from the threaded studs in the mounting flange and that the drawout chassis has been removed from

the drawout case. Install the case from the rear of the mounting panel by aligning the five #6-32 threaded case

studs to the previously drilled holes. With the studs protruding through the holes secure the case on the right hand

side with two #6-32 nuts provided. Install the hinged door on the front of the mounting panel using three #6-32 nuts

provided. There must be at least 1/2" clearance on the hinged side of the drawout relay to allow the door to open.

RELAY REMOVAL - Open the hinged door. Next remove the two ten finger connecting plugs making sure the top

one is removed first. Swivel the cradle-to-case hinged levers at each end of the 169 cradle assembly and slide the

assembly out of the case.

RELAY INSTALLATION - Slide the 169 cradle assembly completely into the case. Swivel the hinged levers in to lock

the 169 cradle assembly into the drawout case. Install the two ten finger connecting plugs making sure the bottom

plug is installed first. Close the hinged door and secure with the captive screw.

IMPORTANT NOTE:

withdrawn first. This isolates the 169 output relay contacts before power is removed from the relay. When installing

the drawout relay cradle assembly the bottom ten finger connecting plug must be installed first. This causes power

to be applied to the 169 relay before the output relay contacts are placed in the circuit.

After a 169 relay cradle assembly has been removed from the drawout case it is recommended that the hinged door

be closed in order to reduce the risk of electric shock.

Due to the hardware configuration of the drawout relay shorting bars, the RELAY FAILSAFE CODE (SETPOINTS,

page 5) should not be changed without consulting the factory. Wiring for the 169 Plus drawout is shown in Figure 2-

12. If it is required that any of the output relay configurations in Figure 2-12 be different than shown, this information

must be stated when the relay is ordered.

When removing the drawout relay cradle assembly the top ten finger connecting plug must be

21

Page 28

2 INSTALLATION

g

GE Power Management

Figure 2-10 169 Drawout Relay Physical Dimensions

22

Page 29

2 INSTALLATION

g

GE Power Management

Figure 2-11 169 Drawout Relay Mounting

23

Page 30

2 INSTALLATION

g

GE Power Management

Figure 2-12 169 Plus Drawout Relay Typical Wiring Diagram

24

Page 31

3 SETUP AND USE

g

GE Power Management

Figure 3-1 Front Panel Controls and Indicators

25

Page 32

3 SETUP AND USE

g

GE Power Management

3.1 Controls and Indicators

Once the 169 relay has been wired and control power applied, it is ready to be programmed for the given application.

Programming is accomplished using the 12 position keypad and 48 character alphanumeric display shown in Figure

3-1. The function of each key on the keypad and each of the indicators is briefly explained in Table 3-1.

Table 3-1 Controls and Indicators

No. Name Description

1 ACTUAL

VALUES

2 SET

POINTS

FUNCTION:

operating parameters. There are six pages of ACTUAL VALUES data:

page 1: Phase Current Data

•

page 2: RTD Temperature Data

•

page 3: Motor Capacity Data

•

page 4: Statistical Data

•

page 5: Pre-trip Data

•

page 6: Learned Parameters

•

EFFECT:

message

ACTUAL VALUES HAS SIX

PAGES OF DATA

will be displayed for 2 seconds. The beginning of page 1 of ACTUAL VALUES mode will

then be shown:

PAGE 1: ACTUAL VAL UES

PHASE CURRENT DATA

USE:

from page to page the PAGE UP and PAGE DOWN keys can be used. To go from line to

line within a page the LINE UP and LINE DOWN keys can be used.

FUNCTION:

other relay setpoints. There are six pages of setpoints data:

page 1: Motor Amps Setpoints

•

page 2: RTD Setpoints

•

page 3: O/L Curve Setpoints

•

page 4: Relay Configuration

•

page 5: System Configuration

•

page 6: Multilin Service Codes

•

The ACTUAL VALUES key allows the user to examine all of the actual motor

Pressing this key will put the relay into ACTUAL VALUES mode. The flash

This key can be pressed at any time, in any mode to view actual motor values. To go

The SET POINTS key allows the user to examine and alter all trip, alarm, and

26

Page 33

3 SETUP AND USE

No. Name Description

g

GE Power Management

EFFECT:

SETPOINTS HAS SIX

PAGES OF DATA

is displayed for 2 seconds. The beginning of page 1 of SETPOINTS mode is then shown:

PAGE 1: SETPOINT VALUES

MOTOR AMPS SETPOINTS

USE:

go from page to page the PAGE UP and PAGE DOWN keys can be used. To go from line to

line within a page the LINE UP and LINE DOWN keys can be used. To alter a setpoint, the

VALUE UP and VALUE DOWN keys can be used. All setpoints will increment and

decrement to pre-determined limits. When the desired value is reached, the STORE key

must be used to save the new setpoint. If an altered setpoint is not stored the previous

value will still be in effect. If the Access jumper is not installed a STORE will not be allowed

and the flash message "ILLEGAL ACCESS" will be displayed for 2 seconds.

3HELP

FUNCTION:

each of the other keys on the keypad and on each of the ACTUAL VALUES, SETPOINTS,

and TRIP/ALARM messages.

EFFECT:

the first line of a page (i.e. a page header) on the display the message,

Press KEY of interest or

HELP again for details

will be displayed. To obtain information on the function of a particular key, the key must be

pressed. To obtain information on the previously displayed ACTUAL VALUES,

SETPOINTS, or TRIP/ALARM message the HELP key should be pressed again. If this key

is pressed with any other message shown on the display, only information on the previous

line will be available.

Pressing this key will put the relay into SETPOINTS mode. The flash message,

This key can be pressed at any time, in any mode, to view or alter relay setpoints. To

The HELP key allows the user to obtain information on the function and use of

Pressing this key will put the relay into HELP mode. If this key is pressed with

4,5 PAGE

UP

PAGE

DOWN

6, 7 LINE UP

LINE DOWN

This key will have no effect when a flash message or HELP message is shown on

USE:

the display. Once HELP mode is entered the LINE UP and LINE DOWN keys can be used

to view the HELP message. The CLEAR key is used to exit from HELP mode and return to

the previous display mode. The ACTUAL VALUES and SET POINTS keys can also be

used to exit HELP mode.

FUNCTION:

previous pages of either ACTUAL VALUES or SETPOINTS modes. If either key is held for

more than 1/2 second the next or previous pages will be selected at a fast rate.

EFFECT:

next page of information. Pressing the PAGE UP key will cause the display to show the first

line of the previous page.

USE:

SETPOINTS modes.

FUNCTION:

previous lines of the currently selected page. If either key is held for more than 1/2 second

the next or previous lines will be selected at a fast rate.

The PAGE DOWN and PAGE UP keys allow the user to scan the next or

Pressing the PAGE DOWN key will cause the display to show the first line of the

These keys can be used any time the relay is in either the ACTUAL VALUES or

The LINE DOWN, and LINE UP keys allow the user to scan the next or

27

Page 34

3 SETUP AND USE

No. Name Description

g

GE Power Management

8,9 VALUE

UP

VALUE

DOWN

10 RESET

EFFECT:

currently selected page of information. Pressing the LINE UP key will cause the display to

show the line immediately in front of the currently displayed line.

USE:

shows the last line of a page the LINE DOWN key will have no effect. If the display shows

the first line of a page the LINE UP key will have no effect.

FUNCTION:

selected setpoint. If either key is held for more than 1/2 second the setpoint selected will

increment or decrement at a fast rate. If either key is held for more than 2 seconds the

setpoint selected will increment or decrement at a very fast rate.

EFFECT:

increment. Pressing the VALUE DOWN key will cause the currently displayed setpoint

value to decrement. For YES/NO questions, pressing either key will cause the answer to

change. Any changed setpoint will not be used internally until the STORE key is pressed.

USE:

when a YES/NO question is displayed in ACTUAL VALUES mode (see STORE key). When

the desired setpoint value is reached the STORE key is used to save it. If an altered

setpoint is not stored the previous value will still be in effect.

FUNCTION:

output relays have become active so that a motor start can be attempted.

EFFECT:

output relay contacts if motor conditions allow (see below). The message,

Pressing the LINE DOWN key will cause the display to show the next line of the

These keys can be used at any time in any relay mode of operation. If the display

The VALUE UP and VALUE DOWN keys allow the user to alter the currently

Pressing the VALUE UP key will cause the currently displayed setpoint value to

These keys can be pressed any time a setpoint is displayed in SETPOINTS mode or

The RESET key allows the user to reset the 169 after any of the latched

Pressing this key will reset (i.e. return to an inactive state) any of the active

11 CLEAR

RESET NOT POSSIBLE Condition still present

will be displayed if any active output relays cannot be reset

A latched relay cannot be reset if the trip/alarm condition persists (e.g. an

USE:

OVERLOAD TRIP lock-out or a high RTD temperature). Pre-trip motor values may be

viewed in ACTUAL VALUES mode page 5 (Pre-trip Data). If an immediate restart is

required after an OVERLOAD or STARTS/HOUR TRIP the Emergency Restart terminals

(see section 2.12) may be shorted together. This will reduce the lock-out time to 0 minutes.

FUNCTION:

non-stored setpoint to its original value. In HELP mode the CLEAR key allows the user to

return to the previous display mode.

EFFECT:

setpoint will be returned to its original value. When this key is pressed in HELP mode the

relay will return to the line and page of the mode active when the HELP key was pressed.

USE:

can only be used when a displayed setpoint has been changed with the VALUE UP/VALUE

DOWN keys but has not yet been stored. After a setpoint has been stored the CLEAR key

will have no effect. In HELP mode the CLEAR key can be used any time there is a HELP

message on the display.

In SETPOINTS mode the CLEAR key allows the user to return an altered,

When this key is pressed in SETPOINTS mode any altered, currently displayed

This key can be used in SETPOINTS or HELP modes only. In SETPOINTS mode it

28

Page 35

3 SETUP AND USE

No. Name Description

g

GE Power Management

12 STORE

FUNCTION:

internal memory.

EFFECT:

will be stored and will immediately come into effect. W hen a setpoint is stored the flash

message,

new setpoint stored

will appear on the display.

The STORE key can be pressed in ACTUAL VALUES mode to clear the maximum actual

temperature data. To do this the following message from page 2 of ACTUAL VALUES

mode must be displayed after the "NO" value is altered to say "YES" by pressing the

VALUE UP/VALUE DOWN key:

CLEAR LAST ACCESS DATA ?

YES

Then when the STORE key is pressed the following flash message will appear on the

display:

last access data cleared

The maximum actual temperature data (see section 3.24) will then be cleared. The STORE

key can be pressed in ACTUAL VALUES mode to start a new motor commissioning (i.e.

clear statistical data). To do this the following message from page 4 of ACTUAL VALUES

mode must be displayed after the "NO" value is altered to say "YES" by pressing the

VALUE UP/VALUE DOWN key:

The STORE key allows the user to store new setpoints into the 169 relay's

When this key is pressed in SETPOINTS mode the currently displayed setpoint

START COMMISSIONING?

YES

Then when the STORE key is pressed the following flash message will appear on the

display:

COMMISSIONI NG data

cleared

All statistical data (see section 3.24) will then be cleared.

The STORE key can be used only in SETPOINTS mode to store new setpoints, or in

USE:

ACTUAL VALUES mode to clear the maximum actual temperature data or start a new

commissioning (i.e. clear statistical data). This key will have no effect unless the Access

terminals are shorted together.

13 TRIP LED indicator used to show the state of the Trip output relay. W hen on, the trip relay is

active. When off, the Trip relay is inactive.

14 ALARM LED indicator used to show the state of the Alarm output relay. When on, the Alarm relay is

active. When off, the Alarm relay is inactive.

15 AUX. 1 LED indicator used to show the state of Auxiliary relay #1. When on, Aux. relay #1 is

active. When off, Aux. relay #1 is inactive.

16 AUX. 2 LED indicator used to show the state of Auxiliary relay #2. When on, Aux. relay #2 is

active. When off, Aux. relay #2 is inactive.

29

Page 36

3 SETUP AND USE

No. Name Description

17 SERVICE LED indicator used to show the result of the 169 self-test feature. When flashing, the relay

has failed the self-test and service is required. When on steady, the supply voltage may be

too low. This LED may be on momentarily during relay power up.

g

GE Power Management

3.2 169 Relay Display Modes

The 169 relay display is used for viewing actual motor values, setpoint values, HELP messages, and TRIP/ALARM

messages. This is accomplished by having the relay in one of four possible modes of operation:

1. ACTUAL VALUES mode

2. SETPOINTS mode

3. HELP mode

4. TRIP/ALARM mode

The relay will operate correctly, giving full motor protection, regardless of which display mode is currently in effect.

The different modes affect only the data that appears on the 169 relay's 48 character alphanumeric display.

TRIP/ALARM mode can only be entered by having one or more of the trip or alarm level setpoints exceeded. The

other display modes can be entered using the ACTUAL VALUES, SET POINTS, or HELP keys (see section 3.1).

The ACTUAL VALUES and SETPOINTS modes are based on a book-like system of "pages" and "lines". One line

from any page may be displayed at any given time. To "turn" a page, the PAGE UP and PAGE DOW N keys are

used. To scan the lines on a page the LINE UP and LINE DOWN keys are used. In the HELP and TRIP/ALARM

modes only the LINE UP and LINE DOWN keys are needed.

When control power is applied to the relay the following power up message will be displayed:

MULTILIN 169 RELAY

REVISION XXX XX/XX

or

MULTILIN 169 PLUS RELAY

REVISION XXX XX/XX

After this the display will show, (factory default settings)

I1= XXX I2= XXX

I3= XXX (AMPS) ---

which is in page 1 of ACTUAL VALUES mode.

A description of each display mode is given in the following sections.

3.3 ACTUAL VALUES Mode

In ACTUAL VALUES mode, any of the parameters monitored or calculated by the 169 relay may be viewed by the

user. This mode is divided into six separate pages of data each of which contains a different group of actual motor

values. The six pages and the lines in each page are as shown in Table 3-2.

30

Page 37

3 SETUP AND USE

Table 3-2 Actual Values

3$*( /,1( '(6&5,37,21

g

GE Power Management

11

12

13

14

15

16

PAGE 1: ACTUAL VALUES

PHASE CURRENT DATA

ACTUAL VALUES page 1 header.

MOTOR STARTING

###1###2###3###4###5###6

Motor starting current level (seen only during a motor start).

I1= XXXX I2= XXXX

I3= XXXX (AMPS) ---

Motor phase current data. ("---" becomes "RUN" when motor is running).

I(3 ph avg) = XXXX AMPS

Max Stator RTD = XXX C

Average of 3 phase currents. Maximum of 6 stator RTDs.

UNBALANCE RATIO (In/Ip)

U/B = XXX PERCENT

Ratio of negative to positive sequence currents.

GROUND FAULT CURRENT

G/F = XX.X AMPS

17

Actual ground fault current.

END OF PAGE ONE

ACTUAL VALUES

Last line of page 1.

31

Page 38

3 SETUP AND USE

3$*( /,1( '(6&5,37,21

g

GE Power Management

21

22

23

24

PAGE 2: ACTUAL VALUES

RTD TEMPERATURE DATA

ACTUAL VALUES page 2 header.

HOTTEST STATOR RTD

RTD # X = XXX C

Maximum stator RTD temperature.

STATOR TEMPERATURE

RTD #1= XXX DEGREES C

or

RTD TEMPERATURE

RTD #1= XXX DEGREES C

RTD #1 temperature.

STATOR TEMPERATURE

RTD #2= XXX DEGREES C

or

RTD TEMPERATURE

RTD #2= XXX DEGREES C

25

26

RTD #2 temperature.

STATOR TEMPERATURE

RTD #3= XXX DEGREES C

or

RTD TEMPERATURE

RTD #3= XXX DEGREES

RTD #3 temperature.

STATOR TEMPERATURE

RTD #4= XXX DEGREES C

or

RTD TEMPERATURE

RTD #4= XXX DEGREES C

RTD #4 temperature.

32

Page 39

3 SETUP AND USE

3$*( /,1( '(6&5,37,21

g

GE Power Management

27

28

29

210

STATOR TEMPERATURE

RTD #5= XXX DEGREES C

or

RTD TEMPERATURE

RTD #5= XXX DEGREES C

RTD #5 temperature.

STATOR TEMPERATURE

RTD #6= XXX DEGREES C

or

RTD TEMPERATURE

RTD #6= XXX DEGREES C

RTD #6 temperature.

RTD TEMPERATURE

RTD #7= XXX DEGREES C

RTD #7 temperature.

RTD TEMPERATURE

RTD #8= XXX DEGREES C

211

212

213

or

AMBIENT TEMPERATURE

RTD #8= XXX DEGREES C

RTD #8 temperature. Ambient seen when RTD #8 is used for ambient sensing on model 169.

RTD TEMPERATURE

RTD #9= XXX DEGREES C

RTD #9 temperature.

RTD TEMPERATURE

RTD #10= XXX DEGREES C

or

AMBIENT TEMPERATURE

RTD #10= XXX DEGREES C

RTD #10 temperature. Ambient seen when RTD #10 is used for ambient sensing on model 169.

MAX. STATOR SINCE LAST

ACCESS: RTD# X = XXX

Maximum stator RTD temperature since last access.

33

Page 40

3 SETUP AND USE

3$*( /,1( '(6&5,37,21

g

GE Power Management

214

215

216

217

218

219

MAXIMUM RTD#7 TEMP SINCE

LAST ACCESS: RTD# X = XXX

Maximum RTD #7 temperature since last access.

MAXIMUM RTD#8 TEMP SINCE

LAST ACCESS = XXX C

Maximum RTD #8 temperature since last access.

MAXIMUM RTD#9 TEMP SINCE

LAST ACCESS = XXX C

Maximum RTD #9 temperature since last access.

MAX. RTD# 10 TEMP SINCE

LAST ACCESS = XXX C

Maximum RTD #10 temperature since last access.

CLEAR LAST ACCESS DATA?

XXX

Used to clear the data in the last 5 lines (see section 3.1, STORE key).

END OF PAGE TWO

ACTUAL VALUES

Last line of page 2.

34

Page 41

3 SETUP AND USE

3$*( /,1( '(6&5,37,21

1

3

PAGE 3: ACTUAL VALUES

MOTOR CAPACITY DATA

ACTUAL VALUES page 3 header.

g

GE Power Management

32

33

34

35

ESTIMATED TIME TO

TRIP = XXX SECONDS

Estimated time to overload trip under present conditions (seen only during overloads).

MOTOR LOAD AS A PERCENT

FULL LOAD = XXX PERCENT

Actual motor current as a percentage of full load.

THERMAL CAPACITY

USED = XXX PERCENT

Percentage of motor thermal capacity used.